Endress+hauser Proline Prowirl 72 User Manual

Operating Instructions

Proline Prowirl 72

Vortex Flow Measuring System

8

BA00085D/06/EN/13.11

71154513

valid as of version

V 1.03.XX (device software)

Proline Prowirl 72 PROFIBUS PA

2 Endress + Hauser

Proline Prowirl 72 PROFIBUS PA Table of contents

Table of contents

Table of contents . . . . . . . . . . . . . . . . . . . . . 3

1 Safety instructions . . . . . . . . . . . . . . . . 5

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Installation, commissioning and operation . . . . . . . . 5

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Notes on safety conventions and icons . . . . . . . . . . . 6

2 Identification . . . . . . . . . . . . . . . . . . . . 7

2.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 Nameplate of the transmitter/sensor . . . . . . 7

2.1.2 Nameplate of the sensor, remote version . . . 8

2.1.3 Service nameplate . . . . . . . . . . . . . . . . . . . . 8

2.2 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 9

2.3 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . 9

3 Installation . . . . . . . . . . . . . . . . . . . . 10

3.1 Incoming acceptance, transport, storage . . . . . . . . . 10

3.1.1 Incoming acceptance . . . . . . . . . . . . . . . . . 10

3.1.2 Transport . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Installation conditions . . . . . . . . . . . . . . . . . . . . . . 11

3.2.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.2 Installation location . . . . . . . . . . . . . . . . . . 11

3.2.3 Orientation . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.4 Heat insulation . . . . . . . . . . . . . . . . . . . . . 13

3.2.5 Inlet and outlet run . . . . . . . . . . . . . . . . . . 14

3.2.6 Vibrations . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.7 Limiting flow . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.1 Mounting sensor . . . . . . . . . . . . . . . . . . . . 16

3.3.2 Rotating the transmitter housing . . . . . . . . 17

3.3.3 Rotating the local display . . . . . . . . . . . . . . 17

3.3.4 Mounting transmitter (remote) . . . . . . . . . 18

3.4 Post-installation check . . . . . . . . . . . . . . . . . . . . . . 19

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1 PROFIBUS PA cable specifications . . . . . . . . . . . . . 20

4.1.1 Shielding and grounding . . . . . . . . . . . . . . 22

4.2 Connecting the remote version . . . . . . . . . . . . . . . 22

4.2.1 Connecting the sensor . . . . . . . . . . . . . . . . 22

4.2.2 Cable specifications,

standard connecting cable . . . . . . . . . . . . . 23

4.2.3 Cable specifications,

armored connecting cable . . . . . . . . . . . . . 24

4.3 Connecting the measuring unit . . . . . . . . . . . . . . . 25

4.3.1 Connecting the transmitter . . . . . . . . . . . . 25

4.3.2 Terminal assignment . . . . . . . . . . . . . . . . . 28

4.3.3 Fieldbus connector . . . . . . . . . . . . . . . . . . 28

4.4 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . 30

4.5 Post-connection check . . . . . . . . . . . . . . . . . . . . . . 31

5 Operation . . . . . . . . . . . . . . . . . . . . . . 32

5.1 Quick operation guide . . . . . . . . . . . . . . . . . . . . . . 32

5.2 Display elements . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.2.1 Display symbols . . . . . . . . . . . . . . . . . . . . . 33

5.3 Error message display . . . . . . . . . . . . . . . . . . . . . . . 34

5.3.1 Type of error . . . . . . . . . . . . . . . . . . . . . . . 34

5.3.2 Type of error message . . . . . . . . . . . . . . . . 34

5.4 Operating options . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.4.1 Operating program "FieldCare" . . . . . . . . . . 35

5.4.2 Operating program "SIMATIC PDM"

(Siemens) . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.4.3 Commuwin II operating program . . . . . . . . 36

5.4.4 Current device description files . . . . . . . . . 43

5.5 Hardware configuration . . . . . . . . . . . . . . . . . . . . . 44

5.5.1 Switching write protection on/off . . . . . . . 44

5.5.2 Configuring the device address . . . . . . . . . . 45

6 Commissioning . . . . . . . . . . . . . . . . . . 46

6.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.1.1 Switching on the measuring device . . . . . . 46

6.2 Commissioning the PROFIBUS interface . . . . . . . . . 47

6.2.1 Commissioning via the Class 2 master . . . . 47

6.3 System integration . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.3.1 Compatibility with previous model

Prowirl 77 . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.4 Cyclic data exchange . . . . . . . . . . . . . . . . . . . . . . . 52

6.4.1 Configuration examples with

Simatic S7 HW-Konfig . . . . . . . . . . . . . . . . 57

6.5 Acyclic data exchange . . . . . . . . . . . . . . . . . . . . . . 62

6.5.1 Class 2 master acyclic (MS2AC) . . . . . . . . . 62

6.5.2 Class 1 master acyclic (MS1AC) . . . . . . . . . 62

7 Maintenance . . . . . . . . . . . . . . . . . . . 63

8 Accessories . . . . . . . . . . . . . . . . . . . . 64

9 Troubleshooting . . . . . . . . . . . . . . . . . 66

9.1 Troubleshooting instructions . . . . . . . . . . . . . . . . . 66

9.2 System error messages . . . . . . . . . . . . . . . . . . . . . . 68

9.3 Process error messages . . . . . . . . . . . . . . . . . . . . . . 70

9.4 Process errors without messages . . . . . . . . . . . . . . . 71

9.5 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.6 Installing and removing electronics boards . . . . . . . 74

9.6.1 Non-Ex / Ex i/IS and Ex n version . . . . . . 74

9.6.2 Ex d/XP version . . . . . . . . . . . . . . . . . . . . 76

9.7 Software history . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10 Technical data . . . . . . . . . . . . . . . . . . 79

10.1 Technical data at a glance . . . . . . . . . . . . . . . . . . . 79

10.1.1 Application . . . . . . . . . . . . . . . . . . . . . . . . 79

10.1.2 Function and system design . . . . . . . . . . . . 79

10.1.3 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Endress+Hauser 3

Table of contents Proline Prowirl 72 PROFIBUS PA

10.1.4 PROFIBUS PA output . . . . . . . . . . . . . . . . 80

10.1.5 Power supply . . . . . . . . . . . . . . . . . . . . . . 81

10.1.6 Performance characteristics . . . . . . . . . . . 81

10.1.7 Operating conditions: Installation . . . . . . . 83

10.1.8 Operating conditions: Environment . . . . . . 83

10.1.9 Operating conditions: Process . . . . . . . . . . 84

10.1.10Frequency ranges for air and water . . . . . . 87

10.1.11Mechanical construction . . . . . . . . . . . . . . 89

10.1.12Human interface . . . . . . . . . . . . . . . . . . . . 90

10.1.13Certificates and approvals . . . . . . . . . . . . . 90

10.1.14Accessories . . . . . . . . . . . . . . . . . . . . . . . . 91

10.1.15Documentation . . . . . . . . . . . . . . . . . . . . 91

10.2 Dimensions of flow conditioner . . . . . . . . . . . . . . 92

11 Operation via PROFIBUS PA . . . . . . . 95

11.1 Block model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

11.2 Physical Block (device block) . . . . . . . . . . . . . . . . 96

11.2.1 Write protection . . . . . . . . . . . . . . . . . . . . 96

11.2.2 Physical Block parameters . . . . . . . . . . . . . 96

11.3 Transducer Block . . . . . . . . . . . . . . . . . . . . . . . . 101

11.3.1 Signal processing . . . . . . . . . . . . . . . . . . 102

11.3.2 Block output variables . . . . . . . . . . . . . . 102

11.3.3 Alarm detection and processing . . . . . . . 102

11.3.4 Accessing the manufacturer-specific

parameters . . . . . . . . . . . . . . . . . . . . . . . 102

11.3.5 Transducer Block parameters . . . . . . . . . 103

11.4 Function blocks, general . . . . . . . . . . . . . . . . . . . 132

11.5 Analog Input function block . . . . . . . . . . . . . . . . 133

11.5.1 Signal processing . . . . . . . . . . . . . . . . . . 133

11.5.2 Selecting the operating mode . . . . . . . . . 134

11.5.3 Selecting the units . . . . . . . . . . . . . . . . . 134

11.5.4 Status of the OUT output value . . . . . . . . 134

11.5.5 Simulation of input/output . . . . . . . . . . . 134

11.5.6 Failsafe mode FAILSAFE TYPE . . . . . . . . 135

11.5.7 Rescaling the input value . . . . . . . . . . . . 135

11.5.8 Limit values . . . . . . . . . . . . . . . . . . . . . . 136

11.5.9 Alarm detection and processing . . . . . . . 136

11.5.10Analog Input function block parameters . 136

11.6 Totalizer function block . . . . . . . . . . . . . . . . . . . 146

11.6.1 Signal processing . . . . . . . . . . . . . . . . . . 146

11.6.2 Selecting the operating mode . . . . . . . . . 146

11.6.3 Unit of the totaled measured value

UNIT TOT . . . . . . . . . . . . . . . . . . . . . . . 147

11.6.4 Status of the TOTAL output value . . . . . . 147

11.6.5 Failsafe mode FAIL TOT . . . . . . . . . . . . . 147

11.6.6 Selecting the direction for totaling,

MODE TOT . . . . . . . . . . . . . . . . . . . . . . 147

11.6.7 Initial setting of the totalizer SET TOT . . 148

11.6.8 Limit values . . . . . . . . . . . . . . . . . . . . . . 148

11.6.9 Alarm detection and processing . . . . . . . 149

11.6.10Totalizer function block parameters . . . . 149

11.7 Slot/Index lists . . . . . . . . . . . . . . . . . . . . . . . . . . 158

11.7.1 General explanatory remarks . . . . . . . . . 158

11.7.2 Device management slot 1 . . . . . . . . . . . 158

11.7.3 Physical Block slot 0 . . . . . . . . . . . . . . . . 158

11.7.4 Transducer Block slot 1 . . . . . . . . . . . . . 160

11.7.5 AI 1 Volume Flow Block slot 1 . . . . . . . . 163

11.7.6 Totalizer 1 Block slot 2 . . . . . . . . . . . . . . 164

12 Factory settings . . . . . . . . . . . . . . . . 165

12.1 Metric units (not for USA and Canada) . . . . . . . . 165

12.2 US units (only for USA and Canada) . . . . . . . . . . 166

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

4 Endress+Hauser

Proline Prowirl 72 PROFIBUS PA 1 Safety instructions

1 Safety instructions

1.1 Designated use

The measuring system is used to measure the volume flow of saturated steam, overheated steam,

gases and liquids. If the process pressure and process temperature are constant, the measuring

device can also output the flow as the calculated mass flow or corrected volume flow.

Resulting from incorrect use or from use other than that designated, the operational safety of the

measuring devices can be suspended. The manufacturer accepts no liability for damages being

produced from this.

1.2 Installation, commissioning and operation

Note the following points:

• Installation, electrical installation, commissioning and maintenance of the device must be carried

out by trained, qualified specialists authorized to perform such work by the facility's owneroperator. The specialist must have read and understood these Operating Instructions and must

follow the instructions they contain.

• The device must be operated by persons authorized and trained by the facility's owner-operator.

Strict compliance with the instructions in these Operating Instructions is mandatory.

• Endress+Hauser is willing to assist in clarifying the chemical resistance properties of parts wetted

by special fluids, including fluids used for cleaning. However, small changes in temperature,

concentration or the degree of contamination in the process can result in changes of the chemical

resistance properties. Therefore, Endress+Hauser can not guarantee or accept liability for the

chemical resistance properties of the fluid wetted materials in a specific application. The user is

responsible for the choice of fluid wetted materials in regards to their in-process resistance to

corrosion.

• The installer must ensure that the measuring system is correctly wired in accordance with the

wiring diagrams.

• Invariably, local regulations governing the operation, maintenance and repair of electrical devices

apply. Special instructions relating to the device can be found in the relevant sections of the

documentation.

1.3 Operational safety

Note the following points:

• Measuring systems for use in hazardous environments are accompanied by separate "Ex

documentation", which is an integral part of these Operating Instructions. Strict compliance with

the installation instructions and ratings as listed in this supplementary documentation is

mandatory. The symbol on the front of the Ex documentation indicates the approval and the

certification center ( 0 Europe, 2 USA, 1 Canada).

• The measuring system complies with the general safety requirements in accordance with

EN 61010-1 and the EMC requirements of IEC/EN 61326 and NAMUR Recommendations NE

21, NE 43 and NE 53.

• The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser distributor will supply you with current information and updates to these

Operating Instructions.

Endress + Hauser 5

1 Safety instructions Proline Prowirl 72 PROFIBUS PA

1.4 Return

The following procedures must be carried out before a flowmeter requiring repair or calibration, for

example, is returned to Endress+Hauser:

• Always enclose a fully completed "Declaration of Contamination" form with the device. Only then

can Endress+Hauser transport, examine and repair a returned device.

• Enclose special handling instructions if necessary, for example a safety data sheet as per European

Directive 91/155/EEC.

• Remove all fluid residues. Pay special attention to the grooves for seals and crevices which could

contain fluid residues.

This is particularly important if the fluid is hazardous to health, e.g. flammable, toxic, caustic,

carcinogenic, etc.

#

!

#

Warning!

• Do not return a measuring device if you are not absolutely certain that all traces of hazardous

substances have been removed, e.g. substances which have penetrated crevices or diffused

through plastic.

• Costs incurred for waste disposal and injury (caustic burns, etc.) due to inadequate cleaning will

be charged to the owner-operator.

Note!

A copy of the "Declaration of Contamination" can be found at the end of these Operating

Instructions.

1.5 Notes on safety conventions and icons

The devices are designed to meet state-of-the-art safety requirements, have been tested and left the

factory in a condition in which they are safe to operate.

The devices comply with the applicable standards and regulations in accordance with EN 61010-1

"Protection Measures for Electrical Equipment for Measurement, Control, Regulation and

Laboratory Procedures". They can, however, be a source of danger if used incorrectly or for anything

other than the designated use.

Consequently, always pay particular attention to the safety instructions indicated in these Operating

Instructions by the following symbols:

Warning!

"Warning" indicates an action or procedure which, if not performed correctly, can result in injury

or a safety hazard. Comply strictly with the instructions and proceed with care.

Caution!

"

!

6 Endress + Hauser

"Caution" indicates an action or procedure which, if not performed correctly, can result in incorrect

operation or destruction of the device. Comply strictly with the instructions.

Note!

"Note" indicates an action or procedure which, if not performed correctly, can have an indirect

effect on operation or trigger an unexpected response on the part of the device.

Proline Prowirl 72 PROFIBUS PA 2 Identification

1

4

9

5

6

7

8

B

9

3.1

K-factor:

Gasket:

TM:

Materials:

CF3M/F316/F316L/1.4404, 316L

Graphite

-200°C...+400°C/-328°F...+752°F

1.0000 P/L

Sensor data:

Ser.No.: 12345678901

PROWIRL W

DN50Size:

PED 97/23/EC: Cat. III

pnom = PS= 40bar / p test = 85bar

Meter Body MB: 25

PROWIRL 72

ABCDEFGHJKLMNPQRSTTAG No.:

Ser.No.:

12345678901

Order Code:

i

IP67 / NEMA/Type4X

-40°F<Ta<+176°F

Ta+10°C/18°F

72XXX-XXXXXXXXXXX

9-32VDC

Pat. US 4,743,837 US 6,003,384

PROFIBUS PAProfile 3.0

0.5W

-40°C<Ta<+80°C

BPU S

R O IF

R

2007

N12895

1

2

3

A

10

11

12

13

2 Identification

2.1 Device designation

The "Proline Prowirl 72 PROFIBUS PA" flowmeter system consists of the following components:

• Transmitter Proline Prowirl 72 PROFIBUS PA

• Prowirl F or Prowirl W sensor

In the compact version, the transmitter and sensor form a mechanical unit; in the remote version

they are mounted separate from one another.

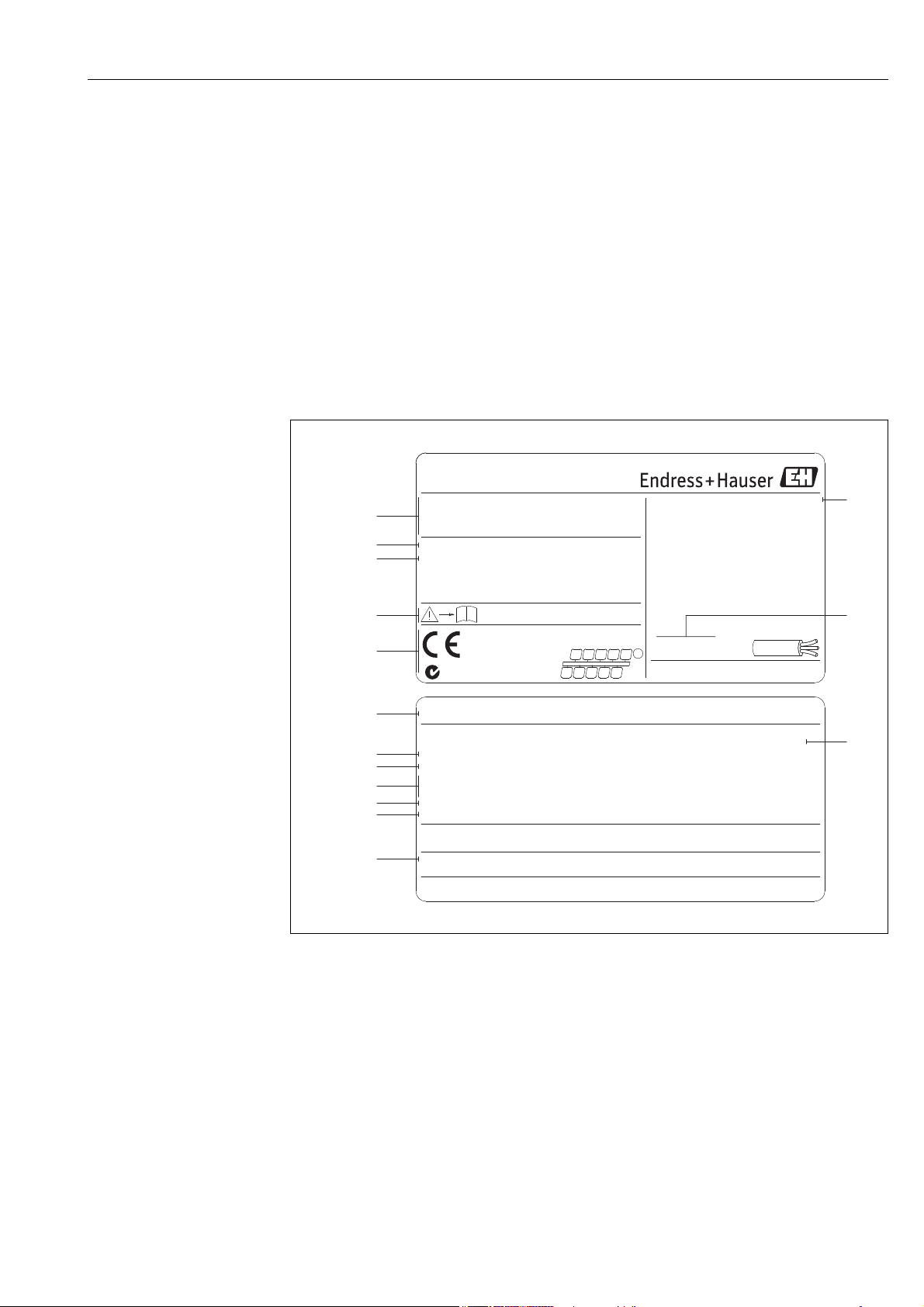

2.1.1 Nameplate of the transmitter/sensor

Fig. 1: Nameplate specifications for transmitter and sensor (example)

A = nameplate on transmitter, B = nameplate on sensor (only compact version)

1 Order code / serial number: see the specifications on the order confirmation for the meanings of the individual

letters and digits.

2 Power supply: 9 to 32 V DC, Power consumption: 1.2 W

3 PROFIBUS PA, Profile 3.0

4 Nominal diameter

5 Calibration factor

6 Material sensor and gasket

7 Medium temperature range

8Reserved for information on special products

9 Data regarding Pressure Equipment Directive (optional)

10 Permitted ambient temperature range

11 Degree of protection

Endress + Hauser 7

A0004806

2 Identification Proline Prowirl 72 PROFIBUS PA

ABCDEFGHJKLMNPQRST

TAG No.:

Ser.No.:

12345678901

Order Code:

Pat. US 4,743,837 US 6,003,384

i

IP67/NEMA/Type 4X

-40°C<Ta<+85°C

-40°F<Ta<+185°F

Gasket:

TM:

Graphite

-200°C...+400°C/-328°F...+752°F

72WXX-XXXXXXXXXXXX

K-factor:

1.0000 P/L

Materials:

CF3M/F316/F316L/1.4404, 316L

PROWIRL W

3.1

Size:

DN50

PED 97/23/EC: Cat. III

2007

N12895

pnom = PS = 10bar / ptest = 20bar

1

2

3

4

6

9

11

5

10

Meter Body:

25

7

8

Service date:

XXXXXXXXXXXSer.No.:

Exworks / ab Werk / réglages usine:

Date: 10.Jul 2008

XX.XX.XX

Device SW:

HART

Communication:

XXXXXXXDrivers:

Update2:

Update1:

1

2

3

4

5

6

7

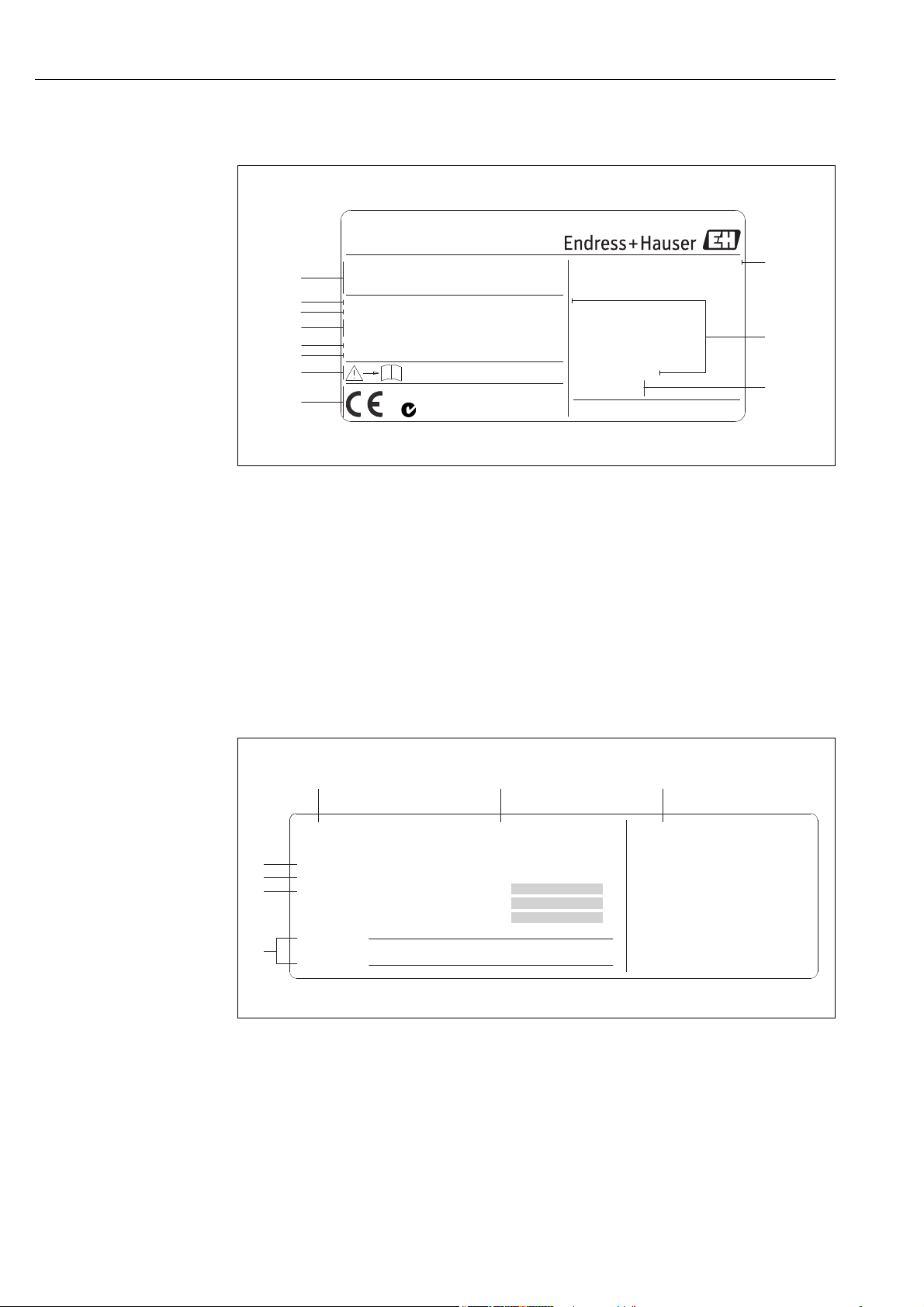

2.1.2 Nameplate of the sensor, remote version

a0001872

Fig. 2: Nameplate specifications for transmitter, remote version (example)

1 Order code / serial number: see the specifications on the order confirmation for the meanings of the individual

letters and digits.

2 Nominal diameter

3 Calibration factor

4 Material sensor and gasket

5 Medium temperature range

6Reserved for information on special products

7 Permitted ambient temperature range

8 Data regarding Pressure Equipment Directive (optional)

9 Degree of protection

2.1.3 Service nameplate

Fig. 3: Service nameplate specifications for transmitter (example)

1 Serial number

2 Date of manufacturing

8 Endress + Hauser

3 Service date

4 Device software

5 Type of device communication (e.g. PROFIBUS PA)

6 Revision number

7 Space for update entries

A0006761

Proline Prowirl 72 PROFIBUS PA 2 Identification

2.2 Certificates and approvals

The devices are designed according to good engineering practice to meet state-of-the-art safety

requirements, have been tested and left the factory in a condition in which they are safe to operate.

The devices comply with the applicable standards and regulations in accordance with EN 61010-1

"Protection Measures for Electrical Equipment for Measurement, Control, Regulation and

Laboratory Procedures" and the EMC requirements as per IEC/EN 61326.

The measuring system described in these Operating Instructions complies with the legal

requirements of the EU Directives. Endress+Hauser confirms this by affixing the CE mark to it and

by issuing the CE declaration of conformity.

The measuring system meets the EMC requirements of the "Australian Communications and Media

Authority (ACMA)".

2.3 Registered trademarks

GYLON

®

Registered trademark of Garlock Sealing Technologies, Palmyar, NY, USA

®

PROFIBUS

Registered trademark of PROFIBUS User Organization e.V., Karlsruhe, Germany

INCONEL

®

Registered trademark of Inco Alloys International Inc., Huntington, USA

KALREZ

®

, VITON

®

Registered trademarks of E.I. Du Pont de Nemours & Co., Wilmington, USA

Fieldcheck

®

, Applicator®, FieldCare

®

Registered or registration-pending trademarks of Endress+Hauser Flowtec AG, Reinach,

Switzerland

Endress + Hauser 9

3 Installation Proline Prowirl 72 PROFIBUS PA

3 Installation

3.1 Incoming acceptance, transport, storage

3.1.1 Incoming acceptance

On receipt of the goods, check the following points:

• Check the packaging and the contents for damage.

• Check the shipment, make sure nothing is missing and that the scope of supply matches your

order.

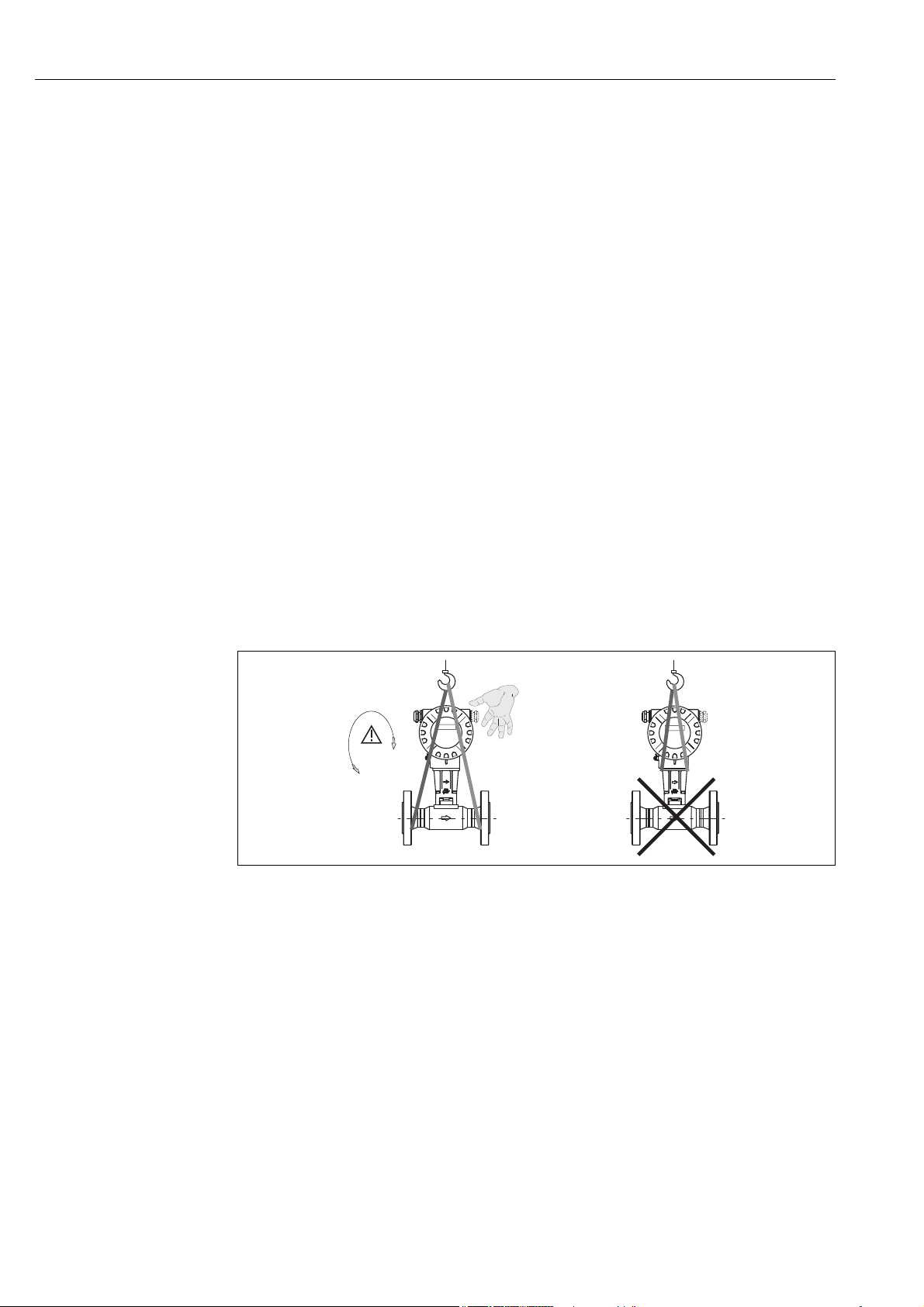

3.1.2 Transport

Please note the following when unpacking or transporting to the measuring point:

• The devices must be transported in the container supplied.

• Devices with nominal diameter DN 40 to 300 (1½ to 12") may not be lifted at the transmitter

housing or at the connection housing of the remote version when transporting (see Fig. 4). Use

carrier slings when transporting and put the slings around both process connections. Avoid chains

as these could damage the housing.

#

Warning!

Risk of injury if the measuring device slips.

The center of gravity of the entire measuring device might be higher than the points around which

the slings are slung. Therefore, when transporting, make sure that the device does not

unintentionally turn or slip.

A0001871

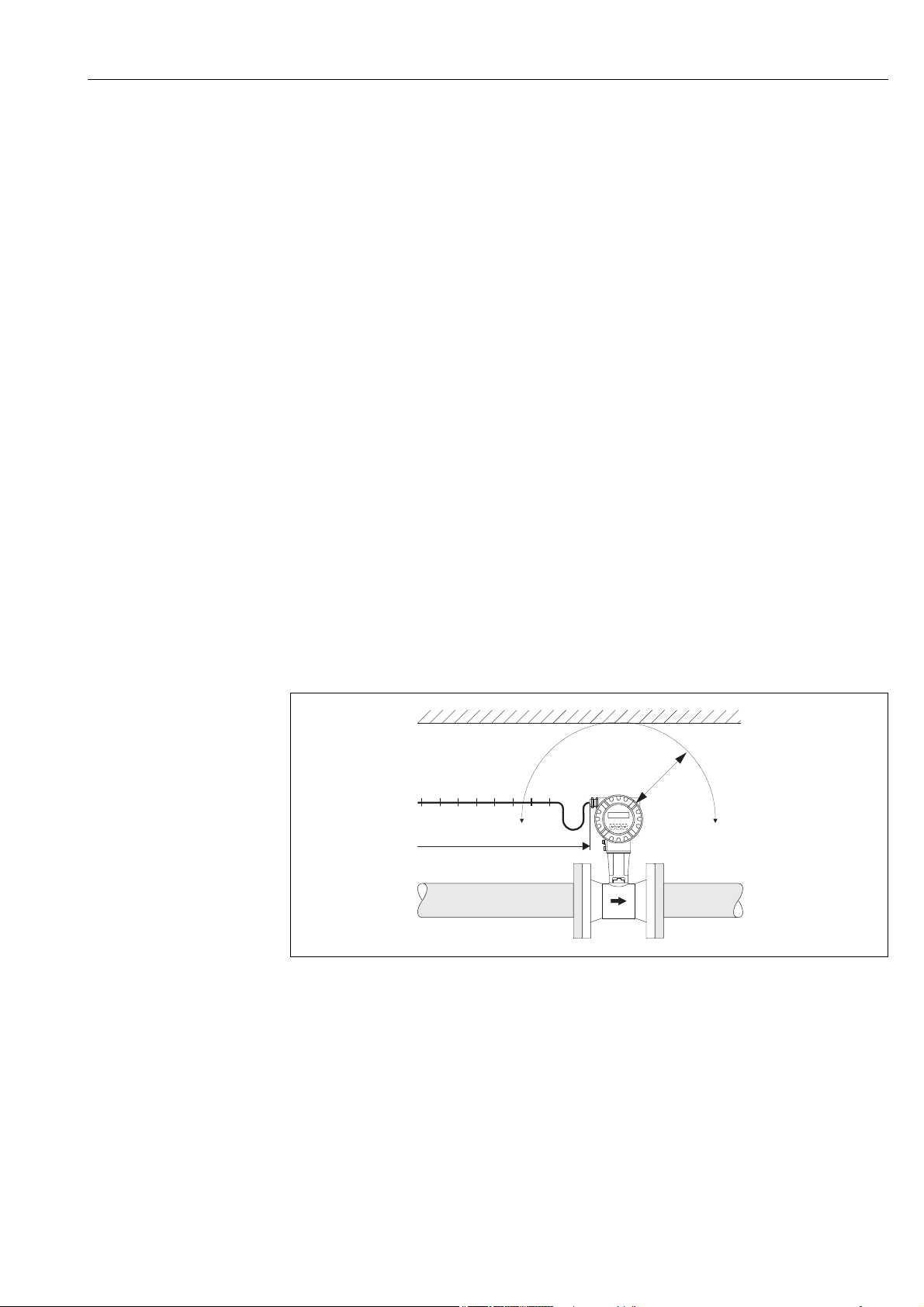

Fig. 4: Transportation instructions for sensors with DN 40 to 300 (1½ to 12")

3.1.3 Storage

Note the following points:

• Pack the measuring device in such a way as to protect it reliably against impact for storage (and

transportation). The original packaging provides optimum protection.

• The permissible storage temperature is:

– Standard: –40 to +80 °C (–40 to +176 °F)

– ATEX II 1/2 GD version/dust ignition-proof: –20 to +55 °C (–4 to +131 °F)

• When in storage, the device should not be exposed to direct sunlight in order to avoid

impermissibly high surface temperatures.

10 Endress + Hauser

Proline Prowirl 72 PROFIBUS PA 3 Installation

L

A

3.2 Installation conditions

Note the following points:

• The measuring device requires a fully developed flow profile as a prerequisite for correct volume

flow measurement. The inlet and outlet runs must be taken into account (see Page 14).

• The maximum permitted ambient temperatures (see Page 83) and fluid temperatures (see

Page 84) must be observed.

• Pay particular attention to the notes on orientation and piping insulation (see Page 12).

• Verify that the correct nominal diameter and pipe standard (DIN/JIS/ANSI) were taken into

account when ordering since the calibration of the device and the achievable accuracy depend on

these factors. If the mating pipe and the device have different nominal diameters/pipe standards,

an inlet correction can be made via the device software by entering the actual pipe diameter (see

MATING PIPE DIAMETER function on Page 115).

• The correct operation of the measuring system is not influenced by plant vibrations up to 1 g,

10 to 500 Hz.

• For mechanical reasons, and in order to protect the piping, it is advisable to support heavy sensors.

For weight information, please refer to Technical Information TI070D/06/en.

3.2.1 Dimensions

The dimensions and lengths of the sensor and transmitter can be found in the Technical Information

TI070D/06/en.

3.2.2 Installation location

We recommend you observe the following dimensions to guarantee problem-free access to the

device for service purposes:

• Minimum spacing (A) in all directions = 100 mm (3.94 inch)

• Necessary cable length (L): L + 150 mm (L + 5.91 inch).

A0001870

Fig. 5: A = Minimum spacing in all directions, L = cable length

Endress + Hauser 11

3 Installation Proline Prowirl 72 PROFIBUS PA

B

D

A

C

3.2.3 Orientation

The device can be installed basically in any orientation. Please consider the following, however

(Fig. 6):

• In the case of liquids, there should be upward flow in vertical pipes to avoid partial pipe filling (see

orientation A).

• The arrow on the meter body has to point in flow direction.

• In order to make sure that the maximum ambient temperature (see Page 83) is not exceeded, we

recommend the following orientations:

– In the case of hot fluids (e.g. steam or fluid temperature 200 °C/392 °F), select orientation

C or D.

– Orientations B and D are recommended for very cold fluids (e.g. liquid nitrogen).

Caution!

"

• If fluid temperature is 200 °C ( 392 °F), orientation B is not permitted for the wafer version

(Prowirl 72 W) with a nominal diameter of DN 100 (4") and DN 150 (6").

• In case of vertical orientation and downward flowing liquid, the piping has always to be

completely filled.

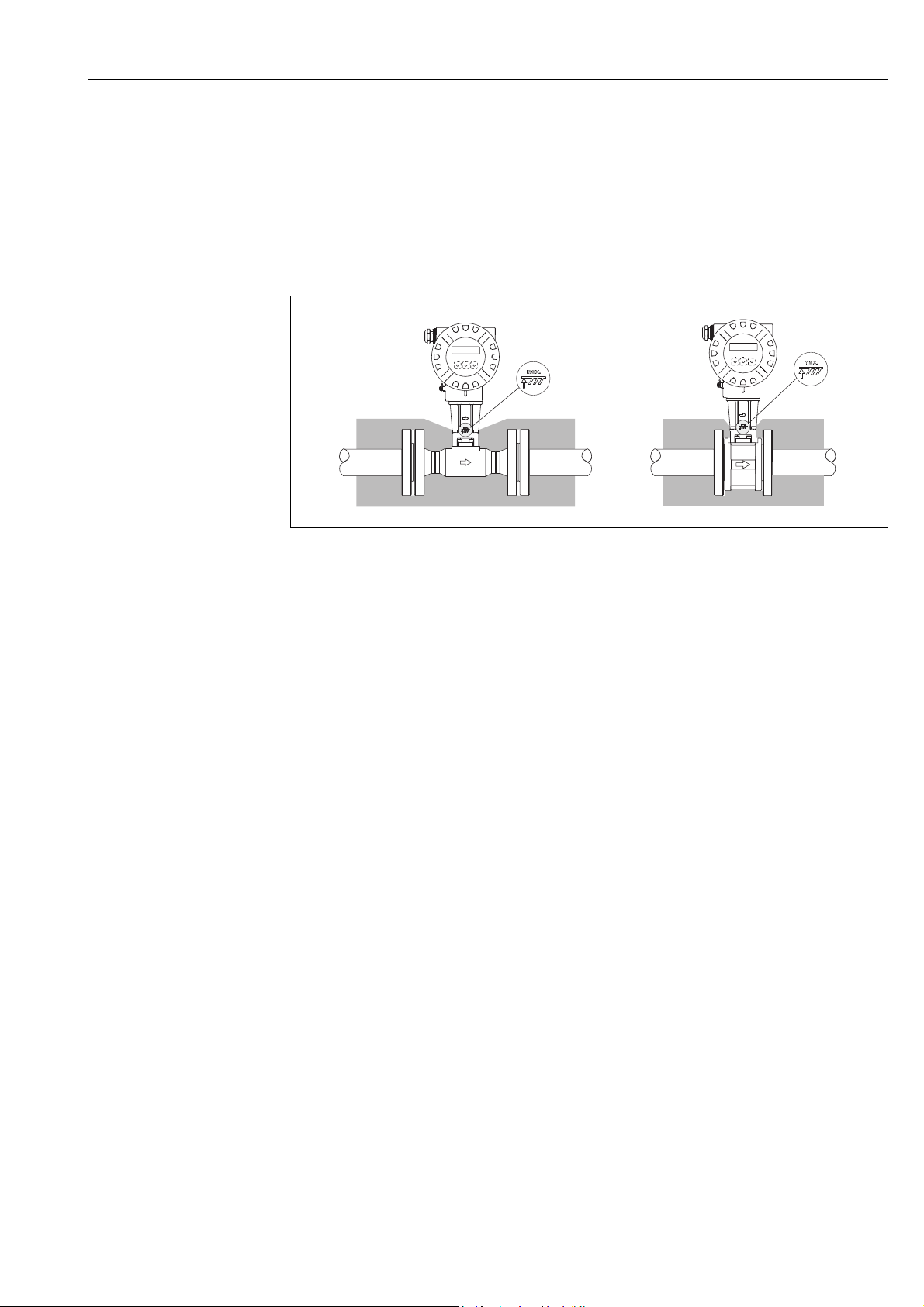

Fig. 6: Possible orientations of the device

High fluid temperature:

– horizontal piping: orientation C or D

– vertical piping: orientation A

Low fluid temperature:

– horizontal piping: orientation B or D

– vertical piping: orientation A

12 Endress + Hauser

A0001869

Proline Prowirl 72 PROFIBUS PA 3 Installation

12

Esc

E

-

+

Esc

E

-

+

3.2.4 Heat insulation

Some fluids require suitable measures to avoid heat transfer at the sensor. A wide range of materials

can be used to provide the required insulation.

When insulating, please ensure that a sufficiently large area of the housing support is exposed. The

uncovered part serves as a radiator and protects the electronics from overheating (or undercooling).

The maximum insulation height permitted is illustrated in the Fig. 7. These apply equally to both

the compact version and the sensor in the remote version.

"

A0001868

Fig. 7: 1 = Flanged version, 2 = Wafer version

Caution!

Danger of electronics overheating!

• Therefore, make sure that the adapter between sensor and transmitter and the connection

housing of the remote version is always exposed.

• Note that a certain orientation might be required, depending on the fluid temperature Page 12.

• Information on permissible temperature ranges Page 83.

Endress + Hauser 13

3 Installation Proline Prowirl 72 PROFIBUS PA

15 x DN 5 x DN

A

1

3

5

2

4

6

A

A

A

A

A

B

B

B

B

B

B

17 x DN + 8 x h

5 x DN

20 x DN

5 x DN

40 x DN 5 x DN

25 x DN

5 x DN

50 x DN

5 x DN

h

PT

TT

3...5 x DN

4...8 x DN

Esc

E

-

+

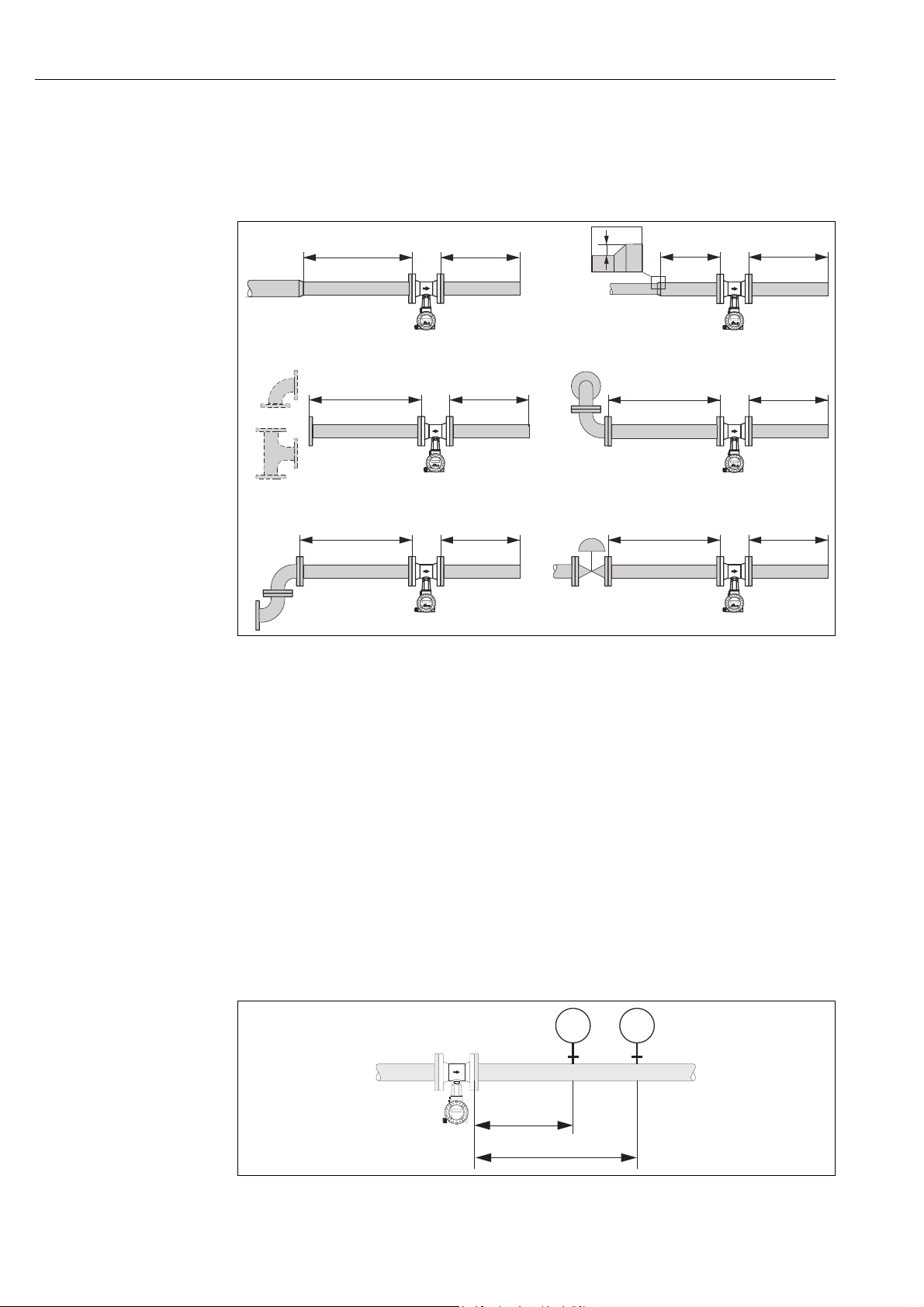

3.2.5 Inlet and outlet run

As a minimum, the inlet and outlet runs shown below must be observed to achieve the specific

accuracy of the device. The longest inlet run shown must be observed if two or more flow

disturbances are present.

A0001867

Fig. 8: Minimum inlet and outlet runs with various flow obstructions

A Inlet run

BOutlet run

1 = Reduction

2 = Expansion

3 = 90° elbow or T-piece

4 = 2 x 90° elbow, 3-dimensional

5 = 2 x 90° elbow

6 = Control valve

!

Note!

A specially designed perforated plate flow conditioner can be installed if it is not possible to observe

the inlet runs required (see Page 15).

Outlet runs with pressure and temperature measuring points

If pressure and temperature measuring points are installed after the device, please ensure there is a

large enough distance between the device and the measuring point so there are no negative effects

on vortex formation in the sensor.

14 Endress + Hauser

Fig. 9: Installation of pressure measuring point (PT) and temperature measuring point (TT)

A0003780

Proline Prowirl 72 PROFIBUS PA 3 Installation

8xDN

2xDN

5xDN

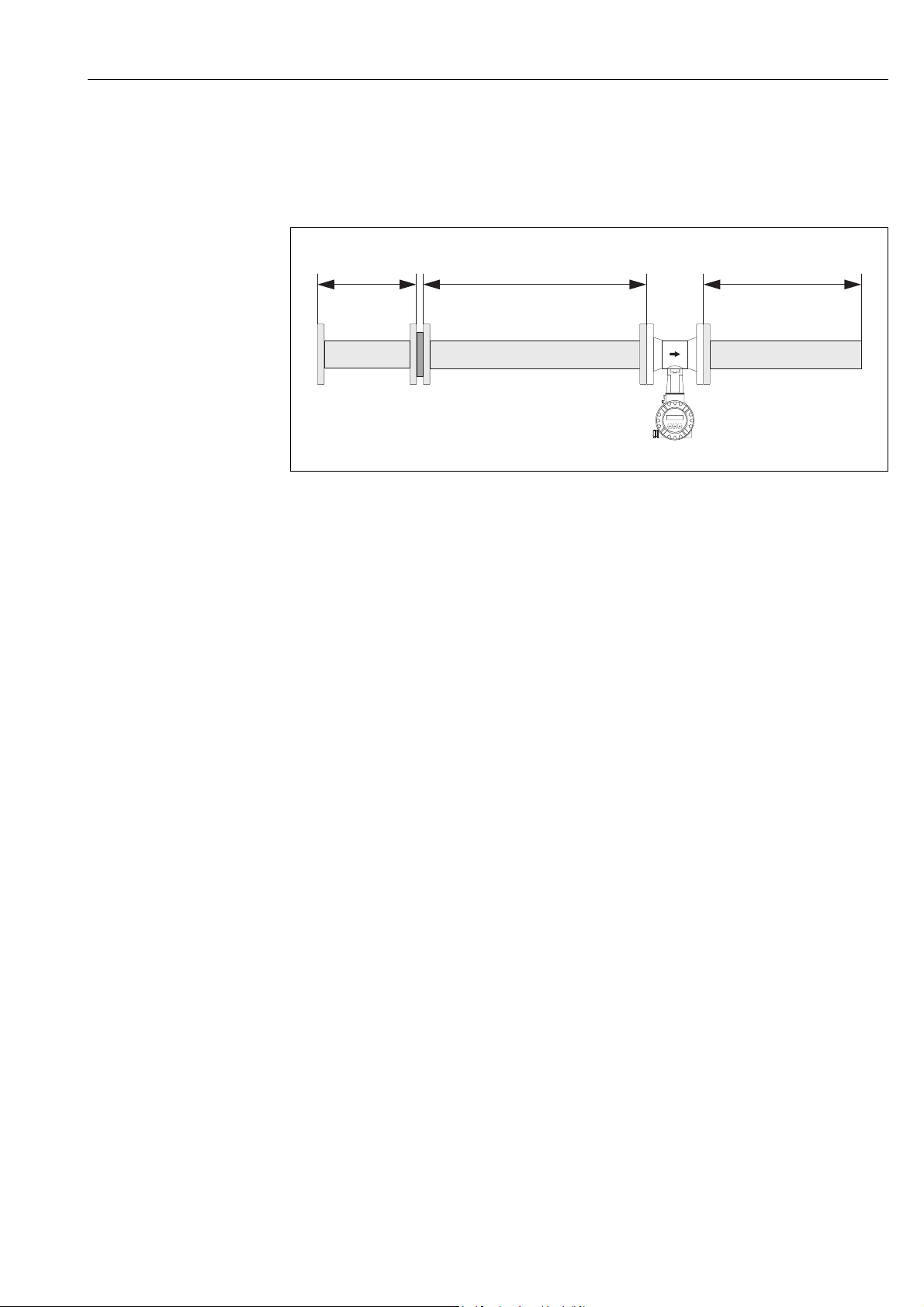

Perforated plate flow conditioner

A specially designed perforated plate flow conditioner, available from Endress+Hauser, can be

installed if it is not possible to observe the inlet runs required. The flow conditioner is fitted between

two piping flanges and centered with mounting bolts. Generally, this reduces the inlet run required

to 10 DN with complete accuracy.

A0001887

Fig. 10: Perforated plate flow conditioner

Calculation examples (SI units) for the pressure loss of flow conditioners:

The pressure loss for flow conditioners is calculated as follows:

p [mbar] = 0.0085 · [kg/m³] · v² [m/s]

• Example with steam

p = 10 bar abs

t = 240 °C = 4.39 kg/m³

v = 40 m/s

• Example with H

= 965 kg/m³

v = 2.5 m/s

p = 0.0085 · 965 · 2.5

O condensate (80°C)

2

= 51.3 mbar

p = 0.0085 · 4.39 · 40² = 59.7 mbar

3.2.6 Vibrations

The correct operation of the measuring system is not influenced by plant vibrations up to 1 g, 10 to

500 Hz. Consequently, the sensors require no special measures for attachment.

3.2.7 Limiting flow

See the information on Page 79 and 86.

Endress + Hauser 15

3 Installation Proline Prowirl 72 PROFIBUS PA

1

2

3

4

5

3.3 Installation

3.3.1 Mounting sensor

Caution!

"

Please note the following prior to mounting:

• Prior to installing the measuring device in the piping, remove all traces of transport packaging and

any protective covers from the sensor.

• Make sure that the internal diameters of seals are the same as, or greater than, those of the

measuring pipe and piping. Seals projecting into the flow current have a negative effect on the

vortex formation after the bluff body and cause inaccurate measurement. The gaskets provided

by Endress+Hauser for the wafer version have therefore an inner diameter with a bigger inner

diameter than the piping.

• Ensure that the arrow on the measuring pipe matches the direction of flow in the piping.

• Lengths:

– Prowirl W (wafer version): 65 mm (2.56 inch)

– Prowirl F (flanged version) See Technical Information TI070D/06/en.

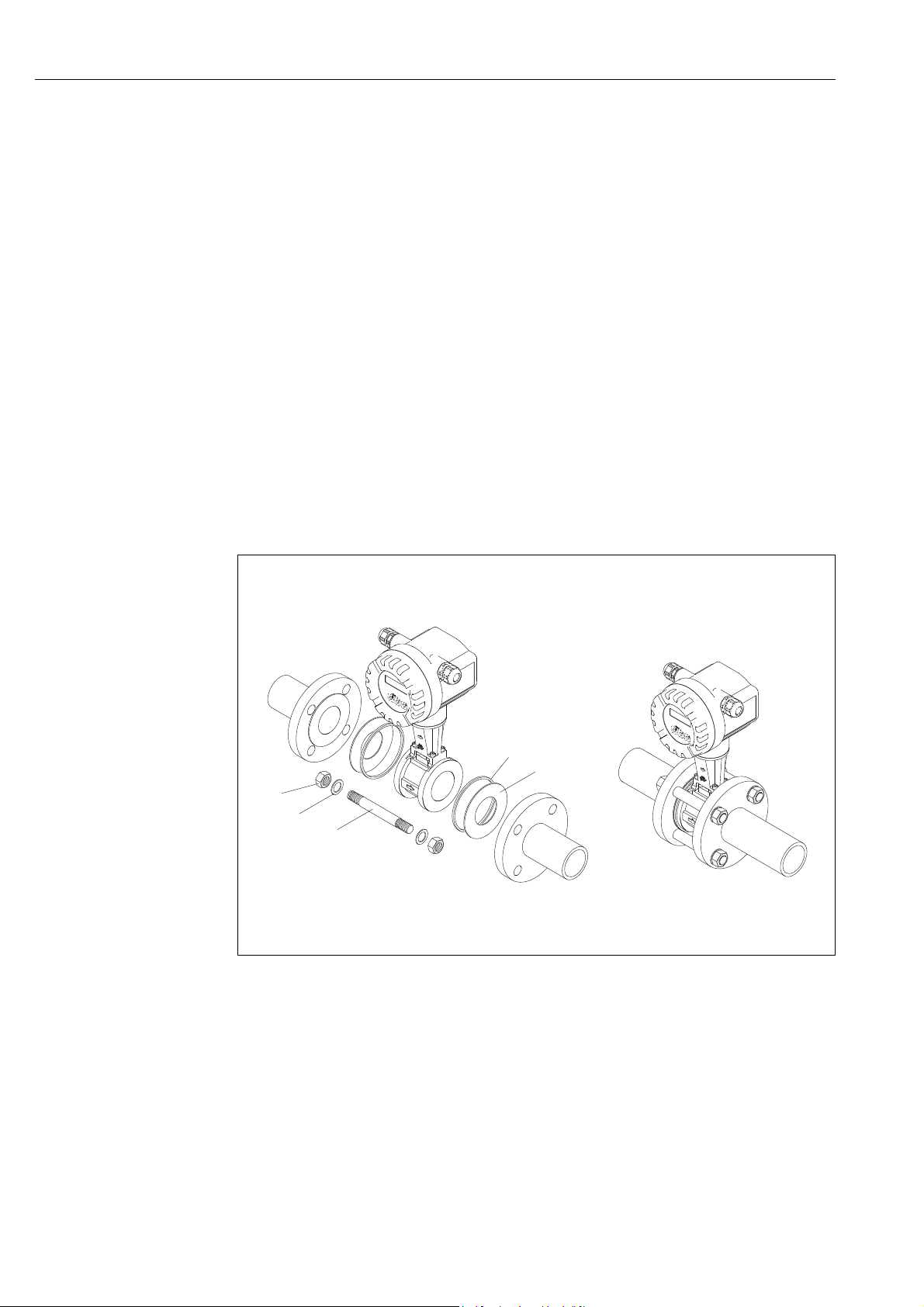

Mounting Prowirl W

The centering rings supplied are used to mount and center the wafer-style devices.

A mounting kit consisting of tie rods, seals, nuts and washers can be ordered separately.

Fig. 11: Mounting the wafer version

1Nut

2Washer

3Tie rod

4 Centering ring (is supplied with the device)

5Seal

16 Endress + Hauser

A0001888

Proline Prowirl 72 PROFIBUS PA 3 Installation

180°

180°

4x45°

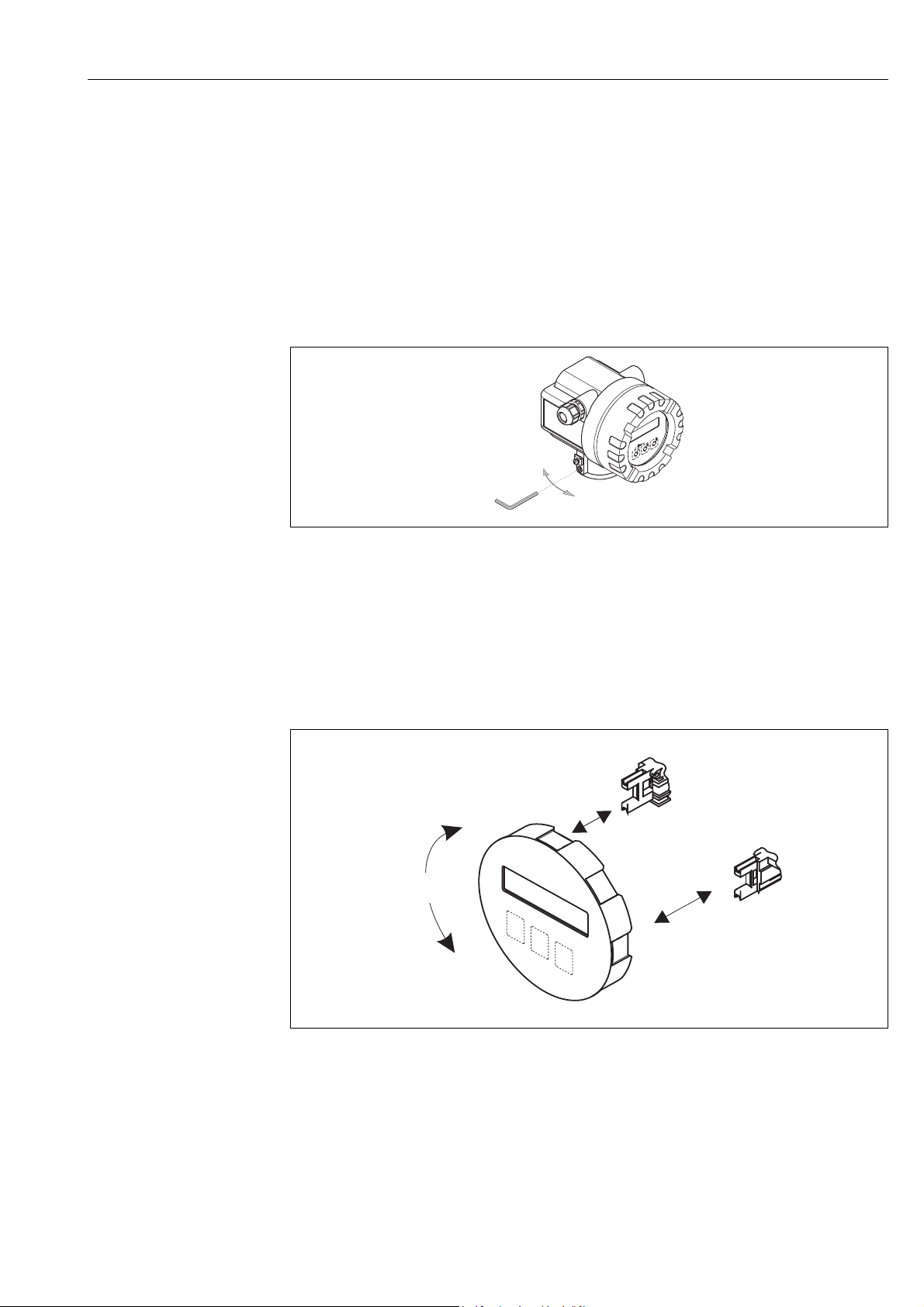

3.3.2 Rotating the transmitter housing

The electronics housing can be rotated continuously 360° on the housing support.

1. Loosen the safety screw.

2. Turn the transmitter housing to the desired position (max. 180° in each direction to the stop).

! Note!

There are recesses in the rotating groove at 90° stages (only compact version).

These help you align the transmitter easier.

3. Tighten the safety screw.

A0001889

Fig. 12: Rotating the transmitter housing

3.3.3 Rotating the local display

1. Unscrew the cover of the electronics compartment from the transmitter housing.

2. Remove the display module from the transmitter retainer rails.

3. Turn the display to the desired position (max. 4 45° in each direction) and reset it onto the

retaining rails.

4. Screw the cover of the electronics compartment firmly back onto the transmitter housing.

A0003237

Fig. 13: Rotating the local display

Endress + Hauser 17

3 Installation Proline Prowirl 72 PROFIBUS PA

ANSCHLUSSKLEMMEN - FIELD TERMINALS

ANSCHLUSSKLEMMEN - FIELD TERMINALS

A

B

220 / *214

215/ *209

(8.66 / *8.43)

(8.46 / *8.23)

mm (inch)

Ø 20…70

(Ø 0.79…2.75)

3.3.4 Mounting transmitter (remote)

The transmitter can be mounted in the following ways:

• Wall mounting

• Pipe mounting (with separate mounting kit, accessories Page 64)

The transmitter and the sensor must be mounted separate in the following circumstances:

• poor accessibility,

• lack of space,

• extreme ambient temperatures.

Caution!

"

If the device is mounted to warm piping, make certain that the housing temperature does not

exceed the max. permissible temperature value.

– Standard: –40 to +80 °C (–40 to +176 °F)

– EEx d/XP version: –40 to +60 °C (–40 to +140 °F)

– ATEX II 1/2 GD version/dust ignition-proof: –20 to +55 °C (–4 to +131 °F)

Mount the transmitter as illustrated in the diagram.

Fig. 14: Mounting the transmitter (remote version)

A Direct wall mounting

BPipe mounting

* Dimensions for version without local operation

A0003801

18 Endress + Hauser

Proline Prowirl 72 PROFIBUS PA 3 Installation

3.4 Post-installation check

Perform the following checks after installing the measuring device in the piping:

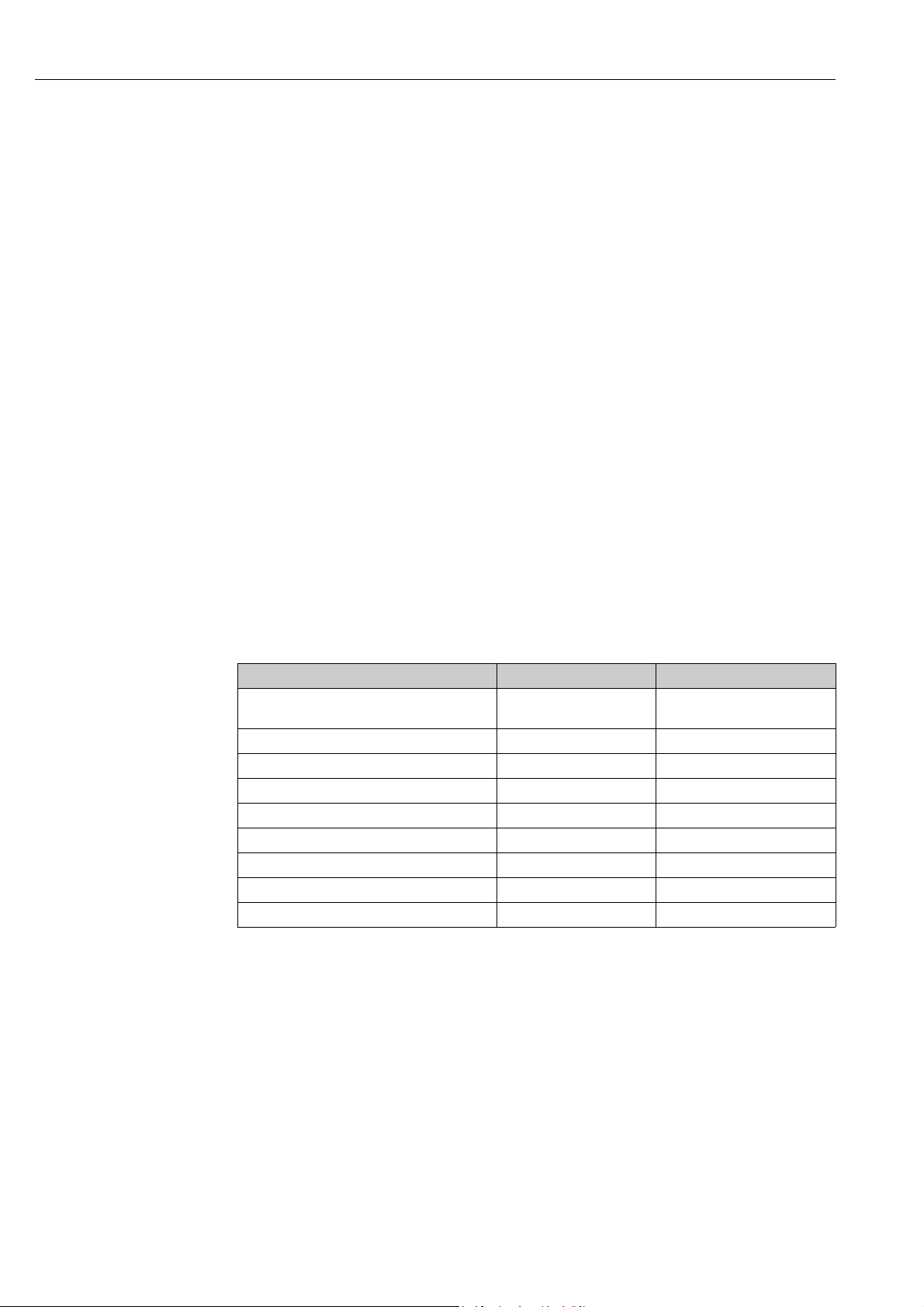

Device condition and specifications Notes

Is the device damaged (visual inspection)?

Do the process temperature/pressure, ambient temperature, measuring range

etc. correspond to the specifications of the device?

Installation Notes

Does the arrow on the pipe stand or on the sensor match the direction of flow

through the pipe?

Are the measuring point number and labeling correct (visual inspection)? –

Is the orientation chosen for the sensor correct, in other words suitable for

sensor type, fluid properties (outgassing, with entrained solids) and fluid

temperature?

Process environment / process conditions Notes

Is the measuring device protected against moisture and direct sunlight?

see Page 79 ff.

see Page 11 ff.

Endress + Hauser 19

4 Wiring Proline Prowirl 72 PROFIBUS PA

4 Wiring

#

Warning!

When connecting Ex-certified devices, please refer to the notes and diagrams in the Ex-specific

supplement to these Operating Instructions. Please do not hesitate to contact your Endress+Hauser

representative if you have any questions.

4.1 PROFIBUS PA cable specifications

Cable type

Twin-core cables are recommended for connecting the device to the fieldbus. Following IEC

61158-2 (MBP), four different cable types (A, B, C, D) can be used with the fieldbus, only two of

which (cable types A and B) are shielded.

• Cable types A or B are particularly preferable for new installations. Only these types have cable

shielding that guarantees adequate protection from electromagnetic interference and thus the

most reliable data transfer. In the case of multi-pair cables (type B), it is permissible to operate

multiple fieldbuses (with the same degree of protection) on one cable. No other circuits are

permissible in the same cable.

• Practical experience has shown that cable types C and D should not be used due to the lack of

shielding, since the freedom from interference generally does not meet the requirements

described in the standard.

The electrical data of the fieldbus cable have not been specified but determine important

characteristics of the design of the fieldbus, such as distances bridged, number of users,

electromagnetic compatibility, etc.

Type A Type B

Cable structure Twisted pair,

shielded

Wire size 0.8 mm

Loop-resistance (direct current) 44 /km 112 /km

Impedance at 31.25 kHz 100 ± 20% 100 ± 30%

Attenuation constant at 39 kHz 3 dB/km 5 dB/km

Capacitive asymmetry 2 nF/km 2 nF/km

Envelope delay distortion (7.9 to 39 kHz) 1.7 s/km *

Shield coverage 90% *

Max. cable length (inc. spurs >1 m (>3 ft)) 1900 m (6200 ft) 1200 m (4000 ft)

* Not specified

(AWG 18) 0.32 mm (AWG 22)

One or more twisted pairs, fully

shielded

Suitable fieldbus cables from various manufacturers for non-hazardous areas are listed below:

• Siemens: 6XV1 830-5BH10

• Belden: 3076F

• Kerpen: CeL-PE/OSCR/PVC/FRLA FB-02YS(ST)YFL

20 Endress + Hauser

Proline Prowirl 72 PROFIBUS PA 4 Wiring

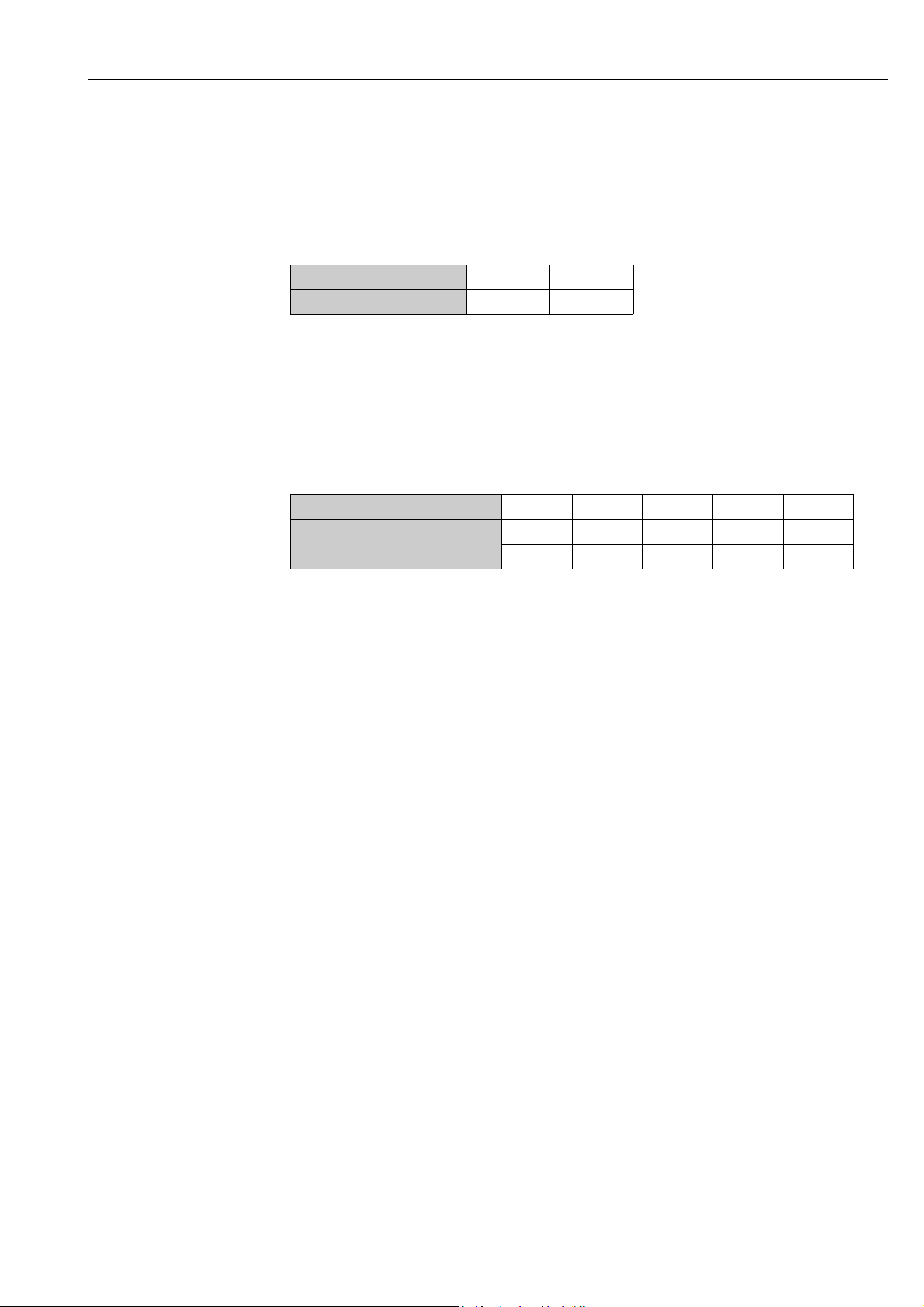

Maximum overall cable length

The maximum network expansion depends on the type of protection and the cable specifications.

The overall cable length combines the length of the main cable and the length of all spurs (>1 m

(>3 ft)).

Note the following points:

• The maximum permissible overall cable length depends on the cable type used:

Type A 1900 m 6200 ft

Type B 1200 m 4000 ft

• If repeaters are used, the maximum permissible cable length is doubled.

A maximum of three repeaters are permitted between user and master.

Maximum spur length

The line between the distribution box and field device is described as a spur.

In the case of non-Ex applications, the max. length of a spur depends on the number of spurs (>1 m)

(>3 ft):

Number of spurs 1 to 12 13 to 14 15 to 18 19 to 24 25 to 32

Max. length per spur

[m] 120 90 60 30 1

[ft] 400 300 200 100 3

Number of field devices

In systems that meet FISCO in the EEx ia type of protection, the line length is limited to

max. 1000 m (3280 ft). A maximum of 32 users per segment in non-Ex areas or a maximum of

10 users in an Ex-area (EEx ia IIC) is possible. The actual number of users must be determined

during project planning.

Bus termination

The start and end of each fieldbus segment are always to be terminated with a bus terminator. With

various junction boxes (non-Ex), the bus termination can be activated via a switch. If this is not the

case, a separate bus terminator must be installed.

Note the following points:

• In the case of a branched bus segment, the device furthest from the segment coupler represents

the end of the bus.

• If the fieldbus is extended with a repeater then the extension must also be terminated at both

ends.

Further information

General information and further notes regarding the wiring can be found in the BA034S/04: "Field

communication PROFIBUS DP/PA: Guidelines for planning and commissioning".

Endress + Hauser 21

4 Wiring Proline Prowirl 72 PROFIBUS PA

4.1.1 Shielding and grounding

When planning the shielding and grounding for a fieldbus system, there are three important points

to consider:

• Electromagnetic compatibility (EMC)

• Explosion protection

• Safety of the personnel

To ensure the optimum electromagnetic compatibility of systems, it is important that the system

components and above all the cables, which connect the components, are shielded and that no

portion of the system is unshielded. Ideally, the cable shields will be connected to the field devices'

housings, which are usually metal. Since these are generally connected to the protective earth, the

shield of the bus cable is grounded many times. Make sure that the stripped and twisted lengths of

cable shield to the terminals are as short as possible.

This approach, which provides the best electromagnetic compatibility and personnel safety, can be

used without restriction in systems with good potential equalization.

In the case of systems without potential equalization, a power supply frequency (50 Hz) equalizing

current can flow between two grounding points which, in unfavorable cases, e.g. when it exceeds

the permissible shield current, may destroy the cable.

To suppress the low frequency equalizing currents on systems without potential equalization, it is

therefore recommended to connect the cable shield directly to the building ground (or protective

earth) at one end only and to use capacitive coupling to connect all other grounding points.

"

!

Caution!

The legal EMC requirements are met only when the cable shield is grounded at both ends!.

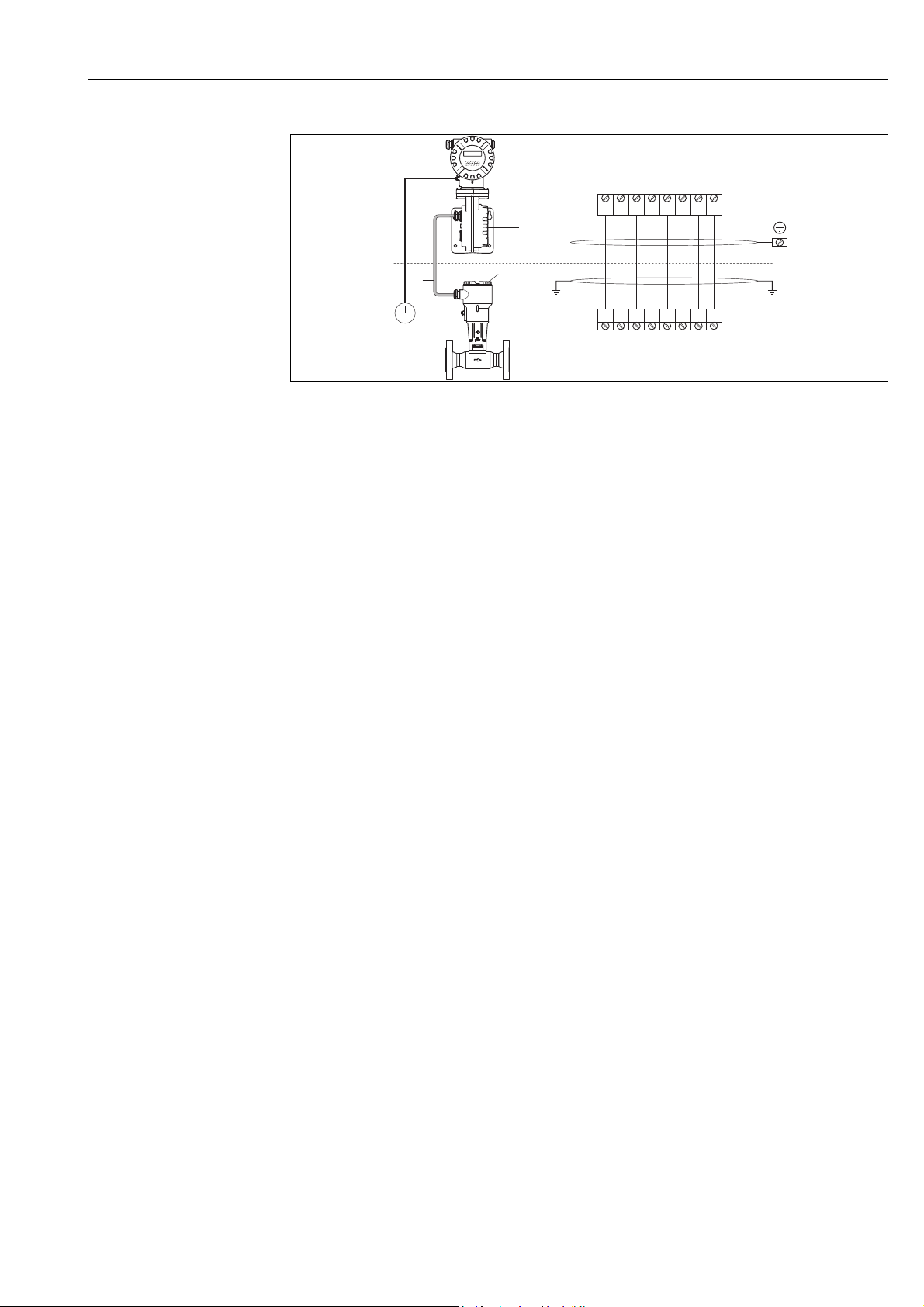

4.2 Connecting the remote version

4.2.1 Connecting the sensor

Note!

• The remote version must be grounded. In doing so, the sensor and transmitter must be connected

to the same potential matching.

• When using the remote version, always make sure that you connect the sensor only to the

transmitter with the same serial number. Compatibility errors (e.g. the incorrect K-factor will be

used) can occur if the devices are not connected in this way.

1. Remove the cover of the connection compartment of the transmitter (a).

2. Remove the cover of the connection compartment of the sensor (b).

3. Feed the connecting cable (c) through the appropriate cable entries.

4. Wire the connecting cable between the sensor and transmitter in accordance with the

electrical connection diagram:

Fig. 15

Wiring diagram in the screw caps

5. Tighten the glands of the cable entries on the sensor housing and transmitter housing.

6. Screw the cover of the connection compartment (a/b) back onto the sensor housing or

transmitter housing.

22 Endress + Hauser

Proline Prowirl 72 PROFIBUS PA 4 Wiring

a

c

b

d

3

3

1

1

4

4

2

2

55667

7

8

8

DIFF +

DIFF +

DIFF –

DIFF –

GROUND

GROUND

+5VA

+5VA

–5VA

–5VA

TEMP 1

TEMP 1

TEMP 2

TEMP 2

TEMP 3

TEMP 3

e

f

A0001893

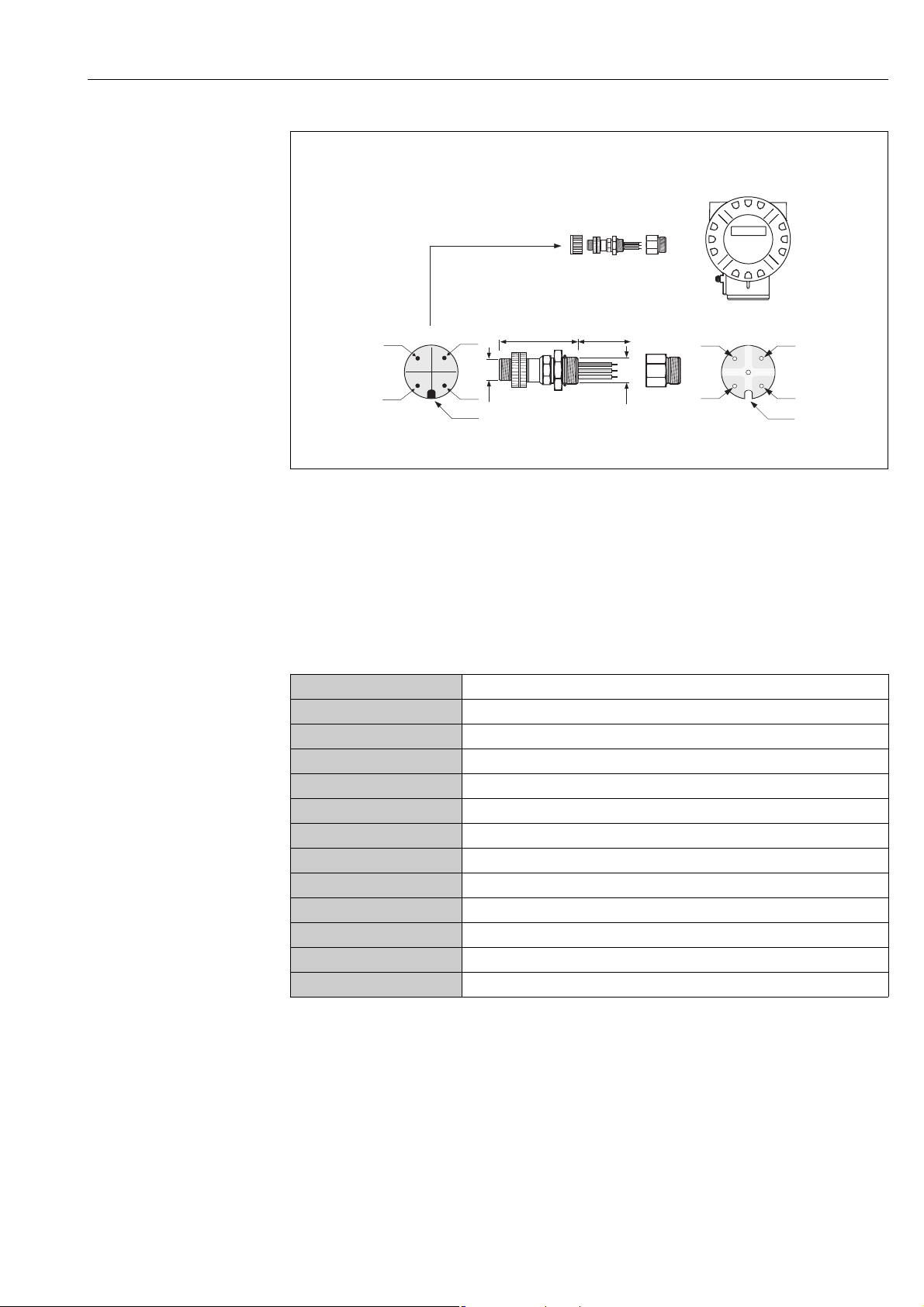

Fig. 15: Connecting the remote version

a Connection compartment cover (transmitter)

b Connection compartment cover (sensor)

c Connecting cable (signal cable)

d Identical potential matching for sensor and transmitter

e Connect shielding to ground terminal in transmitter housing and keep as short as possible

f Connect shielding to cable strain relief clamp in connection housing

!

!

Wire color (colour code according to DIN 47100):

Terminal number: 1 = white; 2 = brown; 3 = green; 4 = yellow, 5 = gray; 6 = pink; 7 = blue; 8 = red

4.2.2 Cable specifications, standard connecting cable

The specifications of the cable connecting the transmitter and the sensor of the remote version are

as follows:

•4 2 0.5 mm

Note!

If the cross-section of a cable deviates from the specification, the value for the cable length has to

be calculated. See "Calculating and entering the cable length".

• Conductor resistance according to DIN VDE 0295 class 5 or IEC 60228 class 5: 39 /km

Note!

The conductor resistance specified by the standard is compensated for.

• Capacity core/screen: < 400 pF/m (< 122 pF/ft)

• Cable length: max. 30 m (98 ft)

• Operating temperature: –40 to +105 °C (–40 to +221 °F)

2

(AWG 20) PVC cable with common shield (4 pairs, pair-stranded).

Endress + Hauser 23

4 Wiring Proline Prowirl 72 PROFIBUS PA

4.2.3 Cable specifications, armored connecting cable

The optionally available armored connecting cable between transmitter and sensor possesses the

following specifications:

•4 2 0.5 mm

2

(AWG 20) PVC cable with common shield (4 pairs, pair-stranded).

!

!

!

Note!

If the cross-section of a cable deviates from the specification, the value for the cable length has to

be calculated. See "Calculating and entering the cable length".

• Conductor resistance according to DIN VDE 0295 class 5 or IEC 60228 class 5: 39 /km

Note!

The conductor resistance specified by the standard is compensated for.

• Extensively resistant against acids, bases and specific oils

• A galvanized braided steel wire forms the total shield

• Outer sheath version: smooth, uniform, round

• Cable length: max. 30 m (98 ft)

• Operating temperature: –30 to +70 °C (–22 to +158 °F)

Note!

The cable resistance specified as 39 /km in accordance with the standard, is compensated. If a

cable is used with a cable cross-section deviating from the specification, the value for the cable

length must be calculated as follows and entered in the CABLE LENGTH function ( Page 107).

Cable resistance of the

cable used [ /km]

Cable resistance

in accordance with specification

[/km]

Actual cable

length [m]

= cable length to be entered [m]

Example:

• Cable resistance of used cable = 26 /km

• Cable resistance as per specification = 39 /km

• Actual cable length = 15 m

26 /km

39 /km

Conclusion:

In the CABLE LENGTH function ( Page 107) the value 10 m (32.81 ft), depending on the unit

selected in the UNIT LENGTH function, must be entered.

15 m = 10 m

24 Endress + Hauser

Proline Prowirl 72 PROFIBUS PA 4 Wiring

4.3 Connecting the measuring unit

4.3.1 Connecting the transmitter

!

"

Note!

• When connecting Ex-certified devices, please refer to the notes and diagrams in the Ex-specific

supplement to these Operating Instructions.

• The remote version must be grounded. In doing so, the sensor and transmitter must be connected

to the same potential equalization.

• The national regulations governing the installation of electrical equipment must be observed.

• When connecting the transmitter, use a connecting cable with a continuous service temperature

of at least –40 °C (–40 °F) to permitted max. ambient temperature plus 10 °C (plus 18 °F).

• A shielded cable must be used for the connection.

• The terminals for the PROFIBUS PA connection (terminal 1 = PA+, terminal 2 = PA –) have

integrated reverse polarity protection. This ensures correct signal transmission via the fieldbus

even if lines are confused.

• Cable cross-section: max. 2.5 mm²

• Observe the grounding concept.

Caution!

• Risk of damaging the PROFIBUS cable!

If the shielding of the cable is grounded at more than one point in systems without additional

potential equalization, power supply frequency equalization currents can occur that damage the

cable or the shielding. In such cases the shielding of the cable is to be grounded on only one side,

i.e. it must not be connected to the ground terminal of the housing. The shield that is not

connected should be insulated!

• We recommend that the PROFIBUS not be looped using conventional cable glands. If you later

replace even just one measuring device, the bus communication will have to be interrupted.

Endress + Hauser 25

4 Wiring Proline Prowirl 72 PROFIBUS PA

e

f

d

a

c

b

d

g

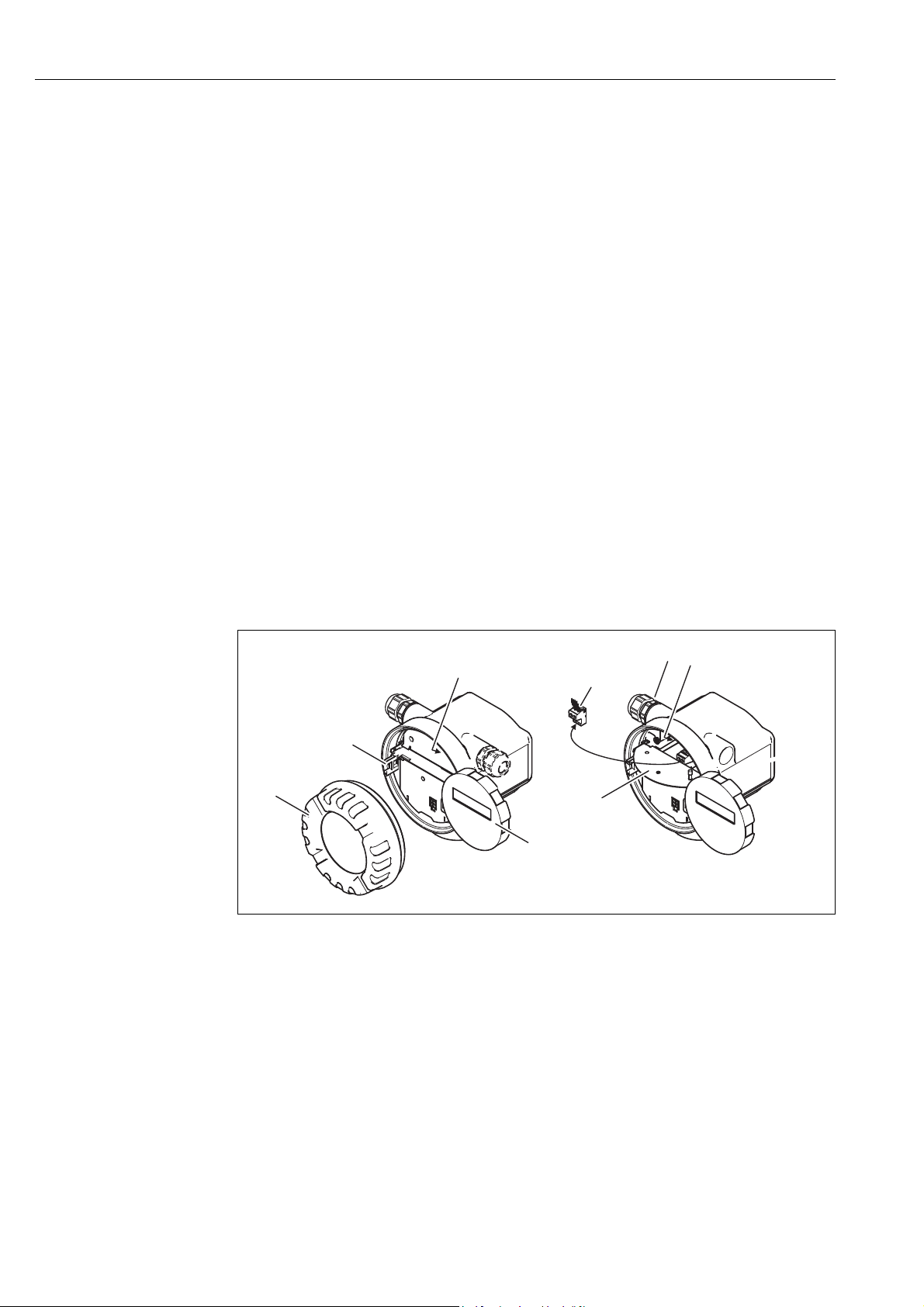

Connecting the transmitter, non-Ex / Ex i/IS and Ex n version ( Fig. 16)

1. Unscrew the cover (a) of the electronics compartment from the transmitter housing.

2. Remove the display module (b) from the retaining rails (c) and refit onto right retaining rail with

the left side (this secures the display module).

3. Loosen screw (d) of the cover of the connection compartment and fold down the cover.

4. Push the power supply/PROFIBUS cable through the cable gland (e).

5. Tighten the cable glands (e) (see also Page 30).

6. Pull the terminal connector (f) out of the transmitter housing and connect the power

supply/PROFIBUS cable ( Fig. 18).

! Note!

The terminal connector (d) is pluggable, i.e. it can be plugged out of the transmitter housing

to connect the cable.

7. Plug the terminal connector (f) into the transmitter housing.

8. Secure the ground cable to the ground terminal (g).

! Note!

Between the stripped PROFIBUS cable and the ground terminal, the cable shielding should not

exceed a length of 5 mm (0.20 inch).

9. Only remote version:

Secure ground cable to the ground terminal ( Fig. 18, B).

10. Fold up the cover of the connection compartment and tighten the screws (d).

11. Remove the display module (b) and fit on the retaining rails (c).

12. Screw the cover of the electronics compartment (a) onto the transmitter housing.

Fig. 16: Procedure when connecting the transmitter, non-Ex/Ex i/IS and Ex n version

a Cover of electronics compartment

b Display module

c Retaining rail for display module

d Connection compartment cover

e Cable gland

f Terminal connector

g Ground terminal

a0003782

26 Endress + Hauser

Proline Prowirl 72 PROFIBUS PA 4 Wiring

b

a

c

d

e

A

D

+

–

12

B

C

5mm(0.20 in)

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

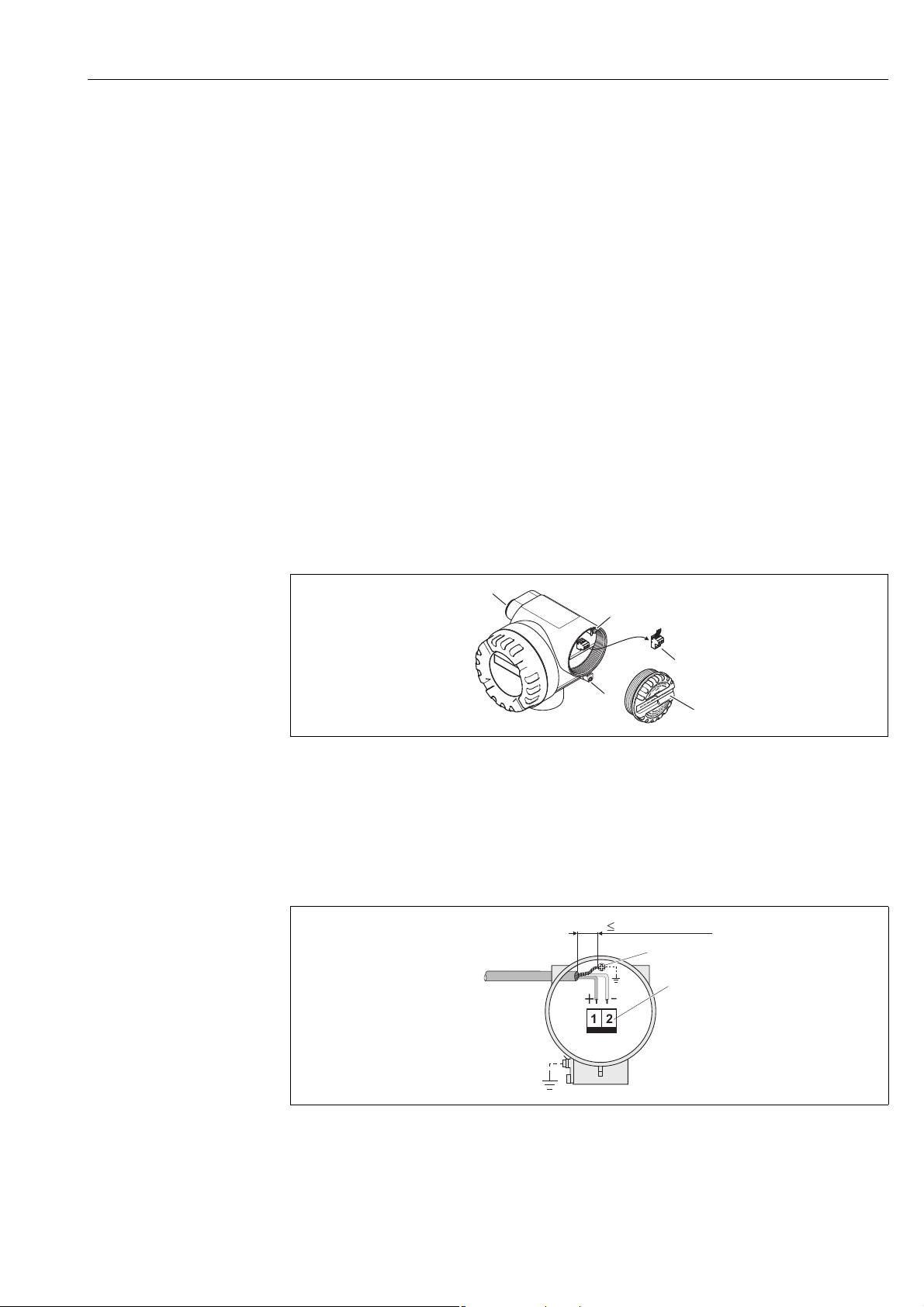

Connecting the transmitter, Ex d/XP version ( Fig. 17)

1. Release the securing clamp (a) of the connection compartment cover.

2. Screw the connection compartment cover (b) off the transmitter housing.

3. Push the power supply/PROFIBUS cable through the cable gland (c).

4. Tighten the cable glands (c) (see also Page 30).

5. Pull the terminal connector (d) out of the transmitter housing and connect the power

supply/PROFIBUS cable (see Fig. 18).

! Note!

The terminal connector (d) is pluggable, i.e. it can be plugged out of the transmitter housing

to connect the cable.

6. Plug the terminal connector (d) into the transmitter housing.

7. Secure the ground cable to the ground terminal (g).

! Note!

Between the stripped PROFIBUS cable and the ground terminal, the cable shielding should not

exceed a length of 5 mm (0.20 inch).

8. Only remote version:

Secure ground cable to the ground terminal (see Fig. 18, B).

9. Screw the connection compartment cover (b) onto the transmitter housing.

10. Tighten the securing clamp (a) of the connection compartment cover.

Fig. 17: Procedure when connecting the transmitter, Ex d/XP version

a Securing clamp for connection compartment cover

b Connection compartment cover

c Cable gland

d Terminal connector

e Ground terminal

Wiring diagram

Fig. 18: Connecting the transmitter

A PROFIBUS cable

B Ground terminal (between the stripped PROFIBUS cable and the ground terminal, the cable shielding should not

exceed a length of 5 mm (0.20 inch)).

C Terminal connector (1 = PA +; 2 = PA –)

D Ground terminal (external, only relevant for remote version)

Endress + Hauser 27

a0003783

a0003784

4 Wiring Proline Prowirl 72 PROFIBUS PA

4.3.2 Terminal assignment

Terminal no. (inputs/outputs)

Order version 1 2

72***-***********H PA + PA –

4.3.3 Fieldbus connector

The connection technology of PROFIBUS PA allows measuring devices to be connected

to the fieldbus via uniform mechanical connections such as T-boxes, distribution modules, etc.

This connection technology using prefabricated distribution modules and plug-in connectors offers

substantial advantages over conventional wiring:

• Field devices can be removed, replaced or added at any time during normal operation.

Communication is not interrupted.

• Installation and maintenance are significantly easier.

• Existing cable infrastructures can be used and expanded instantly, e.g. when constructing new

star distributors using 4-channel or 8-channel distribution modules.

The device can therefore be supplied with the option of a ready-mounted fieldbus connector.

Fieldbus connectors for retrofitting can be ordered from Endress+Hauser as a spare part (see

Page 73).

Supply line/T-box shielding

Use cable glands with good EMC properties, if possible with all-round contact of the cable shielding

(Iris spring). This requires small differences in potential, poss. potential equalization.

• The PA cable shielding must be intact.

• The shielding connection must always be kept as short as possible.

Ideally, cable glands with Iris springs should be used for the shielding connection. The shielding is

positioned on the T-box housing by means of the Iris spring located inside the gland. The shielding

braid is located beneath the Iris spring. When the armored thread is tightened, the Iris spring is

pressed against the shielding, thereby creating a conductive connection between the shielding and

the metal housing.

A connection box or a plug-in connection is to be seen as part of the shielding (Faraday shield). This

applies, in particular, to remote boxes if these are connected to a PROFIBUS PA measuring device

by means of a pluggable cable. In such instances, a metallic connector must be used where the cable

shielding is positioned at the plug housing (e.g. prefabricated cables).

28 Endress + Hauser

Proline Prowirl 72 PROFIBUS PA 4 Wiring

150/300 mm

45.0 mm

(1.766")

PG 13.5

M12x1

BC D

4

1

2

E

3

34

21

F

5

6

7

A

a0003859

Fig. 19: Connectors for connecting to the PROFIBUS PA

A Aluminum field housing

B Protection cap for connector

C Fieldbus connector

D Adapter PG 13.5 / M 20.5

E Connector at housing (male)

F Female connector

Pin assignment / color codes:

1 Brown wire: PA+ (terminal 1)

2Not connected

3 Blue wire: PA – (terminal 2)

4 Black wire: ground

5 Middle female connector not assigned

6 Positioning groove

7 Positioning key

Technical data (connector):

Connection cross section 0.75 mm

Connector thread PG 13.5

Degree of protection IP 67 in accordance with DIN 40 050 IEC 529

Contact surface CuZnAu

Housing material Cu Zn, surface Ni

Flammability V - 2 in accordance with UL - 94

Operating temperature –40 to +85 °C, (–40 to +185 °F)

Ambient temperature range –40 to +150 °C, (–40 to +302 °F)

Nominal current per contact 3 A

Nominal voltage 125 to 150 V DC in accordance with the VDE Standard 01 10/ISO Group 10

Resistance to tracking KC 600

Volume resistance 8 m in accordance with IEC 512 Part 2

Insulation resistance 1012 in accordance with IEC 512 Part 2

2

Endress + Hauser 29

4 Wiring Proline Prowirl 72 PROFIBUS PA

ab

4.4 Degree of protection

The measuring device meets all the requirements for IP 67 (NEMA 4X).

Caution!

"

Do not loosen the screws of the sensor housing, as otherwise the degree of protection guaranteed

by Endress+Hauser no longer applies.

Compliance with the following points is mandatory following installation in the field or servicing in

order to ensure that IP 67 (NEMA 4X) protection is maintained:

• The housing seals must be clean and undamaged when inserted into their grooves. The seals must

be dried, cleaned or replaced if necessary.

• The housing screws and screw caps must be firmly tightened.

• The cables used for connection must be of the specified outside diameter Page 81, cable

entries.

• The cable entries must be firmly tightened (point a Fig. 20).

• The cable must loop down before it enters the cable entry ("water trap") (point b Fig. 20).

This arrangement prevents moisture penetrating the entry.

The cable entries should not point upwards.

• Replace all unused cable entries with dummy plugs.

• Do not remove the grommet from the cable entry.

Fig. 20: Installation instructions for cable entries

a0001914

30 Endress + Hauser

Loading...

Loading...