Page 1

Quick Setup Guide

tekmarNet®2 House Control 402

HVAC Systems

1. Location 2. Install Junction Box

402_Q

02/14

Replaces: 01/14

402

402

OR

3. Size Transformer

Zone

Thermostat Load

Zone Valve Load

Total Zone Load

1234

Floating

Action (VA)

+ ++++

Control

Load (VA)

2

4. Install Sensors 5. Line Voltage Wiring

Outdoor Sensors

Transformer

must exceed:

VA

Sensor with rear

entry wiring

Pipe Sensors

A Watts Water Technologies Company

Sensor with bottom

entry wiring

Retaining Clip

Universal

Sensor 082

Sensor Well

Sensor mounted onto

2" x 4" electrical box

Mix

Boil

DHW

(black)

(black)

(black)

(red)

L

(blue)

Variable

N

G

L

N

115 V (ac)

1

Speed

to pump grounds

Back of House Control 402

Mix System Pump

Boil System Pump

DHW Pump

Pump Power L

Variable

Speed Pump

© 2014 402_Q - 02/14

Strip wires

1/2 inch (13 mm).

Installed wires are

not removable.

12-18 AWG

Page 2

6. Install Enclosure

R

C

L

N

Com

Open

Close

Expansion

tN4 Boil

CtN4

Modulating

Boiler

—+

Expansion

tN4 Mix

CtN4

2

1

WC

WC

Menu

House Control 402

Item

+

Mix ComBoil Out DHW

VlvC VlvC VlvC

Zone 3Zone 1 Zone 2 Zone 4

VlvC

Com

Zone 1

H8007D

Zone 2 Zone 3 Zone 4

tN2 tN2 tN2 tN2 tN2 tN2 tN2 tN2

C

Floating Action

ClsOpn

Sensors - No Power

Call Call

tN4 tN4CC

Mod dc/mA Boil Exp. Mix Exp.

Setpoint DHW

Use at least 167°F

(75°C) conductors

RC

Input Power

Stage 2Stage 1

7. Low Voltage Wiring

tekmarNet

Mix Supply

Sensor 082

Outdoor

Sensor

070

Boiler Supply

Sensor 082

DHW Tank

Sensor 082

®

2 Thermostats

24 V (ac) Floating

Action Actuator

®

tekmarNet

4

Expansion to

Wiring Centers,

Timers, or

User Switch

Setpoint Call

DHW Call

from DHW

Tank Aquastat

(optional)

8. Install Cover

Zone Valves

24 V (ac) Transformer 009

M

e

n

u

I

t

e

m

H

o

u

s

e

C

o

n

t

r

o

l

4

0

2

One or Two Stage

Boiler T-T

A Watts Water Technologies Company

2

© 2014 402_Q - 02/14

Page 3

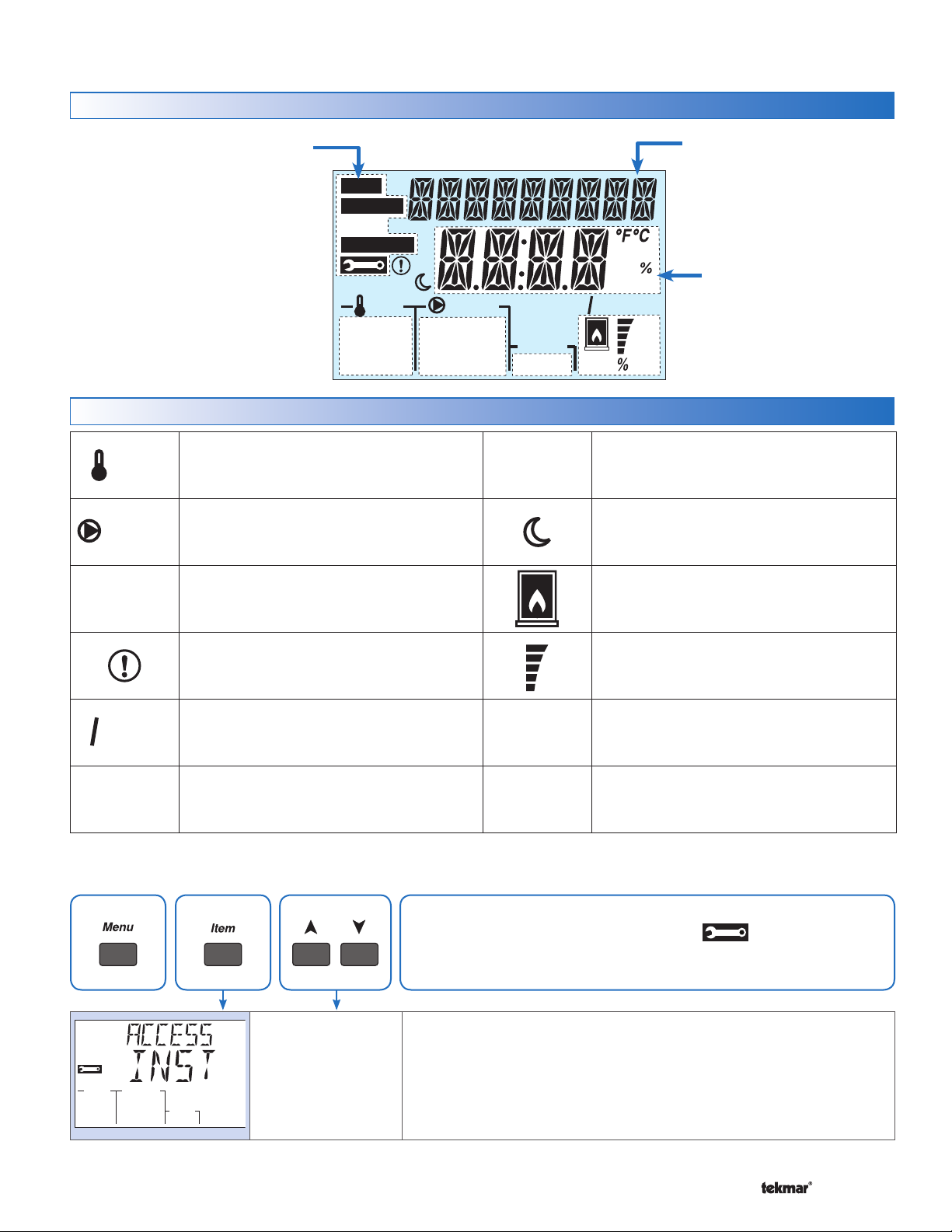

9. User Interface

Display

Menu Field

Displays the

current menu

Item Field

Displays the name

of the selected item

VIEW

ADJUST

Symbols

Calls

Pumps

Zones

1 2 3 4

Status Fields

Displays the current

status of the control’s

inputs, outputs and

operation. Most symbols

in the status field are

only visible when the

VIEW Menu is selected

CALLS

Displays any call for heat the control is

receiving.

PUMPS

Displays any pump currently operating.

ZONES

Displays if an on-board zone is operating.

WARNING

Displays if an error exists on the system.

MONITOR

MAXMIN

Calls

Boil Exp

Mix Exp

DHW Setp

Pumps WWSD Saving

Boil System

Mix System Zones

DHW Var 1 2 3 4

°F°C

minhr

sec%

min

sec

PM

hr

AM

Number Field

Displays the

current value of

the selected item

Cls

Opn

1 2

Mix

°F, °C, %, HOURS, MINUTES, SECOND

Units of measurement for current number.

UNOCCUPIED

Indicates that a User Switch or Timer has

put the system into UnOccupied.

BOILER

Indicates that the boiler should be

heating.

DEVICE OUTPUT SCALE

Displays output of the mixing valve or

injection pump.

ENERGY SAVING INDICATOR

Saving

WWSD

Displays when the system is saving

energy. See the Saving Indicator section.

WWSD

Displays when the system is in Warm

Weather Shut Down.

10. Access Level

INST (Installer)

Default = INST

or USER

Cls

Opn

MAXMIN

Press menu button until the Toolbox Menu is displayed. Press

item button to locate the access level setting.

ACCESS LEVEL

Selects the Access Level of the control, which determines the Menu items

available. USER provides the most limited level of access and shows the

fewest possible items.

When set to USER, all thermostats are locked and the number of thermostat

settings available are reduced.

CLOSE / OPEN

Displays whether the mixing valve motor

is opening or closing.

MIN / MAX

Displays when an operating temperature

reaches a minimum or maximum value.

A Watts Water Technologies Company

3

© 2014 402_Q - 02/14

Page 4

11. Critical Settings

Press menu button until the Adjust Menu is displayed. Press item button

to locate the desired setting.

Item Field Range Access Description Set to

ADJUST

ADJUST

ADJUST

-60 to 45°F

(-51.0 to 7.0°C)

Default = 10°F

(-12.0°C)

70 to 180°F

(21.0 to 82.0°C)

Default = 120°F

(49.0°C)

4-20 mA,

0-10 V (dc)

FLOT,

VAR

Default = VAR

Installer

Installer

Installer

OUTDOOR DESIGN

Typically set to the temperature of the coldest day of

the year. The outdoor air temperature used in the boiler

and mixing heating curves that determine the boiler

target and the mix target temperatures.

MIX DESIGN

The supply water temperature required for the mix

zones to heat the building on the typical coldest day

of the year. Recommendations:

High mass radiant floor = 120°F (50°C)

Low mass radiant floor = 140°F (60°C)

Fancoil or air handling unit = 190°F (90°C)

Copper fin-tube convector = 180°F (80°C)

Radiators = 160°F (70°C)

Low profile baseboard = 150°F (65°C)

MIX TYPE

Select the type of mixing device.

VAR = Variable speed injection pump

FLOT = Floating action motor for mixing valves

0-10 = 0 -10 V (dc) analog signal for mixing valves

4-20 = 4-20 mA analog signal for mixing valves

Note: 0-10 and 4-20 are only available when Boiler

Type = 1 Stage or 2 Stage.

EMS2,

EMS1,

4-20

0-10,

2STG,

1STG

Default = 1STG

tekmar Control Systems Ltd., A Watts Water Technologies Company.

Vernon, B.C. Canada V1B 3K4, 250-545-7749, Fax. 250-545-0650 Web Site: www.tekmarControls.com

Product design, software and literature are Copyright ©2014 by

tekmar Control Systems Ltd.,

A Watts Water Technologies Company

Installer

BOILER TYPE

The type of boiler connected to the control.

1STG = single one-stage on-off boiler

2STG = single two-stage on-off boiler

0-10 = 0-10 V (dc) modulating boiler

4-20 = 4-20 mA modulating boiler

EMS1 = tekmar boiler staging controls

EMS2 = Viessmann modulating boilers with

OpenTherm

Note: Only 1STG and 2STG are available when the

Mix Type is set to 0-10 V (dc) or 4-20 mA.

Head Offi ce: 5100 Silver Star Road,

4

All specifications are subject to change without notice.

Printed in Canada. 402_Q - 02/14.

Page 5

Guide d'installation rapide

tekmarNet®2 House Control 402

Systèmes

HVAC

402_Q

02/14

Remplace:

01/14

1. Emplacement 2. Installez la boîte de jonction

402

402

3. Transformateur de taille

Zone 1234

Charge de

thermostat

Charge de

vannes de zone

Charge de la

zone totale

+ ++++

4. Installez des capteurs

OU

Action flottante

(VA)

Charge de

contrôle (VA)

2

5. Filage ligne tension

Le

transformateur

doit dépasser:

VA

Capteurs extérieurs

Capteur avec filage

d’entrée arrière

Capteurs de tuyau

Une Entreprise de Watts Water Technologies

Capteur avec filage

d’entrée bas

Clip de

maintien

Universel

capteur 082

Capteur monté sur le boîtier

électrique 2" x 4"

Capteur en puit

L’arrière du House Control 402

Pompe du système

Mélange

Faire

bouillir

DHW

(noi r)

(noi r)

(noi r)

(rou ge)

L

Vitesse

N

TNL

115 V (ca)

5

variable

pour des motifs de pompe

(bleu)

de mélange

Pompe du système

d’ébullition

Pompe du DHW

Puissance de

la pompe L

Bande de fil s 1/2 po

(13 mm). Les fil s

Pompe à

vitesse variable

© 2014 402_Q - 02/14

installés ne sont pas

amovibles.

12-18 AWG

Page 6

6. Installez le boîtier

R

C

L

N

Com

Open

Close

CtN4 —+

CtN4

2

1

WC

WC

Menu

House Control 402

Item

+

Mix ComBoil Out DHW

VlvC VlvC VlvC

Zone 3Zone 1 Zone 2 Zone 4

VlvC

Com

Zone 1

H8007D

Zone 2 Zone 3 Zone 4

tN2 tN2 tN2 tN2 tN2 tN2 tN2 tN2

C

Flottant action

ClsOpn

Capteur - Pas d’alime ntation

de consigne

DHW

tN4 tN4CC

Mod dc/mA Boil Exp. Mix Exp.

Appel de point

Appel de

RC

Puissance

d’entrée

Stage 2Stage 1

Utiliser au moins des

conducteurs

de 167°F (75°C)

Expansion

du mélange

tN4

Expansion

d’ébullition

tN4

Chaudière

modulante

7. Filage basse tension

tekmarNet

Mélange

d'alimentation

capteur 082

Capteur

extérieur

070

Capteur

d'alimentation de

chaudière 082

Capteur du

réservoir DHW

082

Appel de point de

consigne

Capteur - Pas d’alim entation

®

2 Thermostats

24 V (ca) flottant

action actionneur

expansion

à tN4

contrôle

des zones

Chaudière

modulante

Appel de DHW

à partir du

réservoir DHW

Aquastat

(facultatif)

8. Installez la couvercle

Vannes de zone

M

e

n

u

I

t

e

m

H

o

u

s

e

C

o

n

t

r

o

l

4

0

2

24 V (ca) Transformateur 009

Chaudière T-T à une

ou deux étapes

Une Entreprise de Watts Water Technologies

6

© 2014 402_Q - 02/14

Page 7

9. Interface d’utilisateur

Afficher

des opérations de contrôle.

sont visibles que lorsque le

Menu Affichage (VIEW) est

Symboles

Calls

Pumps

Menu des

champs

Affiche le menu

actuel

VIEW

ADJUST

Champs d'état

Affiche l'état actuel des

entrants, des sortants et

La plupart des symboles

dans le champ Statut ne

MONITOR

MAXMIN

Calls

Boil Exp

Mix Exp

sélectionné

APPELS

Affiche n'importe quel appel de chaleur que

reçoit le contrôle.

POMPES

Affiche n'importe quelle pompe actuellement

en exploitation.

DHW Setp

Pumps WWSD Saving

Boil System

Mix System Zones

DHW Var 1 2 3 4

° C ° F

minhr

sec %

Champ

d'élément

Affiche le nom

de l'élément

sélectionné

min

sec

PM

hr

AM

Champ numérique

Affiche la valeur actuelle de

l'élément sélectionné

Cls

Opn

1 2

Mix

° F, ° C, %, HEURES, MINUTES, SECONDE

Unités de mesure pour le nombre actuel.

INOCCUPÉ

Indique qu'un interrupteur ou une minuterie de

l’utilisateur a mis le système en Inoccupé.

Zones

1 2 3 4

Saving

WWSD

ZONES

S'affiche si une zone de bord est en marche.

AVERTISSEMENT

S'affiche si une erreur existe sur le système.

INDICATEUR D'ÉCONOMIE D'ÉNERGIE

S'affiche lorsque le système économise

de l'énergie. Reportez-vous à la section de

l'indicateur d’économie.

WWSD

S'affiche lorsque le système s’arrête à cause

d’un sur chauffage.

10. Niveau d'accès

INST (Installateur)

ou USER

Par Défaut= INST

CHAUDIÈRE

Indique que la chaudière devrait chauffer.

ÉCHELLE DE SORTIE PÉRIPHÉRIQUE

Affiche la sortie de la pompe vanne ou

injection de mélange.

Cls

Opn

MAXMIN

Appuyez sur Menu jusqu'à ce que le Menu de la boîte à outils

s'affiche. Appuyer sur le bouton de l’élément pour localiser le paramètre

niveau d'accès.

FERMER / OUVRIR

Indique si le moteur de vanne de mélange est

ouvert ou fermé.

MIN / MAX

S'affiche lorsqu'une la température de

fonctionnement atteint une valeur minimale ou

maximale.

Niveau d’accès

Sélectionne le niveau d’accès du contrôle, qui détermine les éléments

de Menu disponibles. USER fournit le niveau le plus limité d’accès et

affiche un minimum d’éléments possibles.

Si vous sélectionnez USER, tous les thermostats sont verrouillées et le

nombre de paramètres thermostat disponibles est réduit.

Une Entreprise de Watts Water Technologies

7

© 2014 402_Q - 02/14

Page 8

11. Paramètres critiques

Appuyez sur Menu jusqu'à ce que le Menu de réglage soit affiché.

Appuyer sur le bouton de l’élément pour localiser la position désirée.

Champ d'élément Gamme Accès Description Réglez à

ADJUST

ADJUST

ADJUST

-60 à 45°F

(-51,0 à 7,0°C)

Par défaut = 10°F

(-12,0°C)

70 à 180°F

(21,0 à 82,0°C)

Par Default =

120°F (49,0°C)

4-20 mA,

0-10 V (cc)

FLOT,

VAR

Par défaut = VAR

Installateur

Installateur

Installateur

OUT DESIGN (CONCEPTION EXTERIEURE)

Généralement réglée à la température du jour le plus

froid de l'année. La température de l'air extérieure

utilisée dans les chaudières et cuves de mélange de

chauffage déterminent la cible de la chaudière et la

température cible de mélange.

MIX DESIGN (CONCEPTION DU MÉLANGER)

La température de l'eau d'alimentation requise pour les

zones de mélange pour chauffer le bâtiment durant le

jour le plus froid typique de l'année. Recommandations :

Sol chauffant à haute masse = 120°F (50°C)

Sol chauffant à faible masse = 140°F (60°C)

Ventilo-convecteur ou unité de traitement d'air =

190°F (90°C)

Convecteur avec tubes à ailettes de cuivre = 180°F

(80°C)

Radiateurs = 160°F (70°C)

Plinthe à profil bas = 150°F (65°C)

MIX TYPE (TYPE DE MÉLANGE)

Sélectionnez le type du dispositif de mélange.

VAR = pompe d'injection à vitesse Variable

FLOT = moteur à action flottante pour vannes de

mélange

0-10 = signal analogique 0-10 V (dc) pour vannes de

mélange

4-20 = signal analogique 4-20 mA pour vannes de

mélange

Remarque : 0-10 et 4-20 ne sont disponibles que

lorsque la chaudière type = 1 étape ou 2.

EMS2,

EMS1,

4-20

0-10,

Installateur

2STG,

1STG

Par défaut = 1STG

tekmar Control Systems Ltd., Une Entreprise de Watts Water Technologies. Bureau Principal: 5100 Silver Star

Road, Vernon, B.C. Canada V1B 3K4, 250-545-7749, Téléc: 250-545-0650 Site Web: www.tekmarControls.com

Conception de produit, logiciel et littérature sont des droits réservés ©2014 par

tekmar Control Systems Ltd., Une Entreprise de Watts Water Technologies

BOIL TYPE (TYPE DE CHAUDIÈRE)

Le type de chaudière relié à la commande.

1STG = chaudière à une étape unique marche-arrêt

2STG = chaudière à deux étapes marche-arrêt

0-10 = 0-10 V (cc) chaudière modulante

4-20 = 4-20 mA chaudière modulante

EMS1 = contrôles de chaudière à étapes tekmar

EMS2 = chaudières modulante Viessmann avec

OpenTherm

Remarque : Seuls 1STG et 2STG (1ETP et 2ETP)

sont disponibles lorsque le type de mélange est

défini à 0-10 V (cc) ou 4-20 mA.

8

Toutes spécifications sont sujettes à changements sans préavis.

Imprimé au Canada. 402_Q - 02/14.

Page 9

Guía de instalación rápida

tekmarNet®2 House Control 402

1.

Ubicación

402_Q

02/14

Sistemas

de HVAC

(Climatización)

Remplazado

por: 01/14

2. Instalación de la caja de unión

402

402

O

3. Tamaño del transformador

Zona 1234

Carga del

termostato

Carga de la

válvula de la zona

Carga total de la

zona

Actuador de

acción flotante

(VA)

+ ++++

Carga de

control (VA)

2

El

transformador

debe exceder:

VA

4. Instalación sensores 5. Cableado de la línea de voltaje

Sensor de exterior

Parte trasera del House Control 402

Bomba de sistema mixto

Bomba del sistema

de caldera

Bomba DHW

Potencia de la

bomba L

Bomba de

velocidad

variable

Pele los cables

1/2 pu lgada

(13 mm). No se

puede quitar los

cables instalados.

12-18 AWG

Sensor con cableado

de entrada trasera

Sensores de cañerías

Sensor con cableado de

entrada inferior

Seguro de

retención

Sensor

universal 082

Sensor ensamblado en la

caja eléctrica de 2" x 4"

115 V (ca)

Mixto

Caldera

DHW

(neg ro)

(neg ro)

(neg ro)

(roj o)

L

Veloc idad

N

SNL

variable

a tierra

(azu l)

Pozo del sensor

Una Compañía de Watts Water Technologies

9

© 2014 402_Q - 02/14

Page 10

R

C

L

N

Com

Open

Close

CtN4 —+

CtN4

2

1

WC

WC

Menu

House Control 402

Item

+

Mix ComBoil Out DHW

VlvC VlvC VlvC

Zona 3Zona 1 Zona 2 Zona 4

VlvC

Com

Zona 1

H8007D

Zona 2 Zona 3 Zona 4

tN2 tN2 tN2 tN2 tN2 tN2 tN2 tN2

C

Acción flotante

ClsOpn

Sensores – sin potencia

establecida DHW

tN4 tN4CC

Mod dc/mA Boil Exp. Mix Exp.

Orden pre- Orden

RC

Potencia de

entrada

Stage 2Stage 1

Usar con conductores que

como mínimo soporten

167°F (75°C)

Expansión

de la

caldera tN4

Expansión

mixta tN4

Caldera

moduladora

6. Instalación de la caja protectora

7. Cableado de bajo voltaje

®

Termostatos tekmarNet

Sensor de

suministros

mixtos 082

2

24 V (ca) Propulsor de

acción libre de contacto

Sensor del

exterior

070

Sensor del suministro

de la caldera 082

Sensor del tanque

DHW (Agua caliente

doméstica) 082

Orden pre-establecida

Orden DHW

desde el tanque del

Aquastat DHW (Agua

caliente doméstica)

(opcional)

8. Instalación de la tapa

Válvulas de zonas

24 V (ca) Transformador 009

Caldera de una o dos

expansión a

tN4 control de

zonas

etapas T-T

Una Compañía de Watts Water Technologies

M

e

n

u

I

t

e

m

H

o

u

s

e

C

o

n

t

r

o

l

4

0

2

10

© 2014 402_Q - 02/14

Page 11

9. Interfaz del usuario

Pantalla

Campo de Menú

Muestra el menú

actual

VIEW

ADJUST

Campo de ítem

Muestra el

nombre del ítem

seleccionado.

Muestra el estado actual de

las entradas del control, las

mayoría de los símbolos en

el campo de estado solo se

encuentran visible cuando está

seleccionado el menú de vista

Símbolos

Calls

Pumps

Zones

1 2 3 4

Saving

WWSD

Campo de estado

salidas y la operación. La

MONITOR

MAXMIN

Calls

Boil Exp

Mix Exp

(VIEW)

ORDENES

Muestra cualquier orden de calefacción.

BOMBAS

Muestra cualquier bomba que se encuentra

trabajando en ese momento.

ZONAS

Muestra si una zona a bordo se encuentra

trabajando.

ADVERTENCIA

Muestra si hay un error en el sistema.

INDICADOR DE AHORRO DE ENERGÍA

Muestra cuando el sistema se encuentra

ahorrando energía. Véase la sección del

Indicador de ahorro.

WWSD (DESCONEXIÓN POR CLIMA CÁLIDO)

Muestra cuando el sistema se encuentra

trabajando bajo el método de “Desconexión

por clima cálido”.

DHW Setp

Pumps WWSD Saving

Boil System

Mix System Zones

DHW Var 1 2 3 4

°F °C

minhr

sec%

Cls

Opn

MAXMIN

min

sec

PM

hr

AM

Campo del número

Muestra el valor actual

del ítem seleccionado.

Cls

Opn

1 2

Mix

°F, °C, %, HORAS, MINUTOS, SEGUNDOS

Unidades de medida para un número actual.

LIBRE

Indica que un interruptor del usuario o un

temporizador han puesto el sistema en modo

Libre.

CALDERA

Indica que la caldera tendría que estar

emitiendo calor.

ESCALA DE SALIDA DEL DISPOSITIVO

Muestra la salida de la válvula mezcladora o

la bomba de inyección.

CERRAR / ABRIR

Muestra si el motor de la válvula mezcladora

se está cerrando o abriendo.

MIN / MAX

Muestra cuando la temperatura que se

encuentra en pantalla llega a un mínimo o a

un máximo.

10. Nivel de acceso

INST (Instalador)

o USER (Usuario)

Predeterminado =

INST

Una Compañía de Watts Water Technologies

Presione el botón de MENU hasta que aparezca el menú Toolbox

Presione el botón ITEM para encontrar los ajustes del nivel de acceso.

NIVEL DE ACCESO

Seleccione el nivel de acceso del control, esto determinará los ítems de

MENU disponibles. USER muestra el nivel de acceso con más limitaciones

y la menor cantidad de ítems posibles.

Cuando USER se encuentra seleccionado, todos los termostatos se encuentran

bloqueados y la cantidad de ajustes del termostato disponibles es reducida.

11

© 2014 402_Q - 02/14

Page 12

11. Ajustes críticos

Presione el botón MENU hasta que se muestre el menú ADJUST MENU (Menú

de ajustes). Presione el botón ITEM para encontrar los ajustes deseados.

Campo de ítem Rango Acceso Descripción Fijar en

OUT DESIGN (TEMPERATURE EXTERIOR DE

ADJUST

ADJUST

-60 a 45°F

(-51,0 a 7,0°C)

Predeterminado =

10°F

(-12,0°C)

70 a 180°F

(21,0 a 82,0°C)

Predeterminado =

120°F (49,0°C)

Instalador

Instalador

DISEÑO)

Normalmente establecido en el día más frio del año.

La temperatura del aire en el exterior que se utiliza

en la caldera y en las curvas la calefacción mixta que

determinan la temperatura buscada de la caldera y de

la válvula mezcladora.

MIX DESIGN (DISEÑO DE LA MEZCLA)

La temperatura del suministro del agua requerido

en zonas con mezcladores para poder calentar

las instalaciones en el día más frio del año.

Recomendaciones:

Piso de losa radiante de alto rendimiento = 120°F (50°C)

Piso de losa radiante de bajo rendimiento = 140°F (60°C)

Fancoil o climatizador (air handling unit) = 190°F (90°C)

Convector de aletas y tubos de cobre = 180°F (80°C)

Radiadores = 160°F (70°C)

Zócalo discreto = 150°F (65°C)

ADJUST

4-20 mA,

0-10 V (cc)

FLOT,

VAR

Predeterminado =

VAR

EMS2,

EMS1,

4-20

0-10,

2STG,

1STG

Predeterminada =

1STG

Instalador

Instalador

MIX TYPE (TIPO DE MEZCLADOR)

Seleccione el tipo de dispositivo mezclador.

VAR = Bomba de inyección de velocidad variable.

FLOT = Motor de acción libre de contacto para válvulas

mezcladoras.

0-10 = 0 -10 V (cc) señal análoga para válvulas

mezcladoras

4-20 = 4-20 mA señal análoga para válvulas mezcladoras

Nota: 0-10 y 4-20 solo se encuentran disponibles

cuando Boiler Type (Tipo de caldera) = 1 etapa o

2 etapas

BOIL TYPE (TIPO DE CALDERA)

El tipo de caldera conectada al control.

1STG = única caldera de comando de una etapa

2STG = única caldera de comando de dos etapas

0-10 = 0-10 V (cc) caldera con modulación

4-20 = 4-20 mA caldera con modulación

EMS1 = tekmar controles de etapas de la caldera

EMS2 = calderas con modulación Viessmann y

OpenTherm

Nota: Solo 1STG (una etapa) y 2STG (dos etapas)

están disponibles cuando el Mix Type (Tipo de

mezcla) se encuentra en 0-10 V (cc) o 4-20 mA.

tekmar Control Systems Ltd., Una Compañía de Watts Water Technologies. Ofi cina Principal: 5100 Silver Star

Road, Vernon, B.C. Canadá V1B 3K4, 250-545-7749, Fax. 250-545-0650 Sitio Web: www.tekmarControls.com

El diseño del producto, software y la literatura poseen derechos reservados ©2014 a

nombre de tekmar Control Systems Ltd. Una Compañía de Watts Water Technologies

12

Todas las especificaciones pueden cambiar sin previo aviso.

Impreso en Canadá. 402_Q - 02/14.

Loading...

Loading...