Bosch HP270-2, HP270-3, HP200-1, HP250-1 Technical Manual

DOMESTIC HOT WATER

HEAT PUMP 200 / 250 / 270 L

This document is confidential and restricted to exclusive use by the official technical

assistance of Bosch in the countries of destination of this product.

TECHNICAL MANUAL FOR AFTER SALES AND

SERVICE TECHNICIANS

Page 2 from 56 6-720-821-364 SM HP270 – 250 - 200 2016/12 en

1) Introduction

Domestic Hot Water Heat Pumps (DHW-HP), with or without air connections ducts, use the heat existing in the

surrounding air, or the wasted heat from the indoor air, as energy source for DHW preparation.

This model of domestic hot water heat pump provides hot water for residential purposes, using a closed refrigerant

unit filled with R134a. This ensures the energy production taking out the energy from the air – the cold source –

and delivers the energy to a secondary circuit – the water – where a simple circulation pump, ensures the water

movement through a plate heat exchanger, heating the water that is stored in a tank.

2) Working Principle

There are 2 variants of heat pumps, depending on the working conditions:

- Positive working temperatures: +5ºC / +35ºC

- Negative working temperatures: -10ºC / +35ºC

Note: In case the air temperature is out of the specified working range, the appliance automatically activates the

electrical back up (if in Combi mode). One hour after the warning display (HOT or COLD) has appeared; the

appliance checks the air temperature and, in case it is within the range values, returns to heat pump mode

operation.

The control loop for air temperature check is done every hour, while the electrical backup is in operation.

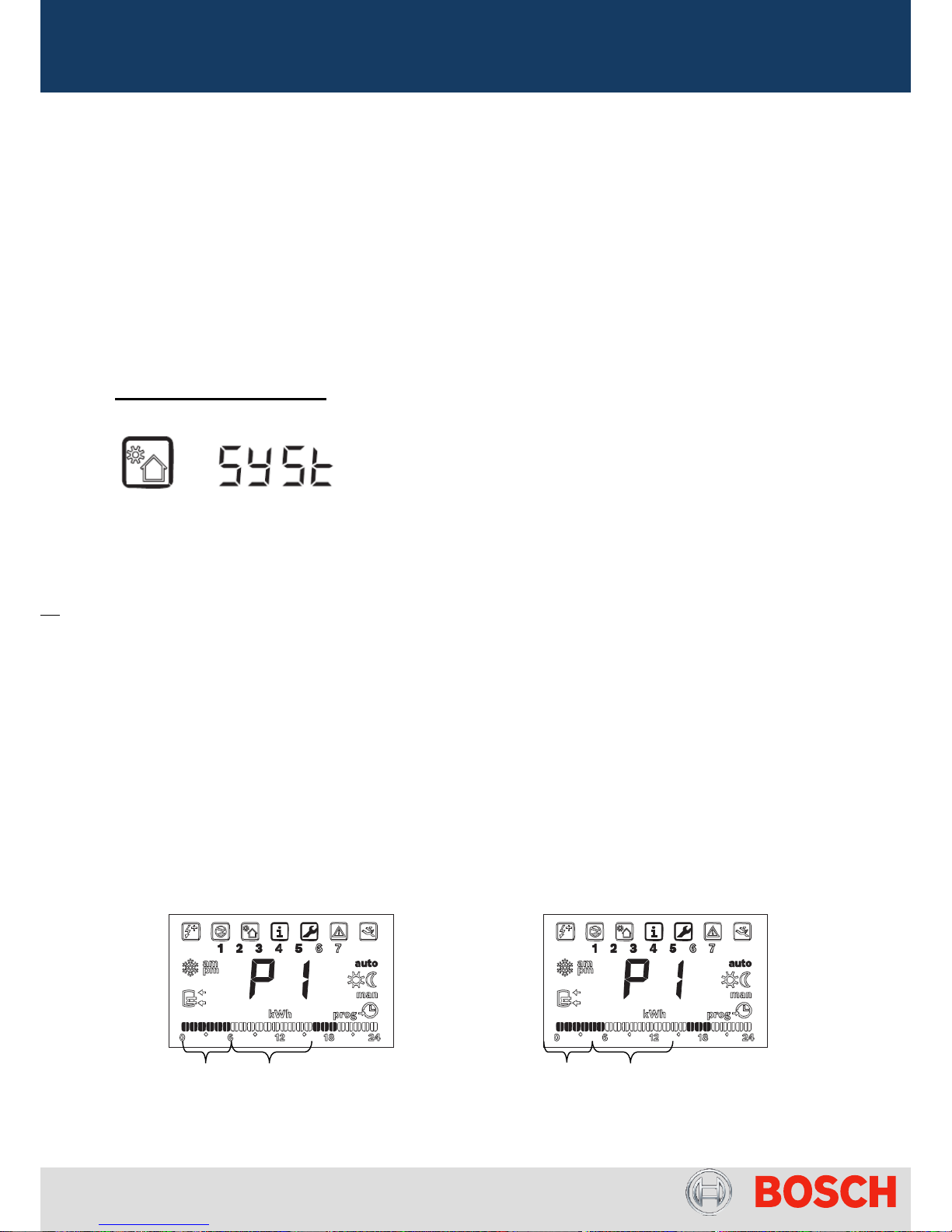

Stand-by mode

HMI actuation

LCD Backlight ON

Active Operation Mode

(default from factory: combi mode + manual operation)

LCD Backlight OFF

(after 15 sec without any selection)

Current Temperature of the Tank

(measured at the top)

Clock & Day Function

(defined at start up and/or current day and hour)

Temperature Selection

(default from factory = 50ºC)

(except FD>555: software

Temperature Blinks

until confirmation with

OK button

Temperature remains as

previous after 10 sec in

case of any other selection

Page 3 from 56 6-720-821-364 SM HP270 – 250 - 200 2016/12 en

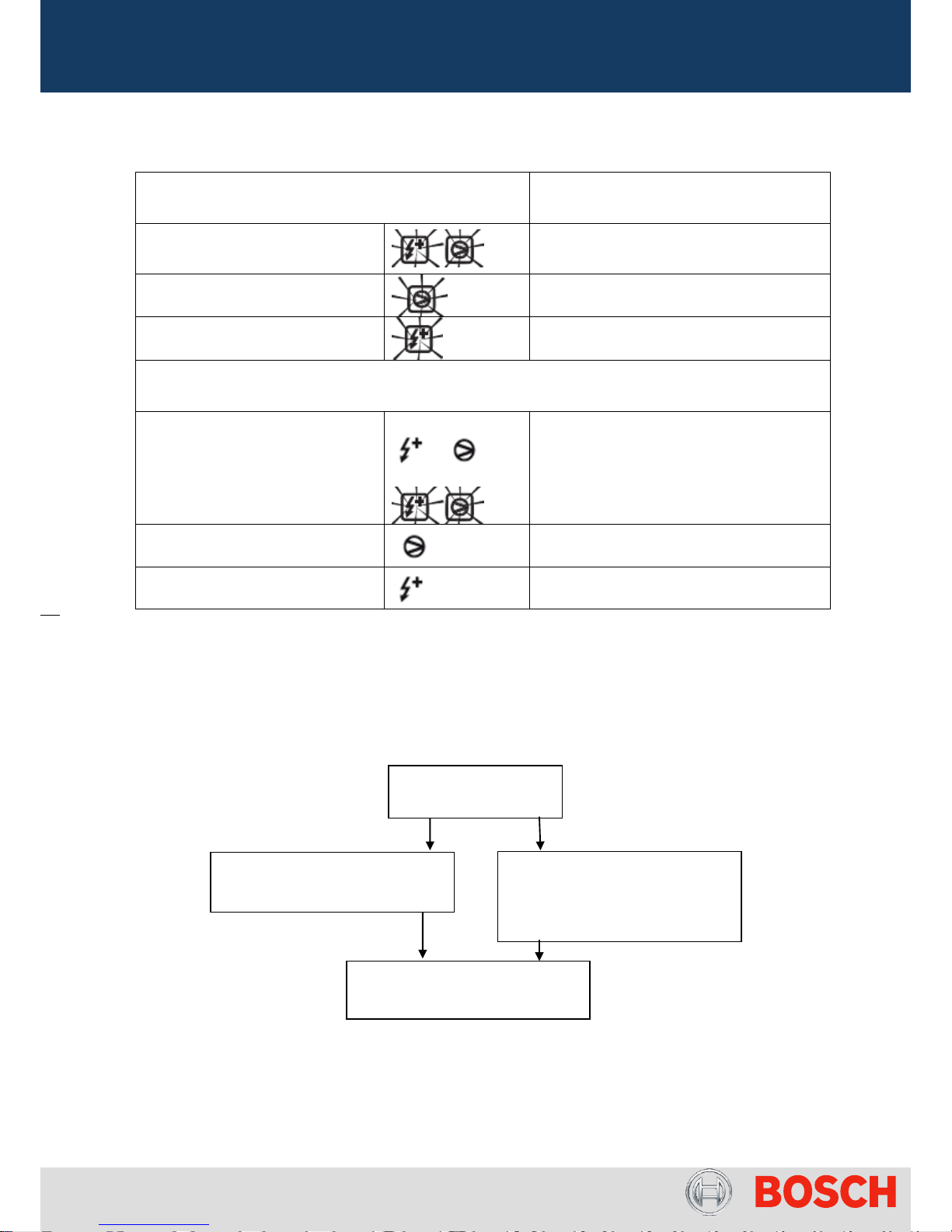

2.1) Operation Modes

Operation Modes (HP 270-2)

Comment

Combi Mode

(default selection from factory)

T

set

= 50ºC / 54ºC (default value depends

software version)

Temperature adjustment: 30ºC to 70ºC

Heat Pump Mode

Temperature adjustment: 30ºC to 60ºC

Electric Heater Mode

Temperature adjustment: 30ºC to 70ºC

New Platform (HP270-3 and HP200/250-1)

Combi Mode

(default selection from factory)

Standby

Operation

T

set

= 53ºC

Temperature adjustment: 30ºC to 70ºC

Economic Mode

Temperature adjustment: 30ºC to 60ºC

Electric Heater Mode

Temperature adjustment: 30ºC to 70ºC

Table 1 – Operation Modes

Conditions for operation:

The heat pump compressor is activated according to the following conditions and control unit settings,

nevertheless, following sequence is always verified when connecting to the main power, when an error code is

reseated or the appliance stops due to reaching the selected temperature.

In the current service manual version, the software specific functions are indicated according Software Version at

control unit identification sticker.

0 – 1 min: Water Pump

ON

1 – 3 min: Standby (Duct off)

or

1 – 2 min: Standby (Duct on)

3 – 4 min: Fan activation when

Duct OFF

or

2 – 4 min: Fan activation when

> 4 min: Compressor and water

pump activation

Page 4 from 56 6-720-821-364 SM HP270 – 250 - 200 2016/12 en

From FD ≥ 306 (June 2013) until FD ≤ 453 (May 2014):

HPAF0501 (-10ºC / + 35ºC models)

HPAF0701 (+5ºC / +35ºC models)

Operation Mode described during manual.

From FD ≥ 454 (June 2014):

HPAF0502 (-10ºC / + 35ºC models)

HPAF0702 (+5ºC / +35ºC models)

Changes done in new version:

- “Syst” message indication in case of detection of PV energy production;

+

- Introduction of new parameter “Rcir” (see IM) for software information about existence of external recirculation of

domestic hot water;

- E09 / E11 lockout activates automatically electrical heater to ensure minimum 40ºC hot water in tank (in combi or

in heat pump mode).

From FD ≥ 555 (July 2015):

HPAF0503 (-10ºC / + 35ºC models)

HPAF0703 (+5ºC / +35ºC models)

o Set Point – default set point of 50ºC was changed to 54ºC due to ErP directive;

o Operation in Automatic Mode – in previous version was not possible to deactivate the external booster

heater (boiler = boil ON) according the defined automatic program mode (P1, P2, P3) in combination with

boiler. The boiler did not switch off after reaching the set point and the correction was using only manual mode.

o Full Mode – the manual (FULL) activation will have from now on, priority even in inactivity periods defined in

P1 / P2 / P3.

Current New

Pict.1 – Behaviour of FULL = Compressor + E-heater / Compressor + Boiler

ON

OFF

ON

ON

Page 5 from 56 6-720-821-364 SM HP270 – 250 - 200 2016/12 en

o Comfort Improvement – to improve comfort a waiting time was introduced, so while heating, the appliance will

be able to detect if the user is tapping water. In situations where the storage tank has an uniform temperature

near the set point and a tapping is detected, the heat pump will stop for 1 hour to maximize the use of hot water

in top part.

o Changes in Air Defrost sequence

(Attention: only +5ºC / +35ºC model)

Current Behavior:

Air defrost sequence is activated during 10 min with fan On and compressor Off when 5ºC < T

air

(3d) < 10ºC for

more than 60 min and compressor is ON for more than 60 min. The number of air defrost (8d) will depend on other

conditions listed in this manual.

This new software version brings additionally an air defrost sequence activated during 45 min when 0ºC < T

air

<

5ºC, as due to ErP directive and to decrease electrical consumption for cold climate the appliance wilkl be allowed

to operate when possible below minimum limit.

2.2) HMI Configuration (see Installation Manual for details)

HP 270-2: From FD ≥ 306 (June 2013) until FD ≤ 660 (Dec 2016):

HPAF0501 / 0502 / 0503 (-10ºC / + 35ºC models)

HPAF0701 / 0702 / 0703 (+5ºC / +35ºC models)

HP Heating Water

T bot < 25ºC

&

Check Tapping Process

(T top - Tbot < 8ºC

&

T set – Ttop < 5ºC for 5 min)

False

True

HP stops for 1 h

Page 6 from 56 6-720-821-364 SM HP270 – 250 - 200 2016/12 en

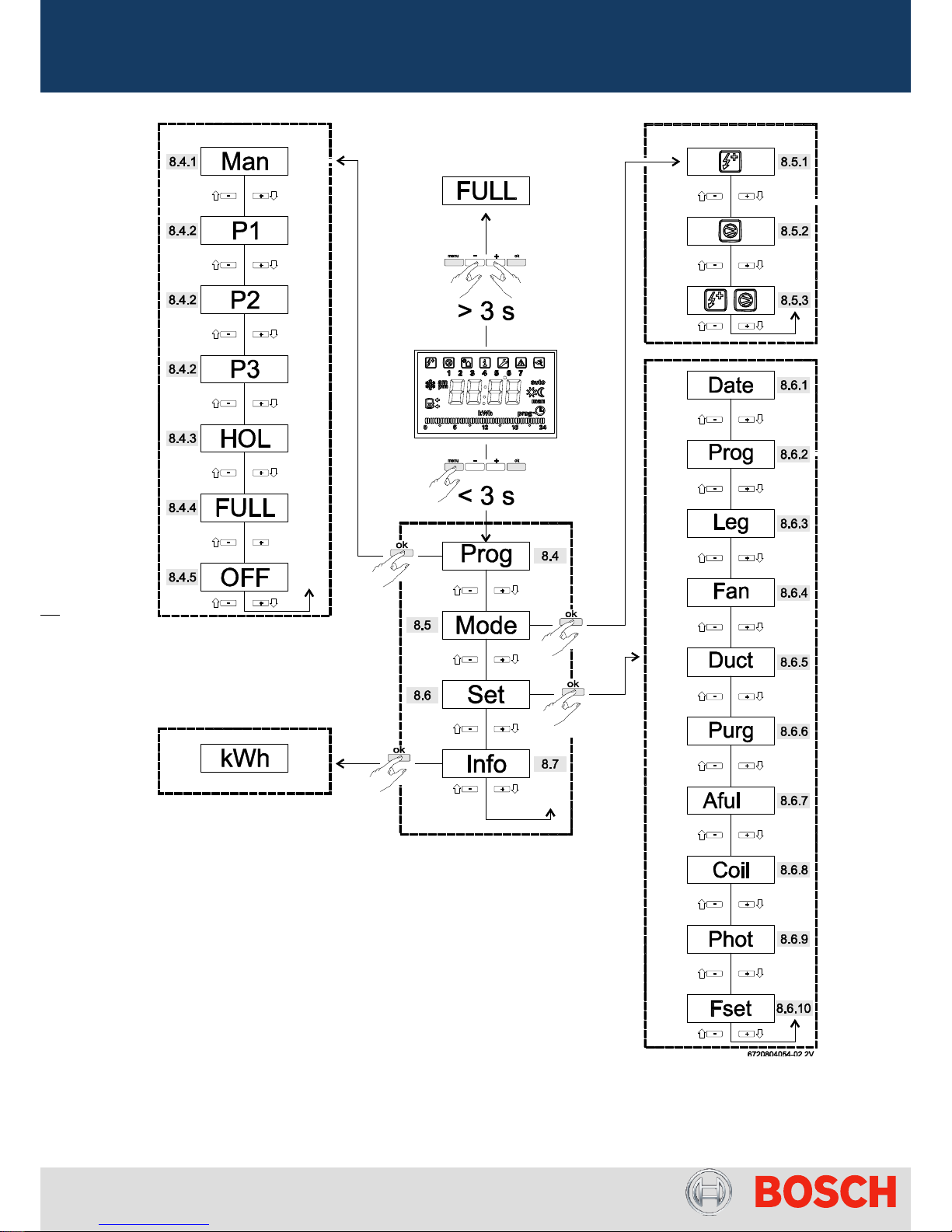

Pict.2 – Parameters overview in main and sub menu of HP270-2

Page 7 from 56 6-720-821-364 SM HP270 – 250 - 200 2016/12 en

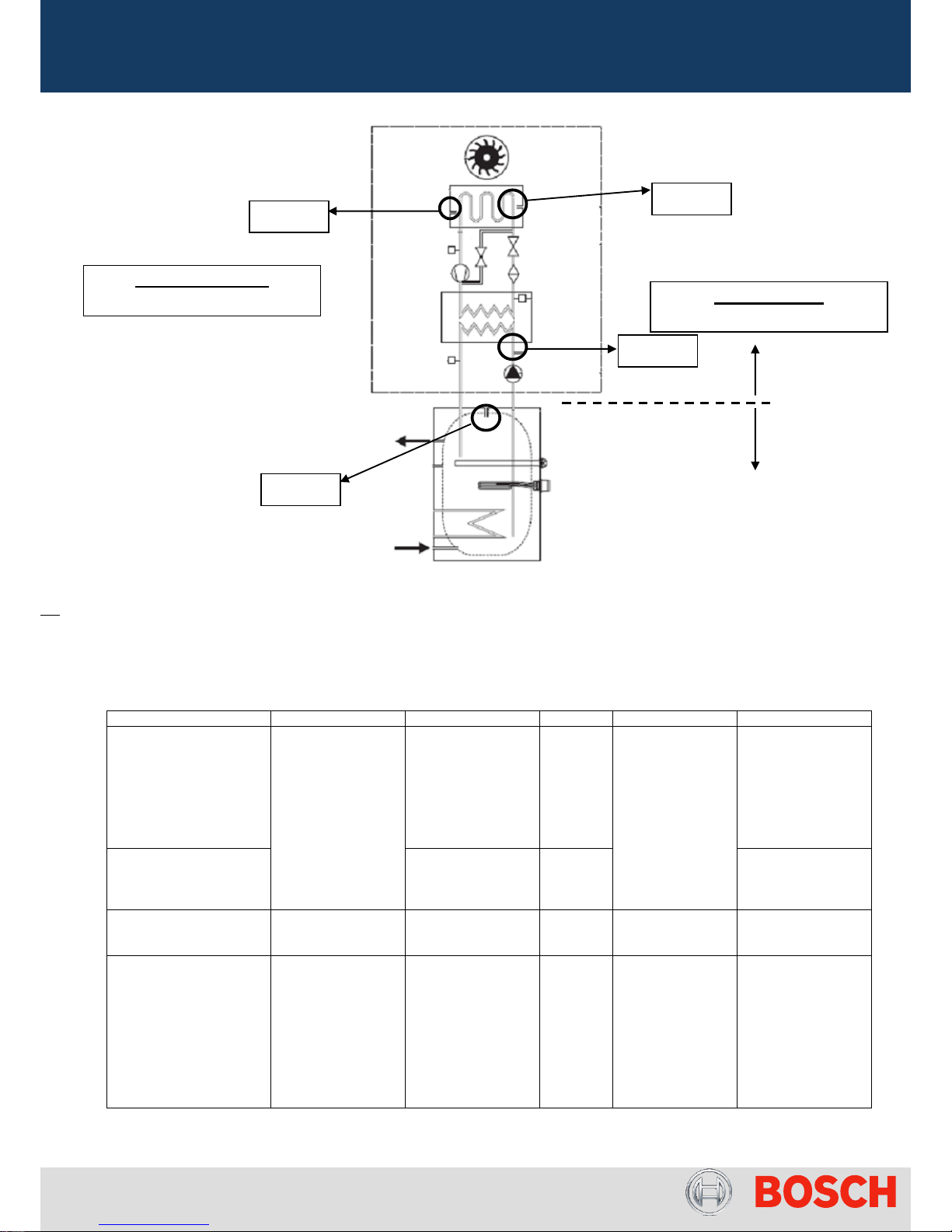

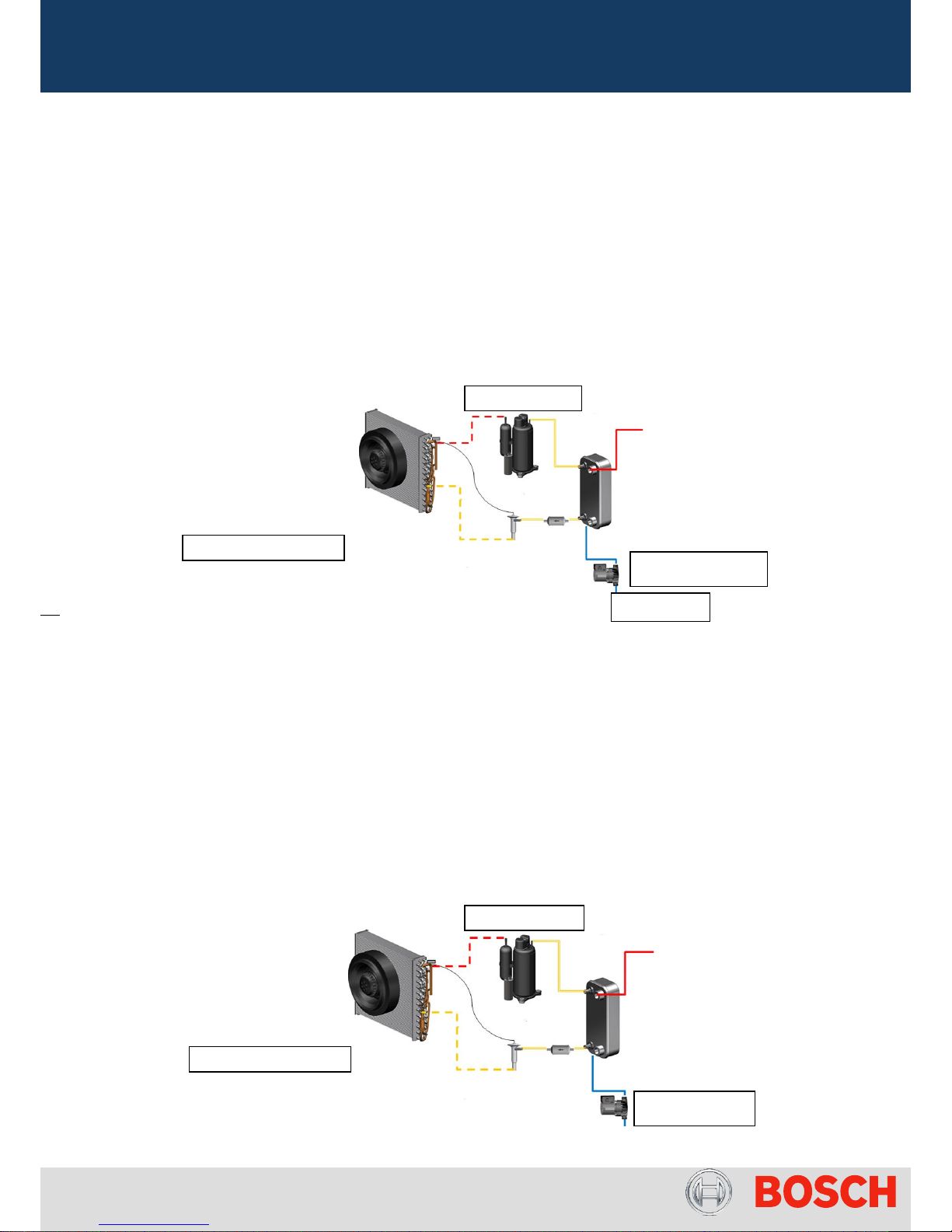

Pict.3 – Heat Pump Diagram (Model HP270-2: -10ºC / +35ºC)

Operation Modes

Applicable to HP-2 with software version:

HPAF0501 / 0502 / 0503 (-10ºC / + 35ºC models)

HPAF0701 / 0702 / 0703 (+5ºC / +35ºC models)

Operation Mode

Evaporator

Compressor

Solenoid

Pump

E-Heater

Combi Mode

Conditions (Man / Aut)

ON if compressor is

ON

Note: If Duct On

starts 2 min before

compressor and if

Duct Off starts 1

min before

compressor in order

to update air

temperature value

ON if -10ºC < T

air

<

+35ºC

and T

bot

< 55ºC

and T

top

< 60ºC

OFF

ON if compressor

is ON or

1 min ON

everyday if

compressor is

OFF

ON if compressor

cannot work due air

temperature

conditions

(T

air

< -10ºC or T

air

>

35ºC)

or Tbot > 55ºC or T

top > 60ºC

Heat Pump Mode

Conditions (Man / Aut)

ON if -10ºC < T

air

<

+35ºC

and T

bot

< 60ºC

OFF

OFF

Electric Heater Mode

Conditions (Man / Aut)

OFF

OFF

OFF

1 min ON every

hour

ON

Full Mode Conditions

ON if compressor is

ON:

Note: If Duct On

starts 2 min before

compressor and if

Duct Off starts 1

min before

compressor in order

to update air

temperature value

ON if -10ºC < T

air

<

+35ºC

and T

bot

< 55ºC

and T

top

< 60ºC

OFF

ON if compressor

is ON or

1 min ON every

hour if E-heater

ON when

compressor is

OFF

ON

Table 2 – Operation Modes Conditions

T

top

T

bottom

T

air

T

fins

Start Up Condition:

T

top

< (T

set

– 3ºC)

Stop Condition:

T

top

≥ T

set

module

tank

Page 8 from 56 6-720-821-364 SM HP270 – 250 - 200 2016/12 en

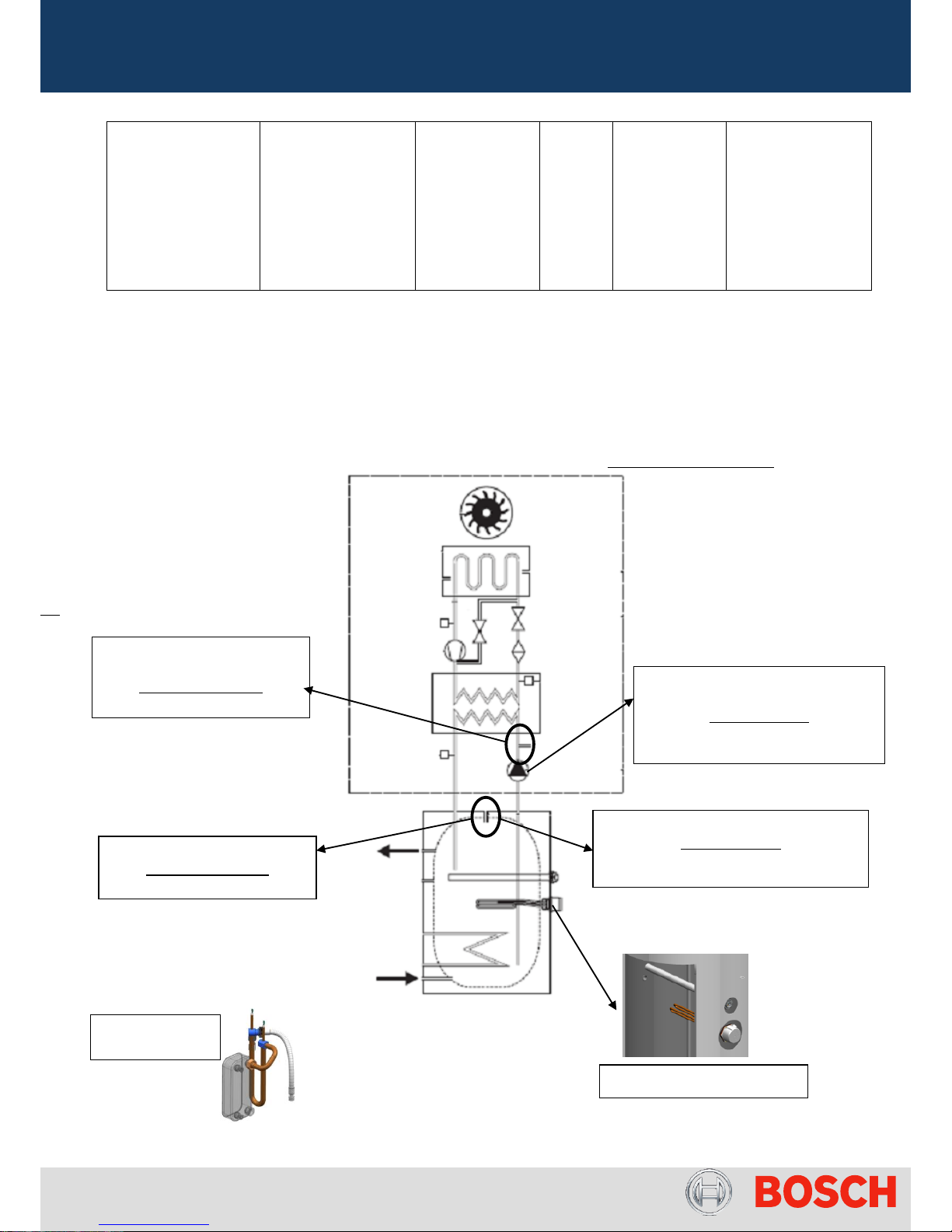

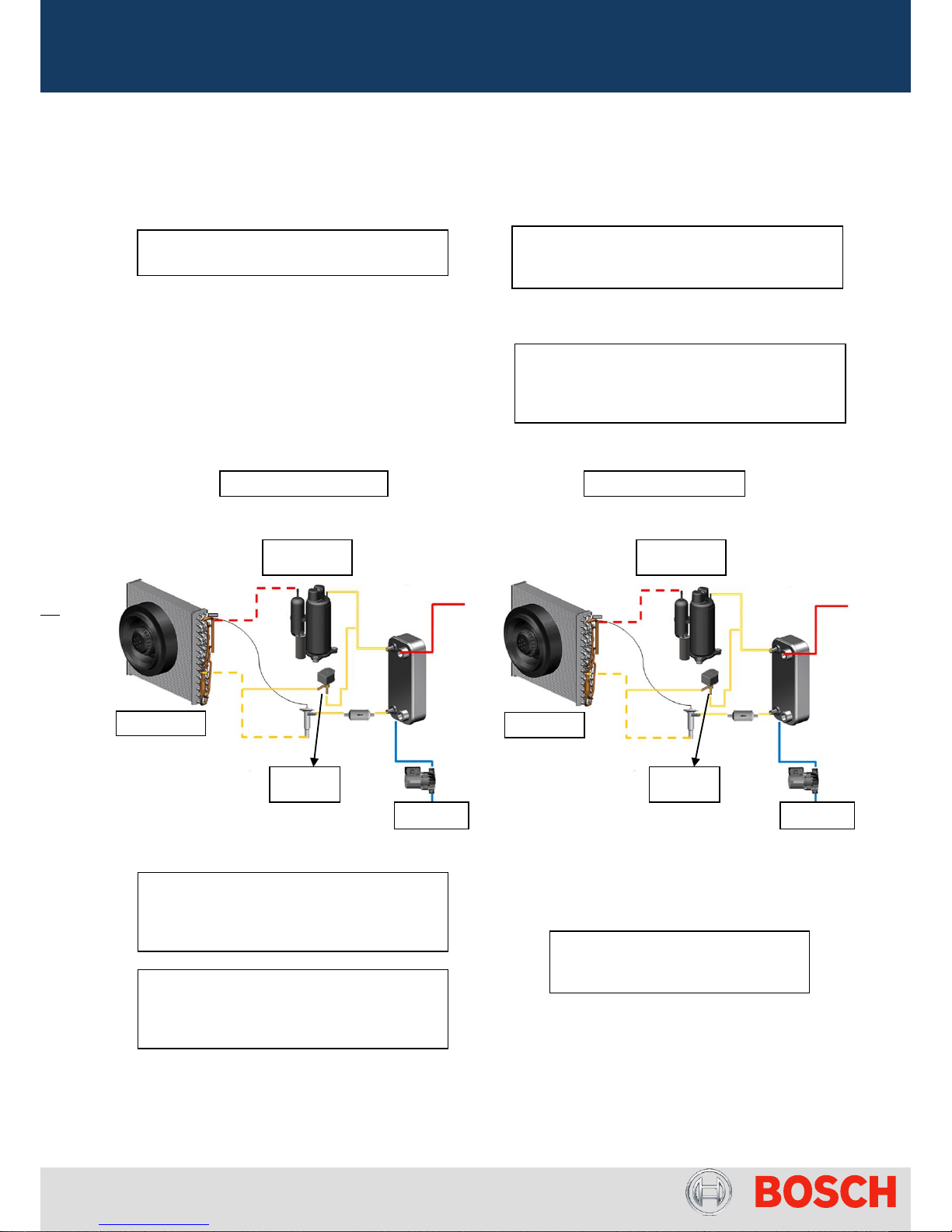

From FD ≥ 660 (Dec 2016):

HPAF2501 (-10ºC / + 35ºC models) (HP270-3)

HPAF2701 (+5ºC / +35ºC models) (HP270-3)

Introduction of HP 270-3 Model

Product Changes:

- New HMI concept;

- Remove of “Rcir” parameter;

- Replacement of Tank Bushes;

- Replacement of charging / measurement point cover;

- Magnesium Anode in tank bottom but possible control by measuring current;

- Electric heater integration in module;

- Change of pump: Electronically controlled with variable speed;

- Change of Fan: Electronically controlled;

Pict. 4 – Detail of impact in hydraulic circuit with electric heater in top of module and new pump

From FD ≥ 660 (Dec 2016):

HPAF2801 (+5ºC / +35ºC models) (HP200/250-1)

Introduction of HP 200/250-1 Platform

Product Changes:

- New Tank Platform (200 / 250 litres)

- New Module design with side connections for air

- Electric heater integrated in module

- Anode in top of tank

Pict. 5 – Detail of new module platform in HP200/250-1

Page 9 from 56 6-720-821-364 SM HP270 – 250 - 200 2016/12 en

Pict.5 – Parameters overview in main and sub menu of HP270-3 / HP200/250-1

Applicable to HP-3 with software version:

HPAF2501 (-10ºC / + 35ºC models) (HP270-3)

HPAF2701 (+5ºC / +35ºC models) (HP270-3)

HPAF2801 (+5ºC / +35ºC models) (HP200/250-1)

Operation Mode

Evaporator

Compressor

Solenoid

Pump

E-Heater

Combi Mode

Conditions (Man /

Aut)

ON if compressor is

ON

Note: If Duct On

starts 2 min before

compressor and if

Duct Off starts 1 min

before compressor in

order to update air

temperature value

ON if -10ºC <

T

air

< +35ºC

and T

dis

< 61ºC

and T

top

< 58ºC

(same for +5ºC

model)

OFF

ON if

compressor is

ON

or

ON

if E-heater ON

when

compressor is

OFF

ON if compressor

cannot work due air

temperature

conditions

(T

air

< -10ºC or T

air

> 35ºC)

or T

dis

> 63ºC or T

top

> 60ºC

Economic Mode

Conditions (Man /

Aut)

ON if -10ºC <

T

air

< +35ºC

and T

top

< 60ºC

OFF

ON if T

air

< -10ºC

Or

T

air

> 35ºC

(same for +5ºC

model)

Electric Heater

Mode Conditions

(Man / Aut)

OFF

OFF

OFF

ON

ON

Page 10 from 56 6-720-821-364 SM HP270 – 250 - 200 2016/12 en

Boost Mode

Conditions

ON if compressor is

ON:

Note: If Duct On

starts 2 min before

compressor and if

Duct Off starts 1 min

before compressor in

order to update air

temperature value

ON if -10ºC <

T

air

< +35ºC

and T

dis

< 61ºC

and T

top

< 58ºC

OFF

ON if

compressor is

ON

or

ON if E-heater

ON when

compressor is

OFF

ON

Table 3 – Operation Modes Conditions

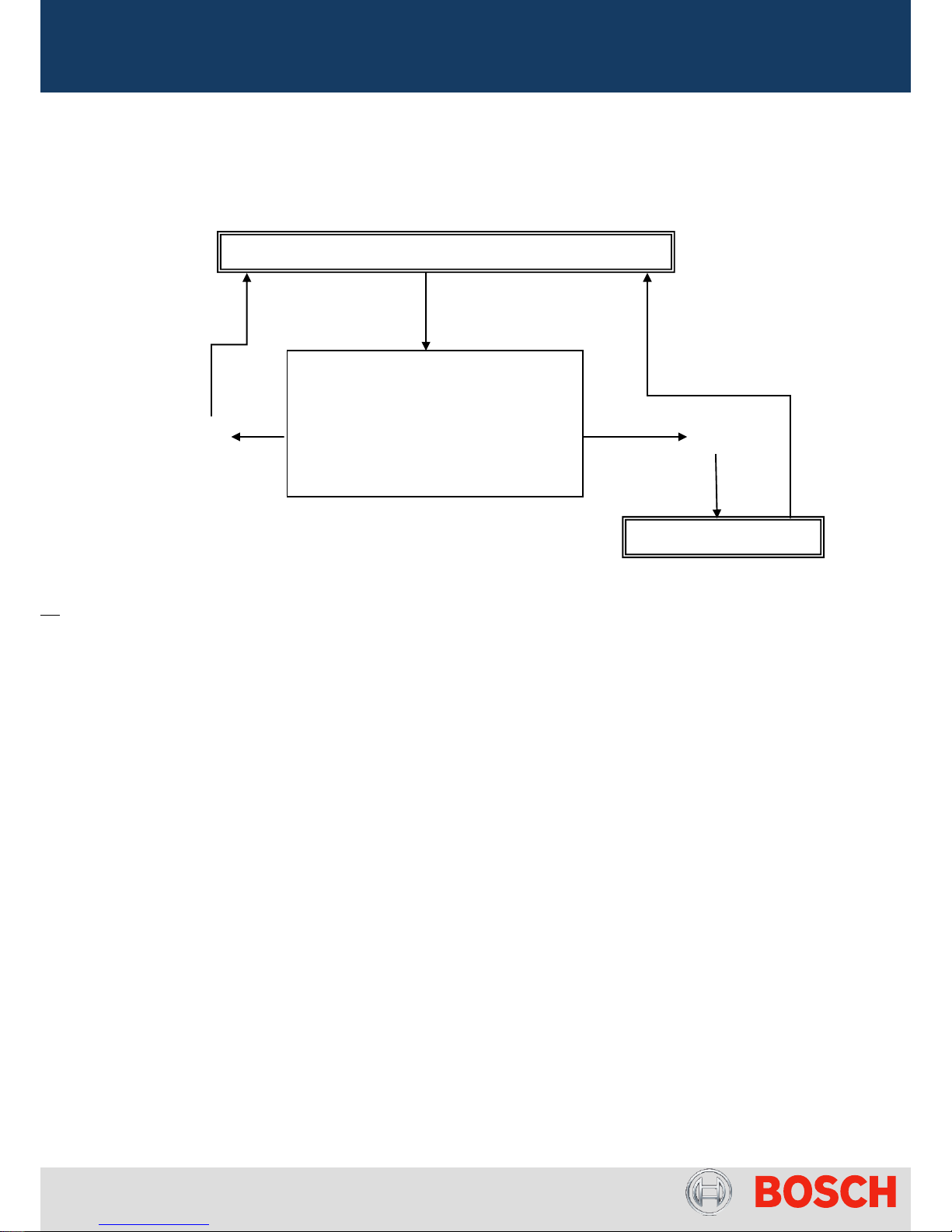

2.2) Protection Modes

Anti-Freeze Protection

The anti freeze protection is designed to protect both the module and the tank and is active in all conditions,

specially, when the appliance is set in Heat Pump, standby, OFF and Holyday (Hol) modes.

Note: In order to ensure the anti freeze protection activation, the mains plug must not be disconnected.

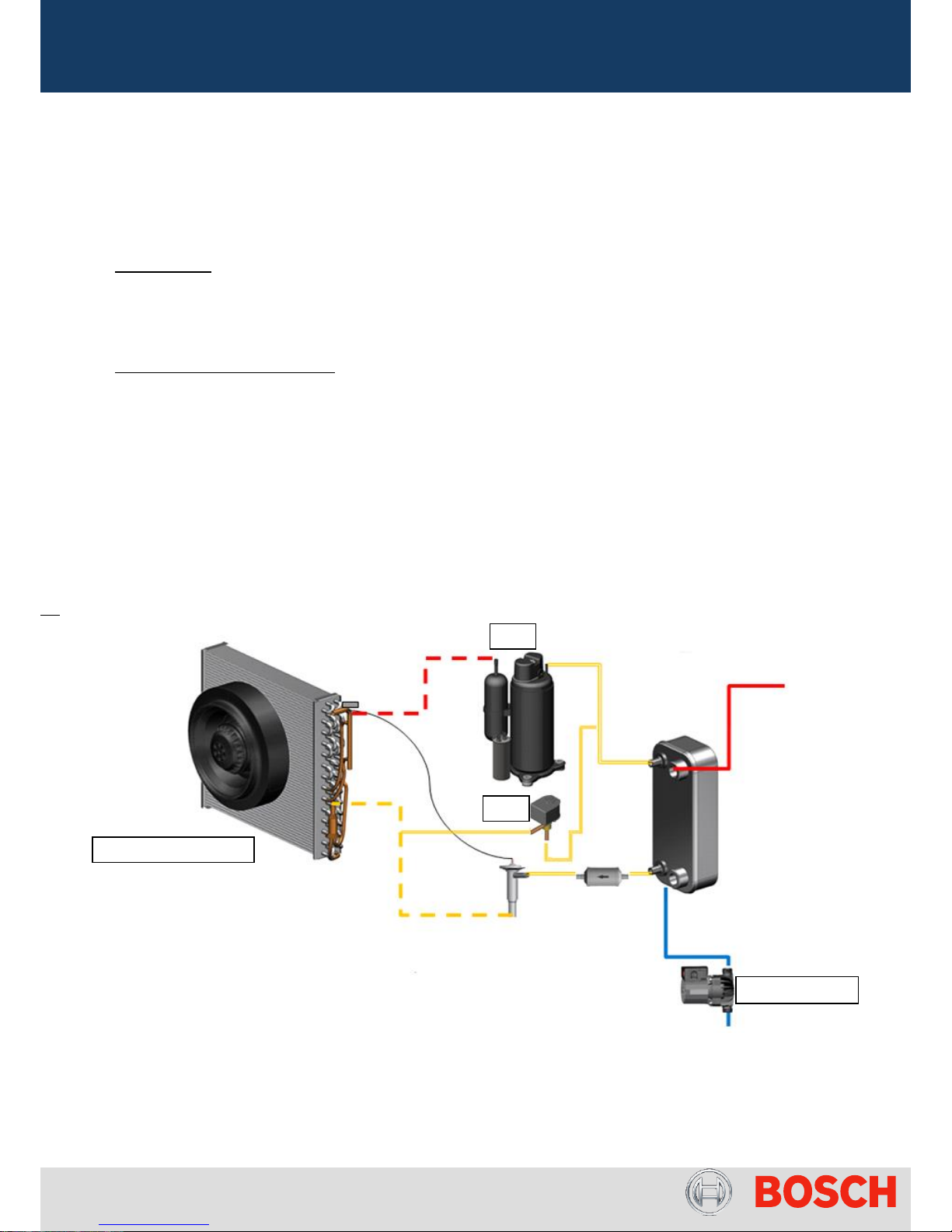

Pict.6 – Heat Pump Diagram (Model HP270-2: -10ºC / +35ºC)

Module Protection

Start Up Condition:

T

Bottom

< 4ºC

Module Protection

Stop Condition:

Until T

bottom

> 6ºC + Water Pump

ON during 1 min

Tank Protection

Start Up Condition:

T

top

< 5ºC

Tank Protection

Stop Condition:

E-Heater ON until T

top

> 8ºC

(not in case of Full or Legionela activation)

Pump + Electric Heater ON

Pump + Electric

Heater ON

Only HP270-3 and HP200/250-1:

Integrated E-Heater in module

Page 11 from 56 6-720-821-364 SM HP270 – 250 - 200 2016/12 en

Legionela disinfection:

From both manual (instantaneous) and automatic (weekly operation) selection, the legionela function will assure

the COMBI mode operation during the 1st 24 hours (compressor until T

top

> 60ºC and only E-Heater until T

top

>

70ºC), nevertheless and if this was not enough to complete LEG function, the HP switch to FULL mode.

Stop condition:

T

top

> 70ºC or T

bottom

> 60ºC or Leg function time > 48h (24 hours in combi and 24 hours in FULL)

Stop condition (only for HP270-3):

T

discharge

> 60ºC during 10 min or Leg function time > 48h (24 hours in combi and 24 hours in BOOST)

Conditions for air-defrost sequence:

Air defrost sequence is activated in both +5ºC / +35ºC and -10ºC / +35ºC models when 5ºC < T

air

< 10ºC for more

than 60 min and compressor is ON for more than 60 min as well with recurrence determined by the temperature

measured by T

bottom

sensor.

Pict.7 – Status diagram for air defrost

Condition HPAF0501/0701:

T

bottom

< 20ºC

(defrost every 90 min)

T

bottom

< 35ºC

(defrost every 360 min)

T

bottom

< 60ºC

(defrost every 840 min)

OFF

ON during 10 min

Water Pump OFF

OFF

Condition

HPAF0502/0702

HPAF0503/0703

T

bottom

< 20ºC

Or

Tair-Tfins > 6ºC

(defrost every 90 min)

Condition

HPAF2501/2701

HPAF2801

T

discharge

< 20ºC

Or

Tair-Tfins > 6ºC

(defrost every 90 min)

Page 12 from 56 6-720-821-364 SM HP270 – 250 - 200 2016/12 en

o Changes in Air Defrost sequence

(Attention: only +5ºC / +35ºC model)

Current Behaviour:

Air defrost sequence is activated when 5ºC < T

air

< 10ºC for more than 60 min and compressor is ON for more than

60 min. the nº of cycles depends on detection of following additional conditions.

Condition (HPAF0702 / HPAF0703):

T

bottom

< 20ºC

Or

T

air

- T

fins

> 6ºC

(defrost every 90 min)

Pict.8 – Air Defrost Sequence

New Behaviour (only in HPAF0703):

In addition to current function in +5ºC / +35ºC models an additional air defrost sequence is programmed. When 0ºC

< T

air

(3d) < + 5ºC will last for more than 60 min and compressor is ON for more than 60 min, the evaporator defrost

will start. The fan will run during 45 min to defrost evaporator and in the meanwhile the electric heater will heat up

the water.

Condition (HPAF0703 + 1701 + 2701):

Compressor is ON for more than 60 min and

T

air -Tfins

> 3.5ºC for more than 1 min or T fins < -17ºC

Pict.9 – Air Defrost Sequence

Fan ON during 10 min

T

bottom

Water Pump OFF

Compressor OFF

Fan ON during 45 min

Water Pump OFF

Compressor OFF

Page 13 from 56 6-720-821-364 SM HP270 – 250 - 200 2016/12 en

Conditions for gas-defrost sequence:

Gas Defrost sequence is activated only in -10ºC / +35ºC models when -10ºC < T

air

< 5ºC for more than 60 min,

performed in 2 steps (Pre-gas defrost + Gas defrost), according to the compressor operation conditions.

Or

or

Pict.10 – Status diagram for gas defrost procedure

1st step: Pre-Gas Defrost

2nd step: Gas Defrost

Fan ON

Fan OFF

Solenoid

ON

Compressor

ON

Compressor

ON

Time for pre-gas defrost (HP270-2):

T

bottom

< 25ºC / Time = 2 min

T

bottom

> 25ºC and < 40ºC / Time = 1 min

T

bottom

> 40ºC / Time = 0.5 min

Gas Defrost sequence stops when

T

fins

> 6ºC or gas defrost lasts for

more than 30 min

Condition 1:

Compressor is ON for more than 180 min

Condition 2.1:

Compressor is ON for more than 60 min and

T

air -Tfins

> 3.5ºC for more than 1 min

Solenoid

OFF

Condition 2.2:

Compressor is ON for more than 60 min and

T fins < -17ºC or compressor stopped for some

reason

OFF

OFF

Time for pre-gas defrost (HP270-3):

T

discharge

< 25ºC / Time = 2 min

T

discharge

> 25ºC and < 40ºC / Time = 1 min

T

discharge

> 40ºC / Time = 0.5 min

Page 14 from 56 6-720-821-364 SM HP270 – 250 - 200 2016/12 en

3) Electric Measurements

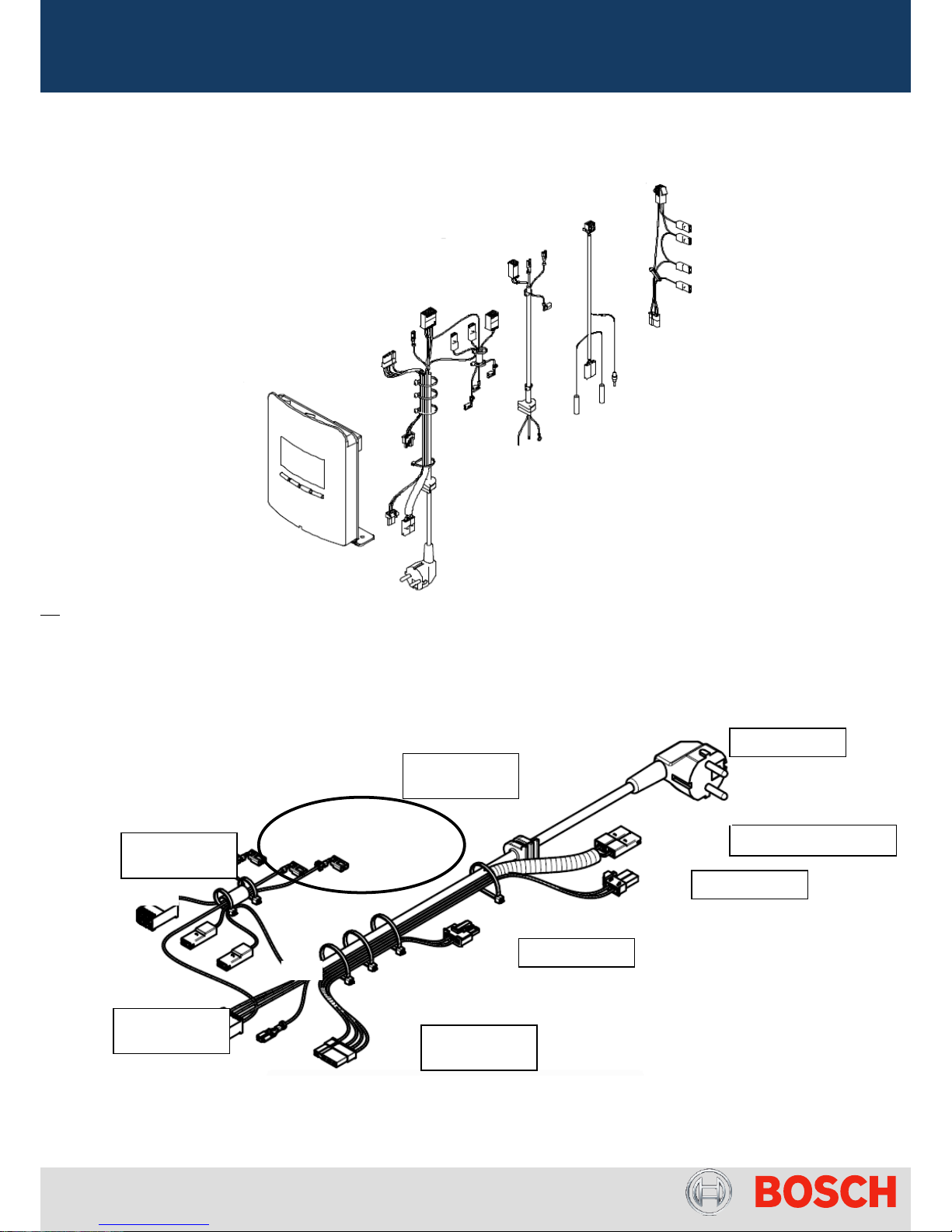

Pict.11 – Control Unit and cables overview

Main Cable supply

Pict.12 – Mains Power Supply

Mains Plug

Solenoid

Water Pump

High Pressure Switch

PCB: AC

Connector

PCB

Connector

Compressor

Connections

Capacitor

Connection

Brown -

Blue

Brown -

Blue

Grey-Grey

White

Blue

Black

Grey

Black

Page 15 from 56 6-720-821-364 SM HP270 – 250 - 200 2016/12 en

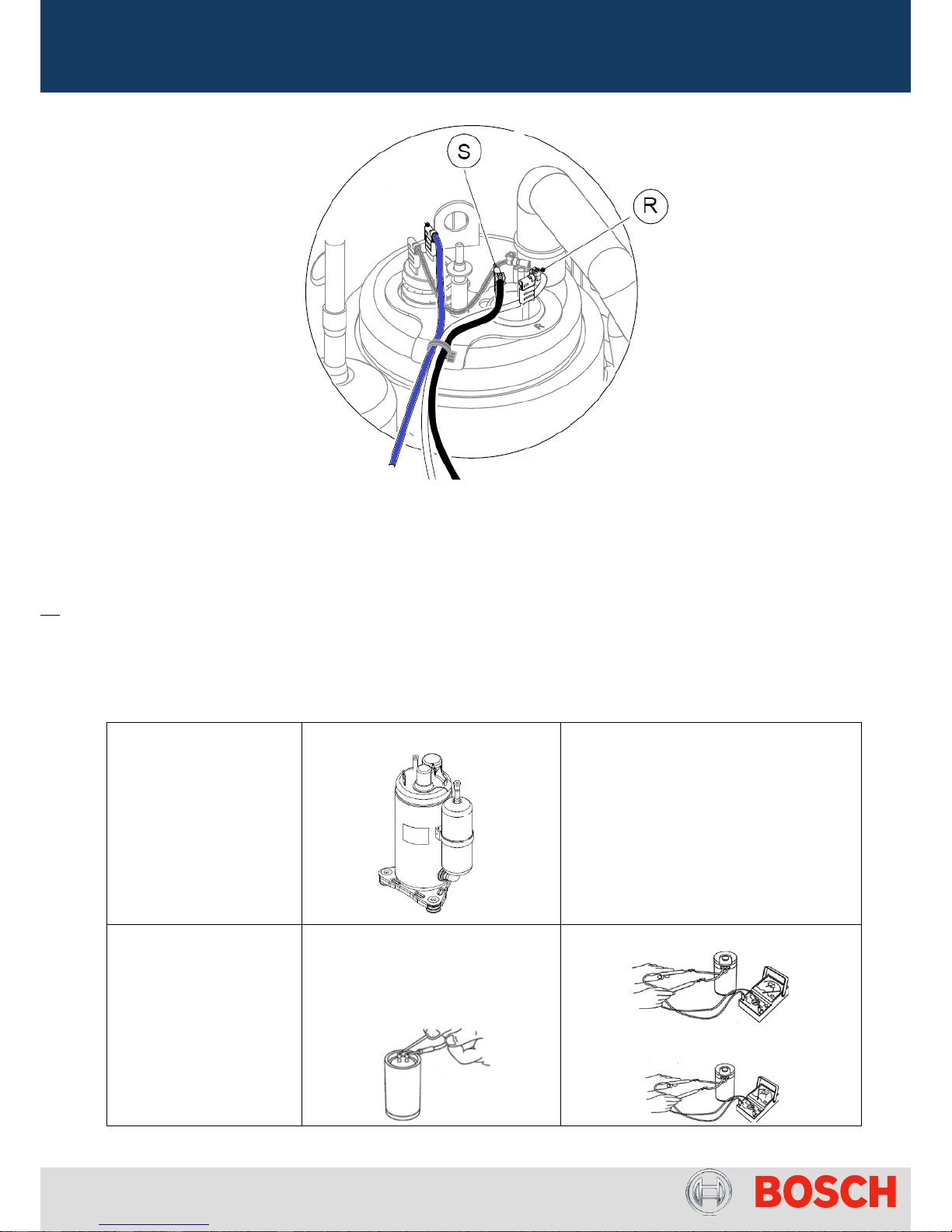

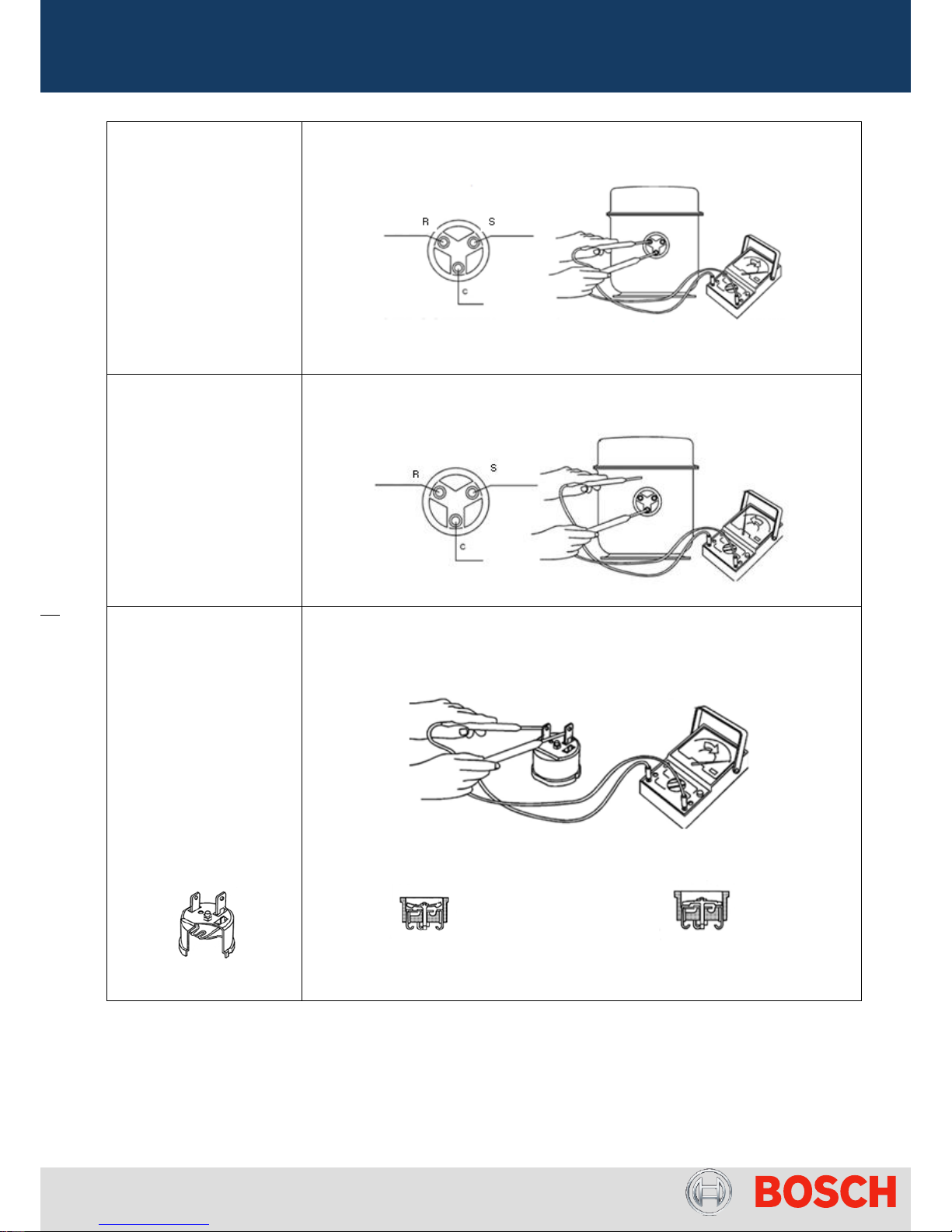

Pict.13 – Compressor Connection Detail

Compressor

- After turn ON the appliance, the compressor should operate for more than 5 minutes.

- The compressor should be operated for more than 20 seconds within 15 minutes after charging refrigerant

into the system to ensure proper lubrication

- The compressor should never be operated while under vacuum, otherwise, internal arcing can damage

some parts.

- The compressor should not be left opened in the atmosphere for more than 5 minutes.

Highly

(model WHP01900BSV)

Specification from supplier:

- Standard condition: 1.9 kW of heating

capacity / 475 W input

- Thermal protection included

(temperature limiter: opens at 160ºC,

closes at 70ºC)

- 270 ml of oil capacity

Capacitor (15 µF)

In case of check capacitor, discharge

electric charge with a resistance of

20kΩ

OK – scale decrease to 0 and pass to ∞

Not OK – 0Ω

Page 16 from 56 6-720-821-364 SM HP270 – 250 - 200 2016/12 en

Between C – R > 0

Highly ≈ 5.84 Ω

Between C – S > 0

Highly ≈ 7.62 Ω

Between R – S > 12 Ω

(values @ 20ºC)

Checking Continuity and Resistance (Ω):

Check earth connection

C – chassis ≠ 0

S – chassis ≠ 0

R – chassis ≠ 0

Attention: In case of

continuity the compressor

is defected

Electric test to compressor:

Thermal Protection

This function is ensured by

a bimetallic temperature

limiter which opens its

contact when high

temperature (T=160ºC

±10ºC) is reached during

operation.

Testing of thermal protection limiter:

Open contact Close contact

temperature activation – T≥160ºC normal operation – T<70ºC

Table 4 – Compressor components overview

Page 17 from 56 6-720-821-364 SM HP270 – 250 - 200 2016/12 en

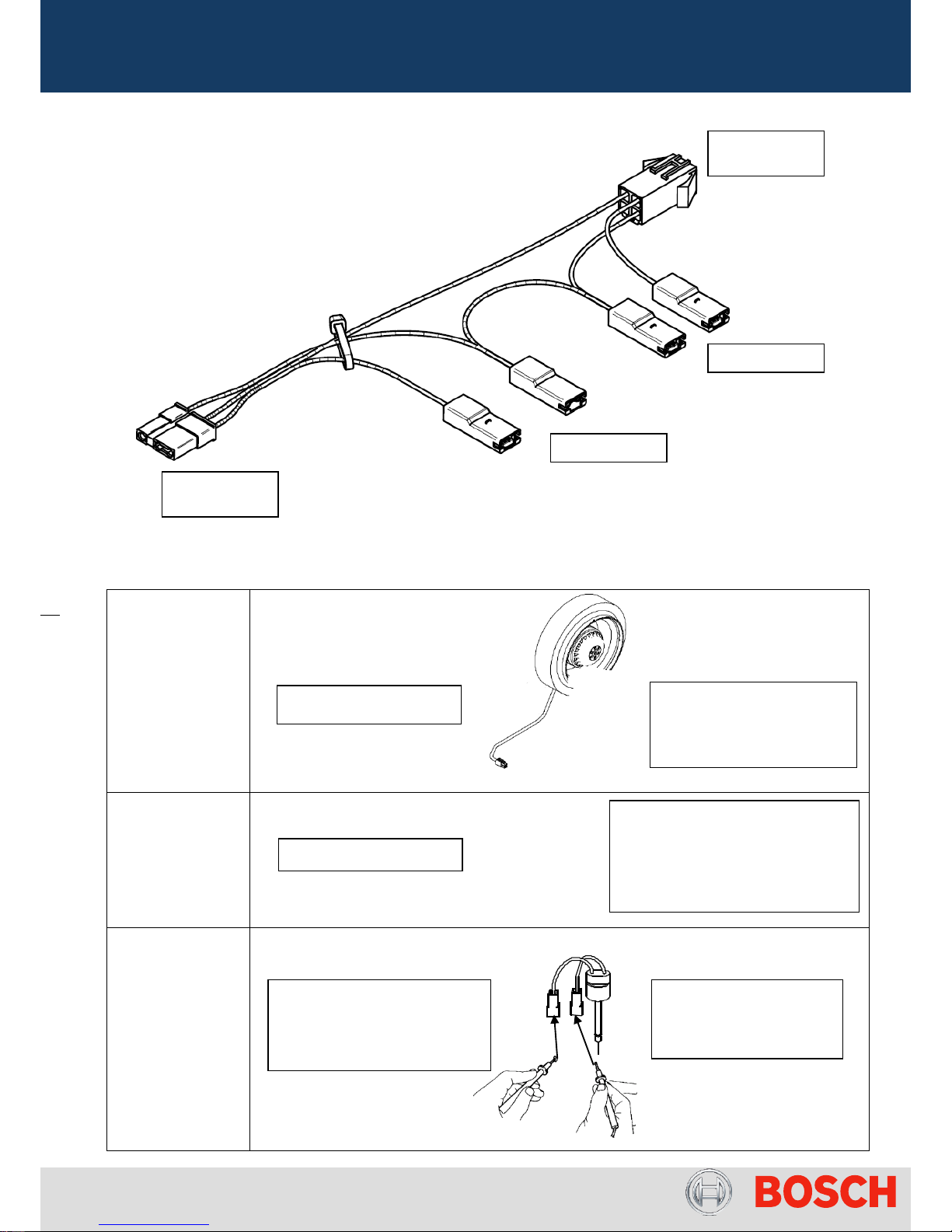

Capacitor / Fan Cable

Pict.14 – Fan Connection (HP270-2)

Fan

(EBM Papst)

AC controlled

Note: Only

HP270-2 and

HP200-250-1

Fan

EC: electronically

controlled

Note:

only HP270-3

High Pressure

Switch connection

(use of multimeter:

continuity or

resistance

measurement)

PCB

Connector

Capacitor 2

Capacitor 1

Fan

Connector

Brown

Brown

Brown

Black

Blue

Contact Normally Closed

Not OK - ∞ (contact opened)

OK - 0Ω (contact closed)

230 V ac between L / N

Note: Continuity Test

performed at atmospheric

pressure or when

component is stopped

HP 270-2

Controlled by 2 capacitors

Start = 2µF

Speed Control = 6.3 µF

230 V ac between L / N

Input Voltage is fix

Variable speed using PWM signal

White: Feedback of speed

Red: Not used

Yellow: PWM Signal

Blue: Ground

Loading...

Loading...