Page 1

Final Datasheet Please read the Important Notice and Warnings at the end of this document Revision 2.1

www.infineon.com 2019-07-15

IM231-L6S1B / IM231-L6T2B

CIPOS™ Micro IPM 600V/6A

IM231-L6S1B / IM231-L6T2B

Description

IM231-L6-series 3-phase Intelligent Power Modules (IPM) are designed for high-efficiency appliance motor drives

such as air-conditioner fans and refrigerator compressors. These advanced IPMs, available in both surface

mount and through-hole configurations, offer a combination of low V

CE(sat)

TRENCHSTOPTM IGBT6 technology and

the industry benchmark rugged half-bridge drivers. The IPMs have several protection features including precise

overcurrent protection and temperature feedback.

Features

600V 3-phase inverter including gate drivers &

bootstrap function

Low V

CE(sat)

TRENCHSTOP™ IGBT6

Temperature monitor

Accurate overcurrent shutdown (±5%)

Fault reporting and programmable fault clear

Advanced input filter with shoot-through

protection

Optimized dV/dt for loss and EMI trade offs

Open-emitter for single and leg-shunt current

sensing

3.3V logic compatible

Isolation 2000VRMS, 1min

SOP 29x12 DIP 29x12

Potential Applications

Air-conditioner fans

Refrigerator compressors

Ventilation fans & blower fans

Low power motor drives

Product validation

Qualified for industrial applications according to the relevant tests of JEDEC47/20/22.

Table 1 Part Ordering Table

Base Part Number

Package Type

Standard Pack

Orderable Part Number

Form

Quantity

IM231-L6T2B

DIP 29x12

Tube

240

IM231L6T2BAKMA1

IM231-L6S1B

SOP 29x12

Tube

240

IM231L6S1BALMA1

IM231-L6S1B

SOP 29x12

Tape & Reel

500

IM231L6S1BAUMA1

Page 2

Final Datasheet 2 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Table of contents

Table of contents

Description 1

Features 1

Potential Applications ..................................................................................................................... 1

Product validation .......................................................................................................................... 1

Table of contents ............................................................................................................................ 2

1 Internal Electrical Schematic .......................................................................................... 3

2 Pin Configuration........................................................................................................... 4

2.1 Pin Assignment ........................................................................................................................................ 4

2.2 Pin Descriptions....................................................................................................................................... 5

3 Absolute Maximum Rating .............................................................................................. 7

3.1 Module ..................................................................................................................................................... 7

3.2 Inverter .................................................................................................................................................... 7

3.3 Control ..................................................................................................................................................... 7

4 Thermal Characteristics ................................................................................................. 8

5 Recommended Operating Conditions ............................................................................... 9

6 Static Parameters ......................................................................................................... 10

6.1 Inverter .................................................................................................................................................. 10

6.2 Control ................................................................................................................................................... 10

7 Dynamic Parameters ..................................................................................................... 12

7.1 Inverter .................................................................................................................................................. 12

7.2 Control ................................................................................................................................................... 12

8 Thermistor Characteristics ............................................................................................ 13

9 Mechanical Characteristics and Ratings........................................................................... 14

10 Qualification Information .............................................................................................. 15

11 Diagrams & Tables ........................................................................................................ 16

11.1 TC Measurement Point ........................................................................................................................... 16

11.2 Backside Curvature Measurement Points ............................................................................................ 16

11.3 Input-Output Logic Table ...................................................................................................................... 17

11.4 Switching Time Definitions ................................................................................................................... 18

12 Application Guide ......................................................................................................... 19

12.1 Typical Application Schematic ............................................................................................................. 19

12.2 TJ vs TTH .................................................................................................................................................. 19

12.3 –VS Immunity ......................................................................................................................................... 20

13 Package Outline ........................................................................................................... 21

13.1 DIP 29x12 ............................................................................................................................................... 21

13.2 SOP 29x12 .............................................................................................................................................. 22

14 Revision History ........................................................................................................... 23

Page 3

Final Datasheet 3 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

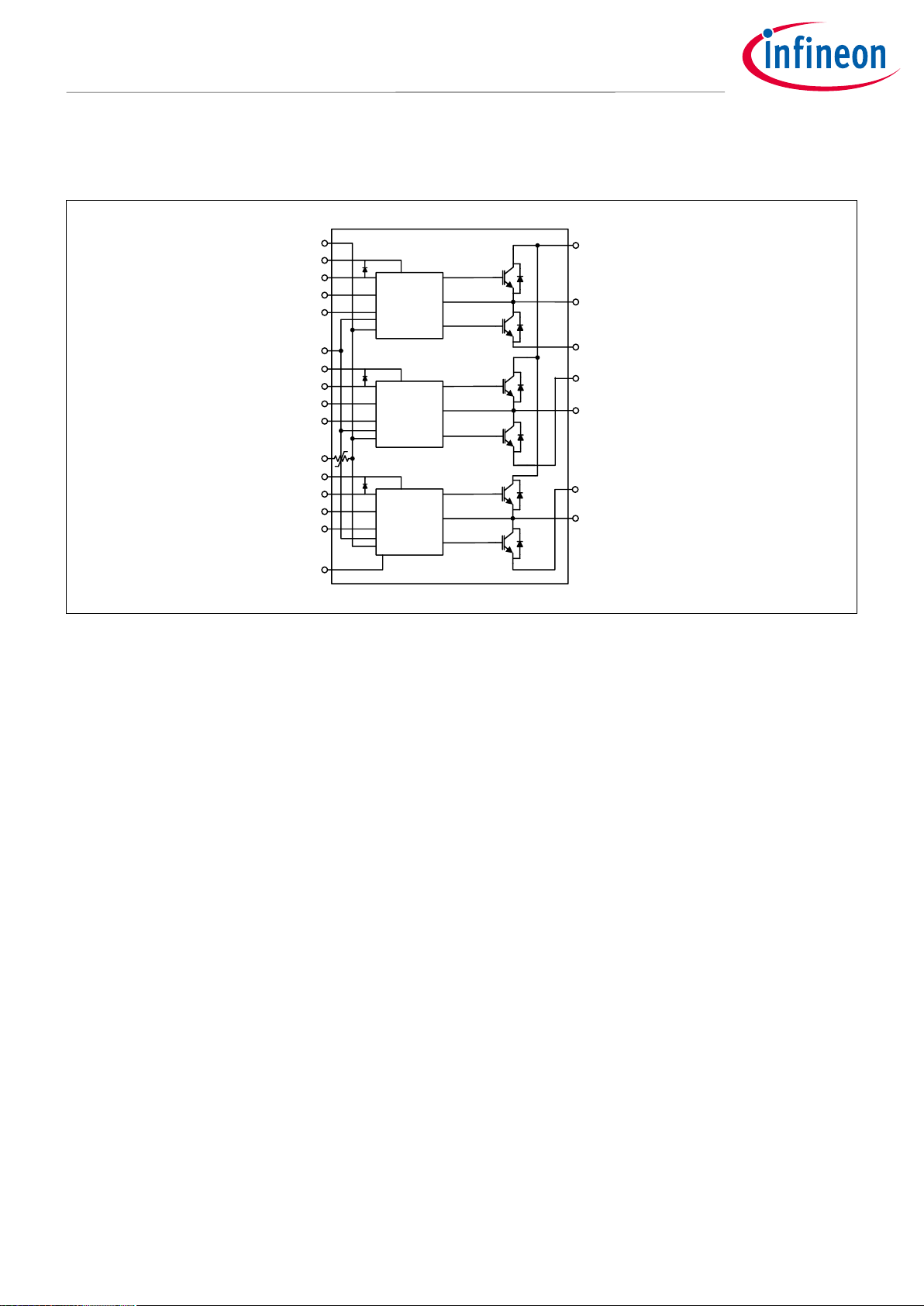

Internal Electrical Schematic

1 Internal Electrical Schematic

Figure 1 Internal electrical schematic.

Half-Bridge

HVIC

Half-Bridge

HVIC

Half-Bridge

HVIC

1 COM

2 V

B1

3 V

CC1

4 HIN1

5 LIN1

6 RFE

7 V

B2

8 V

CC2

9 HIN2

10 LIN2

11 VTH

12 V

B3

13 V

CC3

14 HIN3

15 LIN3

16 ITRIP

17 V+

18 U/V

S1

19 V

R1

20 V

R2

21 V/V

S2

22 V

R3

23 W/V

S3

Page 4

Final Datasheet 4 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Pin Configuration

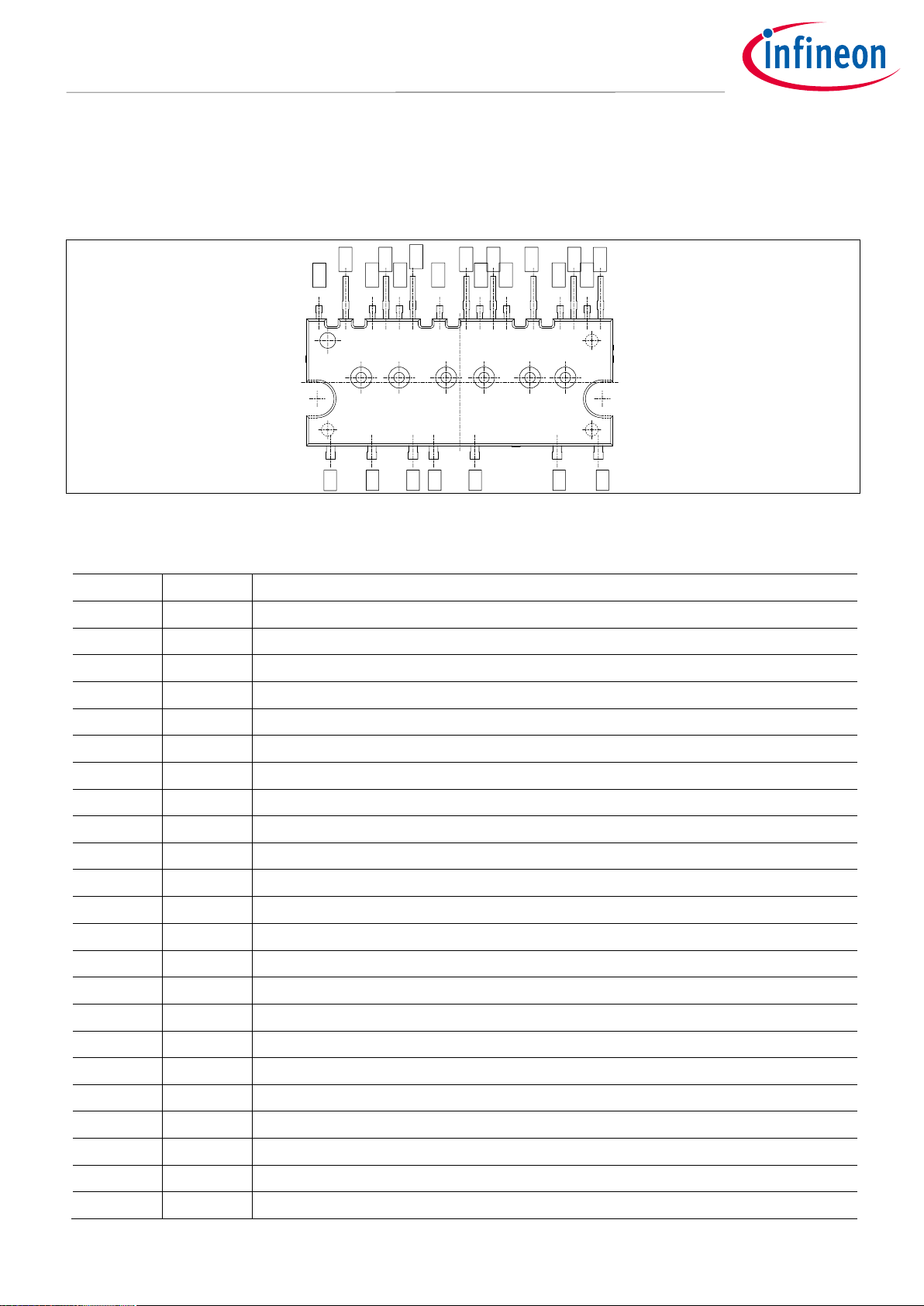

2 Pin Configuration

2.1 Pin Assignment

e

1

2

3

4

5

7

8

9

10

12

13

14

15

16

23

22

21

20

19

18

17

11

6

Figure 2 Module pinout

Table 2 Pin Assignment

Pin

Name

Description

1

COM

Logic ground

2

VB1

High side floating supply voltage 1

3

V

DD1

Low side control supply 1

4

HIN1

Logic Input for high side gate driver - Phase 1

5

LIN1

Logic Input for low side gate driver - Phase 1

6

RFE

RCIN / Fault / Enable

7

VB2

High side floating supply voltage 2

8

V

DD2

Low side control supply 2

9

HIN2

Logic input for high side gate driver - Phase 2

10

LIN2

Logic input for low side gate driver - Phase 2

11

VTH

Thermistor output

12

VB3

High side floating supply voltage 3

13

V

DD3

Low side control supply 3

14

HIN3

Logic Input for high side gate driver - Phase 3

15

LIN3

Logic Input for low side gate driver - Phase 3

16

ITRIP

Current protection pin

17

V+

Dc bus voltage positive

18

U/VS1

Output - phase 1, high side floating supply offset 1

19

VR1

Phase 1 low side emitter

20

VR2

Phase 2 low side emitter

21

V/VS2

Output - phase 2, high side floating supply offset 2

22

VR3

Phase 3 low side emitter

23

W/VS3

Output – phase 3, high side floating suppyl offset 3

Page 5

Final Datasheet 5 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Pin Configuration

2.2 Pin Descriptions

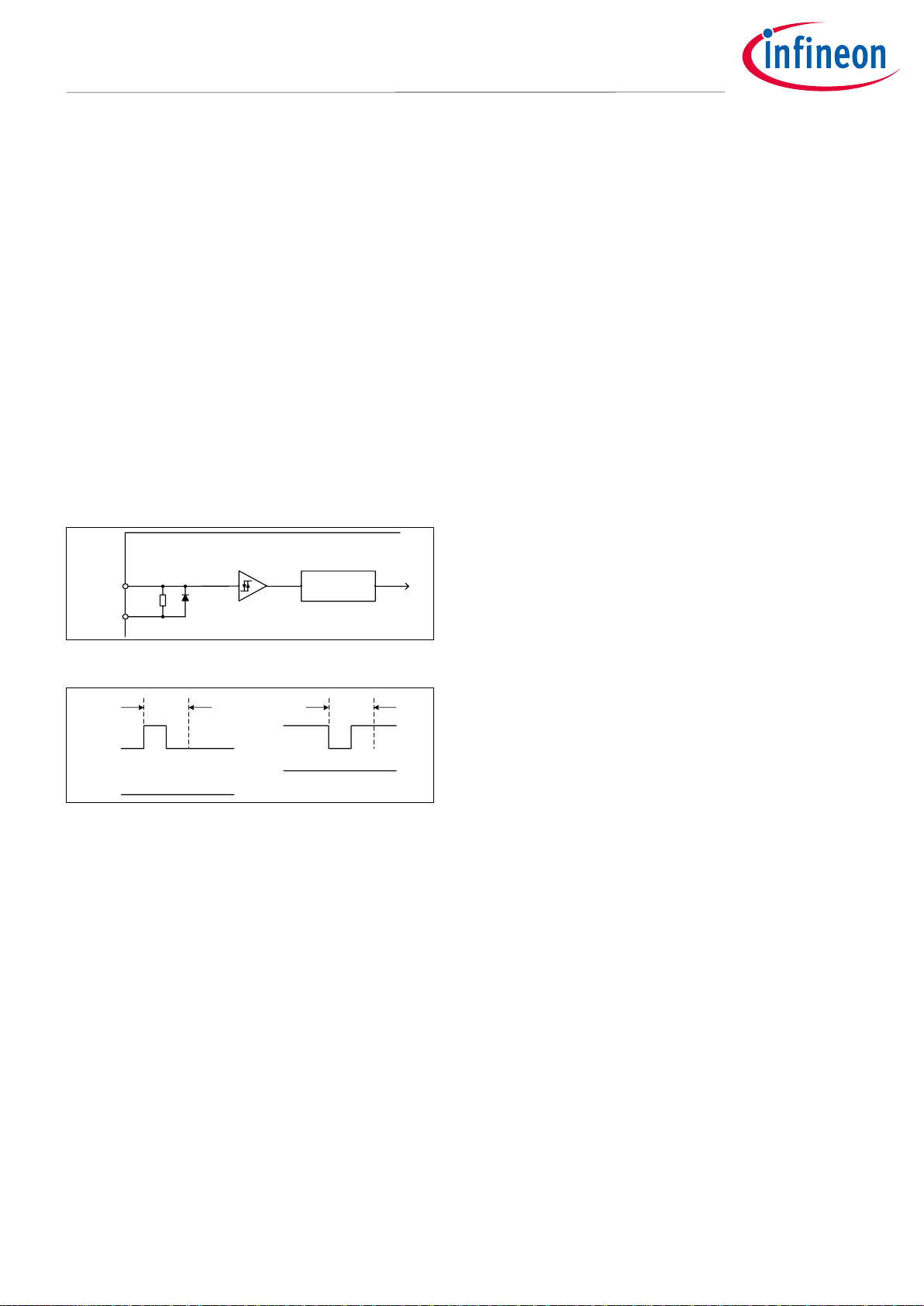

HIN(1,2,3) and LIN(1,2,3) (Low side and high side

control pins)

These pins are positive logic and they are

responsible for the control of the integrated IGBT.

The Schmitt-trigger input thresholds of them are

such to guarantee LSTTL and CMOS compatibility

down to 3.3V controller outputs. Pull-down resistor

of about 800k is internally provided to pre-bias

inputs during supply start-up and an ESD diode is

provided for pin protection purposes. Input

Schmitt-trigger and noise filter provide beneficial

noise rejection to short input pulses.

The noise filter suppresses control pulses which are

below the filter time T

FILIN

. The filter acts according

to Figure 4.

CIPOS

TM

INPUT NOISE

FILTER

M8.0

Schmitt-Trigger

SWITCH LEVEL

V

IH

; V

IL

COM

HINx

LINx

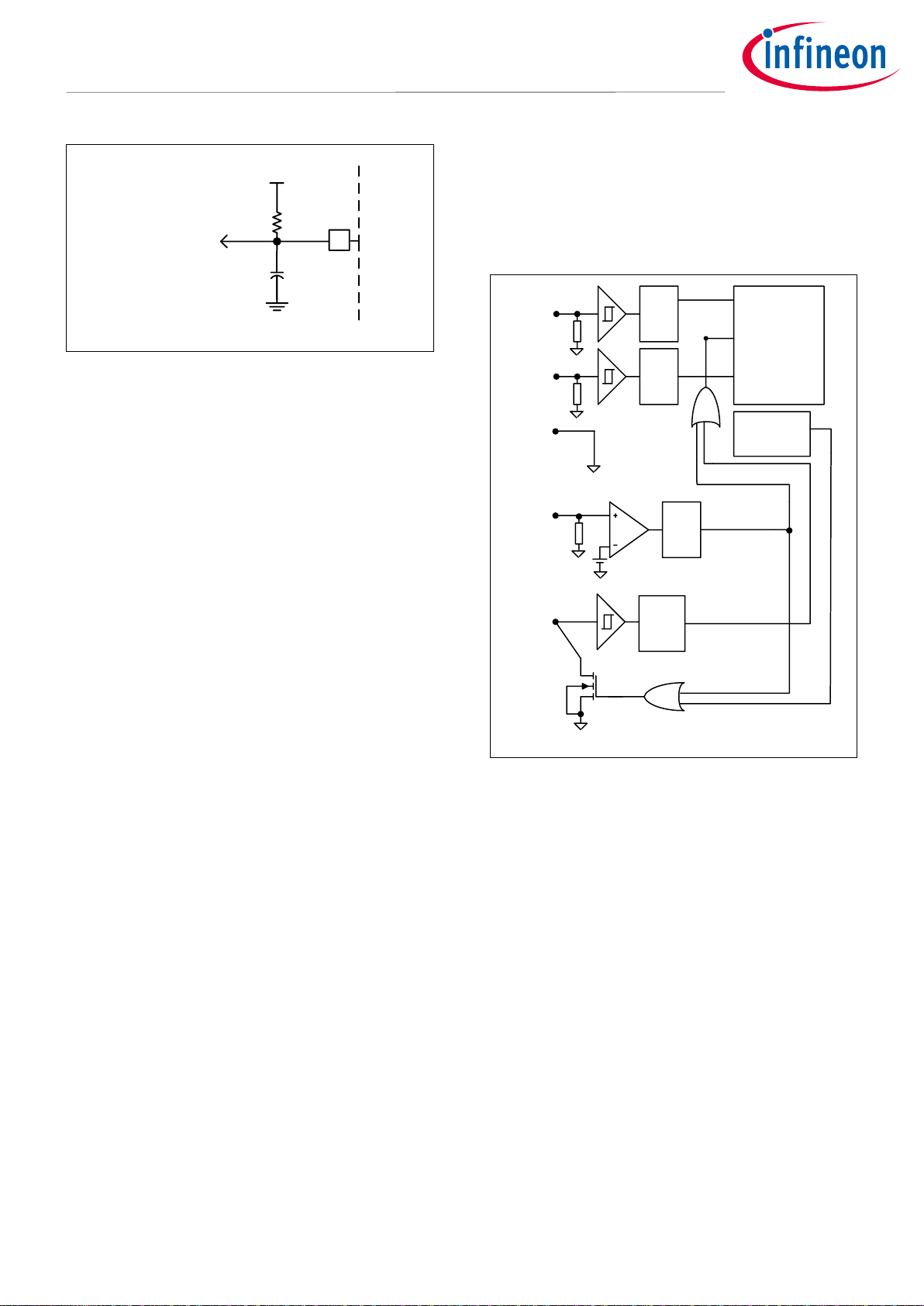

Figure 3 Input pin structure

HIN

LIN

HO

LO

low

high

t

FILIN

t

FILIN

a) b)

HIN

LIN

HO

LO

Figure 4 Input filter timing diagram

The integrated gate drive provides additionally a

shoot through prevention capability which avoids

the simultaneous on-state of the high-side and lowside switch of the same inverter phase. A minimum

deadtime insertion of typically 300ns is also

provided by driver IC, in order to reduce crossconduction of the external power switches.

VDD, COM (Low side control supply and reference)

VDD is the control supply and it provides power both

to input logic and to the output power stage. Input

logic is referenced to COM ground.

The under-voltage circuit enables the device to

operate at power on when a supply voltage of at

least a typical voltage of V

DDUV+

= 11.1V is present.

The IC shuts down all the gate drivers power

outputs, when the VDD supply voltage is below V

DDUV-

= 10.9V. This prevents the external power switches

from critically low gate voltage levels during onstate and therefore from excessive power

dissipation.

V

B(1,2,3)

and V

S(1,2,3)

(High side supplies)

VB to VS is the high side supply voltage. The high side

circuit can float with respect to COM following the

external high side power device emitter voltage.

Due to the low power consumption, the floating

driver stage is supplied by integrated bootstrap

circuit.

The under-voltage detection operates with a rising

supply threshold of typical V

BSUV+

= 11.1V and a falling

threshold of V

BSUV-

= 10.9V.

V

S(1,2,3)

provide a high robustness against negative

voltage in respect of COM. This ensures very stable

designs even under rough conditions.

V

R(1,2,3)

(Low side emitters)

The low side emitters are available for current

measurements of each phase leg. It is

recommended to keep the connection to pin COM as

short as possible in order to avoid unnecessary

inductive voltage drops.

VTH (Thermistor output)

A UL certified NTC resistor is integrated in the

module with one terminal of the chip connected to

COM and the other to VTH. When pulled up to a rail

voltage such as VDD or 3.3V by a resistor, the VTH pin

provides an analog voltage signal corresponding to

the temperature of the thermistor.

RFE (RCIN / Fault / Enable)

The RFE pin combines 3 functions in one pin: RCIN or

RC-network based programmable fault clear timer,

fault output and enable input.

The RFE pin is normally connected to an RC network

on the PCB per the schematic in Figure 5. Under

normal operating conditions, R

RCIN

pulls the RFE pin

to 3.3V, thus enabling all the functions in the IPM.

The microcontroller can pull this pin low to disable

the IPM functionality. This is is the Enable function.

Page 6

Final Datasheet 6 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Pin Configuration

Figure 5 Typical PCB circuit connected to

the RFE pin

The Fault function allows the IPM to report a Fault

condition to the microncontroller by pulling the RFE

pin low in one of two situations. The first is an undervoltage condition on VDD and the second is when the

ITRIP pin sees a voltage rising above V

IT,TH+

.

The programmable fault clear timer function

provides a means of automatically re-enabling the

module operation a preset amount of time (T

FLT-CLR

)

after the fault condition has disappeared. Figure 6

shows the RFE-related circuit block diagram inside

the IPM.

The length of TFLT-CLR can be determined by using

the formula below.

V

RFE

(t) = 3.3V * (1 – e

-t/RC

)

T

FLT-CLR

= -R

RCIN

* C

RCIN

* ln(1-V

IN,TH+

/3.3V)

For example, if R

RCIN

is 1.2MΩ and C

RCIN

is 1nF, the T

FLT-

CLR

is about 1.7ms with V

IN,TH+

of 2.5V. It is also

important to note that C

RCIN

needs to be minimized in

order to make sure it is fully discharged in case of

over current event.

Since the ITRIP pin has a 500ns input filter, it is

appropriate to ensure that C

RCIN

will be discharged

below V

IN,TH-

by the open-drain MOSFET, after 350ns.

Therefore, the max C

RCIN

can be calculated as:

V

RFE

(t) = 3.3V * e

-t/RC

< V

IN,TH-

C

RCIN

< 500ns / ( - ln (V

IN,TH-

/ 3.3V) * R

RFE_ON

)

Consider V

IN,TH-

of 0.8V and R

RFE_ON

of 50ohm, C

RCIN

should be less than 7nF. It is also suggested to use a

R

RCIN

of between 0.5MΩ and 2MΩ.

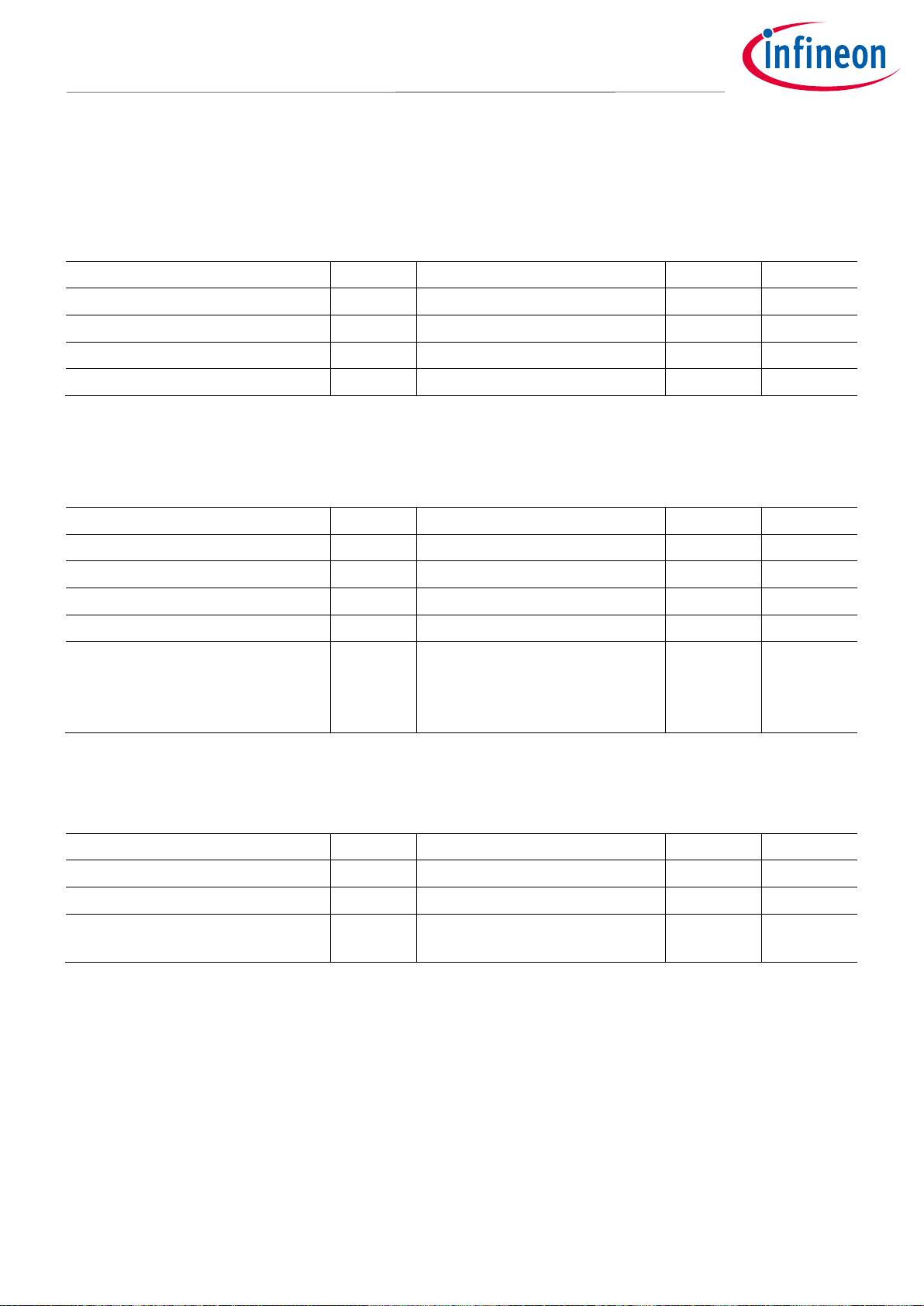

Figure 6 RFE internal circuit structure

U/VS1, V/VS2, W/V

S3

(High side emitter and low side

collector)

These pins are motor U, V, W input pins.

V+ (Positive bus input voltage, Pin 23)

The high side IGBTs are connected to the bus

voltage. It is noted that the bus voltage should not

exceed 450V.

Input

Noise

filter

Input

Noise

filter

Deadtime &

Shoot-Through

Prevention

ITRIP

Noise

filter

HIN

LIN

COM

ITRIP

RFE

Noise

filter

VDD

Undervoltage

detection

+3.3V

R

RCIN

C

RCIN

6 RFE

IM231-L6

To Microcontroller

Page 7

Final Datasheet 7 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Absolute Maximum Rating

3 Absolute Maximum Rating

3.1 Module

Table 3

Parameter

Symbol

Condition

Units

Storage temperature

T

STG

-40 ~ 150

°C

Operating case temperature

TC

-40 ~ 125

°C

Operating junction temperature

TJ

-40 ~ 150

°C

Isolation test voltage

V

ISO

1min, RMS, f = 60Hz

2000

V

3.2 Inverter

Table 4

Parameter

Symbol

Condition

Units

Max. blocking voltage

V

CES/VRRM

600

V

Output current

I

O

TC = 25°C 6 A

Peak output current

IOP

TC = 25°C, tp < 1ms

9

A

Peak power dissipation per IGBT

P

tot

TC = 25°C

10.5

W

Short circuit withstand time

T

SC

VDC = 360V, TJ = 150°C, VDD = 15V

Allowed number of short

circuits: <1000, time between

short circuits: >1s

3

μs

3.3 Control

Table 5

Parameter

Symbol

Condition

Units

Low side control supply voltage

V

DD

-0.3 ~ 20

V

Input voltage

V

IN

LIN, HIN,ITRIP,RFE

-0.3 ~ V

DD

V

High side floating supply voltage

(VB reference to VS)

V

BS

-0.3 ~ 20

V

Page 8

Final Datasheet 8 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Thermal Characteristics

4 Thermal Characteristics

Table 6

Parameter

Symbol

Conditions

Min.

Typ.

Max.

Units

Junction-case thermal

resistance, all IGBTs

operating (per module)

R

TH(J-C)_M

-

2.4

2.8

°C/W

Junction-case thermal

resistance, all diodes

operating (per module)

R

TH(J-C)D_M

-

2.5

2.9

°C/W

Single IGBT thermal

resistance, junction-case

R

TH(J-C)

High side V-phase

IGBT

-

8.4

9.6

°C/W

Single diode thermal

resistance, junction-case

R

TH(J-C)D

High side V-phase

diode

-

9.3

10.8

°C/W

Page 9

Final Datasheet 9 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Recommended Operating Conditions

5 Recommended Operating Conditions

Table 7

Parameter

Symbol

Min.

Typ.

Max.

Units

Positive DC bus input voltage

V+ - - 450

V

Low side control supply voltage

VDD

13.5

-

16.5

V

High side floating supply voltage

V

BS

12.5

-

17.5

V

Input voltage (LIN,HIN,ITRIP,RFE)

V

IN

0 - 5

V

PWM carrier frequency

F

PWM -

20 - kHz

External dead time between HIN & LIN

DT 1 - - µs

Voltage between COM and V

R(1,2,3)

V

COMR

-5 - 5

V

Minimum input pulse width

PW

IN(ON)

,

PW

IN(OFF)

1 - -

µs

Page 10

Final Datasheet 10 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Static Parameters

6 Static Parameters

6.1 Inverter

(VDD-COM) = (VB - VS) = 15 V. TC = 25°C unless otherwise specified.

Table 8

Parameter

Symbol

Conditions

Min.

Typ.

Max.

Units

Collector-to-emitter

saturation voltage

V

CE(sat)

IC = 1A - 1.2 - V

IC = 3A

-

1.65

2.0

V

IC = 3A, TJ = 150℃

-

1.8 - V

Collector emitter leakage

current

I

CES

VIN = 0V, V+ = 600V

- - 80

µA

VIN = 0V, V+ = 600V, TJ

= 150°C

-

24 - µA

Diode forward voltage

V

F

IC = 1A - 1.2 - V

IC = 3A - 1.6

2.0

V

IC = 3A, TJ = 150℃

-

1.5 - V

6.2 Control

(VDD-COM) = (VB - VS) = 15 V. TC = 25°C unless otherwise specified. The VIN and IIN parameters are referenced to COM

and are applicable to all six channels. The V

DDUV

parameters are referenced to COM. The V

BSUV

parameters are

referenced to VS.

Table 9

Parameter

Symbol

Min.

Typ.

Max.

Units

Logic “1” input voltage (LIN, HIN)

V

IN,TH+

2.2 - -

V

Logic “0” input voltage (LIN, HIN)

V

IN,TH-

- - 0.8

V

VDD/V

BS

supply undervoltage, positive going

threshold

V

DD,UV+

,

V

BS,UV+

9.6

10.4

11.2

V

VDD/VBS supply undervoltage, negative going

threshold

V

DD,UV-

,

V

BS,UV-

8.6

9.4

10.2

V

VDD/VBS supply undervoltage lock-out

hysteresis

V

DDUVH

,

V

BSUVH

-

1.0 - V

RFE positive going threshold

V

RFE+

-

1.9

2.2

V

RFE negative going threshold

V

RFE-

0.8

1.1 - V

ITRIP positive going threshold

V

IT,TH+

0.475

0.500

0.525

V

ITRIP negative going threshold

V

IT,TH-

-

0.430 - V

ITRIP input hysteresis

V

IT,HYS

-

0.07 - V

Quiescent VBS supply current

I

QBS

- - 70

µA

Quiescent VDD supply current per channel

I

QDD

- - 2.6

mA

Input bias current VIN=5V for LIN, HIN

I

IN+

-

6.25

12.5

µA

Input bias current VIN=5V for RFE

I

IN,RFE+

- - 1

µA

Page 11

Final Datasheet 11 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Static Parameters

Parameter

Symbol

Min.

Typ.

Max.

Units

Input bias current VIN=5V for ITRIP

I

ITRIP+

- 5 20

µA

Bootstrap resistance

R

BS

-

200

-

Ω

RFE low on resistance

R

RFE

-

34

60

Ω

Page 12

Final Datasheet 12 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Dynamic Parameters

7 Dynamic Parameters

7.1 Inverter

(VDD-COM) = (VB - VS) = 15 V. TC = 25°C unless otherwise specified.

Table 10

Parameter

Symbol

Conditions

Min.

Typ.

Max.

Units

Input to output turn-on

propagation delay

T

ON

IC = 3A, V+ = 300V

-

641 - ns

Turn-on rise time

T

R

-

37 - ns

Turn-on switching time

T

C(on)

-

135 - ns

Input to output turn-off

propagation delay

T

OFF

IC = 3A, V+ = 300V

-

895 - ns

Turn-off fall time

T

F

-

80 - ns

Turn-off switching time

T

C(off)

-

82 - ns

RFE low to six switch turn-off

propagation delay

T

EN

VIN=0 or VIN=5V,

V

RFE

=5V

-

520 - ns

ITRIP to six switch turn-off

propagation delay

T

ITRIP

V+ = 300V,no cap

on RFE

-

1.3 - µs

Turn-on switching energy

E

ON

IC = 3A, V+ = 300V,

VDD = 15V, L = 5mH

-

86

-

µJ

Turn-off switching energy

E

OFF

-

31

-

Diode reverse recovery energy

E

REC

-

20

-

Diode reverse recovery time

T

RR

-

153 - ns

Turn-on switching energy

E

ON

IC = 3A, V+ = 300V,

VDD = 15V, L = 5mH

TJ = 150°C

-

129

-

µJ

Turn-off switching energy

E

OFF

-

50

-

Diode reverse recovery energy

E

REC

-

51

-

Diode reverse recovery time

T

RR

-

211 - ns

7.2 Control

(VDD-COM) = (VB - VS) = 15V. TC = 25°C unless otherwise specified.

Table 11

Parameter

Symbol

Conditions

Min.

Typ.

Max.

Units

Input filter time (HIN, LIN)

T

FIL,IN

V

IN

= 0 or VIN = 5V

-

300 - ns

Input filter time (ITRIP)

T

FIL,ITRIP

VIN=0 or VIN=5V

-

500 - ns

Internal dead time

DT

IC

V

IN

= 0 or VIN = 5V

-

300 - ns

Matching propagation delay

time (on and off) for same

phase high-side and low-side

M

T

External dead time

> 500ns

- - 50

ns

Page 13

Final Datasheet 13 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Thermistor Characteristics

8 Thermistor Characteristics

Table 12

Parameter

Symbol

Conditions

Min.

Typ.

Max.

Units

Resistance

R

25

TC = 25°C, ±5% tolerance

44.65

47

49.35

kΩ

Resistance

R

125

TC = 125°C

1.27

1.39

1.51

kΩ

B-constant

(25/100)

B

±1% tolerance

-

4006 - K

Temperature

Range

-20 - 150

°C

Figure 7 Thermistor resistance – temperature curve, for R

EXT

=9.76kΩ, and thermistor resistance

variation with temperature.

+3.3V

R

EXT

R

V

TH

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

Thermistor Pin Readout Voltage VTH (V)

Thermistor Temperature TTH (°C)

max

typ

min

T

TH

[℃]

Rmin

[kΩ]

Rtyp

[kΩ]

Rmax

[kΩ]

50

15.448

16.432

17.436

60

10.483

11.194

11.924

70

7.245

7.765

8.302

80

5.092

5.477

5.876

90

3.648

3.937

4.237

100

2.653

2.872

3.101

110

1.957

2.125

2.301

120

1.462

1.592

1.729

125

1.269

1.384

1.505

Page 14

Final Datasheet 14 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Mechanical Characteristics and Ratings

9 Mechanical Characteristics and Ratings

Table 13

Parameter

Symbol

Conditions

Min.

Typ.

Max.

Units

Comparative Tracking

Index

CTI

550 - -

V

Curvature of module

backside

BC

See Figure 9

-50 - 50

µm

Mounting Torque

τ

M3 screw & washer,

thermal grease

0.4

0.8

1.2

Nm

M3 screw & washer,

SIL-PAD 1500ST

-

0.6

1.0

Nm

Weight

W

-

3.0 - g

Page 15

Final Datasheet 15 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Qualification Information

10 Qualification Information

Table 14

UL Certification

File number E252584

Moisture sensitivity level

(SOP 29 x 12 only)

MSL3

RoHS Compliant

Yes

Page 16

Final Datasheet 16 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Diagrams & Tables

11 Diagrams & Tables

11.1 T

C

Measurement Point

Figure 8 T

C

measurement point

11.2 Backside Curvature Measurement Points

Figure 9 Curvature measurement points

12.20 mm

4.5 mm

0.50

0.50

0.50

+-

+

-

0.50

0.50

0.50

0.50

Page 17

Final Datasheet 17 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Diagrams & Tables

11.3 Input-Output Logic Table

Figure 10 Module block diagram

Table 15

RFE

ITRIP

HIN1,2,3

LIN1,2,3

U,V,W

1 0 1 0 V+

1 0 0 1 0 1 0 0 0 ‡ 1 0 1 1 ‡ 1 1 x x

‡

0 x x x ‡

‡ Voltage depends on direction of phase current

Page 18

Final Datasheet 18 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Diagrams & Tables

11.4 Switching Time Definitions

HINx

LINx

i

Cx

v

CEx

0.9V

2.1V

90%

10%

10%

10%

90%

t

off

t

f

t

on

t

r

t

c(off)

t

c(on)

10%

t

rr

10%

Figure 11 Switching times definition

Figure 12 ITRIP time waveform

Figure 13 Output disable timing diagram

RFE

50%

50%

U, V, W

T

EN

I

TRIP

LIN(U, V, W)

HIN(U, V, W)

T

FLT-CLR

50%

50%

U, V, W

50%

T

ITRIP

50%

RFE

50%

T

FLT

Page 19

Final Datasheet 19 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Application Guide

12 Application Guide

12.1 Typical Application Schematic

HVICs

VCC

HIN1

HIN2

HIN3

LIN1

LIN2

LIN3

VTH

VB1

VB2 VB3

U/ VS1

V/ VS2

W/ VS3

Power

Supply

PWMWH

PWMVH

PWMUH

PWMVL

PWMWL

GK

VDC

IU/ISS

VSS

VDD

VSP

SPEED

COMMAND

COM

V+

iMotion™

IMC101T

PWMUL

0.25

CIPOS™ Micro

IM231-x6 Series

VDD

ITRIP

NTC

RFE

VR1

VR2

VR3

MOTOR

Figure 14 Application schematic

12.2 T

J

vs TTH

Figure 15 Typical T

J

vs TTH correlation

90

100

110

120

130

140

150

160

65 70 75 80 85 90 95 100 105 110 115

IGBT Junction Temperature

- °C

Internal Thermistor Temperature Equivalent Read Out - °C

T

J avg

= 1.06 x T

Therm

+ 26.48

Page 20

Final Datasheet 20 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Application Guide

12.3 –V

S

Immunity

Figure 16 Negative transient V

s

SOA for integrated gate driver

-60

-50

-40

-30

-20

-10

0

0 100 200 300 400 500

Time (ns)

V

S

(V)

Page 21

Final Datasheet 21 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Package Outline

13 Package Outline

13.1 DIP 29x12

Dimensions in mm

29.00±0.20

12.00±0.20

(2.275)

(1.165)

#17

#1

#23

#23

#17

(1.165)

1.27x21=26.67±0.30

27.60±0.15

1.95x13=25.35±0.30

2-R1.60

Detail "A"

ECN #

REV. DATE

DESCRIPTION CheckDRG.

SIGNATURE

SIGNATURE

SIGNATURE

SIGNATURE

APPROVED BY

UNIT

DRAWN BY

CHECKED BY

APPROVED BY

TITLE

DATE

A

B

C

D

8 7 6 5 4 3 2 1

ZONE

gEM Electronics Co.,Ltd.

The information contained herein is the exclusive property of GEM and shall not be

distributed, reproduced, or disclosed without prior written permission of GEM.

Polaris Li

A

NEW ISSUE

g

Ivan Yang

Ming Zhou

Polaris.Li HB Yang

G-70218

05/25/2017

B

Remove mark area. Change title. Add note 2 & 3.

DIP23P Case Outline

Detail "A"

6X Retractable Pin

5°

6°

5°

6°

R0.10 (ALL)

16-Max 0.70

16-0.50±0.10

#1

7-Max 0.80

7-0.60±0.10

(0.10)

(14.00)

14.00±0.30

(1.85)

(R0.40)

3.15±0.20

(R0.40)

0.50

+0.10

-0.05

3.00±0.30

LEAD ANGLE

0°~3°

6X Retractable Pin

(0.47)

(0.70)

(0.47)

(1.10)

2.90

+0.55

-0.45

5°

5°

6°

#16

4.50±0.15

6°

R0.10 (ALL)

R0.10 (ALL)

R0.10 (ALL)

R0.10 (ALL) R0.20 (ALL)

Note:

1. All Dimension Are In mm.

2. Dimensions are exclusive of burrs, mold flash,

and tie bar extrusions.

3. is Exposed Cu.

Exposed Cu

#16

6.05±0.20

Page 22

Final Datasheet 22 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Package Outline

13.2 SOP 29x12

Dimensions in mm

29.00±0.20

12.00±0.20

(2.275)

(1.165)

7-Max 0.80

7-0.60±0.10

#23

#17

(1.165)

1.27x21=26.67±0.30

1.95x13=25.35±0.30

16-Max 0.70

16-0.50±0.10

#1 #16

17.00±0.20

(1.85)

3.15±0.20

0.15±0.10

0.50

+0.10

-0.05

5°±3°

(2.50)

1.50±0.20

(1.30)

(1.85)

Max 3.50

ECN #

REV. DATE

DESCRIPTION CheckDRG.

SIGNATURE

SIGNATURE

SIGNATURE

DRAWN BY

CHECKED BY

APPROVED BY

TITLE

A

B

C

D

8 7 6 5 4 3 2 1

ZONE

gEM Electronics Co.,Ltd.

The information contained herein is the exclusive property of GEM and shall not be

distributed, reproduced, or disclosed without prior written permission of GEM.

Polaris Li

A

NEW ISSUE

g

Ivan Yang

Polaris.Li

HB Yang

G-70219

05/25/2017

B

Remove mark area. Change title. Add note 2 & 3.

SOP23P Case Outline

(0.47)

(0.70)

(0.47)

(1.10)

Detail "A"

Detail "A"

6X Retractable Pin

5°

6°

5°

6°

R0.10 (ALL)

6X Retractable Pin

7.55

7.55

1.95

1.27

0.64

2.80

1.20

2.80

0.90

1.64

0.75

#17

#1

#16

#23

2.48

Land Pattern

27.60±0.15

2-R1.60

4.50±0.15

5°

6°

5°

6°

#17

#1

#16

#23

#16

R0.10 (ALL)

R0.10 (ALL)

R0.10 (ALL)

R0.10 (ALL)

R0.20 (ALL)

Note:

1. All Dimension Are In mm.

2. Dimensions are exclusive of burrs, mold flash,

and tie bar extrusions.

3. is Exposed Cu.

Exposed Cu

(R0.40)

Page 23

Final Datasheet 23 Revision 2.1

2019-07-15

CIPOS™ Micro

IM231-L6S1B / IM231-L6T2B

Revision History

14 Revision History

Major changes since the last revision

Page or Reference

Description of change

Page 21 -22

Updated font size for Package Outline drawing

Page 24

Published by

Infineon Technologies AG

81726 München, Germany

© 2019 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about this

document?

Email: erratum@infineon.com

Document reference

IMPORTANT NOTICE

The information given in this document shall in no

event be regarded as a guarantee of conditions or

characteristics (“Beschaffenheitsgarantie”) .

With respect to any examples, hints or any typical

values stated herein and/or any information

regarding the application of the product, Infineon

Technologies hereby disclaims any and all

warranties and liabilities of any kind, including

without limitation warranties of non-infringement of

intellectual property rights of any third party.

In addition, any information given in this document

is subject to customer’s compliance with its

obligations stated in this document and any

applicable legal requirements, norms and standards

concerning customer’s products and any use of the

product of Infineon Technologies in customer’s

applications.

The data contained in this document is exclusively

intended for technically trained staff. It is the

responsibility of customer’s technical departments

to evaluate the suitability of the product for the

intended application and the completeness of the

product information given in this document with

respect to such application.

For further information on the product, technology,

delivery terms and conditions and prices please

contact your nearest Infineon Technologies office

(www.infineon.com).

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types

in question please contact your nearest Infineon

Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon

Technologies, Infineon Technologies’ products may

not be used in any applications where a failure of the

product or any consequences of the use thereof can

reasonably be expected to result in personal injury.

Edition 2018-03-02

Trademarks

All referenced product or service names and trademarks are the property of their respective owners.

Loading...

Loading...