Bosch OBD 100 User guide

OBD 100

en Original instructions

EOBD & CAN Scan Tool

en 2 | OBD 100 |

Content English

1. |

Symbols used |

3 |

|

1.1 |

In the documentation |

3 |

|

|

1.1.1 |

Warning notices - Structure and meaning 3 |

|

|

1.1.2 |

Symbols in this documentation |

3 |

1.2 |

On the product |

3 |

|

2. |

User information |

3 |

2.1 |

Terms of warranty |

3 |

2.2 |

Exemption from liability |

3 |

2.3 |

Data and software |

3 |

3. |

Product description |

4 |

|

3.1 |

Intended use |

4 |

|

3.2 |

Prerequisites |

4 |

|

3.3 |

Scope of delivery |

4 |

|

3.4 |

Description of device |

4 |

|

|

3.4.1 |

Button panel |

4 |

|

3.4.2 |

OBD diagnostic connector |

4 |

3.5 |

Cleaning |

4 |

|

4.All you need to know about OBD 5

4.1What are OBD, OBD II, OBD-2 and EOBD 5

4.2 Is my vehicle provided with OBD |

5 |

4.3Where is the OBD diagnostic socket

located |

5 |

4.4Why and when does the malfunction

indicator light (MIL) come on |

5 |

|

4.5 What are trouble codes |

6 |

|

4.5.1 |

Trouble code structure |

6 |

4.5.2 |

Stored trouble codes |

6 |

4.5.3 |

Pending code (Pnd) |

6 |

4.5.4 |

Confirmed code (Cnf) |

6 |

4.5.5 |

Permanent code (Prm) |

6 |

4.5.6 |

Erasing trouble codes |

7 |

5. |

Operation |

7 |

|

5.1 |

Safety information |

7 |

|

5.2 |

Connection to vehicle |

8 |

|

5.3 |

Functions in main menu |

8 |

|

5.4 |

Codes (trouble codes) |

9 |

|

|

5.4.1 |

Reading trouble codes |

9 |

|

5.4.2 |

Erasing trouble codes |

9 |

5.5 |

Live data (PID display) |

10 |

|

5.6MIL status (malfunction indicator light) 11

5.7 |

I/M monitors |

11 |

5.8 |

Freeze frame (data) |

12 |

5.9 |

VIN (vehicle identification number) |

12 |

5.10 |

Faults |

12 |

6. |

Decommissioning |

13 |

|

6.1 |

Change of location |

13 |

|

6.2 |

Disposal and scrapping |

13 |

|

|

|

|

|

7. |

Technical data |

13 |

|

7.1 |

Dimensions and weights |

13 |

|

7.2 |

Temperature and humidity |

13 |

|

|

7.2.1 |

Ambient temperature |

13 |

|

7.2.2 |

Humidity |

13 |

7.3 |

Electromagnetic compatibility (EMC) |

13 |

|

|

|

|

|

8. |

Glossary |

14 |

|

|

|

|

|

9. |

PID definitions |

16 |

|

|

|

|

|

|

|

569624 Rev "A" | 2013-12-19 |

Robert Bosch GmbH |

Symbols used | OBD 100 | 3 en

1.Symbols used

1.1In the documentation

1.1.1Warning notices -

Structure and meaning

Warning notices warn of dangers to the user or people in the vicinity. Warning notices also

indicate the consequences of the hazard as well as preventive action. Warning notices have the following structure:

Warning KEY WORD – Nature and source of symbol hazard!

Consequences of hazard in the event of failure to observe action and information given.

¶¶Hazard prevention action and information.

The key word indicates the likelihood of occurrence and the severity of the hazard in the event of non-observance:

Key word |

Probability of |

Severity of danger |

|

occurrence |

if instructions not |

|

|

observed |

DANGER |

Immediate |

Death or severe |

|

impending danger |

injury |

WARNING |

Possible |

Death or severe |

|

impending danger |

injury |

CAUTION |

Possible dangerous |

Minor injury |

|

situation |

|

1.1.2Symbols in this documentation

Symbol |

Designation |

Explanation |

|

|

|

|

|

! |

Attention |

Warns about possible property |

|

|

damage. |

||

i |

Information |

Practical hints and other |

|

|

useful information. |

||

|

|

||

1. |

Multi-step |

Instruction consisting of |

|

2. |

operation |

several steps. |

|

e |

One-step |

Instruction consisting of one |

|

operation |

step. |

||

|

|||

|

Intermediate |

An instruction produces a |

|

result |

visible intermediate result. |

||

|

|||

" |

Final result |

There is a visible final |

|

|

result on completion of the |

||

|

|

instruction. |

1.2On the product

!!Observe all warning notices on products and ensure they remain legible.

2.User information

These operating instructions describe the functions of the OBD 100 and contain step-by- step directions for use of the OBD 100. Study and observe these operating instructions in full before using the OBD 100. It is also essential to heed all the vehicle manufacturer's safety instructions and information.

2.1Terms of warranty

The warranty is expressly restricted to the first purchasers of Bosch electronic diagnostic testers (referred to in the following as units). A

2-year (24-month) warranty against material and manufacturing defects applies to Bosch units as of the date of delivery. This warranty does not apply to any units used incorrectly, modified or employed for a purpose for which they are not intended or which deviates from that described in the usage instructions. The sole course of action in the event of a defective unit is repair or replacement by Bosch. Under no circumstances is Bosch liable for direct, indirect, special and exemplary damages or consequential damages (including lost profits) whether this is based

on warranty, contract, tort or any other legal theory.

2.2Exemption from liability

The above warranty supersedes all other guarantees made explicitly or implicitly, including guarantees of marketability or suitability for a particular area of application.

2.3Data and software

The system software is protected by copyright. Users have no rights or claims to the system software other than a restricted right of use which can be revoked by Bosch. The system software must not be passed on or disclosed without the written consent of Bosch. Copying of the system software is not permissible.

|

|

Robert Bosch GmbH |

569624 Rev "A" | 2013-12-19 |

en 4 | OBD 100 | Product description

3.Product description

3.1Intended use

The OBD 100 reads and displays emissionrelated diagnostic data via the OBD interface of gasoline and diesel passenger vehicles. It is also possible to erase or reset trouble codes and to display additional electronic control unit information. The diagnostic data can help to establish the cause of problems in the vehicle.

!!The OBD 100 is only to be used with the vehicle stationary. Use whilst driving is prohibited.

3.2Prerequisites

OBD interface (OBD-2 or EOBD) in the vehicle to be tested (refer also to Section "4.1 What are OBD, OBD II, OBD-2 and EOBD").

3.3Scope of delivery

Designation |

Order number |

OBD 100 diagnostic tester |

SP02000002 |

Original operating instructions |

569624 Rev "A" |

Tab. 1: Scope of delivery

3.4Description of device

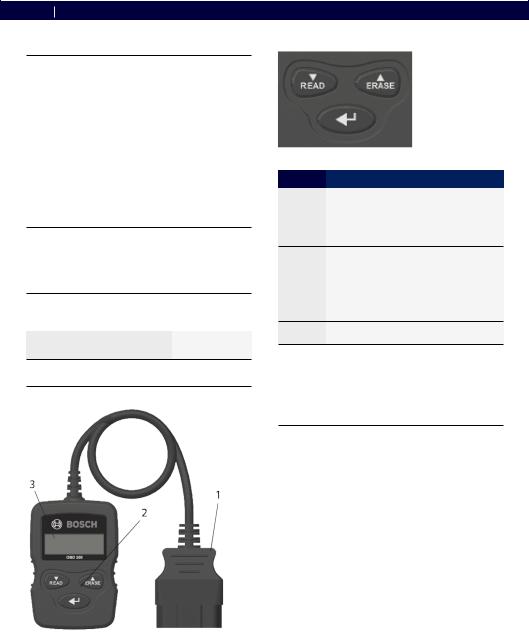

3.4.1Button panel

Fig. 2: OBD 100 buttons

Button Function

READ RR Scrolls down through the screen display when ↓ or ↕ appears on the screen.

RR Reading of electronic control unit diagnostic data (press and hold for 2 seconds).

ERASE RR Scrolls up through the screen display when ↑or ↕ appears on the screen.

RR Erasing of trouble codes in electronic control unit (press and hold for 3 seconds).

RR Resetting of inspection and maintenance monitors in electronic control unit.

ERR Go to function selected. RR Return to main menu.

Tab. 2: Buttons and their functions

3.4.2 OBD diagnostic connector

This connects the OBD 100 to the OBD diagnostic socket in the vehicle.

3.5Cleaning

!!Do not use abrasive cleaning agents and coarse workshop cloths.

¶¶The housing is only to be cleaned with a soft cloth and neutral cleaning agents.

Fig. 1: OBD 100

1OBD diagnostic connector

2Button panel

3LCD (two-line)

|

|

569624 Rev "A" | 2013-12-19 |

Robert Bosch GmbH |

All you need to know about OBD | OBD 100 | 5 en

4.All you need to know about OBD

4.1What are OBD, OBD II, OBD-2 and EOBD

OBD (on-board diagnosis) means that

RR Emission-related components and systems are monitored by the vehicle whilst driving

RR Any malfunctions are recorded and indicated by a warning lamp (MIL)

RR This information can be read by a diagnostic tester

iiA further purpose of OBD is to protect vulnerable components such as catalytic converters.

In these operating instructions, OBD is always used to refer to the standard OBD-2 (OBD II). OBD-2 has been obligatory in the USA for all new vehicles since 1st January 1996. In the EU, OBD-2 was introduced for new vehicles with gasoline engine in January 2001 with the EURO- 3 standard and for diesel vehicles in January 2004. EOBD is the abbreviation for European on-board diagnosis based on OBD-2.

The OBD diagnostic system is integrated into the electronic control unit and constantly monitors defined emission-related components in the vehicle. The malfunction indicator light (MIL) informs the driver of OBD faults reported by the electronic control unit.

A minimum of five monitoring systems are provided:

RR Emission-related components RR Missing combustion

RR Fuel system

RR Upstream and downstream Lambda sensors RR Catalytic converter efficiency

RR Exhaust gas recirculation RR Secondary air system

The following are permanently monitored: RR Missing combustion

RR Fuel system (injection times)

RR Circuits for emission-related components

The following are monitored once per drive cycle:

RR Lambda sensor function

RR Catalytic converter function

iiSpeed, temperature and Lambda sensor values can also be read out by way of the OBD diagnostic socket.

4.2Is my vehicle provided with OBD

In the EU, OBD-2 was introduced for new vehicles with gasoline engine in January 2001 with the EURO-3 standard and for diesel vehicles in January 2003.

iiVehicles manufactured before these dates may however also be provided with OBD.

4.3Where is the OBD diagnostic

socket located

The OBD diagnostic socket is usually situated in the driver's footwell in the area of the center console or in the glove compartment.

iiThe installation location can also be looked up in the owner's manual of the vehicle concerned or found in the internet.

4.4Why and when does the malfunction indicator light (MIL)

come on

The malfunction indicator light must come on briefly when switching on the ignition. The malfunction indicator light must go out at the latest when the engine is started. The MIL status (malfunction indicator light "On" or "Off") is read from the vehicle electronic control unit.

If the vehicle has detected an emission-related fault, the status is set to "faulty". It is then no longer possible to pass the exhaust emission test. In such cases the malfunction indicator light is permanently lit to show the driver that the vehicle should be taken to a workshop.

|

|

Robert Bosch GmbH |

569624 Rev "A" | 2013-12-19 |

en 6 | OBD 100 | All you need to know about OBD

4.5What are trouble codes

The OBD trouble codes (DTC) are defined in SAE J2012 and ISO 15031-6. Manufacturerspecific trouble codes can be defined by vehicle manufacturers.

A trouble code is a 5-position code made up of a letter and four digits. A distinction is made between standard trouble codes which may occur with all vehicle makes and manufacturerspecific trouble codes specified by vehicle manufacturers for certain vehicle models.

iiA plain language text outlining the cause of the problem can be assigned to each trouble code.

4.5.1Trouble code structure

iiThe structure of the trouble codes is shown in the following table. This information facilitates trouble-shooting in situations for which no trouble code description is provided.

Trouble codes are 5-position codes. Example:

P 0 1 22 Throttle position sensor signal too low

Pos. |

Value |

Description |

1 |

B |

Body |

|

C |

Chassis |

|

P |

Powertrain |

|

U |

Network |

2 |

0, 2 |

Trouble code defined by ISO / SAE |

Example |

1 |

Trouble code defined by |

for P |

3 |

manufacturer |

|

Trouble code defined by ISO / SAE |

|

|

|

or by manufacturer |

3 |

0 – F |

Grouped by systems |

Example |

0 – 2 |

Fuel air metering |

for P0 |

3 |

Ignition system |

|

4 |

Auxiliary emission controls |

|

5 |

Vehicle speed and idle control |

|

6 |

Computer and output signals |

|

7 – 9 |

Transmission |

|

A – C |

Hybrid |

|

D – F |

Reserved for ISO / SAE |

4, 5 |

00 – 99 |

Identification of individual |

|

|

components |

Tab. 3: Trouble code structure

4.5.2Stored trouble codes

Stored trouble codes (DTC) are trouble codes which have been stored in the electronic control unit (ECU). The description of the trouble

code and the number of the electronic control unit with the designation of its origin are also displayed.

iiIf a trouble code has been set which causes the malfunction indicator light (MIL) to come on, the electronic control unit stores the current values of the sensors at the time at which the fault occurred.

4.5.3Pending code (Pnd)

The first time a fault occurs this is stored as a pending code in the fault memory. If a

pending code is confirmed in the second drive cycle, it becomes a confirmed code. A pending code stored in the electronic control unit is automatically erased after 40 drive cycles

if the prevailing operating conditions were the same as when the trouble code was set. Otherwise the pending code is erased after 80 engine cycles. Such trouble codes report

those faults which have occurred during a drive cycle but which were not sufficient to cause a trouble code to be stored, i.e. not causing the malfunction indicator light to come on.

4.5.4Confirmed code (Cnf)

If a pending code is confirmed in the second drive cycle, it becomes a confirmed code and the malfunction indicator light comes on.

4.5.5Permanent code (Prm)

Permanent codes are a special form of confirmed codes. Permanent codes have only been set by vehicles since 2010, which means that they are not supported by all vehicles.

iiPermanent codes cannot be erased with a diagnostic tester or by disconnecting the battery voltage. The problem must have been rectified and must not have occurred again for the trouble code to be automatically deleted from the fault memory by the electronic control unit.

iiThe presence of a permanent code will cause the vehicle to fail an Inspection or exhaust emission test.

|

|

569624 Rev "A" | 2013-12-19 |

Robert Bosch GmbH |

Loading...

Loading...