CTLST CAT5112S-20TE13, CAT5112S-00TE13, CAT5112RI-50TE13, CAT5112RI-20TE13, CAT5112RI-10TE13 Datasheet

...

Advance Information

CAT5112

32-Tap Digitally Programmable Potentiometer (DPP™)

FEATURES |

APPLICATIONS |

■ 32 Position Linear Taper Potentiometer |

■ Automated Product Calibration |

■ Non-volatile NVRAM Wiper Storage |

■ Remote Control Adjustments |

■ Low Power CMOS Technology |

■ Offset, Gain and Zero Control Systems |

■ Single Supply Operation: 2.5V-6.0V |

■ Tamper-Proof Calibrations |

■ Increment Up/Down Serial Interface |

■ Contrast, Brightness and Volume Controls |

■ Resistance Values: 10K, 20K, 50K and 100K Ω |

■ Motor Controls and Feedback Systems |

■ Available in PDIP, SOIC, TSSOP and MSOP packages |

■ Programmable Analog Functions |

|

|

DESCRIPTION |

|

The CAT5112 is a single digitally programmable potentiometer (DPP™) designed as a electronic replacement for mechanical potentiometers and trim pots. Ideal for automated adjustments on high volume production lines, they are also well suited for applications where equipment requiring periodic adjustment is either difficult to access or located in a hazardous or remote environment.

The CAT5112 contains a 32-tap series resistor array connected between two terminals RH and RL. An up/ down counter and decoder that are controlled by three input pins, determines which tap is connected to the wiper, RW. The CAT5112 wiper is buffered by an OP AMP that operates rail to rail. The wiper setting, stored in non-volatile NVRAM memory, is not lost when the device is powered down and is automatically recalled

when power is returned. The wiper can be adjusted to test new system values without effecting the stored setting. Wiper-control of the CAT5112 is accomplished with three input control pins, CS, U/D, and INC. The INC input increments the wiper in the direction which is determined by the logic state of the U/D input. The CS input is used to select the device and also store the wiper position prior to power down.

The digitally programmable potentiometer can be used as a three-terminal resistive divider or as a two-terminal variable resistor. DPPs bring variability and programmability to a wide variety of applications including control, parameter adjustments, and signal processing.

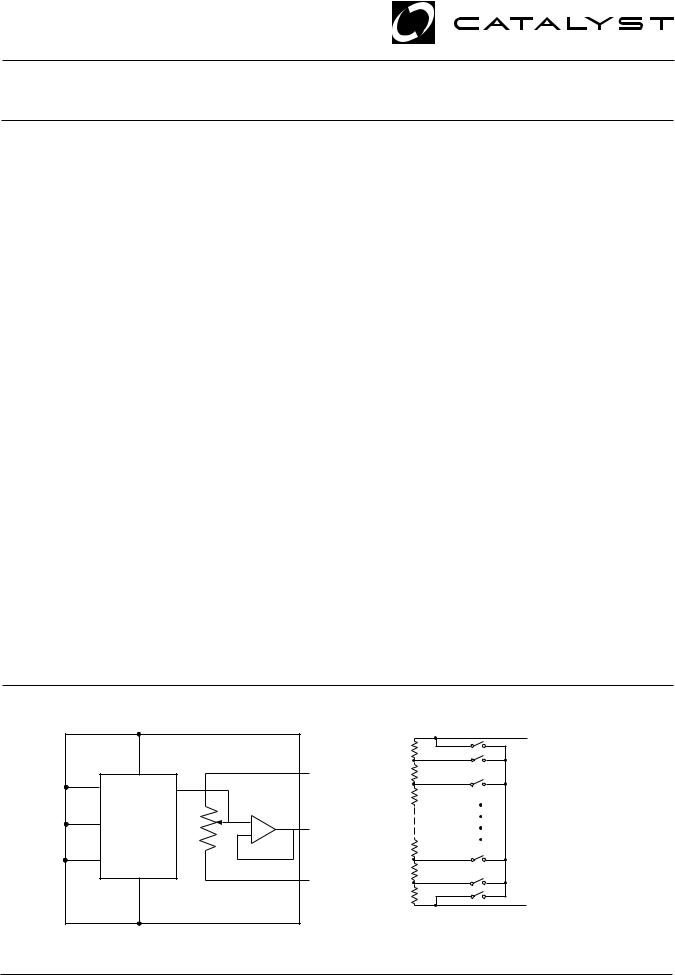

FUNCTIONAL DIAGRAM

VCC

|

|

|

R H |

|

U/D |

|

|

|

|

INC |

Control |

+ |

|

|

and |

R WB |

|||

– |

||||

|

Memory |

|||

|

|

|

||

CS |

|

|

|

|

|

|

|

R L |

VSS

VH /RH

VH /RH

VW /RW

VW /RW

VL / R L

VL / R L

Implementation of the

Electronic Potentiometer

© 2001 by Catalyst Semiconductor, Inc. |

1 |

Doc. No. 25091-00 Rev. 3/28/01 |

Characteristics subject to change without notice |

M-1 |

CAT5112 |

|

|

|

|

|

|

|

|

Advance Information |

|||

PIN CONFIGURATION |

|

|

|

|

|

PIN FUNCTIONS |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

DIP/SOIC Package |

|

TSSOP Package |

Pin Name |

Function |

|

|||||||

|

|

|

|

|||||||||

|

INC |

Increment Control |

|

|||||||||

INC |

|

|

|

VCC |

CS |

|

|

|

RL |

|

||

|

|

|

|

|

|

|

|

|

||||

|

|

|

VCC |

|

|

|

RW |

U/D |

Up/Down Control |

|

||

U/D |

|

|

|

CS |

INC |

|

|

|

GND |

|

|

|

RH |

|

|

|

RL |

|

|

|

RH |

Potentiometer High Terminal |

|

||

|

|

|

U/D |

|

|

|

RH |

|

||||

GND |

|

|

|

RW |

|

|

|

|

|

GND |

Ground |

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

MSOP Package |

|

|

|

||

|

|

|

|

|

|

RW |

Potentiometer Wiper Terminal |

|

||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

INC |

|

|

|

VCC |

|

|

|

|

|

|

|

|

|

|

|

RL |

Potentiometer Low Terminal |

|

||

|

|

|

|

|

U/D |

|

|

|

CS |

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

CS |

Chip Select |

|

|||||

|

|

|

|

|

RH |

|

|

|

RL |

|

||

|

|

|

|

|

GND |

|

|

|

RW |

VCC |

Supply Voltage |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PIN DESCRIPTIONS

INC: Increment Control Input

The INC input moves the wiper in the up or down direction determined by the condition of the U/D input.

U/D: Up/Down Control Input

The U/D input controls the direction of the wiper movement. When in a high state and CS is low, any high- to-low transition on INC will cause the wiper to move one increment toward the RH terminal. When in a low state and CS is low, any high-to-low transition on INC will cause the wiper to move one increment towards the RL terminal.

RH: High End Potentiometer Terminal

RH is the high end terminal of the potentiometer. It is not required that this terminal be connected to a potential greater than the RL terminal. Voltage applied to the RH terminal cannot exceed the supply voltage, VCC or go below ground, GND.

RW: Wiper Potentiometer Terminal

RW is the wiper terminal of the potentiometer. Its position on the resistor array is controlled by the control inputs,INC, U/D and CS. Voltage applied to the RW terminal cannot exceed the supply voltage, VCC or go below ground, GND.

RL: Low End Potentiometer Terminal

RL is the low end terminal of the potentiometer. It is not required that this terminal be connected to a potential less than the RH terminal. Voltage applied to the RL terminal cannot exceed the supply voltage, VCC or go below ground, GND. RL and RH are electrically interchangeable.

CS: Chip Select

The chip select input is used to activate the control input

of the CAT5112 and is active low. When in a high state, activity on the INC and U/D inputs will not affect or change the position of the wiper.

DEVICE OPERATION

The CAT5112 operates like a digitally controlled potentiometer with RH and RL equivalent to the high and low terminals and RW equivalent to the mechanical potentiometer's wiper. There are 32 available tap positions including the resistor end points, RH and RL. There are 31 resistor elements connected in series between the RH and RL terminals. The wiper terminal is connected to one of the 32 taps and controlled by three inputs, INC, U/D and CS. These inputs control a five-bit up/down counter whose output is decoded to select the wiper position. The selected wiper position can be stored in nonvolatile memory using the INC and CS inputs.

With CS set LOW the CAT5112 is selected and will respond to the U/D and INC inputs. HIGH to LOW transitions on INC wil increment or decrement the wiper (depending on the state of the U/D input and fivebit counter). The wiper, when at either fixed terminal, acts like its mechanical equivalent and does not move beyond the last position. The value of the counter is stored in nonvolatile memory whenever CS transitions HIGH while the INC input is also HIGH. When the CAT5112 is powered-down, the last stored wiper counter position is maintained in the nonvolatile memory. When power is restored, the contents of the memory are recalled and the counter is set to the value stored.

With INC set low, the CAT5112 may be de-selected and powered down without storing the current wiper position in nonvolatile memory. This allows the system to always power up to a preset value stored in nonvolatile memory.

Doc. No. 25091-00 Rev. 3/01 |

2 |

|

M-1 |

||

|

Loading...

Loading...