Endress+Hauser FTL33 Specifications

TI01148F/00/EN/03.16

71325893

Products |

Solutions |

Services |

|

|

|

Technical Information

Liquiphant FTL33

Vibronic

Point level switch for liquids in the food sector

Application

The Liquiphant FTL33 is a point level switch for universal use in all liquids. It is used preferably in storage tanks, mixing vessels and pipes, where the internal and external hygiene requirements are particularly stringent.

Ideal for applications in which float switches or conductive, capacitance and optical sensors have been used up to now. The Liquiphant FTL33 also works in areas where these measuring principles are not suitable due to conductivity, buildup, turbulence, flow conditions or air bubbles.

The Liquiphant FTL33 can be used for process temperatures up to:

•100 °C (212 °F), CIP-capable

•150 °C (302 °F), CIPand SIP-capable

Your benefits

•3-A and EHEDG certificates

•CIP and SIP cleanability guaranteed up to 150 °C (302 °F) continuous temperature

•All-metal separation, no plastics in the process

•Robust stainless steel housing, optionally available with M12x1 connector with IP69 protection (optional)

•External function test with test magnet

•Onsite function check possible thanks to LED indication

•Compact design for easy installation even in confined conditions or hard-to-access areas

Liquiphant FTL33

Table of contents

Document information . . . . . . . . . . . . . . . . . . . . . . . 3

Document conventions . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Function and system design . . . . . . . . . . . . . . . . . . . 4

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Switch output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Residual ripple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Cable entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Cable specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . 10

Performance characteristics . . . . . . . . . . . . . . . . . . 11

Reference operating conditions . . . . . . . . . . . . . . . . . . . 11 Switch point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Non-repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Influence of ambient temperature . . . . . . . . . . . . . . . . . 11 Influence of medium temperature . . . . . . . . . . . . . . . . . . 11 Influence of medium pressure . . . . . . . . . . . . . . . . . . . . 11 Switching delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Switch-on delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Measuring frequency . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Measured error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . 12 Length of connecting cable . . . . . . . . . . . . . . . . . . . . . . 14

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . 15 Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Climate class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Shock resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . 16 Reverse polarity protection . . . . . . . . . . . . . . . . . . . . . . 16 Short-circuit protection . . . . . . . . . . . . . . . . . . . . . . . . 16

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Process temperature range . . . . . . . . . . . . . . . . . . . . . . 17 Process pressure range . . . . . . . . . . . . . . . . . . . . . . . . . 17 Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 State of aggregation . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Viscosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Solids contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Lateral loading capacity . . . . . . . . . . . . . . . . . . . . . . . . 17

Mechanical construction . . . . . . . . . . . . . . . . . . . . 18

Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 Tuning fork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 Sensor type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 Surface roughness . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Operability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

LED display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 Function test with test magnet . . . . . . . . . . . . . . . . . . . . 26

Certificates and approvals . . . . . . . . . . . . . . . . . . . 27

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 EAC conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 RCM-Tick marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 Approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 Hygienic compatibility . . . . . . . . . . . . . . . . . . . . . . . . . 27 Hygiene approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Overfill prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 CRN approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Inspection certificates . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Manufacturer declarations . . . . . . . . . . . . . . . . . . . . . . 28 Pressure Equipment Directive . . . . . . . . . . . . . . . . . . . . 28 Other standards and guidelines . . . . . . . . . . . . . . . . . . . 28

Ordering information . . . . . . . . . . . . . . . . . . . . . . |

29 |

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . 29 Services (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Process adapter M24 . . . . . . . . . . . . . . . . . . . . . . . . . . 29 Weld-in adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 Slotted nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 Plug-in jack, cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 Additional accessories . . . . . . . . . . . . . . . . . . . . . . . . . 32

Supplementary documentation . . . . . . . . . . . . . . . 33

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 33 Additional documentation . . . . . . . . . . . . . . . . . . . . . . 33 Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2 |

Endress+Hauser |

Liquiphant FTL33

Document information

Document conventions |

Safety symbols |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

Symbol |

Meaning |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DANGER! |

|

|

|

DANGER |

|

|

|

||

|

|

|

|

|

|

This symbol alerts you to a dangerous situation. Failure to avoid this situation |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

A0011189-EN |

will result in serious or fatal injury. |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING! |

|

|

|

WARNING |

|

||||

|

|

|

|

This symbol alerts you to a dangerous situation. Failure to avoid this situation |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

A0011190-EN |

can result in serious or fatal injury. |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAUTION! |

|

|

|

CAUTION |

|

|

|||

|

|

|

|

This symbol alerts you to a dangerous situation. Failure to avoid this situation |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

A0011191-EN |

can result in minor or medium injury. |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE! |

|

|

|

NOTICE |

|

|

|

|

|

|

|

|

|

This symbol contains information on procedures and other facts which do not |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

A0011192-EN |

result in personal injury. |

|||

|

|

|

|

|

|

|

|

|

Electrical symbols

Symbol Meaning

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a grounding

A0011200 system.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

A0011199

Symbols for certain types of information

Symbol Meaning

Permitted

Indicates procedures, processes or actions that are permitted.

A0011182

Forbidden

Indicates procedures, processes or actions that are forbidden.

A0011184

Tip

Indicates additional information.

A0011193

Reference to documentation

Refers to the corresponding device documentation.

A0011194

Reference to page

Refers to the corresponding page number.

A0011195

Symbols in graphics

Symbol |

Meaning |

|

|

1, 2, 3 ... |

Item numbers |

|

|

A, B, C, ... |

Views |

|

|

Endress+Hauser |

3 |

|

Liquiphant FTL33 |

|

|

|

Function and system design |

|

|

Measuring principle |

A piezoelectric drive causes the tuning fork of the Liquiphant FTL33 to vibrate at its resonance |

|

frequency. When the tuning fork is immersed in a liquid, its intrinsic frequency changes due to the |

|

change in density of the surrounding medium. The electronics system in the point level switch |

|

monitors the resonance frequency and indicates whether the tuning fork is vibrating in air or is |

|

covered by liquid. |

|

A signal is output via the DC-PNP or AC/DC electrical connection. |

|

|

Measuring system |

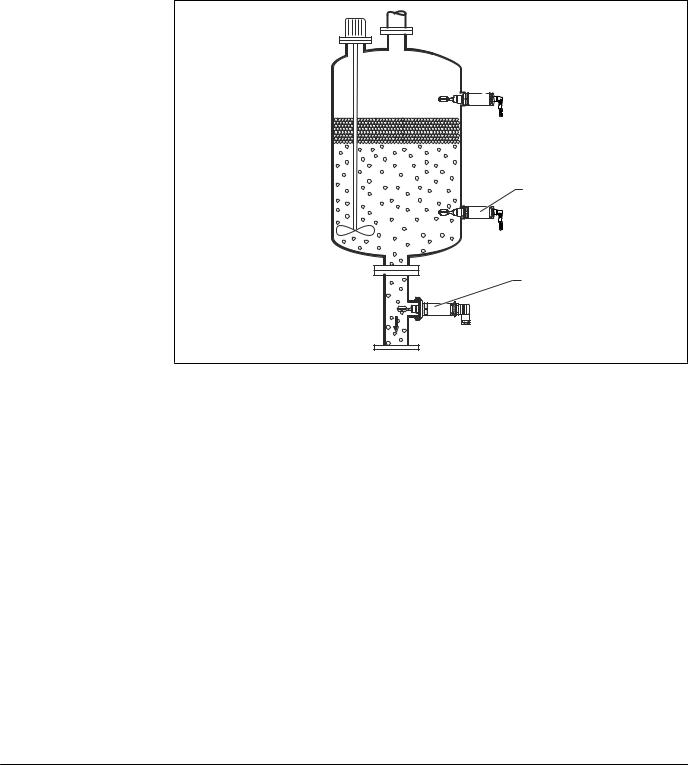

The measuring system consists of a Liquiphant FTL33 point level switch, e.g. for connection to |

|

programmable logic controllers (PLC), a mini-contactor or solenoid valve. |

1

1

2

3

A0020911

1 Overfill prevention or upper level detection MAX (maximum safety)

2Lower level detection MIN (minimum safety)

3Lower level detection MIN, e.g. dry running protection for pump

4 |

Endress+Hauser |

Liquiphant FTL33

|

Input |

|

|

|

|

Measured variable |

Density |

|

|

|

|

Measuring range |

> 0.7 g/cm³ (optionally available: > 0.5 g/cm³) |

|

|

Output |

|

|

|

|

Switch output |

Switching behavior: On/Off |

|

|

Function |

|

|

3-wire DC-PNP: |

|

|

Positive voltage signal at the switch output of the electronics (PNP), switching capacity 200 mA |

|

|

2-wire AC/DC: |

|

|

Load switching in the power supply line, switching capacity 250 mA |

|

|

|

|

Operating modes |

The device has two operating modes: maximum safety (MAX) and minimum safety (MIN). |

|

|

By choosing the corresponding operating mode, the user ensures that the device also switches in a |

|

|

safety-oriented manner even in an alarm condition, e.g. if the power supply line is disconnected. |

|

|

• Maximum safety (MAX) |

|

|

The device keeps the electronic switch closed as long as the liquid level is below the fork. Sample |

|

|

application: overfill prevention |

|

|

• Minimum safety (MIN) |

|

|

The device keeps the electronic switch closed as long as the fork is immersed in liquid. Sample |

|

|

application: Dry running protection for pumps |

|

|

The electronic switch opens if the limit is reached, if a fault occurs or the power fails (quiescent |

|

|

current principle). |

|

|

Power supply |

|

|

|

|

Supply voltage |

DC-PNP: |

10 to 30 V DC, 3-wire |

|

AC/DC: |

20 to 253 V AC/DC, 2-wire |

|

|

|

Power consumption |

DC-PNP: |

< 975 mW |

|

AC/DC: |

< 850 mW |

|

|

|

Current consumption |

DC-PNP: |

< 15 mA |

|

AC/DC: |

< 3.8 mA |

|

|

|

Residual ripple |

DC-PNP: |

5 Vss 0 to 400 Hz |

|

AC/DC: |

— |

|

|

|

Electrical connection |

Two electronic versions and three different connections are available for the device. |

|

• Electronic version 3-wire DC-PNP with connection; M12 plug, valve plug or cable

• Electronic version 2-wire AC/DC with connection; valve plug or cable A fine-wire fuse is necessary for operation: 500 mA slow-blow.

Electronic version 3-wire DC-PNP

3-wire DC-PNP is preferably used in conjunction with programmable logic controllers (PLC), DI modules as per EN 61131-2. Positive signal at the switch output of the electronics (PNP).

Voltage source: non-hazardous contact voltage or Class 2 circuit (North America).

Endress+Hauser |

5 |

Liquiphant FTL33

Connection with M12 plug

Depending on the analysis of the switch outputs, the device works in the MAX (maximum safety) or MIN (minimum safety) mode.

A cable is optionally available for order, see "Accessories" section → 31.

A cable is optionally available for order, see "Accessories" section → 31.

3-wire DC-PNP |

|

|

Operating mode |

|

|

M12 connector |

MAX |

|

|

MIN |

|

|

2 |

1 |

|

2 |

1 |

|

3 |

4 |

|

3 |

4 |

|

K |

0.5A |

K |

0.5A |

|

|

|

|

|

||

|

L– |

L+ |

|

L– |

L+ |

|

A0022901 |

|

|

|

|

|

1 |

2 |

|

1 |

4 |

|

1 |

2 |

|

1 |

4 |

Symbols Description

Yellow LED (ye) lit

Yellow LED (ye) not lit

Kexternal load

Function monitoring with M12 connector

Using a two-channel analysis, function monitoring of the sensor can be implemented in addition to level monitoring, e.g. per relay switch, PLC, AS-i Bus I/O module, …).

When both outputs are connected, the MIN and MAX outputs assume opposite states when the device is operating fault-free (XOR). In the event of an alarm condition or a line break, both outputs are deenergized.

Connection with 3-wire DC-PNP for function monitoring based on XOR logic |

Yellow LED |

Red LED |

|

(ye) |

(rd) |

||

|

|||

|

|

|

2 |

1 |

1 |

2 |

|

Sensor covered |

|

|||

3 |

4 |

|

||

1 |

4 |

|||

|

|

|||

K1 |

K2 |

1 |

2 |

|

Sensor exposed |

|

|||

|

|

|

||

|

0.5A |

1 |

4 |

|

|

|

|

||

|

|

1 |

2 |

|

L– |

L+ |

Fault |

|

|

|

A0022917 |

1 |

4 |

|

Symbols |

Description |

|

|

|

|

LED lit |

|

|

|

|

LED not lit |

|

|

|

|

Fault or warning |

|

|

K1 / K2 external load

6 |

Endress+Hauser |

Liquiphant FTL33

Connection with valve plug or cable

Depending on the assignment of the connector or the wiring of the cable, the device works in either the MAX or MIN operating mode.

3-wire DC-PNP |

|

|

|

Operating mode |

|

|

Valve plug |

MAX |

|

MIN |

|||

|

1 |

|

2 |

|

1 |

2 |

|

|

|

|

|

||

|

|

|

|

+ |

|

|

|

|

3 |

K |

|

3 |

+ |

|

|

|

– |

|

|

|

|

|

|

|

K |

|

|

|

|

|

|

|

– |

|

|

|

|

0.5A |

|

|

|

|

|

|

|

|

0.5A |

|

|

|

|

|

|

|

|

|

L– |

|

L+ |

|

L– |

L+ |

|

3 |

|

2 |

|

2 |

3 |

A0022900 |

|

|

|

|

||

|

|

|

|

|

|

|

|

3 |

|

2 |

|

2 |

3 |

Cable (cannot be |

|

|

3 |

|

|

3 |

dismantled) |

2 |

|

|

|

2 |

|

|

1 |

|

1 |

|||

|

+ |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

+ |

|

K |

|

0.5A |

0.5A |

K |

|

|

|

|

||||

A0022902 |

|

|

L– L+ |

|

L+ |

L– |

|

|

|

|

|

|

|

Core colors: |

3 |

|

2 |

|

2 |

3 |

1 = BK (black) |

|

|

|

|

||

|

|

|

|

|

|

|

2 = GR (gray) |

3 |

|

2 |

|

2 |

3 |

3 = BN (brown) |

|

|

|

|

|

|

Ground = GNYE (green- |

|

|

|

|

|

|

yellow) |

|

|

|

|

|

|

Symbols Description |

|

|

|

|

|

|

Yellow LED (ye) lit |

|

|

|

|

|

|

Yellow LED (ye) not lit |

|

|

|

|

|

|

Kexternal load

Endress+Hauser |

7 |

Liquiphant FTL33

Electronic version 2-wire AC/DC

The load is switched via an electronic switch directly in the power supply circuit. Always connect in series with a load!

Not suitable for connection to low-voltage PLC inputs!

Selection tool for relays

P/S |

|

|

|

|

|

|

|

|

|

|

|

|

2.7 |

|

|

|

|

|

|

|

|

|

|

|

|

2.5 |

|

|

|

|

|

|

|

|

|

|

|

|

2.3 |

|

|

|

|

|

|

|

|

|

|

|

|

2.1 |

|

|

|

|

|

|

|

|

|

|

|

|

1.9 |

|

|

|

|

|

|

|

|

|

|

|

|

1.7 |

|

|

|

|

|

|

|

|

|

|

|

|

1.5 |

|

|

|

|

|

|

|

|

|

|

|

|

1.3 |

P1 |

|

|

|

|

|

|

|

|

|

|

|

1.1 |

|

|

|

|

|

|

|

|

|

|

|

|

0.9 |

|

|

|

|

|

|

|

|

|

|

|

|

0.7 |

P2 |

|

|

|

|

|

|

|

|

|

|

|

0.5 |

|

|

|

|

|

|

|

|

|

|

|

U |

|

20 |

24 |

27 |

43 |

48 |

53 |

60 |

110 |

121 |

207 |

230 |

253 |

A0023486

1 Minimum rated power of the load P/S Rated power in [W] / [VA]

UOperating voltage in [V]

Item |

Supply voltage |

|

Rated power |

|

|

|

|

||

min |

|

max |

||

|

|

|

||

|

|

|

|

|

P1 |

24 V |

> 1.3 VA |

|

< 6 VA |

110 V |

> 1.5 VA |

|

< 27.5 VA |

|

AC mode |

|

|||

230 V |

> 2.5 VA |

|

< 57.5 VA |

|

|

|

|||

|

|

|

|

|

P2 |

24 V |

> 0.7 W |

|

< 6 W |

48 V |

> 0.9 W |

|

< 12 W |

|

DC mode |

|

|||

60 V |

> 1.5 W |

|

< 15 W |

|

|

|

|||

|

|

|

|

|

Relays with a lower rated power can be operated by means of an RC module connected in parallel (optional).

8 |

Endress+Hauser |

Liquiphant FTL33

Connection with valve plug or cable

Depending on the assignment of the connector or the wiring of the cable, the device works in either the MAX or MIN operating mode.

When the cable is wired, one wire of the cable does not have any function in each of the operating modes (brown in the case of MIN, and gray in the case of MAX). The cable with no function must be secured against inadvertent contact.

2-wire AC/DC |

|

Operating mode |

|

|

Valve plug |

MAX |

|

MIN |

|

|

1 |

|

1 |

2 |

|

|

|

||

|

3 |

|

|

|

|

|

|

>20 V |

|

|

>20 V |

|

|

|

|

|

K |

|

K |

|

|

|

|

|

|

0.5A |

|

0.5A |

|

|

L1/L+ |

N/L– |

L1/L+ |

N/L– |

|

|

A0021219 |

|

A0021220 |

A0022900 |

1 |

3 |

1 |

2 |

|

||||

|

|

|

||

|

1 |

3 |

1 |

2 |

|

|

A0021418 |

|

A0021420 |

Cable (cannot be dismantled) |

3 |

|

|

3 |

2 |

1 |

|

2 |

1 |

|

|

|

||

|

>20 V |

>20 V |

||

0.5A |

K |

K |

0.5A |

|

|

|

|||

A0022902 |

L1/L+ |

N/L– |

N/L– |

L1/L+ |

|

|

|

|

|

|

|

A0022161 |

|

A0022225 |

Core colors: |

1 |

3 |

1 |

2 |

1 = BK (black) |

|

|

|

|

2 = GR (gray) |

1 |

3 |

1 |

2 |

3 = BN (brown) |

|

A0021418 |

|

A0021420 |

Ground = GNYE (green-yellow) |

|

|

|

|

Symbols Description

Yellow LED (ye) lit

Yellow LED (ye) not lit

Kexternal load

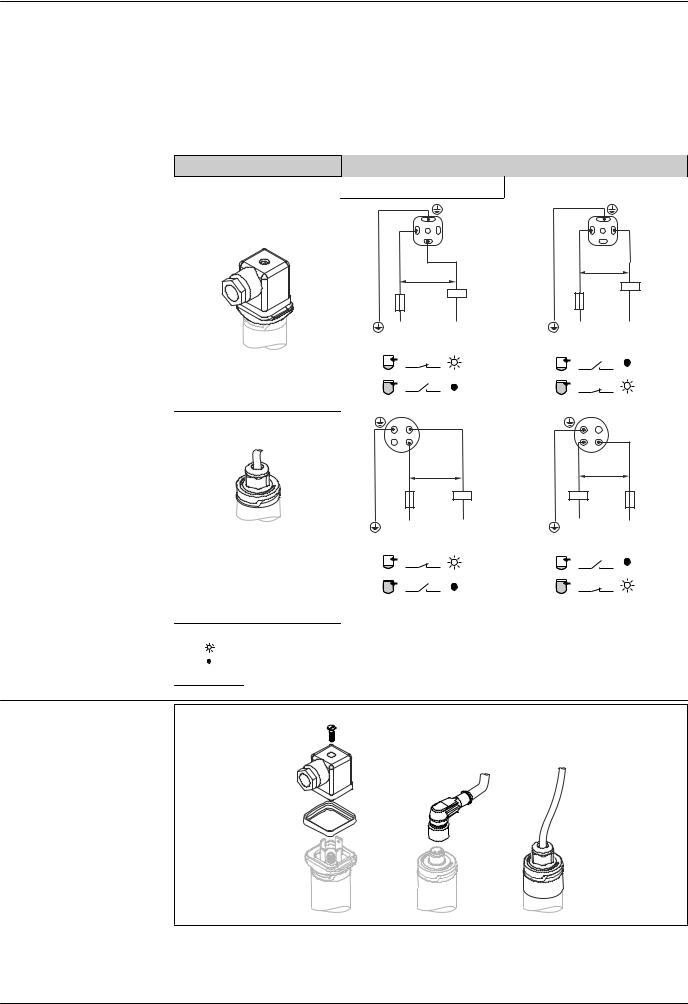

Cable entry

A B C

A0020928

A Valve plug (M16x1.5; NPT ½"; QUICKON)

BM12 connector

CCable 5 m (16 ft); secured in place on delivery and cannot be disassembled

Endress+Hauser |

9 |

Liquiphant FTL33

Cable specification |

• Valve plug |

|

– Cable cross-section: max. 1.5 mm2 (AWG 16) |

|

– Ø 3.5 to 8 mm (0.14 to 0.26 in) |

|

• M12 connector: IEC 60947-5-2 |

|

• Cable (3LPE) |

|

– Cable cross-section: 0.75 mm2 (AWG 20) |

|

– Ø 6 to 8 mm (0.24 to 0.31 in) |

|

– Material: PUR |

|

|

Overvoltage protection |

Overvoltage category II |

10 |

Endress+Hauser |

Liquiphant FTL33

Performance characteristics

Reference operating |

Ambient temperature: |

+25 °C (+77 °F) |

conditions |

Process pressure: |

1 bar (14.5 psi) |

|

||

|

Fluid: |

Water (density: approx. 1 g/cm³, viscosity 1 mm2/s) |

|

Medium temperature: |

25 °C (77 °F) |

|

Density setting: |

> 0.7 g/cm³ |

|

Switching time delay: |

Standard (0.5 s, 1 s) |

|

|

|

Switch point |

13 mm (0.51 in)±1 mm |

|

|

|

|

Hysteresis |

max. 3 mm (0.12 in) |

|

|

|

|

Non-repeatability |

±1 mm (0.04 in) in accordance with DIN 61298-2 |

|

|

|

|

Influence of ambient |

Negligible |

|

temperature |

|

|

|

|

|

Influence of medium |

–25 µm (984 µin)/°C |

|

temperature |

|

|

|

|

|

Influence of medium |

–20 µm (787 µin)/bar |

|

pressure |

|

|

|

|

|

Switching delay |

• 0.5 s when tuning fork is covered |

|

|

• 1.0 s when tuning fork is uncovered |

|

|

• Optionally available: 0.2 s; 1.5 s or 5 s (when the tuning fork is covered and uncovered) |

|

|

|

|

Switch-on delay |

max. 3 s |

|

|

|

|

Measuring frequency |

approx. 1 100 Hz in air |

|

|

|

|

Measured error |

In event of device change: ±2 mm (0.08 in) as per DIN 61298-2 |

|

Endress+Hauser |

11 |

Loading...

Loading...