Endress+Hauser FMB52, FMB53, FMB51, FMB50 Specifications

TI00437P/00/EN/20.16

No. 71316865

Products |

Solutions |

Services |

|

|

|

Technical Information

Deltapilot M

FMB50, FMB51, FMB52, FMB53

Hydrostatic level measurement

Pressure sensor with the CONTITETM measuring cell Condensate-resistant

Application

The device is used for the following measuring tasks:

•Hydrostatic pressure measurement in liquids and paste-like media in all areas of process engineering, process measuring technology, pharmaceuticals and the food industry

•Level, volume or mass measurements in liquids

Your benefits

•Very good reproducibility and long-term stability

•Maximum plant safety provided by one-of-a-kind, condensate-proofed CONTITE measuring cell

•High reference accuracy: ±0.2 % optionally ±0.1 %

•Turn down 100:1

•Standardized platform for differential pressure, hydrostatics, and pressure (Deltabar M – Deltapilot M – Cerabar M)

•Simple, fast commissioning through a user interface designed for real-world applications

•Used for process pressure monitoring up to SIL2, certified to IEC 61508 Edition 2.0 and IEC 61511 by TÜV NORD

•Usage in drinking water: KTW, NSF

Deltapilot M FMB50/51/52/53

Table of contents

Document information . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

Turn down calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

Function and system design . . . . . . . . . . . . . . . . . . . . . .8

Device selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Level measurement in closed tanks with pressure overlay . . 11 Density measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Level measurement with automatic density correction (with media changing in the tank) . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Electrical differential pressure measurement with gauge pressure sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Communication and data processing . . . . . . . . . . . . . . . . . . . . 13

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Signal range – 4 to 20 mA HART . . . . . . . . . . . . . . . . . . . . . . . 15 Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Load - 4 to 20 mA HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Dead time, time constant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Dynamic behavior: current output . . . . . . . . . . . . . . . . . . . . . . . 16 Dynamic behavior: HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Dynamic behavior: PROFIBUS PA . . . . . . . . . . . . . . . . . . . . . . . 17 Dynamic behavior: FOUNDATION Fieldbus . . . . . . . . . . . . . . . 17 Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Firmware version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Galvanic isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Protocol-specific data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 Current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 Cable entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 Cable specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 Start-up current HART. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 Residual ripple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 Influence of power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 Overvoltage protection (optional) . . . . . . . . . . . . . . . . . . . . . . . 26

Performance characteristics . . . . . . . . . . . . . . . . . . . . 27

Reference operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . 27 Influence of orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 Calibration position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 Reference accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 Thermal change in the zero output and the output span . . . . 28 Total performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Long-term stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Total error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Warm-up period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

General installation instructions . . . . . . . . . . . . . . . . . . . . . . . . 29 FMB50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 FMB51/FMB52/FMB53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 Supplementary installation instructions . . . . . . . . . . . . . . . . . . 30 Wall and pipe mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 "Separate housing" version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 Oxygen applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 PWIS cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 Applications with hydrogen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 Special measuring cells for acids, alkalis or sea water

(not FMB50) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Ambient temperature limits . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 Storage temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 Climate class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 Vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Process temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 Lateral load FMB51 (static) . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 Pressure specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . . 36

Device height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 F31 housing, aluminum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 F15 housing, stainless steel (hygienic) . . . . . . . . . . . . . . . . . . . 37 Diameter of the process isolating diaphragm . . . . . . . . . . . . . 37 Process connections FMB50, FMB51, FMB52 . . . . . . . . . . . . 37 Process connections FMB50, FMB51, FMB52 . . . . . . . . . . . . 38 Process connections FMB50, FMB51, FMB52 - continued . . 39 Process connections FMB50, FMB51, FMB52 - continued . . 40 Process connections FMB50 - continued . . . . . . . . . . . . . . . . . 41 Process connections FMB50 - continued . . . . . . . . . . . . . . . . 42 Process connections FMB51 (rod version) . . . . . . . . . . . . . . . . 44 Process connections FMB52 (cable version) . . . . . . . . . . . . . . 46 Dimensions of FMB53 with F31 housing, suspension clamp and mounting bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 Dimensions of FMB53 with F15 housing, suspension clamp and mounting bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49 Wall and pipe mounting with "Separate housing" version . . . 50 Materials not in contact with process . . . . . . . . . . . . . . . . . . . . 53 Materials in contact with the process . . . . . . . . . . . . . . . . . . . . 56

Operability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Operating concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 Onsite operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 Operating languages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61 Remote operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61 System integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

2 |

Endress+Hauser |

Deltapilot M FMB50/51/52/53

Certificates and approvals . . . . . . . . . . . . . . . . . . . . . . 63

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 RCM-Tick marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 Ex approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 EAC conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 Suitability for hygienic processes . . . . . . . . . . . . . . . . . . . . . . . . 63 Certificate of Compliance ASME BPE 2012 (FMB50 only) . . 64 Functional safety SIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64 Overfill protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64 AD2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64 Pressure Equipment Directive (PED) . . . . . . . . . . . . . . . . . . . . . 64 Manufacturer declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64 Marine approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64 Other standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . 65 Drinking water approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 Classification of process sealing between electrical systems and (flammable or combustible) process fluids in accordance with ANSI/ISA 12.27.01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 Inspection certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 Calibration; unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Configuration data sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Suspension clamp (FMB53 only) . . . . . . . . . . . . . . . . . . . . . . . . 69

Extension cable shortening kit (FMB53 only) . . . . . . . . . . . . . 69

M12 connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Welding necks and Weld-in tool flanges . . . . . . . . . . . . . . . . . 69

Adapter Uni for FMB50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Brief Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Functional safety manual (SIL) . . . . . . . . . . . . . . . . . . . . . . . . . 71

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Installation/Control Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Combination certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Overfill protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . . . 73

HART® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

PROFIBUS® . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

FOUNDATION™ Fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3 |

Endress+Hauser |

Deltapilot M FMB50/51/52/53

Document information

Symbols used |

Safety symbols |

|

||||

|

|

|

|

|

|

|

|

Symbol |

Meaning |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

DANGER! |

|

|

DANGER |

|

|||

|

|

|

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in |

|||

|

|

|

|

|

|

|

|

|

A0011189-EN |

serious or fatal injury. |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING! |

|

|

WARNING |

|

|

||

|

|

|

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in |

|||

|

|

|

|

|

|

|

|

|

A0011190-EN |

serious or fatal injury. |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

CAUTION! |

|

|

CAUTION |

|

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in |

||

|

|

|

|

|

|

|

|

|

A0011191-EN |

minor or medium injury. |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE! |

|

|

NOTICE |

|

|

|

|

|

|

|

This symbol contains information on procedures and other facts which do not result in |

|||

|

|

|

|

|

|

|

|

|

A0011192-EN |

personal injury. |

|||

|

|

|

|

|

|

|

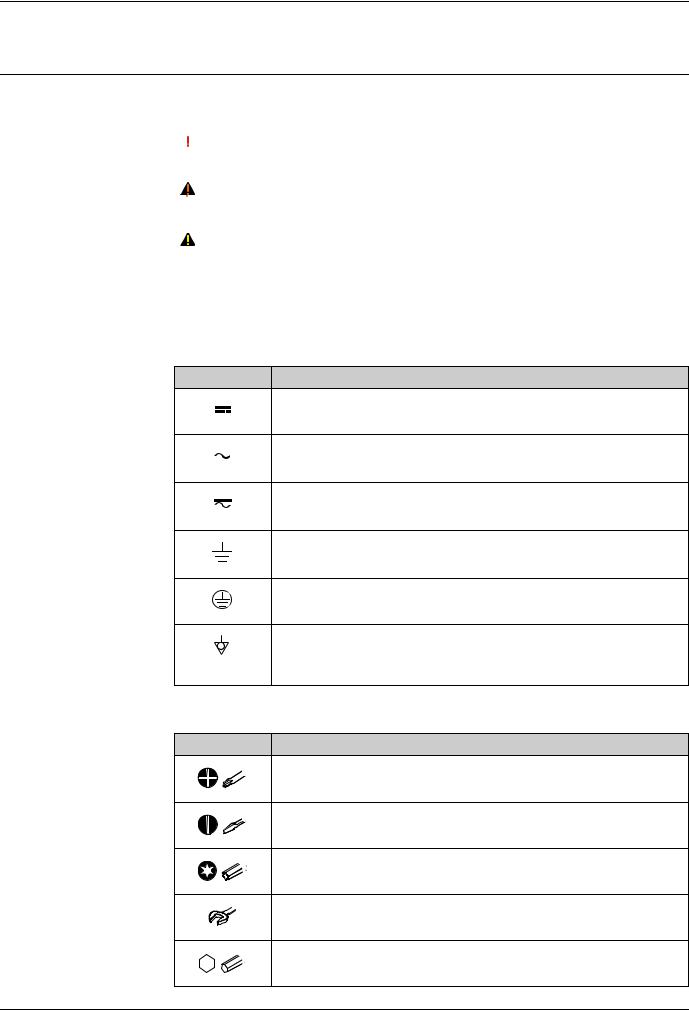

Electrical symbols

Symbol Meaning

Direct current

A terminal at which DC voltage is present or through which direct current flows.

A0018335

Alternating current

A terminal at which alternating voltage is present or through which alternating current

A0018336 flows.

Direct current and alternating current |

|

• |

A terminal at which alternating voltage or DC voltage is present. |

A0018337 • |

A terminal through which alternating current or direct current flows. |

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

A0018338 grounding system.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

A0018339

Equipotential connection

A connection that has to be connected to the plant grounding system: This may be a A0011201 potential equalization line or a star grounding system depending on national or company

codes of practice.

Tool symbols

Symbol Meaning

Phillips head screwdriver

A0011219

Flat-blade screwdriver

A0011220

Torx screwdriver

A0013442

Hexagon wrench

A0011222

Allen screw

A0011221

4 |

Endress+Hauser |

Deltapilot M FMB50/51/52/53

Symbols for certain types of information

Symbol |

Meaning |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Permitted |

|

|

|

|

|

|

|

Indicates procedures, processes or actions that are permitted. |

|

|

|

|

|

|

A0011182 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Preferred |

|

|

|

|

|

|

|

Indicates procedures, processes or actions that are preferred. |

|

|

|

|

|

|

A0011183 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Forbidden |

|

|

|

|

|

|

|

Indicates procedures, processes or actions that are forbidden. |

|

|

|

|

|

|

A0011184 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tip |

|

|

|

|

|

|

|

Indicates additional information. |

|

|

|

|

|

|

A0011193 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reference to documentation |

|

|

|

|

|

|

|

Refers to the corresponding device documentation. |

|

|

|

|

|

|

A0015483 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reference to page |

|

|

|

|

|

|

A0015484 |

Refers to the corresponding page number. |

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reference to graphics |

|

|

|

|

|

|

|

Refers to the corresponding graphic number and page number. |

|

|

|

|

|

|

A0015486 |

|

|

|

|

|

|

|

|

|

|

1. |

, |

2. |

, ... |

Series of steps |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Help in the event of a problem |

|

|

|

|

|

|

A0015488 |

|

|

|

|

|

|

|

|

|

Symbols in graphics |

|||||||

|

|

|

|

|

|

|

|

Symbol |

Meaning |

||||||

|

|

|

|

|

|

|

|

1, 2, 3, 4 etc. |

Numbering for main items |

||||||

|

|

|

|

|

|

|

|

|

1. |

, |

2. |

, ... |

Series of steps |

||

|

|

|

|

|

|

|

|

A, B, C, D etc. |

Views |

||||||

|

|

|

|

|

|

|

|

A-A, B-B, etc. |

Sections |

||||||

|

|

|

|

|

|

|

|

- |

|

Hazardous area |

|||||

|

Indicates the hazardous area. |

||||||

|

|

|

|

|

|

A0011187 |

|

|

|

|

|

|

|

|

|

. |

|

Safe area (non-hazardous area) |

|||||

|

Indicates the non-hazardous area. |

||||||

|

|

|

|

|

|

A0011188 |

|

|

|

|

|

|

|

|

|

Endress+Hauser |

5 |

|

|

|

|

Deltapilot M FMB50/51/52/53 |

|

Terms and abbreviations |

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

2 |

|

|

|

|

3 |

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

p |

|

0 |

|

|

|

|

LRL |

LRV |

URV |

URL |

MWP |

OPL |

|

|

|

|

|

A0029505 |

Position |

Term/Abbreviation |

Explanation |

|

|

|

1 |

OPL |

The OPL (over pressure limit = sensor overload limit) for the sensors |

|

|

depends on the lowest-rated element, with regard to pressure, of the |

|

|

selected components, i.e. the process connection must be taken into |

|

|

consideration in addition to the measuring cell. Also observe pressure- |

|

|

temperature dependency. For the relevant standards and additional notes, |

|

|

see the " ä 35" section. |

|

|

The OPL may be applied for a limited time period. |

|

|

|

2 |

MWP |

The MWP (maximum working pressure) for the sensors depends on the |

|

|

lowest-rated element, with regard to pressure, of the selected components, |

|

|

i.e. the process connection has to be taken into consideration in addition to |

|

|

the measuring cell. Also observe pressure-temperature dependency. For the |

|

|

relevant standards and additional notes, see the " ä 35" section. |

|

|

The MWP may be applied for an unlimited time. |

|

|

|

3 |

Maximum sensor |

Range between LRL and URL |

|

measuring range |

This span is the maximum calibratable/adjustable measuring span. |

|

|

|

4 |

Calibrated/Adjusted |

Range between LRV and URV |

|

measuring span |

Factory setting: 0...URL |

|

|

Other calibrated spans can be ordered with customised settings. |

|

|

|

p |

- |

Pressure |

|

|

|

- |

LRL |

Lower range limit |

|

|

|

- |

URL |

Upper range limit |

|

|

|

- |

LRV |

Lower range value |

|

|

|

- |

URV |

Upper range value |

|

|

|

- |

TD |

Turn down |

|

|

|

6 |

Endress+Hauser |

Deltapilot M FMB50/51/52/53

Turn down calculation

|

|

|

1 = 2 |

|

3 |

|

LRL LRV |

URV |

URL |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A0029545

1Calibrated/Adjusted measuring span

2Zero-based span

3Upper range limit

Example

• Sensor: 10 bar (150 psi) |

|

|

• Calibrated/Adjusted measuring span: 0...5 bar |

||

• Upper range limit (URL) = 10 bar (150 psi) |

(0...75 psi) |

||||

|

|

|

|

|

• Lower range value (LRV) = 0 bar |

Turn down (TD): |

|

|

• Upper range value (URV) = 5 bar (75 psi) |

||

|

|

|

|||

TD |

= |

|

URL |

|

|

|

|

|

|

||

|URV |

- |

LRV| |

|

||

|

|

|

|||

TD |

= |

10 bar (150 psi) |

= 2 |

||

|

|

|

|||

|5 bar (75 psi) |

- |

0 bar (0 psi)| |

|||

In this example, the TD is thus 2:1.

This span is based on the zero point.

Endress+Hauser |

7 |

Deltapilot M FMB50/51/52/53

Function and system design

Device selection

Deltapilot M – |

FMB50 |

|

|

|

FMB51 |

|

|

|

|

|

|

|

|

|

|

|

FMB52 |

|

|

FMB53 |

|||||||||||||||||||||||||

Product family |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A0023537 |

A0023538 |

A0023539 |

A0023540 |

|

Compact version |

Rod version |

Cable version |

Cable version with |

|

|

|

|

Mounting bracket |

|

|

|

|

|

Field of application |

– Level measurement |

|

|

|

|

– Pressure measurement |

|

|

|

|

|

|

||

Industries |

Food, pharmaceuticals, chemicals, power plants, automotive, etc. |

Environment (freshwater |

||

|

|

|

|

and wastewater) |

|

|

|

|

|

Process connections |

– Thread |

– Thread |

– Thread |

Suspension clamp |

|

– Flanges |

– Flanges |

– Flanges |

|

|

– Flush-mounted hygienic |

|

|

|

|

connections |

|

|

|

|

|

|

|

|

Measuring ranges |

From –0.1 to +0.1 (-1.5 to +1.5 psi) bar to –1 bar to +10 bar (-15 to 150 psi) |

|

||

|

|

|

|

|

OPL |

Max. 40 bar (600 psi) |

|

|

|

|

|

|

|

|

Process temperature range |

–10 to +100 °C (+14 to |

–10 to +85 °C |

With PE cable (unmoved): –10 to +70 °C (+14 to +158°F) |

|

|

+212°F) (+135 °C (275°F) for |

(+14 to +185°F) |

With FEP cable (unmoved): |

|

|

30 minutes maximum) |

|

–10 to +80 °C (+14 to +176°F) |

|

|

|

|

|

|

Ambient temperature range |

• Without LCD display: -40 to +85 °C (-40 to +185°F) |

|

|

|

•With LCD display: -20 to +70 °C (-4 to +158°F) (extended temperature application range -40 to 85 °C (-40 to +158°F) with restrictions in optical properties such as display speed and contrast)

•Separate housing: -20 to +60 °C (-4 to +140°F)

Reference accuracy |

0.2 % (option 0.1 %) depends on the measuring range ä 27 |

|

|

|

|

Supply voltage |

– 11.5 to 45 V DC (versions with plug-in connection 35 V DC) |

|

|

– |

For intrinsically safe device versions: 11.5 to 30 V DC |

|

|

|

Output |

4 to 20 mA with superimposed HART protocol, PROFIBUS PA or FOUNDATION Fieldbus |

|

|

|

|

Options |

– Gold/rhodium-coated process isolating diaphragm |

|

|

– |

3.1 inspection certificate |

|

– 3A approval and EHEDG approval for FMB50 |

|

|

– |

Specific firmware versions |

|

– |

Initial device settings can be ordered |

|

– Separate housing |

|

|

|

|

Specialties |

– |

Absolute resistance to condensate thanks to hermetically sealed CONTITETM cell |

|

– Maximum flexibility thanks to modular design |

|

|

– |

Special cleaning of the transmitter to remove paint-wetting substances, for use in paint shops |

8 |

Endress+Hauser |

Deltapilot M FMB50/51/52/53

FMB50, FMB51, FMB52 universal application

•Modular probe program to ensure optimum process adaptation

•FMB50 compact version: installation in the tank from below or from the side

•FMB51, FMB52 rod and cable extension: installation from above, i.e. easy to retrofit ground tanks, no additional opening in the vessel floor

FMB50 optimized for hygienic applications

•All typical flush-mounted process connections can be supplied

•Welding flanges

•Stainless steel housing

•All the sanitary process connections are gap-free and can be cleaned so that the unit is free of residue, e.g. CIP cleaning

•USDA/H1-approved transfer liquid as per FDA Directive

•3A approval or EHEDG approvals

74 -

TYPE EL

February 2010

A0023536 |

A0020029 |

FMB53 for level measurement in water and wastewater

•The housing with the electronic insert is mounted outside shafts and vessels in such a way that it is protected from flooding. The extension cable is secured with a suspension clamp.

•The measuring cell tube made of stainless steel (AISI 316L) and the Alloy process isolating diaphragm allow use in aggressive media such as wastewater for example.

•Extension cable up to 400 m (1312 ft) in length (up to 100 m (328 ft) in Ex-areas) without strain relief.

•Special measuring cell with gold/rhodium coating for applications in which severe hydrogen formation can occur (e.g. digested sludge); ä 32.

•Special measuring cell with gold/platinum coating for acids, alkalis or sea water; ä 32.

Endress+Hauser |

9 |

|

|

|

|

|

Deltapilot M FMB50/51/52/53 |

||

Measuring principle |

|

|

|

|

|

|

|

|

|

|

patm |

|

pmess = pges - patm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

pmess = (patm + phydr.) - patm |

|

|

|

|

|

phydr. |

|

|

|

|

|

|

|

h ~ p |

|

|

|

|

|

|

|

h |

p |

|

|

|

|

|

|

h = |

|

|

|

|

|

|

|

· g |

|

|

||

pges = patm |

+ phydr. |

pges |

patm |

|

|

|

|

|

|

1 |

2 |

3 |

|||

|

|

|

|

|

|||

|

|

|

|

|

p= patm + phydr. |

|

patm |

|

|

|

|

|

|

|

A0023541 |

Deltapilot M hydrostatic level measurement and measuring principle

1Rear isolating membrane of the CONTITE™ measuring cell

2Measuring element

3Process isolating diaphragm

gGravitational acceleration

hLevel height

p ges |

Total pressure = hydrostatic pressure + atmospheric pressure |

p atm |

Atmospheric pressure |

p hydr. |

Hydrostatic pressure |

p mess |

Measured pressure in the measuring cell = hydrostatic pressure |

Density of the medium

Due to its weight, a liquid column creates hydrostatic pressure. If the density is constant, the hydrostatic pressure depends solely on the height h of the liquid column.

The CONTITE™ measuring cell, which works on the principle of the gauge pressure sensor, constitutes the core of Deltapilot M. In contrast to conventional gauge pressure sensors, the precision measuring element (2) in the CONTITE™ measuring cell is absolutely protected, situated between the process isolating diaphragm (3) and the rear isolating membrane (1). Thanks to this hermetic sealing of the measuring element, the CONTITE™ measuring cell is absolutely insensitive to condensate/ condensation and aggressive gases. The pressure applied is transferred from the process isolating diaphragm to the measuring element by means of an oil without any loss in pressure.

Any measured errors due to fluctuations in temperature are compensated for in the electronics unit by means of the sensor temperature.

A linearization function with max. 32 points, based on a table entered either manually or semi-automatically, can be activated locally or remotely. This function facilitates measurement in engineering units, and provides a linear output signal for spherical and horizontal cylindrical vessels, and vessels with a conical outlet.

10 |

Endress+Hauser |

Deltapilot M FMB50/51/52/53

Level measurement in closed You can determine the differential pressure in tanks with pressure overlay using two Deltapilot M. The tanks with pressure overlay pressure measured values of the two probes are sent to a signal processing unit such as

Endress+Hauser RMA or a PLC. The signal processing unit or PLC determines the difference in pressure and uses this to calculate the level and the density where necessary.

2 |

3 |

|

1

1

A0023542

Level measurement in a closed tank with pressure overlay

1Deltapilot 1 measures the total pressure (hydrostatic pressure and top pressure)

2Deltapilot 2 measures the top pressure

3Signal processing unit determines the difference in pressure and uses this to calculate the level

NOTICE

Measured errors can occur.

Large measured errors can occur if the ratio of the level to the top pressure is >1:6. This does not affect reproducibility.

When selecting the measuring cell, make sure you select measuring ranges that are sufficiently wide ( see example).

Example:

•Max. hydrostatic pressure = 600 mbar (9 psi)

•Max. top pressure (Deltapilot 2) = 300 mbar (4.5 psi)

•Max. total pressure, measured with Deltapilot 1 = 300 mbar (4.5 psi) + 600 mbar (9 psi) = 900 mbar (13.5 psi) measuring cell to be selected: 0 to 1200 mbar (0 to 18 psi)

•Max. pressure, measured with Deltapilot 2: 300 mbar (4.5 psi) measuring cell to be selected: 0 to 400 mbar (6 psi)

NOTICE

Possibility of probe 2 flooding during differential pressure measurement.

Measured errors can occur.

When installing, make sure that probe 2 cannot be flooded.

Endress+Hauser |

11 |

|

|

Deltapilot M FMB50/51/52/53 |

Density measurement |

You can measure the density in tanks with pressure overlay using two Deltapilot M and a signal |

|

|

processing unit or a PLC. The signal processing unit or the PLC calculates the density from the known |

|

|

distance between the two Deltapilot M devices h and the two measured values p1 and p2. |

|

|

|

2 |

|

|

3 |

|

|

p2 |

|

|

h |

|

|

p1 |

|

|

1 |

|

|

A0023544 |

|

Level measurement in a closed tank with pressure overlay |

|

|

1 |

Deltapilot 1 determines pressure measured value p1 |

|

2 |

Deltapilot 2 determines pressure measured value p2 |

|

3 |

Signal processing unit determines the density from the two measured values p1 and p2 and the distance h |

Level measurement with automatic density correction (with media changing in the tank)

Level measurement with automatic density correction is possible in conjunction with a limit switch such as Liquiphant and a PLC. The limit switch always switches at the same level. In the switch point, the signal processing unit determines the corrected density from the pressure of the Deltapilot M currently measured and the known distance between Deltapilot M and the limit switch. The signal processing unit then calculates the level from the new density and the measured pressure of the Deltapilot M.

3

2

2

h

1

1

A0023546

Level measurement with automatic density correction

1Deltapilot M

2Liquiphant

3PLC

12 |

Endress+Hauser |

Deltapilot M FMB50/51/52/53

Electrical differential pressure measurement with gauge pressure sensors

|

|

|

Deltapilot M |

|

|

|

|

520 |

|

|

|

|

FXN |

|

|

|

|

1 |

1 |

|

|

Fieldgate |

Multidrop-Connector |

|

|

|

FXA520 |

FXN520 |

|

|

|

|

2 |

|

|

|

|

|

A0023549 |

|

1 |

Shut-off valves |

|

|

|

2 |

e.g. filter |

|

|

|

In the example given, two Deltapilot M devices (each with a gauge pressure sensor) are interconnected. |

|||

|

The pressure difference can thus be measured using two independent Deltapilot M devices. |

|||

|

! |

WARNING |

|

|

|

Risk of explosion! |

|

|

|

|

If using intrinsically safe devices, strict compliance with the rules for interconnecting intrinsically |

|||

|

|

safe circuits as stipulated in IEC60079-14 (proof of intrinsic safety) is mandatory. |

|

|

Communication and data |

• 4 to 20 mA with HART communication protocol |

|

||

processing |

• PROFIBUS PA |

|

|

|

|

– The Endress+Hauser devices meet the requirements of the FISCO model. |

|

||

|

– Due to the low current consumption of 11 mA ± 1 mA, the following number of devices can be |

|||

|

|

operated on one bus segment if installing as per FISCO: |

|

|

– up to 8 Deltapilot M for Ex ia, CSA IS and FM IS applications

– up to 31 Deltapilot M for all other applications, e.g. in non-hazardous areas, Ex nA, etc. Further information on PROFIBUS PA can be found in Operating Instructions BA00034S "PROFIBUS DP/PA: Guidelines for planning and commissioning" and in the PNO Guideline.

• FOUNDATION Fieldbus

– The Endress+Hauser devices meet the requirements of the FISCO model.

– Due to the low current consumption of 16 mA ± 1 mA, the following number of devices can be operated on one bus segment if installing as per FISCO:

– up to 6 Deltapilot M for Ex ia, CSA IS and FM IS applications

– up to 22 Deltapilot M for all other applications, e.g. in non-hazardous areas, Ex nA, etc. Further information on FOUNDATION Fieldbus, such as requirements for bus system components can be found in Operating Instructions BA00013S "FOUNDATION Fieldbus Overview".

Endress+Hauser |

13 |

Deltapilot M FMB50/51/52/53

Input

Measured variable |

|

Hydrostatic pressure |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

Measuring range |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||||

Sensor |

Maximum sensor measuring |

Smallest calibratable |

MWP |

OPL |

Vacuum |

Option 3) |

|||||

|

|

range |

|

measuring span |

|

|

resistance 2) |

|

|||

|

|

lower (LRL) 4) |

|

upper (URL) |

(preset at the factory) 1) |

|

|

Synthetic oil/ |

|

||

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

Inert oil |

|

[bar (psi)] |

[bar (psi)] |

|

[bar (psi)] |

[bar (psi)] |

[bar (psi)] |

[bar (psi)] |

[barabs (psiabs)] |

|

|||

0.1 |

(1.5) |

–0.1 (-1.5) |

|

+0.1 |

(+1.5) |

0.01 |

(0.15) |

2.7 (40.5) |

4 (60) |

0.01/0.04 |

1C |

|

|

|

|

|

|

|

|

|

|

(0.145/0.6) |

|

0.4 |

(6) |

–0.4 (-6) |

|

+0.4 |

(+6) |

0.02 |

(0.3) |

5.3 (79.5) |

8 (120) |

1F |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

1.2 |

(18) |

–1 (-15) |

|

+1.2 |

(+18) |

0.06 |

(1) |

16 (240) |

24 (360) |

|

1H |

|

|

|

|

|

|

|

|

|

|||

4 (60) |

–1 (-15) |

|

+4 (+60) |

0.2 (3) |

16 (240) |

24 (360) |

|

1M |

|||

|

|

|

|

|

|

|

|

|

|||

10 (150) |

–1 (-15) |

|

+10 (+150) |

0.5 (7.5) |

27 (405) |

40 (600) |

|

1P |

|||

|

|

|

|

|

|

|

|

|

|

|

|

1)Factory calibration Turn down: Max 20:1, higher on request.

2)The vacuum resistance applies to the measuring cell at reference conditions.

3)Product Configurator, "Sensor range" ordering feature

4)By default, the device is set to a lower range limit of 0 bar. Please specify in the order if the lower range limit is to be set to a different default value.

14 |

Endress+Hauser |

Deltapilot M FMB50/51/52/53

Output

Output signal |

• 4 to 20 mA with superimposed digital communication protocol HART 6.0, 2-wire |

•Digital communication signal PROFIBUS PA (Profile 3.02)

•Digital communication signal FOUNDATION Fieldbus

Output |

Option 1) |

4 to 20mA HART |

2 |

|

|

PROFIBUS PA |

3 |

|

|

FOUNDATION Fieldbus |

4 |

|

|

1)Product Configurator, "Output" ordering feature

Signal range – |

3.8 to 20.5 mA |

4 to 20 mA HART |

|

|

|

Signal on alarm |

As per NAMUR NE 43 |

•4 to 20 mA HART Options:

–Max. alarm: can be set from 21 to 23 mA (Factory setting: 22 mA)

–Hold measured value: last measured value is held

–Min. alarm: 3.6 mA

•PROFIBUS PA: can be set in the Analog Input block,

Options: Last Valid Out Value (factory setting), Fail-safe Value, Status Bad

•FOUNDATION Fieldbus: can be set in the Analog Input block,

Options: Last Good Value, Fail-safe Value (factory setting), Wrong Value

Load - 4 to 20 mA HART

RLmax |

|

|

|

|

|

|

[ ] |

|

|

|

|

|

|

1456 |

|

|

|

|

|

|

1239 |

|

|

|

|

|

|

804 |

|

|

|

|

|

|

369 |

|

|

|

|

|

|

11.5 |

20 |

|

30 |

40 45 |

U |

|

|

|

1 |

|

|

|

[V] |

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

3 |

RLmax |

|

U – 11.5 V |

|

||

|

|

|

|

23 mA |

|

|

A0023090

Load diagram

1Power supply 11.5 to 30 V DC for intrinsically safe device versions

2Power supply 11.5 to 45 V DC (versions with plug-in connector 35 V DC) for other types of protection and for uncertified device versions

RLmax Maximum load resistance

U Supply voltage

When operating via a handheld terminal or via a PC with an operating program, a minimum communication resistance of 250 must be taken into account.

Endress+Hauser |

15 |

Deltapilot M FMB50/51/52/53

Dead time, time constant

I |

|

|

100 % |

|

|

90 % |

|

|

63 % |

|

|

t1 |

t2 |

t |

|

|

t3 |

A0019786

Presentation of the dead time and the time constant

Dynamic behavior: |

|

|

|

|

|

|

Type |

Dead time (t1) |

Time constant T63 (= t2) [ms] |

Time constant T90 (= t3) [ms] |

|

current output |

|

||||

|

|

[ms] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

max. |

FMB50 |

60 |

90 |

210 |

|

|

|

|

|

|

|

max. |

FMB51 |

|

|

|

|

|

FMB52 |

500 |

250 |

- |

|

|

FMB53 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dynamic behavior: HART |

|

|

|

|

|

|

Type |

Dead time (t1) |

Dead time (t1) [ms] + |

Dead time (t1) [ms] + |

|

|

|

||||

|

|

|

[ms] |

Time constant T63 (= t2) [ms] |

Time constant T90 (= t3) [ms] |

|

min. |

FMB50 |

220 |

310 |

370 |

|

|

|

|

|

|

|

max. |

1020 |

1110 |

1170 |

|

|

|

||||

|

|

|

|

|

|

|

min. |

FMB51 |

660 |

910 |

- |

|

|

FMB52 |

|

|

|

|

max. |

1460 |

1710 |

- |

|

|

FMB53 |

||||

|

|

|

|

|

|

Reading cycle

•Acyclic: max. 3/s, typical 1/s (depends on command # and number of preambles)

•Cyclic (Burst): max. 3/s, typical 2/s

The Deltapilot M commands the BURST MODE function for cyclic value transmission via the HART communication protocol.

Cycle time (update time)

Cyclic (Burst): min. 300 ms

Response time

•Acyclic: min. 330 ms, typical 590 ms (depends on command # and number of preambles)

•Cyclic (Burst): min. 160 ms, typical 350 ms (depends on command # and number of preambles)

16 |

Endress+Hauser |

Deltapilot M FMB50/51/52/53

Dynamic behavior: |

|

|

|

|

|

|

Type |

Dead time (t1) |

Dead time (t1) [ms] + |

Dead time (t1) [ms] + |

|

PROFIBUS PA |

|

||||

|

|

[ms] |

Time constant T63 (= t2) [ms] |

Time constant T90 (= t3) [ms] |

|

|

|

|

|||

|

min. |

FMB50 |

95 |

185 |

245 |

|

|

|

|

|

|

|

max. |

1195 |

1285 |

1345 |

|

|

|

||||

|

|

|

|

|

|

|

min. |

FMB51 |

535 |

785 |

- |

|

|

FMB52 |

|

|

|

|

max. |

1635 |

1885 |

- |

|

|

FMB53 |

||||

|

|

|

|

|

|

Reading cycle

•Cyclic: max. 30/s (dependent on the number and type of function blocks used in a closed-control loop)

•Acyclic: typical 25/s

Cycle time (update time)

min. 100 ms

The cycle time in a bus segment in cyclic data communication depends on the number of devices, on the segment coupler used and on the internal PLC cycle time.

Response time

•Cyclic: approx. 8 to 13 ms (depends on Min. Slave Interval)

•Acyclic: approx. 23 to 35 ms (depends on Min. Slave Interval)

Dynamic behavior: |

|

|

|

|

|

|

|

|

|

|

|

Type |

|

Dead time (t1) |

Dead time (t1) [ms] + |

Dead time (t1) [ms] + |

|

||

FOUNDATION Fieldbus |

|

|

|

|

|||||

|

|

|

|

[ms] |

Time constant T63 (= t2) [ms] |

Time constant T90 (= t3) [ms] |

|

||

|

|

|

|

|

|

||||

|

min. |

|

FMB50 |

|

105 |

195 |

255 |

|

|

|

|

|

|

|

|

|

|

|

|

|

max. |

|

|

1105 |

1195 |

1255 |

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

min. |

|

FMB51 |

|

545 |

795 |

- |

|

|

|

|

|

FMB52 |

|

|

|

|

|

|

|

max. |

|

|

1545 |

1795 |

- |

|

|

|

|

|

FMB53 |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

Reading cycle |

|

|

|

|

|

|||

|

• Cyclic: max. 10/s (dependent on the number and type of function blocks used in a closed-control |

|

|||||||

|

loop) |

|

|

|

|

|

|||

|

• Acyclic: typical 5/s |

|

|

|

|

|

|||

|

Cycle time (update time) |

|

|

|

|

||||

|

Cyclic: min. 100 ms |

|

|

|

|

|

|||

|

Response time |

|

|

|

|

|

|||

|

• Cyclic: max. 20 ms (for standard bus parameter settings) |

|

|

|

|||||

|

• Acyclic: typical 70 ms (for standard bus parameter settings) |

|

|

|

|||||

|

|

|

|

|

|

|

|

||

Damping |

A damping affects all outputs (output signal, display). |

|

|

|

|||||

|

• Via on-site display, handheld terminal or PC with operating program, continuous from 0...999 s |

|

|||||||

|

• Via DIP-switch on the electronic insert, switch position |

|

|

|

|||||

|

"on" (= set value) and "off" (= damping switched off) |

|

|

|

|||||

|

• Factory setting: 2 s |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

Firmware version |

|

|

|

|

|

|

|||

Designation |

|

|

|

Option 1) |

|

||||

|

01.00.zz, FF, DevRev01 |

|

|

76 |

|

||||

|

|

|

|

|

|

||||

|

01.00.zz, PROFIBUS PA, DevRev01 |

|

|

77 |

|

||||

|

|

|

|

|

|

||||

|

01.00.zz, HART, DevRev01 |

|

|

78 |

|

||||

|

|

|

|

|

|

||||

|

1) |

Product Configurator, "Firmware version" ordering feature |

|

|

|

||||

Endress+Hauser |

17 |

Deltapilot M FMB50/51/52/53

Galvanic isolation |

The following devices have a galvanic isolation between electronic and probe: |

|

|

• FMB51, FMB52, FMB53 |

|

|

• FMB50 with separate housing |

|

|

|

|

Protocol-specific data |

HART |

|

|

|

|

|

Manufacturer ID |

17 (11 hex) |

|

|

|

|

Device Type Code |

35 (23 hex) |

|

|

|

|

Device Revision |

01 (01 hex) - SW version 01.00.zz |

|

|

|

|

HART specification |

6 |

|

|

|

|

DD Revision |

• 01 (Dutch) |

|

|

• 02 (Russian) |

|

|

|

|

Device description files |

Information and files can be found: |

|

(DTM, DD) |

• www.endress.com |

|

|

• www.hartcomm.org |

|

|

|

|

HART load |

Min. 250 |

|

|

|

|

HART device variables |

The measured values can be freely assigned to the device variables: |

|

|

Measured values for PV (primary variable) |

|

|

• Pressure |

|

|

• Level |

|

|

• Tank content |

|

|

Measured values for SV, TV (second and third variable) |

|

|

• Pressure |

|

|

• Level |

|

|

Measured values for QV (fourth variable) |

|

|

• Temperature |

|

|

|

|

Supported functions |

• Burst mode |

|

|

• Additional Transmitter Status |

|

|

• Device Locking |

|

|

• Alternative operating modes |

|

|

|

PROFIBUS PA

Manufacturer ID |

17 (11 hex) |

|

|

|

|

Ident number |

1554 hex |

|

|

|

|

Profile Version |

3.02 |

|

|

• SW Version 01.00.zz |

|

|

|

|

GSD Revision |

5 |

|

|

|

|

DD Revision |

1 |

|

|

|

|

GSD File |

Information and files can be found: |

|

|

• www.endress.com |

|

DD Files |

||

• www.profibus.org |

||

|

||

|

|

|

Output values |

Measured values for PV (via Analog Input Function Block) |

|

|

• Pressure |

|

|

• Flow |

|

|

• Level |

|

|

• Tank content |

|

|

Measured values for SV |

|

|

• Pressure |

|

|

• Temperature |

|

|

|

18 |

Endress+Hauser |

Deltapilot M FMB50/51/52/53

Input values |

Input value sent from PLC, can be shown on display |

|

|

Supported functions |

• Identification & Maintenance |

|

Simple device identification via control system and nameplate |

|

• Condensed status1) |

|

• Automatic ident number adaptation and switchable to following ident |

|

numbers ): |

|

– 9700: Profile-specific transmitter identification number with the |

|

"Classic" or "Condensed" status". |

|

– 1503: Compatibility mode for the old Deltapilot M (DB50, DB50L, |

|

DB51, DB52, DB53). |

|

– 1555: Identification number for the new Deltapilot M (FMB50, |

|

FMB51, FMB52, FMB53). |

|

• Device locking: The device can be locked by hardware or software. |

|

|

1)Only with Profile Version 3.02

Data of the FOUNDATION Fieldbus interface

Basic data

Device Type |

0x1023 |

|

|

Device Revision |

01 (hex) |

|

|

DD Revision |

0x01021 |

|

|

CFF Revision |

0x000102 |

|

|

ITK Version |

5.2.0 |

|

|

ITK Certification Driver No. |

IT067500 |

|

|

Link-Master (LAS) capable |

Yes |

|

|

Link Master / Basic Device |

Yes; Factory setting: Basic Device |

selectable |

|

|

|

Number of VCRs |

44 |

|

|

Number of Link Objects in VFD |

50 |

|

|

Number of FB-Schedule Objects |

40 |

|

|

Virtual communication references (VCRs)

Permanent Entries |

44 |

|

|

Client VCRs |

0 |

|

|

Server VCRs |

5 |

|

|

Source VCRs |

8 |

|

|

Sink VCRs |

0 |

|

|

Subscriber VCRs |

12 |

|

|

Publisher VCRs |

19 |

|

|

Link settings

Slot time |

4 |

|

|

Min. inter PDU delay |

12 |

|

|

Max. response delay |

40 |

|

|

Endress+Hauser |

19 |

|

|

|

|

|

|

|

Deltapilot M FMB50/51/52/53 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Transducer Blocks |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Block |

|

Content |

|

|

Output values |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TRD1 Block |

|

Contains all parameters related to the measurement |

|

• Pressure or level (channel 1) |

|

|||

|

|

|

|

|

|

• Process temperature (channel 2) |

|

||

|

|

|

|

|

|

• Measured pressure value |

|

||

|

|

|

|

|

|

|

(channel 3) |

|

|

|

|

|

|

|

|

• Max. pressure (channel 4) |

|

||

|

|

|

|

|

|

• |

Level before linearization |

|

|

|

|

|

|

|

|

|

(channel 5) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Diagnostic |

|

Contains diagnostic information |

|

|

• Error code via DI channels |

|

||

|

Block |

|

|

|

|

|

(channel 10 to 15) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Display Block |

|

Contains parameters to configure the onsite display |

|

No output values |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Function blocks |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Block |

Content |

Number |

Execution time |

Functionality |

|

|||

|

|

|

|

of |

|

|

|

|

|

|

|

|

|

blocks |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Resource |

The Resource Block contains all the data that |

1 |

|

|

|

enhanced |

|

|

|

Block |

uniquely identify the device. It is an electronic |

|

|

|

|

|

|

|

|

|

version of a nameplate of the device. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Analog Input |

The AI Block receives the measuring data from |

2 |

|

|

25 ms |

enhanced |

|

|

|

Block 1 |

the Sensor Block, (selectable via a channel |

|

|

|

|

|

|

|

|

Analog Input |

number) and makes the data available to other |

|

|

|

|

|

|

|

|

Block 2 |

function blocks at its output. Enhancement: |

|

|

|

|

|

|

|

|

|

digital outputs for process alarms, fail safe mode. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Digital Input |

This block contains the discrete data of the |

1 |

|

|

20 ms |

Standard |

|

|

|

Block |

Diagnose Block (selectable via a channel number |

|

|

|

|

|

|

|

|

|

10 to 15) and provides them for other blocks at |

|

|

|

|

|

|

|

|

|

the output. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Digital Output |

This block converts the discrete input and thus |

1 |

|

|

20 ms |

Standard |

|

|

|

Block |

initiates an action (selectable via a channel |

|

|

|

|

|

|

|

|

|

number) in the DP Flow Block or in the TRD1 |

|

|

|

|

|

|

|

|

|

Block. Channel 20 resets the counter for max. |

|

|

|

|

|

|

|

|

|

pressure transgressions value and Channel 21 |

|

|

|

|

|

|

|

|

|

resets the Totalizer. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PID Block |

The PID Block serves as a proportional-integral- |

1 |

|

|

40 ms |

Standard |

|

|

|

|

derivative controller and is used almost |

|

|

|

|

|

|

|

|

|

universally for closed-loop-control in the field |

|

|

|

|

|

|

|

|

|

including cascade and feedforward. Input IN can |

|

|

|

|

|

|

|

|

|

be indicated on the display. The selection is |

|

|

|

|

|

|

|

|

|

performed in the Display Block |

|

|

|

|

|

|

|

|

|

(DISPLAY_MAIN_LINE_CONTENT). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Arithmetic |

This block is designed to permit simple use of |

1 |

|

|

35 ms |

Standard |

|

|

|

Block |

popular measurement math functions. The user |

|

|

|

|

|

|

|

|

|

does not have to know how to write equations. |

|

|

|

|

|

|

|

|

|

The math algorithm is selected by name, chosen |

|

|

|

|

|

|

|

|

|

by the user for the function to be performed. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Input Selector |

The Input Selector Block facilitates the selection |

1 |

|

|

30 ms |

Standard |

|

|

|

Block |

of up to four inputs and generates an output |

|

|

|

|

|

|

|

|

|

based on the configured action. This block |

|

|

|

|

|

|

|

|

|

normally receives its inputs from AI Blocks. The |

|

|

|

|

|

|

|

|

|

block performs maximum, minimum, average |

|

|

|

|

|

|

|

|

|

and ‘first good’ signal selection. Inputs IN1 to IN4 |

|

|

|

|

|

|

|

|

|

can be indicated on the display. The selection is |

|

|

|

|

|

|

|

|

|

performed in the Display Block |

|

|

|

|

|

|

|

|

|

(DISPLAY_MAIN_LINE_1_CONTENT). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

Endress+Hauser |

Deltapilot M FMB50/51/52/53

Block |

Content |

Number |

Execution time |

Functionality |

|

|

of |

|

|

|

|

blocks |

|

|

|

|

|

|

|

Signal |

The Signal Characterizer Block has two sections, |

1 |

40 ms |

Standard |

Characterizer |

each with an output that is a non-linear function |

|

|

|

Block |

of the respective input. The non-linear function is |

|

|

|

|

generated by a single look-up table with |

|

|

|

|

21 arbitrary x-y pairs. |

|

|

|

|

|

|

|

|

Integrator |

The Integrator Block integrates a variable as a |

1 |

35 ms |

Standard |

Block |

function of the time or accumulates the counts |

|

|

|

|

from a Pulse Input Block. The block may be used |

|

|

|

|

as a totalizer that counts up until reset or as a |

|

|

|

|

batch totalizer that has a setpoint, where the |

|

|

|

|

integrated or accumulated value is compared to |

|

|

|

|

pre-trip and trip settings, generating a binary |

|

|

|

|

signal when the setpoint is reached. |

|

|

|

|

|

|

|

|

Additional function block information: |

|

|

|

|

|

|

|

|

|

Instantiate Function Block |

|

|

YES |

|

|

|

|

|

|

Number of instantiate blocks |

|

|

20 |

|

|

|

|

|

|

Endress+Hauser |

21 |

Deltapilot M FMB50/51/52/53

Power supply

! WARNING

Incorrect connection can limit electrical safety!

When using the measuring device in hazardous areas, installation must comply with the corresponding national standards and regulations and the Safety Instructions or Installation or Control Drawings ä 71 ff, "Safety instructions" and "Installation/Control Drawings" ordering features.

All explosion protection data are given in separate documentation which is available upon request. The Ex documentation is provided with all Ex-systems as standard ä 71 ff, "Safety instructions" and "Installation/Control Drawings" ordering features.

According to IEC/EN61010 a suitable disconnector has to be installed for the device

HART: Overvoltage protection HAW569-DA2B for the non-hazardous area, ATEX II 2 (1) Ex ia IIC and IEC Ex ia can be ordered as an option (see "Ordering information" ordering feature).

Protective circuits against reverse polarity, HF influences and overvoltage peaks are installed.

The digital communication signal is transmitted to the bus via a 2-wire connection. The bus also provides the power supply.

Terminal assignment

1

7 |

|

|

6 |

- |

+ |

|

||

|

|

2 |

5 |

|

|

4 |

|

|

|

|

3 |

A0023505

Electrical connection

1External grounding terminal

2Internal grounding terminal

3Supply voltage ä 22

44...20 mA for HART devices

5For HART and FOUNDATION Fieldbus devices: With a handheld terminal, all the parameters can be configured anywhere along the bus line via menu operation.

6Terminals

7For HART devices: test terminals, see section "Taking 4 to 20 mA test signal"

Supply voltage |

4 to 20 mA HART |

Type of protection |

Supply voltage |

|

|

|

|

• |

Intrinsically safe |

11.5 ... 30 V DC |

|

|

|

• Other types of protection |

11.5 to 45 V DC (versions with plug-in connection 35 V DC) |

|

• |

Devices without certificate |

|

|

|

|

Taking 4 to 20 mA test signal

A 4 to 20 mA test signal may be measured via the test terminals without interrupting the measurement.

22 |

Endress+Hauser |

Deltapilot M FMB50/51/52/53

PROFIBUS PA

• Version for non-hazardous areas: 9 to 32 V DC

FOUNDATION Fieldbus

• Version for non-hazardous areas: 9 to 32 V DC

Current consumption |