Bosch AVENAR FAP-425, AVENAR FAH-425 Operation Manual

AVENAR detector 4000

FAP-425 / FAH-425

en Operation Guide

Table of contents

1

Product Description 4

2

System Overview 5

2.1 Functional Description of the Sensor Technology 5

2.1.1 Optical Sensor (Smoke Detector) 5

2.1.2 Thermal Sensor (Heat Detector) 5

2.1.3 Chemical Sensor (Gas Sensor) 6

2.2 System Description 6

2.3 Flash Frequency and Error Detection 6

2.4 Features 6

2.5 Accessories 7

2.5.1 Remote Indicators 9

3

Planning 13

3.1 Basic Installation/Configuration Notes 13

3.2 Use in a Local Security Network (LSN/LSN improved version) 13

4

Programming 14

4.1 FAP-425-DOTC-R 14

4.2 FAP‑425‑DOT‑R / FAP‑425‑OT‑R / FAP‑425‑OT 15

4.3 FAP‑425‑DO‑R / FAP‑425‑O‑R / FAP‑425‑O 16

4.4 FAH‑425‑T‑R 17

5

Connection 19

5.1 Overview of Detector Bases 19

5.2 Installing the Base 20

5.3 Connection 21

5.3.1 Connecting the MS 400/MS 400 B 22

5.3.2 Connecting the FAA‑MSR 420 22

5.4 Detector Base Sounders 23

5.5 Installation of the Detector Module 24

5.6 Detector Removal 25

5.7 Address Setting 25

6

Order Information 27

6.1 Detector Variants 27

6.2 Detector Bases 27

6.3 Detector Accessories 27

6.4 Installation Accessories 28

6.5 Detector Base Sounders 28

6.6 Service accessories 28

7

Maintenance and Service 30

7.1 Detector Type Encoding 30

7.2 Test Instructions for LSN improved version Fire Detectors 31

7.2.1 Test Instructions for All Fire Detectors With Optical Sensor 31

7.2.2 Test Instructions for FAP‑425‑DOTC‑R / FAP‑425‑DOT‑R / FAP‑425‑OT‑R / FAP‑425‑OT 32

7.3 Diagnostic Data 32

7.4 Warranty 34

7.5 Repair 34

7.6 Disposal 34

8

Technical Data 35

AVENAR detector 4000 Table of Contents | en 3

Bosch Sicherheitssysteme GmbH Operation Guide 2014.11 | 1.1 | F.01U.283.550

Product Description

AVENAR detector 4000 combines standard detection procedures such as scattered light and

temperature measurement with gas measuring technology at the highest configuration level.

This method uses intelligent evaluation electronics (Intelligent Signal Processing - ISP) to

evaluate the signals from the smoke, thermal and gas sensor. Thus, immunity against false

alarms is increased significantly and detection time is reduced in comparison to the fire

detectors available on the market today.

Thanks to the combined information collected by the multi-sensor detectors, they can be used

in environments where simple smoke detectors cannot be employed.

AVENAR detector 4000 is suitable for surface and flush mounting and includes separate

mounting points for dropped ceiling and concealed sockets.

AVENAR detector 4000 is available in different versions of single-sensor and multi-sensor

detectors.

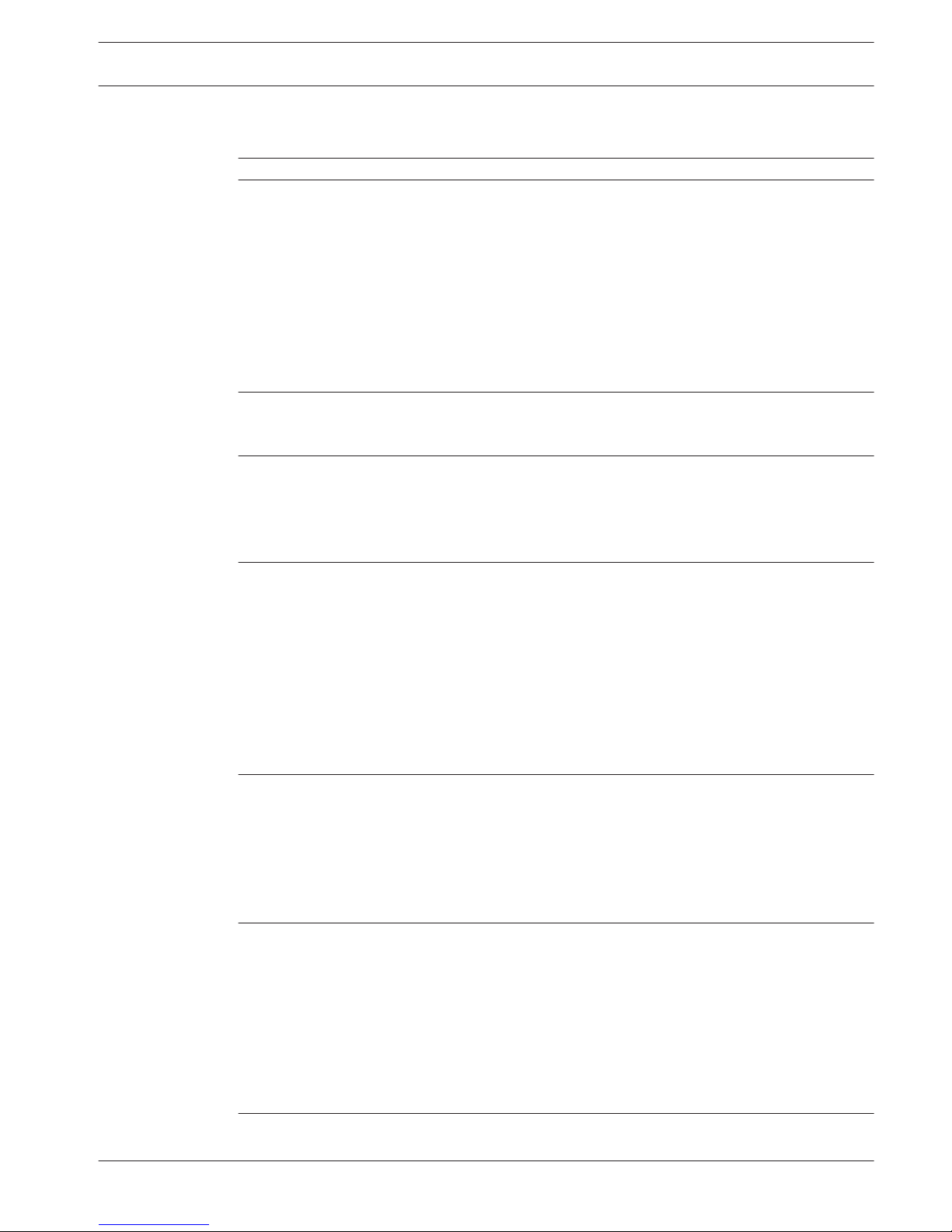

Identifier

Description Material no. Category

FAP-425-O-R Optical smoke detector,

automatic and manual address

setting

F.01U.280.244 Single sensor

FAP-425-OT-R Combined optical and thermal

smoke detector, automatic and

manual address setting

F.01U.280.245 Multi-sensor

FAP-425-O Optical smoke detector,

automatic address setting only

F.01U.279.893 Single sensor

FAP-425-OT Combined optical and thermal

smoke detector, automatic

address setting only

F.01U.279.987 Multi-sensor

FAH-425-T-R Thermal detector, automatic and

manual address setting

F.01U.280.243 Single sensor

FAP-425-DO-R Dual-optical smoke detector,

automatic and manual address

setting

F.01U.279.988 Double sensor

FAP-425-DOT-R Combined dual-optical and

thermal smoke detector,

automatic and manual address

setting

F.01U.279.989 Multi-sensor

FAP-425-DOTC-R Combined dual-optical, thermal

and chemical smoke detector,

automatic and manual address

setting

F.01U.280.451 Multi-sensor

1

4 en | Product Description AVENAR detector 4000

2014.11 | 1.1 | F.01U.283.550 Operation Guide Bosch Sicherheitssysteme GmbH

System Overview

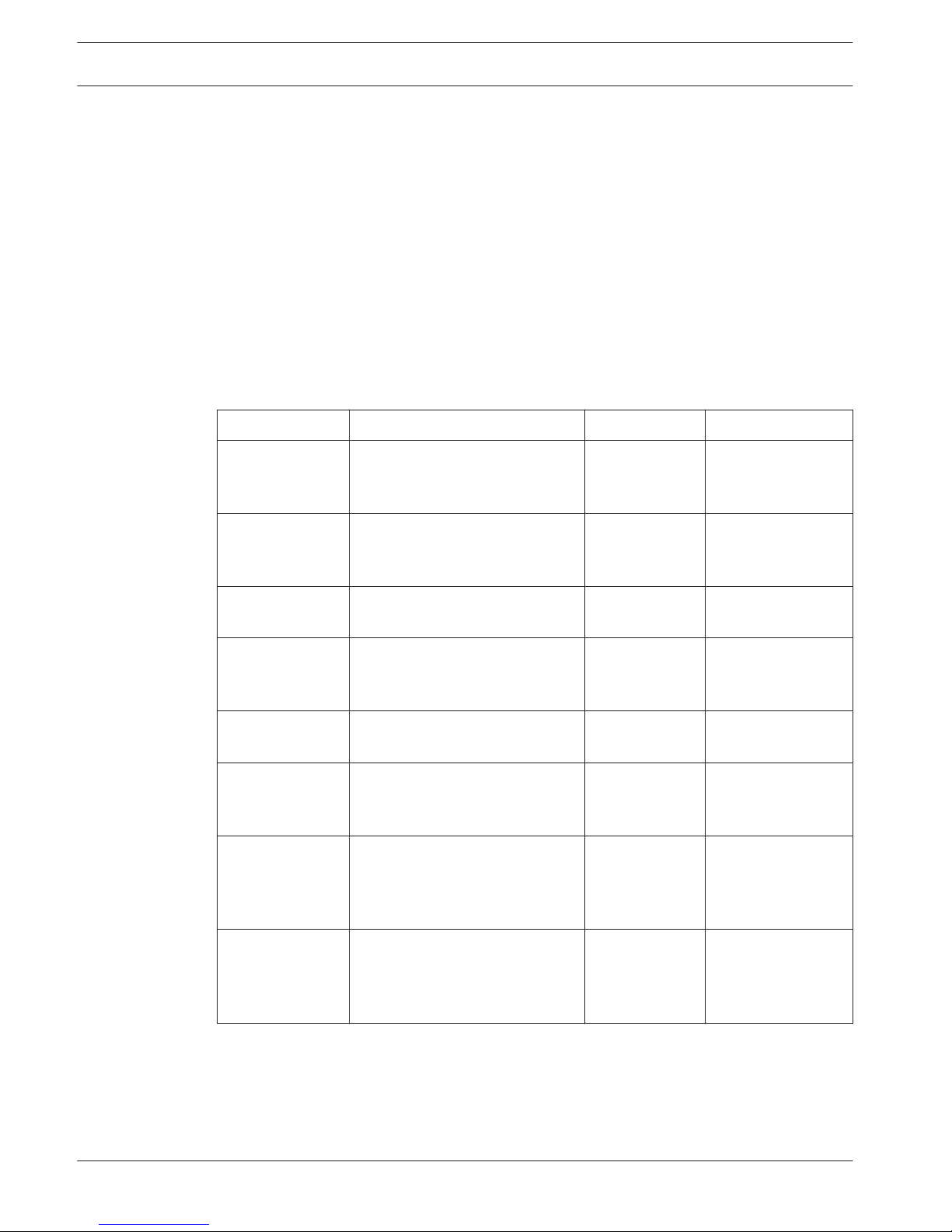

6

4

5

2

1

3

Figure 2.1: Detector set-up

1

Smoke measurement chamber with

optical sensor

4 Individual display

2 Thermal sensor 5 PC board with evaluation electronics

3 Chemical sensor (covered on the cross-

section)

6 MS 400 / MS 400 B Detector Base

Functional Description of the Sensor Technology

Optical Sensor (Smoke Detector)

This optical sensor utilizes the scattered-light method.

An LED sends light into the measuring chamber, where it is absorbed by the labyrinth

structure. In the event of a fire, smoke enters the measuring chamber. The light is scattered by

the smoke particles and hits the photo diodes, which transform the quantity of light into a

proportional electrical signal.

The DO detectors have a dual optical sensor that uses the different infrared and blue light

wavelengths (Dual Ray technology). This allows fires to be detected early and even the

smallest quantities of smoke (TF1, TF9) to be reliably detected.

Notice!

The FAP-425-DO-R smoke detector makes an alarm decision based on an intelligent

combination of the following criteria:

Amount of smoke density measured

Speed of smoke density increase

Size of smoke particles (as measured by Dual Ray technology)

Thermal Sensor (Heat Detector)

A thermistor in a resistance network is used as a thermal sensor; an analog-digital converter

measures the temperature-dependent voltage at regular intervals.

Depending on the specified detector class, the thermal sensor triggers the alarm status when

the maximum temperature of 54 °C or 69 °C is exceeded (thermal maximum), or if the

temperature rises by a defined amount within a specified time (thermal differential).

2

2.1

2.1.1

2.1.2

AVENAR detector 4000 System Overview | en 5

Bosch Sicherheitssysteme GmbH Operation Guide 2014.11 | 1.1 | F.01U.283.550

Chemical Sensor (Gas Sensor)

The gas sensor detects mainly the carbon monoxide (CO)

that is produced by a fire, but it also detects hydrogen (H)

and nitrogen monoxide (NO).

The underlying measurement principle is CO oxidation and

the measurable current that it creates. The sensor signal

value is proportional to the concentration of gas.

The gas sensor supplies additional information in order to

reliably suppress disturbance variables.

3

Chemical sensor

System Description

Up to three detection principles are integrated in FAP-425/FAH-425 series detectors:

– Optical (for smoke): O

– Dual-optical (for smoke): DO

– Thermal (for heat): T

– Chemical (for CO gas): C

– Detector with rotary switch: R, automatic and manual addressing

The individual sensors are programmed via the LSN network manually or using a timer. All

sensor signals are analyzed continually by the internal signal analysis electronics (ISP) and are

linked with each other. By linking the sensors (combined detectors), the detector can also be

used in places where the work carried out gives rise to light smoke, steam or dust. If a signal

combination fits the selected identifier for the area of operation for the detectors, an alarm is

triggered automatically.

Flash Frequency and Error Detection

The LSN improved detector has two centrally positioned two-color LEDs that flash green to

display the operational status.

The green LED on LSN improved FAP-425/FAH-425 series detectors is deactivated when

delivered. It can be activated as required via the programming software.

The LSN improved detector permanently monitors and adjusts itself throughout its life cycle in

order to adapt its sensitivity to the set threshold value.

A message is sent to the fire panel if the detector becomes too contaminated.

The LED will start to flash red as soon as an alarm is triggered.

The detector will return to its normal operating condition when the alarm is canceled via the

control panel or if the alarm cause disappears.

Features

– Active self-monitoring of the sensors, with display on the fire panel:

– Active adjustment of the threshold (drift compensation) if the optical sensor

becomes contaminated.

– Active adjustment of the threshold (drift compensation) of the chemical sensor.

– EMC safety is 50 V/m and is therefore much higher than normatively required.

– Preservation of LSN loop functions in the event of wire break or short-circuit of a detector

through integrated isolators.

– Individual detector identification on the fire panel in the event of an alarm. Alarm

indication on the detector with a flashing red LED.

– Programmable, i.e. can be adjusted to the area of operation.

2.1.3

2.2

2.3

2.4

6 en | System Overview AVENAR detector 4000

2014.11 | 1.1 | F.01U.283.550 Operation Guide Bosch Sicherheitssysteme GmbH

– Increased detection and false alarm security thanks to evaluation of the temporal

behavior of fire and disturbance variables.

– Activation of a remote indicator is possible.

– Optional mechanical removal safeguard (can be activated/deactivated).

– Dust-resistant labyrinth and cap construction.

– Every detector base has a Chamber Maid Plug (a cleaning opening with a plug) for

blowing out the optical chamber with compressed air (not required for the FAH-425-T-R

Heat Detector).

– For connecting to the FPA-5000 and FPA-1200 fire panels with extended range of LSN

features.

– In classic mode, can be connected to the BZ 500 LSN, UEZ 2000 LSN and UGM 2020 LSN

fire panels and to other panels or their receiver modules with identical connection

properties but with the existing LSN system limits.

– It is possible to read out the serial number, contamination level (for the O sensor),

operating hours, EMC strength level and current analog values for each configured

detector via LSN.

– Use of shielded and unshielded cables.

– The LSN improved version line technology supports the connection of up to 254 FAP-425/

FAH-425 series detectors per loop or stub (please observe national regulations in this

regard).

– Flexible network structures without additional elements are possible (T-tapping is not

feasible with detector versions without rotaries).

– Automatic or manual detector addressing selectable.

– Compliant with EN 54, EN 50131 and VdS guidelines.

For DO detectors, note:

Notice!

The device cannot be used with the FPA-5000 type A panel controller.

Accessories

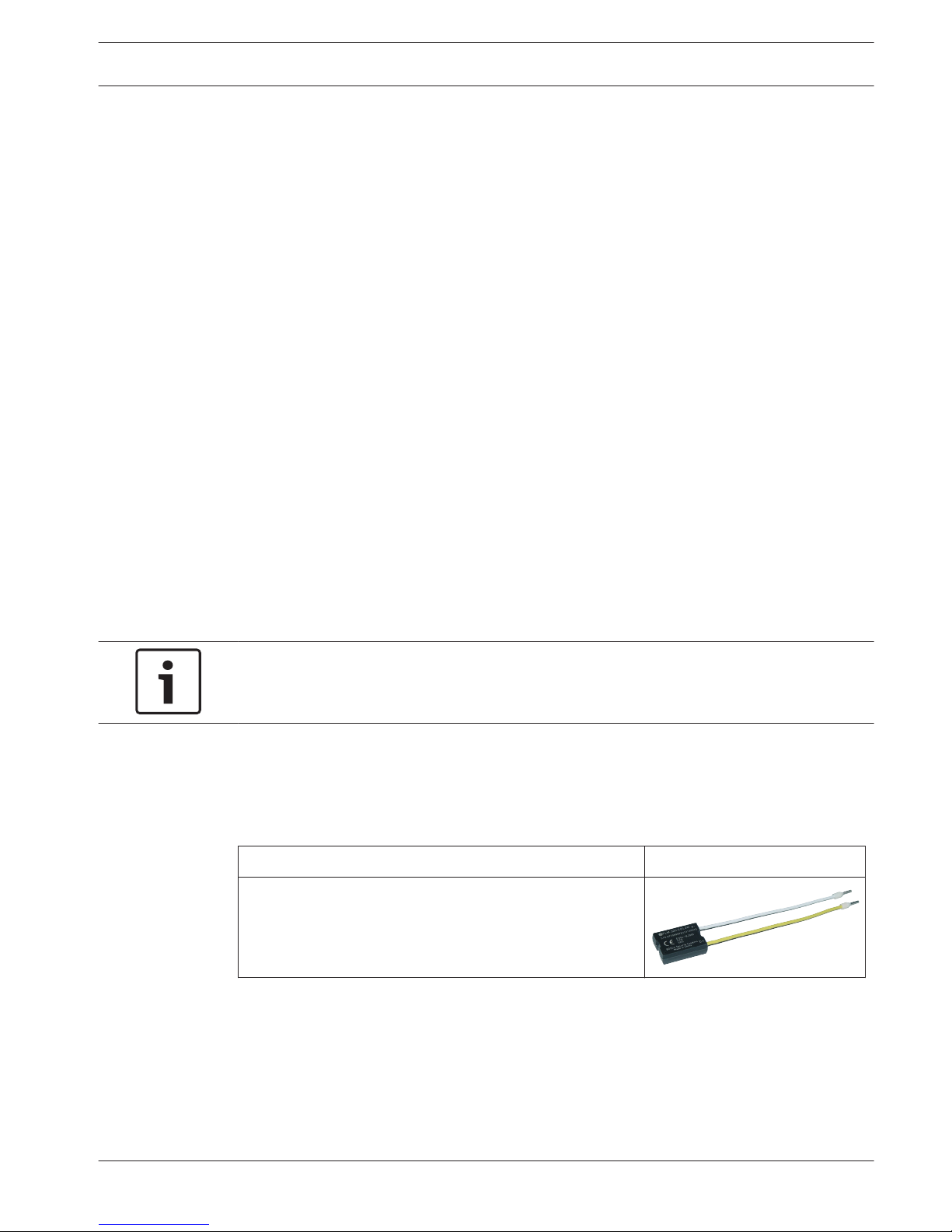

FLM-320-EOL2W EOL Module

FLM-320-EOL2W EOL Module

The FLM-320-EOL2W EOL module is a 2-wire module for

terminating a line according to EN 54-13.

The module detects faults according to EN 54-13 and

reports errors to the fire panel.

Support Plates

The support plates are made from 1.8 mm thick ABS plastic and are clamped between the

detector base and the ceiling.

2.5

AVENAR detector 4000 System Overview | en 7

Bosch Sicherheitssysteme GmbH Operation Guide 2014.11 | 1.1 | F.01U.283.550

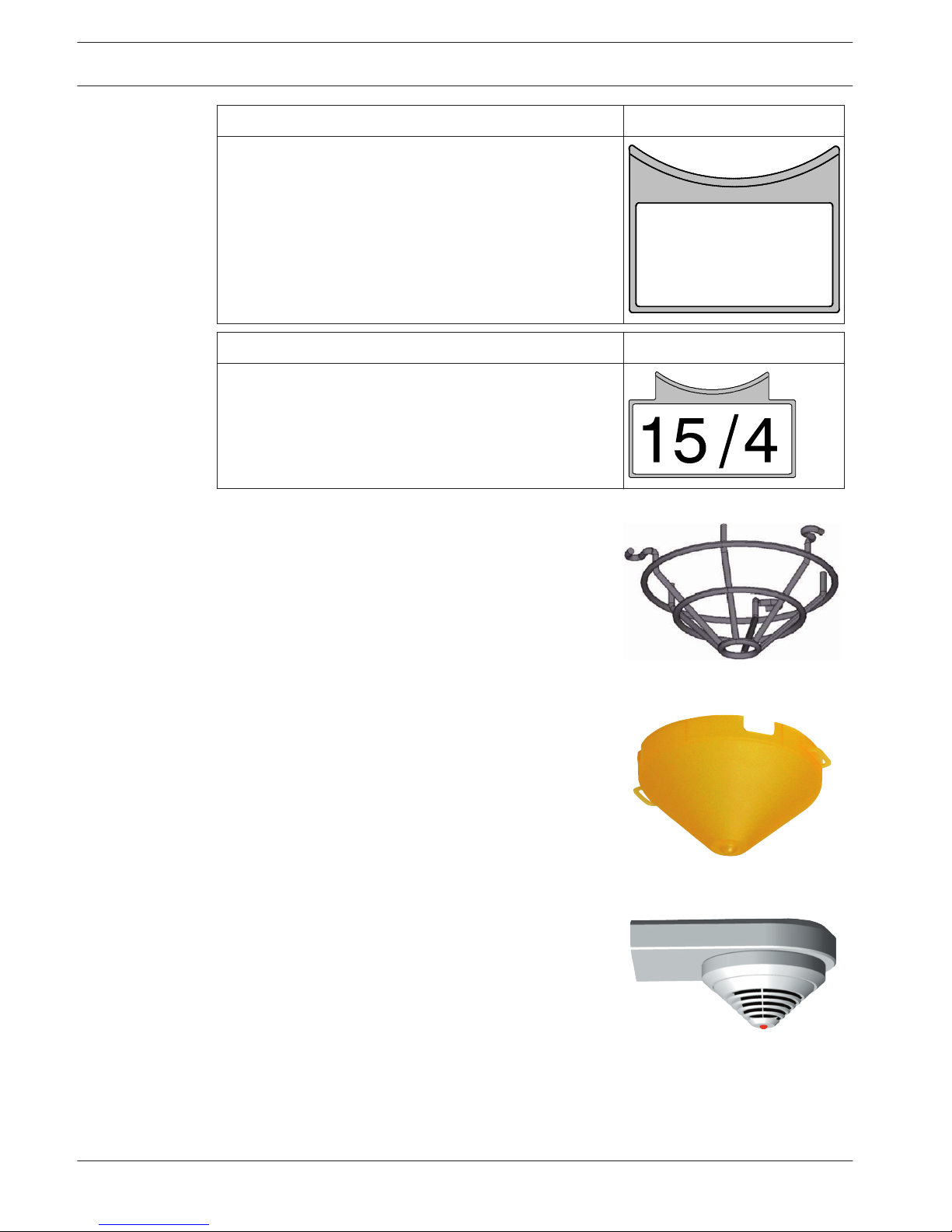

TP4 400 Support Plate

The TP4 400 Support Plate is intended for an installation

height up to 4 m and is designed for labels up to a size of

approx. 65 x 34 mm.

15 / 4

TP8 400 Support Plate

The TP8 400 Support Plate is intended for an installation

height up to 8 m and is designed for labels up to a size of

approx. 97 x 44 mm.

SK 400 Protective Basket

The SK 400 Protective Basket is installed over the detector

and gives the detector substantial protection against

damage.

If the detector is mounted in a sports facility, for example,

the protective basket prevents balls or other sports

equipment from hitting the detector and damaging it.

SSK 400 Protective Dust Cover

The SSK 400 Protective Dust Cover is necessary during

construction work to protect an installed detector base,

with or without detector module, from contamination. The

protective dust cover made of polypropylene (PP) is

pushed onto the installed detector base.

MK 400 Detector Console

The MK 400 Detector Console is used to install detectors

above door frames or similar in compliance with DIBt.

The console is supplied with a pre-mounted MS 400

Detector Base (the detector shown is not included in the

scope of delivery).

8 en | System Overview AVENAR detector 4000

2014.11 | 1.1 | F.01U.283.550 Operation Guide Bosch Sicherheitssysteme GmbH

MH 400 Detector Heating Element

The MH 400 Detector Heating Element is required if the

detector is used in an environment where water

condensation can occur, such as in a warehouse that must

frequently be opened briefly for delivery vehicles.

The detector heating element is connected to the + V/0 V

terminals in the detector base.

Operating voltage: 24 V DC

Resistance: 1 kΩ

Power consumption: 3 W.

The heating is supplied with power either by the fedthrough supply voltage via the central unit or by a separate

power pack.

With supply via the central unit, the number of detector

heating elements depends on the cable diameter and line

length used.

Remote Indicators

A remote indicator is required if the detector is not directly visible or has been mounted in

false ceilings or floors. The remote indicator should be installed in corridors or access

pathways to the corresponding building sections or rooms.

Installation of the FAA-420-RI Remote Indicator

!

Warning!

Malfunction and Damage

If maximum current consumption of the connected detector is larger than 20 mA, it can result

in malfunction and damage to the remote indicator.

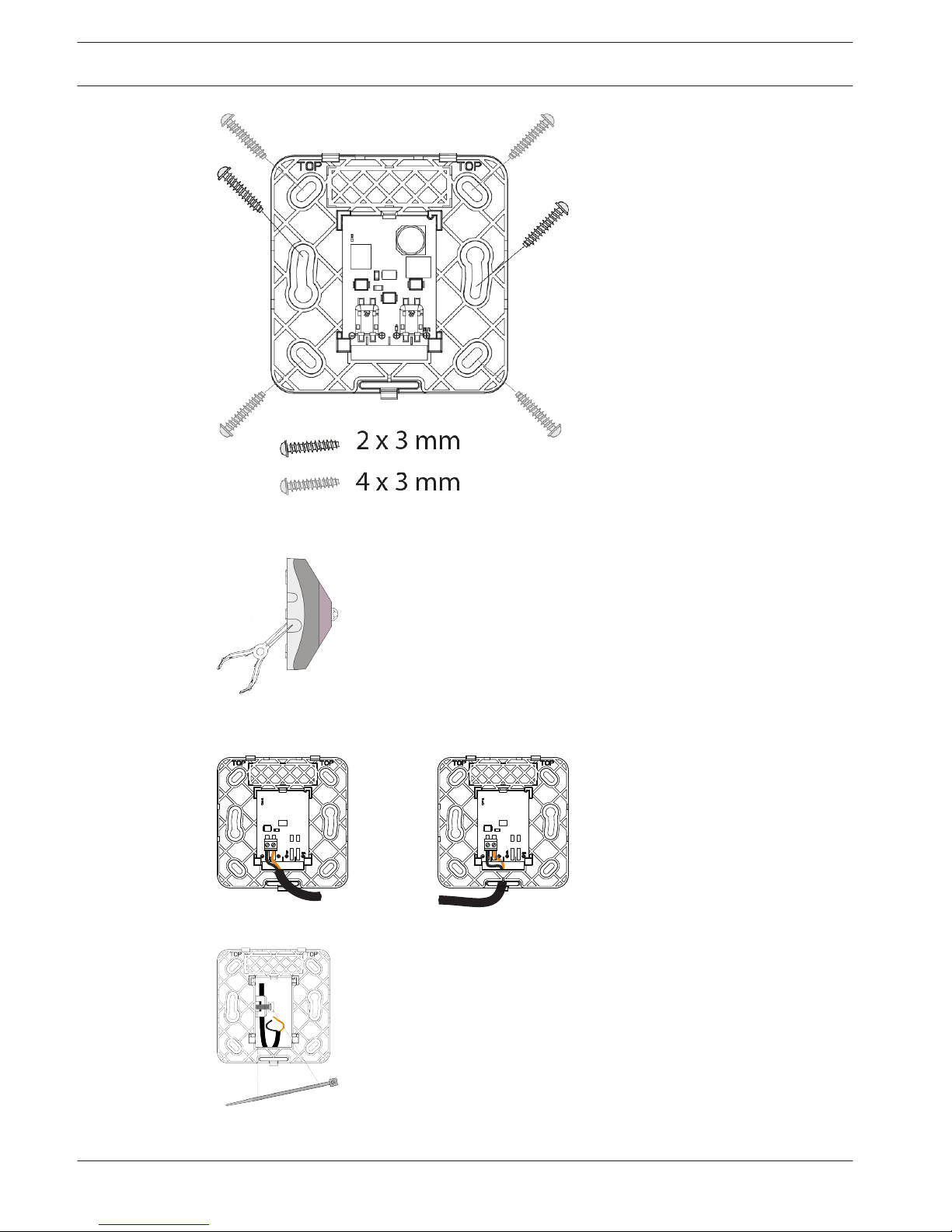

Before assembly remove the cap from the base plate

1. Unlock the snap‑fit hook by pressing on it with a flat object and lift the cap carefully

2. Remove the connection board for easy access.

3. Mount the base plate directly on a dry, level surface with two or four screws.

2.5.1

AVENAR detector 4000 System Overview | en 9

Bosch Sicherheitssysteme GmbH Operation Guide 2014.11 | 1.1 | F.01U.283.550

1. For surface-mounted cables, break out the prepunched cable entries.

2. For flush-mounted cables, insert the cable through the opening under the connection

board.

3. Secure the cable with a zip tie on the base plate.

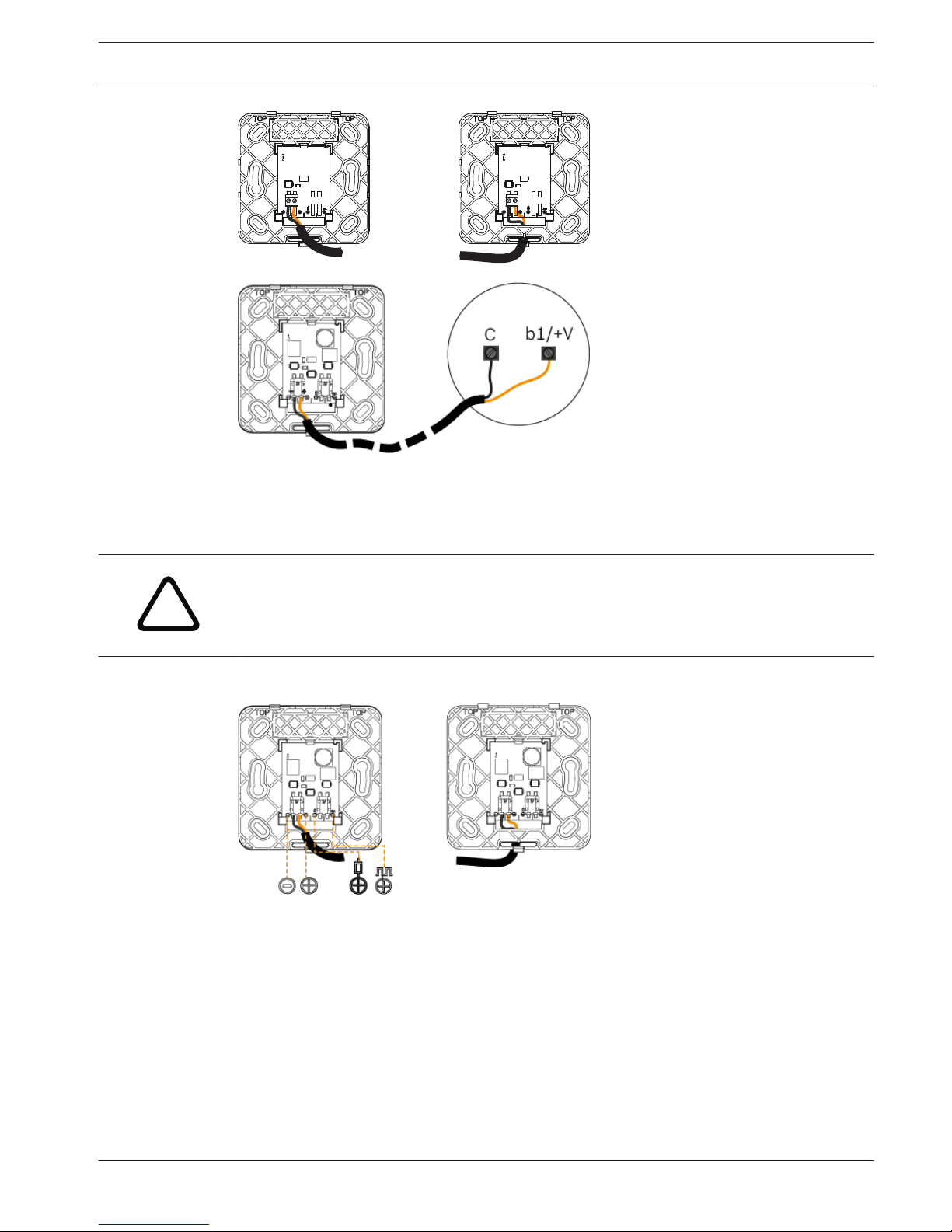

Wiring FAA‑420‑RI‑ROW

1. Wire the remote indicator as shown.

10

en | System Overview AVENAR detector 4000

2014.11 | 1.1 | F.01U.283.550 Operation Guide Bosch Sicherheitssysteme GmbH

2. Place the cap on the base plate in such a way that the two hooks are inserted into the

slits.

3. Press the cap lightly onto the base plate until the snap‑fit‑hook engages.

Wiring FAA‑420‑RI‑DIN

!

Warning!

Malfunction and Damage

Note the maximum permitted current supply respectively the input voltage range of the

functional modes.

4 Wire the remote indicator as shown.

AVENAR detector 4000 System Overview | en 11

Bosch Sicherheitssysteme GmbH Operation Guide 2014.11 | 1.1 | F.01U.283.550

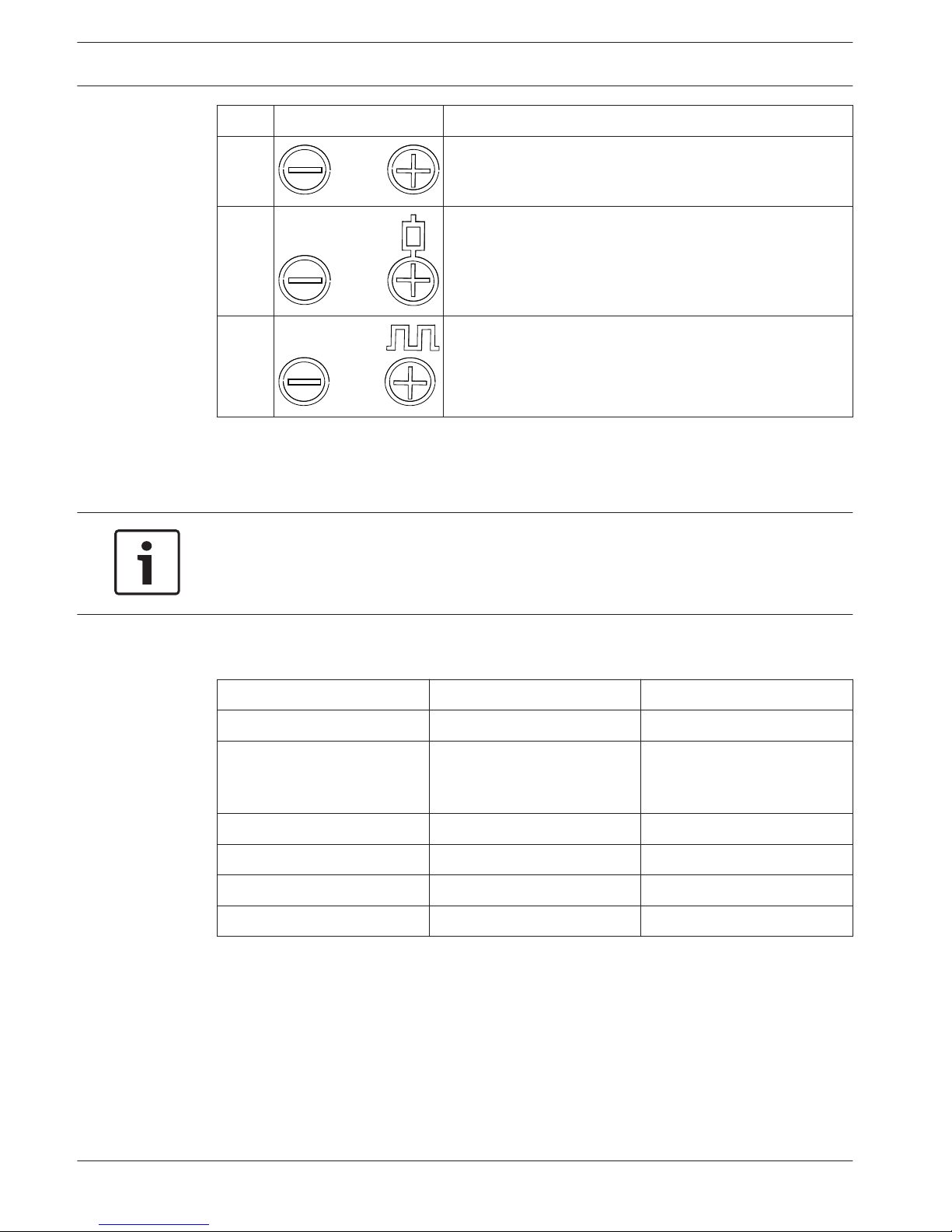

Mode Terminal connection Alarm condition

1

+

The remote indicator shows steady red light. Current has

to be limited to max. 30 mA.

2

+

The remote indicator shows steady red light. Input voltage

range: 8.5 V DC … 33 V DC. Constant current consumption

13 mA.

3

+

The remote indicator shows flashing red light. Input voltage

range: 11 V DC … 33 V DC. Constant current consumption

3 mA.

Operate in mode 1 and 3 only, when connected to LSN detectors.

1. Place the cap on the base plate in such a way that the two hooks are inserted into the

slits.

2. Press the cap lightly onto the base plate until the snap‑fit‑hook engages.

Notice!

Malfunction

The cable length between the detector and the remote indicator must not exceed 3 m when

connected by an unshielded cable.

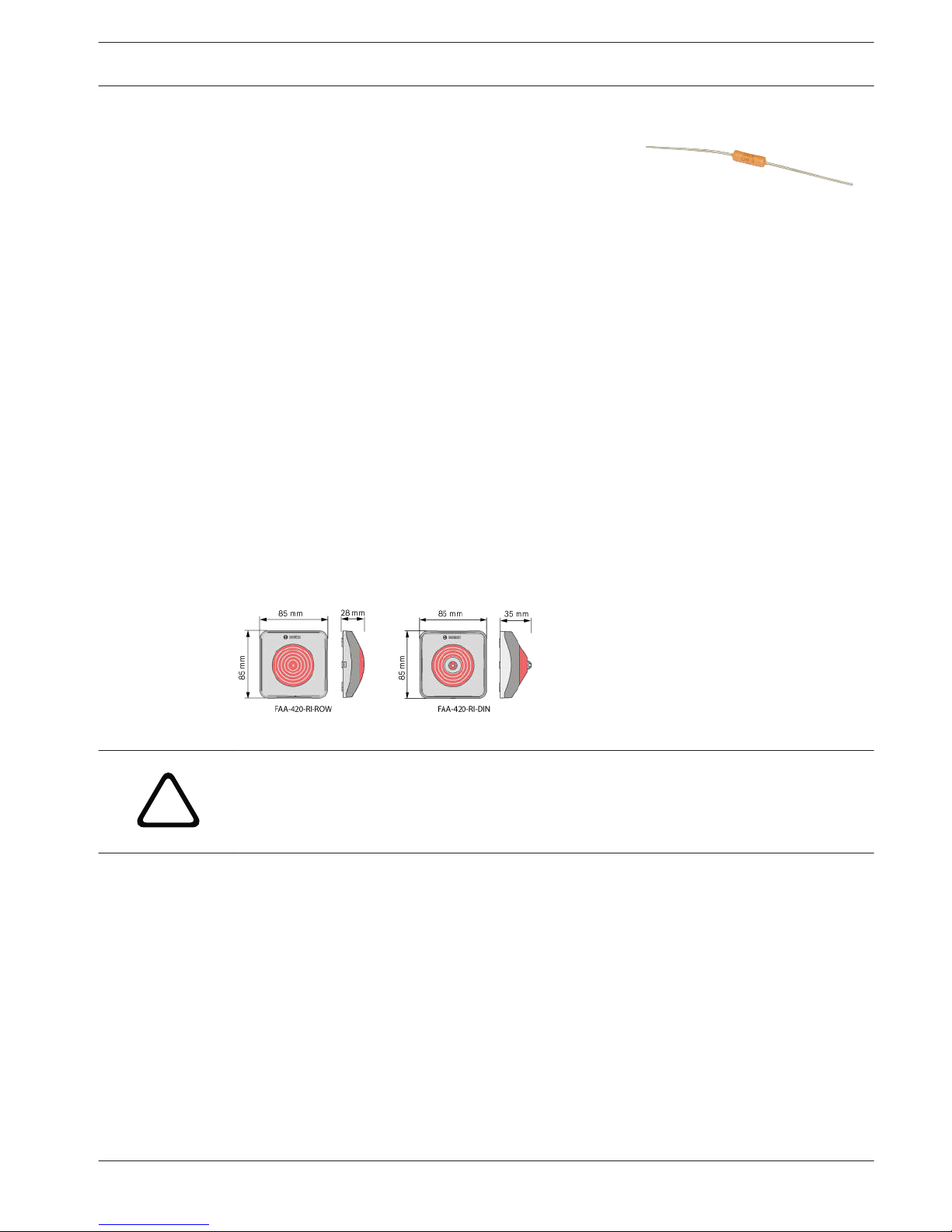

Technical specifications

FAA‑420‑RI‑ROW FAA‑420‑RI‑DIN

Operating Voltage 5 ‑ 30 V DC 9 ‑ 30 V DC

Maximum current

consumption

20 mA Mode 1: limited to 30 mA

Mode 2: 13 mA

Mode 3 : 3 mA

Permissible wire gauge 0,6 – 2 mm 0,6 ‑ 0,8 mm

Display medium 1 LED 2 LED

Dimensions 85 x 85 x 28 mm 85 x 85 x 35 mm

Weight 45 g 65 g

12 en | System Overview AVENAR detector 4000

2014.11 | 1.1 | F.01U.283.550 Operation Guide Bosch Sicherheitssysteme GmbH

Loading...

Loading...