Sharp MX-M160, MX-M200 Service Manual

MX-M160D MX-M160

SERVICE MANUAL

CODE : 00ZMXM200DS1E

DIGITAL

MULTIFUNCTIONAL

SYSTEM

MX-M200D

MX-M200DK

MX-M160D

MX-M160DK

MX-M200D MODEL MX-M160

As for the content of the MX-M200DK/MX-M160DK, refer to the content of the MX-M200D/MX-M160D as long as there is no proviso.

CONTENTS

[ 1 ] |

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 1 |

- 1 |

|

[ 2 ] |

CONFIGURATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

- 1 |

|

[ 3 ] |

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

- 1 |

|

[ 4 ] |

CONSUMABLE PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

- 1 |

|

[ 5 ] |

EXTERNAL VIEWS AND INTERNAL STRUCTURES . . . . . . . |

5 |

- 1 |

|

[ 6 |

] |

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

- 1 |

[ 7 |

] |

SIMULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

- 1 |

[ 8 |

] |

USER PROGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

- 1 |

[ 9 |

] |

TROUBLE CODE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

- 1 |

[10] |

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

- 1 |

|

[11] |

DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . |

11 |

- 1 |

|

[12] |

FLASH ROM VERSION UP PROCEDURE . . . . . . . . . . . . . . |

12 |

- 1 |

|

[13] |

ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

- 1 |

|

Parts marked with “ “ are important for maintaining the safety of the set.

“ are important for maintaining the safety of the set.

Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

|

|

SHARP CORPORATION |

This document has been published to be used for |

after sales service only. |

The contents are subject to change without notice.

CONTENTS

[1] GENERAL

1. Note for servicing . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] CONFIGURATION

1. System Configurations . . . . . . . . . . . . . . . . . . . . . . 2-1 2. Machine configuration . . . . . . . . . . . . . . . . . . . . . . . 2-1 3. Option list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

[3] SPECIFICATIONS

1. Copy mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[4] CONSUMABLE PARTS

1, Supply system table . . . . . . . . . . . . . . . . . . . . . . . . 4-1 2. Environmental conditions . . . . . . . . . . . . . . . . . . . . 4-2 3. Production number identification . . . . . . . . . . . . . . . 4-2

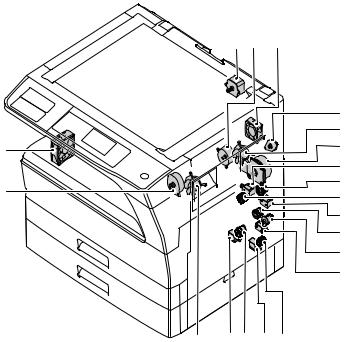

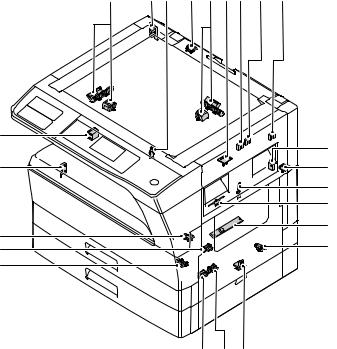

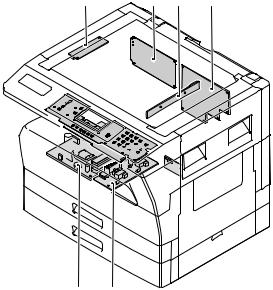

[5] EXTERNAL VIEWS AND INTERNAL STRUCTURES

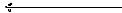

1. Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 2. Internal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 3. Operation Section . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3 4. Motor, solenoid, clutch. . . . . . . . . . . . . . . . . . . . . . . 5-4 5. Sensor, switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5 6. PWB unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6 7. Cross sectional view . . . . . . . . . . . . . . . . . . . . . . . . 5-7

[6] ADJUSTMENTS

1. Adjustment item list . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 2. Copier adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] SIMULATIONS

[12] FLASH ROM VERSION UP PROCEDURE

1. Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1 2. Installation procedure . . . . . . . . . . . . . . . . . . . . . .12-1 3. Firmware update procedure . . . . . . . . . . . . . . . . . .12-2

[13] ELECTRICAL SECTION

1. Block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-1 2, Actual wiring diagram . . . . . . . . . . . . . . . . . . . . . . .13-2 3. Signal name list . . . . . . . . . . . . . . . . . . . . . . . . . . .13-9

LEAD-FREE SOLDER

1. Entering the simulation mode . . . . . . . . . . . . . . . . . 7-1 2. Canceling the simulation mode . . . . . . . . . . . . . . . . 7-1 3. List of simulations . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 4. Contents of simulations . . . . . . . . . . . . . . . . . . . . . . 7-3

[8] SYSTEM SETTINGS

1. List of user programs. . . . . . . . . . . . . . . . . . . . . . . . 8-1 2. Using the system settings . . . . . . . . . . . . . . . . . . . . 8-2

[9] TROUBLE CODE LIST

1. Trouble code list . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1 2. Details of trouble codes. . . . . . . . . . . . . . . . . . . . . . 9-1

[10] MAINTENANCE

1. Maintenance table . . . . . . . . . . . . . . . . . . . . . . . . . 10-1 2. Maintenance display system . . . . . . . . . . . . . . . . . 10-2 3. Note for replacement of consumable parts . . . . . . 10-2

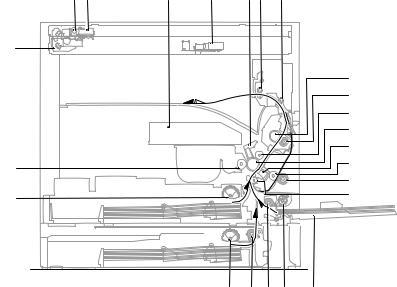

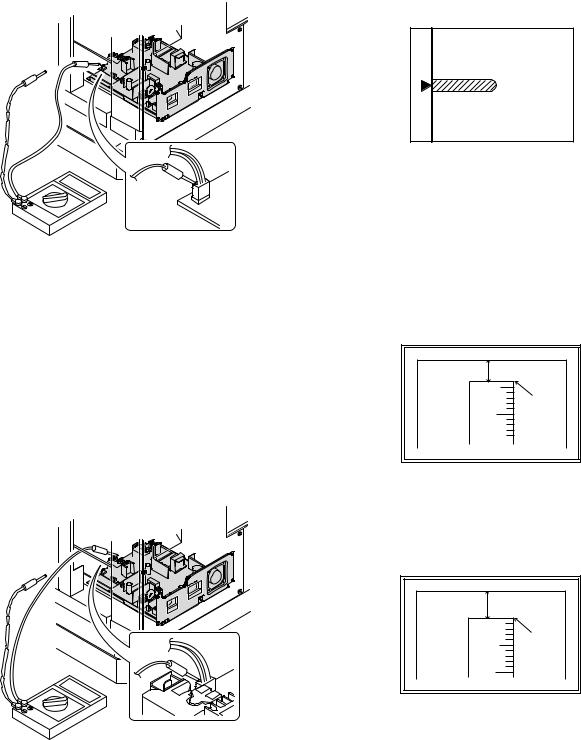

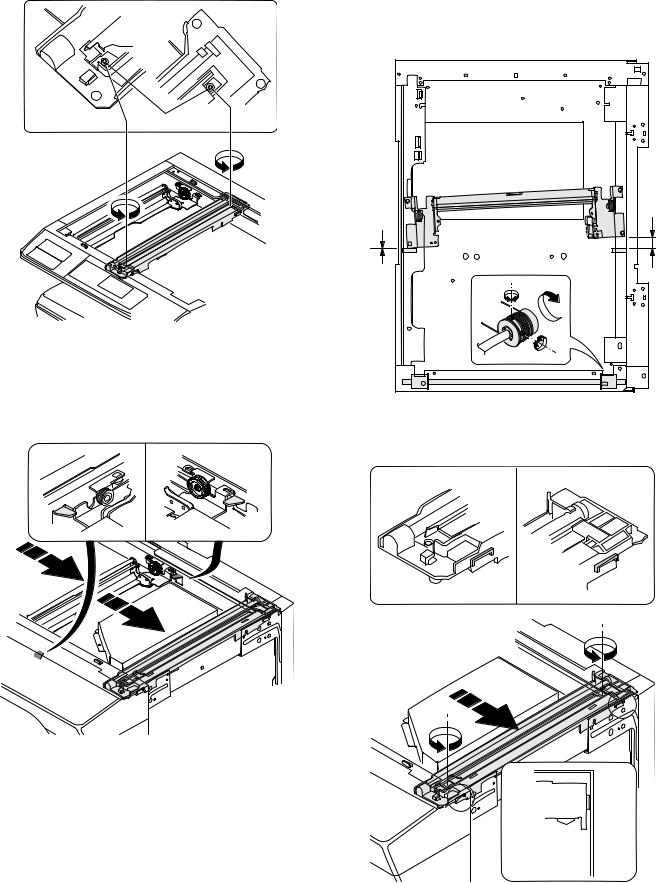

[11] DISASSEMBLY AND ASSEMBLY

1. High voltage section/Duplex transport section . . . 11-1 2. Optical section. . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2 3. Fusing section . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4 4. Paper exit section . . . . . . . . . . . . . . . . . . . . . . . . . 11-6 5. MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-8 6. Optical frame unit . . . . . . . . . . . . . . . . . . . . . . . . . 11-9 7. LSU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9 8. Tray paper feed section/Paper transport section. . 11-9 9. Bypass tray section . . . . . . . . . . . . . . . . . . . . . . 11-11 10.Power section . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-13 11.Developing section . . . . . . . . . . . . . . . . . . . . . . . 11-14 12.Process section . . . . . . . . . . . . . . . . . . . . . . . . . . 11-15 13.Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-15

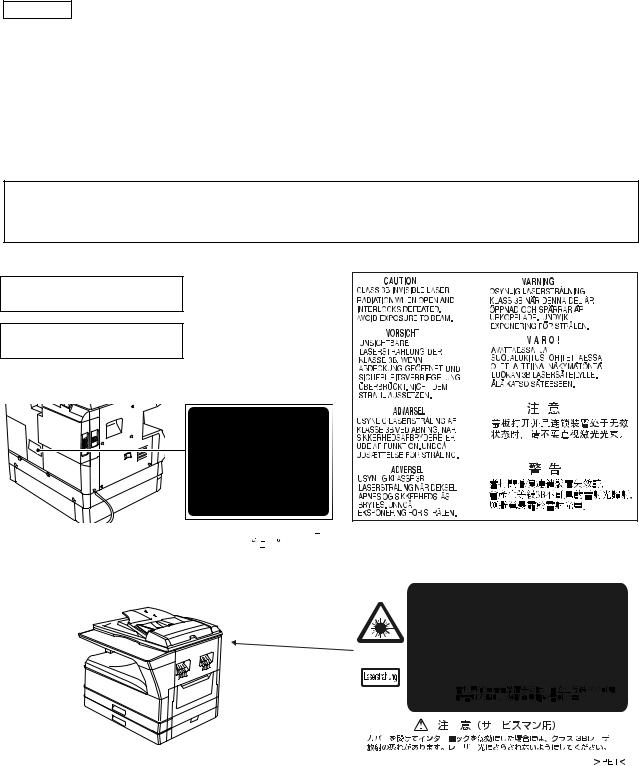

CAUTION

This product is a class 1 laser product that complies with 21CFR 1040.10 and 1040.11 of the CDRH standard and IEC60825-1 Edition 1.2-2001. This means that this machine does not produce hazardous laser radiation. The use of controls, adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

This laser radiation is not a danger to the skin, but when an exact focusing of the laser beam is achieved on the eye's retina, there is the danger of spot damage to the retina.

The following cautions must be observed to avoid exposure of the laser beam to your eyes at the time of servicing.

1)When a problem in the laser optical unit has occurred, the whole optical unit must be exchanged as a unit, not as individual parts.

2)Do not look into the machine with the main switch turned on after removing the developer unit, toner cartridge, and drum cartridge.

3)Do not look into the laser beam exposure slit of the laser optical unit with the connector connected when removing and installing the optical system.

4)The middle frame contains the safety interlock switch.

Do not defeat the safety interlock by inserting wedges or other items into the switch slot.

Warning:

This is a Class A product. In a domestic environment this product may cause radio interference in which case the user may be required to take adequate measures.

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Disconnect the AC cord before servicing the unit. |

LASER WAVE - LENGTH: 785 nm + 10 nm/ 15 nm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Pulse times : (8.141 s |

0.1 s/7 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

Output power : 0.14 mW |

0.22 mW |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

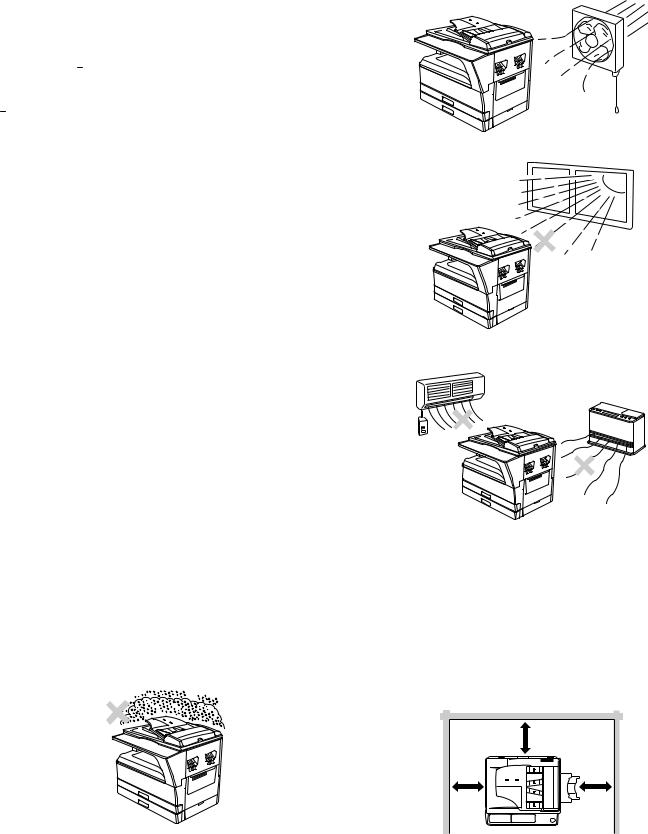

[1] GENERAL

1. Note for servicing

Pictogram

The label (

) in the fusing area of the machine indicates the following:

) in the fusing area of the machine indicates the following:

: Caution, risk of danger

: Caution, risk of danger  : Caution, hot surface

: Caution, hot surface

A. Warning for servicing

•The fusing area is hot. Exercise care in this area when removing misfed paper.

•Do not look directly at the light source. Doing so may damage your eyes.

B. Cautions for servicing

•Do not switch the machine rapidly on and off. After turning the machine off, wait 10 to 15 seconds before turning it back on.

•Machine power must be turned off before installing any supplies. •Place the machine on a firm, level surface.

•Do not install the machine in a humid or dusty location.

•When the machine is not used for a long time, for example, during prolonged holidays, turn the power switch off and remove the power cord from the outlet.

•When moving the machine, be sure to turn the power switch off and remove the power cord from the outlet.

•Do not cover the machine with a dust cover, cloth or plastic film while the power is on. Doing so may prevent heat dissipation, damaging the machine.

•Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous laser radiation exposure.

•The socket-outlet shall be installed near the machine and shall be easily accessible.

C. Note for installation place

Improper installation may damage the machine. Please note the following during initial installation and whenever the machine is moved.

Caution : If the machine is moved from a cool place to a warm place, condensation may form inside the machine. Operation in this condition will cause poor copy quality and malfunctions. Leave the machine at room temperature for at least 2 hours before use.

Do not install your machine in areas that are:

•damp, humid, or very dusty

•poorly ventilated

•exposed to direct sunlight

•subject to extreme temperature or humidity changes, e.g., near an air conditioner or heater.

The machine should be installed near an accessible power outlet for easy connection and disconnection.

Be sure to connect the power cord only to a power outlet that meets the specified voltage and current requirements. Also make certain the outlet is properly grounded.

Note : Connect the machine to a power outlet which is not used for other electric appliances. If a lighting fixture is connected to the same outlet, the light may flicker.

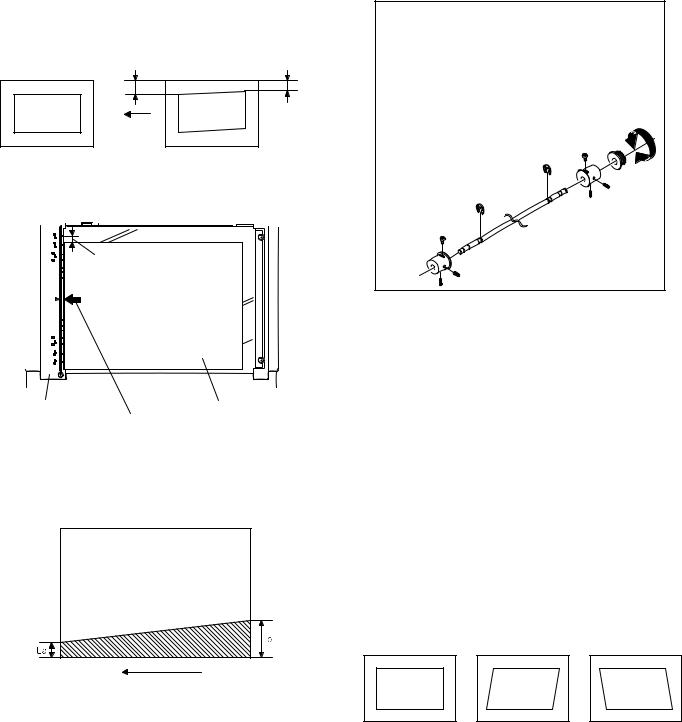

Be sure to allow the required space around the machine for servicing and proper ventilation.

|

20 cm (8") |

20 cm |

20 cm |

(8") |

(8") |

MX-M160 GENERAL 1-1

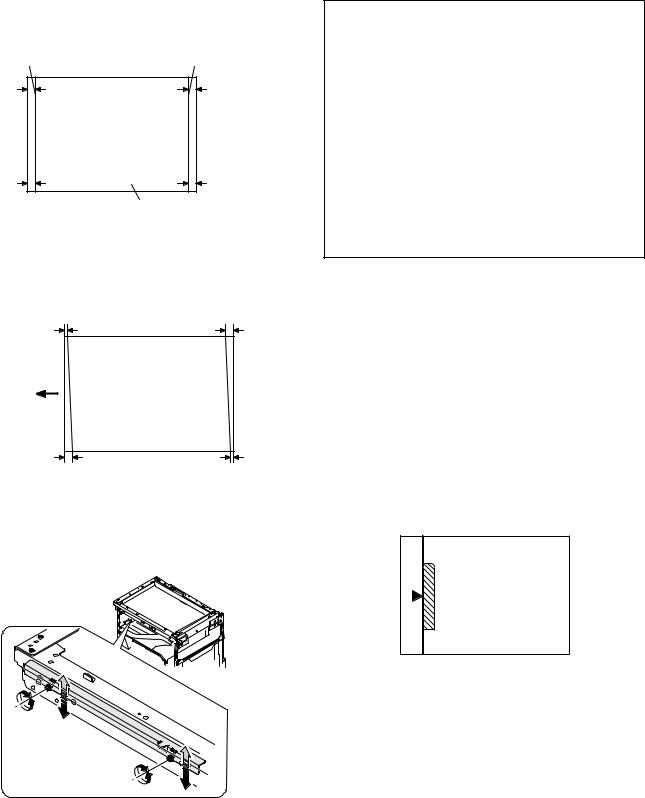

D. Note for handling PWB and electronic parts

When handling the PWB and the electronic parts, be sure to observe the following precautions in order to prevent against damage by static electricity.

1)When in transit or storing, put the parts in an anti-static bag or an anti-static case and do not touch them with bare hands.

2)When and after removing the parts from an anti-static bag (case), use an earth band as shown below:

• Put an earth band to your arm, and connect it to the machine.

3)When repairing or replacing an electronic part, perform the procedure on an anti-static mat.

MX-M160 GENERAL 1-2

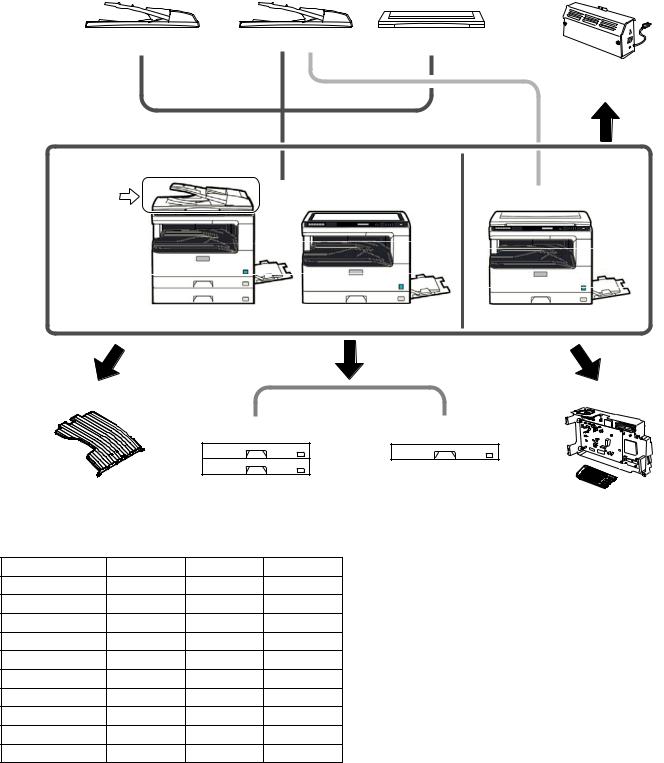

[2] CONFIGURATION

1. System Configurations

[AR-RP10] |

[AR-SP10] |

[AR-VR7] |

[MX-NB10] |

(REVERSING SINGLE PASS FEEDER) |

(SINGLE PASS FEEDER) |

(DOCUMENT COVER) |

|

|

|

|

(NEWORK PRINTING / |

|

|

|

SCANNING |

|

|

|

EXPANSION KIT) |

Standard for North America only

AR-RP10

[MX-M200D] |

[MX-M160D] |

[MX-M160] |

[MX-TR10] |

|

|

|

[MX-FX10] |

|

|

|

|

|

||

|

|

[AR-D35] |

|

[AR-D34] |

|

|

|

|

|

|

(250-sheet paper |

(JOB SEPARATOR) |

(2 x 250-sheet paper |

feed unit) |

|||

feed unit) |

|

|

(FACSIMILE |

||

|

|

|

|

||

|

|

|

|

|

EXPANSION KIT) |

2. Machine configuration |

|

|

|

|

|

|

MX-M200D |

MX-M160D |

MX-M160 |

|

|

Copy |

STD |

STD |

|

STD |

|

Color scanner |

STD |

STD |

|

STD |

|

SPLC printer |

STD |

STD |

|

STD |

|

PCL printer |

OPT |

OPT |

|

OPT |

|

Fax |

OPT |

OPT |

|

OPT |

|

Network |

OPT |

OPT |

|

OPT |

|

Duplex |

STD |

STD |

|

N/A |

|

Sort |

STD |

STD |

|

STD |

|

Shifter 1 |

STD |

STD |

|

STD |

|

Paper tray |

2-stage |

1-stage |

|

1-stage |

|

1: Except for North America

MX-M200D CONFIGURATION 2-1

3. Option list

Model name |

Name |

MX-M200D |

MX-M160D |

MX-M160 |

Product key |

|

target |

||||||

|

|

|

|

|

||

|

|

|

|

|

|

|

AR-RP10 |

REVERSING SINGLE PASS FEEDER |

North/South America: STD |

OPT |

N/A |

— |

|

|

|

Europe, Australia, Agency: OPT |

|

|

|

|

|

|

|

|

|

|

|

AR-SP10 |

SINGLE PASS FEEDER |

North/South America: N/A |

OPT |

OPT |

— |

|

|

|

Europe, Australia, Agency: OPT |

|

|

|

|

|

|

|

|

|

|

|

AR-VR7 |

DOCUMENT COVER |

North/South America:N/A |

OPT |

STD |

— |

|

|

|

Europe, Australia, Agency: OPT |

|

|

|

|

|

|

|

|

|

|

|

AR-D34 |

250-SHEET PAPER FEED UNIT |

OPT |

OPT |

OPT |

— |

|

|

|

|

|

|

|

|

AR-D35 |

2X250-SHEET PAPER FEED UNIT |

OPT |

OPT |

OPT |

— |

|

|

|

|

|

|

|

|

MX-TR10 |

JOB SEPARATOR TRAY KIT |

OPT |

OPT |

OPT |

— |

|

|

|

|

|

|

|

|

MX-NB10 |

N E WO R K P R I N T I N G / S C A N N I N G |

OPT |

OPT |

OPT |

— |

|

|

EXPANSION KIT |

|

|

|

|

|

|

|

|

|

|

|

|

MX-FX10 |

FACSIMILE EXPANSION KIT |

OPT |

OPT |

OPT |

— |

|

|

|

|

|

|

|

|

AR-SM5 |

256MB EXPANTION MEMORY BOARD |

OPT |

OPT |

OPT |

— |

|

|

|

|

|

|

|

|

AR-MM9 |

FAX EXPANTION MEMORY BOARD |

OPT |

OPT |

OPT |

— |

|

|

|

|

|

|

|

|

AR-PF1 |

BARCODE FONT KIT |

OPT |

OPT |

OPT |

— |

|

|

|

|

|

|

|

|

MX-PK10 |

PS3 EXPANSION KIT |

OPT |

OPT |

OPT |

Yes |

|

|

|

|

|

|

|

|

AR-PF2 |

MACRO FONT FLASH ROM KIT |

OPT |

OPT |

OPT |

— |

|

|

|

|

|

|

|

O: Option installation enable X: Option installation disable

MX-M200D CONFIGURATION 2-2

[3] SPECIFICATIONS

1. Copy mode

A. Type

Type |

Desk-top |

|

|

Paper exit |

center tray / internal |

|

|

B. Machine composition

MX-M160D/MX-M160 |

16-CPM multi function model |

|

|

MX-M200D |

20-CPM multi function model |

|

|

C. Copy speed

(1) Engine speed (ppm)

Paper size |

MX-M200D |

MX-M160D/MX-M160 |

|

|

|

A4/ 8.5”x11” |

20ppm |

16ppm |

|

|

|

A4R |

14ppm |

12ppm |

|

|

|

8.5”x11”R |

15ppm |

12ppm |

|

|

|

A5/ 5.5”x8.5” |

20ppm |

16ppm |

|

|

|

B5/ 16K |

20ppm |

16ppm |

|

|

|

B5R |

16ppm |

14ppm |

|

|

|

16KR |

15ppm |

14ppm |

|

|

|

8.5x13” |

12ppm |

11ppm |

|

|

|

B4/ 8.5”x14 |

12ppm |

10ppm |

|

|

|

A3 |

11ppm |

9ppm |

|

|

|

11”x17” |

10ppm |

9ppm |

|

|

|

8K |

11ppm |

10ppm |

|

|

|

(2) Document replacement speed (Copy mode)

Copy mode |

MX-M200D |

MX-M160D/MX-M160 |

||

|

|

|

|

|

S to S |

20cpm |

(100%) |

16cpm |

(100%) |

|

|

|

|

|

S to S : Tray1 A4/8.5”X11” document 11 sheets (11 pages), copy 1 set

(3) Job efficiency

Copy mode |

MX-M200D |

MX-M160D |

MX-M160 |

||

|

|

|

|

||

S to S |

18cpm (90%) |

15cpm (49%) |

15cpm (94%) |

||

|

|

|

|

|

|

S to D |

10cpm |

(50%) |

10cpm |

(63%) |

— |

|

|

|

|

|

|

D to D |

10cpm |

(50%) |

10cpm |

(63%) |

— |

|

|

|

|

|

|

S to S : Tray1 A4/8.5”X11” document 10 sheets (10 pages), copy 5 sets S to D : Tray1 A4/8.5”X11” document 10 sheets (10 pages), copy 5 sets D to D : Tray1 A4/8.5”X11” document 10 sheets (20 pages), copy 5 sets

(4) First copy time

Tray |

Content |

|

|

1st tray |

7.2 sec or less |

|

|

2nd tray |

8.5 sec or less |

|

|

3rd tray |

9.5 sec or less |

|

|

4th tray |

10.5 sec or less |

|

|

Bypass tray |

7.5 sec or less |

|

|

600x300dpi, AE mode, A4/Letter, single surface copy with OC, in polygon ready state

D. Document

Max. document size |

A3, 11" X 17" |

|

|

Document reference position |

Left bottom reference |

|

|

Detection (Platen) |

Yes |

|

|

E. Paper feed

(1) Paper feed section details

Item |

|

1st tray |

2nd tray |

Bypass tray |

|

|

|

|

|

Paper capacity |

|

250 |

250 |

100 sheets |

|

|

sheets |

sheets |

|

|

|

|

|

|

Paper size detection |

|

|

No |

|

|

|

(Paper size is set with |

||

|

|

the system setting.) |

||

|

|

|

|

|

Paper type setting |

|

No |

No |

No |

|

|

|

|

(Heavy |

|

|

|

|

paper setting |

|

|

|

|

is enabled.) |

|

|

|

|

|

Paper size changing method |

The paper guide is set by the user. |

|||

|

|

|

|

|

Paper when shipping |

AB series |

A4 |

A4 |

- |

|

|

|

|

|

Size setting |

Inch series |

8 1/2” x11” |

8 1/2” x11” |

- |

|

|

|

|

|

Remaining paper quantity |

Only empty detection available |

|||

detection |

|

|

|

|

|

|

|

|

|

(2) Feedable paper

Paper size |

|

1st tray |

2nd tray |

Bypass |

|

|

|

|

tray |

A3 |

297x420 |

Yes |

Yes |

Yes |

|

|

|

|

|

B4 |

257x364 |

Yes |

Yes |

Yes |

|

|

|

|

|

A4 |

297x210 |

Yes |

Yes |

Yes |

|

|

|

|

|

A4-R |

210x297 |

Yes |

Yes |

Yes |

|

|

|

|

|

B5 |

257x182 |

Yes |

Yes |

Yes |

|

|

|

|

|

B5R |

182x257 |

Yes |

Yes |

Yes |

|

|

|

|

|

A5 |

210x148.5 |

Yes |

N/A |

Yes |

|

|

|

|

|

A5R |

148.5x210 |

N/A |

N/A |

Yes |

|

|

|

|

|

A6R |

105x148.5 |

N/A |

N/A |

Yes |

|

|

|

|

|

B6R |

128.5x182 |

N/A |

N/A |

Yes |

|

|

|

|

|

Ledger 11 x 17 in |

279.4x431.8 |

Yes |

Yes |

Yes |

|

|

|

|

|

Legal 8.5x14in. |

215.9x355.6 |

Yes |

Yes |

Yes |

|

|

|

|

|

Foolscap 8.5 x 13 in |

215.9x330.2 |

Yes |

Yes |

Yes |

|

|

|

|

|

Letter 11x8.5in |

279.4x215.9 |

Yes |

Yes |

Yes |

|

|

|

|

|

Letter-R 8.5x11in |

215.9x279.4 |

Yes |

Yes |

Yes |

|

|

|

|

|

Executive-R 7.25x10.5in. |

184.2x266.7 |

N/A |

N/A |

Yes |

|

|

|

|

|

Invoice 8.5x5.5 in. |

215.9x139.7 |

Yes |

N/A |

Yes |

|

|

|

|

|

Invoice-R 5.5x8.5 in |

139.7x215.9 |

N/A |

N/A |

Yes |

|

|

|

|

|

8K |

270x390 |

Yes |

Yes |

Yes |

|

|

|

|

|

16K |

270x195 |

Yes |

Yes |

Yes |

|

|

|

|

|

16KR |

195x270 |

Yes |

Yes |

Yes |

|

|

|

|

|

COM10 |

104.8x241.3 |

N/A |

N/A |

Yes |

|

|

|

|

|

COM9 |

98.4x225.4 |

N/A |

N/A |

Yes |

|

|

|

|

|

C5 |

162x229 |

N/A |

N/A |

Yes |

|

|

|

|

|

DL |

110x220 |

N/A |

N/A |

Yes |

|

|

|

|

|

Postcard |

100x148 |

N/A |

N/A |

Yes |

|

|

|

|

|

Return postcard |

200x148 |

N/A |

N/A |

Yes |

|

|

|

|

|

Long format No. 3 |

120.1x235 |

N/A |

N/A |

Yes |

|

|

|

|

|

Monarch |

98.4x190.5 |

N/A |

N/A |

Yes |

|

|

|

|

|

Western format No. 2 |

114x162 |

N/A |

N/A |

Yes |

|

|

|

|

|

Western format No. 4 |

105x235 |

N/A |

N/A |

Yes |

|

|

|

|

|

MX-M200D SPECIFICATIONS 3-1

(3)Types of feedable paper

Types of paper |

1st tray |

2nd tray |

Bypass tray |

||

|

|

|

|

|

|

Thin paper |

56-59g/m2 |

Yes |

Yes |

Yes |

|

15-15.9lbs |

|||||

|

|

|

|

||

|

|

|

|

|

|

|

60-90g/m2 |

|

|

Yes |

|

Plain paper |

Yes |

Yes |

(Multi paper |

||

16-24lbs |

|||||

|

|

|

feed enable) |

||

|

|

|

|

||

|

|

|

|

|

|

|

91-105g/m2 |

|

|

Yes |

|

Heavy paper |

N/A |

N/A |

(Multi paper |

||

16-24lbs |

|||||

|

|

|

feed enable) |

||

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Yes |

|

Heavy paper |

106-128g/m2 |

N/A |

N/A |

(A4 or less) |

|

24.1-33.5lbs |

(Multi paper |

||||

|

|

|

|||

|

|

|

|

feed enable) |

|

|

|

|

|

|

|

|

|

|

|

Yes |

|

Heavy paper |

129-200g/m2 |

N/A |

N/A |

(A4 or less) |

|

33.6-53.2lbs |

(Only single |

||||

|

|

|

|||

|

|

|

|

paper feed) |

|

|

|

|

|

|

|

Heavy paper |

201-256g/m2 |

N/A |

N/A |

N/A |

|

53.3-68lbs |

|||||

|

|

|

|

||

|

|

|

|

|

|

Envelope |

75-90g/m2 |

N/A |

N/A |

Yes |

|

20-24lbs |

|||||

|

|

|

|

||

|

|

|

|

|

|

Postcard |

|

N/A |

N/A |

Yes |

|

|

|

|

|

|

|

OHP film |

|

N/A |

N/A |

Yes |

|

|

|

|

|

|

|

Label sheet |

|

N/A |

N/A |

Yes |

|

|

|

|

|

|

|

Tab paper 20 |

|

N/A |

N/A |

No |

|

|

|

|

|

|

|

F. Multi copy

Max. number of |

999 sheets |

multi copy |

|

|

|

G. Warm-up time

Warm-up time |

45 seconds or less |

|

|

Pre-heat |

Available |

|

|

Jam recovery |

Within 45 sec |

|

|

H. Copy magnification ratio

Fixed |

AB system: |

magnification |

400, 200, 141, 122, 115, 100, 86, 81, 70, 50, 25% |

ratio |

|

Inch system: |

|

|

400, 200, 141, 129, 121, 100, 95, 77, 64, 50, 25% |

|

|

Zooming |

25 ~ 400% |

|

SPF/RSPF(50 ~ 200%) |

|

|

Independent |

Available (25 ~ 400%) |

zooming(vertical) |

SPF/RSPF(50 ~ 200%) |

|

|

Independent |

Available (25 ~ 400%) |

zooming |

SPF/RSPF(50 ~ 200%) |

(horizontal) |

|

|

|

I. Print density

Density mode |

Auto / Text / Photo |

|

|

|

|

No. of manual |

5 steps (Text / Photo) |

|

adjustment |

|

|

|

|

|

Resolution |

Writing: 600 x 600dpi |

|

|

Reading: 600 |

(main) x 600 (sub) (PHOTO mode) |

|

600 |

(main) x 300 (sub) (AUTO exposure |

|

mode) |

|

|

600 |

(main) x 300 (sub) dpi (TEXT mode) |

|

|

|

Gradation |

Reading: 256 gradations |

|

|

Writing: Binary |

|

|

|

|

Toner save mode |

Set by the user program |

|

|

|

|

J. Void width

Void area |

Lead edge 1 ~ 4mm, |

|

rear edge 4mm or less, |

|

Total of both sides: 6mm or less |

|

|

Image loss |

4.0mm or less |

|

|

K. Paper exit / finishing

Paper exit section |

Face down 250 sheets |

capacity |

|

|

|

Full detection |

Detection of 250 sheets count is for only copy mode |

|

When the job separator is installed, only detection |

|

is available |

|

Upper stage: 100 sheets or 10.6mm or less |

|

Lower stage: 150 sheets |

|

|

Finishing |

Shifter (Standard except for North America) |

|

Job separator (Option) |

|

|

Electronic sort |

A4/ 8.5" x 11" standard document (6% coverage) |

capacity |

160 sheets |

|

|

Offset function |

Yes (Except for North America) |

|

|

Staple function |

None |

|

|

L. Additional functions

APS |

|

O |

|

|

|

AMS |

|

O |

|

|

|

Auto tray switching |

|

O |

|

|

|

Memory copy |

|

O |

|

|

|

Rotation copy |

|

O |

|

|

|

E-sort |

O |

Single surface, A4, Max. 80 sheets |

(Sorting function) |

|

|

|

|

|

E-sort (Grouping |

|

O |

function) |

|

|

|

|

|

|

|

|

Rotation sort |

|

X |

|

|

|

Prevention of sky |

|

X |

shot |

|

|

|

|

|

|

|

|

Independent |

|

O |

zooming |

|

|

|

|

|

|

|

|

1 set 2 copy |

O SPF: Disable |

|

|

|

OC: Enlargement is disable. |

|

|

|

Binding margin |

O |

Default AB series: 10mm (5, 10, 15, 20mm) |

|

|

Inch series: 1/2 inch (1/4, 1/2, 3/4, 1 inch) |

|

|

|

Edge erase |

O |

Default AB series: 10mm (5, 10, 15, 20mm) |

|

|

Inch series: 1/2 inch (1/4, 1/2, 3/4, 2 inch) |

|

|

|

Center erase |

O |

Default AB series: 10mm (5, 10, 15, 20mm) |

|

|

Inch series: 1/2 inch (1/4, 1/2, 3/4, 3 inch) |

|

|

|

Black/white |

|

X |

reverse |

|

|

|

|

|

|

|

|

Multi shot |

|

O |

|

|

|

Offset |

|

X |

|

|

|

Preheating |

O |

The conditions are set by the user program. |

|

|

|

Auto shut-off |

O |

The conditions are set by the user program. |

|

|

|

User programming |

|

O |

|

|

|

Total counter |

O |

Supports Total counter and Copy counter and |

|

|

Scanner counter. |

|

|

|

Coin vendor |

O |

(Supports I/F only.) |

support |

|

|

|

|

|

Auditor support |

O |

(Supports I/F only.) |

|

|

|

Toner save |

O |

(Set according to the destination) |

|

|

|

Department |

O |

(Total of copy, printer, and scanner: 50 Dept., |

management |

|

Fax: 50 Dept.) |

|

|

|

O : Available X : Not available

MX-M200D SPECIFICATIONS 3-2

M. Other specifications

Photoconductor type |

OPC (Organic Photo Conductor) |

|

|

Photoconductor drum dia. |

30mm |

|

|

Copy lamp |

Cold cathode fluorescent lamp (CCFL) |

|

|

Developing system |

Dry 2-component magnetic brush |

|

development |

|

|

Charging system |

Saw teeth charging |

|

|

Transfer system |

(+) DC corotron |

|

|

Separation system |

(-) DC corotron |

|

|

Fusing system |

Heat roller |

|

|

Cleaning system |

Contact blade |

|

|

N. Package form

Body |

Body / Accessories |

|

|

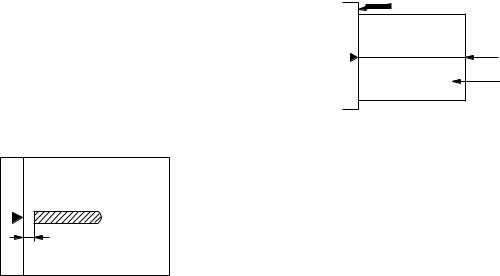

O. External view

|

MX-M200D |

MX-M160D |

|

MX-M160 |

|

|

|

|

|

External |

590 mm(W) x |

590 mm (W) x |

|

590 mm (W) x |

dimensions |

574 mm(D) x |

574 mm (D) x |

|

574 mm (D) x |

(With the bypass |

522 mm(H) |

437 mm (H) |

|

470 mm (H) |

tray closed) |

(Except for North |

|

|

|

|

America) |

|

|

|

|

651 mm(H) |

|

|

|

|

(For North America) |

|

|

|

|

|

|

|

|

Occupying area |

|

|

|

|

(With the bypass |

883mm(W) x 574mm(D) |

|

||

tray opened) |

|

|

|

|

|

|

|

|

|

Weight |

33.0Kg |

|

|

|

(Excluding |

(Except for North |

|

|

|

developer) |

America) |

28.1Kg |

|

29.7Kg |

|

38.3Kg |

|

|

|

|

(For North America) |

|

|

|

|

|

|

|

|

P. Power source

Voltage |

100 - 127V 220 - 240V |

|

|

Frequency |

50/60Hz common |

|

|

Q. Power consumption

Max. power consumption |

1200W |

|

|

|

|

* EnergyStar conformity |

|

|

|

|

|

Power consumption when |

10W (Not including option) |

|

standby |

|

|

|

|

|

R. Digital performance |

|

|

|

|

|

Resolution |

Reading |

600 x 600dpi (PHOTO mode) |

|

|

600 x 300dpi (AUTO exposure mode) |

|

|

600 (main) x 600 (sub) dpi (TEXT mode) |

|

|

|

|

Writing |

600 x 600dpi |

|

|

|

Gradation |

Reading |

256 gradations |

|

|

|

|

Writing |

Binary |

|

|

|

Memory |

64MB |

|

|

|

|

Hard disk |

None |

|

|

|

|

S. Printing function

(1) Platform

Item |

Content |

|

|

Support platform |

IBM PC/AT compatible machine |

|

|

(2) Support OS

|

OS |

SPLC |

PCL6 |

PCL5e |

PS |

PPD |

Rerease |

|

SPDL2 |

method |

|||||

|

|

|

|

|

|

|

|

Windows |

98/Me |

No |

No |

No |

No |

No |

|

|

|

|

|

|

|

|

|

|

NT 4.0 SP5 or |

No |

No |

No |

No |

No |

|

|

later |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2000 |

Yes |

Yes |

Yes |

Yes |

Yes |

CD-ROM |

|

|

|

|

|

|

|

|

|

XP |

Yes |

Yes |

Yes |

Yes |

Yes |

CD-ROM |

|

|

|

|

|

|

|

|

|

XP x64 |

Yes |

Yes |

No |

Yes |

Yes |

Web |

|

|

|

|

|

|

|

|

|

Server 2003 |

No |

Yes |

Yes |

Yes |

Yes |

CD-ROM |

|

|

|

|

|

|

|

|

|

Server 2003 |

No |

Yes |

No |

Yes |

Yes |

Web |

|

x64 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vista |

Yes |

Yes |

Yes |

Yes |

Yes |

CD-ROM |

|

|

|

|

|

|

|

|

|

Vista x64 |

Yes |

Yes |

No |

Yes |

Yes |

Web |

|

|

|

|

|

|

|

|

|

Server 2008 |

No |

Yes |

No |

Yes |

Yes |

CD-ROM |

|

|

|

|

|

|

|

|

|

Server 2008 |

No |

Yes |

No |

Yes |

Yes |

Web |

|

x64 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mac |

9.0-9.2.2 |

No |

No |

No |

No |

Yes |

CD-ROM |

|

|

|

|

|

|

|

|

|

X 10.2.8 |

No |

No |

No |

No |

Yes |

CD-ROM |

|

|

|

|

|

|

|

|

|

X 10.3.9 |

No |

No |

No |

No |

Yes |

CD-ROM |

|

|

|

|

|

|

|

|

|

X 10.4.11 |

No |

No |

No |

No |

Yes |

CD-ROM |

|

|

|

|

|

|

|

|

|

X 10.5-10.5.6 |

No |

No |

No |

No |

Yes |

CD-ROM |

|

|

|

|

|

|

|

|

(3) Printer driver function (SPLC)

|

Item |

|

SPLC |

|

|

|

|

Common |

Custom settings |

Yes |

|

|

|

|

|

|

Reset to default |

Yes |

|

|

|

|

|

|

MIMIC |

|

Yes |

|

|

|

|

Configuration |

Paper feed option |

Tray1/ Tray2/ Tray3/ Tray4 |

|

|

|

|

|

|

Tray |

Paper tray |

Tray1/ Tray2/ Tray3/ Tray4/ |

|

Settings |

|

Manual paper feed |

|

|

|

|

|

|

Set Paper |

Not set/ A3/ A4-R/ A5-R/ A6/ B4/ |

|

|

size |

B5-R/ B6/ Ledger/ Letter-R/ Legal/ |

|

|

|

Executive/ Invoice-R/ Foolscap/ |

|

|

|

Folio/ Com10/ DL/ C5/ 8k/ 16k-R/ |

|

|

|

Custom paper |

|

|

|

|

|

Status window |

Yes |

|

|

|

|

|

|

Version information |

Yes |

|

|

|

|

|

Main |

Number of copies |

1-999 |

|

|

|

|

|

|

Print in the unit of |

On/ Off |

|

|

copies |

|

|

|

|

|

|

|

N-UP printing |

1/ 2/ 4 /6 up |

|

|

|

|

|

|

frame line |

On/ Off |

|

|

|

|

|

|

Order |

|

From left to right */ From right to |

|

|

|

left */ From top to bottom */ From |

|

|

|

top right to downward **/ From top |

|

|

|

left to right **/ From top right to left |

|

|

|

**/ From top right to downward ** |

|

|

|

(“*” is displayed for 2UP only. |

|

|

|

“**” is displayed except for 1UP |

|

|

|

and 2UP.) |

|

|

|

|

|

Print direction |

Vertical/Horizontal |

|

|

|

|

|

|

Print after rotating |

Yes |

|

|

180°C |

|

|

|

|

|

|

MX-M200D SPECIFICATIONS 3-3

|

Item |

|

SPLC |

|

|

|

|

Paper |

Paper size |

A3/ A4/ A5/ A6/ B4/ B5/ B6/ |

|

|

|

|

Ledger/ Letter/ Legal/ Executive/ |

|

|

|

Invoice/ Foolscap/ Folio/ Com10/ |

|

|

|

DL/ C5/ 8k/ 16k/ Custom page |

|

|

|

|

|

|

|

- Custom paper: |

|

|

|

Width [100.0] -[297.0] |

|

|

|

[3.94”] -[11.69”] |

|

|

|

Length [148.0] -[431.8] |

|

|

|

[5.83”] - [17.00”] |

|

|

|

- Milimeters/ Inches |

|

|

|

|

|

Setting for zoom |

None/ Fit page printing/ zoom |

|

|

|

|

(“24” - “400”) |

|

|

|

|

|

Setting |

|

Yes |

|

|

|

|

|

Paper feed system |

Auto paper feed/ manual feed/ |

|

|

|

|

Tray1/ Tray2/ Tray3/ Tray4 |

|

|

|

|

Advanced |

Image |

brightness |

“0” - “100” |

setting |

adjust- |

|

|

Contrast |

“0” - “100” |

||

|

ment |

|

|

|

|

|

|

|

Print text in black |

On/ Off |

|

|

|

|

|

|

Print line in black |

On/ Off |

|

|

|

|

|

Advanced |

Compati |

Input |

300dpi/ 600dpi |

setting |

-bility |

resolution |

|

|

|

|

|

|

|

Hatching |

Standard/Fine |

|

|

pattern |

|

|

|

|

|

|

|

Spool type |

RAW/ EMF |

|

|

|

|

|

|

Reduction |

Standard/Unit of page/Unit of object |

|

|

system |

|

|

|

|

|

|

|

“1” - “5” |

|

|

|

density |

|

|

|

adjustment |

|

|

|

|

|

|

|

Priority on |

On/ Off |

|

|

the driver |

|

|

|

setting - |

|

|

|

Print in the |

|

|

|

unit of |

|

|

|

copies |

|

|

|

|

|

|

|

Priority on |

On/ Off |

|

|

the driver |

|

|

|

setting - |

|

|

|

Duplex |

|

|

|

|

|

|

|

|

|

Watermark |

Watermark |

Top secret/ Confidential/ Draft/ |

|

|

|

|

Original/ Copy |

|

|

|

|

|

Position |

|

X: [-50] - [50] |

|

|

|

Y: [-50] - [50] |

|

|

|

Sets to the center position. |

|

|

|

|

|

Size |

|

“6” - “300” |

|

|

|

|

|

Angle |

|

“-90” - “90” |

|

|

|

|

|

Edit |

Font name |

|

|

|

|

|

|

|

Bold text |

On/ Off |

|

|

|

|

|

|

Italic face |

On/ Off |

|

|

|

|

|

|

Text set |

It depends on the font name. |

|

|

|

|

|

|

Color |

“0” - “255” |

|

|

density |

|

|

|

|

|

|

Print the first page |

On/ Off |

|

|

only |

|

|

|

|

|

|

T. Scanner function

Type |

Flat bed scanner |

|

|

Scan system |

Document table/document feed unit |

|

|

Light source |

White CCFL |

|

|

Resolution |

Color: 600 x 600dpi |

|

B/W: 600 x 300dpi (Default) |

|

600 x 600dpi |

|

|

Document |

Sheet/Book |

|

|

Effective scan range |

OC/SPF/RSPF: |

|

about 297(length) x 431(width) mm |

|

|

Scan speed |

OC/SPF/R-SPF: |

|

0.962msec/line(300 dpi) |

|

|

Input data |

1bit or 12bit |

|

|

Output data |

1bit or 8bit |

|

|

Scan color |

B/W(Simple binary) / B/W(error diffusion) / |

|

Gray scale / Full color |

|

|

Protocol |

TWAIN/WIA(XP,Vista)/STI |

|

|

Interface |

USB2 |

|

|

Scanner utility |

Button Manager/Sharpdesk |

|

|

Drop-out color |

Yes (Red/Green/Blue/White) |

|

|

Scanner button |

Provided (6) |

|

|

Supported OS |

Windows 2000/XP/VISTA |

|

|

Void area |

Lead edge/rear edge (2.5mm) on the driver |

|

side Left/right: 3.0mm |

|

|

WHQL support |

Support by running change |

|

|

MX-M200D SPECIFICATIONS 3-4

[4] CONSUMABLE PARTS

1.Supply system table

A. USA/Canada

MX-M200D

No. |

Name |

Product name |

Content |

|

Life |

Remark |

|

|

|

|

|

|

|

1 |

Toner cartridge |

MX-206NT |

Toner cartridge |

x1 |

16K |

Life setting by A4 6% document |

|

|

|

(Toner:Net 547g With IC) |

|

|

|

|

|

|

|

|

|

|

2 |

Developer |

AR-205MD |

Developer |

x10 |

500K |

|

|

|

|

(Net 300g) |

|

(50x10) |

|

|

|

|

|

|

|

|

3 |

Drum KIT |

AR-205DR |

Drum |

x1 |

50K |

|

|

|

|

Drum fixing plate |

x1 |

|

|

|

|

|

|

|

|

|

B. South and Central America (200V series)

MX-M160/MX-M160D/MX-M200D

No. |

Name |

Product name |

Content |

|

Life |

Remark |

|

|

|

|

|

|

|

1 |

Toner cartridge |

MX-206GT |

Toner cartridge |

x1 |

19K |

Life setting by A4 6% document |

|

|

|

(Toner:Net 547g With IC) |

|

|

(In a toner save mode) |

|

|

|

|

|

|

|

2 |

Developer |

AR-205LD |

Developer |

x10 |

500K |

|

|

|

|

(Net 300g) |

|

(50x10) |

|

|

|

|

|

|

|

|

3 |

Drum KIT |

AR-205DM |

Drum |

x1 |

50K |

|

|

|

|

Drum fixing plate |

x1 |

|

|

|

|

|

|

|

|

|

C. Europe

MX-M160D/MX-M200D

No. |

Name |

Product name |

Content |

|

Life |

Remark |

|

|

|

|

|

|

|

1 |

Toner cartridge |

MX-206GT |

Toner cartridge |

x1 |

16K |

Life setting by A4 6% document |

|

|

|

(Toner:Net 547g With IC) |

|

|

|

|

|

|

|

|

|

|

2 |

Developer |

AR-205LD |

Developer |

x10 |

500K |

|

|

|

|

(Net 300g) |

|

(50x10) |

|

|

|

|

|

|

|

|

3 |

Drum KIT |

AR-205DM |

Drum |

x1 |

50K |

|

|

|

|

Drum fixing plate |

x1 |

|

|

|

|

|

|

|

|

|

D. Australia/New Zealand

MX-M160/MX-M160D/MX-M200D

No. |

Name |

Product name |

Content |

|

Life |

Remark |

|

|

|

|

|

|

|

1 |

Toner cartridge |

MX-206GT |

Toner cartridge |

x1 |

16K |

Life setting by A4 6% document |

|

|

|

(Toner:Net 547g With IC) |

|

|

|

|

|

|

|

|

|

|

2 |

Developer |

AR-205LD |

Developer |

x10 |

500K |

|

|

|

|

(Net 300g) |

|

(50x10) |

|

|

|

|

|

|

|

|

3 |

Drum KIT |

AR-205DM |

Drum |

x1 |

50K |

|

|

|

|

Drum fixing plate |

x1 |

|

|

|

|

|

|

|

|

|

E. Middle East/Africa/Israel/Palestine/Philippine/Taiwan

MX-M160/MX-M160D/MX-M200D

No. |

Name |

Product name |

Content |

|

|

Life |

|

|

|

|

|

|

|

1 |

Toner cartridge |

MX-206FT |

Toner cartridge |

x1 |

16K |

Life setting by A4 6% document |

|

|

|

(Toner:Net 547g With IC) |

|

|

|

|

|

|

|

|

|

|

2 |

Developer |

AR-205CD |

Developer |

x10 |

500K |

|

|

|

|

(Net 300g) |

|

(50x10) |

|

|

|

|

|

|

|

|

3 |

Drum KIT |

AR-205DR |

Drum |

x1 |

50K |

|

|

|

|

Drum fixing plate |

x1 |

|

|

|

|

|

|

|

|

|

F. Asia (Except the above)

MX-M160/MX-M160D/MX-M200D

No. |

Name |

Product name |

Content |

|

Life |

Remark |

|

|

|

|

|

|

|

1 |

Toner cartridge |

MX-206AT |

Toner cartridge |

x1 |

16K |

Life setting by A4 6% document |

|

|

|

(Toner:Net 547g With IC) |

|

|

|

|

|

|

|

|

|

|

2 |

Developer |

AR-205CD |

Developer |

x10 |

500K |

|

|

|

|

(Net 300g) |

|

(50x10) |

|

|

|

|

|

|

|

|

3 |

Drum KIT |

AR-205DR |

Drum |

x1 |

50K |

|

|

|

|

Drum fixing plate |

x1 |

|

|

|

|

|

|

|

|

|

MX-M200D CONSUMABLE PARTS 4-1

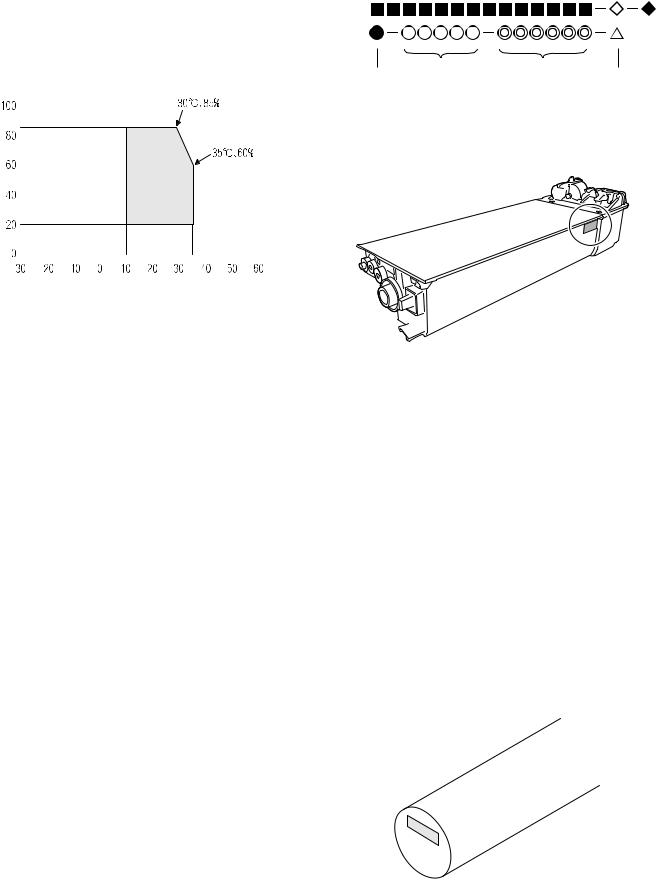

2. Environmental conditions

A. Transport conditions

(1) Transport conditions

-20°C - 45°C (No condensation)

(2) Storage conditions

-10°C - 40°C (Unopened, No condensation)

B. Use conditions

(%) |

|

|

|

|

|

Use envi- |

|||||

|

|

|

|

|

|||||||

|

|||||||||||

Humidity |

|

|

|

|

|

ronment |

|||||

|

|

|

|

|

|

||||||

|

|

|

|

|

|

conditions |

|||||

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Temperature

C. Life(packed conditions)

Photoconductor drum (36 months from the production month) Developer, toner (24 months from the production month)

3. Production number identification

<Toner cartridge>

The label on the toner cartridge shows the date of production.

Production |

Serial |

Year/ |

Ver.No. |

place |

number |

Month/ |

|

|

|

Day |

|

<Drum cartridge>

The lot number, printed on the front side flange, is composed of 6 digits, each digit showing the following content:

1 |

2 |

3 |

4 |

5 |

6 |

1Alphabet

Indicates the model conformity code. A for this model.

2Number

Indicates the end digit of the production year.

3Number or X, Y, Z

Indicates the month of packing.

X stands for October, Y November, and Z December.

4/5 Number

Indicates the day of the month of packing.

6Alphabet

Indicates the production factory. "A" for Nara Plant, “C“ for SOCC

MX-M200D CONSUMABLE PARTS 4-2

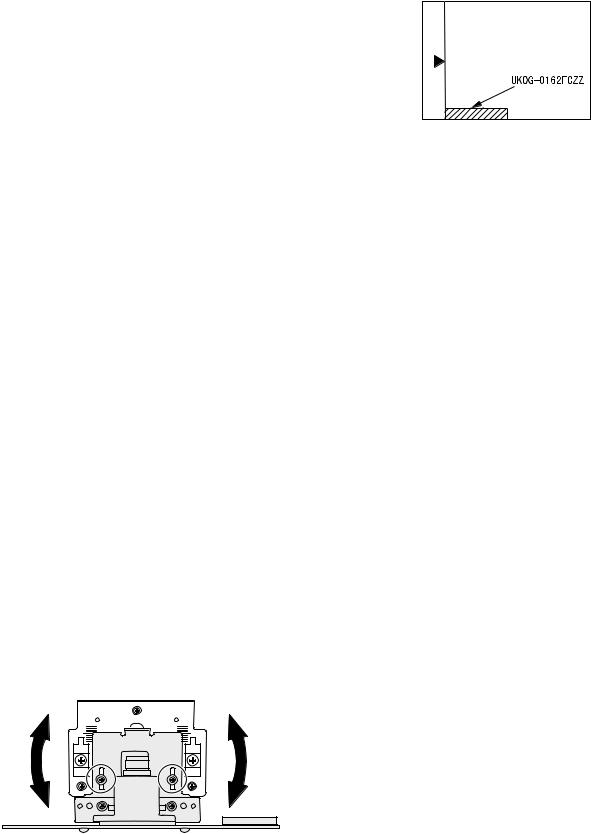

[5] EXTERNAL VIEWS AND INTERNAL STRUCTURES

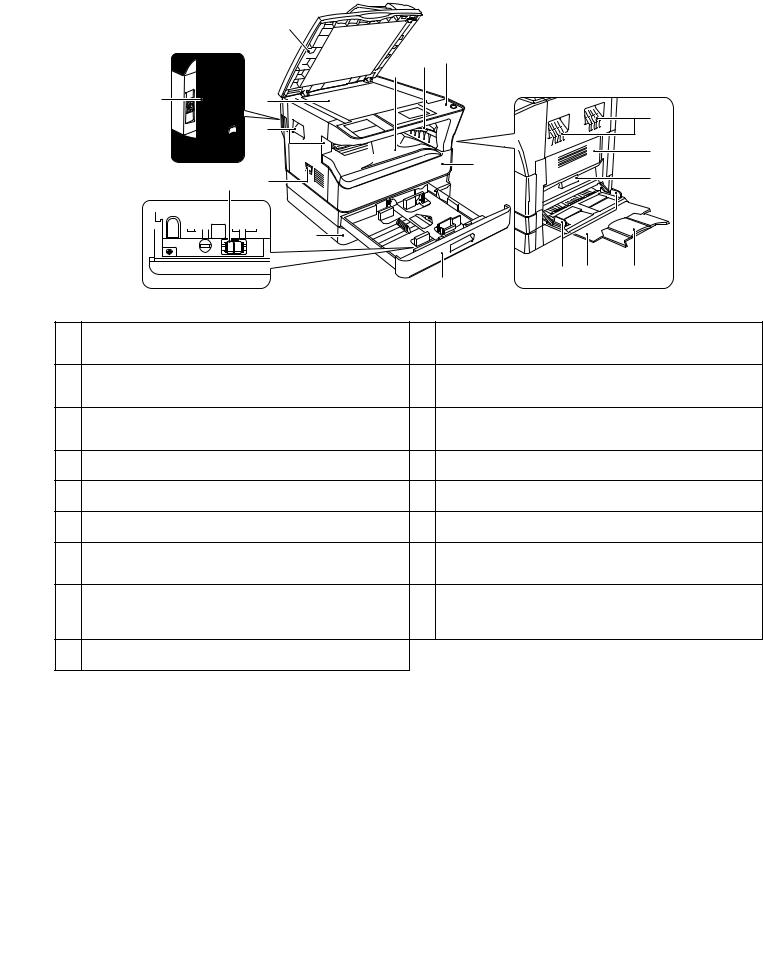

1. Appearance

|

|

3 |

|

|

|

|

|

|

|

|

7 |

8 |

9 |

|

|

|

|

|

|

|

|

|

|

|

1 |

4 |

|

|

|

|

5 |

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

13 |

|

2 |

6 |

|

|

|

14 |

|

|

|

|

|

|

|||

|

|

|

12 |

|

|

|

|

|

|

|

|

|

15 |

16 |

17 |

|

|

|

|

|

11 |

|

|

1 |

USB 2.0 port |

|

|

10 |

Front cover |

|

|

|

Connect to your computer to this port to use the printer and scanner |

|

Open to remove paper misfeeds or replace the toner cartridge. |

||||

|

functions. |

|

|

|

|

|

|

2 |

Charger cleaner |

|

|

11 |

Tray 1 |

|

|

|

Use to clean the transfer charger. |

|

|

|

Tray 1 can hold approximately 250 sheets of copy paper (20 lbs. (80 |

||

|

|

|

|

|

g/m2 )). |

|

|

3 |

Glass cleaner |

|

|

12 |

Tray 2 |

|

|

|

Use to clean the original scanning glass. |

|

|

Tray 2 can hold approximately 250 sheets of copy paper (20 lbs. (80 |

|||

|

|

|

|

|

g/m2 )). |

|

|

4 |

Document glass |

|

|

13 |

Side cover |

|

|

|

Place an original that you wish to scan face |

down here. |

|

Open to remove misfed paper. |

|

||

5 |

Handles |

|

|

14 |

Side cover handle |

|

|

|

Use to move the machine. |

|

|

|

Pull to open the side cover. |

|

|

6 |

Power switch |

|

|

15 |

Bypass tray guides |

|

|

|

Press to turn the machine power on and off. |

|

|

Adjust to the width of the paper when using the bypass tray. |

|||

7 |

Center tray |

|

|

16 |

Bypass tray |

|

|

|

Copies and printed pages are output to this |

tray. |

|

Special paper (heavy paper or transparency film) can be fed from |

|||

|

|

|

|

|

the bypass tray. |

|

|

8 |

Top tray |

|

|

17 |

Bypass tray extension |

|

|

|

(when the job separator tray kit is installed) |

|

Pull out when feeding large paper such as 11" x 17" and 8-1/2" x 14" |

||||

|

Received faxes (when the fax option is installed) and print jobs are |

|

(A3 and B4). |

|

|

||

|

delivered to this tray. |

|

|

|

|

|

|

9Operation panel

Contains operation keys and indicator lights.

MX-M200D EXTERNAL VIEWS AND INTERNAL STRUCTURES 5-1

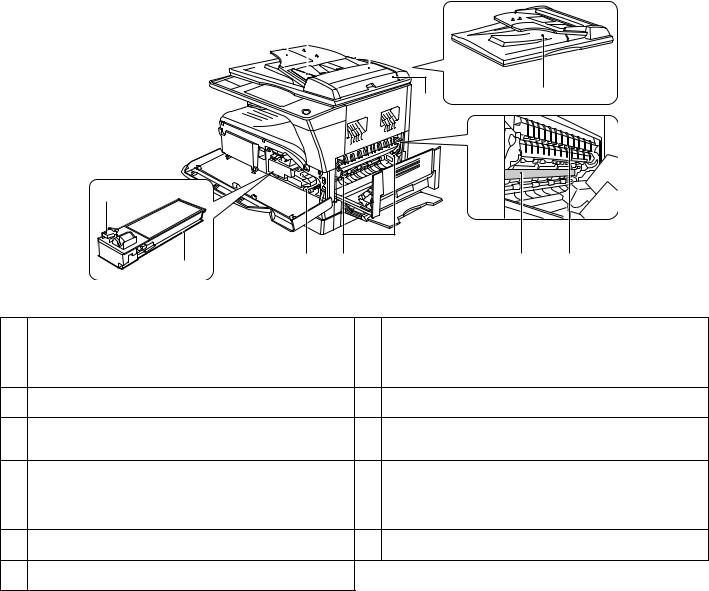

2. Internal

20 21 |

22 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

23 |

26 |

|

|

18 |

|

|

|

|

|

|

19 |

25 |

24 |

|

27 |

28 |

|

|

|

|

|

|

|

18 |

Toner cartridge lock release lever |

|

|

24 |

Fusing unit release levers |

|

|

To replace the toner cartridge, pull out the toner cartridge while |

|

|

To remove the paper misfed in the fusing unit, push down on these |

||

|

pushing on this lever. |

|

|

|

levers and remove the paper. |

|

|

|

|

|

|

* The fusing unit is hot. Do not touch the fusing unit when removing misfed |

|

|

|

|

|

|

paper. Doing so may cause a burn or injury. |

|

19 |

Toner cartridge |

|

|

25 |

Roller rotating knob |

|

|

Contains toner.. |

|

|

|

Rotate to remove misfed paper. |

|

20 |

Document feeder tray |

|

|

26 |

Exit area |

|

|

Place the original(s) that you wish to scan face up here. Up to 40 |

|

|

Originals exit the machine here after copying/scanning when the |

||

|

sheets can be placed. |

|

|

|

SPF is used. |

|

21 |

Original guides |

|

|

27 |

Photoconductive drum |

|

|

Adjust to the size of the originals. |

|

|

|

Images are formed on the photoconductive drum. |

|

|

|

|

|

|

* Do not touch the photoconductive drum (green portion) when removing the |

|

|

|

|

|

|

misfed paper. Doing so may damage the drum and cause smudges on cop- |

|

|

|

|

|

|

ies. |

|

22 |

Feeding roller cover |

|

|

28 |

Fusing unit paper guide |

|

|

Open to remove misfed originals. |

|

|

|

Open to remove misfed paper. |

|

23Right side cover

Open to remove misfed originals.

MX-M200D EXTERNAL VIEWS AND INTERNAL STRUCTURES 5-2

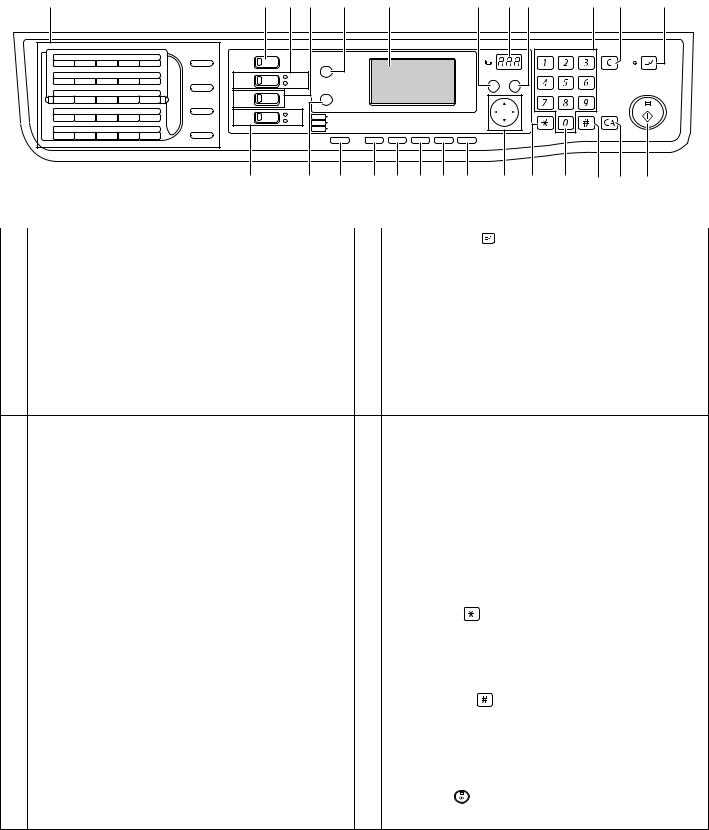

3. Operation Section

1 |

2 |

3 |

4 |

6 |

8 |

10 |

9 11 |

12 13 |

14 |

01 |

02 |

03 |

04 |

05 |

SPEAKER |

|

|

|

|

|

|

|

|

|

|

ABC |

DEF |

INTERRUPT |

COPY |

|

FAX STATUS |

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

SHIFT |

|

|

|

|

|

|

|

|

|

GHI |

JKL |

MNO |

|

06 |

07 |

08 |

09 |

10 |

|

|

ON LINE |

|

|

|

|

|

|

BACK |

|

|||

REDIAL/PAUSE |

|

|

|

|

|

|

OK |

|

|

|

||||||||

|

|

|

|

|

DATA |

SPECIAL |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

11 |

12 |

13 |

14 |

15 |

|

|

|

FUNCTION |

|

|

|

|

|

PQRS |

TUV |

WXYZ |

|

|

|

SCAN |

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

SPEED |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

17 |

18 |

19 |

20 |

SYMBOL |

FAX |

LINE |

COPY |

EXPOSURE |

PAPER |

ZOOM |

AUTO% |

OUTPUT |

DUPLEX |

|

|

@.-_ |

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

DATA |

|

|

|

|

|||||||||

|

|

|

|

|

|

|

SCAN |

COLOR MODE |

RESOLUTION |

ADDRESS |

FORMAT |

ORIGINAL SIZE |

DUPLEX SCAN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

21 |

22 |

23 |

24 |

25 |

COMM. SETTING |

|

|

FAX |

PROGRAM |

RESOLUTION |

ADDRESS |

BROADCAST |

ORIGINAL SIZE |

DUPLEX SCAN |

ACC. #-C |

|

READ-END |

|

|

|

|

|

|

|

|

|