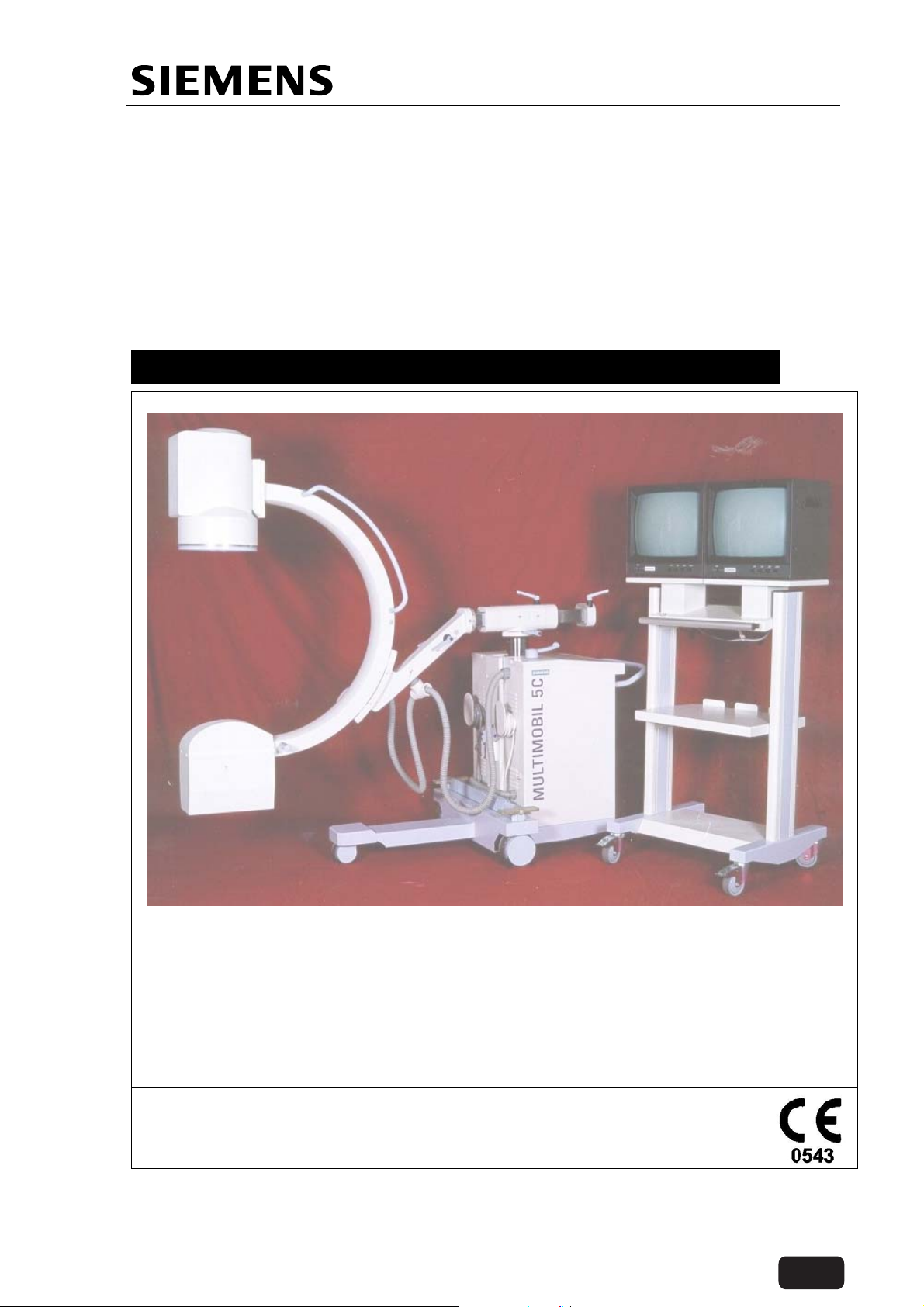

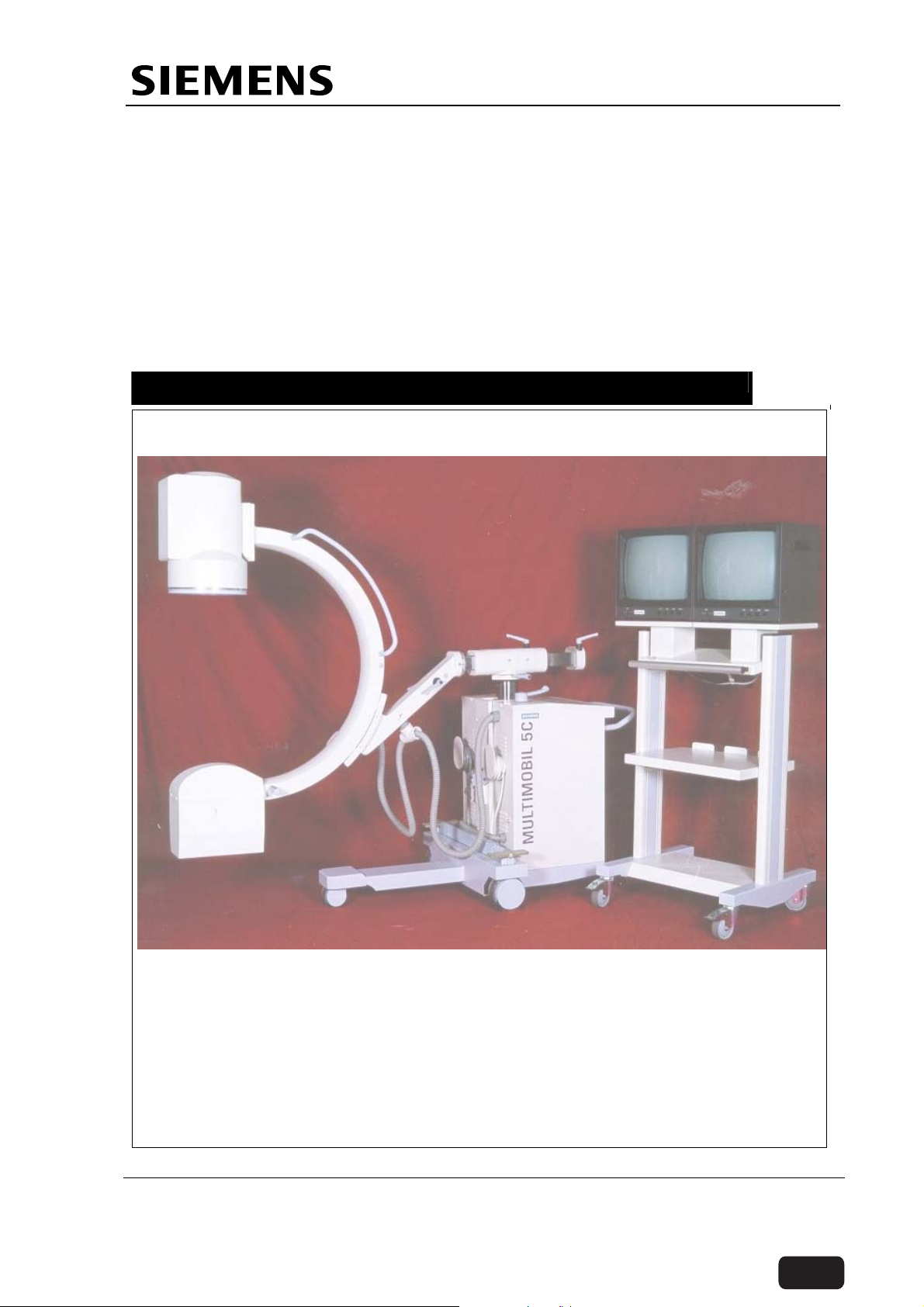

Siemens Multimobil 5C Service manual

Multimobil 5C

Med

SERVICE MANUAL

Version 2.0

Copyright © SIEMENS LTD. Med INDIA

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

5605

5422040

001/002/003/004

Prepared by

Multimobil 5C

Multimobil 5C

Service Manual

Med

Service Manual

Version: 2.0

Status: Released

Copyright SIEMENS LTD.,Med INDIA

Name: Mahadevan.J

Dept: GW/Engg

Signature:

Date:09.06.2004

Siemens Ltd. Med India

Mahadevan.J

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

DMR 4.10

SPU Number

Item Number

Version

Reviewed by Released by

Name: H.S.Usgaonkar

Dept: GW/Engg

Signature:

Date: 09.06.2004

Version 2.0 Released

Copyright SIEMENS LTD. All rights reserved. For internal use only

Name:V.P.Khandeparker

Dept: GW/Q

Signature:

Date: 09.06.2004

Page 1 of 2

Back

Multimobil 5C

Service Manual

1 History

1.1 Alteration History

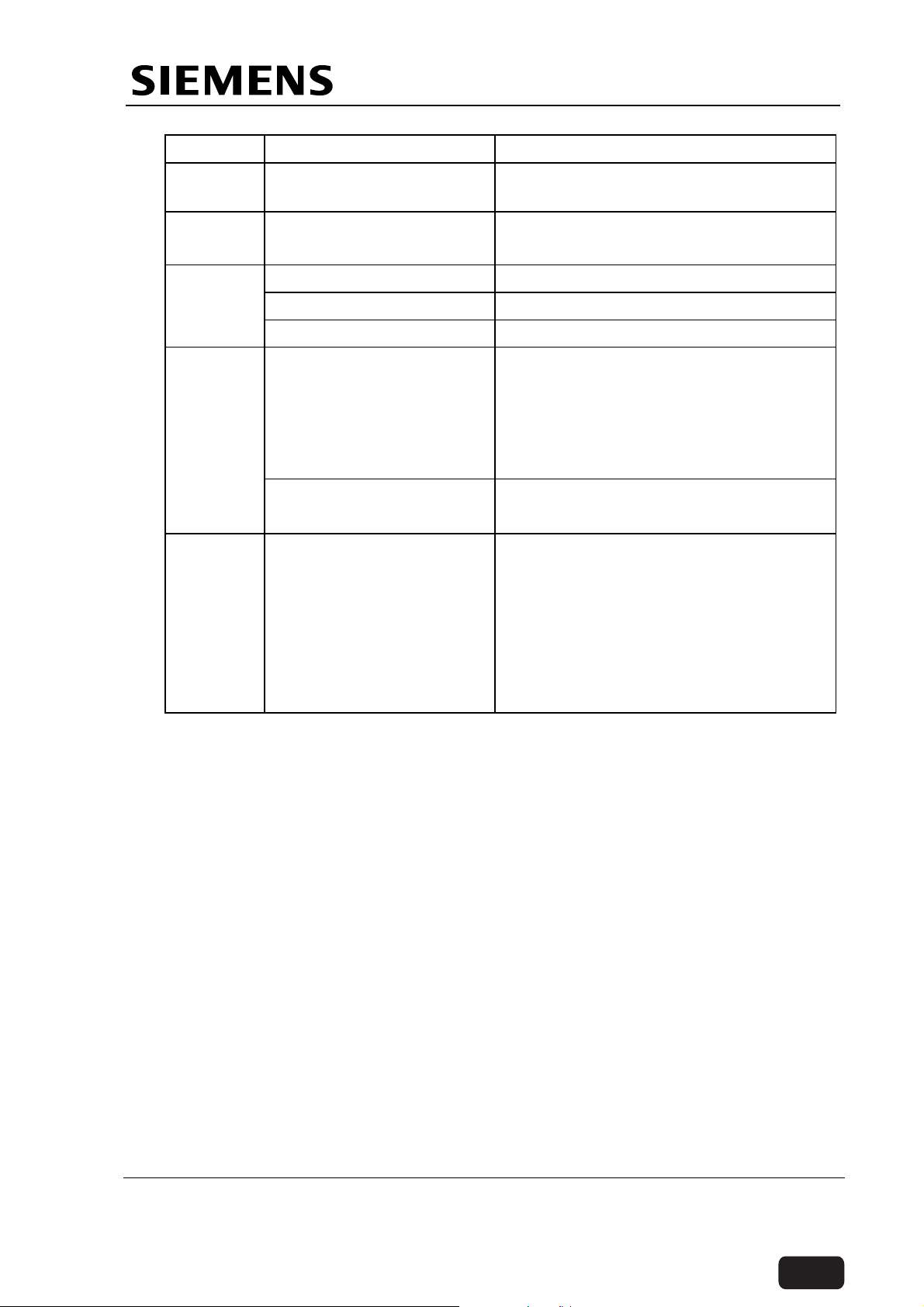

Version Date Prepared by / Dept. CCI NO. Change and Reason for

change

01 11.07.2003 S.K.Kutty GW/SP ---- First Release

2.0 09.06.2004 Mahadevan.J

GW/Engg

6148 Upgrade w.r to 110V and

60Hz requirements & common

manual for all versions of the

product.

Siemens Ltd. Med India

Mahadevan.J

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Copyright SIEMENS LTD. All rights reserved. For internal use only

Version 2.0 Released

Page 2 of 2

Back

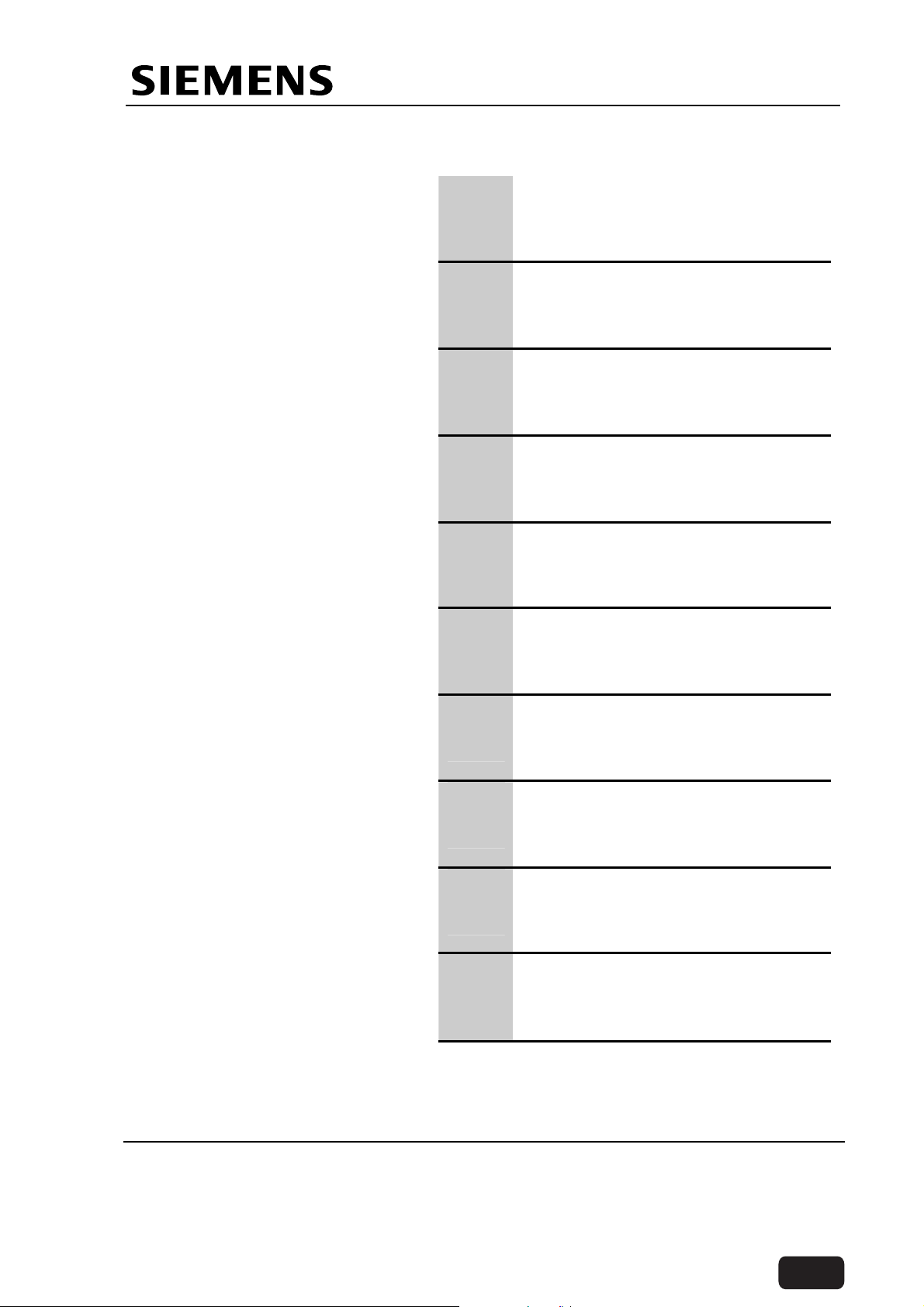

Main Index

Multimobil 5C

Service Manual

5422040 002

1 Pre-installation

2 Installation Instructions

3 Service Instructions

4 Wiring Diagrams

5 Wiring Description

6 Circuit Description

Siemens Ltd. Med India Version 2.0 Pages 1 of 1

7 Circuit Diagrams

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Copyright © SIEMENS LTD. All rights reserved. For internal use only

Back

Pre-installation Instructions

Multimobil 5C

Med

Pre-installation

Version 2.0

Siemens Ltd. Med India Version 2.0 Page 1 of 10

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Copyright © SIEMENS LTD.,Med INDIA

Copyright © SIEMENS LTD. All rights reserved. For internal use only

Back

Pre-installation Instructions

INDEX

1 PRE-INSTALLATION...................................................................................................................3

1.1 TECHNICAL SPECIFICATIONS .......................................................................................................3

1.2 INFORMATION ON ROOM PLANNING..............................................................................................6

1.3 PACKAGING................................................................................................................................6

1.4 UNLOADING................................................................................................................................7

1.5 UNPACKING THE MM5C..............................................................................................................8

1.6 UNPACKING THE MONITOR TROLLEY.............................................................................................9

1.7 INSTALLATION OF THE MONITORS ...............................................................................................9

Siemens Ltd. Med India Version 2.0 Page 2 of 10

Copyright © SIEMENS LTD. All rights reserved. For internal use only

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Pre-installation Instructions

1 Pre-installation

1.1 Technical Specifications

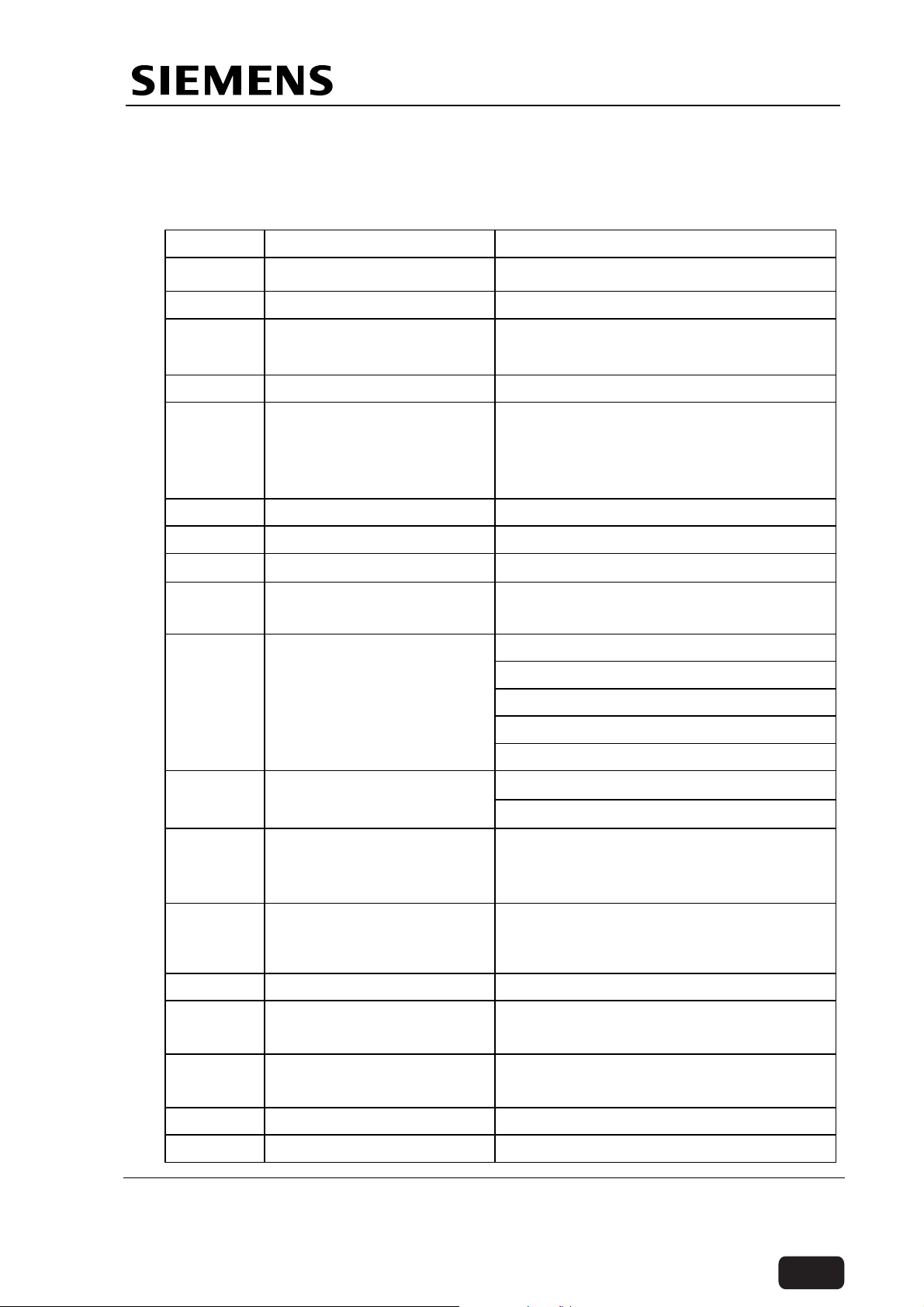

Sr.No Parameter Value

1. Mains Voltage

110V/190 -240V∼

2. Line frequency 50 / 60Hz

3. Line impedance

1.5 Ω (max) @ 190-240 V

0.36Ω (max) @ 110V

4. Length of power cable 5 m

5. Power Output –

Radiography

2.5 kW (100 kV, 25 mA) @ 190-240V

1.6KW (100 kV, 16 mA) @110V

Nominal Electric power at

100kV and 100mSec.

6. Wave Shape Multipulse DC - Ripple 5kV max

7. KVp Range 40 – 100kV in 20 steps

8. KV Accuracy

9. mA-range

≤ ± 5 %

13 – 63 mA @ 190-240V input

10 – 40 mA @ 110V input

10. mAs Range

0.32 – 200mAs at 40kV

0.32 – 160mAs at 42 - 50kV

0.32 – 125mAs at 52 - 63kV

0.32 – 100mAs at 66 - 77kV

0.32 – 80 mAs at 81 - 100kV

11. mAs Accuracy

≤ 10 % + 0.2 mAsfor mAs ≤ 20 mAs

≤ 5 % + 0.2 mAs for mAs > 20 mAs

12. Exposure Time 20mSec - 5 Sec in 24 steps @190240V

20mSec – 8 Sec in 26 steps @ 110V

For details of kV, mA and exposure

time combinations as per EN 60601-27 refer to exposure chart on page 6-14.

13. Fluoroscopy voltage 40-110 kV

14. Fluoroscopy Modes ADR(Automatic dosage regulation):

Anti-isowatt & Contrast.

15. Fluroscopy mA range Anti-isowatt 0.5 to 5 mA

16. Fluroscopy Power 550W continous

Contrast 0.5 to 7mA

17. Timer Fluoroscopy time display with timer

Siemens Ltd. Med India Version 2.0 Page 3 of 10

Copyright © SIEMENS LTD. All rights reserved. For internal use only

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Pre-installation Instructions

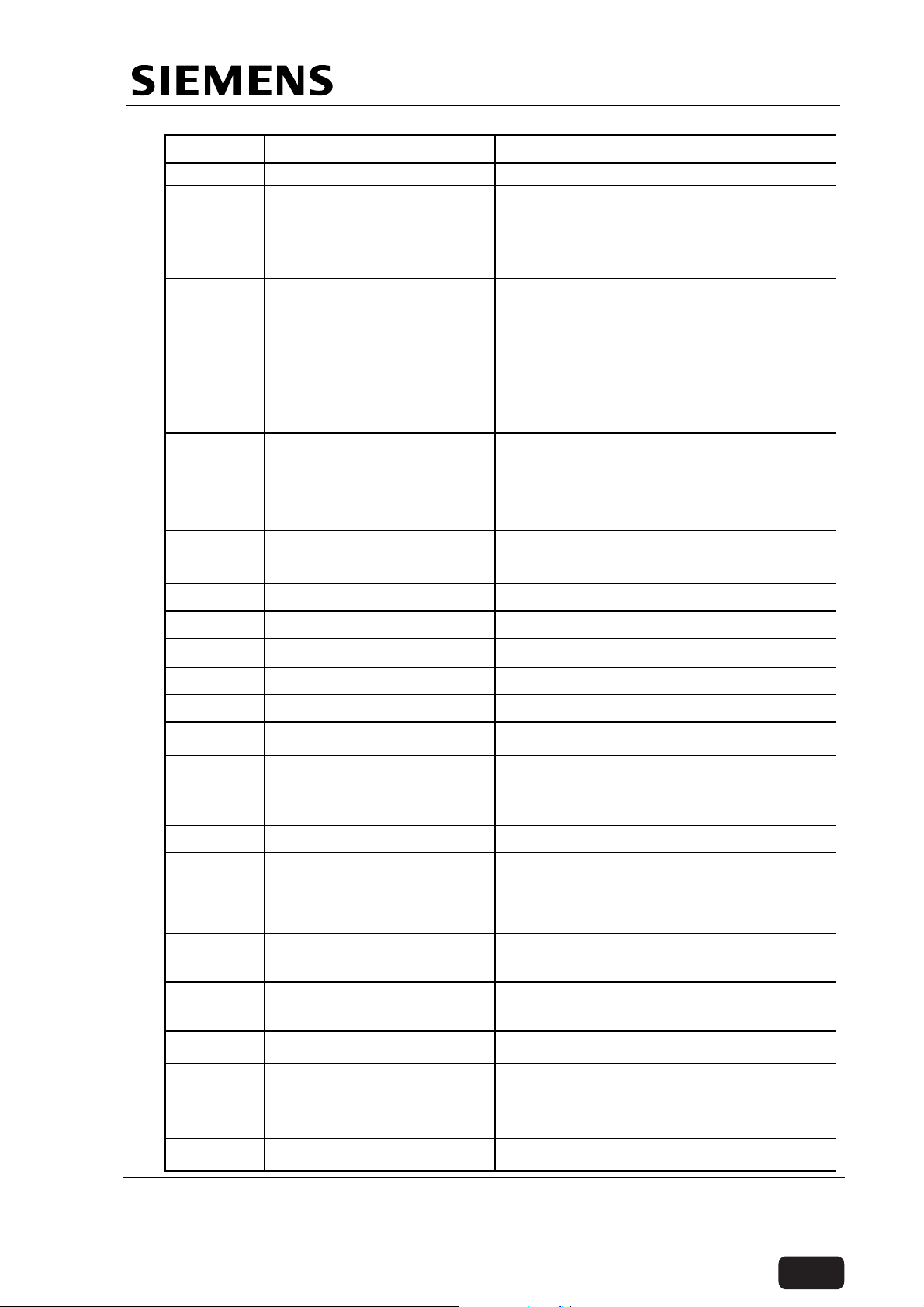

Sr.No Parameter Value

reset and 5 minute buzzer indication

18. Thermal Protection Auto cutoff of fluoroscopy and

radiography in case of tube head

temperature exceeding 60°(+ 5°)

celcius

19. Power Input:

Continous

Instantaneous

20. Mains Isolation

External: done by the

user

21. Type and degree of

1.5kVA

3.5kVA

Power supply cord shall be plugged

where both poles (L & N) are isolated

simaltaneously.

Class – I, Type B equipment

protection against electric

shock (EN 60601 – 1)

22. X - ray Tube Stationary Anode DF-151R

23. Focal Spot – nominal

value

0.5 for Fluoroscopy

1.5 for radiography

24. Inherent tube Filtration 0.8 mm Al at 50kV

25. Nominal kV 110 kV

26. Target Angle

16°

27. Collimator Motorised, multileaf Iris Collimator

28. Total filtration 5.3 mm Al at 100kV

29. Exposure release Switch 2 Step

30. Exposure Rate for

Radiography

Pulse to pause ratio 1:30; corresponds

to a cool down period of 4 minutes at

maximum output.

31. Max. X-ray coverage 430X430mm at SID 909 mm

32. Mode of Operation Continuous operation

33. Focus-II distance 860mm for 9“ system

900mm for 6“ system

34. Max. cassette size at 900

10“X12“

cm SID

35. Grid Circular grid placed at the input of the

II tube , 40 Ip/cm, 8:1

36. Image Intensifier 9“ / 6“

37. Image Intensifier tube

resolution

Nominal 52lp/cm and zoom 68 Ip/cm

for 9“ system

Nominal 66 lp/cm and zoom 77 Ip/cm

38. Nominal entrance field 230mm for 9“ system

Siemens Ltd. Med India Version 2.0 Page 4 of 10

Copyright © SIEMENS LTD. All rights reserved. For internal use only

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Pre-installation Instructions

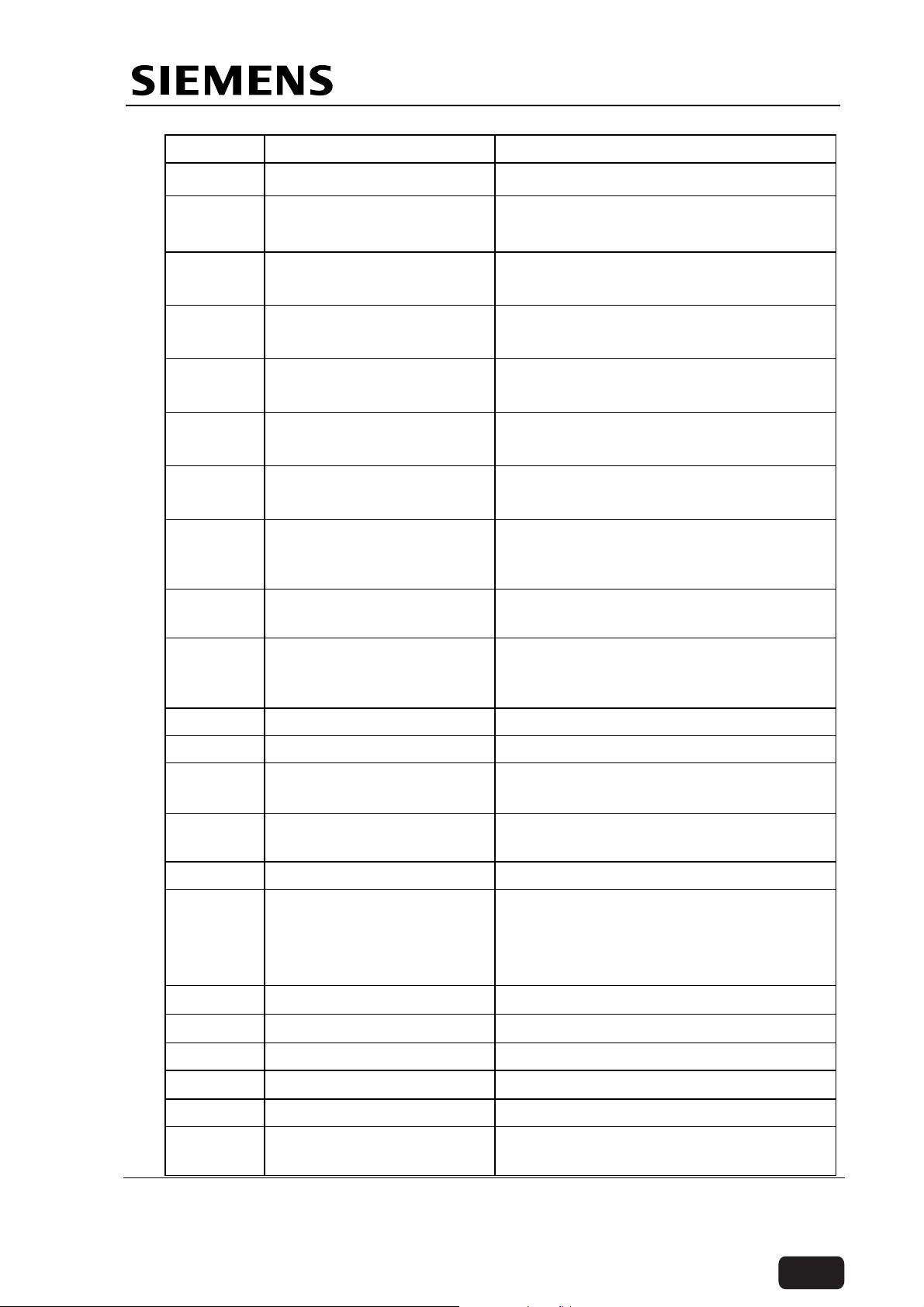

Sr.No Parameter Value

150mm for 6“ system

39. II output image size

diameter

25±0.5mm for 9“ system

20±0.5mm for 6“ system

40. Zoom (field size) 230mm/160mm for 9“ system

150 mm/100 mm for 6“ system

41. TV camera

AC100∼220V±10%

Input Voltage

42. Pick Up device

Pick UP area

CCD

6.4X4.8mm

43. Effective Pixels 752(H)X582(V)(CCIR)

768(H)X494(V)(EIA)

44. TV System 625lines/50Hz(CCIR)

525lines/60Hz(EIA)

45. No. of monitors 2 monitors one each for Live/Last

Image Hold(LIH) and stored memory

display

46. Monitor size 17“monochrome with 9“ system and

15“ monochrome with 6“ system

47. Monitor screen High brightness,high resolution with

independent brightness and contrast

control

48. TV standard CCIR 625 lines at 50 Hz

49. Aspect ratio 4:3

50. Image rotation Endless clockwise and anti-clockwise

wih complete 360°rotation in 10sec

51. Recursive filter Steps of 1,1.5,2,3,4,8,10,12,14,

16,24&32 to minimize dynamic blur

52. Image reversal Left/right and top/bottom

53. II Chain Resolution Nominal 1.2 lp/cm Zoom 1.6 lp/cm for

9” system

Nominal 1.4 lp/cm Zoom 2.0 lp/cm for

6” system

54. C-arm orbital movement

55. Angulation

125°(+90°to -35°)

±190°

56. Horizontal travel 200mm

57. Swivel range

58. Vertical travel 400 mm

±12.5°

59. Mobility Directional lock on rear wheels

enabling excellent manuerability

Siemens Ltd. Med India Version 2.0 Page 5 of 10

Copyright © SIEMENS LTD. All rights reserved. For internal use only

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Pre-installation Instructions

Sr.No Parameter Value

60. Max. floor incline for

transport

61. Mechanical Dimensions

(lxbxh)

62.

Weight

Without packing 280kg

With packing 680kg

63.

Environmental conditions

Transport and Storage

Temp range.

Relative Humidity range

Atmospheric pressure

Operating Temperature

Relative Humidity range

64. Conformance to

Standards

5°

2000 x 800 x1720 mm (min)

2070x1050 x2120 mm (max)

-15° C to 45° C

Upto 90%

50 kpa to 106 kpa

10° C to 40° C

Upto 85% non condensing

EN 60601-1:1990

EN 60601-2-7:1998

EN 60601-1-3:1994

EN 60601-1-2:2001

Compliance to AERB Type Approval

Ceritification

Compliance to BIS test certification.

1.2 Information on Room Planning

No specific conditions required. Following are the recommended room conditions for

proper functioning of the unit.

Ambient Temperature (Room temperature): + 40 °C Max

Air Humidity: up to 75%, Non-condensing.

During Transport and storage of the product the ambient temperature should not be

below -15°C or rise above +45°C. Storage is permissible in rooms with minimum

amount of dust and Humidity in range of 30% to 95% RH provided no condensation

occurs.

1.3 Packaging

The Multimobil 5C unit is delivered in two wooden boxes.

One box consists of the Monitor trolley. This is a wooden box with the trolley mounted

on the wooden base and is fixed using clamping brackets.

The second box contains the MM5C unit along with monitors and accessories .The Carm unit is clamped using brackets on the wooden base. The two monitors are packed

in the corrugated box and placed on the wooden platform.

One box consists of standard accessories i.e. sterile cloth, Clips and user manual.

Siemens Ltd. Med India Version 2.0 Page 6 of 10

Copyright © SIEMENS LTD. All rights reserved. For internal use only

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Pre-installation Instructions

MM5C with

monitors and

accessories

Monitor trolley

for MM5C

1.4 Unloading

The unloading of the unit from the truck can be carried out using any of the following

ways depending on the site conditions:

1) Using a forklift.

2) Using an overhead travelling crane.

3) Using a chain pulley block and tripod.

Siemens Ltd. Med India Version 2.0 Page 7 of 10

Copyright © SIEMENS LTD. All rights reserved. For internal use only

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Pre-installation Instructions

4) Using conventional ways i.e. Using wedges, wooden planks, pipes or rods and

labour etc.

Note: 1. All boxes are provided with transport base.

2. Do not roll the boxes.

3. Do not drop the boxes from a height of more than 20cms.

4. Observe the stickers

(This side up) and (handle with care) on the

Packing for proper handling.

Once the unit is removed from the transport, place it on the ground on the base.

1.5 Unpacking the MM5C

The complete system must be inspected for physical damage and / or material

short-fall and factory must be informed accordingly.

The Multimobil 5C consists of fragile components like camera, Image intensifier, X-ray

Tube etc. Sufficient care must be taken while unloading / Unpacking the unit.

Refer the

unpacking instructions provided on the packing.

Observe the following steps:

1) Remove the restraining strips by cutting it. Use a cutting plier for this purpose.

2) Start removing the wooden planks. For this purpose the service engineer should use

a claw hammer or nail pulling plier and preferably a crow bar.

3) First of all remove the top planks. Upon opening this plank you will be able to see the

unit inside. Ensure that the unit has not received any transit damages.

4) Now, remove the front and rear wall of the box one by one. The front wall is provided

with a ramp. Hence, place this plank carefully for pushing the unit out of the platform.

5) Now you will see three wooden blocks fixed across the unit for supporting the wall

and also to support the image intensifier and single tank.This are supporting beams.

6) Loosen these blocks from one side and remove them gently.Now, remove the side

walls.

7) Care should be taken to see that the wooden planks or the nails do not damage the

unit.

8) Now, you can easily remove the ESD bags.

9) After removing the ESD bags, remove the monitor boxes and accessories and take

them to the OT.

10) Remove the packing strips and thermocol packing from the control, II and single

tank. Also, remove the wooden lever fixed at the base by cutting the strap.

11) Next step is to remove the clamping brackets. First of all, remove the bracket used

for clamping the single tank and Image intensifier. Secondly, remove the bracket

used to clamp C-arm. Third, remove the brackets on the rear wheels. Next remove

the brackets used to clamp the base.

12) Now ensure that the rear wheels are in locked condition. Also the C-Arm should be

in locked condition.

13) Remove the bolts of the clamping brackets at the rear side on which the housing is

resting. Now, using the lever, gently lift the base along the bracket so that the rubber

block can be removed. Once the rubber blocks are removed, remove the clamping

bracket.

14) Now, remove the two brackets on the front end of the base. Lift from sides using

wooden lever. Remove the rubber buffer and remove the bracket.

Siemens Ltd. Med India Version 2.0 Page 8 of 10

Copyright © SIEMENS LTD. All rights reserved. For internal use only

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Pre-installation Instructions

15) Now the unit will be resting on the wooden platform. Release the brakes and push

the unit down to the ground through the ramp.

DO NOT HOLD THE UNIT AT POINTS

WARNING

MARKED

WHILE LIFTING

Observe the following steps for transporting the unit to the OT.

Unlock the C-arm and turn it to the position shown in the figure and lock it. This is

the suitable position for moving the unit from the platform.

Now , release the brake of the C-Arm and swing the C-Arm back to the normal position

as shown in the figure for transportation. This is also the parking position.

Roll all the cables and hang it on the cable holder provided on the housing.

Unbrake the wheels and move the unit to the OT. Use the steering for easy

manouverabilty.

1.6 Unpacking the monitor trolley

Observe the following steps:

1) Remove the restraining strips by cutting it .Use a cutting plier for this purpose.

2) Remove the top plank.

3) Remove the front and rear wall of the box.

4) Remove the supporting beams fixed across the sidewalls.

5) Remove the side planks. The trolley is mounted on the clamping brackets.

6) Remove the ESD bag.

7) Now, using a spanner of 16-17, remove the clamping brackets.

8) Lift the trolley gently by holding at the base and supporting it from top. Place it on the

floor.

9) Release the brakes and the trolley can be shifted to the OT.

1.7 Installation Of The Monitors

1) Open the corrugated box and remove the monitors.

2) Open the accessories box and remove the packet of hardware.

Siemens Ltd. Med India Version 2.0 Page 9 of 10

Copyright © SIEMENS LTD. All rights reserved. For internal use only

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Pre-installation Instructions

3) Place the monitors on the top tray of the monitor trolley and fasten them using

socket HD screw M4x20, spring washer and plain washers.

4) Make use of the connector provided on the monitor trolley for providing power supply

to the monitors.

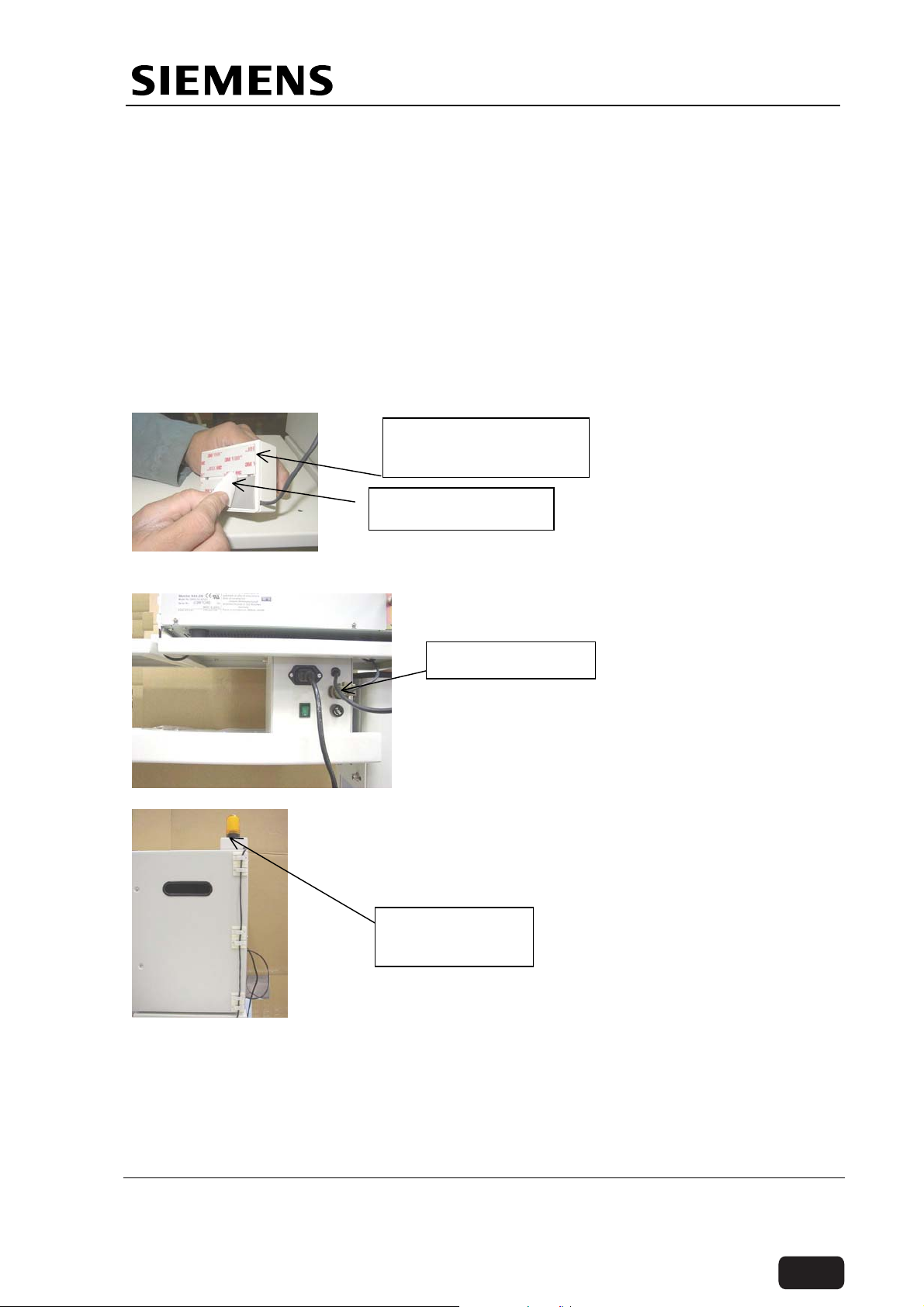

5) Install the radiation indication lamp as explained below.

The Radiation Indication lamp assembly has been packed along with the

monitor.

Unpack the monitors and remove the radiation indication lamp assembly.

Fix the monitor having clamps on it for cable routing, on to the left side monitor

tray using hardwares provided in the accessories box.

Peel off the protection layer of the double-sided tape and fix the radiationindicating lamp on top of this monitor.

Radiation indication

lamp assembly

Double sided Tape

Route the cables through the clamps and Connect the male part of allied

connector to the female part fixed on the monitor trolley.

Allied connector

Route the cable in between the monitors.

Radiation

indication lamp

Siemens Ltd. Med India Version 2.0 Page 10 of 10

Copyright © SIEMENS LTD. All rights reserved. For internal use only

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Multimobil 5C

Installation Instructions

Med

Installation Instructions

Version 2.0

Siemens Ltd. Med India Version 2.0

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Copyright © SIEMENS LTD.,Med INDIA

Copyright © SIEMENS LTD. All rights reserved. For internal use only

Page 1 of 9

Back

Installation Instructions

INDEX

1 INSTALLATION ...........................................................................................................................3

1.1 TRANSPORT POSITION OF UNIT ...................................................................................................3

1.2 SAFETY INFORMATION.................................................................................................................3

1.2.1 General ................................................................................................................................3

1.2.2 Safety Checks......................................................................................................................4

1.2.3 Overload Protection.............................................................................................................4

1.2.4 Radiation Protection.............................................................................................................5

1.3 PRELIMINARY CHECKS ................................................................................................................5

1.3.1 Mechanical Check................................................................................................................5

1.3.2 Electrical Check...................................................................................................................5

1.3.3 Collimator.............................................................................................................................7

1.3.4 Exposure..............................................................................................................................8

1.4 GENERAL CHECK........................................................................................................................9

Siemens Ltd. Med India Version 2.0

Page 2 of 9

Copyright © SIEMENS LTD. All rights reserved. For internal use only

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Installation Instructions

1 Installation

1.1 Transport Position of Unit

After unpacking the unit as explained in pre installation, bring the unit to its transport

position as explained below.

• Adjust the column to the bottom most

position.

• Bring the holder and C-Arm in the

default transport setting and lock all

the levers.

• Hang all the cables on the cable

winder. Place the foot switch in the

holder.

• Loosen the foot brake.

• Pay attention that the wheels do not

strike against any obstacles.

• For transport of monitor trolley,

loosen the brakes.

• For more details Refer Operational

Manual.

• Label is provided on the unit showing

the transport position.

NOTE: While transporting the unit on

the slope ensure that the slope should

not exceed +10°.If the slope is more

than 10°,there is a risk of toppling.

1.2 Safety Information

1.2.1 General

It shall be the duty of the installation personnel and the user to ensure that all the

safety measures concerning the unit operation and installation are adhered to.

The unit must be checked for the status of its safety measures at least every year or

any time desired by the user, not exceeding one year.

However, we recommend in the interest of the safety of the patient, the user, and

other personnel to have a yearly drill on operational safety.

If there are any special regulations of the hospital/institute, to be followed over and

above the general safety regulations pertaining to the installation, the same must be

ensured.

Siemens Ltd. Med India Version 2.0

Page 3 of 9

Copyright © SIEMENS LTD. All rights reserved. For internal use only

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Installation Instructions

Before commencing the operation, the user must convince himself/herself regarding

all safety aspects and their proper functioning. He should also ascertain that all

displays and indicators are functioning as described.

The radiation indication lamp should light only when the exposure is released. In

case the lamp lights in any other condition, the unit should be immediately switched

off and SIEMENS SERVICE DEPARTMENT should be informed.

Any change / or replacement in the unit must be carried out by the manufacturer or

a person authorised by manufacturer ONLY. The record of such work must be

maintained clearly at the site.

Before opening / closing the covers ensure that

the mains is switched off and the plug is removed

WARNING

from the socket.

Ensure that the protective earth connections of

the sub assemblies are properly connected.

1.2.2 Safety Checks

1.2.2.1 Before operation

Brakes and locks

All C-Arm movement in braked and unbraked condition

Open the Front Cover and check for any loose connection or transport damage.

Check for Mains supply as specified in Technical specification and ensure that

the voltage difference between Earth and Neutral should not be more than 5

Volts.

1.2.2.2 During Operation

Follow the Operating Instructions provided with the Unit.

Vertical movement of C-Arm

The radiation indication lamp should only glow when fluoroscopy or radiography

is performed.

Proper positioning of the unit.(refer to the operating instructions for positioning of

the unit)

While shifting a patient on the operating table, take care that the wheels of the

unit are locked properly.

1.2.3 Overload Protection

The unit is designed to work on 110 / 190-240V, single phase, 15A socket. For

safety purposes 16A HRC fuses are provided which will blow when a current

exceeding 16A sustains for its response time.

Siemens Ltd. Med India Version 2.0

WARNING

Ensure that the mains socket is properly earthed.

Page 4 of 9

Copyright © SIEMENS LTD. All rights reserved. For internal use only

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Installation Instructions

In case of fault if the kV tries to build beyond the safe limit of X-ray tube the

protection circuit blocks the HT.

In case of fault if the Filament current tries to increase beyond the safe limit the

protection circuit blocks filament boosting.

Maximum permissible resistance between the Earthing lead terminal in the control

and on the HT transformer shall not exceed 0.1 ohms.

1.2.4 Radiation Protection

Do not put any part of your body in the direct line of

radiation.

WARNING

Collimate the X-ray beam.

Keep maximum possible distance from the object being

radiographed. For this make the best use of 5 mt of

recoilable exposure release switch.

In the room , wear protective clothing (lead Apron).

Monitor radiation received using the personal TLDbadges or pen-dosimeter.

1.3 Preliminary Checks

1.3.1 Mechanical Check

1.3.1.1 Unit Movements

Force required to push/pull the unit on a horizontal surface should not exceed 5

kgf. Force required to push/pull the unit on a 10° slope should not exceed 30 kgf.

1.3.1.2 Orbital Movement

125° ± 2° counterbalanced in all positions.Force required should not exceed 6 kgf at

the handles provided, in a direction tangential to the C arm.

1.3.1.3 Angulation Movement

190° ± 3° counterbalanced in all positions. Force required should not exceed 6 kgf

at the handles provided.

1.3.1.4 Horizontal Movement

200 ± 5mm. Force required should not exceed 5 kgf in either direction.

1.3.1.5 Swivel Movement

± 12.5° ± 1°. Force required should not exceed 3 kgf at the handles.

1.3.1.6 Steering movement

Ensure that the rear wheels can be revolved using the steering lever.This will

confirm that the chain connecting the various links are intact and has not sliped off.

1.3.2 Electrical Check

1.3.2.1 Mains supply

For units with 190-240V supply

1. Check available mains voltage at the site.

Siemens Ltd. Med India Version 2.0

Page 5 of 9

Copyright © SIEMENS LTD. All rights reserved. For internal use only

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Installation Instructions

2. Check if the mains voltage is within ± 10% of the nominal range 190-240V.

3. Check if the Mains resistance is ≤ 1.5 Ω.

For units with 110V supply

1. Check available mains voltage at the site.

2. Check if the mains voltage is within ± 10% of the nominal value 110V.

3. Check if the Mains resistance is ≤ 0.36 Ω.

1.3.2.2 Switching ON

Press on the top panel. The kV-mAs display will light up.

The Display will indicate for the set-up

time. (3 seconds approx)

After setup and initial hardware checks

the display changes to the default kV

and mAs settings.

The Control Unit contains Non volatile Memory

NOTICE

which retains the last selected kV and mAs. So the

initial display after set-up will depend on the last

settings done.

The kV & mAs display and settings will now respond to the corresponding switches

on the panel.

In case of any errors while setting up / hardware check / stand-by operation, the

corresponding Error code will be displayed on the same displays.

The display will indicate CodE 99 in case the

unit while setting up/ after set-up detects that

last reset of the unit was due to watch-dog and

not hardware RESET.

If the unit is being installed after six months from

the date of despatch, the capacitors need

WARNING

forming. Refer Service instructions for forming.

1.3.2.3 Up/Down movement

Once the unit is switched on, Check column Up and down movement. Check for the

operation of the limit switches. Do the Up/Dn movements several times to confirm

that there is no wear and tear of belt/bearings and no abnormal noise from the

mechanism.Keep the colum in the upper most position and switch off the unit.

Siemens Ltd. Med India Version 2.0

Page 6 of 9

Copyright © SIEMENS LTD. All rights reserved. For internal use only

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Installation Instructions

After the unit is switched on, the capacitors

charge to 300VDC. (Approx) After switching the

WARNING

unit OFF, it takes about 4 minutes for capacitors

to discharge. The presence of DC voltage is

indicated by Green LED on D61.

1.3.2.4 Cable Connections

Switch off the unit and disconnect the mains supply. Wait for 5 minutes. Open the

front cover and top panel.Check the cable connections as per the table below.

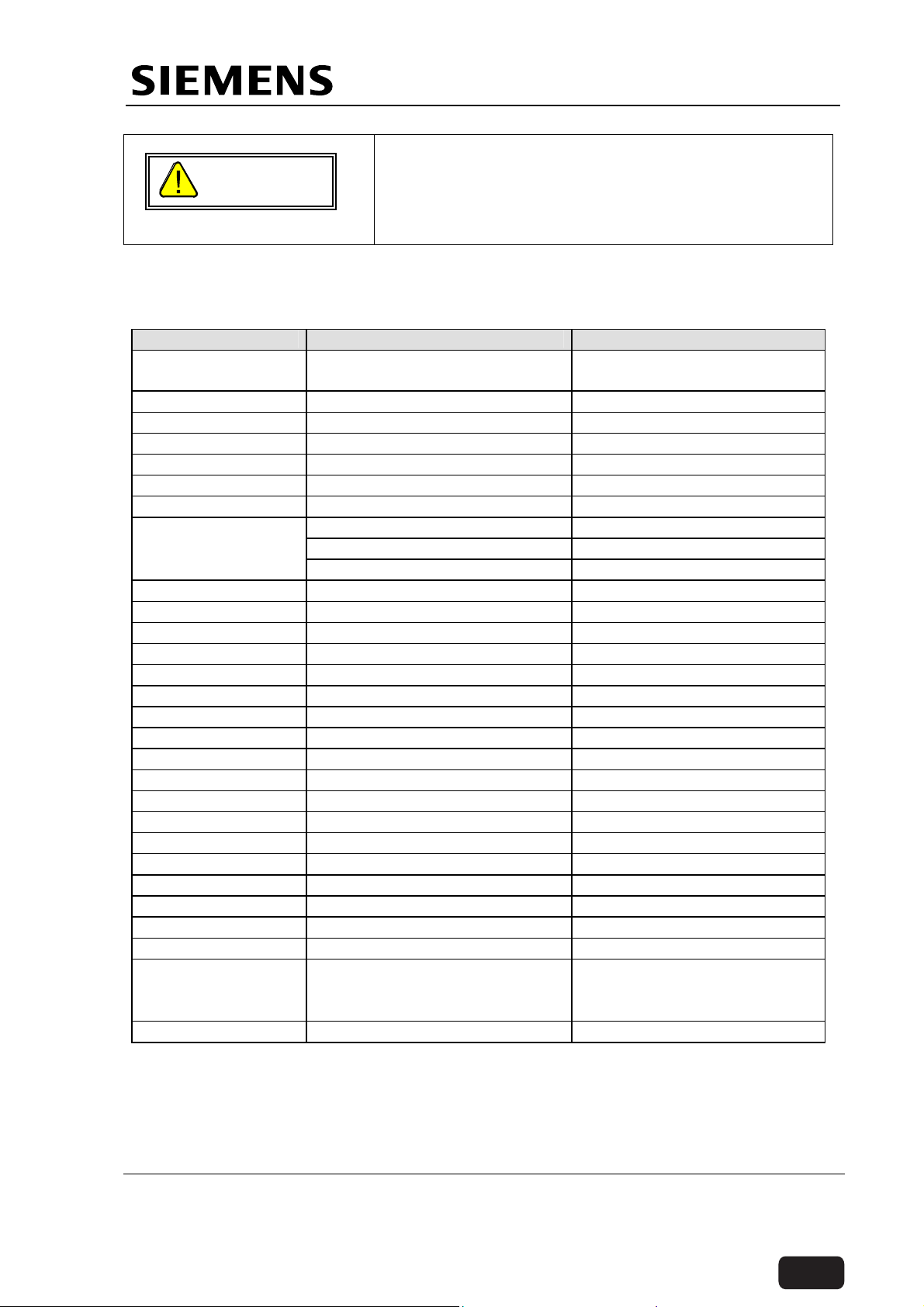

Type Description Specifications

Mains Mains Cable 3 x 1.5 mm sq.(15A Moulded

Plug)- 5mtr length

Control to single Tank HT Cables U & V 6 mm sq. black twisted with braid

Filament cables Y, 12 & 22 3 Core shielded PVC insulated

Collimator Cable 12 Core Grey

Earth Cable 6 mm sq. Black/ Yellow-Green

kV feedback Cable 2 Core shielded PVC insulated

Ground Wire (X) 1.5 mm sq. Yellow

Control to Monitor

Trolley

Control to CCU Mains Cable 3 x 1.5 mm sq.

Interconnections D915.X20 to D506X20 20p FRC

D915.X10 to D506.X10 26p FRC

D915.X11 to D506.X11 16p FRC

D915.X12 to D507.X12 14p FRC

D915.X50 to D507.X50 20p FRC

D915.X8 to D506.X8 10p Bonded

D915.X15 to D981.X7 Bunch

D915.X40 to D509.X40 34p FRC

D507 X70 to D509 X70 20p FRC

D507.X80 to D508.X80 40p FRC

D508.X2 to Collimator.X2 15p D type

D506.X6 to D6.X6 D type soldered connections

D506.X27 to S27 3 Core cable

D508.X90 to CCU X.18 20p FRC

D508.X3 to wire bunch Bunch

D508.X4 to up/dn Motor Control Bunch

D506.X1 to T1 input Bunch

D506.X4 (Pin 1 to 5) to T1 output.

Mains Cable 3 x 1.5 mm sq.

Composite Video Cable 2 x RG 59 with BNC termination

Radiation indication lamp 2 x 1.5 mm. Sq.

Bunch

D506.X4(pin6& 8) to D982 (24V &

0V) (pin 7&8) to D983 (+15 V &0v)

D506.X2 to Single Tank Bunch

Close the top panel and front cover.

1.3.3 Collimator

Switch the unit ON. It will be going to stand by mode.

Siemens Ltd. Med India Version 2.0

Page 7 of 9

Copyright © SIEMENS LTD. All rights reserved. For internal use only

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Installation Instructions

Check the opening and Closing of Iris Collimator. In Fluoroscopy the maximum

opening of the Iris will be limited to the maximum diameter of the Image Intensifier

(6” or 9” as the case may be).

In case of Radiography the Iris Collimator will open automatically to it’s maximum

opening diameter for the cassette exposure.

Use Radiation Protection

Presence of High Tension

Observe Safety Precautions

1.3.4 Exposure

1.3.4.1 Fluoroscopy

Switch ON the unit. Enter in to the Fluoroscopy Mode, press foot switch check for

the Initialization of the Fluoroscopy at the same time radiation Indication, Yellow

LED on the top panel and the lamp on the monitor trolley, will light up.The Image

will appear on the Monitor in ‘Live‘ Mode, by releasing the foot switch The Last

Image On the Monitor will be frozen (LIH function).

1.3.4.2 Exposure

Set the exposure parameters as 60kV, 10mAs.

Pull the recoilable Exposure Release Switch and release an exposure. The yellow

LED on the top panel will light up for duration equal to exposure time.

An audible indication by a muffled sound from single tank as well as from the buzzer

will confirm the working of the inverter and the exposure.

1.3.4.3 Timing

Set 40 kV 160mAs.

Release an exposure. The radiation indication LED will light for 5 sec ± 0.5 sec.

Set 90 kV 80mAs

Release an exposure. The radiation indication LED will light for 5 sec ± 0.5 sec.

Siemens Ltd. Med India Version 2.0

Page 8 of 9

Copyright © SIEMENS LTD. All rights reserved. For internal use only

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Installation Instructions

1.4 General Check

Check for the following before handing over the unit to the customer.

1. Cassette Holder: It should be possible to mount the cassette holder on I.I. ring

in any position of the C arm. A 10” x 12" cassette shall not slip from the

cassette holder in any position of the C arm. It shall be possible to mount the

cassette holder even if the unit is covered with sterile covers on the Image

Intensifier.

2. Sterile Cover: The sterile cover should be easily fitted with the clips provided

and shall not slip out or hinder free movement in any condition.

3. Exposure: Radiation indication as explained tin the section 1.3.4

4. Front cover and top panel are protectively earthed.

5. All the handles shall be of the same colour & smooth in movement.

6. Unit brake pedal shall be fixed with rubber jacket.

7. Footswitch holder shall be fixed on the rear panel of control trolley.

8. Check for all PVC caps are fixed on all visible holes.

Siemens Ltd. Med India Version 2.0

Page 9 of 9

Copyright © SIEMENS LTD. All rights reserved. For internal use only

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Multimobil 5C

Service Instructions

Med

Service Instructions

Version 2.0

Copyright SIEMENS LTD.,Med INDIA

Siemens Ltd. Med India Version 2.0

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Copyright SIEMENS LTD. All rights reserved. For internal use only

Page 1 of 71

Back

Service Instructions

INDEX

1 SAFETY........................................................................................................................................ 5

1.1 SAFETY PRECAUTIONS................................................................................................................ 5

1.2 OVERLOAD PROTECTION............................................................................................................. 5

1.3 RADIATION PROTECTION .............................................................................................................5

1.4 MEASURING WITH OSCILLOSCOPE ................................................................................................ 6

1.5 HANDLING PRECAUTIONS ............................................................................................................ 6

1.6 MECHANICAL SAFETY.................................................................................................................. 6

1.7 MAINTENANCE ............................................................................................................................ 7

1.7.1 Product Disposal.................................................................................................................. 7

1.7.2 Radioprotection Material...................................................................................................... 8

1.7.3 Transformer Oil .................................................................................................................... 8

1.7.4 Plastics................................................................................................................................. 8

1.7.5 Electrolytic Capacitors .........................................................................................................8

2 SERVICING .................................................................................................................................. 9

2.1 TOOLS AND MEASURING INSTRUMENTS REQUIRED ........................................................................ 9

2.2 REPLACING DAMAGED OR MISSING SCREWS ................................................................................. 9

2.3 CLEANING AND DISINFECTING...................................................................................................... 9

2.3.1 Cleaning the Unit ................................................................................................................. 9

2.3.2 Disinfecting......................................................................................................................... 10

2.4 PROTECTING THE SYSTEM FROM FLUIDS..................................................................................... 10

2.5 ROUTINE CHECKS..................................................................................................................... 10

2.5.1 Daily checks ....................................................................................................................... 10

2.5.2 Monthly checks ..................................................................................................................11

2.5.3 Performance Check (Every Six months)............................................................................ 11

2.6 CALIBRATION CHECK ................................................................................................................ 12

2.6.1 Control Voltages ................................................................................................................12

2.6.2 Signals ...............................................................................................................................12

2.6.3 Exposure ............................................................................................................................ 13

2.6.4 Timing ................................................................................................................................13

2.6.5 kVp Measurement.............................................................................................................. 13

2.6.6 mA / mAs Measurement .................................................................................................... 14

2.6.7 Tuning ................................................................................................................................ 14

2.7 YEARLY CHECKS ...................................................................................................................... 14

2.8 PARTS SUBJECT TO WEAR ........................................................................................................ 15

2.9 CHECKS PRIOR TO SWITCH ON AFTER PROLONGED SHELF LIFE .................................................... 15

2.10 CHECKS PRIOR TO TRANSPORT.................................................................................................. 16

3 EXPOSURE CHARTS................................................................................................................ 17

3.1 FOR UNITS WITH 230V INPUT .................................................................................................... 17

3.2 FOR UNITS WITH 110V INPUT .................................................................................................... 18

4 ERROR CODES ......................................................................................................................... 19

5 TROUBLESHOOTING ............................................................................................................... 20

5.1 CHECKING THE LINE VOLTAGE, FUSES AND LEDS ....................................................................... 20

5.1.1 Checking the line voltage................................................................................................... 20

5.1.2 Checking the fuses ............................................................................................................ 21

5.1.3 Checking the LEDs ............................................................................................................ 21

5.2 CHECKING THE CONTROL VOLTAGES ......................................................................................... 22

5.2.1 Checking the Line voltage display. .................................................................................... 22

5.2.2 Checking the Intermediate circuit voltage.......................................................................... 22

5.3 CHECKING FOR EXPOSURE PARAMETERS................................................................................... 22

5.3.1 Checking the Main inverter frequency ............................................................................... 22

Siemens Ltd. Med India Version 2.0

Copyright SIEMENS LTD. All rights reserved. For internal use only

Page 2 of 71

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Service Instructions

5.3.2 Checking the Filament frequency ...................................................................................... 23

5.3.3 Filament current measurement .......................................................................................... 23

5.3.4 Checking of kV and mAs values ........................................................................................ 23

5.4 AUTOMATIC DOSAGE REGULATION ............................................................................................ 24

5.4.1 ADR Stop Mode (Manual).................................................................................................. 25

5.5 REPLACING THE SINGLE TANK.................................................................................................... 25

5.5.1 Replacing the collimator..................................................................................................... 25

5.5.2 Aligning the X-ray field to Image Intensifier ....................................................................... 26

6 CCU AND CAMERA CONTROL ............................................................................................... 27

6.1 INTRODUCTION....................................................................................................................27

6.2 RATINGS................................................................................................................................ 27

6.3 CONNECTION TERMINALS OF CAMERA CONTROL UNIT (CCU) ...................................28

6.4 PERFORMANCES /FUNCTIONS.......................................................................................... 28

6.5 ADJUSTMENTS & EXTERNAL CONTROL .......................................................................... 32

6.6 OSD PARAMETERS SETTINGS ................................................................................................... 35

6.7 PIN ASSIGNMENT ...................................................................................................................... 40

6.7.1 Pin assignment & interfacing details.................................................................................. 41

6.8 PERIODIC CHECKS.................................................................................................................... 41

7 MECHANICAL CHECKS AND ADJUSTMENTS ......................................................................42

7.1 PARTS WHICH NEEDS PERIODIC ADJUSTMENTS ...........................................................................42

7.1.1 BRAKES............................................................................................................................. 42

7.1.2 BEARINGS......................................................................................................................... 43

7.1.3 V-BELT............................................................................................................................... 44

7.1.4 CHAIN ................................................................................................................................ 44

7.2 PARTS WHICH NEEDS SERVICING OR REPLACEMENTS.................................................................. 44

7.2.1 V-Belt .................................................................................................................................44

7.2.2 Bearings ............................................................................................................................. 45

7.2.3 Brake liners ........................................................................................................................ 45

7.3 TROUBLE SHOOTING AND RECTIFICATION ................................................................................... 45

8 APPENDIX I ............................................................................................................................... 48

8.1 SPECIFIC ERROR CODE HANDLING ............................................................................................48

8.1.1 Unit not turning ON ............................................................................................................ 48

8.1.2 No Radiography ................................................................................................................. 49

8.1.3 No Standby ........................................................................................................................51

8.2 INITIALISATION ERROR CODES ................................................................................................... 52

8.2.1 CodE 90 (EPROM CHECKSUM FAILURE) .....................................................................52

8.2.2 CodE 96 (KV SOLL FAILURE) .........................................................................................52

8.2.3 CodE 97 ( mA FAILURE) .................................................................................................. 52

8.2.4 CodE 99 (LAST RESET BY WATCH DOG TIMER)......................................................... 52

8.3 STANDBY ERROR CODES........................................................................................................... 53

8.3.1 CodE 02 : +15 V Supply Error ........................................................................................... 53

8.3.2 CodE 03 & 04 : Iheiz < Istby & Iheiz > Istby ...................................................................... 54

8.3.3 CodE 05 : kVist <> 0 .......................................................................................................... 57

8.3.4 CodE 06 : JR <> 0 ............................................................................................................. 58

8.3.5 CodE 33 : Main Inverter Short Circuit ................................................................................ 59

8.4 EXPOSURE ERROR CODES ............................................................................................... 60

8.4.1 CodE 11 : Main Inverter Short Circuit ................................................................................ 60

8.4.2 CodE 12 : kVist > kVmax ................................................................................................... 61

8.4.3 CodE 13 : Iheiz > Imax OR JR > Jrmax............................................................................ 62

8.4.4 CodE 14 : kVist < kVsoll .................................................................................................... 63

8.4.5 CodE 15 : JR < JRS........................................................................................................... 64

8.4.6 CodE 17 : Exposure terminated by Backup Timer ............................................................ 65

8.4.7 CodE 18 : Premature termination of Exposure .................................................................. 66

8.4.8 CodE 21 : Iheiz > Iheiz maximum ...................................................................................... 67

Siemens Ltd. Med India Version 2.0

Copyright SIEMENS LTD. All rights reserved. For internal use only

Page 3 of 71

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Service Instructions

8.4.9 CodE 22 : Maximum Preparation Time.............................................................................. 68

8.5 PCB LAYOUT DRAWINGS .......................................................................................................... 69

8.5.1 Master card D915 .............................................................................................................. 69

8.5.2 Filament interface PCB D506 ............................................................................................70

8.5.3 ADR and Collimator control PCB D508 ............................................................................. 71

Siemens Ltd. Med India Version 2.0

Copyright SIEMENS LTD. All rights reserved. For internal use only

Page 4 of 71

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Service Instructions

1 Safety

1.1 Safety Precautions

Before opening / closing the covers ensure that the

WARNING

Precaution should be observed while working on the

WARNING

mains is switched off and the plug is removed from

the socket.

Ensure that the protective earth connections of the

sub assemblies are properly connected.

single tank. During continuos fluoroscopy, the

temperature of the oil in the single tank raise. The

thermal switch provided on the single tank cuts off

the radiation after the temperature is reached to

60+5°C. Hence the surface becomes hot and can

cause burns. Avoid contacting the surface of the

single tank at this instance.

1.2 Overload Protection

The unit is designed to work on 110 / 190-240V, single phase, 15A socket. For safety

purposes 16A HRC fuses are provided which will blow when a current exceeding 16A

sustains for its response time.

WARNING

Ensure that the mains socket is properly earthed.

In case of fault if the kV tries to build beyond the safe limit of X-ray tube the protection

circuit blocks the HT.

In case of fault if the Filament current tries to increase beyond the safe limit the

protection circuit blocks filament boosting.

Maximum permissible resistance between the Earthing lead terminal in the control and

on the HT transformer shall not exceed 0.1 ohms.

1.3 Radiation Protection

• Do not put any part of your body in the direct line

of radiation. Collimate the X-ray beam.

WARNING

• Keep maximum possible distance from the object

being radiographed. For this make the best use of

5 mt of recoilable exposure release switch.

• In the room.

• Wear protective clothing (lead Apron).

• Monitor radiation received using the personal TLD-

badges or pen-dosimeter.

Siemens Ltd. Med India Version 2.0

Copyright SIEMENS LTD. All rights reserved. For internal use only

Page 5 of 71

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Service Instructions

1.4 Measuring with oscilloscope

For normal working, the protective earthing of mains must not be removed.

In case system noise is getting coupled to the scope, use the scope in differential

mode.

To measure high voltage use DIFFERENTIAL probe isolated from ground.

1.5 Handling precautions

1. Strictly observe ESD precautions while

handling PCBs and ESD sensitive devices.

WARNING

2. After the unit is switched on, the capacitors

charge to 300VDC. (Approx) After switching

the unit OFF, it takes about 4 minutes for

capacitors to discharge. The presence of DC

voltage is indicated by Green LED on D61.

3. Lead is used for radiation protection inside the

single tank. The collimator flaps are made of

lead. Lead rings are used on the Image

intensifier for counter balancing. Lead is used

inside the C-arm profile for counter balancing.

Hence, special precautions should be

observed during handling these parts to avoid

lead poisoning and contamination.

4. If the Temperature of the single tank exceeds

60°C, then the Temperature. Sensor (switch)

operates and D915 blocks the firing pulses to

the inverter. This overload protection will

automatically again switching ON after the

temperature of single tank goes below the

threshold level (60°C) of the thermal switch

which is indicated by the thermometer symbol

on the top panel. Cool-down periods are

recommended if used extensively.

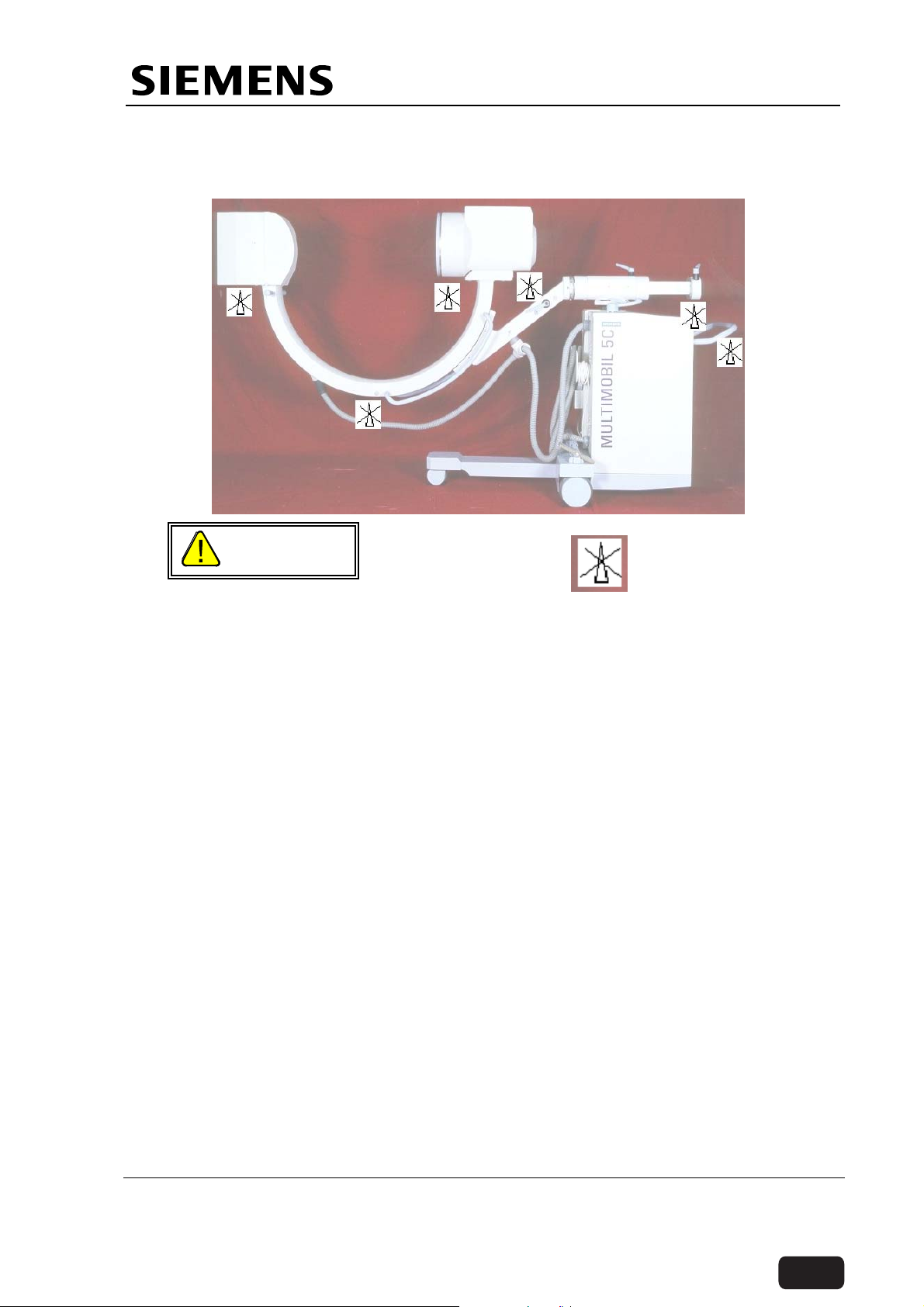

1.6 Mechanical Safety

Due to the manoeuvrability of the system, the collision probability of the image

intensifier and the single tank with the patient or the table is greatly increased if

adequate care is not taken.

While moving various parts of the unit with hand, use of handgrips and handles is

recommended. The figure shows location where there is a danger of crushing for

patient or user due to parts moving relative to each other.

Siemens Ltd. Med India Version 2.0

Copyright SIEMENS LTD. All rights reserved. For internal use only

Page 6 of 71

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Service Instructions

The system should be moved only manually, by the handles provided for this purpose.

whenever exceptions must be made , note the points of potential injury between the

movable system parts and their guide openings. The system areas marked in the

drawings indicate points of crushing or impact hazards for the patient or the operator.

Points of injury for operator

Note: The system shown above is with 9“ II system.The points of injury are identical for 6“ II system.

Points of injury for patients.

1.7 Maintenance

All parts, modules of this product must be tested, inspected, for performance and

safety aspects every 12 months to ensure that the product functions properly and is

safe for patients, operating personnel and other persons.

Every 12 months, trained technical personnel should inspect and if necessary replace

system components of the generator, which may result in hazard due to excessive

wear and tear.

If more frequent inspections and maintenance are required by federal or local

regulations, ensure compliance with them.

1.7.1 Product Disposal

Legal regulations may contain special prescriptions concerning the disposal of this

product. In order to avoid environmental damage and/or personal injury, please inform

SIEMENS Customer Service if you want to put the unit out of operation and dispose it.

Siemens Ltd. Med India Version 2.0

Copyright SIEMENS LTD. All rights reserved. For internal use only

Page 7 of 71

The information in this CD is not a controlled document and to be used only for reference.

Before ordering any parts HO-Med-CS-SP to be contacted for obtaining the latest information.

Back

Loading...

Loading...