Danfoss OFV 20, OFV 25, OFV-SS 20, OFV-SS 25 Data sheet

Data Sheet

Pressure regulating valve

Type OFV and OFV-SS 20-25

Efficient control of defrosting pressure

OFV are angle-way pressure regulating valves, which have ajustable opening pressure and cover the di€erential pressure range (ΔP): 2 - 8 bar (29 116 psi). The valve can be closed manually, e.g. during plant service and have backseating, enabling the spindle seal to be replaced with the valve still under pressure.

The valves are especially designed to prevent ‚uttering due to low velocity and/or low density. In consequence it is possible to apply the valves with wide ‚uctuations in capacity demands, i.e. from maximum performance to part load. A ‚exible O-ring provides perfect sealing over the seat.

Features

• Applicable to HCFC, HFC, R717(Ammonia) and R744 (CO2).

• Full temperature range packing gland -50 °C / +150 °C (-58 °F / +302 °F)

• Maximum operating pressure: 40 bar (580 psig)

• Three functions in one valve. The OFV valve combines the functions of a pressure reegulating valve, a check valve and a shut- o€ valve

• Classification: DNV, CRN, BV, EAC etc. To get an updated list of certification on the products please contact your local Danfoss Sales Company.

• Special features for OFV-SS

◦ Low temperature stainless steel housing and bonnet

◦ Low temperature packing gland -60 °C / +150 °C (-76 °F / +302 °F)

◦ Maximum operating pressure 52 bar (754 psig)

AI234986440301en-000601

Pressure regulating valve, type OFV and OFV-SS 20-25

Application

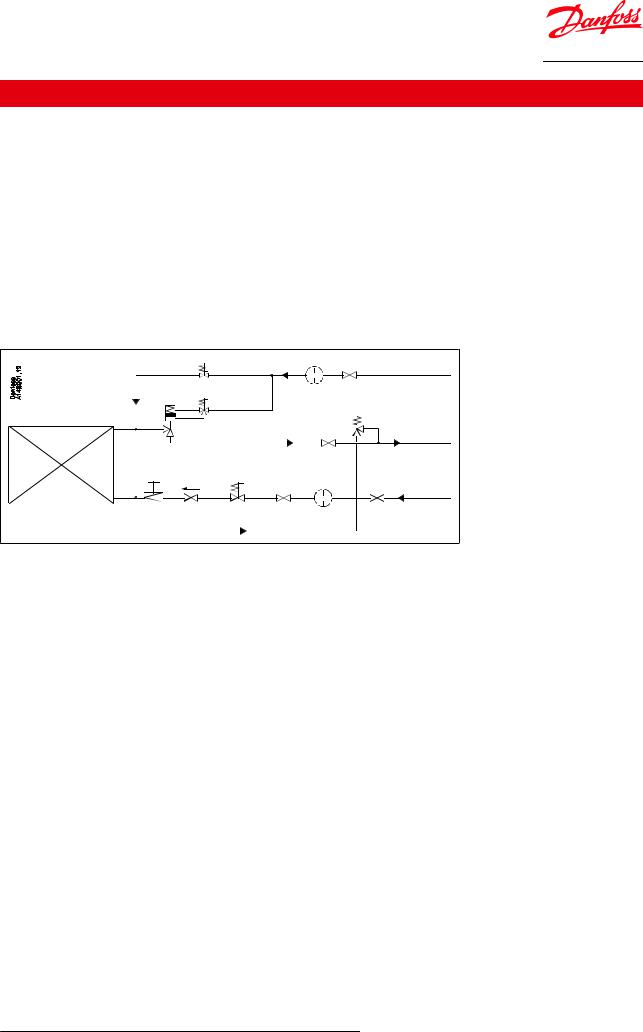

Pressure/temperature control during hot gas defrosting

In order to obtain efficient hot gas defrosting the temperature (pressure) must be increased to approx. 10°C (50°F). The OFV is the optimal solution for controlling the defrosting pressure and thus the corresponding temperature. It is recommended to start the defrosting cycle by closing the ICLX valve in the liquid supply line and allowing some of the cold liquid contained in the evaporator to return to the liquid separator.

Close the ICLX valve in the suction line and after a delay open the solenoid valve in the hot gas supply in order to build up the defrosting pressure in the evaporator. When the defrosting pressure reaches the set OFV-pressure, the OFV will open and the defrosting pressure will increase to the working pressure ΔPset + ΔPover.

After defrosting, it is normal practice to open the ICLX in the return line to equalize the pressure to the suction side before opening to the pump side.

Figure 1: Pressure/temperature control

|

|

|

|

|

Hot gas supply |

|

ICLX |

|

|

FIA |

SVA |

|

|

|

|

|

|

|||

|

|

|

|

|

||

|

|

|

|

|

OFV |

Flooded |

|

|

|

|

|

|

return line |

|

|

|

|

SVA |

|

|

|

|

|

|

|

|

Liquid |

|

|

|

|

|

|

supply |

REG |

SCA |

EVRA |

SVA |

FIA |

SVA |

|

© Danfoss | Climate Solutions | 2021.02 |

AI234986440301en-000601 | 2 |

Pressure regulating valve, type OFV and OFV-SS 20-25

Media

Refrigerants

Applicable to HCFC, HFC, R717(Ammonia) and R744 (CO2).

Flammable hydrocarbons are not recommended. For further information please contact your local Danfoss Sales Company.

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specific refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.02 |

AI234986440301en-000601 | 3 |

Pressure regulating valve, type OFV and OFV-SS 20-25

Product specification

Design

Packing gland OFV

The “full temperature range” packing gland consists of a double O-ring sealing arrangement combined with permanent lubrication from a grease reservoir. This ensures perfect tightness throughout the whole range: -50/+150 °C (-58/+302 °F).

Flexible O-ring provides perfect sealing over the seat.

Packing gland OFV-SS

The stainless steel packing gland comprises a spring loaded seal packing gland which ensures a perfect tightness in the range: -60/+150 °C (-76/+302 °F).

The packing glands are equipped with a scraper ring to prevent penetration of dirt and ice into the packing gland.

Installation

The valve is designed to resist very high internal pressure, but as to the pipe system in general, hydraulic pressure caused by thermal expansions in entrapped refrigerants should be avoided. For further information please see OFV installation instruction.

Figure 2: Example of Marking

Ring, Valve type OFV.

Pressure and temperature data

Table 1: Pressure and temperature range

Description |

Values |

Temperature range |

OFV: -50/+150 °C (-58/+302 °F) |

|

OFV-SS: -60/+150 °C (-76/+302 °F) |

Maximum operating pressure |

OFV: 40 bar (580 psig) |

|

OFV-SS: 52 bar (754 psig) |

Set pressure (Δp) |

2 - 8 bar (29 - 116 psi) |

|

|

Understanding the OFV in practice

(when working in a defrosting application)

How the OFV works

The opening pressure of the OFV can be adjusted to a specific di€erential pressure ΔPset by turning the spindle. ΔPset indirectly determines the defrosting pressure.

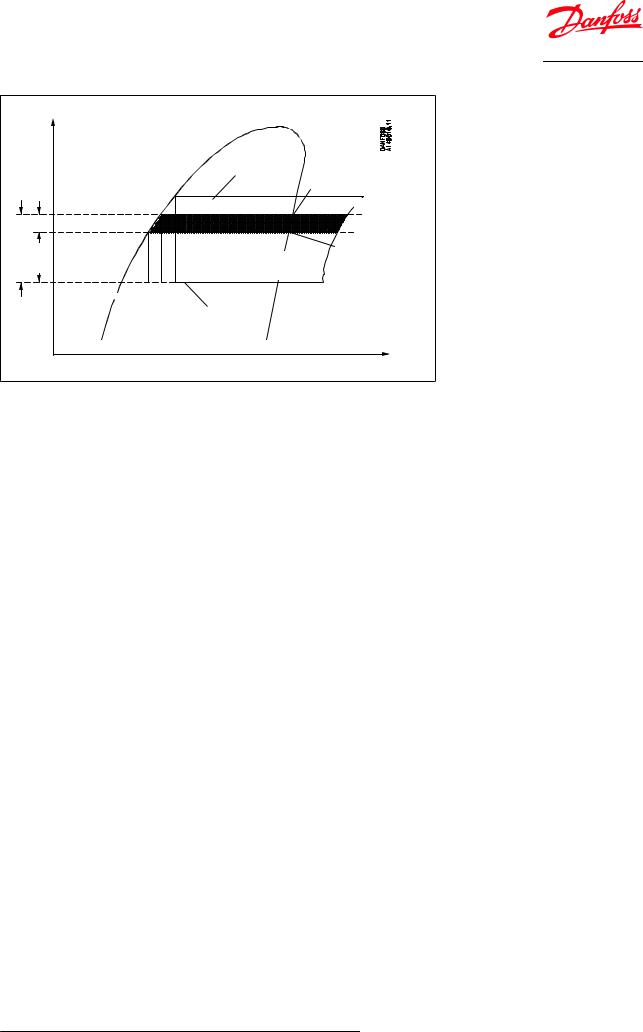

As illustrated in Figure 3: Pressure and temperature the OFV will work at a pressure somewhat higher than ΔPset,

namely the ΔPtotal which will be situated somewhere in the area marked with grey in Figure 3: Pressure and temperature.

© Danfoss | Climate Solutions | 2021.02 |

AI234986440301en-000601 | 4 |

Pressure regulating valve, type OFV and OFV-SS 20-25

Figure 3: Pressure and temperature

| <![if ! IE]> <![endif]>total |

Condensing |

temperature/pressure |

|

| <![if ! IE]> <![endif]>over |

|

|

|

| <![if ! IE]> <![endif]>P |

<![if ! IE]> <![endif]>P |

|

max. temperature |

|

|

|

|

|

|

|

(defrosting temperature) |

| <![if ! IE]> <![endif]>over |

|

|

|

| <![if ! IE]> <![endif]>P |

|

|

min. temperature |

| <![if ! IE]> <![endif]>+ |

<![if ! IE]> <![endif]>set |

|

|

|

|

||

| <![if ! IE]> <![endif]>set |

<![if ! IE]> <![endif]>P |

|

|

| <![if ! IE]> <![endif]>P |

|

|

|

|

Evaporating |

temperature/pressure |

|

As ΔPover is plant specific, it follows that the total working pressure (ΔPtotal = ΔPset + ΔPover) is plant specific too. By adjusting the opening di€erential pressure ΔPset it is possible to adjust the working pressure ΔPset + ΔPover until you

get the required defrosting pressure.

Defrosting pressure ≈ Evaporating pressure + ΔPset + ΔPover.

IMPORTANT:

The OFV valve is back pressure dependent.

Adjusting set pressure

The set pressure is the pressure at which the valve starts to open.

The set pressure is adjustable in the range 2 8 bar di€erential pressure. When the valve is delivered, a distance piece is supplied seperately with the valve. The distance piece can be mounted under the spring, thus increasing the initial tension of the spring. Therefore the valve covers the complete range 2 - 8 bar di€erential pressure, as follows:

2 bar - 6.5 bar di€erential pressure without distance piece. 3.5 bar - 8 bar di€erential pressure with distance piece.

© Danfoss | Climate Solutions | 2021.02 |

AI234986440301en-000601 | 5 |

Loading...

Loading...