Page 1

K

Service Source

StyleWriter II

Page 2

K

Service Source

Basics

StyleWriter II

Page 3

Basics Test Page - 1

Test Page

Online Key

Turn on the printer and hold

down the online key for at

least 6 seconds or until the

test page prints.

Page 4

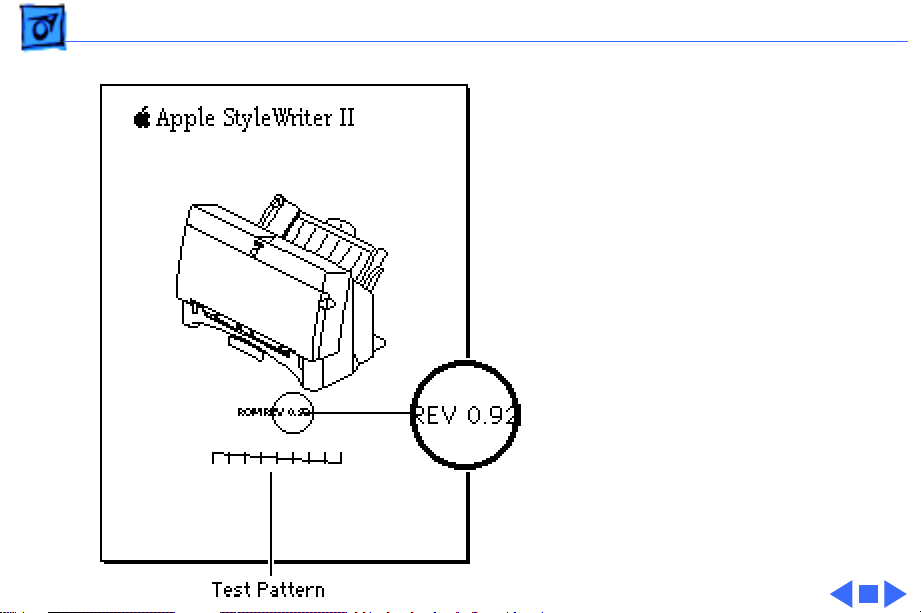

Basics Test Page - 2

The test page shows the ROM

revision and a test pattern.

Use the test pattern to

determine if the ink jets are

functioning properly. If

lines appear broken,

proceed to the “Printing”

topic in the Troubleshooting

chapter.

Page 5

K

Service Source

Specifications

StyleWriter II

Page 6

Specifications Characteristics - 1

Characteristics

Print Methods

Throughput

Print Head

Print Head Life

Input Buffer

Serial bubble jet ink-on-demand

SHQ mode 124 cps (10 cpi)

HQ mode 173 cps (10 cpi)

HS mode 248 cps (10 cpi)

1 by 64 nozzles

Approximately 500 pages (normal mode)

9K

Page 7

Specifications Graphics - 2

Graphics

Resolution

360 dpi (at best mode)

Page 8

Specifications Paper Handling - 3

Paper Handling

Paper

Envelopes

Transparencies

Size: LTR, LGL, A4

Weight: 16–24 lb.

Capacity: 100 sheets (A4, LTR)

Size: Commercial number 10 size only (4.1 in. by 9.5 in)

Capacity: 10 envelopes

Coated transparencies, or most inkjet transparencies

Page 9

Specifications Ink Cartridges - 4

Ink Cartridges

Type

Ink Color

Ink Amount

Life

Ink cartridge

Black

Approximately 28 g (per cartridge)

Approximately 500 pages

Page 10

Specifications Environmental - 5

Environmental

Acoustic Noise Level

Temperature

Humidity

Approximately 40 dB (reference level)

41–95° F (5–35° C)

10–90% (no condensation)

Page 11

Specifications Electrical - 6

Electrical

Power Source

Power Consumption

U.S./Canada: 120 VAC, 60 Hz, 0.36 A

U.K./Australia: 240 VAC, 50 Hz, 24 W

Europe: 220 VAC, 50 Hz, 24 W

48 W maximum

Page 12

Specifications Physical - 7

Physical

Dimensions

Weight

Height: 6.8 in. (173 mm)

Width: 13.7 in. (347 mm)

Depth: 7.6 in. (193.5 mm)

Approximately 6 lb. (3 kg)

Page 13

K

Service Source

Troubleshooting

StyleWriter II

Page 14

Troubleshooting General/ - 1

General

The Symptom Charts included in this chapter will help you

diagnose specific symptoms related to your product. Because cures

are listed on the charts in the order of most likely solution, try

the first cure first. Verify whether or not the product continues to

exhibit the symptom. If the symptom persists, try the next cure.

(Note: If you have replaced a module, reinstall the original module

before you proceed to the next cure.)

If you are not sure what the problem is, or if the Symptom Charts

do not resolve the problem, refer to the Flowchart for the product

family.

For additional assistance, contact Apple Technical Support.

Page 15

Troubleshooting Symptom Charts /Preliminary Checks - 2

Symptom Charts

Preliminary Checks

Computer cannot find

printer

No lights or

movement

Print quality

problems

1 Verify that StyleWriter II driver is installed.

2 Verify that Chooser and Control Panel settings are correct.

3 Verify that serial cable is connected.

4 Replace serial cable.

1 Verify that printer is turned on and plugged into wall socket.

2 Replace fuse.

1 Verify that paper is correct weight.

2 Purge ink cartridge.

3 Replace ink cartridge.

4 Replace printer.

Page 16

Troubleshooting Symptom Charts /Preliminary Checks - 3

Mechanical problems 1 Verify that paper is correct weight.

2 Clear paper jam.

3 Verify that cut sheet feeder aligns with printer.

4 Replace printer.

Page 17

Troubleshooting Symptom Charts /Status Light - 4

Status Light

No status lights 1 Replace fuse.

2 Verify that operation cable is securely connected to logic

board.

3 Replace printer.

Error light on 1 Printer is out of paper; add paper.

2 Check for paper jam; remove jam and then press power

switch.

3 Check for carriage jam.

4 Replace printer.

Page 18

Troubleshooting Symptom Charts /Printing - 5

Printing

No printing 1 Verify that interface cable between printer and computer is

tightly connected.

2 Make sure printer is selected in Chooser.

3 Purge ink cartridge.

4 Replace ink cartridge.

5 Verify that right-margin sensor is seated correctly.

6 Replace printer.

Garbled printing 1 Verify that interface cable between printer and computer is

tightly connected.

2 Purge ink cartridge.

3 Replace ink cartridge.

4 Replace printer.

Page 19

Troubleshooting Symptom Charts /Printing - 6

Overprinting 1 Verify that program being used is set for correct line

spacing and line length.

2 Verify that correct printer driver is installed.

3 Replace printer.

Image too light or too dark

White lines in printing

1 Purge ink cartridge.

2 Use 16–24 lb. cotton bond paper.

3 Verify that forms thickness lever is set correctly (up for

standard paper and down for envelopes, transparencies,

labels, and heavy paper).

4 Replace ink cartridge.

1 Purge ink cartridge.

2 Replace ink cartridge.

3 Replace printer.

Page 20

Troubleshooting Symptom Charts /Printing - 7

Page prints off center; images are out of place

Ink appears on back of paper

Image wavy, splotchy, or distorted

1 Use 16–24 lb. cotton bond paper.

2 Verify that sheet feeder holds no more than 50 sheets.

3 Verify that paper is inserted properly.

4 Verify that margins in document and paper size in Page Setup

are set correctly.

5 Replace printer.

1 Clean platen with soft, dry cloth.

2 Clean platen rollers.

3 Replace printer.

1 Purge ink cartridge.

2 Replace ink cartridge.

3 Replace printer.

Page 21

Troubleshooting Symptom Charts /Carrier Movement - 8

Carrier Movement

Erratic carrier motion

Power light is on; carrier does not move

Printer does not

perform self-test;

ready light is on

Carrier grinds, hums loudly, or locks

Replace printer.

1 Make sure carrier area is clear of obstructions.

2 Replace printer.

Replace printer.

1 Verify that right-margin sensor is seated correctly.

2 Replace printer.

Page 22

Troubleshooting Symptom Charts/Paper Feed - 9

Paper Feed

No paper feed 1 Verify that cut sheet feeder aligns with printer.

2 Release paper pressure plate on cut sheet feeder.

3 Make sure paper path is clear of obstructions.

4 Replace printer.

Grinding during paper feed

1 Make sure paper path is clear of obstructions.

2 Verify that forms thickness lever is set correctly (up for

standard paper and down for envelopes, transparencies,

labels, and heavy paper).

3 Verify that cut sheet feeder aligns with printer.

4 Replace printer.

Page 23

Troubleshooting Symptom Charts /Paper Feed - 10

Paper feed difficulties: binding, tearing

Envelope feed problems

1 Verify that forms thickness lever is set correctly (up for

standard paper and down for envelopes, transparencies,

labels, and heavy paper).

2 Make sure paper path is clear of obstructions.

3 Verify that paper is inserted properly.

4 Use 16-24 lb. cotton bond paper.

5 Verify that cut sheet feeder aligns with printer.

6 Replace printer.

1 When printing envelopes: (a) adjust paper thickness lever,

(b) do not run cut sheets and envelopes in same print job,

and (c) reset paper thickness lever when finished printing

envelopes.

2 Replace printer.

Page 24

Troubleshooting Symptom Charts /Miscellaneous - 11

Miscellaneous

Operations panel buttons don’t work

Software-specific problem

1 Verify that operations panel cable is securely connected to

logic board and operations panel.

2 Replace printer.

1 Verify that software is known-good.

2 Verify that software is compatible with TrueType fonts.

(Check your software application manual.)

Page 25

K

Service Source

T ak e Apart

StyleWriter II

Page 26

Take Apart Covers - 1

Covers

No preliminary steps are

required before you begin

this procedure.

Review the ESD precautions

in Bulletins/Safety.

Caution:

excessive force to release a

latch or tab.

Note:

the removal of all the covers

on the printer.

Do not use

This procedure covers

Page 27

Take Apart Covers - 2

Front Access Cover

1

Note:

The front access

cover is held in place by

two arms that function

as hinges. Plastic tabs at

the end of the arms fit

into knobs on the inside

of the upper case.

2 Open the front access

Arm

Arm

cover.

3 Press the end of each

arm inward and free the

arm tabs from the

upper case.

Front Access Cover

4 Lift off the front access

cover.

Page 28

Take Apart Covers - 3

Upper Case

Upper Case

1 Release the right side

latch and lift the upper

case a short distance.

Repeat for the left side

latch and remove the

case.

Latch

Page 29

Take Apart Covers - 4

Output T ray Assembly

1 Pull out the tray until

the two tabs rest against

the stops. Press down

and remove the tray.

0utput Tray

Page 30

Take Apart Covers - 5

Rear Cover

Rear Cover

Top Latch

Bottom Latch

1 Press out the two latches

on the bottom of the

printer and press up on

the rear cover.

2 Release the two latches

on the top of the printer.

3 Lift up and remove the

rear cover.

Page 31

Take Apart Covers - 6

Cut Sheet Feeder Cover

Cut Sheet Feeder

1 Press in the front latch

Side Latch

Front Latch

Front Latch

and release the side

latch.

2 Pull back and remove the

cover.

Page 32

Take Apart Covers - 7

Paper Support

Paper Support

1 Pull out the paper

support until it rests

against the stops.

2 Push the support

forward and disconnect

the latches.

3 Slide out the paper

support.

Page 33

Take Apart Covers - 8

Bottom Cover

1 Using a screwdriver,

push out the two front

latches.

2 Pull up and remove the

bottom cover.

Front

Latch

Bottom Cover

Front Latch

Page 34

Take Apart Covers - 9

Replacement Note:

sure the bottom cover

circular tabs fit into the

proper position in the

printer frame.

Make

Page 35

Take Apart Covers - 10

Latch

On/Off Button

Replacement Note:

Make

sure the latch on the

upper case engages the

on/off button on the logic

board.

Page 36

Take Apart Cut Sheet Feeder - 11

Cut Sheet Feeder

Before you begin, remove

covers.

Review the ESD precautions

in Bulletins/Safety.

Cut Sheet Feeder

Caution:

on your hands or clothes.

Although the ink is water

soluble, it contains dyes that

will stain.

Do not get the ink

Page 37

Take Apart Cut Sheet Feeder - 12

1 Using a Phillips

screwdriver, remove

the two screws that

secure the cut sheet

feeder to the printer.

2 Press in the latch and

remove the cut sheet

Alignment Pin

Latch

feeder.

Replacement Note:

Make

sure the alignment pins

on the cut sheet feeder

are aligned with the

printer frame.

Page 38

Take Apart Roller and Spring - 13

Roller and Spring

Before you begin, remove

front cover.

Review the ESD precautions

in Bulletins/Safety.

Front Cover

Page 39

Take Apart Roller and Spring - 14

1 Push the roller forward

slightly.

2 Carefully lift up and

remove the roller and

spring.

Page 40

Take Apart Cut Sheet Feeder Roller - 15

Cut Sheet Feeder Roller

Before you begin, remove

the following:

• Covers

• Cut sheet feeder

Review the ESD precautions

in Bulletins/Safety.

Cut Sheet Feeder

Roller

Page 41

Take Apart Cut Sheet Feeder Roller - 16

Roller

Caution:

When the roller

is removed, the feeder

gear is loose. Remove the

roller slowly so that the

gear will not fly off.

1 Press in the two latches

on the cut sheet feeder

roller and push out the

roller.

2 Remove the gear.

3 Lift up on one end of the

roller and remove the

other end from the

mounting hole.

Page 42

Take Apart Cut Sheet Feeder Roller - 17

Line/Notch

Line/Notch

Replacement Note:

Align

the notch on the upper

gear with the upper line

on the cut sheet feeder.

Align the notch on the

lower gear with the

lower line on the cut

sheet feeder.

Page 43

Take Apart Carriage Assembly - 18

Carriage Assembly

Before you begin, remove

the following:

• Covers

• Cut sheet feeder

Review the ESD precautions

in Bulletins/Safety.

Carriage Assembly

Caution:

print nozzles from clogging,

do not touch or wipe them.

To prevent the

Page 44

Take Apart Carriage Assembly - 19

1 Disconnect connector

CNH from the logic

board.

Connector CNH

Page 45

Take Apart Carriage Assembly - 20

2 Remove the plastic

ribbon cable and cable

holder.

Replacement Note:

sure the ribbon cable

holes are mounted on the

two tabs on the inside of

the ribbon cable holder.

Make

Page 46

Take Apart Carriage Assembly - 21

3 Press in the two latches.

4 Push up and remove the

carriage release clip.

Carriage Release Clip

Latch

Latch

Page 47

Take Apart Carriage Assembly - 22

5 Carefully remove the

shaft clips from each

side of the carriage

assembly.

Shaft Clip

Page 48

Take Apart Carriage Assembly - 23

6 Move the carriage to the

far right and disconnect

the carriage from the

Carriage Guide

carriage guide.

Caution:

Do not remove

or loosen the two screws

on top of the carriage

guide. Loosening or

removing these screws

will cause the carriage

to go out of alignment.

Page 49

Take Apart Carriage Assembly - 24

7 Using a flat-blade

screwdriver, carefully

press in the idler roller

and disconnect the

carriage belt.

Page 50

Take Apart Carriage Assembly - 25

8 Hold the carriage

assembly and push back

the carriage shaft.

9 Slide out the carriage

shaft.

Page 51

Take Apart Carriage Motor - 26

Carriage Motor

Carriage

Motor

Before you begin, remove

the following:

• Covers

• Cut sheet feeder

Review the ESD precautions

in Bulletins/Safety.

Page 52

Take Apart Carriage Motor - 27

1 Disconnect connectors

CNH and CNCR from the

main board.

Connector

CNCR

Connector CNH

Page 53

Take Apart Carriage Motor - 28

2 Using a flat-blade

screwdriver, press in

the idler roller and

disconnect the carriage

belt.

Page 54

Take Apart Carriage Motor - 29

3 Using a Phillips

screwdriver, remove

the two mounting

screws.

4 Lift up and pull out the

carriage motor.

Page 55

Take Apart Eject Roller - 30

Eject Roller

Before you begin, remove

covers.

Review the ESD precautions

in Bulletins/Safety.

Eject Roller

Page 56

Take Apart Eject Roller - 31

1 Grasp one end of the

roller, press it firmly

to the side, and snap the

roller out of the

mounting holes.

Page 57

Take Apart Fuse - 32

Fuse

Before you begin, remove

the following:

• Covers

• Cut sheet feeder

Review the ESD precautions

Fuse

in Bulletins/Safety.

Page 58

Take Apart Fuse - 33

1 Remove the fuse cover

and replace the fuse.

Page 59

K

Service Source

Exploded V ie w

StyleWriter II

Page 60

Exploded View 1

Whole Unit

110V 661-0785

220V 661-1010

Rear Cover

922-0184

Front Cover

922-0186

Carriage

Motor

922-0195

Eject Roller

922-0191

Carriage Belt

922-0193

Carriage Unit

922-0194

Feet, Bottom

922-0182

Output Tray

922-0187

Chassis*

Upper Case

Cover

922-0185

Cut Sheet

Feeder

Cover

922-0188

Paper

Support

922-0189

Cut Sheet

Feeder

Roller

922-0192

Carriage Release Clips

922-0197

Clip, Shaft

922-0196

Fuse

125 V 922-0180

250 V 922-0181

BottomCase

922-0198

Loading...

Loading...