Futaba 4GRS User Manual

I

NSTRUCTION MANUAL

NSTRUCTION MANUAL

1M23N29602

R

Digital Proportional R/C System

Thank you for purchasing a Futaba 4GRS-2.4GHz system.

Before using your 4GRS-2.4GHz system, read this manual carefully in order to use your R/C set safely.

After reading this manual, store it in a safe place.

IN NORTH AMERICA

Please feel free to contact the Futaba Service Center for assistance in operation, use and programming. Please be sure to regularly visit the 4GRS Frequently Asked Questions web site at www.futaba-rc.com/faq/. This page includes extensive programming, use, set up and safety information on the 4GRS radio system and is updated regularly. Any technical updates and US manual corrections will be available on this web page. If you do not find the answers to your questions there, please see the end of our F.A.Q. area for information on contacting us via email for the most rapid and convenient response.

Don’t have Internet access? Internet access is available at no charge at most public libraries, schools, and other public resources. We find internet support to be a fabulous reference for many modelers as items can be printed and saved for future reference, and can be accessed at any hour of the day, night, weekend or holiday. If you do not wish to access the internet for information, however, don’t worry. Our support teams are available Monday through Friday 8-5 Central time to assist you.

FOR SERVICE ONLY: |

FOR SUPPORT : |

Futaba Service Center |

(PROGRAMMING AND USER |

3002 N. Apollo Drive, Suite 1 |

QUESTIONS) |

Champaign, IL 61822 |

Please start here for answers to most questions: |

Phone: 217-398-0007 |

www.futaba-rc.com/faq/ |

www.futaba-rc.com/service.html |

Fax: 217-398-7721 |

Email: futabaservice@hobbico.com |

Phone: 217-398-8970 option 2 |

OUTSIDE NORTH AMERICA

Please contact your Futaba importer in your region of the world to assist you with any questions, problems or service needs.

Please recognize that all information in this manual, and all support availability, is based upon the systems sold in North America only. Products purchased elsewhere may vary. Always contact your region’s support center for assistance.

Application, Export, and Modification

1. This product may be used for models only. It is not intended for use in any application other than the control of models for hobby and recreational purposes.

2. Exportation precautions:

(a)When this product is exported from the country of manufacture, its use is to be approved by the laws governing the country of destination for devices that emit radio frequencies. If this product is then re-exported to other countries, it may be subject to restrictions on such export. Prior approval of the appropriate government authorities may be required. If you have purchased this product from an exporter outside your country, and not the authorized Futaba distributor in your country, please contact the seller immediately to determine if such export regulations have been met.

(b)Use of this product with other than models may be restricted by Export and Trade Control Regulations, and an application for export approval must be submitted.

3. Modification, adjustment, and replacement of parts:

Futaba is not responsible for unauthorized modification, adjustment, and replacement of parts on this product. Any such changes may void the warranty.

Battery Recycling (for U.S.A.)

The RBRC™ SEAL on the (easily removable) nickel-cadmium battery and

nickel-metal-hydride battery contained in Futaba products indicates that Fu-

nickel-metal-hydride battery contained in Futaba products indicates that Fu-

taba Corporation is voluntarily participating in an industry program to col-

taba Corporation is voluntarily participating in an industry program to col-

lect and recycle these batteries at the end of their useful lives, when taken out of service within the United States. The RBRC™ program provides a convenient alternative to placing used nickel-cadmium batteries and nickel-metal-hy-

lect and recycle these batteries at the end of their useful lives, when taken out of service within the United States. The RBRC™ program provides a convenient alternative to placing used nickel-cadmium batteries and nickel-metal-hy-

dride batteries into the trash or municipal waste system, which is illegal in some areas.

You may contact your local recycling center for information on where to return the spent battery. Please call 1-800-8-BATTERY for information on NiCd/NiMH battery recycling in your area. Futaba Corporation's involvement in this program is part of its commitment to protecting our environment and conserving natural resources.

NOTE: Our instruction manuals encourage our customers to return spent batteries to a local recycling center in order to keep a healthy environment.

RBRC™ is a trademark of the Rechargeable Battery Recycling Corporation.

•No part of this manual may be reproduced in any form without prior permission.

•The contents of this manual are subject to change without prior notice.

•This manual has been carefully written. Please write to Futaba if you feel that any corrections or clarifications should be made.

•Futaba is not responsible for the use of this product.

3

Table Of Contents |

|

For Your Safety As Well As That Of Others |

.........................8 |

Explanation Of Symbols................................................................ |

8 |

2.4GHz System Precautions......................................................... |

8 |

Receiver Mode Precautions.......................................................... |

8 |

Operation Precautions.................................................................. |

9 |

NiMH/NiCd Battery Handling Precautions................................. |

10 |

Storage And Disposal Precautions............................................ |

10 |

Other Precautions........................................................................ |

11 |

Before Using ....................................................................... |

12 |

Features ....................................................................................... |

12 |

Set Contents ................................................................................ |

14 |

Transmitter T4GRS....................................................................... |

15 |

Nomenclature........................................................................... |

15 |

Battery Replacement Method................................................... |

16 |

When Using The Optional Battery............................................ |

17 |

When Charging The Optional Battery....................................... |

18 |

Low Battery Alarm.................................................................... |

19 |

Power & Display Switch............................................................ |

20 |

Display When Power Switch Is Turned On................................ |

21 |

Stick Operation CH1 CH2......................................................... |

22 |

Switch Dial Operation CH3 CH4............................................... |

23 |

Digital Trim Operation............................................................... |

24 |

Stick Lever Head Adjustment.................................................... |

25 |

Stick Mounting Angle Adjustment............................................. |

25 |

Stick Tension Adjustment.......................................................... |

26 |

Mechanical Throttle Stick Stroke Adjustment............................ |

27 |

Neutral Adjuster Operation....................................................... |

28 |

Changing to Ratchet Type Throttle Stick................................... |

30 |

About Transmitter Antenna And Receiver................................. |

31 |

About The Transmitter Antenna................................................ |

31 |

Receiver Terminology............................................................... |

32 |

Receiver Installation.................................................................. |

32 |

Installation .......................................................................... |

33 |

Receiver and Servo Connections .............................................. |

33 |

Installation Safety Precautions................................................... |

34 |

4

Initial Set-Up ....................................................................... |

|

37 |

|

|

|

|

|

|

|

|

|

|

..........................................................Preparations (Transmitter) |

|

37 |

|

|

|

Receiver Type Check (RX MODE) |

37 |

|

|

|

|

For Your Safety |

||||

|

Receiver Type Change & How To Link |

38 |

|

||

|

|

As Well As |

|||

|

Throttle Mode Check................................................................. |

41 |

|

||

|

Trims Initial Set-Up.................................................................... |

41 |

|

That Of Others |

|

|

|

|

|

|

|

Function Map ...................................................................... |

|

43 |

|

|

|

|

|

||||

|

|

|

|

|

|

|

Operation Of Screen.................................................................... |

43 |

|

|

Before |

|

Selecting the Menu Screen....................................................... |

43 |

|

|

Using |

|

Selecting Items On The Menu Screen...................................... |

44 |

|

|

|

|

Value Of Each Function And Changing The Set Value |

44 |

|

|

|

|

|

|

|||

|

Basic Menu Japanese Katakana Character Display |

45 |

|

|

|

|

|

|

|||

|

Function List................................................................................ |

46 |

|

|

Installation |

|

|

|

|

|

|

Functions ............................................................................ |

|

47 |

|

|

|

|

|

|

|

|

|

Model "MODEL".......................................................................... |

47 |

Model Menu Display................................................................. |

47 |

Model Selection "SELECT" ..................................................... |

48 |

Model memory select |

|

Model Copy "COPY"................................................................. |

49 |

Model memory copy |

|

Model Reset "RESET"............................................................. |

50 |

Model memory reset |

|

Model Name "MDL NAME"......................................................... |

51 |

Model memory name & User name, set/modify |

|

Servo Reverse "REVERSE"......................................................... |

52 |

Servo operation reversing |

|

Sub trim "SUBTRIM"................................................................... |

53 |

Servo center position fine adjustment |

|

End Point Adjuster "END POINT".............................................. |

54 |

End point adjustment |

|

Fail Safe Function "FAIL SAFE"................................................. |

57 |

Fail safe, battery fail safe function |

|

Exponential Adjustment "EXP".................................................. |

59 |

Steering operation curve / Throttle curve adjustment |

|

Servo Speed "SPEED"................................................................. |

62 |

Steering/ Throttle servo delay adjustment |

|

Throttle Acceleration "TH ACCEL"............................................ |

65 |

Function which adjusts the initial response from the throttle neutral position |

|

A.B.S. Function "TH A.B.S"........................................................ |

67 |

Pulse brake |

|

Initial

Set-Up

Function

Map

Functions

Reference

5

Channel 3/4 "CH3/CH4"................................................................ |

71 |

Channel 3/4 Position |

|

Steering Dual Rate/ Throttle ATL "D/R ATL".............................. |

72 |

Steering D/R, Throttle ATL Rate |

|

Select Switch Dial Function "SW/ DIAL"................................... |

73 |

Selection of functions operated by dial, digital trim and switch |

|

Brake Mixing "BRAKE MIX"........................................................ |

76 |

Front and rear independent brake control for 1/5GP car, etc. |

|

Programmable Mixing "PROG MIX"........................................... |

78 |

Programmable mixing between specific channels |

|

4WS Mixing "4WS"....................................................................... |

80 |

Special mixing used with Crawler and other 4WS type vehicles |

|

Dual ESC Mixing "DUAL ESC".................................................... |

82 |

Special mixing used with Crawler and other 4WD type vehicles |

|

Gyro Mixing "GYRO MIX"............................................................. |

84 |

Used to set the Futaba car rate gyro. |

|

CPS Mixing "CPS MIX"................................................................. |

86 |

Controls the Futaba CPS-1 channel power switch. |

|

Throttle Mode "TH MODE"......................................................... |

88 |

Throttle Servo Neutral Position "SXNT".................................... |

88 |

Throttle servo forward and brake operation proportion setting |

|

Idle-Up "IDLUP"....................................................................... |

89 |

Idle up at engine start |

|

Neutral Brake "NTBRK"............................................................ |

90 |

Neutral brake function |

|

Throttle Off (Engine Cut) "THOFF".......................................... |

91 |

Engine cut off by switch |

|

ESC Link Function "MC LINK".................................................... |

92 |

Special function, Futaba ESC (MC940CR, MC960CR, MC950CR, MC851C, MC602C, MC402CR, etc.)

Data Transfer "MDL TRANS"..................................................... |

100 |

The T4GRS model memory data to another T4GRS |

|

Timer Function "TIMER".......................................................... |

102 |

Up, Fuel down, or lap timer |

|

Lap List "LAP LIST".................................................................. |

108 |

Lap timer data check |

|

System Functions "SYSTEM" .................................................. |

109 |

Liquid crystal screen contrast adjustment |

|

Liquid crystal screen backlighting display mode setup |

|

Backlight display time setup |

|

Backlight brightness setup |

|

Battery type setting |

|

Buzzer sound tone adjustment |

|

6

Alarm Setting if Tx is left switched ON

Item which displays the basic menu screen in katakana characters for Japanese use Throttle stick adjustment

HOME screen display mode setting

Adjuster "ADJUSTER"............................................................... |

113 |

Steering wheel and throttle trigger correction |

|

Telemetry "TELEMETRY".......................................................... |

115 |

Telemetry/ Log Screen Map.................................................... |

116 |

Telemetry Function ON/OFF................................................... |

117 |

Telemetry Sensor Setting........................................................ |

118 |

Log Setting, Start/ Stop.......................................................... |

120 |

Log Data List........................................................................... |

122 |

Reference .......................................................................... |

123 |

Ratings ....................................................................................... |

123 |

Warning Displays ...................................................................... |

124 |

Optional Parts ............................................................................ |

126 |

When requesting repair............................................................. |

126 |

For Your Safety

As Well As

That Of Others

Before

Using

Installation

Initial

Set-Up

Function

Map

Functions

Reference

7

For Your Safety As Well As That Of Others

For Your Safety As Well As That Of Others

Others Of That As Well As Safety Your For

Use this product in a safe manner. Please observe the following safety precautions at all times.

Explanation Of Symbols

The parts of this manual indicated by the following symbols are extremely important and must be observed.

|

Symbols |

|

Explanation |

||

|

|

|

|

||

|

Danger |

cause death or serious injury if ignored and not performed properly. |

|||

|

|

Indicates a procedure which could lead to a dangerous situation and may |

|||

|

|

|

|

|

|

|

Warning |

Indicates procedures which may lead to dangerous situations and could |

|||

|

cause death or serious injury as well as superficial injury and physical |

||||

|

|

damage. |

|

|

|

|

|

|

|

|

|

|

Caution |

Indicates procedures that may not cause serious injury, but could lead to |

|||

|

physical damage. |

|

|

|

|

|

Symbols: |

: Prohibited |

: Mandatory |

||

2.4GHz System Precautions

Warning

Warning

Special attention should be paid before turning on the system while other cars are running or other airplanes are flying because the 2.4GHz RC system could potentially affect them.

Be sure to set the Fail Safe function.

Be sure to set the Fail Safe function.

Receiver Mode Precautions

Caution

Caution

When using the T4GRS in the T-FHSS (HIGH) and S-FHSS (HIGH) mode, always use it under the following conditions:

When using the T4GRS in the T-FHSS (HIGH) and S-FHSS (HIGH) mode, always use it under the following conditions:

Servos |

:Futaba digital servo (including BLS Series brushless servos) |

Receiver’s battery |

:Matched to the ratings of the receiver and connected digital servo (dry cell battery cannot be used). |

Transmitter mode |

:RX MODE |

Under other conditions, the set will not operate, or the specified performance will not be displayed even if it operates. In addition, it may cause servo trouble. Futaba will not be responsible for damage, etc. caused by combination with the products of other companies.

In addition, the FSU Fail Safe Unit cannot be used because the system is different. Use the fail safe function of the transmitter.

When using analog servos, always switch the T4GRS servo response to the "NORM" mode.

When using analog servos, always switch the T4GRS servo response to the "NORM" mode.

Transmitter mode:"T-FHSS(NORM)", "T-FHSS(NORM)"and FHSS mode

Receiver’s battery :Matched to the ratings of the receiver and connected servo (dry cell battery cannot be used).

The set cannot operate in the "HIGH" mode. Operation in this mode will cause trouble with the servo and other equipment.

Digital servos (including BLS Series brushless servos) can also be used in the "NORM" mode.

8

Operation Precautions

Warning

Warning

Do not operate outdoors on rainy days, run through puddles of water or use when visibility is limited.

Do not operate outdoors on rainy days, run through puddles of water or use when visibility is limited.

Should any type of moisture (water or snow) enter any component of the system, erratic operation and loss of control may occur.

Do not operate in the following places.

Do not operate in the following places.

-Near other sites where other radio control activity may occur. -Near people or roads.

-On any pond when passenger boats are present.

-Near high tension power lines or communication broadcasting antennas.

Interference could cause loss of control. Improper installation of your Radio Control System in your model could result in serious injury.

Do not operate this R/C system when you are tired, not feeling well or under the influence of alcohol or drugs.

Do not operate this R/C system when you are tired, not feeling well or under the influence of alcohol or drugs.

Your judgment is impaired and could result in a dangerous situation that may cause serious injury to yourself as well as others.

Do not touch the engine, motor, speed control or any part of the model that will generate heat while the model is operating or immediately after its use.

Do not touch the engine, motor, speed control or any part of the model that will generate heat while the model is operating or immediately after its use.

These parts may be very hot and can cause serious burns.

Always perform an operating range check prior to use.

Always perform an operating range check prior to use.

Problems with the radio control system as well as improper installation in a model could cause loss of control.

(Simple range test method)

Have a friend hold the model, or clamp it down or place it where the sticks or prop cannot come in contact with any object. Walk away and check to see if the servos follow the movement of the controls on the transmitter. Should you notice any abnormal operation, do not operate the model. Also check to be sure the model memory matches the model in use.

Turning on the power switches.

Turning on the power switches.

Always check the throttle stick on the transmitter to be sure it is at the neutral position.

1.Turn on the transmitter power switch.

2.Turn on the receiver or speed control power switch.

Turning off the power switches

Always be sure the engine is not running or the motor is stopped.

1.Turn off the receiver or speed control power switch.

2. Then turn off the transmitter power switch.

If the power switches are turned off in the opposite order, the model may unexpectedly run out of control and cause a very dangerous situation.

When making adjustments to the model, do so with the engine not running or the motor disconnected.

When making adjustments to the model, do so with the engine not running or the motor disconnected.

You may unexpectedly lose control and create a dangerous situation.

Before running (cruising), check the fail safe function.

Before running (cruising), check the fail safe function.

Check Method; Before starting the engine, check the fail safe function as follows:

1)Turn on the transmitter and receiver power switches.

2)Wait at least one minute, then turn off the transmitter power switch. (The transmitter automatically transfers the fail safe data to the receiver every minute.)

3)Check if the fail safe function moves the servos to the preset position when reception fails.

The fail safe function is a safety feature that minimizes set damage by moving the servos to a preset position when reception fails. However, if set to a dangerous position, it has the opposite effect. When the reverse function was used to change the operating direction of a servo, the fail safe function must be reset.

Setting example: Throttle idle or brake position

For Your Safety As Well As That Of Others

9

Others Of That As Well As Safety Your For

NiMH / NiCd / LiFe Battery Handling Precautions

(Only when NiMH/NiCd /LiFe batteries are used)

Warning

Warning

Never plug the charger into an outlet of other than the indicated voltage.

Never plug the charger into an outlet of other than the indicated voltage.

Plugging the charger into the wrong outlet could result in an explosion or fire.

Never insert or remove the charger while your hands are wet.

Never insert or remove the charger while your hands are wet.

You may get an electric shock.

Do not use the T4GRS transmitter's battery, as the receiver's battery.

Do not use the T4GRS transmitter's battery, as the receiver's battery.

Since the transmitter's battery has an overload protection circuit, the output power will be shut down when the high current load is applied. This may result in runaway or fatal crash.

Always check to be sure your batteries have been charged prior to operating the model.

Always check to be sure your batteries have been charged prior to operating the model.

Should the battery go dead while the model is operating, loss of control will occur and create a very dangerous situation.

To recharge the transmitter battery, use the special charger made for this purpose.

To recharge the transmitter battery, use the special charger made for this purpose.

Overcharging could cause the battery to overheat, leak or explode. This may lead to fire, burns, loss of sight and many other types of injuries.

Caution

Caution

Do not use commercial AA size NiCd and NiMH batteries.

Do not use commercial AA size NiCd and NiMH batteries.

Quick charging may cause the battery contacts to overheat and damage the battery holder.

Do not short circuit the battery terminals.

Do not short circuit the battery terminals.

A short circuit across the battery terminals may cause abnormal heating, fire and burns.

Do not drop the battery or expose it to strong shocks or vibrations.

Do not drop the battery or expose it to strong shocks or vibrations.

The battery may short circuit and overheat; electrolyte may leak out and cause burns or chemical damage.

When the model is not being used, always remove or disconnect the battery.

When the model is not being used, always remove or disconnect the battery.

Leaving the battery connected could create a dangerous situation if someone accidentally turns on the receiver power switch. Loss of control could occur.

Always keep the charger disconnected from the outlet while it is not in use.

Always keep the charger disconnected from the outlet while it is not in use.

Storage And Disposal Precautions

Warning

Warning

Do not leave the radio system or models within the reach of small children.

Do not leave the radio system or models within the reach of small children.

A small child may accidentally operate the system. This could cause a dangerous situation and injuries. NiCd batteries can be very dangerous when mishandled and cause chemical damage.

Do not throw NiMH/NiCd/LiFe batteries into a fire. Do not expose batteries to extreme heat. Also do not disassemble or modify a battery pack.

Do not throw NiMH/NiCd/LiFe batteries into a fire. Do not expose batteries to extreme heat. Also do not disassemble or modify a battery pack.

Overheating and breakage will cause the electrolyte to leak from the cells and cause skin burns, loss of sight, and other injuries.

10

When the system will not be used for any length of time, store the system with NiMH/NiCd batteries in a discharged state. Be sure to recharge the batteries prior to the next time the system is used.

When the system will not be used for any length of time, store the system with NiMH/NiCd batteries in a discharged state. Be sure to recharge the batteries prior to the next time the system is used.

If the batteries are repeatedly recharged in a slightly discharged state, the memory effect of the NiMH/NiCd battery may considerably reduce the capacity. A reduction in operating time will occur even when the batteries are charged for the recommended time. (After discharge to 1cell E.V.=1V)

When the LiFe batteries will not be used for a long time, to prevent it from deteriorating we recommend that it be kept in about the half capacity state instead of fully charged. Also be careful that the battery does not enter the over-discharged state due to self-discharge.

When the LiFe batteries will not be used for a long time, to prevent it from deteriorating we recommend that it be kept in about the half capacity state instead of fully charged. Also be careful that the battery does not enter the over-discharged state due to self-discharge.

Periodically (about every 3 months) charge the battery.

<NiMH/NiCd Battery Electrolyte>

The electrolyte in NiCd/NiMH batteries is a strong alkali. Should you get even the smallest amount of the electrolyte in your eyes, DO NOT RUB. Wash immediately with water, and seek medical attention at once. The electrolyte can cause blindness. If electrolyte comes in contact with your skin or clothes, wash with water immediately.

Warning

Warning

Do not store your R/C system in the following places.

-Where it is extremely hot or cold.

-Where the system will be exposed to direct sunlight.

-Where the humidity is high.

-Where vibration is prevalent.

-Where dust is prevalent.

-Where the system would be exposed to steam and condensation.

Storing your R/C system under adverse conditions could cause deformation and numerous problems with operation.

If the system will not be used for a long period of time, remove the batteries from the transmitter and model and store in a cool, dry place.

If the batteries are left in the transmitter, electrolyte may leak and damage the transmitter. This applies to the model also. Remove the batteries from it also to prevent damage.

<NiMH/NiCd/Li-ion Battery Recycling>

A used battery is a valuable resource. Insulate the battery terminals and dispose of the battery by taking it to a battery recycling center.

For Your Safety As Well As That Of Others

Other Precautions

Caution

Caution

Do not expose plastic parts to fuel, motor spray, waste oil or exhaust.

Do not expose plastic parts to fuel, motor spray, waste oil or exhaust.

The fuel, motor spray, waste oil and exhaust will penetrate and damage the plastic.

Always use only genuine Futaba transmitters, receivers, servos, ESCs (electronic speed controls), NiMH/NiCd batteries and other optional accessories.

Futaba will not be responsible for problems caused by the use of other than genuine Futaba parts. Use the parts specified in the instruction manual and catalog.

Never use the R304SB-E in GP (Engine) models.

Never use the R304SB-E in GP (Engine) models.

Receiver R304SB-E can be used only with EP car.

11

Using Before

12

Before Using

Features

-Telemetry system

The T4GRS transmitter has adopted the newly developed bidirectional communication system "T-FHSS"

-2.4GHzSS (Spread Spectrum) radio communication system

Frequency channel setting is unnecessary: Channel shifting takes place within the 2.4GHz band automatically. This system minimizes the interference from other 2.4GHz systems.

-Model memory for 40 models

Model names can use up to 10 letters, numbers, and symbols, so that logical names may be used. A model memory with different setups can be created by using the model copy function.

- Menu Selection

The setup screens are called from menu screens. The menu screen can be selected from among 2 levels (LEVEL1/LEVEL2).

-Brake mixing for large cars (BRAKE)

Brake mixing of the front and rear sticks of 1/5GP and other large cars can be adjusted independently.

-4WS mixing for crawlers and other 4WS type (4WS)

This function can be used with crawlers and other 4WS type vehicles.

-Dual ESCs mixing for crawlers cars (DUAL ESC)

ESC at the front and rear are controlled independently.

-Gyro mixing (GYRO MIX)

The sensitivity of Futaba car rate gyros can be adjusted from the T4GRS.

-CPS-1 mixing (CPS MIX)

LED lighting and flashing control using our CPS-1 channel power switch can be matched to steering and throttle operation by switch only.

-Anti-skid braking system (TH A.B.S)

This function applies the brakes so that the tires of gasoline engine cars, etc. do not lose their grip on the road even when braking at corners.

-Throttle acceleration (ACCEL)

Gasoline engine cars have a time lag before the clutch and brakes become effective. The throttle acceleration function reduces this time lag.

-Throttle speed (SPEED)

Sudden stick operation on a slippery road surface will only cause the tires to spin and the model to not accelerate smoothly. By setting the throttle speed function, operation can be performed smoothly and easily. It also suppresses battery consumption.

-Steering speed (SPEED)

When you sense that the steering servo is too fast, etc., the servo operating speed (direction that suppresses the maximum speed) can be adjusted.

-Racing timer (TIMER)

The lap timer can record 100 lap times and total time. The timer can also be started automatically by stick operation. The race time and audible alarm can be set.

Re-/fueling time are indicated by an audible alarm. An up timer is also provided.

-Digital trim

The current trim position is displayed on the LCD screen. The operating amount of 1 step can also be adjusted.

Trim operation has no effect on the maximum travel of the steering and throttle servos.

-Function select switch / dial function (TRIM DIAL)

This function assigns functions to 2 switches and dials (digital trim, digital dial). The step amount and operating direction can also be adjusted. Trim positioning at each model call is unnecessary because all the dials are digital.

-ESC-Link function (MC-LINK)

This is a dedicated function which allows setting of the contents of the Link software which makes possible Futaba speed controller (ESC), MC950CR, MC850C, MC851C, MC602C, MC402CR, etc. variable frequency and other data changes by T4GRS.

-Tension adjustment function

The tension of the steering stick & throttle stick springs can be adjusted from the inside.

-Adjustable Throttle Stick Travel (Mechanical ATL Adjustment)

Make this adjustment when you want to decrease the total travel of the forward (up) side or brake (down) side of the throttle stick.

-Display switch

Display switch allows function setup without transmitting.

Before Using

13

Set Contents

After opening the box, first check if the contents conform to the following. The contents depend on the set as shown below.

Using Before

Transmitter |

T4GRS |

|

|

Receiver |

R304SB or R304SB-E(Built-in Antenna for EP car models) |

|

|

|

Receiver switch |

|

* It is not attached to R304 SB-E set. |

Miscellaneous |

Mini screwdriver |

|

|

|

* It is used for receiver. |

|

Instruction manual |

|

|

- If any of the set contents are missing, or you have any questions, please contact your dealer.

Caution

Caution

When using the T4GRS in the T-FHSS (HIGH) and S-FHSS (HIGH) mode, always use it under the following conditions:

Servos |

:Futaba digital servo (including BLS Series brushless servos) |

Receiver’s battery |

:Matched to the ratings of the receiver and connected digital servo (dry cell battery cannot be used). |

Transmitter mode |

:RX MODE |

Under other conditions, the set will not operate, or the specified performance will not be displayed even if it operates. In addition, it may cause servo trouble. Futaba will not be responsible for damage, etc. caused by combination with the products of other companies.

In addition, the FSU Fail Safe Unit cannot be used because the system is different. Use the fail safe function of the transmitter.

When using analog servos, always switch the T4GRS servo response to the "NORM" mode.

When using analog servos, always switch the T4GRS servo response to the "NORM" mode.

Transmitter mode:"T-FHSS(NORM)", "T-FHSS(NORM)"and FHSS mode

Receiver’s battery :Matched to the ratings of the receiver and connected servo (dry cell battery cannot be used).

The set cannot operate in the "HIGH" mode. Operation in this mode will cause trouble with the servo and other equipment. Digital servos (including BLS Series brushless servos) can also be used in the "NORM" mode.

Always use only genuine Futaba transmitters, receivers, servos, ESCs (electronic speed controls), NiMH, NiCd, Li-ion batteries and other optional accessories.

Futaba will not be responsible for problems caused by the use of other than Futaba genuine parts. Use the parts specified in the instruction manual and catalog.

14

Transmitter T4GRS

Nomenclature

Digital Dial 1 (DL1)

(default CH4)

Switch 2 (SW2)

(default CH3)

Digital Trim 4 (DT4)

(default ATL)

LCD screen

Throttle stick

Digital Trim 2 (DT2)  (default throttle trim)

(default throttle trim)

Hook

Power&Display

switch

Grip Handle

Battery

Antenna |

|

Switch 1 (SW1) |

|

Digital Trim 3 (DT3) |

|

(default dual rate) |

|

Steering stick |

|

Digital Trim1 (DT1) |

Using |

(default steering trim) |

|

Button |

Before |

|

|

Button

Jog Button

Jog Button

Edit Button

Antenna cannot be removed.

Damage will occur if the antenna is forcibly removed.

Do not carry the transmitter by the antenna.

There is the danger that the antenna wire will break and operation will become impossible.

Stick lever head the precautions.

There is a small projection at the tip of the lever heads to prevent slipping. When carrying the transmitter, be careful these projections do not damage your skin, clothes, or other objects.

Charge jack (Only for NiMH)

Communication port

Communication port

*The switches, dial, and trimmers in the figure are shown in the initial setting position.

15

Using Before

Battery Replacement Method (4 AA Size Batteries)

Load the four batteries in accordance with the polarity markings on the battery holder.

Battery Replacement Method

1 Remove the battery cover from the transmitter by sliding it in the direction of the arrow in the figure.

2 Remove the used batteries.

3 Load the new AA size batteries. Pay very close attention to the polarity markings and reinsert accordingly.

4 Slide the battery cover back onto the case.

Check:

Battery cover

Slide battery cover while pressing here.

Turn the power switch on the transmitter to the ON position. Check the battery voltage display on the LCD screen. If the voltage is low, check the batteries for insufficient contact in the case or incorrect battery polarity.

Disposal of the Dry Cell Batteries:

The method to dispose of used dry cell batteries depends on the area in which you reside. Dispose of the batteries in accordance with the regulations for your area.

Caution

Caution

Never try to recharge a dry cell battery.

Never try to recharge a dry cell battery.

The transmitter may be damaged or the battery electrolyte may leak or the battery may break.

Insert the batteries in the correct polarity.

Insert the batteries in the correct polarity.

If the polarity is incorrect, the transmitter may be damaged.

When the transmitter is not in use, remove the batteries.

When the transmitter is not in use, remove the batteries.

If the battery electrolyte leaks, wipe off the case and contacts.

Do not use commercial AA size NiCd and NiMH batteries.

Do not use commercial AA size NiCd and NiMH batteries.

Quick charging may cause the battery contacts to overheat and damage the battery holder.

16

When Using The Optional Battery

When using an optional rechargeable battery, replace the battery as described below. -Always use the optional HT5F1800B or FT2F1700BV2/2100BV2 rechargeable battery. -The type of power source used must be set by system setting.

-When the transmitter will not be used for a long time, remove the battery.

Battery Replacement Method

1 Refer to the previous description and remove the transmitter battery cover.

2 After removing the dry cell battery box from the transmitter, disconnect the connector.

3 Insert the connector of the new battery and load the new battery into the transmitter.

CAPACITY:HT5F1700B6. |

|

CHARGING: 0VDC- |

|

170mA-1700mAh |

|

|

12hours |

4 Finish by installing the battery cover.

Caution

Caution

When closing the battery cover, be careful that the battery cover does not pinch the battery lead wires.

When closing the battery cover, be careful that the battery cover does not pinch the battery lead wires.

Shorting of the battery lead wires may lead to fire and abnormal heating and cause burns or fire disaster.

HT5F1700B

CAPACITY: 6.0VDC-1700mAh

CHARGING: 170mA-12hours

Before Using

17

Using Before

When Charging the Optional Battery

Charging a NiMH Battery

(Example: When using the HT5F1800B with the special charger)

1 Plug the transmitter cord of the special charger into the charging jack on the rear of the transmitter.

2 Plug the charger into an AC outlet.

3 Check that the charging LED lights.

The charging time when charging the HT5F1800B battery with the optional special charger is approximately 15 hours. However, when the battery has not been used for some time, repeat charging 2 or 3 times to activate the battery.

Over current protection

The transmitter charging circuit is equipped with an over current protection circuit (1.0A). If the battery is charged with a quick charger for other than digital proportional R/C sets, it may not be fully charged.

AC outlet

AC outlet

Charger

Transmitter

Transmitter

charging LED

To receiver |

To transmitter |

Ni-Cd battery |

charging jack |

Charging A LiFe Battery

(Example: When using the FT2F1700BV2/2100BV2 with the special charger)

1 Remove the battery cover.

2 Disconnect the battery from the 4GRS

3 Balance charging cannot be done through the transmitter, you must remove the LiFe battery to do this charge.

Charging jack

Cannot be used for charge of LiFe.

Charge the optional FT2F1700BV2/2100BV2 (LiFe) battery with the special charger in accordance with the instruction manual supplied.

When the battery will not be used for a long time, to prevent it from deteriorating we recommend that it be kept in about the half capacity state instead of fully charged. Also be careful that the battery does not enter the over-discharged state due to self-discharge.

Periodically (about every 3 months) charge the battery.

Balance charging connector for

LiFe battery charger.

LiFe battery charger.

LiFe battery is removed from transmitter.

18

Warning

Warning

Never plug it into an outlet other than the indicated voltage.

Never plug it into an outlet other than the indicated voltage.

Plugging the charger into the wrong outlet could result in an explosion or fire.

Do not insert and remove the charger when your hands are wet.

Do not insert and remove the charger when your hands are wet.

It may cause an electric shock.

Always use the special charger or a quick charger for digital proportional R/C sets to charge a digital proportional R/C set NiMH battery.

Always use the special charger or a quick charger for digital proportional R/C sets to charge a digital proportional R/C set NiMH battery.

Overcharging a Ni-MH battery can result in burns, fire, injuries, or loss of sight due to overheating, breakage, or electrolyte leakage.

Caution

Caution

When the charger is not in use, disconnect it from the AC outlet.

When the charger is not in use, disconnect it from the AC outlet.

Do this to prevent accidents and to avoid overheating.

Low Battery Alarm

If the transmitter battery voltage drops below the usable range, an audible alarm will sound and "BATTERY LOW VOLTAGE" will be displayed on the LCD screen. If the battery goes dead while running (cruising), you will lose control of the vehicle (boat). Therefore, retrieve the vehicle (boat) immediately and cease operation.

Because the low battery alarm voltage of a dry cell battery is different from that of a rechargeable battery pack (genuine Futaba option), the type of power source used must be set by system setting.

Warning

Warning

When a low battery alarm is generated, cease operation immediately and retrieve the model.

If the battery goes dead while in operation, you will lose control of the model.

Before Using

19

LCD screen

Using Before

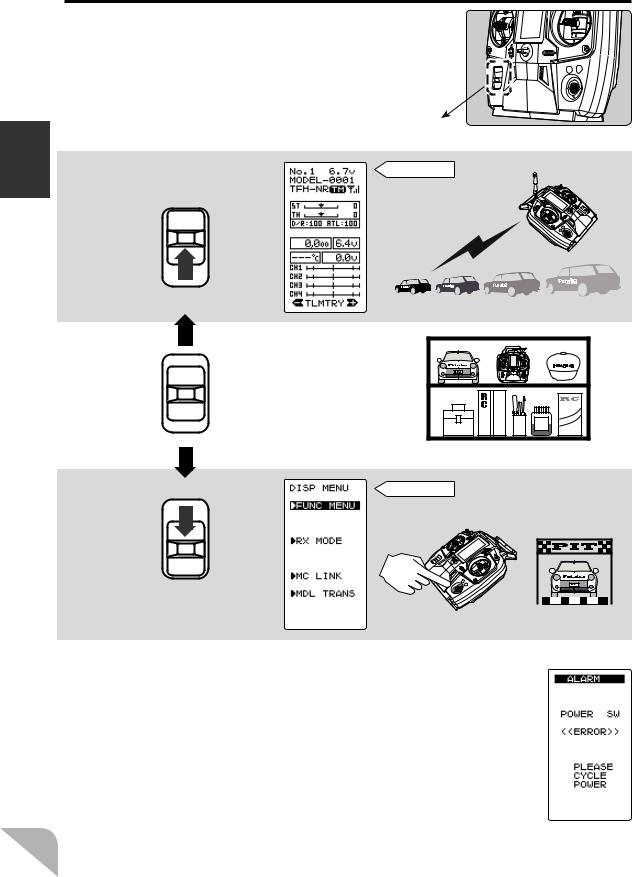

When you do not run, turn OFF.

It cannot operate.

-When the data is changed using the edit buttons or trim levers, wait at least two seconds before turning off the power. If the power is turned off within two seconds after the data is changed, the new data will not be written to memory.

-If the power switch is quickly switched from the DISP mode to the PW ON mode or vice versa, the switch error shown at the right may be generated. If this occurs, cycle the power.

20

Display When Power Switch Is Turned On

Power switch turned on

Battery voltage display |

|

|

|

|

|

|

|

|

|

|

|

|

Telemetry function :ON/OFF |

||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Receiver -> Transmitter: |

||

|

|

|

|

|

|

|

|

|

|

|

|

||||

Model number |

|

|

|

|

|

|

|

|

|

|

|

|

The reception strength is shown. |

||

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model name (10 characters) |

|

|

|

|

|

|

|

|

|

|

|

|

ST |

:Steering trim display |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

The current receiver mode is |

|

|

|

|

|

|

|

|

|

|

|

|

TH |

:Throttle trim display |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

displayed. |

|

|

|

|

|

|

|

|

|

|

|

|

D/R :Steering D/R display |

||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

Telemetry data |

|

|

|

|

|

|

|

|

|

|

|

|

ATL :Throttle ATL display |

||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

Servo operation of each |

|||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

channel can be checked. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Beep confirmation sound is generated and the |

|

|

|||||||||||

|

|

HOME screen shown below appears. |

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LCD Screen Contrast

The LCD screen contrast can be adjusted.

Caution

Do not adjust the contrast so that the LCD is too bright or too dark.

When the display cannot be read due to a temperature change, data cannot be set.

Before Using

Alarm Setting if Tx is left switched ON

When the steering stick, throttle stick, push switch, or edit button are not operated for 10 minutes (default), an alarm sounds and "NOT OPERATED FOR A LONG

TIME" is displayed on the LCD screen.

When the steering stick, throttle stick, push switch, or edit button are operated, the alarm is reset. If the system is not to be used, turn off the power.

The function can be deactivated in the system menu.

21

Using Before

Stick Operation CH1 CH2

(CH1: Steering stick, CH2: Throttle stick,)

Throttle Stick Function: Controls the speed of the model as well as the direction of travel - forward or reverse.

Steering Stick Function: Turns the model right or left.

Servo operation of steering channel (CH1)can be checked.

Servo operation of steering channel (CH1)can be checked.

Servo operation of throttle channel (CH2) can be checked.

Servo operation of throttle channel (CH2) can be checked.

|

|

|

|

Throttle stick |

Steering stick |

|

|

||||||

|

|

|

|

CH2 |

CH1 |

|

|

||||||

|

Throttle stick function |

|

Steering stick function |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UP |

Forward |

Left turn |

Right turn |

Down |

brake or back |

Right |

|

Left |

( RC Car example shown

22

Switch Dial Operation CH3 CH4

(CH3: Switch SW2, CH4: Dial DL1)

The three-position switch SW2 will result in the servo arm moving to three different positions when operated.

Note that this function cannot be assigned to the spring return switch SW1.

Rotating the Dial (DL1) will proportionally control a servo on CH4.  The SW2 switch and DL1 dial can be assigned to either function.

The SW2 switch and DL1 dial can be assigned to either function.

Switch SW2 Dial DL1 Switch SW1 The function cannot

3position Return be assigned to SW1

Before Using

Operation of CH3 can be checked.

Operation of CH3 can be checked.

Initial setting |

Operation of CH4 can |

|

be checked. |

||

|

SW2 3CH Servo |

DL1 4CH Servo

T4GRS beeps when the dial reaches center and limit position.

•The servo arm position and dial do not necessarily always match exactly.

23

Using Before

Digital Trim Operation DT1 DT2

(Initial settings: DT1: Steering trim, DT2: Throttle trim,)

Operated by the lever: Push the lever to the left or right (up or down) The current position is displayed on the LCD screen.

Steering trim display

Steering trim display

Throttle trim display

Throttle trim display

DT2 DT1

•Each step is indicated by a tone.

•When the trim exceeds the maximum trim adjustment range, the beep will change and the servo will not move any farther.

•Trim lever adjustments have no effect on the maximum servo travel. This prevents the linkages from binding when adjustments are made.

Trim Operation

With the center trim feature, trim adjustments have no effect on the maximum servo travel. This prevents the linkages from binding when adjustments are made.

Digital Trim Operation DT3 DT4

(Initial setting: DT3; Steering D/R, DT4; ATL)

Operated by the lever: Push the lever to up or down. The current position is displayed on the LCD screen.

DT4 ATL Brake amount adjustment

DT3 Steering D/R

Steering D/R

Steering D/R

display

ATL display

ATL display

•Each step is indicated by a tone.

•When the trim exceeds the maximum trim adjustment range, the tone will change pitch and the servo will not move any farther.

24

Stick Lever Head Adjustment

The length of the lever head of the steering and throttle sticks can be adjusted.

Adjustment |

Lever head |

Lever head |

1 Unlock lever head "A" by turning it counterclockwise. |

|

|

2 Adjust the head to the length best for you, then lock the heads by turning lever head "A" clockwise and lever head "B" counterclockwise.

Before Using

Stick Mounting Angle Adjustment

The mounting angle of the throttle and steering sticks can be adjusted.

Setting

1 Loosen the two set screws.

2 Change the stick angle.

3 Re tighten the two set screws.

•The figure at the right shows the throttle stick. The steering stick can adjusted similarly.

Set screws

25

Using Before

Stick Tension Adjustment

Make this adjustment when you want to change the steering stick or throttle stick spring tension.

Adjustment

1 Remove the battery from the transmitter.

2 Using Phillips screwdriver, as shown in a figure, four screws are removed, and a rear case is removed.

• Don't touch internal electronic components.

Rear case

3 Turn the adjusting screw using a small Phillips screwdriver such as a watchmaker's screwdriver.

•Turning the adjusting screw clockwise, increases the spring tension.

• The adjustment range is about five turns in both directions, from the initial position.

Steering stick adjusting |

Throttle stick adjusting |

screw |

screw |

4 When the adjustment is completed, re-attach the rear case with a Phillips screwdriver.

•Take great care not to damage the wiring when re-attaching the rear case.

•Foreign substances must not be allowed to get into the interior of the case.

Caution

If turned too far counterclockwise, the adjusting screw may fall out.

26

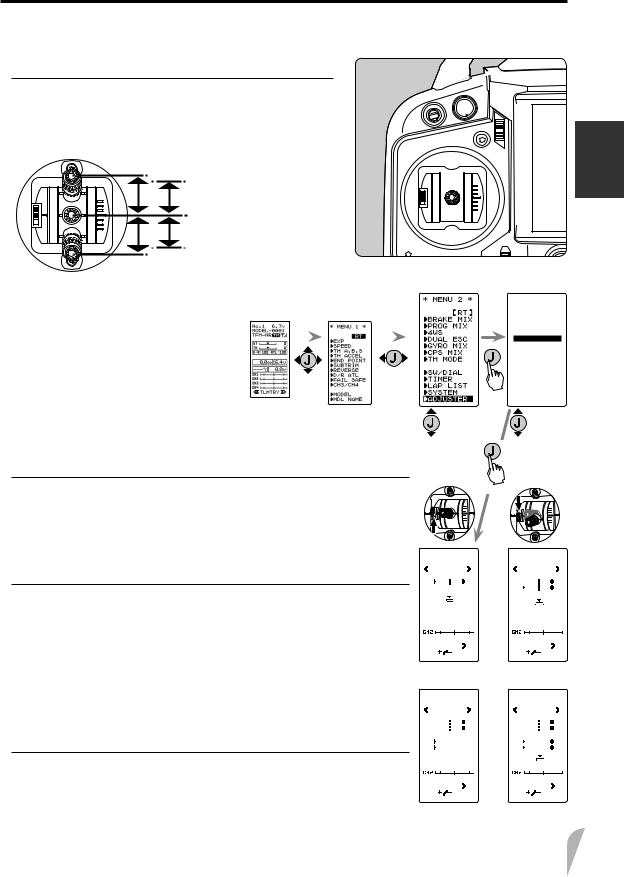

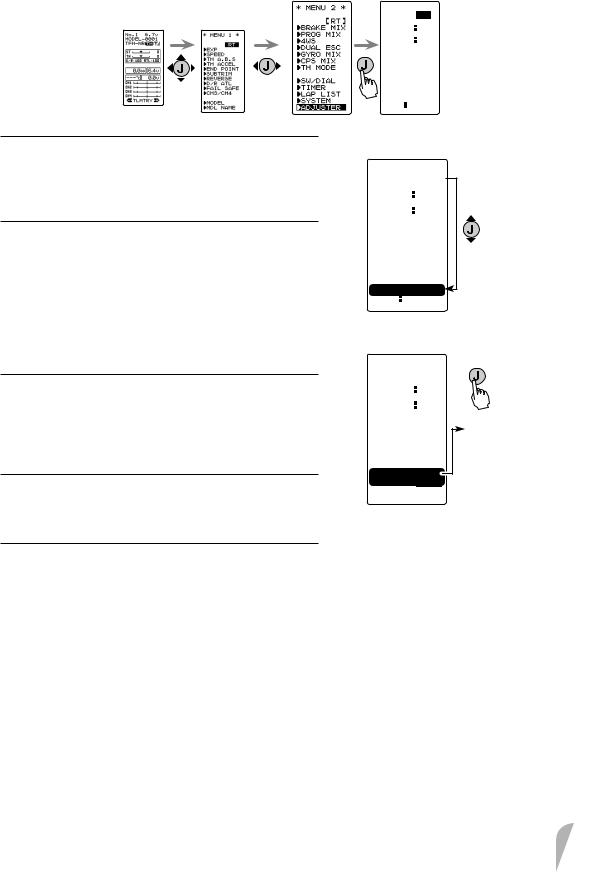

Mechanical Throttle Stick Stroke Adjustment

Make this adjustment when you want to reduce the throttle stick range at the full power or brake/reverse positions.

Stick stroke adjustment

1 Make this adjustment by turning the adjusting screw above the stick with a Phillips screwdriver.

• When the adjusting screw is turned counter clockwise, the stroke is reduced.

Brake (reverse) side

High side

Stroke can be reduced mechanically.

|

|

HOME |

|

|

|

|

|

|

|

2 On the MENU2 screen, select the |

|

|

MENU1 |

|

|

|

|||

|

setting item "ADJUSTER" using the |

|

|

|

|

|

|

||

|

(JOG) button, and pressing the (JOG) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||

|

button. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 (Selection of THROTTLE) |

|

|

|

|

|

|

|

|

Move the cursor to "THROTTLE" using the (JOG) button up or down function, and pressing the (JOG) button.

4 (Throttle 5:5 neutral adjustment )

Neutral adjuster is set to 5:5 the Neutral Adjuster switch (see next page). In the 5:5 neutral setup screen (fig-1) state, pull the stick back slightly then allow to return to neutral and press the (JOG) button whilst ensuring the stick is not touched.

5 (Throttle 7:3 neutral adjustment )

Neutral adjuster is set to 7:3 by the Neutral Adjuster switch (see next page). In the 7:3 neutral setup screen (fig-2) state, pull the stick back slightly then allow to return to neutral and press the (JOG) button whilst ensuring the stick is not touched.

Note that both the 5:5 and 7:3 neutral adjustment procedures have to be completed as part of the set-up process. Once complete the required option should be selected.

6 (Throttle throw adjustment)

MENU2

|

ADJUSTER |

|

[ RT ] |

|

STEERING |

|

THROTTLE |

|

Push |

Select |

Select |

ADJUSTER |

THROTTLE |

|

Push |

ADJUSTER |

ADJUSTER |

||

THROTTLE |

THROTTLE |

||

N5 |

5 |

N5 |

5 |

|

|

N7 |

3 |

CANCELKey |

CANCELKey |

||

fig-1 |

fig-2 |

||

ADJUSTER |

ADJUSTER |

||

THROTTLE |

THROTTLE |

||

N5 |

5 |

N5 |

5 |

N7 |

3 |

N7 |

3 |

BRK |

BRK |

||

FWD |

FWD |

||

Before Using

In the throw setup screen state (fig-3), gently move the stick fully |

CANCEL |

CANCEL |

|

Key |

Key |

to the brake /reverse and full power positions and when button |

fig-3 |

fig-4 |

|

27

Using Before

mark (fig-4) is displayed, pressing the (JOG) button.

An internal check is performed automatically. When each adjustment point is within a fixed range, correction is performed and "COMPLETE!" (fig-5) is displayed.

If an adjustment point is not within a fixed range, correction is not performed and the correction data is not updated.

If the stroke is made too narrow, this will cause an error. In that case, extend the stroke.

7 When complete, return to the ADJUSTER screen by press the (JOG) button.

8 Next, move the cursor to [RT] by the (JOG) button, and press the (JOG) button.

Caution

ADJUSTER THROTTLE

N5 5

N7  3

3

BRK

FWD

COMPLETE!

CANCELKey

fig-5

When the stroke is adjusted, the throttle servo travel should also be adjusted electronically. If the stroke is mechanically reduced too far the adjusting screw may fall out.

Neutral Adjuster Operation

The neutral adjuster selects the throttle stick neutral position. Neutral Adjuster

1 Neutral adjuster is set to 5 : 5 when in the upper position. It will be set to 7 : 3 when moved to the lower position

•If 7 : 3 is used, the neutral to full power stick range is increased.

Caution

When a neutral adjuster change is made, be sure to carry out system change.

2 On the MENU2 screen, select the setting item "SYSTEM" using the (JOG) button, and press the (JOG) button.

5

5

7

3

28

MENU2

HOME MENU1

3 (Selection of TH-STK)

Move the cursor to "TH-STK" using the (JOG) button up or down operation.

4 (Selection of your 4GRS neutral position)

Use the (+) and (-) buttons to select either 5:5 or 7:3.

•"F10" should be selected only when using a ratchet on the throttle stick. (for GP boats)

5 (Neutral position execution)

Press the (JOG) button for about 1 second. A beeping sound is generated and the neutral position is selected.

6 When completed, return to the MENU2 screen by pressing the (JOG) button.

7 Next, move the cursor to [RT] using the (JOG) button, and press the (JOG) button.

SYSTEM

RT

CONTRA 0

BK-LHT  ALL

ALL

LHT-TM 10s

LHT-PW  15

15

BATT  DRY4

DRY4

BUZZER  65

65

OPE-TM  OFF

OFF

MENU  ENG

ENG

Push TH-STK  5

5  5 DISP TLMTR

5 DISP TLMTR

SYSTEM [ RT ]

CONTRA 0 BK-LHT  ALL LHT-TM 10s LHT-PW

ALL LHT-TM 10s LHT-PW  15

15

BATT  DRY4

DRY4

BUZZER  65 OPE-TM

65 OPE-TM  OFF MENU

OFF MENU  ENG

ENG

SYSTEM [ RT ]

CONTRA 0 BK-LHT  ALL LHT-TM 10s LHT-PW

ALL LHT-TM 10s LHT-PW  15

15

BATT  DRY4

DRY4

BUZZER  65 OPE-TM

65 OPE-TM  OFF MENU

OFF MENU  ENG

ENG

DISP  TLMTR

TLMTR

|

|

|

|

|

UP or DOWN |

Using |

|

|

|||

|

|

|

|

|

|

Before |

|

Selection of your 4GRS |

|||

neutral position |

|||

5:5 |

|

|

|

7:3 |

|

|

|

F10 (Next page) |

|

|

|

Push

Press (JOG) about 1second

29

Using Before

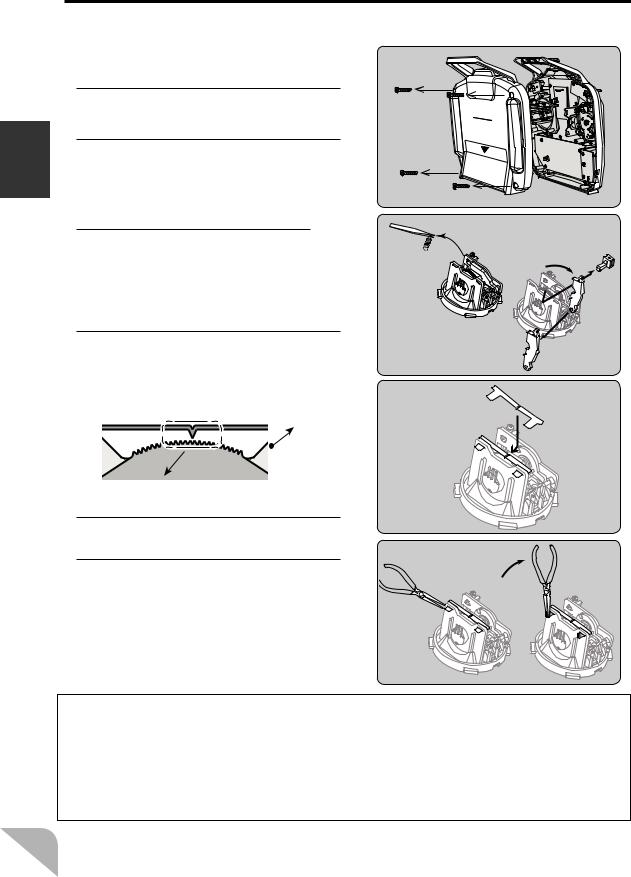

Changing to Ratchet Type Throttle Stick

Changing the throttle stick from the self-centering type to ratchet type that stops at an arbitrary position. (To make this modification, the optional ratchet plate must be purchased.)

Adjustment

1 Remove the battery from the transmitter.

Rear case

2 Using Phillips screwdriver, as shown in a figure, four screws are removed, and the rear case is removed.

• Don't touch internal electronic components.

3 Remove the swing arm, spring and |

Spring |

|

hook |

||

spring hook from the throttle stick as |

Spring |

|

shown in the figure. |

|

|

• Retain these parts in case the stick is to be |

|

|

changed back to self-centering type later. |

|

|

4 Install the ratchet plate to the throttle stick. |

Swing |

|

|

|

arm |

• The V section of the direc- |

|

|

tion of a ratchet plate is |

|

Ratchet |

downward. |

Ratchet |

plate |

|

||

|

plate |

(Option) |

• If the ratchet action is too harsh, a small amount of servo gear grease should be applied to the ratchet teeth.

5 Fasten by twisting the retaining tabs with needle-nosed pliers.

6 When the work is completed, re-attach the rear case using a Phillips screwdriver.

• Take great care not to damage the wiring when reattaching the rear case.

• Foreign substances must not be allowed to get into the interior of the case.

Caution

*If TH-STK is changed to F10 (see previous page), the now unnecessary brake function can be disabled.

*If the throttle stick is not in the stop/idle position when the transmitter is switched "ON" an alarm will sound. Ensure that the throttle stick is in the stop/idle position when switching "ON" - if the alarm sounds the throttle output will default to stop/idle.

*The adjustment of the throttle range cannot be carried out if a ratchet is being used, only if the throttle stick is self-centering.

30

Loading...

Loading...