Endress+Hauser FMR52, FMR51 Specifications

TI01040F/00/EN/09.18

71394703

2018-04-12

Products |

Solutions |

Services |

|

|

|

Technical Information

Micropilot FMR51, FMR52

Free space radar

Level measurement in liquids

Application

•Continuous, non-contact level measurement of liquids, pastes and slurries

•Horn antenna (FMR51); flush mounted, completely filled PTFE horn antenna (FMR52)

•Maximum measuring range: 70 m (230 ft)

•Process temperature: –196 to +450 °C (–321 to +842 °F)

•Process pressure: –1 to +160 bar (–14.5 to +2 320 psi)

•Accuracy: ± 2 mm

•International explosion protection certificates; WHG; marine approvals

•Linearity protocol (3-point, 5-point)

Your benefits

•Reliable measurement even for changing product and process conditions

•HistoROM data management for easy commissioning, maintenance and diagnostics

•Highest reliability due to Multi-Echo Tracking

•SIL2 according to IEC 61508, SIL3 in case of homogeneous or heterogeneous redundancy

•Seamless integration into control or asset management systems

•Intuitive user interface in national languages

•Bluetooth® wireless technology for commissioning, operation and maintenance via free iOS / Android app SmartBlue

•Easy proof test for SIL and WHG

•Heartbeat Technology™

Micropilot FMR51, FMR52

Table of contents

Wichtige Hinweise zum Dokument . . . . . . . . . . . . . . 4

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . 6 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Function and system design . . . . . . . . . . . . . . . . . . . 8

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Operating frequency . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Transmitting power . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Linearization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Galvanic isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Protocol-specific data . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . 22 Device plug connectors . . . . . . . . . . . . . . . . . . . . . . . . . 30 Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 Current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . 33 Power supply failure . . . . . . . . . . . . . . . . . . . . . . . . . . 34 Potential equalization . . . . . . . . . . . . . . . . . . . . . . . . . 34 Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 Cable entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 Cable specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 Overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . 35

Performance characteristics . . . . . . . . . . . . . . . . . . 36

Reference operating conditions . . . . . . . . . . . . . . . . . . . 36 Maximum measured error . . . . . . . . . . . . . . . . . . . . . . . 36 Measured value resolution . . . . . . . . . . . . . . . . . . . . . . 37 Reaction time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 Influence of ambient temperature . . . . . . . . . . . . . . . . . 37 Influence of gas layer . . . . . . . . . . . . . . . . . . . . . . . . . . 37 Gas phase compensation with external pressure sensor (PROFIBUS PA, FOUNDATION Fieldbus) . . . . . . . . . . . . . 38

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Installation conditions . . . . . . . . . . . . . . . . . . . . . . . . . 39 Measuring conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 43 Mounting cladded flanges . . . . . . . . . . . . . . . . . . . . . . . 44 Installation in vessel (free space) . . . . . . . . . . . . . . . . . . 44 Installation in stilling well . . . . . . . . . . . . . . . . . . . . . . . 48 Installation in bypass . . . . . . . . . . . . . . . . . . . . . . . . . . 50 Container with heat insulation . . . . . . . . . . . . . . . . . . . . 52

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . 53 Ambient temperature limits . . . . . . . . . . . . . . . . . . . . . 53 Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Climate class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

62 |

Altitude according to IEC61010-1 Ed.3 . . . . . . . . . . . . . . |

62 |

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . |

62 |

Vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . |

62 |

Cleaning the antenna . . . . . . . . . . . . . . . . . . . . . . . . . . |

62 |

Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . |

62 |

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Process temperature, Process pressure . . . . . . . . . . . . . . 63 Dielectric constant . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Mechanical construction . . . . . . . . . . . . . . . . . . . . 66

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 Materials: GT18 housing (stainless steel, corrosion-

resistant) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77 Materials: GT19 housing (plastic) . . . . . . . . . . . . . . . . . . 78 Materials: GT20 housing (die-cast aluminum, powder-

coated) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79 Materials: Antenna and process connection . . . . . . . . . . . 80 Materials: Weather protection cover . . . . . . . . . . . . . . . . 82

Operability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Operating concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83 Local operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84 Operation with remote display and operating module

FHX50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84 Operation via Bluetooth® wireless technology . . . . . . . . . . 85 Remote operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86 Integration in tank gauging system . . . . . . . . . . . . . . . . . 89 SupplyCare inventory management software . . . . . . . . . . 90

Certificates and approvals . . . . . . . . . . . . . . . . . . . |

93 |

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

93 |

RoHS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

93 |

RCM-Tick marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

93 |

Ex approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

93 |

Dual seal according to ANSI/ISA 12.27.01 . . . . . . . . . . . . |

93 |

Functional safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

93 |

WHG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

93 |

Sanitary compatibility . . . . . . . . . . . . . . . . . . . . . . . . . |

93 |

NACE MR 0175 / ISO 15156 . . . . . . . . . . . . . . . . . . . . . |

94 |

NACE MR 0103 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

94 |

Pressure equipment with allowable pressure |

|

≤ 200 bar (2 900 psi) . . . . . . . . . . . . . . . . . . . . . . . . . . |

94 |

Marine certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

94 |

Radio standard EN302729-1/2 . . . . . . . . . . . . . . . . . . . |

94 |

Radio standard EN302372-1/2 . . . . . . . . . . . . . . . . . . . |

95 |

FCC / Industry Canada . . . . . . . . . . . . . . . . . . . . . . . . . |

95 |

Japanese radio approval . . . . . . . . . . . . . . . . . . . . . . . . |

96 |

CRN approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

96 |

Track record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

97 |

Test, Certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

98 |

Hard-copy product documentation . . . . . . . . . . . . . . . . . |

98 |

Other standards and guidelines . . . . . . . . . . . . . . . . . . . |

99 |

Ordering information . . . . . . . . . . . . . . . . . . . . . . 100

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . 100

2 |

Endress+Hauser |

Micropilot FMR51, FMR52

3-point linearity protocol . . . . . . . . . . . . . . . . . . . . . . 101 5-point linearity protocol . . . . . . . . . . . . . . . . . . . . . . 102 Customized parametrization . . . . . . . . . . . . . . . . . . . . 103 Tagging (TAG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103 Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Application Packages . . . . . . . . . . . . . . . . . . . . . . 104

Heartbeat Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . 104

Heartbeat Verification . . . . . . . . . . . . . . . . . . . . . . . . 105

Heartbeat Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . 106

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Device-specific accessories . . . . . . . . . . . . . . . . . . . . . . 107 Communication-specific accessories . . . . . . . . . . . . . . . 113 Service-specific accessories . . . . . . . . . . . . . . . . . . . . . 114 System components . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Standard documentation . . . . . . . . . . . . . . . . . . . . . . . 115

Supplementary documentation . . . . . . . . . . . . . . . . . . . 115

Safety Instructions (XA) . . . . . . . . . . . . . . . . . . . . . . . 115

Endress+Hauser |

3 |

|

|

|

|

|

|

|

|

|

|

Micropilot FMR51, FMR52 |

|

|

|

|

|

|

|

|

|

|

|

|

Wichtige Hinweise zum Dokument |

|||||||||

|

|

|

|

|||||||

Symbols |

Safety symbols |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Symbol |

|

Meaning |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DANGER! |

|

|

|

DANGER |

|

|

|

This symbol alerts you to a dangerous situation. Failure to avoid this situation will |

|||

|

|

|

|

|

|

|

|

|

|

result in serious or fatal injury. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING! |

|

|

|

WARNING |

|

This symbol alerts you to a dangerous situation. Failure to avoid this situation can |

|||||

|

|

|

|

|

|

|

|

|

|

result in serious or fatal injury. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAUTION! |

|

|

|

CAUTION |

|

|

This symbol alerts you to a dangerous situation. Failure to avoid this situation can |

||||

|

|

|

|

|

|

|

|

|

|

result in minor or medium injury. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE! |

|

|

|

NOTICE |

|

|

This symbol contains information on procedures and other facts which do not result in |

||||

|

|

|

|

|

|

|

|

|

|

personal injury. |

|

|

|

|

|

|

|||||

|

Electrical symbols |

|

|

|||||||

|

|

|

|

|

|

|

|

|||

|

|

|

Symbol |

|

Meaning |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Direct current |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alternating current |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Direct current and alternating current |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ground connection |

|

|

|

|

|

|

|

|

|

|

A grounded terminal which, as far as the operator is concerned, is grounded via a |

|

|

|

|

|

|

|

|

|

|

grounding system. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Protective Earth (PE) |

|

|

|

|

|

|

|

|

|

|

A terminal which must be connected to ground prior to establishing any other |

|

|

|

|

|

|

|

|

|

|

connections. |

|

|

|

|

|

|

|

|

|

|

The ground terminals are situated inside and outside the device: |

|

|

|

|

|

|

|

|

|

|

• Inner ground terminal: Connects the protectiv earth to the mains supply. |

|

|

|

|

|

|

|

|

|

|

• Outer ground terminal: Connects the device to the plant grounding system. |

|

|

|

|

|

|

|

|

|

|

|

Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation.

A |

Reference to page. |

Reference to graphic.

Visual inspection.

4 |

Endress+Hauser |

Micropilot FMR51, FMR52

Symbols in graphics

|

Symbol |

Meaning |

|||||

|

|

|

|

|

|

|

|

1, 2, 3 ... |

Item numbers |

||||||

|

|

|

|

|

|

|

|

|

|

, |

|

, |

|

… |

Series of steps |

|

1. |

2. |

3. |

||||

|

|

|

|||||

|

A, B, C, ... |

Views |

|||||

|

|

||||||

A-A, B-B, C-C, ... |

Sections |

||||||

|

|

|

|

|

|

|

|

- |

|

Hazardous area |

|||||

|

Indicates a hazardous area. |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

. |

|

Safe area (non-hazardous area) |

|||||

|

Indicates the non-hazardous area. |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Symbols at the device

Symbol Meaning

Safety instructions

Observe the safety instructions contained in the associated Operating Instructions.

Temperature resistance of the connection cables

Specifies the minimum value of the temperature resistance of the connection cables.

Endress+Hauser |

5 |

Micropilot FMR51, FMR52

Terms and abbreviations |

Term/abbreviation |

Explanation |

|

|

|

|

BA |

Document type "Operating Instructions" |

|

|

|

|

KA |

Document type "Brief Operating Instructions" |

|

|

|

|

TI |

Document type "Technical Information" |

|

|

|

|

SD |

Document type "Special Documentation" |

|

|

|

|

XA |

Document type "Safety Instructions" |

|

|

|

|

PN |

Nominal pressure |

|

|

|

|

MWP |

Maximum Working Pressure |

|

|

The MWP can also be found on the nameplate. |

|

|

|

|

ToF |

Time of Flight |

|

|

|

|

FieldCare |

Scalable software tool for device configuration and integrated plant asset management |

|

|

solutions |

|

|

|

|

DeviceCare |

Universal configuration software for Endress+Hauser HART, PROFIBUS, |

|

|

FOUNDATION Fieldbus and Ethernet field devices |

|

|

|

|

DTM |

Device Type Manager |

|

|

|

|

DD |

Device Description for HART communication protocol |

|

|

|

|

εr (DC value) |

Relative dielectric constant |

|

Operating tool |

The term "operating tool" is used in place of the following operating software: |

|

|

• FieldCare / DeviceCare, for operation via HART communication and PC |

|

|

• SmartBlue (app), for operation using an Android or iOS smartphone or tablet. |

|

|

|

|

BD |

Blocking Distance; no signals are analyzed within the BD. |

|

|

|

|

PLC |

Programmable Logic Controller |

|

|

|

|

CDI |

Common Data Interface |

|

|

|

|

PFS |

Pulse Frequence Status (Switching output) |

|

|

|

|

MBP |

Manchester Bus Powered |

|

|

|

|

PDU |

Protocol Data Unit |

|

|

|

6 |

Endress+Hauser |

Micropilot FMR51, FMR52

Registered trademarks |

HART® |

|

Registered trademark of the FieldComm Group, Austin, USA |

|

PROFIBUS® |

|

Registered trademark of the PROFIBUS User Organization, Karlsruhe, Germany |

|

FOUNDATIONTM Fieldbus |

|

Registered trademark of the FieldComm Group, Austin, Texas, USA |

|

Bluetooth® |

|

The Bluetooth® word mark and logos are registered trademarks owned by the Bluetooth SIG, Inc. and |

|

any use of such marks by Endress+Hauser is under license. Other trademarks and trade names are |

|

those of their respective owners. |

|

Apple® |

|

Apple, the Apple logo, iPhone, and iPod touch are trademarks of Apple Inc., registered in the U.S.and |

|

other countries. App Store is a service mark of Apple Inc. |

|

Android® |

|

Android, Google Play and the Google Play logo are trademarks of Google Inc. |

|

KALREZ®, VITON® |

|

Registered trademark of DuPont Performance Elastomers L.L.C., Wilmington, USA |

|

TEFLON® |

|

Registered trademark of E.I. DuPont de Nemours & Co., Wilmington, USA |

|

TRI CLAMP® |

|

Registered trademark of Alfa Laval Inc., Kenosha, USA |

Endress+Hauser |

7 |

|

|

Micropilot FMR51, FMR52 |

|

Function and system design |

|

Measuring principle |

The Micropilot is a "downward-looking" measuring system, operating based on the time-of-flight |

|

|

method (ToF). It measures the distance from the reference point (process connection) to the product |

|

|

surface. Radar impulses are emitted by an antenna, reflected off the product surface and received |

|

|

again by the radar system. |

|

|

R |

|

|

D |

100% |

|

|

|

|

|

E |

|

|

F |

|

L |

|

|

|

0% |

A0017871

1 Setup parameters of the Micropilot

R Reference point of the measurement (lower edge of the flange or threaded connection) E Empty calibration ( = zero)

F Full calibration (= span) D Measured distance

LLevel (L = E - D)

Input

The reflected radar impulses are received by the antenna and transmitted into the electronics. A microprocessor evaluates the signal and identifies the level echo caused by the reflection of the radar impulse at the product surface. The unambiguous signal identification is accomplished by the PulseMaster® eXact software together with the Multi-echo tracking algorithms, based on many years of experience with time-of-flight technology.

The distance D to the product surface is proportional to the time of flight t of the impulse: D = c · t/2,

with c being the speed of light.

Based on the known empty distance E, the level L is calculated: L = E – D

The reference point R of the measurement is located at the process connection. For details see the dimensional drawing:

•FMR51: → 67

•FMR52: → 73

The Micropilot is equipped with functions to suppress interference echoes. The user can activate these functions. Together with the multi-echo tracking algorithms they ensure that interference echoes (i.e. from edges and weld seams) are not interpreted as level echo.

8 |

Endress+Hauser |

Micropilot FMR51, FMR52

Output

The Micropilot is commissioned by entering an empty distance "E" (=zero), a full distance "F" (=span) and application parameters which automatically adapt the instrument to the process conditions. For models with a current output, the factory adjustment for zero point "E" and span "F" is 4 mA and 20 mA. For digital outputs and the display module, the factory adjustment for zero point "E" and span "F" is 0 % and 100 %.

A linearization with max. 32 points, based on a table entered either manually or semi-automatically, can be activated locally or remotely. This function provides a measurement in engineering units and a linear output signal for spheres, horizontal cylindrical tanks and vessels with conical outlet.

Life cycle of the product

Engineering

•Universal measuring principle

•Measurement unaffected by medium properties

•Hardware and software developed according to SIL IEC 61508

Procurement

•Endress+Hauser being the world market leader in level measurement guarantees asset protection

•Worldwide support and service

Installation

•Special tools are not required

•Reverse polarity protection

•Modern, detachable terminals

•Main electronics protected by a separate connection compartment

Commissioning

•Fast, menu-guided commissioning in only a few steps on site or from the control room

•Plain text display in national languages reduces the risk of error or confusion

•Direct local access of all parameters

•Short instruction manual at the device

Operation

•Multi-echo tracking: Reliable measurement through self-learning echo-search algorithms taking into account the short-term and long-term history in order to check the found echoes for plausibility and to suppress interference echoes.

•Diagnostics in accordance with NAMUR NE107

Maintenance

•HistoROM: Data backup for instrument settings and measured values

•Exact instrument and process diagnosis to assist fast decisions with clear details concerning remedies

•Intuitive, menu-guided operating concept in national languages saves costs for training, maintenance and operation

•Cover of the electronics compartment can be opened in hazardous areas

Retirement

•Order code translation for subsequent models

•RoHS-conforming (Restriction of certain Hazardous Substances), unleaded soldering of electronic components

•Environmentally sound recycling concept

Endress+Hauser |

9 |

|

|

|

|

|

Micropilot FMR51, FMR52 |

|

|

|

|

|

|

|

Input |

|

|

|

|

|

|

|

|

|

|

Measured variable |

The measured variable is the distance between the reference point and the product surface. |

||||

|

The level is calculated from this distance, taking into account the empty distance "E" entered by the |

||||

|

user. |

|

|

|

|

|

If required, the level can be converted into other variables (volume, mass) by means of a linearization |

||||

|

(up to 32 points). |

|

|

|

|

|

|

|

|||

Measuring range |

Maximum measuring range |

|

|||

|

|

|

|

|

|

|

Device |

|

|

|

Maximum measuring range |

|

|

|

|

|

|

|

FMR51 - standard version |

|

|

40 m (131 ft) |

|

|

|

|

|

|

|

|

FMR51 - with "Advanced dynamics" application package |

|

70 m (230 ft) |

||

|

|

|

|

|

|

|

FMR52 - standard version |

|

|

40 m (131 ft) |

|

|

|

|

|

|

|

|

FMR52 - with "Advanced dynamics" application package |

|

60 m (197 ft) |

||

|

|

|

|

|

|

|

Usable measuring range |

|

|

|

|

|

The usable measuring range depends on the size of the antenna, the reflectivity of the medium, the |

||||

|

mounting location and eventual interference reflections. |

|

|||

|

The following tables describe the groups of media as well as the achievable measuring range as a |

||||

|

function of application and media group. If the dielectric constant of a medium is unknown, it is |

||||

|

recommended to assume media group B to ensure a reliable measurement. |

||||

|

Media groups |

|

|

|

|

|

|

|

|

|

|

|

Media groups |

DC (εr) |

Example |

|

|

|

A |

1.4 to 1.9 |

non-conducting liquids, e.g. liquefied gas 1) |

|

|

|

B |

1.9 to 4 |

non-conducting liquids, e.g. benzene, oil, toluene, … |

||

|

|

|

|

||

|

C |

4 to 10 |

e.g. concentrated acids, organic solvents, esters, aniline, alcohol, acetone, … |

||

|

|

|

|

||

|

D |

> 10 |

conducting liquids, e.g. aqueous solutions, dilute acids and alkalis |

||

|

|

|

|

|

|

1)Treat Ammonia NH3 as a medium of group A.

For dielectric constants (DC values) of many media commonly used in various industries refer to:

•the Endress+Hauser DC manual (CP01076F)

•the Endress+Hauser "DC Values App" (available for Android and iOS)

10 |

Endress+Hauser |

Micropilot FMR51, FMR52

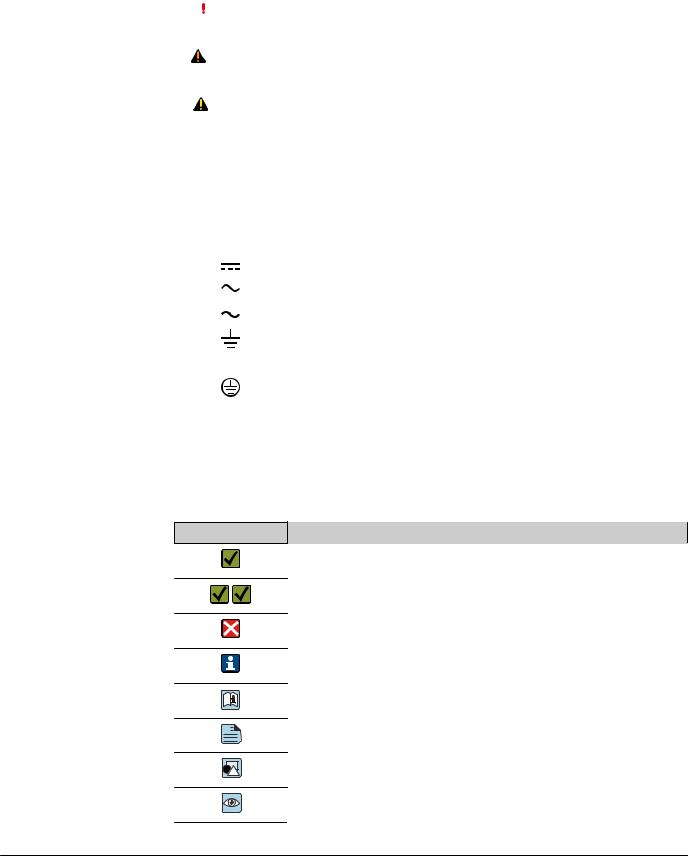

Device |

|

|

|

Storage tank |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A0018833

Calm product surface (e.g. intermittent filling, filling from bottom, immersion tubes)

Antenna size

FMR51 |

40 mm (1½ in) |

|

50 mm (2 in) |

80 mm (3 in) |

|

100 mm (4 in) |

||||

FMR52 |

|

- |

|

|

50 mm (2 in) |

80 mm (3 in) |

|

- |

|

|

|

A B C D |

A B C D |

A B C D |

A B C D |

||||||

|

3 |

|

|

4 |

|

|

|

|

|

|

|

(9.9) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

5 |

|

(13) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

(16) |

(16) |

|

8 |

8 |

|

|

|

|

|

|

|

8 |

|

|

8 |

|

|

|

||

|

|

|

(26) |

(26) |

|

|

|

|

||

|

|

|

|

(26) |

|

|

|

|||

|

|

(26) |

|

|

|

|

|

|||

|

|

10 |

|

|

|

|

10 |

|

10 |

|

|

|

|

|

|

|

|

(32) |

|

||

|

|

(32) |

|

|

12 |

|

(32) |

|

|

|

|

|

15 |

15 |

|

(39) |

15 |

15 |

|

15 |

|

|

|

(49) |

(49) |

|

|

(49) |

(49) |

|

(49) |

|

|

|

|

25 |

|

|

25 |

20 |

|

25 |

|

|

|

|

|

|

(65) |

|

|

|||

|

|

|

(82) |

|

|

(82) |

|

(82) |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

A0018858 |

|

|

|

30 |

|

30 |

|

|

|

|

|

|

|

(98) |

|

(99) |

|

|

|

|

|

|

|

|

35 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(110) |

|

|

|

|

|

|

|

|

|

|

40 |

40 |

40 |

40 |

40 |

|

|

|

|

|

|

(131) |

(131) |

(131) |

(131) |

(131) |

|

|

|

|

|

|

|

A0018859 |

|

45 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60 |

(148) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(197) |

|

70 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A0018860 |

|

(229) |

|

|

|

|

|

|

|

|

|

|

A0018862 |

Measuring range [m (ft)]

Legend

Measuring range of the standard version

Measuring range for the "Advanced dynamics" application package (product structure: feature 540: "Application Package", Option EM: "Advanced dynamics")

Endress+Hauser |

11 |

Micropilot FMR51, FMR52

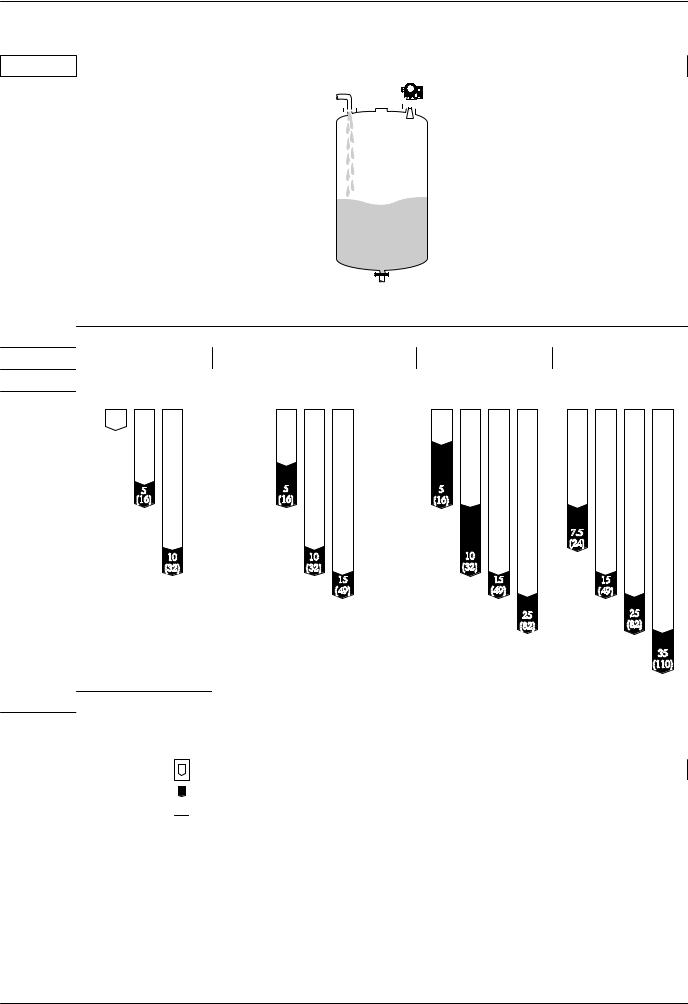

Device |

Buffer tank |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A0018835

Moving surfaces (e.g. continuous filling, from above, mixing jets)

Antenna size

FMR51 |

40 mm (1½ in) |

50 mm (2 in) |

|

80 mm (3 in) |

|

100 mm (4 in) |

||||

FMR52 |

- |

50 mm (2 in) |

|

80 mm (3 in) |

|

|

- |

|

||

|

B C D |

B C D |

A B C D |

A B C D |

||||||

|

2 |

|

|

|

|

|

|

|

|

|

|

(6.6) |

|

|

2.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(8) |

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

(9.9) |

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

|

|

(13) |

|

|

|

|

|

|

|

|

|

|

5 |

5 |

|

5 |

5 |

|

|

5 |

|

|

|

(16) |

(16) |

|

(16) |

(16) |

|

|

(16) |

|

|

|

7.5 |

7.5 |

|

|

|

|

|

7.5 |

|

|

|

(24) |

(24) |

|

|

|

|

|

(24) |

|

|

|

10 |

10 |

10 |

|

10 |

10 |

|

10 |

|

|

|

(32) |

(32) |

(32) |

|

(32) |

(32) |

|

(32) |

|

|

|

|

A0018863 |

15 |

|

|

15 |

15 |

15 |

15 |

|

|

|

(49) |

|

|

(49) |

(49) |

(49) |

(49) |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

A0018864 |

|

|

|

|

25 |

25 |

|

|

|

|

|

|

|

25 |

|

||

|

|

|

|

|

|

|

(82) |

|

(82) |

(82) |

|

|

|

|

|

|

|

A0018865 |

|

|

|

|

|

|

|

|

|

|

|

|

|

35 |

|

|

|

|

|

|

|

|

|

|

(110) |

|

|

|

|

|

|

|

|

|

|

A0018866 |

Measuring range [m (ft)]

Legend

Measuring range of the standard version

Measuring range for the "Advanced dynamics" application package (product structure: feature 540: "Application Package", Option EM: "Advanced dynamics")

12 |

Endress+Hauser |

Micropilot FMR51, FMR52 |

|

|

|

|

|

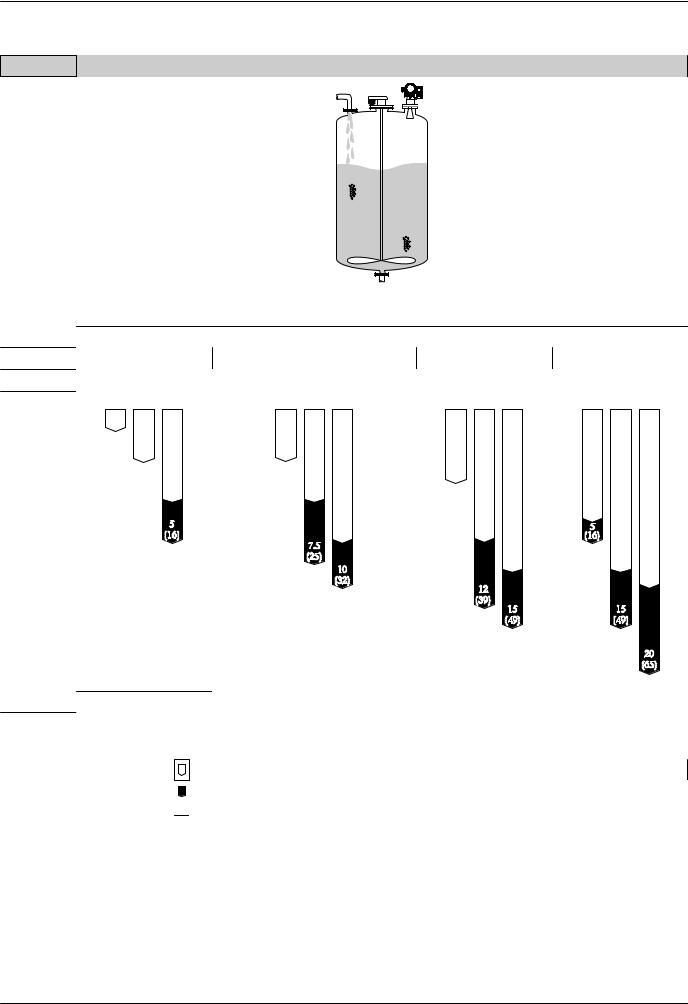

Device |

|

Process tank with agitator |

|

|

|

|

|

|

|

|

A0018837 |

|

|

Turbulent surface (e.g. filling from above, agitators, baffles) |

|

|

|

|

|

Antenna size |

|

|

|

FMR51 |

40 mm (1½ in) |

50 mm (2 in) |

80 mm (3 in) |

100 mm (4 in) |

|

FMR52 |

- |

50 mm (2 in) |

80 mm (3 in) |

- |

|

|

B C D |

B C D |

B C D |

B C D |

|

|

1 |

|

|

|

|

|

(3.2) |

|

|

|

|

|

2 |

2 |

|

|

|

|

(6.6) |

(6.6) |

|

|

|

|

|

|

2.5 |

|

|

|

3 |

3 |

(8.2) |

|

|

|

|

|

|

||

|

(9.8) |

(9.8) |

|

4 |

|

|

|

|

|

|

|

|

|

|

|

(13) |

|

|

5 |

5 |

5 |

5 |

|

|

(16) |

(16) |

(16) |

|

|

|

(16) |

|

|||

|

A0018867 |

7.5 |

8 |

8 |

|

|

(25) |

|

|||

|

|

(26) |

(26) |

|

|

|

|

10 |

10 |

||

|

|

|

|

||

|

|

(32) |

|

|

(32) |

|

|

A0018868 |

12 |

|

|

|

|

(39) |

|

|

|

|

|

|

|

|

|

|

|

|

15 |

15 |

|

|

|

|

(49) |

(49) |

|

|

|

|

|

A0018869 |

|

|

|

|

|

|

20 |

|

|

|

|

|

(65) |

|

|

|

|

|

A0018870 |

|

|

Measuring range [m (ft)] |

|

|

|

Legend

Measuring range of the standard version

Measuring range for the "Advanced dynamics" application package (product structure: feature 540: "Application Package", Option EM: "Advanced dynamics")

Endress+Hauser |

13 |

|

|

|

|

|

|

Micropilot FMR51, FMR52 |

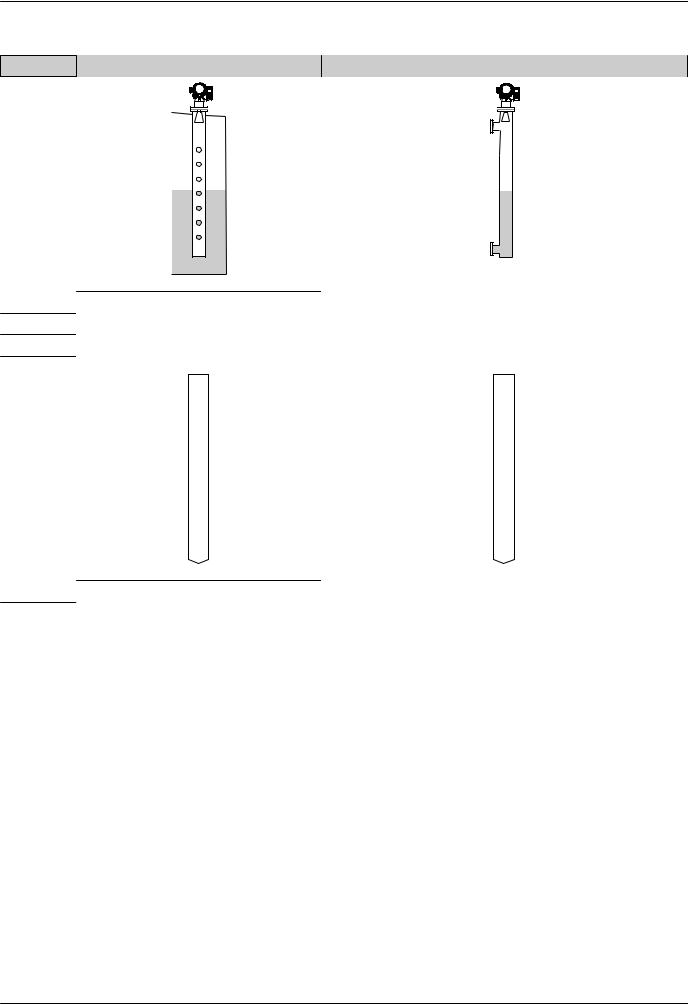

Device |

|

Stilling well |

|

|

Bypass |

|

|

|

|

|

|

|

A0018840 |

|

|

|

|

A0018842 |

|

|

|

|

Antenna size |

|

|

Antenna size |

|

FMR51 |

40 ... |

100 mm ( 1½ ... |

4 in) |

40 ... |

100 mm ( 1½ ... |

4 in) |

FMR52 |

50 ... |

80 mm ( 2 ... |

3 in) |

50 ... |

80 mm ( 2 ... |

3 in) |

|

|

A, B, C, D |

|

|

C, D |

|

20 |

20 |

(66) |

(66) |

A0018851 |

A0018852 |

Measuring range [m (ft)]

14 |

Endress+Hauser |

Micropilot FMR51, FMR52

Operating frequency |

K-band (~ 26 GHz) |

|

Up to 8 Micropilot transmitters can be installed in the same tank because the transmitter pulses are |

|

statistically coded. |

Transmitting power |

Distance |

|

Average energy density in beam direction |

|

|

|

Standard version |

|

With "Advanced dynamics" application |

|

|

|

||

|

|

|

|

package 1) |

|

1 m (3.3 ft) |

< 12 nW/cm2 |

|

< 64 nW/cm2 |

|

5 m (16 ft) |

< 0.4 nW/cm2 |

|

< 2.5 nW/cm2 |

1)Product structure, feature 540: "Application package", option EM: "Advanced dynamics"

Endress+Hauser |

15 |

|

|

|

Micropilot FMR51, FMR52 |

|

|

|

|

|

Output |

|

|

|

|

|

|

Output signal |

HART |

|

|

|

|

|

|

|

Signal coding |

|

FSK ±0.5 mA over current signal |

|

|

|

|

|

Data transmission rate |

|

1 200 Bit/s |

|

|

|

|

|

Galvanic isolation |

|

Yes |

|

|

|

|

|

Bluetooth® wireless technology |

||

|

|

|

|

|

Device version |

Ordering feature 610 "Accessory mounted", option NF "Bluetooth" |

|

|

|

|

|

|

Operation / configuration |

By the SmartBlue app. |

|

|

|

|

|

|

Range under reference conditions |

> 10 m (33 ft) |

|

|

|

|

|

|

Encryption |

Encrypted communication and password encryption prevent incorrect |

|

|

|

operation by unauthorized persons. |

|

|

|

|

|

|

PROFIBUS PA |

|

|

|

|

|

|

|

Signal coding |

|

Manchester Bus Powered (MBP) |

|

|

|

|

|

Data transmission rate |

|

31.25 kBit/s, voltage mode |

|

|

|

|

|

Galvanic isolation |

|

Yes |

|

|

|

|

|

FOUNDATION Fieldbus |

|

|

|

|

|

|

|

Signal coding |

|

Manchester Bus Powered (MBP) |

|

|

|

|

|

Data transmission rate |

|

31.25 kBit/s, voltage mode |

|

|

|

|

|

Galvanic isolation |

|

Yes |

|

|

|

|

Switch output

For HART devices, the switch output is available as an option. See product structure, feature 20: "Power Supply, Output", option B: "2-wire; 4-20mA HART, switch output"

Devices with PROFIBUS PA and FOUNDATION Fieldbus always have a switch output.

16 |

Endress+Hauser |

Micropilot FMR51, FMR52

|

Switch output |

|

|

|

|

|

|

|

Function |

Open collector switching output |

|

|

|

|

|

|

Switching behavior |

Binary (conductive or non-conductive), switches when the programmable switch |

|

|

|

point is reached |

|

|

|

|

|

|

Failure mode |

non-conductive |

|

|

|

|

|

|

Electrical connection values |

U = 16 to 35 VDC, I = 0 to 40 mA |

|

|

Internal resistance |

RI < 880 Ω |

|

|

|

The voltage drop at this internal resistance has to be taken into account on |

|

|

|

planning the configuration. For example, the resulting voltage at a connected |

|

|

|

relay must be sufficient to switch the relay. |

|

|

|

|

|

|

Insulation voltage |

floating, Insulation voltage 1 350 VDC to power supply aund 500 VAC to ground |

|

|

Switch point |

freely programmable, separately for switch-on and switch-off point |

|

|

|

|

|

|

Switching delay |

freely programmable from 0 to 100 s, separately for switch-on and switch-off |

|

|

|

point |

|

|

|

|

|

|

Number of switching cycles |

corresponds to the measuring cycle |

|

|

|

|

|

|

Signal source |

• |

Level linearized |

|

device variables |

• |

Distance |

|

|

• Terminal voltage |

|

|

|

• Electronic temperature |

|

|

|

• Relative echo amplitude |

|

|

|

• Diagnostic values, Advanced diagnostics |

|

|

|

|

|

|

Number of switching cycles |

unlimited |

|

|

|

|

|

|

|

||

Signal on alarm |

Depending on the interface, failure information is displayed as follows: |

||

•Current output (for HART devices)

–Failsafe mode selectable (in accordance with NAMUR Recommendation NE 43): Minimum alarm: 3.6 mA

Maximum alarm (= factory setting): 22 mA

–Failsafe mode with user-selectable value: 3.59 to 22.5 mA

•Local display

–Status signal (in accordance with NAMUR Recommendation NE 107)

–Plain text display

•Operating tool via digital communication (HART, PROFIBUS PA, FOUNDATION Fieldbus) or service interface (CDI)

–Status signal (in accordance with NAMUR Recommendation NE 107)

–Plain text display

Linearization |

The linearization function of the device allows the conversion of the measured value into any unit of |

|

|

length or volume. Linearization tables for calculating the volume in cylindrical tanks are pre- |

|

|

programmed. Other linearization tables of up to 32 value pairs can be entered manually or semi- |

|

|

automatically. |

|

|

|

|

Galvanic isolation |

All circuits for the outputs are galvanically isolated from each other. |

|

|

|

|

Protocol-specific data |

HART |

|

|

|

|

|

Manufacturer ID |

17 (0x11) |

|

|

|

|

Device type ID |

0x1128 |

|

|

|

|

HART specification |

7.0 |

|

|

|

|

Device description files (DTM, DD) |

Information and files under: |

|

|

• www.endress.com |

|

|

• www.fieldcommgroup.org |

|

|

|

|

HART load |

min. 250 Ω |

|

|

|

Endress+Hauser |

17 |

|

|

Micropilot FMR51, FMR52 |

|

|

|

|

|

|

|

HART device variables |

The measured values can be freely assigned to the device variables. |

|

|

Measured values for PV (primary variable) |

|

|

• Level linearized |

|

|

• Distance |

|

|

• Electronic temperature |

|

|

• Relative echo amplitude |

|

|

• Area of incoupling |

|

|

• Analog output adv. diagnostics 1 |

|

|

• Analog output adv. diagnostics 2 |

|

|

Measured values for SV, TV, FV (second, third and fourth variable) |

|

|

• Level linearized |

|

|

• Distance |

|

|

• Electronic temperature |

|

|

• Terminal voltage |

|

|

• Relative echo amplitude |

|

|

• Absolute echo amplitude |

|

|

• Area of incoupling |

|

|

• Analog output adv. diagnostics 1 |

|

|

• Analog output adv. diagnostics 2 |

|

|

|

|

Supported functions |

• Burst mode |

|

|

• Additional transmitter status |

|

|

|

Wireless HART data

Minimum start-up voltage |

16 V |

|

|

Start-up current |

3.6 mA |

|

|

Start-up time |

65 s |

|

|

Minimum operating voltage |

14.0 V |

|

|

Multidrop current |

4.0 mA |

|

|

Set-up time |

15 s |

|

|

PROFIBUS PA

Manufacturer ID |

17 (0x11) |

|

|

|

|

Ident number |

0x1559 |

|

|

|

|

Profile version |

3.02 |

|

|

|

|

GSD file |

Information and files under: |

|

|

• www.endress.com |

|

GSD file version |

||

• www.profibus.org |

||

|

||

|

|

|

Output values |

Analog Input: |

|

|

• Level linearized |

|

|

• Distance |

|

|

• Terminal voltage |

|

|

• Electronic temperature |

|

|

• Absolute echo amplitude |

|

|

• Relative echo amplitude |

|

|

• Analog output adv. diagnostics 1 |

|

|

• Analog output adv. diagnostics 2 |

Digital Input:

•Digital output AD 1

•Digital output AD 2

•Switch output

18 |

Endress+Hauser |

Micropilot FMR51, FMR52

Input values |

Analog Output: |

|

|

• |

Analog value from PLC (for sensor block external pressure to compensate gas phase |

|

|

effects) |

|

• |

Analog value from PLC to be indicated on the display |

Digital Output:

•Extended diagnostic block

•Level limiter

•Sensor block measurement on

•Sensor block save history on

•Status output

Supported functions • Identification & Maintenance

Einfachste Geräteidentifizierung seitens des Leitsystems und des Typenschildes

•Automatic Ident Number Adoption

GSD compatibility mode with respect to the preceding product Micropilot M FMR2xx

•Physical Layer Diagnostics

Installation check of the PRFIBUS segment and the Micropilot FMR5x via the terminal voltage and telegram surveillance.

•PROFIBUS Up-/Download

Up to 10 times faster writing and reading of parameters via PROFIBUS up-/download

•Condensed Status

Simple and self-explanatory diagnostic information by categorization of occurring diagnostic messages.

FOUNDATION Fieldbus

Manufacturer ID |

0x452B48 |

|

|

|

|

Device type |

0x1028 |

|

|

|

|

Device Revision |

0x01 |

|

|

|

|

DD Revision |

Information and files can be found: |

|

|

• www.endress.com |

|

CFF Revision |

||

• www.fieldcommgroup.org |

||

|

||

|

|

|

Device Tester Version (ITK Version) |

6.0.1 |

|

|

|

|

ITK Test Campaign Number |

IT085300 |

|

|

|

|

Link Master (LAS) capable |

yes |

|

|

|

|

Link Master / Basic Device selectable |

yes; default: Basic Device |

|

|

|

|

Node address |

Default: 247 (0xF7) |

|

|

|

|

Features supported |

Following methods are supported: |

|

|

• Restart |

|

|

• ENP Restart |

|

|

• Setup |

|

|

• Linearization |

|

|

• Self Check |

|

|

|

|

Virtual Communication Relationships (VCRs) |

|

|

|

|

|

Number of VCRs |

44 |

|

|

|

|

Number of Link Objects in VFD |

50 |

|

|

|

|

Permanent entries |

1 |

|

|

|

|

Client VCRs |

0 |

|

|

|

|

Server VCRs |

10 |

|

|

|

|

Source VCRs |

43 |

|

|

|

|

Sink VCRs |

0 |

|

|

|

|

Subscriber VCRs |

43 |

|

|

|

|

Publisher VCRs |

43 |

|

|

|

|

Device Link Capabilities |

|

|

|

|

|

Slot time |

4 |

|

|

|

Endress+Hauser |

19 |

Micropilot FMR51, FMR52

Min. inter PDU delay |

8 |

|

|

Max. response delay |

20 |

|

|

Transducer Blocks

Block |

Content |

Output values |

|

|

|

Setup Transducer Block |

Contains all parameters for a standard commissioning |

• Level or volume 1) |

|

procedure |

(Channel 1) |

|

|

• Distance (Channel 2) |

|

|

|

Advanced Setup |

Contains all parameters for a more detailed |

no output values |

Transducer Block |

configuration of the device |

|

|

|

|

Display Transducer Block |

Contains all parameters for the configuration of the |

no output values |

|

display module |

|

|

|

|

Diagnostic Transducer |

Contains diagnostic information |

no output values |

Block |

|

|

|

|

|

Advanced Diagnostic |

Contains parameters for the Advanced Diagnostic |

no output values |

Transducer Block |

|

|

|

|

|

Expert Configuration |

Contains parameters which require detailed knowledge |

no output values |

Transducer Block |

of the functionalities of the device |

|

|

|

|

Expert Information |

Contains information about the state of the device |

no output values |

Transducer Block |

|

|

|

|

|

Service Sensor Transducer |

Contains parameters which can only be operated by |

no output values |

Block |

Endress+Hauser service personnel |

|

|

|

|

Service Information |

Contains information on the state of device which is |

no output values |

Transducer Block |

relevant for service operations |

|

|

|

|

Data Transfer Transducer |

Contains parameters which allow to backup the device |

no output values |

Block |

configuration in the display module and to restore it |

|

|

into the device. Access to these parameters is restricted |

|

|

to the Endress+Hauser service. |

|

|

|

|

1)depending on the configuration of the block

Function Blocks

Block |

Content |

Number of |

Number of |

Execution |

Functionality |

|

|

permanent |

instantiable |

time |

|

|

|

blocks |

blocks |

|

|

|

|

|

|

|

|

Resource Block |

The Resource Block contains all the |

1 |

0 |

- |

enhanced |

|

data that uniquely identifies the |

|

|

|

|

|

field device. It is an electronic |

|

|

|

|

|

version of a nameplate of the |

|

|

|

|

|

device. |

|

|

|

|

|

|

|

|

|

|

Analog Input |

The AI block takes the |

2 |

3 |

25 ms |

enhanced |

Block |

manufacturer's input data, selected |

|

|

|

|

|

by channel number, and makes it |

|

|

|

|

|

available to other function blocks at |

|

|

|

|

|

its output. |

|

|

|

|

|

|

|

|

|

|

Discrete Input |

The DI block takes a discrete input |

1 |

2 |

20 ms |

standard |

Block |

value (e.g. indication of an level |

|

|

|

|

|

limit), and makes it available to |

|

|

|

|

|

other function blocks at its output. |

|

|

|

|

|

|

|

|

|

|

Mutiple |

This block is used to transfer analog |

1 |

0 |

20 ms |

standard |

Analog Output |

data from the bus into the device |

|

|

|

|

Block |

|

|

|

|

|

|

|

|

|

|

|

Mutiple |

This block is used to transfer |

1 |

0 |

20 ms |

standard |

Discrete |

discrete data from the bus to the |

|

|

|

|

Output Block |

device. |

|

|

|

|

|

|

|

|

|

|

20 |

Endress+Hauser |

Micropilot FMR51, FMR52

Block |

Content |

Number of |

Number of |

Execution |

Functionality |

|

|

permanent |

instantiable |

time |

|

|

|

blocks |

blocks |

|

|

|

|

|

|

|

|

PID Block |

The PID block serves as |

1 |

1 |

25 ms |

standard |

|

proportional-integralderivative |

|

|

|

|

|

controller and is used almost |

|

|

|

|

|

universally to do closed-loop- |

|

|

|

|

|

control in the field including |

|

|

|

|

|

cascade and feedforward. |

|

|

|

|

|

|

|

|

|

|

Arithmetic |

This block is designed to permit |

1 |

1 |

25 ms |

standard |

Block |

simple use of popular measurement |

|

|

|

|

|

math functions. The user does not |

|

|

|

|

|

have to know how to write |

|

|

|

|

|

equations. The math algorithm is |

|

|

|

|

|

selected by name, chosen by the |

|

|

|

|

|

user for the function to be done. |

|

|

|

|

|

|

|

|

|

|

Signal |

The signal characterizer block has |

1 |

1 |

25 ms |

standard |

Characterizer |

two sections, each with an output |

|

|

|

|

Block |

that is a non-linear function of the |

|

|

|

|

|

respective input. The non-linear |

|

|

|

|

|

function is determined by a single |

|

|

|

|

|

look-up table with 21 arbitrary x-y |

|

|

|

|

|

pairs. |

|

|

|

|

|

|

|

|

|

|

Input Selector |

The input selector block provides |

1 |

1 |

25 ms |

standard |

Block |

selection of up to four inputs and |

|

|

|

|

|

generates an output based on the |

|

|

|

|

|

configured action. This block |

|

|

|

|

|

normally receives its inputs from AI |

|

|

|

|

|

blocks. The block performs |

|

|

|

|

|

maximum, minimum, middle, |

|

|

|

|

|

average and ‘first good’ signal |

|

|

|

|

|

selection. |

|

|

|

|

|

|

|

|

|

|

Integrator |

The Integrator Function Block |

1 |

1 |

25 ms |

standard |

Block |

integrates a variable as a function |

|

|

|

|

|

of the time or accumulates the |

|

|

|

|

|

counts from a Pulse Input block. |

|

|

|

|

|

The block may be used as a |

|

|

|

|

|

totalizer that counts up until reset |

|

|

|

|

|

or as a batch totalizer that has a |

|

|

|

|

|

setpoint, where the integrated or |

|

|

|

|

|

accumulated value is compared to |

|

|

|

|

|

pre-trip and trip settings, |

|

|

|

|

|

generating discrete signals when |

|

|

|

|

|

these settings are reached. |

|

|

|

|

|

|

|

|

|

|

Analog Alarm |

|

1 |

1 |

25 ms |

standard |

Block |

|

|

|

|

|

|

|

|

|

|

|

Up to 20 blocks can be instantiated in the device altogether, including the blocks already instantiated on delivery.

Endress+Hauser |

21 |

Micropilot FMR51, FMR52

Power supply

Terminal assignment

Terminal assignment 2-wire: 4-20 mA HART

|

|

|

2 |

|

A |

|

B |

|

|

|

|

|

||

1 |

|

+ |

- |

|

2 |

1 |

|||

|

2 |

|||

+ |

|

|||

|

|

|||

- |

|

|

||

|

|

|

||

1 |

|

|

3 |

|

|

|

|

||

|

|

|

A0036498 |

|

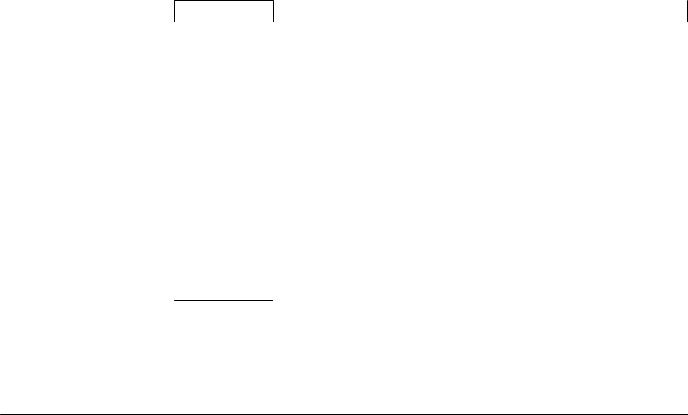

2 Terminal assignment 2-wire: 4-20 mA HART |

|

|

||

A Without integrated overvoltage protection

BWith integrated overvoltage protection

1 Connection 4-20 mA HART passive: terminals 1 and 2, without integrated overvoltage protection 2 Connection 4-20 mA HART passive: terminals 1 and 2, with integrated overvoltage protection

3Terminal for cable screen

Block diagram 2-wire: 4-20 mA HART

3 |

|

|

4 |

2 |

|

|

5 |

1 |

|

|

6 |

|

|

|

|

+ |

+ 1 |

I |

|

- |

- |

|

|

2 |

|

||

|

|

|

Y |

A0036499

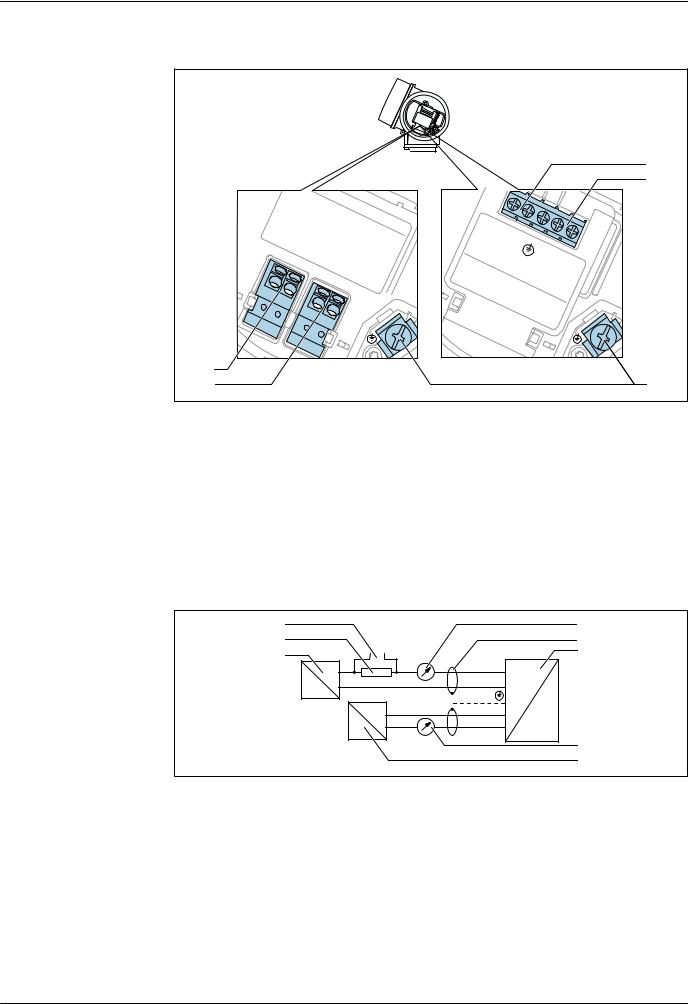

3 Block diagram 2-wire: 4-20 mA HART

1 Active barrier with power supply (e.g. RN221N); observe terminal voltage

2HART communication resistor (≥ 250 Ω); observe maximum load

3 Connection for Commubox FXA195 or FieldXpert SFX350/SFX370 (via VIATOR Bluetooth modem) 4 Analog display device; observe maximum load

5 Cable screen; observe cable specification

6Measuring device

22 |

Endress+Hauser |

Micropilot FMR51, FMR52

Terminal assignment 2-wire: 4-20 mA HART, switch output

|

|

|

|

|

3 |

|

|

|

|

|

4 |

A |

|

|

|

B |

|

|

|

|

|

|

|

3 |

|

4 |

|

3 |

|

+ |

|

|

|

||

|

|

|

|

||

- |

|

|

+ |

|

|

|

1 |

|

- |

||

|

|

1 |

|||

|

|

2 |

|||

|

|

|

2 |

||

|

|

+ |

|

||

|

|

|

|

||

|

|

- |

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

1 |

|

|

|

|

5 |

|

|

|

|

|

A0036500 |

4 Terminal assignment 2-wire: 4-20 mA HART, switch output A Without integrated overvoltage protection

BWith integrated overvoltage protection

1Connection 4-20 mA HART passive: terminals 1 and 2, without integrated overvoltage protection

2 Connection switch output (Open Collector): terminals 3 and 4, without integrated overvoltage protection 3 Connection switch output (Open Collector): terminals 3 and 4, with integrated overvoltage protection

4 Connection 4-20 mA HART passive: terminals 1 and 2, with integrated overvoltage protection

5Terminal for cable screen

Block diagram 2-wire: 4-20 mA HART, switch output

3 |

|

|

4 |

2 |

|

|

5 |

1 |

|

|

6 |

|

|

|

|

+ |

+ 1 |

I |

|

- |

- |

|

|

2 |

|

||

+ |

3 |

Y |

|

- |

|||

4 |

|

||

|

|

7

A0036501

5 Block diagram 2-wire: 4-20 mA HART, switch output

1 Active barrier with power supply (e.g. RN221N); observe terminal voltage

2HART communication resistor (≥ 250 Ω); observe maximum load

3 Connection for Commubox FXA195 or FieldXpert SFX350/SFX370 (via VIATOR Bluetooth modem) 4 Analog display device; observe maximum load

5 Cable screen; observe cable specification

6Measuring device

7Switch output (Open Collector)

Endress+Hauser |

23 |

|

|

|

|

|

Micropilot FMR51, FMR52 |

|

Terminal assignment 2-wire: 4-20 mA HART, 4-20 mA |

|

|

||||

|

|

|

|

|

|

3 |

|

|

|

|

|

|

4 |

A |

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

3 |

|

4 |

|

3 |

|

|

+ |

|

|

|

||

|

|

|

|

|

||

|

- |

|

|

+ |

|

|

|

|

1 |

|

- |

||

|

|

|

1 |

|||

|

|

|

2 |

|||

|

|

|

|

2 |

||

|

|

|

+ |

|

||

|

|

|

|

|

||

|

|

|

- |

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

1 |

|

|

|

|

|

5 |

|

|

|

|

|

|

A0036500 |

6 Terminal assignment 2-wire: 4-20 mA HART, 4-20 mA |

|

|

||||

A Without integrated overvoltage protection

BWith integrated overvoltage protection

1Connection current output 1, 4-20 mA HART passive: terminals 1 and 2, without integrated overvoltage protection

2 Connection current output 2, 4-20 mA: terminals 3 and 4, without integrated overvoltage protection

3Connection current output 2, 4-20 mA: terminals 3 and 4, with integrated overvoltage protection

4Connection current output 1, 4-20 mA HART passive: terminals 1 and 2, with integrated overvoltage protection

5Terminal for cable screen

Block diagram 2-wire: 4-20 mA HART, 4-20 mA

3 |

|

|

4 |

2 |

|

|

5 |

1 |

|

|

6 |

|

|

|

|

+ |

+ 1 |

I |

|

- |

- |

|

|

2 |

|

||

+ |

+ 3 |

Y |

- |

- 4 |

|

7

8

A0036502

7 Block diagram 2-wire: 4-20 mA HART, 4-20 mA

1 Active barrier with power supply (e.g. RN221N); observe terminal voltage

2HART communication resistor (≥ 250 Ω); observe maximum load

3 Connection for Commubox FXA195 or FieldXpert SFX350/SFX370 (via VIATOR Bluetooth modem) 4 Analog display device; observe maximum load

5 Cable screen; observe cable specification

6Measuring device

7Analog display device; observe maximum load

8Active barrier with power supply (e.g. RN221N), current output 2; observe terminal voltage

24 |

Endress+Hauser |

Micropilot FMR51, FMR52

Terminal assignment 4-wire: 4-20 mA HART (10.4 to 48 VDC)

1 |

2 |

|

|

L+ |

|

|

|

L- |

3 |

|

|

|

4 |

||

|

|

+ |

|

|

|

- |

|

|

|

|

2 |

3 |

1

A0036516

8 Terminal assignment 4-wire: 4-20 mA HART (10.4 to 48 VDC)

1 Connection 4-20 mA HART (active): terminals 3 and 4 2 Connection supply voltage: terminals 1 and 2

3Terminal for cable screen

Block diagram 4-wire: 4-20 mA HART (10.4 to 48 VDC)

3 |

|

4 |

2 |

|

5 |

1 |

|

6 |

|

|

|

+ 3 |

I |

|

- |

|

|

4 |

|

|

L+ |

1 |

Y |

L- |

2 |

|

|

|

|

|

|

7 |

A0036526

9 Block diagram 4-wire: 4-20 mA HART (10.4 to 48 VDC)

1Evaluation unit, e.g. PLC

2HART communication resistor (≥ 250 Ω); observe maximum load

3 Connection for Commubox FXA195 or FieldXpert SFX350/SFX370 (via VIATOR Bluetooth modem) 4 Analog display device; observe maximum load

5 Cable screen; observe cable specification

6Measuring device

7Supply voltage; observe terminal voltage, observe cable specification

Endress+Hauser |

25 |

Micropilot FMR51, FMR52

Terminal assignment 4-wire: 4-20 mA HART (90 to 253 VAC)

1 |

2 |

|

|

L |

|

|

|

N |

|

|

|

|

3 |

4 |

|

|

|

+ |

|

|

|

- |

|

|

|

|

2 |

3 |

1

A0036519

10 Terminal assignment 4-wire: 4-20 mA HART (90 to 253 VAC)

1 Connection 4-20 mA HART (active): terminals 3 and 4 2 Connection supply voltage: terminals 1 and 2

3Terminal for cable screen

LCAUTION

To ensure electrical safety:

Do not disconnect the protective connection.

Disconnect the supply voltage before disconnecting the protective earth.

Connect protective earth to the internal ground terminal (3) before connecting the supply voltage. If necessary, connect the potential matching line to the external ground terminal.

In order to ensure electromagnetic compatibility (EMC): Do not only ground the device via the protective earth conductor of the supply cable. Instead, the functional grounding must also be connected to the process connection (flange or threaded connection) or to the external ground terminal.

An easily accessible power switch must be installed in the proximity of the device. The power switch must be marked as a disconnector for the device (IEC/EN61010).

26 |

Endress+Hauser |

Micropilot FMR51, FMR52

Block diagram 4-wire: 4-20 mA HART (90 to 253 VAC)

3 |

|

4 |

2 |

|

5 |

1 |

|

6 |

|

|

|

+ 3 |

I |

|

- |

|

|

4 |

|

|

|

|

|

L |

1 |

Y |

N |

2 |

|

|

|

7 |

A0036527

11 Block diagram 4-wire: 4-20 mA HART (90 to 253 VAC)

1Evaluation unit, e.g. PLC

2HART communication resistor (≥ 250 Ω); observe maximum load

3 Connection for Commubox FXA195 or FieldXpert SFX350/SFX370 (via VIATOR Bluetooth modem) 4 Analog display device; observe maximum load

5 Cable scree; observe cable specification

6Measuring device

7Supply voltage; observe terminal voltage, observe cable specification

Terminal assignment PROFIBUS PA / FOUNDATION Fieldbus

|

|

|

|

|

3 |

|

|

|

|

|

4 |

A |

|

|

|

B |

|

|

|

|

|

|

|

3 |

|

4 |

|

3 |

|

+ |

|

|

|

||

|

|

|

|

||

- |

|

|

+ |

|

|

|

1 |

|

- |

||

|

|

1 |

|||

|

|

2 |

|||

|

|

|

2 |

||

|

|

+ |

|

||

|

|

|

|

||

|

|

- |

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

1 |

|

|

|

|

5 |

|

|

|

|

|

A0036500 |

12 Terminal assignment PROFIBUS PA / FOUNDATION Fieldbus A Without integrated overvoltage protection

BWith integrated overvoltage protection

1Connection PROFIBUS PA / FOUNDATION Fieldbus: terminals 1 and 2, without integrated overvoltage protection

2 Connection switch output (Open Collector): terminals 3 and 4, without integrated overvoltage protection

3Connection switch output (Open Collector): terminals 3 and 4, with integrated overvoltage protection

4 Connection PROFIBUS PA / FOUNDATION Fieldbus: terminals 1 and 2, with integrated overvoltage protection

5Terminal for cable screen

Endress+Hauser |

27 |

Micropilot FMR51, FMR52

Block diagram PROFIBUS PA / FOUNDATION Fieldbus

2 |

3 |

1 |

+ 1 |

I |

|

- |

|

|

2 |

|

|

+ 3 |

Y |

|

- |

4 |

|

4

A0036530

13 Block diagram PROFIBUS PA / FOUNDATION Fieldbus

1Cable screen; observe cable specifications

2 Connection PROFIBUS PA / FOUNDATION Fieldbus

3Measuring device

4Switch output (open collector)

28 |

Endress+Hauser |

Micropilot FMR51, FMR52

Connection examples for the switch output

For HART devices, the switch output is available as an option. See product structure, feature 20: "Power Supply, Output", option B: "2-wire; 4-20 mA HART, switch output"