Danfoss Oil Nozzles H, Oil Nozzles S-S, Oil Nozzles B Data sheet

Data sheet

Oil Nozzles Type H, S-S and B

Application |

|

|

|

|

Danfoss Hago oil nozzles are designed for |

|

|

|

|

||

|

|

|

|

|

domestic and commercial high pressure oil |

|

|

|

|

|

burners operating with light or heavy fuel. |

|

|

|

|

|

An optimal combustion process is only achieved |

|

|

|

|

|

by a perfect match between nozzle capacity and |

|

|

|

|

|

spray pattern, air supply and air distribution and |

|

|

|

|

|

the design of combustion chamber. |

|

|

|

|

|

Danfoss Hago offers a very broad range of |

|

|

|

|

|

nozzles with different capacity and spray |

|

|

|

|

|

patterns – which means that it is possible to |

|

|

|

|

|

cover all demands in the market. |

|

|

|

|

|

Features: Light and heavy fuel. |

|

|

|

|

|

|

|

|

|

|||

Identification |

The nozzles are marked with the following |

||||

|

information (example): |

|

|

|

|

|

0.65 60°B |

SOLID |

12345 |

|

|

|

|

|

|

|

|

|

Stamped on the flats |

|

|

|

|

|

0.65 |

|

|

GPH at 100 psi, (~ 7 bar) 35 SSU (2.7 cSt) |

|

|

60°B |

|

|

Spray angle and pattern: B Solid, S-S Semi Solid and H Hollow |

|

|

SOLID |

|

|

SOLID for “Solid” spray pattern. Only on B nozzles |

|

|

12345 |

|

|

Batch code |

|

|

|

|

|

|

|

Technical Data |

Material and construction |

|

Nozzle tip and disc AISI 416 grade stainless steel |

|

filters size dependent |

|

Recommended and maximum tightening |

|

torque |

|

Recommended 200-310 in-lbs (25-30 Nm) and |

|

max. 310 in-lbs (35 Nm).for steel and nickel |

|

plated adapters. |

|

Recommended 130-180 in-lbs (15-20 Nm) and |

|

max. 220 in-lbs (25 Nm).for brass adapters. |

Filters

Capacity 0.40 – 1.35 GPH 30-40 μm sintered bronze filter

Capacity from 1.50 GPH 120 mesh stainless steel strainer

© Danfoss | 2019.05 |

VD.CE.Y3.02 | 1 |

Data sheet |

Oil Nozzles Type H, S-S and B |

|

|

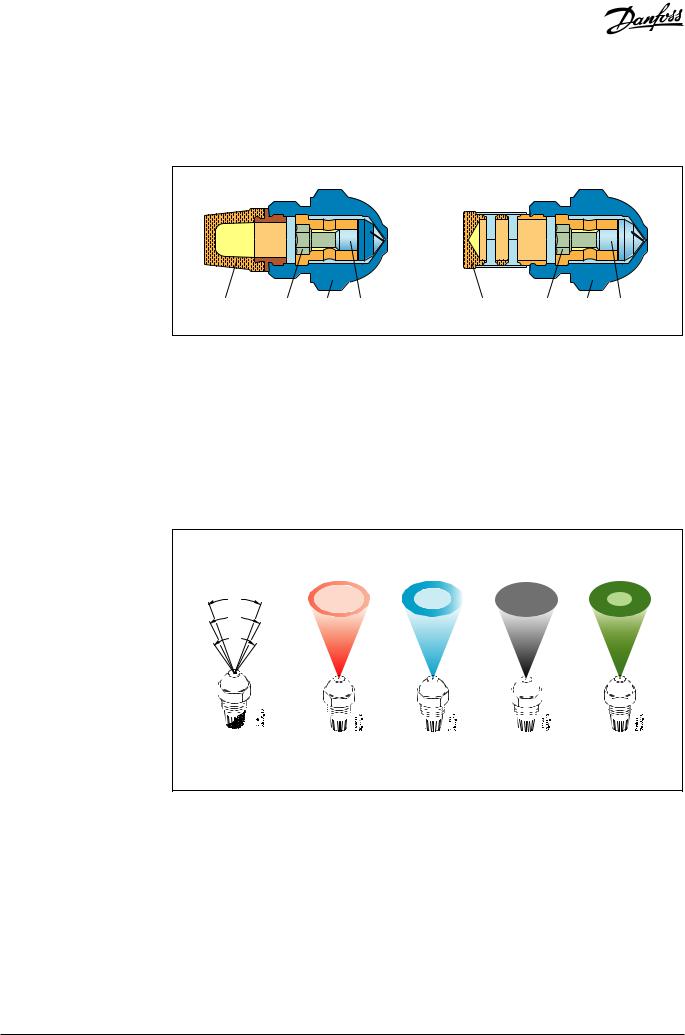

Design and dimensions |

A: |

Tip |

|

B: |

Disc |

|

C: |

Bronze filter or strainer |

|

D: |

Locknut |

C D A B C D A B

Available spray patterns:

H: Hollow Cone (red caps)

Hollow spray pattern with higher volume concentration in the periphery of the spray. Well suited for low firing rates and burners with hollow air pattern.

S-S: Semi Solid Cone (blue caps)

Semi solid spray pattern which is the optimal choice for applications where exact air pattern or spray pattern requirements can’t be established.

B: Solid Cone (black caps)

Even distributed spray pattern – well suited for burners with even distributed air pattern. Well suited for high static pressure flame retention burners.

Spray angles |

Schematic spray patterns |

45

60

80

H series |

S-S series |

B series 0.50 |

B series 2.25 |

|

|

to 2.00 USgal/h |

to 6.00 USgal/h |

2 | VD.CE.Y3.02 |

© Danfoss | 2019.05 |

Loading...

Loading...