Danfoss KVS 1C, KVS 2C, KVS 3C, KVS 5C Data sheet

Data Sheet

Electric regulating valve

Type KVS 1C, 2C, KVS 3C, KVS 5C

KVS Colibri® is a series of electric suction modulating valves for AC transport and refrigeration applications.

Accurate temperature or pressure control is obtained by modulating the refrigerant flow in the evaporator with a current or voltage driver.

The balanced design provides bi-flow operation as well as solenoid shut-off function in both flow directions at MOPD 40 bar (580 psig).

AI285537379493en-000202

Electric regulating valve, Type KVS 1C, KVS 2C, KVS 3C, KVS 5C

Features

•Precise control

◦Precise pressure and temperature control

•Liniar flow chararateristic

◦Repetitive operation of the valve at all conditions

•Balanced cage design

◦Higher MOPD

◦Easily fits in various application and operating conditions

◦Bi-flow

•Direct driven valve motor technology

◦Powerful motor that guarantees precise flow control and increased energy efficiency of the system

◦Reduced complexity by reducing number of parts

•Supports variety of refrigerants, approved for oil free applications

◦Wide application scope

◦Supports an extended list of refrigerants

◦Approved for oil free application

•Fast opening/closing time of 2.5 sec.

◦Quick reaction to the operation condition

•Solenoid tight shut-off

◦Prevents migration of the refrigerant during stand-still

•Compact, lightweight and in-line design

◦Flexible and easy integration in any system

•Bi-Metal connectors

◦Fast and improved brazing process – no wet wrap needed

•Stainless construction

◦Internal and external corrosion resistant

•Fully hermetic laser welded design

◦Hermetic valve in accordance to EU F-gas Regulation EU 517/2014

◦No external leakage which saves cost on maitenance and refrigerant loss

◦Protecting the environment and climate

•Manufactured according to ISO/TS 16949

◦Second – to – none quality and reliability

© Danfoss | Climate Solutions | 2022.03 |

AI285537379493en-000202 | 2 |

Electric regulating valve, Type KVS 1C, KVS 2C, KVS 3C, KVS 5C

Applications

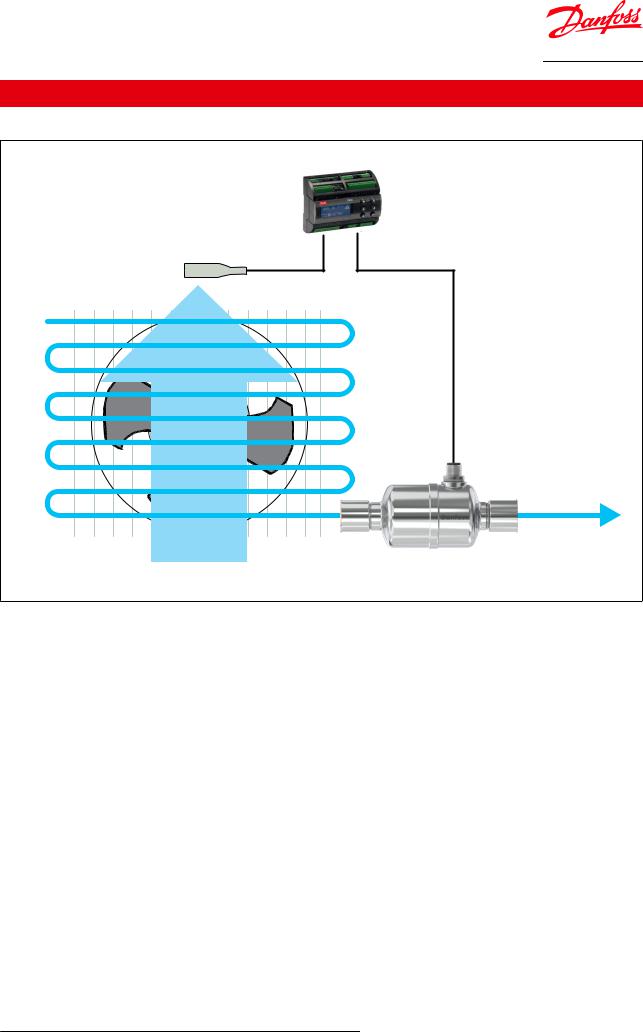

Figure 1: Typical application

Controller |

Temperature sensor |

KVS Colibri® |

regulating valve |

Evaporator |

© Danfoss | Climate Solutions | 2022.03 |

AI285537379493en-000202 | 3 |

Electric regulating valve, Type KVS 1C, KVS 2C, KVS 3C, KVS 5C

Product specification

Technical data

Table 1: Technical data

Features |

Description |

|

R1233zd(E), R1234yf, R1234ze(E), R1270, R134a, R22, R227ea, R23, R245fa, R290, |

|

R32, R404A, R407A, R407B, R407C, R407F, R407H, R410A, R412A, R413A, R417A, |

Compatible refrigerants |

R422A, R422B, R422D, R427A, R438A, R442A, R444B, R447A, R448A, R449A, R449B, |

|

R450A, R452A, R452B, R454A, R454B, R454C, R455A, R463A, R500, R502, R507A, |

|

R512A, R513A, R513B, R515A, R515B, R516A, R600, R600a |

Refrigerant oil |

POE, PVE, All mineral oils, ester oils and supports oil free |

Complies with PED |

Yes, Fluid group 1 and 2, Article 4 paragraph 3 |

MOPD |

40 bar / 580 psi |

Max. working pressure PS/MWP |

50 bar (g) / 725 psi (g) |

Refrigerant temperature range (measured at the inlet of the valve) |

-40 – 100 °C / -40 – 212 °F |

Ambient temperature |

-40 – 70 °C / -40 – 158 °F |

Capacity control range |

10% – 100% of total opening degree |

Initial opening |

5% = 30 full steps |

Environmental transport/storage temperature and humidity |

Max. 75 °C / 167 °F, Humidity: <100% RH |

Material of construction |

Body: Stainless Steel / Connector: Bimetal (stainless steel and copper) |

|

|

Electrical data

Table 2: Electrical data

Features |

Description |

|

Motor enclosure |

IP67 |

|

Stepper motor type |

Bi-polar - permanent magnet |

|

Step mode |

Microstepping (recommended), 2 phase full step or half step |

|

Phase current |

800 mA peak / 600 mA RMS |

|

Holding current |

No permanent holding current needed. Max. 20% permanent holding current |

|

|

recommended For optimal performance, driver should keep 100% current on |

|

|

coils 10ms after last step |

|

Phase resistance |

10 Ω ± 10% at +20 °C / 68 °F |

|

Inductance |

14 mH ± 25% |

|

Duty cycle |

20% |

|

Nominal Power consumption |

7.44 W RMS at 20 °C (total, both coils) |

|

Total number of full steps |

600 |

|

Step rate |

Current control driver: a. Step type: Microstep (1⁄4 th or higher): 240 full steps/sec. |

|

|

recommended b. Step type: Full step or Half steps: 240 full steps/sec. recommen- |

|

|

ded Emergency close : 240 full steps/sec. OEMs with 3rd party controller, please |

|

|

contact Danfoss |

|

|

NOTE! For refrigerant temperatures above 70 deg.C => only use micro step! |

|

Step translation |

0.0167 mm/step |

|

Full travel time |

2.5 seconds at 240 steps/sec |

|

Opening stroke |

10 mm / 0.4 in. |

|

Reference position |

Overdriving against the full close position |

|

Overdriving performance |

1% (6 full steps) Overdrive is recommended for optimum performance 628 steps |

|

|

in closing direction recommended for initialisation Overdriving in open position |

|

|

not recommended |

|

M12 connector |

According to EN 61076-2-101 |

|

Compatible driver |

Danfoss driver: EKE 1A, EKE1B and EKE 1C |

|

|

Certain third party drivers. Contact Danfoss for details |

|

|

|

© Danfoss | Climate Solutions | 2022.03 |

AI285537379493en-000202 | 4 |

Loading...

Loading...