Danfoss POV 600, POV 1050, POV 2150 Installation guide

Installation Guide

Compressor overflow valve

POV

| <![if ! IE]> <![endif]>148R9525 |

Installation |

|

|

||||

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

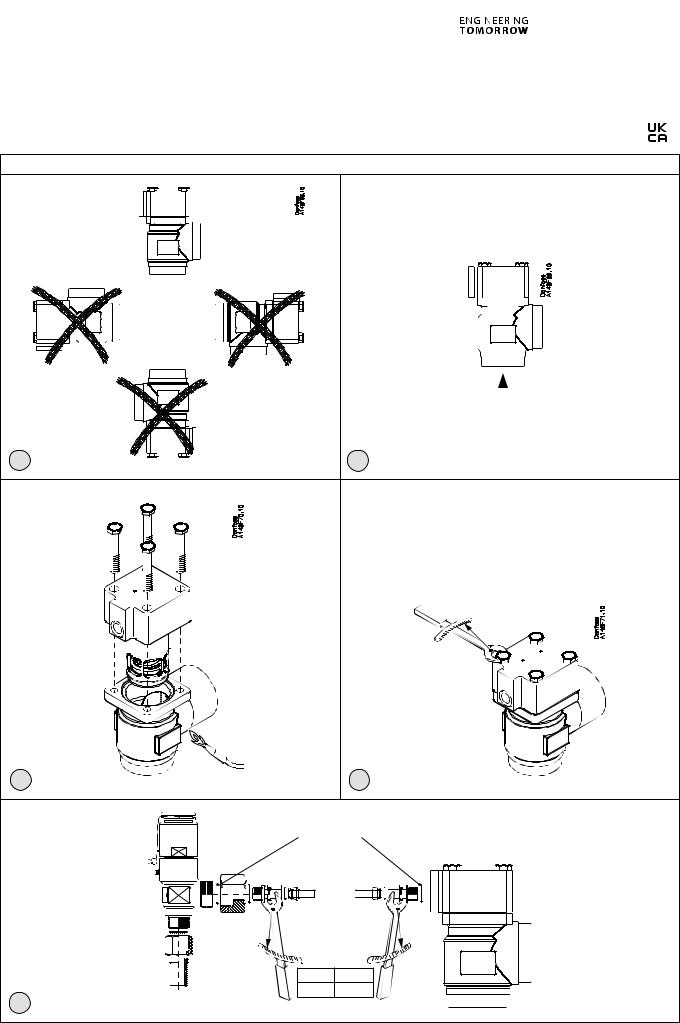

1 |

2 |

3 |

4 |

Alu washer

Nm LB-feet

35 26

5

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nm |

|

LB-feet |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

POV 600 |

|

|

|

44 |

|

|

32 |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

POV 1050 |

|

|

|

75 |

|

|

53 |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

POV 2150 |

|

|

|

44 |

|

|

32 |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<![endif]>Danfoss 148F105

<![endif]>148R9525

<![if ! IE]><![endif]>Info for UK customers only:Danfoss Ltd. Oxford Road, UB9 4LH Denham, UK

© Danfoss | DCS (hhr) | 2021.01 |

AN14978643320301-00701 | 1 |

ENGLISH

Installation

Note!

Valve type POV is categorized as a compressor overflow accessory (not as a safety accessory). Hence a safety valve (e.g. SFV) has to be installed to protect the system against excessive pressure.

Refrigerants

Applicable to HCFC, HFC, R717 (Ammonia) and R744 (CO ).

Flammable hydrocarbons are not recommended. The valve is only recommended for use in closed circuits. For further information please contact Danfoss.

Temperature range

POV: -50/+150 °C (-58/+302 °F)

Pressure range

The valves are designed for a max. working pressure of 40 barg (580 psig).

Installation

The POV valve is used in conjunction with the BSV back pressure independent safety relief valve and is specifically designed for protecting compressors against excessive pressure (fig. 5).

See technical leaflet for further installation instructions.

The valve should be installed with the spring housing upwards (fig. 1). By mounting of the valve it is important to avoid the influence of thermic and dynamic stress (vibrations).

The valve is designed to withstand a high internal pressure. However, the piping system should be designed to avoid liquid traps and reduce the risk of hydraulic pressure caused by thermal expansion. It must be ensured that the valve is protected from pressure transients like “liquid hammer” in the system.

Recommended flow direction

The valve should be installed with the flow towards the valve cone as indicated by the arrow on fig. 2.

Flow in the opposite direction is not acceptable.

Welding

The top should be removed before welding (fig. 3) to prevent damage to the O-rings between the valve body and top, as well as the teflon gasket in the valve seat. Do not use high-speed tools for dismantling and reassembling. Be sure that grease on bolts is intact before reassembling.

Only materials and welding methods compatible with the valve housing material must be applied. The valve should be cleaned internally to remove welding debris on completion of welding and before the valve is reassembled.

Avoid welding debris and dirt in the threads of the housing and the top. Removing the top can be omitted provided that:

The temperature in the area between the valve body and top as well as in the area between the seat and the teflon cone during welding does not exceed

+150 °C/+302 °F. This temperature depends on the welding method as well as on

any cooling of the valve body during the welding itself (cooling can be ensured by, for example, wrapping a wet cloth around the valve body). Make sure that no dirt, welding debris etc. get into the valve during the welding procedure.

Be careful not to damage the teflon cone ring.

The valve housing must be free from stresses (external loads) after installation.

Assembly

Remove welding debris and any dirt from pipes and valve body before assembly.

Tightening

Tighten the top with a torque wrench to the values indicated in the table (fig. 4). Do not use high-speed tools for dismantling and reassembling. Be sure that grease on bolts is intact before reassembling.

Colours and identification

Precise identification of the valve is made via the ID label on the top, as well as by the stamping on the valve body. The external surface of the valve housing must be prevented against corrosion with a suitable protective coating after installation and assembly.

Protection of the ID label when painting the valve is recommended.

In cases of doubt, please contact Danfoss. Danfoss accepts no responsibility for errors and omissions. Danfoss Industrial Refrigeration reserves the right to make changes to products and specifications without prior notice.

2 | AN14978643320301-000701 |

© Danfoss | DCS (hhr) | 2021.01 |

Loading...

Loading...