Danfoss PAH 2, PAH 4, PAH 6.3, PAH 10, PAH 12.5 Data sheet

...

Data sheet

PAH pumps

PAH 2/4/6.3, PAH 10/12.5,

PAH 20/25/32 and

PAH 50/63/70/80/100

hpp.danfoss.com

|

|

|

|

|

|

|

|

Data sheet |

PAH 2/4/6.3, PAH 10/12.5, PAH 20/25/32 and PAH 50/63/70/80/100 pumps |

|

|

|

|

||

|

|

|

|

|

|

|

|

Table of Contents |

Contents |

|

|

|

|

|

|

|

1. |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . |

. |

2 |

|

|

|

2. |

Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . |

. |

3 |

|

|

|

3. |

Application examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

.3 |

|

|

|

4. |

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . |

. |

4 |

|

|

|

4.1 |

PAH 2-12.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . |

. |

4 |

|

|

|

4.2 |

PAH 20-32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . |

. |

5 |

|

|

|

4.3 |

PAH 50-100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

.6 |

|

|

|

5. |

Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

.7 |

|

|

|

5.1 |

PAH 2-6.3 typical flow curves at max pressure . . . . . . . . . . . . . . . . . |

. . . |

. |

.7 |

|

|

|

5.2 |

PAH 10-12.5 typical flow curves at max pressure . . . . . . . . . . . . . . . . |

. . . |

. |

.8 |

|

|

|

5.3 |

PAH 20-32 typical flow curves at max pressure . . . . . . . . . . . . . . . . . |

. . . |

. |

.9 |

|

|

|

5.4 |

PAH 50-100 typical flow curves at max pressure . . . . . . . . . . . . . . . . |

. . . . 10 |

|

|||

|

6. |

Motor requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . .11 |

|

|||

|

7. |

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 12 |

|

|||

|

7.1 |

Filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 12 |

|

|||

|

7.2 |

Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . .12 |

|

|||

|

7.3 |

Open-system design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . .13 |

|

|||

|

7.4 |

Closed-system design . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . .14 |

|

|||

|

8. |

Dimensions and connections . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 15 |

|

|||

|

8.1 |

PAH 2-6.3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 15 |

|

|||

|

8.2 |

PAH 10-12.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . .16 |

|

|||

|

8.3 |

PAH 20-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . .17 |

|

|||

|

8.4 |

PAH 50-100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 18 |

|

|||

|

9. |

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. |

19 |

|

|

1. Introduction |

The data sheet is valid for PAH pumps both non |

|

ATEX and ATEX certified. The ATEX certified |

|

versions are indicated with Ex in the designation. |

|

The Danfoss range of PAH high-pressure pumps |

|

is designed to supply water flow under high- |

|

pressure for a varity of tap water applications. |

|

Danfoss PAH pumps are positive displacement |

|

pumps, with axial pistons that move a fixed |

|

amount of water in each cycle. Flow is propor- |

|

tional to the number of input shaft revolutions |

|

(rpm). Unlike centrifugal pumps, they produce |

|

the same flow at a given speed no matter what |

|

the discharge pressure. |

All components are designed to provide long service life with a constantly high efficiency and minimum service required.

In the following all pumps are named PAH.

2 | AI073186502976en-001801 |

© Danfoss | DCS (im) | 2021.11 |

Data sheet |

PAH 2/4/6.3, PAH 10/12.5, PAH 20/25/32 and PAH 50/63/70/80/100 pumps |

|

|

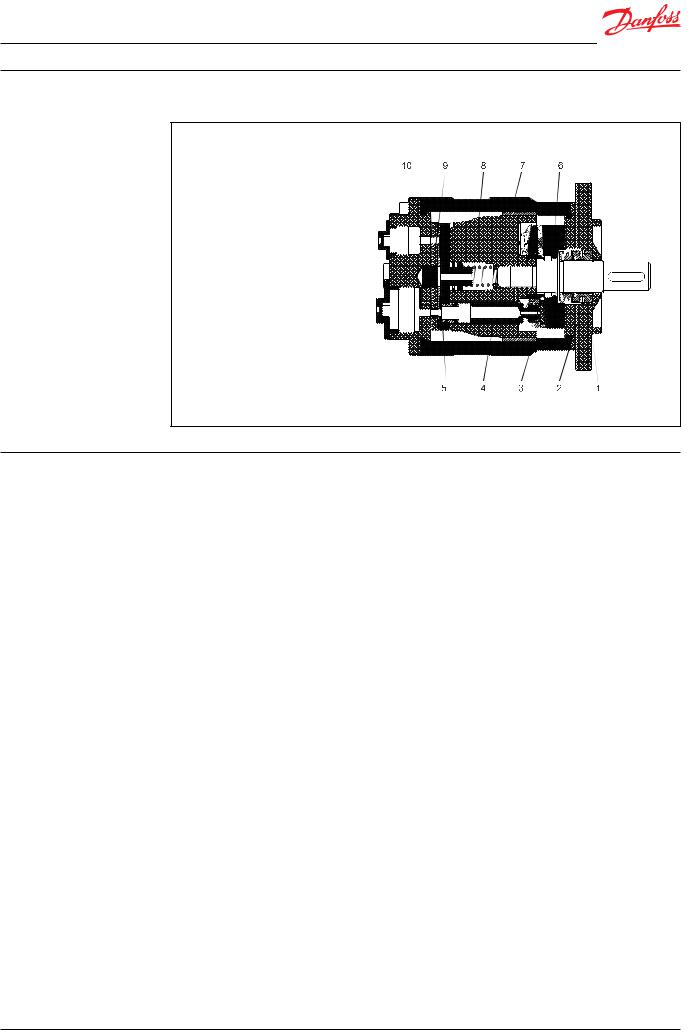

Below sectional drawing is an example of a PAH pump. |

|

|

1: |

Shaft sealing |

|

2: |

Mounting flange/ |

|

|

housing with bearing |

|

3: |

Retaining ring |

|

4: |

Piston/shoe |

|

5: |

Valve trust plate |

|

6: |

Swash plate |

|

7: |

Cylinder barrel8: |

|

8: |

Spring |

|

9: |

Port plate |

10: Connecting flange

2. Benefits |

• |

Zero risk of lubricant contamination: |

|

- Pump can be installed horizontally or |

|

|

- Oil lubricants are replaced with the |

|

vertically. |

|

|

pumped medium, water, so there is no |

|

- No pulsation dampeners necessary due |

|

|

contamination risk from the pump. |

|

to extremely low-pressure pulsation. |

|

• |

Low maintenance costs: |

|

- Powered by electric motors or combus- |

|

|

- Efficient design and all-stainless steel |

|

tion engines. |

|

|

construction ensure exceptionally long |

|

- Suitable for both boosted inlet |

|

|

lifetime. When Danfoss specifications |

|

pressure and water supply from a tank. |

|

|

are met, service intervals of up to 8,000 |

|

- No need for cooling circuits due to very |

|

|

hours can be expected. Service is easy, |

|

high mechanical efficiency. |

|

|

and can be carried out on site due to |

• |

Certified quality: |

|

|

the simple design and few parts. |

|

Certificates: |

|

• |

Low energy costs: |

|

ISO 9001, ISO 14001, ITF 16949 |

|

|

- The highly efficient axial piston design |

|

ATEX available on request |

|

|

provides the lowest energy consump- |

|

ABS and DNV GL certifications on |

|

|

tion of any comparable pump on the |

|

request |

|

|

market. |

|

|

|

• |

Easy installation: |

|

|

|

|

- The lightest and most compact design |

|

|

|

|

available. |

|

|

|

|

|

|

|

3. Application examples |

• |

Stationary and mobile hydraulic systems |

|

• |

High-pressure systems |

|

• |

Fire fighting |

•Flushing and cleaning processes

•Humidification systems

© Danfoss | DCS (im) | 2021.11 |

AI073186502976en-001801 | 3 |

|

|

|

|

Data sheet |

PAH 2/4/6.3, PAH 10/12.5, PAH 20/25/32 and PAH 50/63/70/80/100 pumps |

|

|

|

|

|

|

4. |

Technical data |

4.1 PAH 2-12.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pump size |

|

2 |

4 |

6.3 |

10 |

12.5 |

|

|

|

|

|

|

|

|

|

|

|

Code number |

|

180B0024 |

180B0022 |

180B0023 |

180B0008 |

180B0007 |

|

|

|

|

|

|

|

|

|

|

|

Code number ATEX2) |

180B6124 |

180B6122 |

180B6123 |

180B6108 |

180B6107 |

|

|

|

Housing material |

AISI 304 |

AISI 304 |

AISI 304 |

AISI 304 |

AISI 304 |

|

|

|

|

|

|

|

|

|

|

|

|

Geometric |

cm³/rev |

2 |

4 |

6.3 |

10 |

12.5 |

|

|

displacement |

|

|

|

|

|

|

|

|

in³/rev |

0.12 |

0.24 |

0.38 |

0.60 |

0.75 |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

Pressure |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Min. outlet |

barg |

30 |

30 |

30 |

30 |

30 |

|

|

pressure |

|

|

|

|

|

|

|

|

psig |

435 |

435 |

435 |

435 |

435 |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

Max. outlet |

barg |

140 |

140 |

140 |

160 |

160 |

|

|

pressure |

|

|

|

|

|

|

|

|

psig |

2030 |

2030 |

2030 |

2320 |

2320 |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

Inlet pressure, |

barg |

0-4 |

0-4 |

0-4 |

0-4 |

0-4 |

|

|

continuous |

|

|

|

|

|

|

|

|

psig |

0-58 |

0-58 |

0-58 |

0-58 |

0-58 |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

Speed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Min. speed, |

rpm |

700 |

700 |

700 |

700 |

700 |

|

|

continuous |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Max. speed |

rpm |

1800 |

1800 |

1800 |

1800 |

1800 |

|

|

|

|

|

|

|

|

|

|

|

Typical flow - Flow curves available in section 5 |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

1000 rpm at |

l/min |

1.0 |

3.2 |

5.6 |

8.4 |

11.0 |

|

|

max. pressure |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1500 rpm at |

l/min |

2.0 |

5.2 |

8.7 |

13.4 |

17.2 |

|

|

max. pressure |

||||||

|

|

|

|

|

|

|

|

|

|

|

1200 rpm at |

gpm |

0.4 |

1.0 |

1.8 |

2.7 |

3.5 |

|

|

max. pressure |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1800 rpm at |

gpm |

0.7 |

1.7 |

2.8 |

4.3 |

5.5 |

|

|

max. pressure |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Typical motor size |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1500 rpm at |

kW |

0.9 |

1.7 |

2.6 |

4.5 |

5.6 |

|

|

max. pressure |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1800 rpm at |

hp |

1.5 |

2.7 |

4.2 |

7.3 |

9.0 |

|

|

max. pressure |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Torque at max. |

Nm |

5.9 |

10.9 |

16.7 |

29.0 |

35.8 |

|

|

spec. |

|

|

|

|

|

|

|

|

lbf-ft |

4.4 |

8.0 |

12.3 |

21.4 |

26.4 |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

Media |

°C |

2-50 |

2-50 |

2-50 |

2-50 |

2-50 |

|

|

temperature |

|

|

|

|

|

|

|

|

°F |

36-122 |

36-122 |

36-122 |

36-122 |

36-122 |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

Ambient |

°C |

0-50 |

0-50 |

0-50 |

0-50 |

0-50 |

|

|

temperature |

|

|

|

|

|

|

|

|

°F |

32-122 |

32-122 |

32-122 |

32-122 |

32-122 |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

Sound |

dB(A) |

76 |

76 |

76 |

75 |

75 |

|

|

pressure level 1) |

||||||

|

|

Weight |

kg |

4.4 |

4.4 |

4.4 |

7.7 |

7.7 |

|

|

|

|

|

|

|

|

|

|

|

|

lbs |

9.7 |

9.7 |

9.7 |

17.0 |

17.0 |

|

|

|

|

|

|

|

|

|

For certified pumps specifications on inlet and outlet pressure is stated on the 3.1 inspection certificate and may vary from generic specifications stated above.

1)Measurements according to EN ISO 3744: 2010 / dB(A) [LPA, 1m] values are calculated. Measured at max pressure and rpm for a motor pump unit.

2)Category 2, Zone 1 or Category 3, Zone 2.

4 | AI073186502976en-001801 |

© Danfoss | DCS (im) | 2021.11 |

|

|

|

|

Data sheet |

PAH 2/4/6.3, PAH 10/12.5, PAH 20/25/32 and PAH 50/63/70/80/100 pumps |

|

|

|

|

|

|

4.2 PAH 20-32

Pump size |

|

20 |

25 |

32 |

|

|

|

|

|

|

|

Code number |

|

180B0079 |

180B0036 |

180B0037 |

|

|

|

|

|

|

|

Code number ATEX3) |

180B6179 |

180B6136 |

180B6137 |

||

Housing material |

AISI 304 |

AISI 304 |

AISI 304 |

||

|

|

|

|

|

|

Geometric |

cm³/rev |

20 |

25 |

32 |

|

displacement |

|

|

|

|

|

in³/rev |

1.22 |

1.53 |

1.95 |

||

|

|||||

|

|

|

|

|

|

Pressure |

|

|

|

|

|

|

|

|

|

|

|

Min. outlet |

barg |

30 |

30 |

30 |

|

pressure |

|

|

|

|

|

psig |

435 |

435 |

435 |

||

|

|||||

|

|

|

|

|

|

Max. outlet |

barg |

80 |

160 |

160 |

|

pressure |

|

|

|

|

|

psig |

1160 |

2321 |

2321 |

||

|

|||||

|

|

|

|

|

|

Inlet pressure, |

barg |

0-4 |

0-4 |

0-4 |

|

continuous 1) |

|

|

|

|

|

psig |

0-58 |

0-58 |

0-58 |

||

|

|||||

|

|

|

|

|

|

Speed |

|

|

|

|

|

|

|

|

|

|

|

Min. speed, |

rpm |

700 |

700 |

700 |

|

continuous |

|||||

|

|

|

|

||

|

|

|

|

|

|

Max. speed |

rpm |

1800 |

1800 |

1800 |

|

|

|

|

|

|

|

Typical flow - Flow curves available in section 5 |

|

||||

|

|

|

|

|

|

1000 rpm at |

l/min |

18.8 |

22.5 |

29.7 |

|

max pressure |

|||||

|

|

|

|

||

|

|

|

|

|

|

1500 rpm at |

l/min |

28.9 |

35.2 |

45.9 |

|

max pressure |

|||||

|

|

|

|

||

|

|

|

|

|

|

1200 rpm at |

gpm |

5.9 |

7.2 |

9.4 |

|

max. pressure |

|||||

|

|

|

|

||

|

|

|

|

|

|

1800 rpm at |

gpm |

9.1 |

11.1 |

14.5 |

|

max. pressure |

|||||

|

|

|

|

||

|

|

|

|

|

|

Typical motor size |

|

|

|

||

|

|

|

|

|

|

1500 rpm at |

kW |

4.4 |

10.8 |

13.8 |

|

max. pressure |

|

||||

|

|

|

|

||

|

|

|

|

|

|

1800 rpm at |

hp |

7.1 |

17.3 |

22.3 |

|

max. pressure |

|

||||

|

|

|

|

||

|

|

|

|

|

|

Torque at max. |

Nm |

28.0 |

68.5 |

88.1 |

|

spec. |

|

|

|

|

|

lbf-ft |

20.7 |

50.2 |

65.0 |

||

|

|||||

|

|

|

|

|

|

Media |

°C |

2-50 |

2-50 |

2-50 |

|

temperature |

|

|

|

|

|

°F |

36-122 |

36-122 |

36-122 |

||

|

|||||

|

|

|

|

|

|

Ambient |

°C |

0-50 |

0-50 |

0-50 |

|

temperature |

|

|

|

|

|

°F |

32-122 |

32-122 |

32-122 |

||

|

|||||

|

|

|

|

|

|

Sound |

dB(A) |

79 |

79 |

79 |

|

pressure level 2) |

|

||||

Weight |

kg |

16 |

16 |

16 |

|

|

|

|

|

|

|

|

lbs |

35 |

35 |

35 |

|

|

|

|

|

|

|

For certified pumps specifications on inlet and outlet pressure is stated on the 3.1 inspection certificate and may vary from generic specifications stated above.

1)Above 1800 rpm inlet pressure 2-6 barg

2)Measurements according to EN ISO 3744: 2010 / dB(A) [LPA, 1m] values are calculated. Measured at max pressure and rpm for a motor pump unit.

3)Category 2, Zone 1 or Category 3, Zone 2.

© Danfoss | DCS (im) | 2021.11 |

AI073186502976en-001801 | 5 |

|

|

|

|

Data sheet |

PAH 2/4/6.3, PAH 10/12.5, PAH 20/25/32 and PAH 50/63/70/80/100 pumps |

|

|

|

|

|

|

4.3 PAH 50-100

Pump size |

|

50 |

63 |

70 |

80 |

100 |

|

|

|

|

|

|

|

|

|

Code number |

|

180B0047 |

180B0040 |

180B0042 |

180B0041 |

180B0076 |

|

|

|

|

|

|

|

|

|

Code number ATEX2) |

180B6147 |

180B6140 |

180B6142 |

180B6141 |

180B6176 |

||

Housing material |

AISI 304 |

AISI 304 |

AISI 304 |

AISI 304 |

AISI 304 |

||

|

|

|

|

|

|

|

|

Geometric |

cm³/rev |

50 |

63 |

70 |

80 |

100 |

|

displacement |

|

|

|

|

|

|

|

in³/rev |

3.05 |

3.84 |

4.27 |

4.88 |

6.00 |

||

|

|||||||

|

|

|

|

|

|

|

|

Pressure |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Min. outlet |

barg |

30 |

30 |

30 |

30 |

30 |

|

pressure |

|

|

|

|

|

|

|

psig |

435 |

435 |

435 |

435 |

435 |

||

|

|||||||

|

|

|

|

|

|

|

|

Max. outlet |

barg |

80 |

160 |

160 |

160 |

80/1604) |

|

pressure |

|

|

|

|

|

|

|

psig |

1160 |

2321 |

2321 |

2321 |

1160/23214) |

||

|

|||||||

Inlet pressure, |

barg |

0-4 |

0-4 |

0-4 |

0-4 |

0-4 |

|

continuous |

|

|

|

|

|

|

|

psig |

0-58 |

0-58 |

0-58 |

0-58 |

0-58 |

||

|

|||||||

|

|

|

|

|

|

|

|

Speed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Min. speed, |

rpm |

700 |

700 |

700 |

700 |

700 |

|

continuous |

|

||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Max. speed |

rpm |

1800 |

1800/24003) |

1800/24003) |

1800/24003) |

1500/18004) |

|

Typical flow - Flow curves available in section 5 |

|

|

|

||||

|

|

|

|

|

|

|

|

1000 rpm at |

l/min |

47.0 |

56.2 |

63.4 |

73.9 |

96.7 |

|

max. pressure |

|||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

1500 rpm at |

l/min |

72.1 |

87.9 |

98.5 |

114.1 |

146.9 |

|

max. pressure |

|||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

1200 rpm at |

gpm |

14.8 |

17.9 |

20.1 |

23.4 |

30.4 |

|

max. pressure |

|||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

1800 rpm at |

gpm |

22.7 |

27.8 |

31.1 |

35.9 |

45.8 |

|

max. pressure |

|||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

2400 rpm at |

l/min |

- |

145 |

162 |

187 |

- |

|

max. pressure |

|||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Typical motor size |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

1500 rpm at |

kW |

10.6 |

26.8 |

29.8 |

34.0 |

44.1 |

|

max. pressure |

|

||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

1800 rpm at |

hp |

17.1 |

43.1 |

47.9 |

54.8 |

71.0 |

|

max. pressure |

|

||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Torque at max. |

Nm |

67.8 |

170.8 |

189.7 |

216.8 |

281.1 |

|

spec. |

|

|

|

|

|

|

|

lbf-ft |

50.0 |

126.0 |

140.0 |

160.0 |

207.3 |

||

|

|||||||

|

|

|

|

|

|

|

|

Media |

°C |

2-50 |

2-50 |

2-50 |

2-50 |

2-50 |

|

temperature |

|

|

|

|

|

|

|

°F |

36-122 |

36-122 |

36-122 |

36-122 |

36-122 |

||

|

|||||||

|

|

|

|

|

|

|

|

Ambient |

°C |

0-50 |

0-50 |

0-50 |

0-50 |

0-50 |

|

temperature |

|

|

|

|

|

|

|

°F |

32-122 |

32-122 |

32-122 |

32-122 |

32-122 |

||

|

|||||||

|

|

|

|

|

|

|

|

Sound |

dB(A) |

80 |

80 |

80 |

80 |

81 |

|

pressure level 1) |

|||||||

Weight |

kg |

31 |

31 |

31 |

31 |

31 |

|

|

|

|

|

|

|

|

|

|

lbs |

68 |

68 |

68 |

68 |

68 |

|

|

|

|

|

|

|

|

|

For certified pumps specifications on inlet and outlet pressure is stated on the 3.1 inspection certificate and may vary from generic specifications stated above.

1)Measurements according to EN ISO 3744: 2010 / dB(A) [LPA, 1m] values are calculated. Measured at max pressure and rpm for a motor pump unit.

2)Category 2, Zone 1 or Category 3, Zone 2.

3)If PAH 63/70/80 run 1800 - 2400 rpm the following conditions apply:

Inlet pressure 2 -4 barg, outlet pressure max. 140 barg for a maximum of 500 hours in between service inspection

4)Pump operation, with full service life of 8000 hours, is max 80 barg (1160 psig) and 1500 rpm. Under following conditions, PAH 100 can handle outlet pressures up to 160 barg (2321 psig):

-at maximum 1500 rpm up to 500 hours operation in between service inspection. Maximum flow is 143 l/min (37 gmp)

-at maximum 1800 rpm up to 250 hours operation in between service inspection. Maximum flow is 173 l/min (45 gpm)

6 | AI073186502976en-001801 |

© Danfoss | DCS (im) | 2021.11 |

Loading...

Loading...