CTLST CAT24WC129PI-3TE13, CAT24WC129PI-1.8TE13, CAT24WC129PA-TE13, CAT24WC129PA-3TE13, CAT24WC129PA-1.8TE13 Datasheet

...

Preliminary

CAT24WC129

128K-Bit I2C Serial CMOS E2PROM

FEATURES

■1MHz I2C Bus Compatible*

■1.8 to 6 Volt Operation

■Low Power CMOS Technology

■64-Byte Page Write Buffer

■Self-Timed Write Cycle with Auto-Clear

■Commercial, Industrial and Automotive Temperature Ranges

■ Write Protect Feature

– Top 1/4 Array Protected When WP at V

IH

■100,000 Program/Erase Cycles

■100 Year Data Retention

■8-Pin DIP or 8-Pin SOIC

DESCRIPTION

The CAT24WC129 is a 128K-bit Serial CMOS E2PROM internally organized as 16384 words of 8 bits each. Catalyst’s advanced CMOS technology substantially reduces device power requirements. The

CAT24WC129 features a 64-byte page write buffer. The device operates via the I2C bus serial interface and is available in 8-pin DIP or 8-pin SOIC packages.

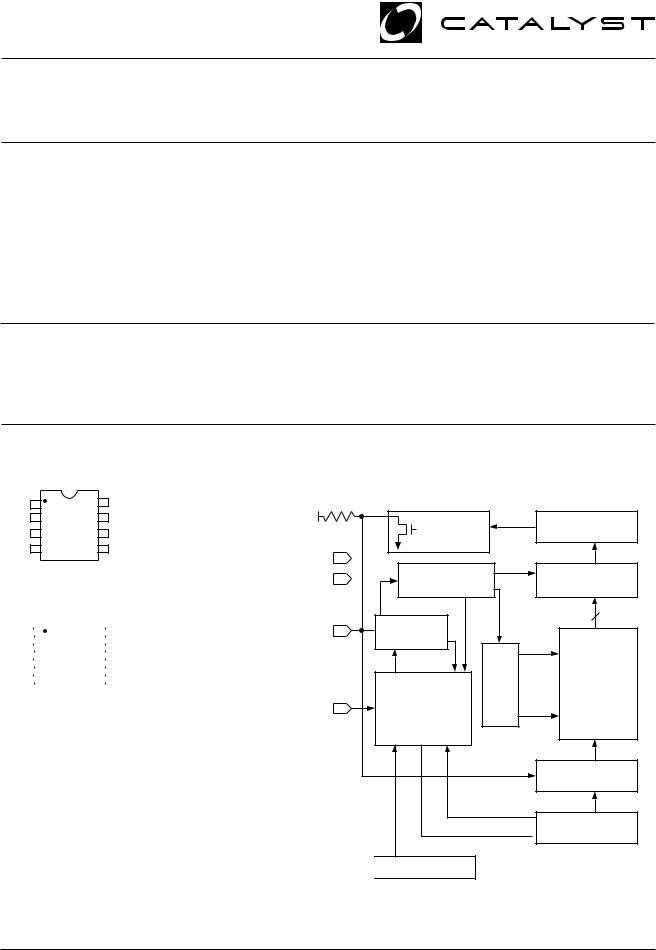

PIN CONFIGURATION |

BLOCK DIAGRAM |

DIP Package (P) |

|

NC |

1 |

8 |

VCC |

NC |

2 |

7 |

WP |

NC |

3 |

6 |

SCL |

VSS |

4 |

5 |

SDA |

SOIC Package (J,K)

NC |

|

|

|

|

|

1 |

8 |

|

|

|

VCC |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

2 |

7 |

|

|

|

||

NC |

|

|

|

|

|

|

|

WP |

|||

|

|

|

3 |

6 |

|

|

|

||||

NC |

|

|

|

|

|

|

|

|

SCL |

||

|

|

|

|

|

|

|

|

||||

|

|

4 |

5 |

|

|

|

|

||||

VSS |

|

|

|

|

|

|

|

|

SDA |

||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

24WC129 F01 |

||||

PIN FUNCTIONS

Pin Name |

Function |

|

|

SDA |

Serial Data/Address |

|

|

SCL |

Serial Clock |

|

|

WP |

Write Protect |

|

|

VCC |

+1.8V to +6V Power Supply |

|

|

VSS |

Ground |

|

|

EXTERNAL LOAD

|

DOUT |

|

SENSE AMPS |

|

SHIFT REGISTERS |

||

|

ACK |

||

|

|

|

|

VCC |

|

|

|

VSS |

WORD ADDRESS |

|

COLUMN |

BUFFERS |

|

DECODERS |

|

|

|

||

|

|

|

512 |

SDA |

START/STOP |

|

|

LOGIC |

|

|

|

|

|

|

|

|

XDEC |

256 |

E2PROM |

|

256X512 |

||

|

|

|

|

WP |

CONTROL |

|

|

LOGIC |

|

|

|

|

|

|

|

|

|

DATA IN STORAGE |

|

HIGH VOLTAGE/

TIMING CONTROL

TIMING CONTROL

SCL

STATE COUNTERS

STATE COUNTERS

24WC129 F02

* Catalyst Semiconductor is licensed by Philips Corporation to carry the I2C Bus Protocol.

© 1998 by Catalyst Semiconductor, Inc. |

1 |

Doc. No. 25065-00 6/99 S-1 |

|

Characteristics subject to change without notice |

|||

|

CAT24WC129 |

Preliminary |

ABSOLUTE MAXIMUM RATINGS*

Temperature Under Bias |

–55°C to +125°C |

|

Storage Temperature ....................... |

–65°C to +150°C |

|

Voltage on Any Pin with |

|

|

Respect to Ground(1) ........... |

–2.0V to +VCC + 2.0V |

|

VCC with Respect to Ground ............... |

|

–2.0V to +7.0V |

Package Power Dissipation |

|

|

Capability (Ta = 25°C) ................................... |

|

1.0W |

Lead Soldering Temperature (10 secs) |

............ 300°C |

|

Output Short Circuit Current(2) ........................ |

|

100mA |

*COMMENT

Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional operation of the device at these or any other conditions outside of those listed in the operational sections of this specification is not implied. Exposure to any absolute maximum rating for extended periods may affect device performance and reliability.

RELIABILITY CHARACTERISTICS

Symbol |

Parameter |

Min. |

Max. |

Units |

Reference Test Method |

|

|

|

|

|

|

NEND(3) |

Endurance |

100,000 |

|

Cycles/Byte |

MIL-STD-883, Test Method 1033 |

TDR(3) |

Data Retention |

100 |

|

Years |

MIL-STD-883, Test Method 1008 |

VZAP(3) |

ESD Susceptibility |

2000 |

|

Volts |

MIL-STD-883, Test Method 3015 |

ILTH(3)(4) |

Latch-up |

100 |

|

mA |

JEDEC Standard 17 |

D.C. OPERATING CHARACTERISTICS

VCC = +1.8V to +6.0V, unless otherwise specified.

|

|

|

Limits |

|

|

|

|

|

|

|

|

|

|

|

|

Symbol |

Parameter |

Min. |

|

Typ. |

Max. |

Units |

Test Conditions |

|

|

|

|

|

|

|

|

ICC1 |

Power Supply Current - Read |

|

|

|

1 |

mA |

fSCL = 100 KHz |

|

|

|

|

|

|

|

VCC=5V |

ICC2 |

Power Supply Current - Write |

|

|

|

3 |

mA |

fSCL = 100 KHz |

|

|

|

|

|

|

|

VCC=5V |

ISB(5) |

Standby Current |

|

|

|

0 |

μA |

VIN = GND or VCC |

|

|

|

|

|

|

|

VCC=5V |

ILI |

Input Leakage Current |

|

|

|

3 |

μA |

VIN = GND to VCC |

ILO |

Output Leakage Current |

|

|

|

3 |

μA |

VOUT = GND to VCC |

VIL |

Input Low Voltage |

–1 |

|

|

VCC x 0.3 |

V |

|

VIH |

Input High Voltage |

VCC x 0.7 |

|

|

VCC + 0.5 |

V |

|

VOL1 |

Output Low Voltage (VCC = +3.0V) |

|

|

|

0.4 |

V |

IOL = 3.0 mA |

VOL2 |

Output Low Voltage (VCC = +1.8V) |

|

|

|

0.5 |

V |

IOL = 1.5 mA |

CAPACITANCE TA = 25°C, f = 1.0 MHz, VCC = 5V

Symbol |

Test |

Max. |

Units |

Conditions |

|

|

|

|

|

CI/O(3) |

Input/Output Capacitance (SDA) |

8 |

pF |

VI/O = 0V |

CIN(3) |

Input Capacitance (SCL, WP) |

6 |

pF |

VIN = 0V |

Note:

(1)The minimum DC input voltage is –0.5V. During transitions, inputs may undershoot to –2.0V for periods of less than 20 ns. Maximum DC voltage on output pins is VCC +0.5V, which may overshoot to VCC + 2.0V for periods of less than 20ns.

(2)Output shorted for no more than one second. No more than one output shorted at a time.

(3)This parameter is tested initially and after a design or process change that affects the parameter.

(4)Latch-up protection is provided for stresses up to 100 mA on address and data pins from –1V to VCC +1V.

(5)Standby current (ISB ) = 0 μA (<900 nA).

Doc. No. 25065-00 6/99 S-1 |

2 |

Preliminary |

CAT24WC129 |

A.C. CHARACTERISTICS

VCC = +1.8V to +6V, unless otherwise specified

Output Load is 1 TTL Gate and 100pF

Read & Write Cycle Limits

|

Symbol |

|

Parameter |

VCC=1.8V - 6.0V |

VCC=2.5V - 6.0V |

VCC=3.0V - 5.5V |

|

|

|

|||||

|

|

|

|

Min. |

Max. |

Min. |

Max. |

Min. |

Max. |

|

Units |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FSCL |

|

Clock Frequency |

|

100 |

|

|

400 |

|

|

1000 |

|

kHz |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tAA |

|

SCL Low to SDA Data Out |

0.1 |

3.5 |

0.05 |

0.9 |

0.05 |

0.55 |

|

μs |

|

||

|

|

|

and ACK Out |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tBUF(1) |

|

Time the Bus Must be Free Before |

4.7 |

|

1.2 |

|

0.5 |

|

|

|

μs |

|

|

|

|

|

a New Transmission Can Start |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tHD:STA |

|

Start Condition Hold Time |

4.0 |

|

0.6 |

|

0.25 |

|

|

μs |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tLOW |

|

Clock Low Period |

4.7 |

|

1.2 |

|

0.6 |

|

|

|

μs |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tHIGH |

|

Clock High Period |

4.0 |

|

0.6 |

|

0.4 |

|

|

|

μs |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tSU:STA |

|

Start Condition Setup Time |

4.0 |

|

0.6 |

|

0.25 |

|

|

μs |

|

||

|

|

|

(for a Repeated Start Condition) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tHD:DAT |

|

Data In Hold Time |

0 |

|

0 |

|

|

0 |

|

|

|

ns |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tSU:DAT |

|

Data In Setup Time |

100 |

|

100 |

|

100 |

|

|

|

ns |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tR(1) |

|

SDA and SCL Rise Time |

|

1.0 |

|

|

0.3 |

|

|

0.3 |

|

μs |

|

|

tF(1) |

|

SDA and SCL Fall Time |

|

300 |

|

|

300 |

|

|

100 |

|

ns |

|

|

tSU:STO |

|

Stop Condition Setup Time |

4.7 |

|

0.6 |

|

0.25 |

|

|

μs |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tDH |

|

Data Out Hold Time |

100 |

|

50 |

|

50 |

|

|

|

ns |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tWR |

|

Write Cycle Time |

|

10 |

|

|

10 |

|

|

10 |

|

ms |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power-Up Timing (1)(2) |

|

|

|

|

|

|

|

|

|

|

|

||

|

Symbol |

Parameter |

|

|

|

|

Max. |

|

|

Units |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tPUR |

Power-Up to Read Operation |

|

|

|

|

1 |

|

|

ms |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tPUW |

Power-Up to Write Operation |

|

|

|

|

1 |

|

|

ms |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note:

(1)This parameter is tested initially and after a design or process change that affects the parameter.

(2)tPUR and tPUW are the delays required from the time VCC is stable until the specified operation can be initiated.

The write cycle time is the time from a valid stop condition of a write sequence to the end of the internal program/erase cycle. During the write cycle, the bus interface circuits are disabled, SDA is allowed to remain high, and the device does not respond to its slave address.

FUNCTIONAL DESCRIPTION

The CAT24WC129 supports the I2C Bus data transmission protocol. This Inter-Integrated Circuit Bus protocol defines any device that sends data to the bus to be a transmitter and any device receiving data to be a receiver. The transfer is controlled by the Master device which generates the serial clock and all START and STOP conditions for bus access. The CAT24WC129

operates as a Slave device. Both the Master device and Slave device can operate as either transmitter or receiver, but the Master device controls which mode is activated.

3 |

Doc. No. 25065-00 6/99 S-1 |

Loading...

Loading...