Endress+Hauser I 300 Specifications

TI01274D/06/EN/06.19

71451431

2019-09-16

Products |

Solutions |

Services |

|

|

|

Technical Information

Proline Promass I 300

Coriolis flowmeter

Combines in line viscosity and flow measurement with a compact, easily accessible transmitter

Application

•Measuring principle operates independently of physical fluid properties such as viscosity or density

•Measuring liquids and gases in applications requiring low pressure loss and gentle fluid treatment

Device properties

•Straight, easy-to-clean single-tube system

•TMB technology

•Measuring tube made of Titanium

•Compact dual-compartment housing with up to 3 I/Os

•Backlit display with touch control and WLAN access

•Remote display available

Your benefits

•Energy-saving – full bore design enables minimal pressure loss

•Fewer process measuring points – multivariable measurement (flow, density, temperature)

•Space saving installation – no inlet/outlet run needs

•Full access to process and diagnostic information – numerous, freely combinable I/Os and fieldbuses

•Reduced complexity and variety – freely configurable I/O functionality

•Integrated verification – Heartbeat Technology

Proline Promass I 300

Table of contents

About this document . . . . . . . . . . . . . . . . . . . . . . . . 4

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Function and system design . . . . . . . . . . . . . . . . . . . 5

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Equipment architecture . . . . . . . . . . . . . . . . . . . . . . . . . 7 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Operable flow range . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Input signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Output and input variants . . . . . . . . . . . . . . . . . . . . . . . 13 Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 Ex connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 Low flow cut off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 Galvanic isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 Protocol-specific data . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

30 |

Terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . |

30 |

Device plugs available . . . . . . . . . . . . . . . . . . . . . . . . . . |

30 |

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

Current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

Power supply failure . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

Potential equalization . . . . . . . . . . . . . . . . . . . . . . . . . |

42 |

terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

42 |

Cable entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

42 |

Pin assignment, device plug . . . . . . . . . . . . . . . . . . . . . . |

42 |

Cable specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

43 |

Performance characteristics . . . . . . . . . . . . . . . . . . 46

Reference operating conditions . . . . . . . . . . . . . . . . . . . 46 Maximum measured error . . . . . . . . . . . . . . . . . . . . . . . 46 Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 Response time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 Influence of ambient temperature . . . . . . . . . . . . . . . . . 48 Influence of medium temperature . . . . . . . . . . . . . . . . . . 48 Influence of medium pressure . . . . . . . . . . . . . . . . . . . . 49 Design fundamentals . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Mounting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 Inlet and outlet runs . . . . . . . . . . . . . . . . . . . . . . . . . . 52 Special mounting instructions . . . . . . . . . . . . . . . . . . . . 52

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . 54 Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Climate class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

54 |

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . |

54 |

Vibrationand shock-resistance . . . . . . . . . . . . . . . . . . . |

54 |

Interior cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

55 |

Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . |

55 |

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Medium temperature range . . . . . . . . . . . . . . . . . . . . . . 55 Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56 Pressure-temperature ratings . . . . . . . . . . . . . . . . . . . . 56 Sensor housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 Flow limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 Pressure loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 System pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 Thermal insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . 61 Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61 Vibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Mechanical construction . . . . . . . . . . . . . . . . . . . . 62

Dimensions in SI units . . . . . . . . . . . . . . . . . . . . . . . . . 62 Dimensions in US units . . . . . . . . . . . . . . . . . . . . . . . . . 75 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83 Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84 Process connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 86 Surface roughness . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Human interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Operating concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87 Languages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87 Local operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87 Remote operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88 Service interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94 Network integration . . . . . . . . . . . . . . . . . . . . . . . . . . 95 Supported operating tools . . . . . . . . . . . . . . . . . . . . . . . 96 HistoROM data management . . . . . . . . . . . . . . . . . . . . . 97

Certificates and approvals . . . . . . . . . . . . . . . . . . . 99

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99 RCM-tick symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99 Ex approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99 Sanitary compatibility . . . . . . . . . . . . . . . . . . . . . . . . . 100 Pharmaceutical compatibility . . . . . . . . . . . . . . . . . . . . 100 Functional safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 HART certification . . . . . . . . . . . . . . . . . . . . . . . . . . . 101 FOUNDATION Fieldbus certification . . . . . . . . . . . . . . . 101 Certification PROFIBUS . . . . . . . . . . . . . . . . . . . . . . . . 101 EtherNet/IP certification . . . . . . . . . . . . . . . . . . . . . . . 101 Certification PROFINET . . . . . . . . . . . . . . . . . . . . . . . . 101 Pressure Equipment Directive . . . . . . . . . . . . . . . . . . . 101 Radio approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102 Additional certification . . . . . . . . . . . . . . . . . . . . . . . . 102 Other standards and guidelines . . . . . . . . . . . . . . . . . . 102

Ordering information . . . . . . . . . . . . . . . . . . . . . . 102

Application packages . . . . . . . . . . . . . . . . . . . . . . 103

Diagnostics functions . . . . . . . . . . . . . . . . . . . . . . . . . 103

2 |

Endress+Hauser |

Proline Promass I 300

Heartbeat Technology . . . . . . . . . . . . . . . . . . . . . . . . 103 Concentration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104 Viscosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104 Special density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104 OPC-UA server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Device-specific accessories . . . . . . . . . . . . . . . . . . . . . . 105 Communication-specific accessories . . . . . . . . . . . . . . . 106 Service-specific accessories . . . . . . . . . . . . . . . . . . . . . 107 System components . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Supplementary documentation . . . . . . . . . . . . . . 108

Standard documentation . . . . . . . . . . . . . . . . . . . . . . . 108 Device-dependent additional documentation . . . . . . . . . 108

Registered trademarks . . . . . . . . . . . . . . . . . . . . . 109

Endress+Hauser |

3 |

Proline Promass I 300

About this document

Symbols |

Electrical symbols |

|

||

|

|

|

|

|

|

Symbol |

Meaning |

||

|

|

|

|

|

|

|

|

|

Direct current |

|

|

|

|

|

|

|

|

|

Alternating current |

|

|

|

|

|

|

|

|

|

Direct current and alternating current |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ground connection |

|

|

|

|

A grounded terminal which, as far as the operator is concerned, is grounded via a |

|

|

|

|

grounding system. |

|

|

|

|

|

|

|

|

|

Protective Earth (PE) |

|

|

|

|

A terminal which must be connected to ground prior to establishing any other |

|

|

|

|

connections. |

|

|

|

|

The ground terminals are situated inside and outside the device: |

|

|

|

|

• Inner ground terminal: Connects the protectiv earth to the mains supply. |

|

|

|

|

• Outer ground terminal: Connects the device to the plant grounding system. |

|

|

|

|

|

Communication symbols

Symbol Meaning

Wireless Local Area Network (WLAN)

Communication via a wireless, local network.

LED

Light emitting diode is off.

LED

Light emitting diode is on.

LED

Light emitting diode is flashing.

Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation.

A |

Reference to page. |

Reference to graphic.

Visual inspection.

4 |

Endress+Hauser |

Proline Promass I 300

Symbols in graphics

|

Symbol |

Meaning |

|||||

|

|

|

|

|

|

|

|

1, 2, 3, ... |

Item numbers |

||||||

|

|

|

|

|

|

|

|

|

|

, |

|

, |

|

, … |

Series of steps |

|

1. |

2. |

3. |

||||

|

|

|

|||||

|

A, B, C, ... |

Views |

|||||

|

|

||||||

A-A, B-B, C-C, ... |

Sections |

||||||

-Hazardous area

. |

Safe area (non-hazardous area) |

|

|

|

|

|

Flow direction |

Function and system design

Measuring principle |

The measuring principle is based on the controlled generation of Coriolis forces. These forces are |

|

|

always present in a system when both translational and rotational movements are superimposed. |

|

|

Fc = |

2 · ∆m (ν · ω) |

|

Fc = |

Coriolis force |

|

∆m = |

moving mass |

|

ω = |

rotational velocity |

|

ν = |

radial velocity in rotating or oscillating system |

The amplitude of the Coriolis force depends on the moving mass ∆m, its velocity ν in the system and thus on the mass flow. Instead of a constant rotational velocity ω, the sensor uses oscillation.

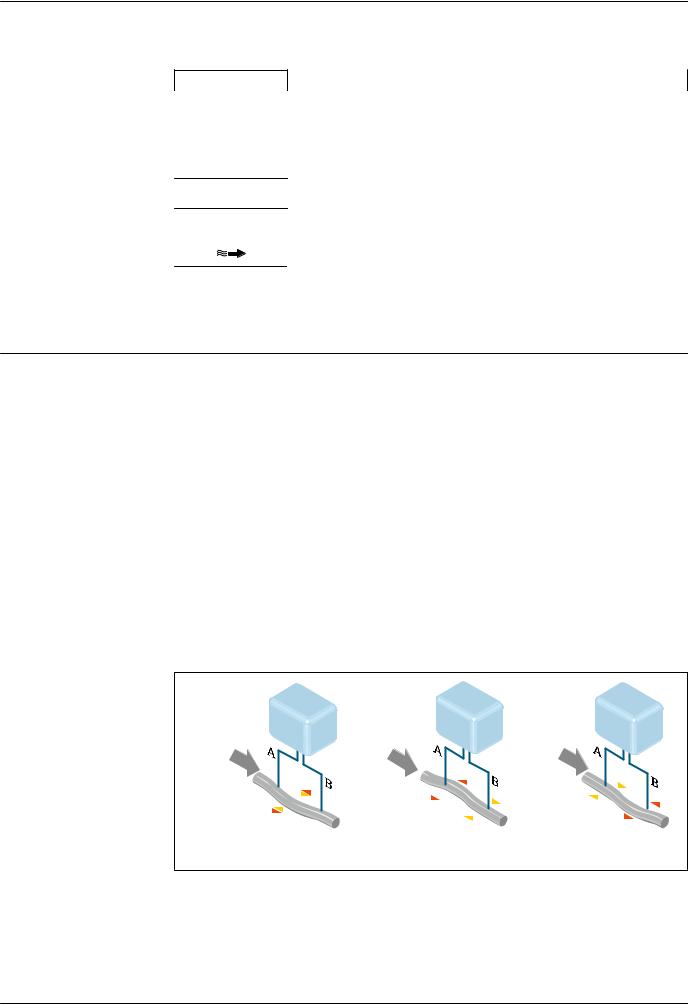

In the sensor, an oscillation is produced in the measuring tube. The Coriolis forces produced at the measuring tube cause a phase shift in the tube oscillations (see illustration):

•If there is zero flow (i.e. when the fluid stands still), the oscillation measured at points A and B has the same phase (no phase difference) (1).

•Mass flow causes deceleration of the oscillation at the inlet of the tubes (2) and acceleration at the outlet (3).

|

|

|

|

|

|

1 |

|

2 |

3 |

||

A0029932

The phase difference (A-B) increases with increasing mass flow. Electrodynamic sensors register the tube oscillations at the inlet and outlet. System balance is created by exciting an eccentrically arranged swinging mass to antiphase oscillation. The measuring principle operates independently of temperature, pressure, viscosity, conductivity and flow profile.

Endress+Hauser |

5 |

Proline Promass I 300

Density measurement

The measuring tube is continuously excited at its resonance frequency. A change in the mass and thus the density of the oscillating system (comprising measuring tube and fluid) results in a corresponding, automatic adjustment in the oscillation frequency. Resonance frequency is thus a function of medium density. The microprocessor utilizes this relationship to obtain a density signal.

Volume measurement

Together with the measured mass flow, this is used to calculate the volume flow.

Temperature measurement

The temperature of the measuring tube is determined in order to calculate the compensation factor due to temperature effects. This signal corresponds to the process temperature and is also available as an output signal.

Measuring system |

The device consists of a transmitter and a sensor. |

||

|

The device is available as a compact version: |

||

|

The transmitter and sensor form a mechanical unit. |

||

|

Transmitter |

|

|

|

Promass 300 |

Device versions and materials: |

|

|

|

• Transmitter housing |

|

|

|

• Aluminum, coated: aluminum, AlSi10Mg, coated |

|

|

|

• |

Stainless, hygienic: stainless steel, 1.4404 |

|

|

• |

Cast, stainless: cast, stainless steel, 1.4409 (CF3M) similar to 316L |

|

|

• Material of window in transmitter housing: |

|

|

|

• Aluminum, coated: glass |

|

|

A0026708 |

• |

Stainless, hygienic: polycarbonate |

|

• |

Cast, stainless: glass |

|

|

|

||

|

|

Configuration: |

|

|

|

• External operation via 4-line, backlit, graphic local display with touch |

|

|

|

control and guided menus ("Make-it-run" wizards) for application- |

|

|

|

specific commissioning. |

|

|

|

• Via service interface or WLAN interface: |

|

|

|

• |

Operating tools (e.g. FieldCare, DeviceCare) |

|

|

• Web server (access via Web browser, e.g. Microsoft Internet |

|

|

|

|

Explorer, Microsoft Edge) |

|

Sensor |

|

|

|

Promass I |

• Sensitive fluid handling thanks to straight single-tube system |

|

|

|

• Simultaneous measurement of viscosity, flow, volume flow, density and |

|

|

|

temperature (multivariable) |

|

|

|

• Immune to process influences |

|

|

|

• Nominal diameter range: DN 8 to 80 (³⁄ to 3") |

|

|

A0026709 |

• Materials: |

|

|

|

• Sensor: stainless steel, 1.4301/1.4307 (304L) |

|

|

|

• Measuring tubes: titanium Grade 9 |

|

|

|

• |

Process connections: stainless steel, 1.4301 (304), wetted parts: |

|

|

|

titanium Grade 2 |

6 |

Endress+Hauser |

Proline Promass I 300 |

|

Equipment architecture |

|

1 |

|

5 |

|

2 |

3 |

|

|

|

4 |

6 |

|

|

3 |

7 |

|

|

A0027512 |

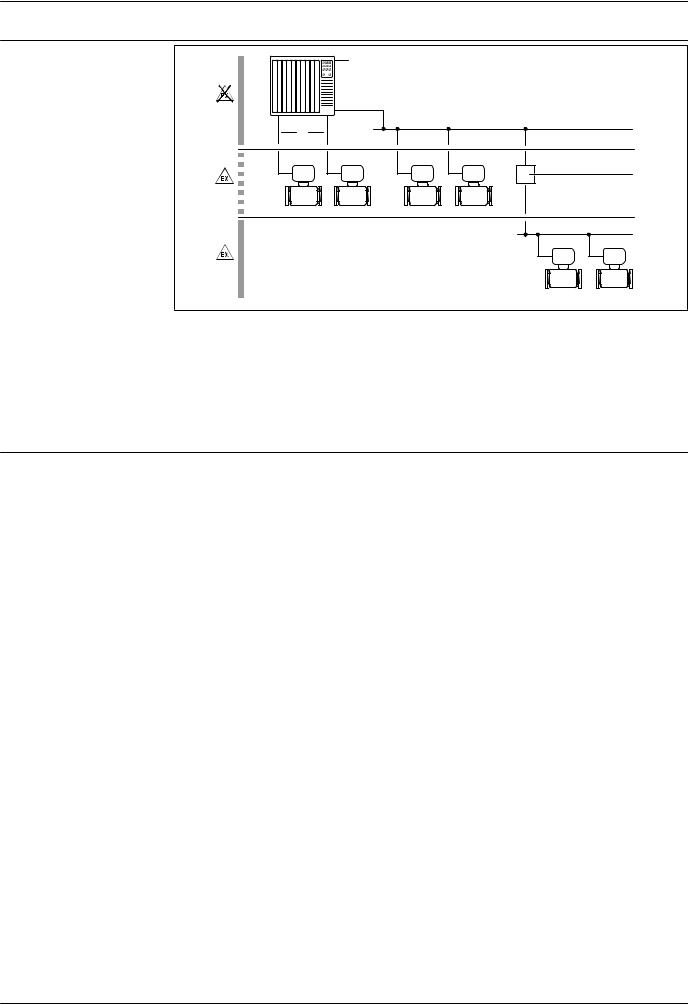

1 Possibilities for integrating measuring devices into a system |

|

1Control system (e.g. PLC)

2Connecting cable (0/4 to 20 mA HART etc.)

3Fieldbus

4Coupler

5Non-hazardous area

6 Hazardous area: Zone 2; Class I, Division 2

7Hazardous area: Zone 1; Class I, Division 1

Safety |

IT security |

Our warranty is valid only if the device is installed and used as described in the Operating Instructions. The device is equipped with security mechanisms to protect it against any inadvertent changes to the settings.

IT security measures, which provide additional protection for the device and associated data transfer, must be implemented by the operators themselves in line with their security standards.

Device-specific IT security

The device offers a range of specific functions to support protective measures on the operator's side. These functions can be configured by the user and guarantee greater in-operation safety if used correctly. An overview of the most important functions is provided in the following section.

Function/interface |

Factory setting |

Recommendation |

|

|

|

Write protection via hardware write |

Not enabled. |

On an individual basis following risk |

protection switch → 8 |

|

assessment. |

|

|

|

Access code |

Not enabled |

Assign a customized access code during |

(also applies for Web server login or |

(0000). |

commissioning. |

FieldCare connection) → 8 |

|

|

|

|

|

WLAN |

Enabled. |

On an individual basis following risk |

(order option in display module) |

|

assessment. |

|

|

|

WLAN security mode |

Enabled (WPA2- |

Do not change. |

|

PSK) |

|

|

|

|

WLAN passphrase |

Serial number |

Assign an individual WLAN passphrase during |

(password) → 8 |

|

commissioning. |

|

|

|

WLAN mode |

Access Point |

On an individual basis following risk |

|

|

assessment. |

|

|

|

Web server→ 8 |

Enabled. |

On an individual basis following risk |

|

|

assessment. |

|

|

|

CDI-RJ45 service interface → 9 |

– |

On an individual basis following risk |

|

|

assessment. |

|

|

|

Endress+Hauser |

7 |

Proline Promass I 300

Protecting access via hardware write protection

Write access to the device parameters via the local display, Web browser or operating tool (e.g. FieldCare, DeviceCare) can be disabled via a write protection switch (DIP switch on the motherboard). When hardware write protection is enabled, only read access to the parameters is possible.

Hardware write protection is disabled when the device is delivered.

Protecting access via a password

Different passwords are available to protect write access to the device parameters or access to the device via the WLAN interface.

•User-specific access code

Protect write access to the device parameters via the local display, Web browser or operating tool (e.g. FieldCare, DeviceCare). Access authorization is clearly regulated through the use of a userspecific access code.

•WLAN passphrase

The network key protects a connection between an operating unit (e.g. notebook or tablet) and the device via the WLAN interface which can be ordered as an option.

•Infrastructure mode

When the device is operated in infrastructure mode, the WLAN passphrase corresponds to the WLAN passphrase configured on the operator side.

User-specific access code

Write access to the device parameters via the local display, Web browser or operating tool (e.g. FieldCare, DeviceCare) can be protected by the modifiable, user-specific access code.

WLAN passphrase: Operation as WLAN access point

A connection between an operating unit (e.g. notebook or tablet) and the device via the WLAN interface, which can be ordered as an optional extra, is protected by the network key. The WLAN authentication of the network key complies with the IEEE 802.11 standard.

When the device is delivered, the network key is pre-defined depending on the device. It can be changed via the WLAN settings submenu in the WLAN passphrase parameter.

Infrastructure mode

A connection between the device and WLAN access point is protected by means of an SSID and passphrase on the system side. Please contact the relevant system administrator for access.

General notes on the use of passwords

•The access code and network key supplied with the device should be changed during commissioning.

•Follow the general rules for generating a secure password when defining and managing the access code or network key.

•The user is responsible for the management and careful handling of the access code and network key.

Access via Web server

The device can be operated and configured via a Web browser with the integrated Web server. The connection is via the service interface (CDI-RJ45) or the WLAN interface. For device versions with the EtherNet/IP and PROFINET communication protocols, the connection can also be established via the terminal connection for signal transmission with EtherNet/IP or PROFINET (RJ45 connector).

The Web server is enabled when the device is delivered. The Web server can be disabled if necessary (e.g. after commissioning) via the Web server functionality parameter.

The device and status information can be hidden on the login page. This prevents unauthorized access to the information.

For detailed information on device parameters, see:

The "Description of Device Parameters" document → 108

Access via OPC-UA

The "OPC UA Server" application package is available in the device version with the HART communication protocol → 104.

8 |

Endress+Hauser |

Proline Promass I 300

The device can communicate with OPC UA clients using the "OPC UA Server" application package.

The OPC UA server integrated in the device can be accessed via the WLAN access point using the WLAN interface - which can be ordered as an optional extra - or the service interface (CDIRJ45) via Ethernet network. Access rights and authorization as per separate configuration.

The following Security Modes are supported as per the OPC UA Specification (IEC 62541):

•None

•Basic128Rsa15 – signed

•Basic128Rsa15 – signed and encrypted

Access via service interface (CDI-RJ45)

The device can be connected to a network via the service interface (CDI-RJ45). Device-specific functions guarantee the secure operation of the device in a network.

The use of relevant industrial standards and guidelines that have been defined by national and international safety committees, such as IEC/ISA62443 or the IEEE, is recommended. This includes organizational security measures such as the assignment of access authorization as well as technical measures such as network segmentation.

Transmitters with an Ex de approval may not be connected via the service interface (CDI-RJ45)!

Order code for "Approval transmitter + sensor", options (Ex de): BA, BB, C1, C2, GA, GB, MA, MB, NA, NB

The device can be integrated in a ring topology. The device is integrated via the terminal connection for signal transmission (output 1) and the connection to the service interface (CDIRJ45) .

Endress+Hauser |

9 |

Proline Promass I 300

|

Input |

|

|

|

|

|

|

|

|

|

|

Measured variable |

Direct measured variables |

|

|

|

|

|

• Mass flow |

|

|

|

|

|

• Density |

|

|

|

|

|

• Temperature |

|

|

|

|

|

• Viscosity |

|

|

|

|

|

Calculated measured variables |

|

|

|

|

|

• Volume flow |

|

|

|

|

|

• Corrected volume flow |

|

|

|

|

|

• Reference density |

|

|

|

|

|

|

|

|

|

|

Measuring range |

Measuring range for liquids |

|

|

|

|

|

|

|

|

|

|

|

DN |

|

Measuring range full scale values min(F) to max(F) |

||

|

[mm] |

|

[in] |

[kg/h] |

[lb/min] |

|

|

|

|

|

|

|

8 |

|

³⁄ |

0 to 2 000 |

0 to 73.50 |

|

|

|

|

|

|

|

15 |

|

½ |

0 to 6 500 |

0 to 238.9 |

|

|

|

|

|

|

|

15 FB |

|

½ FB |

0 to 18 000 |

0 to 661.5 |

|

|

|

|

|

|

|

25 |

|

1 |

0 to 18 000 |

0 to 661.5 |

|

|

|

|

|

|

|

25 FB |

|

1 FB |

0 to 45 000 |

0 to 1 654 |

|

|

|

|

|

|

|

40 |

|

1½ |

0 to 45 000 |

0 to 1 654 |

|

|

|

|

|

|

|

40 FB |

|

1½ FB |

0 to 70 000 |

0 to 2 573 |

|

|

|

|

|

|

|

50 |

|

2 |

0 to 70 000 |

0 to 2 573 |

|

|

|

|

|

|

|

50 FB |

|

2 FB |

0 to 180 000 |

0 to 6 615 |

|

|

|

|

|

|

|

80 |

|

3 |

0 to 180 000 |

0 to 6 615 |

|

|

|

|

|

|

|

FB = Full bore |

|

|

|

|

|

|

|

|

|

|

Measuring range for gases

The full scale value depends on the density and the sound velocity of the gas used and can be calculated with the formula below:

max(G) = minimum ( max(F) · ρG : x ; ρG · cG · π/2 · (di)2 · 3600)

|

max(G) |

Maximum full scale value for gas [kg/h] |

|

||

|

max(F) |

Maximum full scale value for liquid [kg/h] |

|

||

|

max(G) < max(F) |

max(G) can never be greater than max(F) |

|

||

|

ρG |

Gas density in [kg/m³] at operating conditions |

|

||

|

x |

Constant dependent on nominal diameter |

|

||

|

|

|

|

|

|

|

cG |

Sound velocity (gas) [m/s] |

|

||

|

|

|

|

|

|

|

di |

Measuring tube internal diameter [m] |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

DN |

|

|

x |

|

|

|

|

|

|

|

|

[mm] |

|

[in] |

|

[kg/m3] |

|

8 |

|

³⁄ |

|

60 |

|

|

|

|

|

|

|

15 |

|

½ |

|

80 |

|

|

|

|

|

|

|

15 FB |

|

½ FB |

|

90 |

|

|

|

|

|

|

|

25 |

|

1 |

|

90 |

|

|

|

|

|

|

|

|

|

|

|

|

10 |

Endress+Hauser |

Proline Promass I 300

|

DN |

x |

|

[mm] |

|

[in] |

[kg/m3] |

|

|||

25 FB |

|

1 FB |

90 |

|

|

|

|

40 |

|

1½ |

90 |

|

|

|

|

40 FB |

|

1½ FB |

90 |

|

|

|

|

50 |

|

2 |

90 |

|

|

|

|

50 FB |

|

2 FB |

110 |

|

|

|

|

80 |

|

3 |

110 |

|

|

|

|

FB = Full bore

To calculate the measuring range, use the Applicator sizing tool → 107

To calculate the measuring range, use the Applicator sizing tool → 107

Calculation example for gas

•Sensor: Promass I, DN 50

•Gas: Air with a density of 60.3 kg/m³ (at 20 °C and 50 bar)

•Measuring range (liquid): 70 000 kg/h

•x = 90 kg/m³ (for Promass I, DN 50)

Maximum possible full scale value:

max(G) = max(F) · ρG : x = 70 000 kg/h · 60.3 kg/m³ : 90 kg/m³ = 46 900 kg/h

|

Recommended measuring range |

|

Flow limit → 60 |

|

|

Operable flow range |

Over 1000 : 1. |

|

Flow rates above the preset full scale value do not override the electronics unit, with the result that |

|

the totalizer values are registered correctly. |

|

|

Input signal |

Input and output versions |

|

→ 13 |

|

External measured values |

|

To increase the accuracy of certain measured variables or to calculate the corrected volume flow for |

|

gases, the automation system can continuously write different measured values to the measuring |

|

device: |

|

• Operating pressure to increase accuracy (Endress+Hauser recommends the use of a pressure |

|

measuring device for absolute pressure, e.g. Cerabar M or Cerabar S) |

|

• Medium temperature to increase accuracy (e.g. iTEMP) |

|

• Reference density for calculating the corrected volume flow for gases |

|

Various pressure transmitters and temperature measuring devices can be ordered from Endress |

|

+Hauser: see "Accessories" section → 107 |

|

It is recommended to read in external measured values to calculate the corrected volume flow. |

|

HART protocol |

|

The measured values are written from the automation system to the measuring device via the HART |

|

protocol. The pressure transmitter must support the following protocol-specific functions: |

|

• HART protocol |

|

• Burst mode |

|

Current input |

|

The measured values are written from the automation system to the measuring device via the |

|

current input → 12. |

Endress+Hauser |

11 |

Proline Promass I 300

Digital communication

The measured values can be written from the automation system to the measuring via:

• FOUNDATION Fieldbus

• PROFIBUS DP

• PROFIBUS PA

• Modbus RS485

• EtherNet/IP

• PROFINET

Current input 0/4 to 20 mA

Current input |

0/4 to 20 mA (active/passive) |

|

|

|

|

Current span |

• 4 to 20 mA (active) |

|

|

• 0/4 to 20 mA (passive) |

|

|

|

|

Resolution |

1 |

µA |

|

|

|

Voltage drop |

Typically: 0.6 to 2 V for 3.6 to 22 mA (passive) |

|

|

|

|

Maximum input voltage |

≤ 30 V (passive) |

|

|

|

|

Open-circuit voltage |

≤ 28.8 V (active) |

|

|

|

|

Possible input variables |

• Pressure |

|

|

• Temperature |

|

|

• Density |

|

|

• |

|

|

|

|

Status input

Maximum input values |

• DC –3 to 30 V |

|

|

• If status input is active (ON): Ri >3 kΩ |

|

Response time |

Configurable: 5 to 200 ms |

|

|

|

|

Input signal level |

• Low signal: DC –3 to +5 V |

|

|

• High signal: DC 12 to 30 V |

|

|

|

|

Assignable functions |

• Off |

|

|

• |

Reset the individual totalizers separately |

|

• |

Reset all totalizers |

|

• Flow override |

|

|

|

|

12 |

Endress+Hauser |

Proline Promass I 300

Output

Output and input variants Depending on the option selected for output/input 1, different options are available for the other outputs and inputs. Only one option can be selected for each output/input 1 to 3. The following tables must be read vertically (↓).

Example: If the option BA "4–20 mA HART" was selected for output/input 1, one of the options A, B, D, E, F, H, I or J is available for output 2 and one of the options A, B, D, E, F, H, I or J is available for output 3.

Output/input 1 and options for output/input 2

Options for output/input 3

Options for output/input 3

Order code for "Output; input 1" (020) → |

|

|

|

|

Possible options |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Current output 4 to 20 mA HART |

BA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Current output 4 to 20 mA HART Ex i passive |

↓ |

CA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Current output 4 to 20 mA HART Ex i active |

|

↓ |

CC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FOUNDATION Fieldbus |

|

|

↓ |

SA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FOUNDATION Fieldbus Ex i |

|

|

|

↓ |

TA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PROFIBUS DP |

|

|

|

|

↓ |

LA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PROFIBUS PA |

|

|

|

|

|

↓ |

GA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PROFIBUS PA Ex i |

|

|

|

|

|

|

↓ |

HA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Modbus RS485 |

|

|

|

|

|

|

|

↓ |

MA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EtherNet/IP 2-port switch integrated |

|

|

|

|

|

|

|

|

↓ |

NA |

|

|

|

|

|

|

|

|

|

|

|

|

|

PROFINET 2-port switch integrated |

|

|

|

|

|

|

|

|

|

↓ |

RA |

|

|

|

|

|

|

|

|

|

|

|

|

Order code for "Output; input 2" (021) → |

↓ |

↓ |

↓ |

↓ |

↓ |

↓ |

↓ |

↓ |

↓ |

↓ |

↓ |

|

|

|

|

|

|

|

|

|

|

|

|

Not assigned |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

|

|

|

|

|

|

|

|

|

|

|

|

Current output 4 to 20 mA |

B |

|

|

B |

|

B |

B |

|

B |

B |

B |

|

|

|

|

|

|

|

|

|

|

|

|

Current output 4 to 20 mA Ex i passive |

|

C |

C |

|

C |

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

User-configurable input/output 1) |

D |

|

|

D |

|

D |

D |

|

D |

D |

D |

Pulse/frequency/switch output |

E |

|

|

E |

|

E |

E |

|

E |

E |

E |

|

|

|

|

|

|

|

|

|

|

|

|

Double pulse output 2) |

F |

|

|

|

|

|

|

|

F |

|

|

Pulse/frequency/switch output Ex i passive |

|

G |

G |

|

G |

|

|

G |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Relay output |

H |

|

|

H |

|

H |

H |

|

H |

H |

H |

|

|

|

|

|

|

|

|

|

|

|

|

Current input 0/4 to 20 mA |

I |

|

|

I |

|

I |

I |

|

I |

I |

I |

|

|

|

|

|

|

|

|

|

|

|

|

Status input |

J |

|

|

J |

|

J |

J |

|

J |

J |

J |

|

|

|

|

|

|

|

|

|

|

|

|

1)A specific input or output can be assigned to a user-configurable input/output → 20.

2)If double pulse output (F) is selected for output/input 2 (021), only the double pulse output (F) option is available for selection for output/input 3 (022).

Endress+Hauser |

13 |

Proline Promass I 300

Output/input 1 and options for output/input 3

Options for output/input 2 → 13

Options for output/input 2 → 13

Order code for "Output; input 1" (020) → |

|

|

|

|

Possible options |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Current output 4 to 20 mA HART |

BA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Current output 4 to 20 mA HART Ex i passive |

↓ |

CA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Current output 4 to 20 mA HART Ex i active |

|

↓ |

CC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FOUNDATION Fieldbus |

|

|

↓ |

SA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FOUNDATION Fieldbus Ex i |

|

|

|

↓ |

TA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PROFIBUS DP |

|

|

|

|

↓ |

LA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PROFIBUS PA |

|

|

|

|

|

↓ |

GA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PROFIBUS PA Ex i |

|

|

|

|

|

|

↓ |

HA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Modbus RS485 |

|

|

|

|

|

|

|

↓ |

MA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EtherNet/IP 2-port switch integrated |

|

|

|

|

|

|

|

|

↓ |

NA |

|

|

|

|

|

|

|

|

|

|

|

|

|

PROFINET 2-port switch integrated |

|

|

|

|

|

|

|

|

|

↓ |

RA |

|

|

|

|

|

|

|

|

|

|

|

|

Order code for "Output; input 3" (022) → |

↓ |

↓ |

↓ |

↓ |

↓ |

↓ |

↓ |

↓ |

↓ |

↓ |

↓ |

|

|

|

|

|

|

|

|

|

|

|

|

Not assigned |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

A |

|

|

|

|

|

|

|

|

|

|

|

|

Current output 4 to 20 mA |

B |

|

|

|

|

B |

|

|

B |

B |

B |

|

|

|

|

|

|

|

|

|

|

|

|

Current output 4 to 20 mA Ex i passive |

|

C |

C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

User-configurable input/output |

D |

|

|

|

|

D |

|

|

D |

D |

D |

|

|

|

|

|

|

|

|

|

|

|

|

Pulse/frequency/switch output |

E |

|

|

|

|

E |

|

|

E |

E |

E |

|

|

|

|

|

|

|

|

|

|

|

|

Double pulse output (slave) 1) |

F |

|

|

|

|

|

|

|

F |

|

|

Pulse/frequency/switch output Ex i passive |

|

G |

G |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Relay output |

H |

|

|

|

|

H |

|

|

H |

H |

H |

|

|

|

|

|

|

|

|

|

|

|

|

Current input 0/4 to 20 mA |

I |

|

|

|

|

I |

|

|

I |

I |

I |

|

|

|

|

|

|

|

|

|

|

|

|

Status input |

J |

|

|

|

|

J |

|

|

J |

J |

J |

|

|

|

|

|

|

|

|

|

|

|

|

1)If double pulse output (F) is selected for output/input 2 (021), only the double pulse output (F) option is available for output/input 3 (022).

14 |

Endress+Hauser |

Proline Promass I 300

Output signal |

Current output 4 to 20 mA HART |

|

|

|

|

|

Order code |

"Output; Input 1" (20): |

|

|

Option BA: current output 4 to 20 mA HART |

|

|

|

|

Signal mode |

Can be set to: |

|

|

• Active |

|

|

• Passive |

|

|

|

|

Current range |

Can be set to: |

|

|

• 4 to 20 mA NAMUR |

|

|

• 4 to 20 mA US |

|

|

• 4 to 20 mA |

|

|

• 0 to 20 mA (only with signal mode active) |

|

|

• Fixed current value |

|

|

|

|

Open-circuit voltage |

DC 28.8 V (active) |

|

|

|

|

Maximum input voltage |

DC 30 V (passive) |

|

|

|

|

Load |

250 to 700 Ω |

|

|

|

|

Resolution |

0.38 µA |

|

|

|

|

Damping |

Configurable: 0 to 999 s |

|

|

|

|

Assignable measured |

• Mass flow |

|

variables |

• Volume flow |

|

|

• Corrected volume flow |

|

|

• Density |

|

|

• Reference density |

|

|

• Temperature |

|

|

• Electronics temperature |

|

|

• Oscillation frequency 0 |

|

|

• Oscillation damping 0 |

|

|

• Signal asymmetry |

|

|

• Exciter current 0 |

|

|

The range of options increases if the measuring device has one or more |

|

|

application packages. |

|

Current output 4 to 20 mA HART Ex i |

|

|

|

|

|

Order code |

"Output; Input 1" (20) can be set to: |

|

|

• Option CA: current output 4 to 20 mA HART Ex i passive |

|

|

• Option CC: current output 4 to 20 mA HART Ex i active |

|

|

|

|

Signal mode |

Depending on the ordered variant. |

|

|

|

|

Current range |

Can be set to: |

|

|

• 4 to 20 mA NAMUR |

|

|

• 4 to 20 mA US |

|

|

• 4 to 20 mA |

|

|

• 0 to 20 mA (only with signal mode active) |

|

|

• Fixed current value |

|

|

|

|

Open-circuit voltage |

DC 21.8 V (active) |

|

|

|

|

Maximum input voltage |

DC 30 V (passive) |

|

|

|

|

Load |

• 250 to 400 Ω (active) |

|

|

• 250 to 700 Ω (passive) |

|

|

|

|

Resolution |

0.38 µA |

|

|

|

Endress+Hauser |

15 |

Proline Promass I 300

Damping |

Configurable: 0 to 999 s |

|

|

Assignable measured |

• Mass flow |

variables |

• Volume flow |

|

• Corrected volume flow |

|

• Density |

|

• Reference density |

|

• Temperature |

|

• Electronics temperature |

|

• Oscillation frequency 0 |

|

• Oscillation damping 0 |

|

• Signal asymmetry |

|

• Exciter current 0 |

|

The range of options increases if the measuring device has one or more |

|

application packages. |

FOUNDATION Fieldbus |

|

|

|

FOUNDATION Fieldbus |

H1, IEC 61158-2, galvanically isolated |

|

|

Data transfer |

31.25 kbit/s |

|

|

Current consumption |

10 mA |

|

|

Permitted supply voltage |

9 to 32 V |

|

|

Bus connection |

With integrated reverse polarity protection |

|

|

PROFIBUS DP |

|

|

|

Signal encoding |

NRZ code |

|

|

Data transfer |

9.6 kBaud…12 MBaud |

|

|

PROFIBUS PA |

|

|

|

PROFIBUS PA |

In accordance with EN 50170 Volume 2, IEC 61158-2 (MBP), galvanically |

|

isolated |

|

|

Data transmission |

31.25 kbit/s |

|

|

Current consumption |

10 mA |

|

|

Permitted supply voltage |

9 to 32 V |

|

|

Bus connection |

With integrated reverse polarity protection |

|

|

Modbus RS485 |

|

|

|

Physical interface |

RS485 in accordance with EIA/TIA-485 standard |

|

|

Terminating resistor |

Integrated, can be activated via DIP switches |

|

|

EtherNet/IP |

|

|

|

Standards |

In accordance with IEEE 802.3 |

|

|

PROFINET |

|

|

|

Standards |

In accordance with IEEE 802.3 |

|

|

16 |

Endress+Hauser |

Proline Promass I 300

Current output 4 to 20 mA

Order code |

"Output; Input 2" (21), "Output; Input 3" (022): |

|

Option B: current output 4 to 20 mA |

|

|

Signal mode |

Can be set to: |

|

• Active |

|

• Passive |

|

|

Current range |

Can be set to: |

|

• 4 to 20 mA NAMUR |

|

• 4 to 20 mA US |

|

• 4 to 20 mA |

|

• 0 to 20 mA (only with signal mode active) |

|

• Fixed current value |

|

|

Maximum output values |

22.5 mA |

|

|

Open-circuit voltage |

DC 28.8 V (active) |

|

|

Maximum input voltage |

DC 30 V (passive) |

|

|

Load |

0 to 700 Ω |

|

|

Resolution |

0.38 µA |

|

|

Damping |

Configurable: 0 to 999 s |

|

|

Assignable measured |

• Mass flow |

variables |

• Volume flow |

|

• Corrected volume flow |

|

• Density |

|

• Reference density |

|

• Temperature |

|

• Electronics temperature |

|

• Oscillation frequency 0 |

|

• Oscillation damping 0 |

|

• Signal asymmetry |

|

• Exciter current 0 |

|

The range of options increases if the measuring device has one or more |

|

application packages. |

Current output 4 to 20 mA Ex i passive |

|

|

|

Order code |

"Output; Input 2" (21), "Output; Input 3" (022): |

|

Option C: current output 4 to 20 mA Ex i passive |

|

|

Signal mode |

Passive |

|

|

Current range |

Can be set to: |

|

• 4 to 20 mA NAMUR |

|

• 4 to 20 mA US |

|

• 4 to 20 mA |

|

• Fixed current value |

|

|

Maximum output values |

22.5 mA |

|

|

Maximum input voltage |

DC 30 V |

|

|

Load |

0 to 700 Ω |

|

|

Resolution |

0.38 µA |

|

|

Endress+Hauser |

17 |

Proline Promass I 300

Damping |

Configurable: 0 to 999 s |

|

|

Assignable measured |

• Mass flow |

variables |

• Volume flow |

|

• Corrected volume flow |

|

• Density |

|

• Reference density |

|

• Temperature |

|

• Electronics temperature |

|

• Oscillation frequency 0 |

|

• Oscillation damping 0 |

|

• Signal asymmetry |

|

• Exciter current 0 |

|

The range of options increases if the measuring device has one or more |

|

application packages. |

Pulse/frequency/switch output |

|

|

|

Function |

Can be set to pulse, frequency or switch output |

|

|

Version |

Open collector |

|

Can be set to: |

|

• Active |

|

• Passive |

|

• Passive NAMUR |

|

Ex-i, passive |

Maximum input values |

DC 30 V, 250 mA (passive) |

|

|

Open-circuit voltage |

DC 28.8 V (active) |

|

|

Voltage drop |

For 22.5 mA: ≤ DC 2 V |

|

|

Pulse output |

|

|

|

Maximum input values |

DC 30 V, 250 mA (passive) |

|

|

Maximum output current |

22.5 mA (active) |

|

|

Open-circuit voltage |

DC 28.8 V (active) |

|

|

Pulse width |

Configurable: 0.05 to 2 000 ms |

|

|

Maximum pulse rate |

10 000 Impulse/s |

|

|

Pulse value |

Adjustable |

|

|

Assignable measured |

• Mass flow |

variables |

• Volume flow |

|

• Corrected volume flow |

|

|

Frequency output |

|

|

|

Maximum input values |

DC 30 V, 250 mA (passive) |

|

|

Maximum output current |

22.5 mA (active) |

|

|

Open-circuit voltage |

DC 28.8 V (active) |

|

|

Output frequency |

Adjustable: end value frequency 2 to 10 000 Hz (f max = 12 500 Hz) |

Damping |

Configurable: 0 to 999 s |

|

|

Pulse/pause ratio |

1:1 |

|

|

18 |

Endress+Hauser |

Proline Promass I 300

Assignable measured |

• Mass flow |

variables |

• Volume flow |

|

• Corrected volume flow |

|

• Density |

|

• Reference density |

|

• Temperature |

|

• Electronics temperature |

|

• Oscillation frequency 0 |

|

• Oscillation damping 0 |

|

• Signal asymmetry |

|

• Exciter current 0 |

|

The range of options increases if the measuring device has one or more |

|

application packages. |

Switch output |

|

|

|

Maximum input values |

DC 30 V, 250 mA (passive) |

|

|

Open-circuit voltage |

DC 28.8 V (active) |

|

|

Switching behavior |

Binary, conductive or non-conductive |

|

|

Switching delay |

Configurable: 0 to 100 s |

|

|

Number of switching |

Unlimited |

cycles |

|

|

|

Assignable functions |

• Off |

|

• On |

|

• Diagnostic behavior |

|

• Limit value |

|

• Mass flow |

|

• Volume flow |

|

• Corrected volume flow |

|

• Density |

|

• Reference density |

|

• Temperature |

|

• Totalizer 1-3 |

|

• Flow direction monitoring |

|

• Status |

|

• Partially filled pipe detection |

|

• Low flow cut off |

|

The range of options increases if the measuring device has one or more |

|

application packages. |

Double pulse output |

|

|

|

Function |

Double pulse |

|

|

Version |

Open collector |

|

Can be set to: |

|

• Active |

|

• Passive |

|

• Passive NAMUR |

|

|

Maximum input values |

DC 30 V, 250 mA (passive) |

|

|

Open-circuit voltage |

DC 28.8 V (active) |

|

|

Voltage drop |

For 22.5 mA: ≤ DC 2 V |

|

|

Output frequency |

Configurable: 0 to 1 000 Hz |

|

|

Damping |

Configurable: 0 to 999 s |

|

|

Endress+Hauser |

19 |

Proline Promass I 300

Pulse/pause ratio |

1:1 |

|

|

Assignable measured |

• Mass flow |

variables |

• Volume flow |

|

• Corrected volume flow |

|

• Density |

|

• Reference density |

|

• Temperature |

|

The range of options increases if the measuring device has one or more |

|

application packages. |

Relay output |

|

|

|

Function |

Switch output |

|

|

Version |

Relay output, galvanically isolated |

|

|

Switching behavior |

Can be set to: |

|

• NO (normally open), factory setting |

|

• NC (normally closed) |

|

|

Maximum switching |

• DC 30 V, 0.1 A |

capacity (passive) |

• AC 30 V, 0.5 A |

|

|

Assignable functions |

• Off |

|

• On |

|

• Diagnostic behavior |

|

• Limit value |

|

• Mass flow |

|

• Volume flow |

|

• Corrected volume flow |

|

• Density |

|

• Reference density |

|

• Temperature |

|

• Totalizer 1-3 |

|

• Flow direction monitoring |

|

• Status |

|

• Partially filled pipe detection |

|

• Low flow cut off |

|

The range of options increases if the measuring device has one or more |

|

application packages. |

User-configurable input/output

One specific input or output is assigned to a user-configurable input/output (configurable I/O) during device commissioning.

The following inputs and outputs are available for assignment:

•Choice of current output: 4 to 20 mA (active), 0/4 to 20 mA (passive)

•Pulse/frequency/switch output

•Choice of current input: 4 to 20 mA (active), 0/4 to 20 mA (passive)

•Status input

The technical values correspond to those of the inputs and outputs described in this section.

Signal on alarm |

Depending on the interface, failure information is displayed as follows: |

|

|

HART current output |

|

|

|

|

|

Device diagnostics |

Device condition can be read out via HART Command 48 |

|

|

|

20 |

Endress+Hauser |

Proline Promass I 300

PROFIBUS PA

Status and alarm |

Diagnostics in accordance with PROFIBUS PA Profile 3.02 |

messages |

|

|

|

Failure current FDE (Fault |

0 mA |

Disconnection Electronic) |

|

|

|

PROFIBUS DP

Status and alarm |

Diagnostics in accordance with PROFIBUS PA Profile 3.02 |

messages |

|

|

|

EtherNet/IP

Device diagnostics |

Device condition can be read out in Input Assembly |

|

|

PROFINET

Device diagnostics |

According to "Application Layer protocol for decentralized periphery", Version 2.3 |

|

|

FOUNDATION Fieldbus

Status and alarm |

Diagnostics in accordance with FF-891 |

messages |

|

|

|

Failure current FDE (Fault |

0 mA |

Disconnection Electronic) |

|

|

|

Modbus RS485

Failure mode |

Choose from: |

|

|

• |

NaN value instead of current value |

|

• |

Last valid value |

|

|

|

Current output 0/4 to 20 mA

4 to 20 mA

Failure mode |

Choose from: |

|

• 4 to 20 mA in accordance with NAMUR recommendation NE 43 |

|

• 4 to 20 mA in accordance with US |

|

• Min. value: 3.59 mA |

|

• Max. value: 22.5 mA |

|

• Freely definable value between: 3.59 to 22.5 mA |

|

• Actual value |

|

• Last valid value |

|

|

0 to 20 mA

Failure mode |

Choose from: |

|

• Maximum alarm: 22 mA |

|

• Freely definable value between: 0 to 20.5 mA |

|

|

Endress+Hauser |

21 |

Proline Promass I 300

Pulse/frequency/switch output

Pulse output |

|

|

|

Failure mode |

Choose from: |

|

• Actual value |

|

• No pulses |

|

|

Frequency output |

|

|

|

Failure mode |

Choose from: |

|

• Actual value |

|

• 0 Hz |

|

• Defined value (f max 2 to 12 500 Hz) |

Switch output |

|

|

|

Failure mode |

Choose from: |

|

• Current status |

|

• Open |

|

• Closed |

|

|

Relay output

Failure mode |

Choose from: |

|

• Current status |

|

• Open |

|

• Closed |

|

|

Local display

Plain text display |

With information on cause and remedial measures |

|

|

Backlight |

Red backlighting indicates a device error. |

|

|

Status signal as per NAMUR recommendation NE 107

Status signal as per NAMUR recommendation NE 107

Interface/protocol

•Via digital communication:

•HART protocol

•FOUNDATION Fieldbus

•PROFIBUS PA

•PROFIBUS DP

•Modbus RS485

•EtherNet/IP

•PROFINET

•Via service interface

•CDI-RJ45 service interface

•WLAN interface

Plain text display |

With information on cause and remedial measures |

|

|

Additional information on remote operation → 88

Additional information on remote operation → 88

Web browser

Plain text display |

With information on cause and remedial measures |

|

|

22 |

Endress+Hauser |

Proline Promass I 300

Light emitting diodes (LED)

Status information |

Status indicated by various light emitting diodes |

The following information is displayed depending on the device version:

•Supply voltage active

•Data transmission active

•Device alarm/error has occurred

•EtherNet/IP network available

•EtherNet/IP connection established

•PROFINET network available

•PROFINET connection established

•PROFINET blinking feature

Ex connection data |

Safety-related values |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order code for |

Output type |

|

|

Safety-related values |

|

|||

|

"Output; input 1" |

|

|

|

"Output; input 1" |

|

|||

|

|

|

26 (+) |

|

27 (–) |

|

|||

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

Option BA |

Current output |

UN = 30 VDC |

|

|

|

|

|

|

|

|

4 to 20 mA HART |

UM = 250 VAC |

|

|

|

|

|

|

|

Option GA |

PROFIBUS PA |

UN = 30 VDC |

|

|

|

|

|

|

|

|

|

UM = 250 VAC |

|

|

|

|

|

|

|

Option LA |

PROFIBUS DP |

UN = 30 VDC |

|

|

|

|

|

|

|

|

|

UM = 250 VAC |

|

|

|

|

|

|

|

Option MA |

Modbus RS485 |

UN = 30 VDC |

|

|

|

|

|

|

|

|

|

UM = 250 VAC |

|

|

|

|

|

|

|

Option SA |

FOUNDATION Fieldbus |

UN = 30 VDC |

|

|

|

|

|

|

|

|

|

UM = 250 VAC |

|

|

|

|

|

|

|

Option NA |

EtherNet/IP |

UN = 30 VDC |

|

|

|

|

|

|

|

|

|

UM = 250 VAC |

|

|

|

|

|

|

|

Option RA |

PROFINET |

UN = 30 VDC |

|

|

|

|

|

|

|

|

|

UM = 250 VAC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Order code for |

Output type |

|

|

Safety-related values |

|

|||

|

"Output; input 2"; |

|

Output; input 2 |

|

Output; input 3 |

||||

|

|

|

|||||||

|

"Output; input 3" |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

24 (+) |

|

25 (–) |

|

22 (+) |

|

23 (–) |

|

|

|

|

|

|

|

|

|

|

|

Option B |

Current output |

UN = 30 VDC |

|

|

|

|

|

|

|

|

4 to 20 mA |

UM = 250 VAC |

|

|

|

|

|

|

|

Option D |

User-configurable input/ |

UN = 30 VDC |

|

|

|

|

|

|

|

|

output |

UM = 250 VAC |

|

|

|

|

|

|

|

Option E |

Pulse/frequency/switch |

UN = 30 VDC |

|

|

|

|

|

|

|

|

output |

UM = 250 VAC |

|

|

|

|

|

|

|

Option F |

Double pulse output |

UN = 30 VDC |

|

|

|

|

|

|

|

|

|

UM = 250 VAC |

|

|

|

|

|

|

|

Option H |

Relay output |

UN = 30 VDC |

|

|

|

|

|

|

|

|

|

IN =100 mADC/500 mAAC |

|

|

|

|

||

|

|

|

UM = 250 VAC |

|

|

|

|

|

|

|

Option I |

Current input 4 to 20 mA |

UN = 30 VDC |

|

|

|

|

|

|

|

|

|

UM = 250 VAC |

|

|

|

|

|

|

|

Option J |

Status input |

UN = 30 VDC |

|

|

|

|

|

|

|

|

|

UM = 250 VAC |

|

|

|

|

|

|

Endress+Hauser |

23 |

|

|

|

|

|

Proline Promass I 300 |

|

|

|

|

|

|

|

Intrinsically safe values |

|

|

|

|

|

|

|

|

|

|

|

Order code for |

Output type |

Intrinsically safe values |

||

|

"Output; input 1" |

|

|

"Output; input 1" |

|

|

|

|

26 (+) |

|

27 (–) |

|

|

|

|

||

|

|

|

|

|

|

|

Option CA |

Current output |

Ui = 30 V |

|

|

|

|

4 to 20 mA HART Ex i |

li = 100 mA |

|

|

|

|

passive |

Pi = 1.25 W |

|

|

|

|

|

Li = 0 µH |

|

|

|

|

|

Ci = 6 nF |

|

|

|

Option CC |

Current output |

Ex ia 1) |

|

Ex ic 2) |

|

|

4 to 20 mA HART Ex i |

U0 = 21.8 V |

|

U0 = 21.8 V |

|

|

active |

l0 = 90 mA |

|

l0 = 90 mA |

|

|

|

P0 = 491 mW |

|

P0 = 491 mW |

|

|

|

L0 = 4.1 mH (IIC)/15 mH L0 = 9 mH (IIC)/39 mH |

||

|

|

|

(IIB) |

|

(IIB) |

|

|

|

C0 = 160 nF (IIC)/ |

|

C0 = 600 nF (IIC)/ |

|

|

|

1 160 nF (IIB) |

|

4 000 nF (IIB) |

|

|

|

Ui = 30 V |

|

|

|

|

|

li = 10 mA |

|

|

|

|

|

Pi = 0.3 W |

|

|

|

|

|

Li = 5 µH |

|

|

|

|

|

Ci = 6 nF |

|

|

|

Option HA |

PROFIBUS PA Ex i |

Ex ia 3) |

|

Ex ic 4) |

|

|

(FISCO Field Device) |

Ui = 30 V |

|

Ui = 32 V |

|

|

|

li = 570 mA |

|

li = 570 mA |

|

|

|

Pi = 8.5 W |

|

Pi = 8.5 W |

|

|

|

Li = 10 µH |

|

Li = 10 µH |

|

|

|

Ci = 5 nF |

|

Ci = 5 nF |

|

Option TA |

FOUNDATION Fieldbus |

Ex ia 3) |

|

Ex ic 4) |

|

|

Ex i |

Ui = 30 V |

|

Ui = 32 V |

|

|

|

li = 570 mA |

|

li = 570 mA |

|

|

|

Pi = 8.5 W |

|

Pi = 8.5 W |

|

|

|

Li = 10 µH |

|

Li = 10 µH |

|

|

|

Ci = 5 nF |

|

Ci = 5 nF |

1)Only available for the Zone 1; Class I, Division 1 version

2)Only available for the Zone 2; Class I, Division 2 version transmitter

3)Only available for the Zone 1; Class I, Division 1 version

4)Only available for the Zone 2; Class I, Division 2 version transmitter

|

Order code for |

Output type |

Intrinsically safe values or NIFW values |

||||

|

"Output; input 2"; |

|

Output; input 2 |

|

Output; input 3 |

||

|

|

|

|||||

|

"Output; input 3" |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

24 (+) |

25 (–) |

|

22 (+) |

23 (–) |

|

|

|

|

|

|

|

|

|

Option C |

Current output |

Ui = 30 V |

|

|

|

|

|

|

4 to 20 mA Ex i |

li = 100 mA |

|

|

|

|

|

|

|

Pi = 1.25 W |

|

|

|

|

|

|

|

Li = 0 |

|

|

|

|

|

|

|

Ci = 0 |

|

|

|

|

|

Option G |

Pulse/frequency/switch |

Ui = 30 V |

|

|

|

|

|

|

output Ex i |

li = 100 mA |

|

|

|

|

|

|

|

Pi = 1.25 W |

|

|

|

|

|

|

|

Li = 0 |

|

|

|

|

|

|

|

Ci = 0 |

|

|

|

|

|

|

|

|

|

|

||

Low flow cut off |

The switch points for low flow cut off are user-selectable. |

|

|

|

|

||

|

|

|

|

||||

Galvanic isolation |

The outputs are galvanically isolated from one another and from earth (PE). |

|

|

||||

24 |

Endress+Hauser |

Proline Promass I 300

Protocol-specific data |

HART |

|

|

|

|

|

Manufacturer ID |

0x11 |

|

|

|

|

Device type ID |

0x3B |

|

|

|

|

HART protocol revision |

7 |

|

|

|

|

Device description files |

Information and files under: |

|

(DTM, DD) |

www.endress.com |

|

|

|

|

HART load |

Min. 250 Ω |

|

|

|

|

System integration |

Information on system integration: Operating Instructions → 108. |

|

|

• Measured variables via HART protocol |

|

|

• Burst Mode functionality |

|

|

|

FOUNDATION Fieldbus

Manufacturer ID |

0x452B48 (hex) |

|

|

|

|

Ident number |

0x103B (hex) |

|

|

|

|

Device revision |

1 |

|

|

|

|

DD revision |

Information and files under: |

|

|

• www.endress.com |

|

CFF revision |

||

• www.fieldbus.org |

||

|

||

|

|

|

Interoperability Test Kit (ITK) |

Version 6.2.0 |

|

|

|

|

ITK Test Campaign Number |

Information: |

|

|

• www.endress.com |

|

|

• www.fieldbus.org |

|

|

|

|

Link Master capability (LAS) |

Yes |

|

|

|

|

Choice of "Link Master" and |

Yes |

|

"Basic Device" |

Factory setting: Basic Device |

|

|

|

|

Node address |

Factory setting: 247 (0xF7) |

|

|

|

|

Supported functions |

The following methods are supported: |

|

|

• Restart |

|

|

• ENP Restart |

|

|

• Diagnostic |

|

|

• Set to OOS |

|

|

• Set to AUTO |

|

|

• Read trend data |

|

|

• Read event logbook |

|

|

|

|