SHARP MX-FNX6, MX-FNX7, MX-PNX4 Service Manual

SERVICE MANUAL

CODE: 00ZMXFNX6/S2E

FINISHER/

SADDLE STITCH FINISHER /PUNCH MODULE

MODEL

CONTENTS

MX-FNX6 MX-FNX7 MX-PNX4

[1] SPECIFICATION

1. MX-FNX6/PNX4 . . . . . . . . . . . . . . . . .1 - 1 2. MX-FNX7/PNX4 . . . . . . . . . . . . . . . . .1 - 2 3. Paper size/Type/Weight . . . . . . . . . . .1 - 3

[2] MAINTENANCE LIST . . . . . . . . . . . . 2 - 1 [3] MECHANISM

1. Composition layout (* In the figure: |

|

For the MX-FNX7 only) . . . . . . . . . . . |

3 - 1 |

2. Electric parts layout . . . . . . . . . . . . . .3 - 1 3. Drive layout . . . . . . . . . . . . . . . . . . . .3 - 3 4. Branch mechanism. . . . . . . . . . . . . . .3 - 3 5. Pre-stack mechanism. . . . . . . . . . . . .3 - 4 6. Rise-fall mechanism . . . . . . . . . . . . . .3 - 5 7. Staple jogger mechanism . . . . . . . . . .3 - 5

8. Center binding staple mechanism (MX-FNX7 only) . . . . . . . . . . . . . . . . .3 - 7

9. Discharge mechanism . . . . . . . . . . . .3 - 8

10. Punch mechanism . . . . . . . . . . . . . . .3 - 10

11. Punch dust collection mechanism . . .3 - 10

[4] REPLACEMENT AND ADJUSTMENT

1. External cover replacement . . . . . . . 4 - 1

2. Tray assembly, left cover |

|

replacement . . . . . . . . . . . . . . . . . . . |

4 - 1 |

3. Shift roller replacement . . . . . . . . . . . 4 - 2 4. Rollers . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

5. Proof tray paper exit sensor |

|

replacement . . . . . . . . . . . . . . . . . . . |

4 - 2 |

6. Shift tray paper surface sensor upper/lower replacement. . . . . . . . . . 4 - 2

7. Shift tray paper exit sensor, proof tray paper surface sensor replacement . . 4 - 4

8. Finisher inlet sensor replacement . . . 4 - 4

9. Staple paper exit sensor |

|

replacement . . . . . . . . . . . . . . . . . . . |

4 - 5 |

10.Punch unit replacement . . . . . . . . . . 4 - 5

11. Center folding horizontal shift |

|

adjustment (MX-FNX7 only) . . . . . . . |

4 - 6 |

12.Center folding vertical shift |

|

adjustment (MX-FNX7 only) . . . . . . . |

4 - 7 |

13.Center folding unit replacement and center binding stapler replacement

and adjustment (MX-FNX7 only). . . . 4 - 8

14.Horizontal resist adjustment . . . . . . . 4 - 10

[5] ELECTRICAL COMPONENTS

1. Block diagram . . . . . . . . . . . . . . . . . . 5 - 1

Parts marked with "  " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

" are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the safety and performance of the set.

This document has been published to be used SHARP CORPORATION for after sales service only.

The contents are subject to change without notice.

[1] SPECIFICATION

1. MX-FNX6/PNX4

Form |

Floor type |

|

|

Transport |

Supports 85 sheets/minute |

||

speed |

|

|

|

Paper |

Center alignment |

|

|

Transport |

|

|

|

standard |

|

|

|

Pause Switch |

Available |

|

|

|

Stacker Section |

||

Tray form |

Top tray |

|

Fixed |

|

Offset tray |

|

Up and down tray |

Paper size |

Top tray |

|

A3W, A4W, A3, B4, A4, A4-R, B5, B5- |

allowed |

Offset tray |

|

R, A5-R, 8K,16K,16KR, Postcard, |

|

|

|

11”x17”, 8.5”x14”, 8.5”x13.4”, |

|

|

|

8.5”x13”, 8.5"x11", 8.5"x11"-R, |

|

|

|

5.5"x8.5"-R,12"x 18", 9"x12", |

|

|

|

7.25"x10.5"R |

Stored paper |

Top tray: 52-205g/m2, 16lbs Bond-110lbs Index |

||

weight (Non- |

Offset tray :52-300g/m2, 16lbs Bond-170 lbs Index |

||

stitched) |

|

|

|

Stored |

Top tray |

|

|

Sheets |

250 sheets: A4, 8.5"x11" or less (80g/m2, 20lbs Bond) |

||

|

50 sheets: B4, 8.5"x14" or more (80g/m2, 20lbs Bond) |

||

|

* A5/5.5x8.5 are feeded from Inserter Tray of Inserter Unit. |

||

|

Offset tray |

|

|

|

3000sheets: A4, 8.5"x11" (80g/m2, 20lbs Bond) |

||

|

1500sheets: A3W, A4W, A3, B4, A4-R, B5, B5-R, 8K, 16K, |

||

|

16KR, 12"x18", 11"x17", 8.5"x14", 8.5"x13.4", 8.5"x13", |

||

|

8.5"x11"-R, 9"x12" (80g/m2, 20lbs Bond) |

||

|

100 sheets: |

|

|

|

A5-R*, 5.5"x8.5"-R*, Postcard* (80g/m2, 20lbs Bond) |

||

|

*Impossible to Offset. |

||

Stacking |

Non-offset |

|

12 mm or less |

performance |

|

|

(B5R and A5R are 50mm or less) |

|

Offset |

|

12 mm or less |

|

|

|

(B5R and A5R are 50mm or less) |

|

Offset volume |

|

30 mm |

|

Stitched |

|

3mm or less |

|

Staple section |

||

Number of |

50 sheets: A4, 8.5"x11" or less |

||

sheets to be |

30 sheets: B4, 8.5"x14" or more |

||

stitched |

Mixed (same width): 30 sheets |

||

|

Max. 176g/m2 (65lbs Index) paper 2 sheets+80g/m2 paper |

||

|

48 sheets |

|

|

Paper weight |

60-105g/m2,16lbs-28lbs Bond |

||

to be stitched |

|

|

|

Number of |

A4, 8.5x11 |

|

2-19 sheets 150 bundles |

stored sheets |

|

|

20-50 sheets 150-60 bundles |

when stapled |

A4R, B5, 8.5x11R |

|

2-14 sheets 100 bundles |

(80g/m2) |

|

|

15-50 sheets 100-30 bundles |

|

Others: |

|

2-14 sheets 100 bundles |

|

|

|

15-30 sheets 100-50 bundles |

|

When mixed size: |

|

2-30 sheets 50 bundles |

|

A3 and A4, |

|

|

|

B4 and B5, |

|

|

|

11x17 and 8.5x17 |

|

|

Staple |

4 position (Top, Top Slant, Bottom, 2 Staples) |

||

position |

|

|

|

Stapling |

Staple cartridge (5,000 staples) |

||

method |

Changeable by user |

|

|

Adjustment of |

-1 - +3.5mm (For 1 position staple only), Adjustment pitch |

||

Staple |

0.5mm, Controlled by main unit. |

||

position |

|

|

|

Detection of |

Available |

|

|

no staple |

|

|

|

Manual |

(When the inserter is installed, it can be operated on the |

||

staple |

operation panel of the main unit.) |

||

Life |

5 year or 9,900K |

|

|

Dimensions |

640mm x 614mm x 960mm |

||

(WxDxH) |

745mm x 614mm x 960mm (Tray extended) |

||

Weight |

46.0kg |

|

|

Power source |

DC24V (supplied by the main unit) |

||

Power |

96W (Include Punch module) |

consumption |

|

Punch Module for 50 sheets stapling (Option) *3

Form |

|

Built in the Finisher |

|

|

|

|

Punch style |

Reciprocal type |

|

|

|

||

Type |

Hole location |

|

Hole |

Paper Size |

||

|

|

|

|

|

diameter |

|

2-hole |

|

|

|

2-hole: |

2-hole: |

2-hole: |

|

|

|

|

A: |

φ6.5mm |

A3, A4, A4- |

|

|

A |

|

80±1mm |

|

R, B4, B5, |

|

|

|

B: |

|

B5-R, |

|

|

|

|

B |

12±3mm |

|

11"x17", |

|

|

|

|

|

8.5"x14", |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8.5" x13.4", |

|

|

A |

A |

|

|

8.5" x13", |

|

|

|

|

|

|

8.5"x11", |

|

|

|

B |

|

|

8.5"x11"-R, |

|

|

|

|

|

8K, 16K, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16K-R |

North |

|

|

|

2-hole: |

φ8.0mm |

3-hole: |

America |

|

|

|

A: |

|

A3, A4, |

2-hole |

|

|

|

70±1mm |

|

11"x17", |

3-hole*1 |

|

|

|

B: |

|

8.5"x11" |

|

|

|

|

12±3mm |

|

2-hole: |

|

|

|

|

|

|

A3, A4, |

|

|

|

|

3-hole: |

|

A4R, B5, |

|

|

|

|

A: |

|

B5R, |

|

|

|

|

108±1mm |

|

11”x17”, |

|

|

|

|

B: |

|

8.5"x11"-R, |

|

|

|

|

9.5±3mm |

|

8.5"x14", |

|

|

|

|

|

|

8.5"x13.4", |

|

|

|

|

|

|

8.5"x13" |

2-hole |

|

|

|

2-hole: |

φ6.5mm |

4-hole: |

4-hole*2 |

|

|

|

A: |

|

A3, B4, A4, |

|

|

A A |

A |

80±1mm |

|

B5, 11"x17", |

|

|

B: |

|

8.5"x11" |

||

|

|

|

|

|

||

|

|

|

B |

12±3mm |

|

2-hole: |

|

|

|

|

|

A3, A4, |

|

|

|

|

|

4-hole: |

|

A4R, B5, |

|

|

A |

|

A: |

|

B5R, |

|

|

|

80±1mm |

|

11"x17", |

|

|

|

|

|

|

||

|

|

|

B |

B: |

|

8.5"x11"-R, |

|

|

|

12±3mm |

|

8.5"x14", |

|

|

|

|

|

|

||

|

|

|

|

|

|

8.5"x13.4", |

|

|

|

|

|

|

8.5"x13" |

4-hole |

|

|

|

A: |

φ6.5mm |

A3, A4, |

wide |

|

|

|

70±1mm |

|

A4-R, B4, |

|

|

|

|

B: |

|

B5, B5-R, |

|

|

A |

C |

12±3mm |

|

11"x17", |

|

|

|

|

C: |

|

8.5"x14", |

|

|

|

B |

21±1mm |

|

8.5"x13.4", |

|

|

|

|

|

|

8.5"x13", |

|

|

|

|

|

|

8.5"x11", |

|

|

|

|

|

|

8.5"x11"-R |

Adjustment of |

Feeding direction(X): ±3mm, Adjustment pitch 0.5mm, |

Punch |

Control by main unit. |

position |

Y direction: ±2mm, Adjustment pitch 0.4mm, Control by |

|

main unit. |

Can be manually adjusted in the B direction.

Manual |

Yes (When the inserter is installed, it can be operated on |

Punch |

the operation panel of the main unit.) |

Punchable |

52-163g/m2,16lbs Bond, 90lbs Index |

Paper Weight |

|

Power source |

In the finisher |

Dimensions 130mmx515mmx140mm (WxDxH)

Weight 1.4kg

*1: Manual (OPE) Switching: 2-hole/3-hole *2: Manual (OPE) switching 2-hole/4-hole

MX-FNX6 SPECIFICATION 1 – 1

2.MX-FNX7/PNX4

Saddle finisher (85 only)

Form |

Floor type |

|

|

Transport |

Supports 85 sheets/minute |

||

speed |

|

|

|

Paper |

Center alignment |

|

|

Transport |

|

|

|

standard |

|

|

|

|

Stacker section |

||

Tray Form |

Top tray |

|

Fixed |

|

Offset tray |

|

Up-down Offset tray |

|

Saddle Tray |

|

Fixed |

Paper sizes |

Top tray |

|

A3W, A4W, A3, B4, A4, A4-R, B5, B5- |

allowed |

Offset tray |

|

R, A5-R, 8K, 16K, 16KR, Postcard, |

|

|

|

11"x17", 8.5"x14", 8.5"x13.4", |

|

|

|

8.5"x13", 8.5"x11", 8.5"x11"-R, |

|

|

|

5.5"x8.5"-R, 12"x18", 9"x12", |

|

|

|

7.25"x10.5"R |

Stored paper |

Top tray: 52 - 205g/m2, 16lbs Bond-110lbs Index |

||

weight (Non- |

Offset tray: 52 - 300g/m2, 16lbs Bond-170lbs Index |

||

stitched) |

|

|

|

Stored sheets |

Top tray |

|

|

|

250 sheets: A4, 8.5"x11" or less |

||

|

50 sheets: B4, 8.5"x14" or more |

||

|

Offset tray |

|

|

|

2000 sheets: A4, 8.5"x11" |

||

|

1000 sheets: A3W, A4W, A3, B4, A4-R, B5, B5-R, |

||

|

8K,16K,16KR, 12"x18", 11"x17", 8.5"x14", 8.5"x13.4" , |

||

|

8.5"x13", 8.5"x11"-R, 9"x12" |

||

|

100 sheets: A5-R*, 5.5"x 8.5"-R*, Postcard* |

||

|

*Impossible to Offset. |

||

Stacking |

Non-offset |

|

12 mm or less |

performance |

|

|

(B5R and A5R are 50mm or less) |

|

Offset |

|

12 mm or less |

|

|

|

(B5R and A5R are 50mm or less) |

|

Offset volume |

|

30 mm |

|

Stitched |

|

3 mm or less |

|

Staple section |

||

Number of |

50 sheets: A4, 8.5"x11" or less |

||

sheets to be |

30 sheets: B4, 8.5"x14" or more |

||

stitched |

Mixed size: 30 sheets |

||

|

Max. 2 x 176g/m2 (65lbs Index) paper |

||

|

+ 48 sheets x 80g/m2 paper |

||

Paper weight |

60 - 105g/m2,16lbs-28lbs Bond |

||

to be stitched |

|

|

|

Number of |

A4, 8.5x11 |

|

2-12 sheets 150 bundles |

stored sheets |

|

|

13-50 sheets 150-40 bundles |

when stapled |

A4R, B5, 8.5x11R |

|

2-9 sheets 100 bundles |

(80g/m2) |

|

|

10-50 sheets 100-20 bundles |

|

Others: |

|

2-9 sheets 100 bundles |

|

|

|

10-30 sheets 100-33 bundles |

|

When mixed size: |

|

2-30 sheets 50 bundles |

|

A3 and A4, |

|

|

|

B4 and B5, |

|

|

|

11x17 and 8.5x17 |

|

|

Staple |

4 position (Top, Top Slant, Bottom, 2 Staples) |

||

Position |

|

|

|

Stapling |

Staple cartridge (5000 staples) Changeable by user |

||

method |

|

|

|

Adjustment of |

-1 - +3.5mm (For 1 position staple only), Adjustment pitch |

||

Staple |

0.5mm, Controlled by main unit. |

||

position |

|

|

|

Detection of |

Available |

|

|

no staple |

|

|

|

Manual |

No |

|

|

Staple |

|

|

|

|

Saddle section |

||

Paper sizes |

A3W, A3, B4, A4-R, |

B5-R, 11"x17", 8.5"x14", 8.5"x11"-R, |

|

allowed for |

12"x18" |

|

|

saddle |

|

|

|

Paper type/ |

60 - 90g/m2, 16lbs-24lbs Bond, Cover is possible up to |

||

weight |

176g/m2. |

|

|

allowed for |

|

|

|

saddle |

|

|

|

Stitching |

|

|

2-point center stitch |

|

|

|

|

|

||||||||||||||||

method |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Stitched |

|

|

15 sheets |

|

|

|

|

|

||||||||||||||||

sheet |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Folding |

|

|

Center folding |

|

|

|

|

|

||||||||||||||||

location |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Loading |

|

|

|

2 - 5 sheets staple: 30 bundles |

|

|

|

|||||||||||||||||

number of |

|

|

|

6 - 10 sheets staple: 15 bundles |

|

|

|

|||||||||||||||||

sheet |

|

|

11 - 15 sheets staple: 10 bundles |

|

|

|

||||||||||||||||||

Adjustment of |

|

|

±3mm (Feeding direction), Adjustment pitch 0.2mm, |

|||||||||||||||||||||

Centre staple |

|

|

Controlled by main unit. |

|

|

|

||||||||||||||||||

position |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Adjustment of |

|

±3mm (Feeding direction), Adjustment pitch 0.2mm, |

||||||||||||||||||||||

Centre |

|

|

Controlled by main unit. |

|

|

|

||||||||||||||||||

folding |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

position |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Detection of |

|

|

Available |

|

|

|

|

|

||||||||||||||||

no staple |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Stapling |

|

|

Staple cartridge (2000 staples) x2 |

|

|

|

||||||||||||||||||

method |

|

|

Changeable by user |

|

|

|

|

|

||||||||||||||||

Reliability |

|

|

MCBJ |

|

|

|

|

|

|

|

|

|

|

in compliance with the main unit |

||||||||||

|

|

|

|

|

|

MCBF |

|

|

|

|

|

|

|

|

|

|

in compliance with the main unit |

|||||||

Life |

|

|

5 year or 9,900K |

|

|

|

|

|

||||||||||||||||

Dimensions |

|

|

640mm x 614mm x 960mm |

|

|

|

||||||||||||||||||

(W x D x H) |

|

|

745mm x 614mm x 960mm (Tray extended) |

|

||||||||||||||||||||

Weight |

|

|

60.6Kg |

|

|

|

|

|

||||||||||||||||

Power |

|

|

DC24V (supplied by the main unit) |

|

||||||||||||||||||||

Source |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Power |

|

|

96W (Include Punch module) |

|

|

|

||||||||||||||||||

Consumption |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Manual |

|

|

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Staple |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

Punch Module for 50 sheets stapling(Option) *3 |

|

|||||||||||||||||||

Form |

|

|

Built in the finisher |

|

|

|

|

|

||||||||||||||||

Punch style |

|

|

Reciprocal |

|

|

|

|

|

||||||||||||||||

Type |

|

|

|

|

|

|

|

|

|

Hole location |

|

|

Hole |

|

Paper Size |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

diameter |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-hole |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-hole |

|

2-hole: |

|

2-hole: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A: |

|

φ6.5mm |

|

A3, A4, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

80±1mm |

|

|

|

A4-R, B4, |

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

B: |

|

|

|

B5, B5-R, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

12±3mm |

|

|

|

11"x17", |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8.5"x14", |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8.5" x13.4", |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8.5"x13", |

|

|

|

|

|

|

|

A |

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

"8.5"x11", |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8.5"x11"-R, |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

8K, 16K, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16K-R |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

North |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-hole: |

|

φ8.0mm |

|

3-hole: |

America |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A: |

|

|

|

A3, A4, |

2-hole |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

70±1mm |

|

|

|

11"x17", |

3-hole*1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B: |

|

|

|

8.5"x11" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12±3mm |

|

|

|

2-hole: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A3, A4, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3-hole: |

|

|

|

A4R, B5, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A: |

|

|

|

B5R, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

108±1mm |

|

|

|

11"x17", |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B: |

|

|

|

8.5"x11"-R, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9.5±3mm |

|

|

|

8.5"x14", |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8.5"x13.4", |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8.5"x13" |

2-hole |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-hole: |

|

φ6.5mm |

|

4-hole: |

4-hole*2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A: |

|

|

|

A3, B4, A4, |

|

|

|

|

|

|

A |

A |

A |

|

|

|

|

|

|

|

80±1mm |

|

|

|

B5, 11"x17", |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

B: |

|

|

|

8.5"x11" |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

12±3mm |

|

|

|

2-hole: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A3, A4, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4-hole: |

|

|

|

A4R, B5, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

A |

|

A |

|

|

|

|

|

|

|

|

A: |

|

|

|

B5R, |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

80±1mm |

|

|

|

11"x17", |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

B: |

|

|

|

8.5"x11"-R, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12±3mm |

|

|

|

8.5"x14", |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8.5"x13.4", |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8.5"x13" |

MX-FNX6 SPECIFICATION 1 – 2

4-hole |

|

|

|

|

|

A: |

φ6.5mm |

A3, A4, |

wide |

|

|

|

|

|

70±1mm |

|

A4-R, B4, |

|

|

|

|

|

|

|||

|

|

|

|

A C |

|

B: |

|

B5, B5-R, |

|

|

|

|

|

12±3mm |

|

11"x17", |

|

|

|

|

|

|

B |

C: |

|

8.5"x14", |

|

|

|

|

|

21±1mm |

|

8.5" x13.4", |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

8.5"x13", |

|

|

|

|

|

|

|

|

8.5"x11", |

|

|

|

|

|

|

|

|

8.5"x11"-R |

Adjustment of |

Feeding direction(X): ±3mm, Adjustment pitch 0.5mm, |

|||||||

Punch |

Controlled by main unit. |

|

|

|||||

position |

Y direction: ±2mm, Adjustment pitch 0.4mm, Control by |

|||||||

|

|

|

main unit. |

|

|

|

||

B-direction can be adjustable manually.

Manual |

No |

Punch |

|

Punchable |

2-hole/ 2-hole3-hole: 52-163g/m2 /16lbs Bond-90lbs Index |

Paper Weight |

4-hole/ 4-hole-broad space: 52-163g/m2 /16lbs Bond- |

|

90lbs Index |

Power |

Supplied by the finisher |

Source |

|

Dimensions |

130mm x 515mm x 140mm |

(WxDxH) |

|

Weight |

1.4kg |

*1: Manual (OPE) switching: 2-hole/3-hole *2: Manual (OPE) switching: 2-hole/4-hole

3. Paper size/Type/Weight

|

|

2- sided |

Reverse |

Straight |

|

|

Saddle Finisher/ Finisher (For 85 sheets) |

|

|

|||

|

|

pass |

Output |

Output |

Top tray |

Offset |

At the |

Punch |

Punch |

Punch |

Punch |

Saddle |

|

|

|

Pass |

Pass |

|

tray |

staple |

(2- |

(2/3 - |

(2/4 - |

(4-holes |

tray |

|

|

|

|

|

|

|

|

holes) |

holes) |

holes) |

wide) |

|

Minimum paper weight |

60g/m2 |

52g/m2 |

52g/m2 |

52g/m2 |

52g/m2 |

60g/m2 |

52g/m2 |

52g/m2 |

52g/m2 |

52g/m2 |

60g/m2 |

|

|

|

(16lbs |

(14lbs |

(14lbs |

(14lbs |

(14lbs |

(16lbs |

(14lbs |

(16lbs |

(14lbs |

(14lbs |

(16lbs |

|

|

bond) |

bond) |

bond) |

bond) |

bond) |

bond) |

bond) |

bond) |

bond) |

bond) |

bond) |

Maximum paper weight |

205g/m2 |

205g/m2 |

300g/m2 |

205g/m2 |

300g/m2 |

105g/m2 |

163g/m2 |

163g/m2 |

163g/m2 |

163g/m2 |

90g/m2 |

|

|

|

(40lbss |

(40lbss |

(40lbs |

(40lbs |

(40lbs |

(28lbs |

(90lbs |

(90lbs |

(90lbs |

(90lbs |

(24lbs |

|

|

bond) |

bond) |

bond) |

bond) |

bond) |

bond) |

Index) |

Index) |

Index) |

Index) |

bond) |

|

|

(110lbss |

(110lbss |

(140lbs |

(110lbs |

(140lbs |

As for |

|

|

|

|

As for |

|

|

index) |

index) |

index) |

index) |

index) |

the |

|

|

|

|

the |

|

|

(65lbs |

(65lbs |

(100lbs |

(65lbs |

(100lbs |

cover |

|

|

|

|

cover |

|

|

cover) |

cover) |

cover) |

cover) |

cover) |

sheet, |

|

|

|

|

sheet, |

|

|

|

|

|

|

|

Even |

|

|

|

|

Even |

|

|

|

|

|

|

|

176g/m2 |

|

|

|

|

176g/m2 |

|

|

|

|

|

|

|

is |

|

|

|

|

is |

|

|

|

|

|

|

|

possible |

|

|

|

|

possible |

Paper |

Thin paper |

No |

Yes |

Yes |

Yes |

Yes |

No |

Yes |

Yes |

Yes |

Yes |

No |

type |

|

|

(Even |

(Even |

(Even |

(Even |

|

(Even |

(Even |

(Even |

(Even |

|

|

|

|

52g/m2 |

52g/m2 |

52g/m2 |

52g/m2 |

|

52g/m2 |

52g/m2 |

52g/m2 |

52g/m2 |

|

|

|

|

is |

is |

is |

is |

|

is |

is |

is |

is |

|

|

|

|

possible) |

possible) |

possible) |

possible) |

|

possible) |

possible) |

possible) |

possible) |

|

|

Plain paper |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

|

Recycled paper |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

|

Colored paper |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

|

Letter head |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

|

Pre-printed paper |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

|

Pre-punched paper |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

No |

No |

No |

No |

Yes |

|

Heavy paper1 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

|

(106-128g/m2) |

|

|

|

|

|

|

|

|

|

|

|

|

Heavy paper2 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

|

(129-176g/m2) |

|

|

|

|

|

|

|

|

|

|

|

|

Heavy paper3 |

Yes |

Yes |

Yes |

Yes |

Yes |

No |

No |

No |

No |

No |

No |

|

(177-205g/m2) |

|

|

|

|

|

|

|

|

|

|

|

|

Heavy paper4 |

No |

No |

Yes |

No |

Yes |

No |

No |

No |

No |

No |

No |

|

(206-300g/m2) |

|

|

|

|

|

|

|

|

|

|

|

|

Tab paper |

No |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

No |

|

Transparency paper |

No |

No |

Yes |

Yes |

No |

No |

No |

No |

No |

No |

No |

|

Label paper |

No |

No |

Yes |

Yes |

No |

No |

No |

No |

No |

No |

No |

MX-FNX6 SPECIFICATION 1 – 3

|

|

|

|

2- sided |

Reverse |

Straight |

|

|

Saddle Finisher/ Finisher (For 85 sheets) |

|

|

|||

|

|

|

|

pass |

Output |

Output |

Top tray |

Offset |

At the |

Punch |

Punch |

Punch |

Punch |

Saddle |

|

|

|

|

|

Pass |

Pass |

|

tray |

staple |

(2- |

(2/3 - |

(2/4 - |

(4-holes |

tray |

|

|

|

|

|

|

|

|

|

|

holes) |

holes) |

holes) |

wide) |

|

Paper |

12"x18" |

|

305 |

Yes |

Yes |

Yes |

Yes |

Yes |

No |

No |

No |

No |

No |

Yes |

size |

(A3W) |

|

x457 |

|

|

|

|

|

|

|

|

|

|

|

|

Ledger |

|

279 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

|

(11"x17") |

|

x432 |

|

|

|

|

|

|

|

|

|

|

|

|

Ledger |

|

279 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

(11"x17") |

|

x216 |

|

|

|

|

|

|

|

|

|

|

|

|

Zfolding |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Legal |

|

216 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

yes |

yes |

Yes |

Yes |

|

(8.5"x14") |

|

x356 |

|

|

|

|

|

|

|

(2-holes) |

(2-holes) |

|

|

|

Legal |

|

216 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

(8.5"x14") |

|

x178 |

|

|

|

|

|

|

|

|

|

|

|

|

Z folding |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mexican |

|

216 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

yes |

yes |

Yes |

No |

|

Legal |

|

x340 |

|

|

|

|

|

|

|

(2-holes) |

(2-holes) |

|

|

|

(8.5"x13.4") |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Foolscap |

|

216 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

yes |

yes |

Yes |

No |

|

(8.5"x13") |

|

x330 |

|

|

|

|

|

|

|

(2-holes) |

(2-holes) |

|

|

|

Letter |

|

279 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

No |

|

(8.5"x11") |

|

x216 |

|

|

|

|

|

|

|

|

|

|

|

|

Letter R |

|

216 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

yes |

yes |

Yes |

Yes |

|

(8.5"x11"R) |

|

x279 |

|

|

|

|

|

|

|

(2-holes) |

(2-holes) |

|

|

|

Letter R |

|

216 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

(8.5"x11"R) |

|

x140 |

|

|

|

|

|

|

|

|

|

|

|

|

Z folding |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Invoice |

|

216 |

No |

No |

No |

- |

- |

- |

- |

- |

- |

- |

- |

|

(5.5"x8.5") |

|

x140 |

|

|

|

|

|

|

|

|

|

|

|

|

Invoice R |

|

140 |

Yes |

Yes |

Yes |

Yes |

yes |

No |

No |

No |

No |

No |

No |

|

(5.5" |

|

x216 |

|

|

|

|

(Impossi |

|

|

|

|

|

|

|

x8.5"R) |

|

|

|

|

|

|

ble to |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

offset) |

|

|

|

|

|

|

|

Exective R |

|

184 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

No |

No |

No |

No |

No |

|

(7.25"x10.5") |

|

x266 |

|

|

|

|

|

|

|

|

|

|

|

|

9x12 (A4W) |

|

305 |

Yes |

Yes |

Yes |

Yes |

Yes |

No |

No |

No |

No |

No |

No |

|

|

|

x229 |

|

|

|

|

|

|

|

|

|

|

|

|

A3 |

|

297 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

|

|

|

x420 |

|

|

|

|

|

|

|

|

|

|

|

|

A3 |

|

297 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

Z folding |

|

x210 |

|

|

|

|

|

|

|

|

|

|

|

|

B4 |

|

257 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

yes |

Yes |

Yes |

Yes |

|

|

|

x364 |

|

|

|

|

|

|

|

(2-holes) |

|

|

|

|

B4 |

|

257 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

Z folding |

|

x182 |

|

|

|

|

|

|

|

|

|

|

|

|

A4 |

|

297 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

No |

|

|

|

x210 |

|

|

|

|

|

|

|

|

|

|

|

|

A4-R |

|

210 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

yes |

yes |

Yes |

Yes |

|

|

|

x297 |

|

|

|

|

|

|

|

(2-holes) |

(2-holes) |

|

|

|

A4-R |

|

210 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

Z folding |

|

x148 |

|

|

|

|

|

|

|

|

|

|

|

|

B5 |

|

257 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

yes |

Yes |

Yes |

No |

|

|

|

x182 |

|

|

|

|

|

|

|

(2-holes) |

|

|

|

|

B5-R |

|

182 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

yes |

yes |

Yes |

Yes |

|

|

|

x257 |

|

|

|

|

|

|

|

(2-holes) |

(2-holes) |

|

|

|

A5 |

|

210 |

No |

No |

No |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

|

x148 |

|

|

|

|

|

|

|

|

|

|

|

|

A5-R |

|

148 |

Yes |

Yes |

Yes |

Yes |

yes |

No |

No |

No |

No |

No |

No |

|

|

|

x210 |

|

|

|

|

(Impossi |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ble to |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

offset) |

|

|

|

|

|

|

|

SRA3 |

|

320 |

Yes |

Yes |

Yes |

No |

No |

No |

No |

No |

No |

No |

No |

|

|

|

x450 |

|

|

|

|

|

|

|

|

|

|

|

|

SRA4 |

|

320 |

Yes |

Yes |

Yes |

No |

No |

No |

No |

No |

No |

No |

No |

|

|

|

x225 |

|

|

|

|

|

|

|

|

|

|

|

|

318x234.75mm |

|

Yes |

Yes |

Yes |

No |

No |

No |

No |

No |

No |

No |

No |

|

|

312.5x220mm |

|

Yes |

Yes |

Yes |

No |

No |

No |

No |

No |

No |

No |

No |

|

|

318x469.5mm |

|

Yes |

Yes |

Yes |

No |

No |

No |

No |

No |

No |

No |

No |

|

|

312.5x440mm |

|

Yes |

Yes |

Yes |

No |

No |

No |

No |

No |

No |

No |

No |

|

|

8K |

|

270 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

No |

|

|

|

x390 |

|

|

|

|

|

|

|

|

|

|

|

|

16K |

|

270 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

No |

|

|

|

x195 |

|

|

|

|

|

|

|

|

|

|

|

|

16K-R |

|

195 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

yes |

yes |

Yes |

No |

|

|

|

x270 |

|

|

|

|

|

|

|

(2-holes) |

(2-holes) |

|

|

MX-FNX6 SPECIFICATION 1 – 4

|

|

|

2- sided |

Reverse |

Straight |

|

|

Saddle Finisher/ Finisher (For 85 sheets) |

|

|

|||

|

|

|

pass |

Output |

Output |

Top tray |

Offset |

At the |

Punch |

Punch |

Punch |

Punch |

Saddle |

|

|

|

|

Pass |

Pass |

|

tray |

staple |

(2- |

(2/3 - |

(2/4 - |

(4-holes |

tray |

|

|

|

|

|

|

|

|

|

holes) |

holes) |

holes) |

wide) |

|

Paper |

Postcard |

100 |

No |

No |

Yes |

Yes |

yes |

No |

No |

No |

No |

No |

No |

size |

|

x148 |

|

|

|

|

(Impossi |

|

|

|

|

|

|

|

|

|

|

|

|

|

ble to |

|

|

|

|

|

|

|

|

|

|

|

|

|

Offset) |

|

|

|

|

|

|

|

Special-Custom size |

No |

Yes |

Yes |

Yes |

yes |

No |

No |

No |

No |

No |

No |

|

|

|

|

|

|

|

|

(Impossi |

|

|

|

|

|

|

|

|

|

|

|

|

|

ble to |

|

|

|

|

|

|

|

|

|

|

|

|

|

Offset) |

|

|

|

|

|

|

|

(Custom |

min |

- |

140 |

100 |

100 |

140 |

- |

- |

- |

- |

- |

- |

|

Range) |

Main |

|

(5.5) |

(4.0) |

(4.0) |

(5.5) |

|

|

|

|

|

|

|

|

max |

- |

320 |

320 |

320 |

306 |

- |

- |

- |

- |

- |

- |

|

|

Main |

|

(12.5) |

(12.5) |

(12.5) |

(12.1) |

|

|

|

|

|

|

|

|

min |

- |

182 |

140 |

140 |

140 |

- |

- |

- |

- |

- |

- |

|

|

Sub |

|

(7.25) |

(5.5) |

(5.5) |

(5.5) |

|

|

|

|

|

|

|

|

max |

- |

470 |

470 |

470 |

470 |

- |

- |

- |

- |

- |

- |

|

|

Sub |

|

(18.5) |

(18.5) |

(18.5) |

(18.5) |

|

|

|

|

|

|

|

Special-Size |

|

No |

Yes |

Yes |

Yes |

No |

No |

No |

No |

No |

No |

No |

|

uncertain |

|

|

|

|

|

|

|

|

|

|

|

|

*1: Cover and back cover only. *2: 2-holes only.

MX-FNX6 SPECIFICATION 1 – 5

1 07’.07.27

[2] MAINTENANCE LIST

: Check {: Clean S: Replace U: Adjust : Lubricate : Shift position (Clean, replace, or adjust as needed.)

|

|

|

|

|

|

|

|

|

|

|

|

Tool, oil, chemicals |

|

Unit name |

No. |

Part name |

When |

500K |

1000K |

1500K |

2000K |

2500K |

3000K |

Life judgement |

Procedure |

|

calling |

(Reference) |

Treatment after |

|||||||||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

procedure |

|

Finisher |

1 |

Transport rollers |

|

{ |

{ |

{ |

{ |

{ |

{ |

|

When there is dirt, |

|

(for 85-sheet |

|

|

|

|

|

|

|

|

|

|

wipe with wet cloth |

|

machine) |

|

|

|

|

|

|

|

|

|

|

and water. |

|

[MX-FNX6] |

2 |

Transport paper guide |

|

{ |

{ |

{ |

{ |

{ |

{ |

|

When there is dirt, |

|

|

|

|

|

|

|

|

|

|

|

|

wipe with wet cloth |

|

|

|

|

|

|

|

|

|

|

|

|

and water. |

|

|

3 |

Gears |

|

|

|

|

|

|

|

|

UKOG-0307FCZZ |

|

|

4 |

Discharge brush |

|

|

|

|

|

|

|

|

When there is dirt, |

|

|

|

|

|

|

|

|

|

|

|

|

wipe brush part with |

|

|

|

|

|

|

|

|

|

|

|

|

wet cloth and water. |

|

|

|

|

|

|

|

|

|

|

|

|

* Refer to the NOTE: |

|

|

5 |

Sintered bearing |

|

|

|

|

|

|

|

Lubricate when an |

Tellus oil: |

|

|

|

|

|

|

|

|

|

|

|

abnormal sound is |

0CW4110K701// |

|

|

|

|

|

|

|

|

|

|

|

heard. |

|

|

|

6 |

Sensor |

|

{ |

{ |

{ |

{ |

{ |

{ |

|

Clean by air |

|

|

7 |

Edge binding stapler |

|

Replacement reference: Replace the unit after 500K of staple. |

|

||||||

|

|

8 |

Punch |

|

Replacement reference: Replace the unit after 1,000K of panch. |

|

||||||

1 |

|

9 |

Drag roller |

|

S |

S |

S |

S |

S |

S |

|

|

|

Saddle |

1 |

Drive roller |

|

{ |

{ |

{ |

{ |

{ |

{ |

|

When there is dirt, |

|

finisher |

|

|

|

|

|

|

|

|

|

|

wipe with wet cloth |

|

(for 85-sheet |

|

|

|

|

|

|

|

|

|

|

and water. |

|

machine) |

2 |

Follower roller |

|

{ |

{ |

{ |

{ |

{ |

{ |

|

When there is dirt, |

|

[MX-FNX7] |

|

|

|

|

|

|

|

|

|

|

wipe with wet cloth |

|

|

|

|

|

|

|

|

|

|

|

|

and water. |

|

|

3 |

Discharge brush |

|

|

|

|

|

|

|

|

When there is dirt, |

|

|

|

|

|

|

|

|

|

|

|

|

wipe brush part with |

|

|

|

|

|

|

|

|

|

|

|

|

wet cloth and water. |

|

|

|

|

|

|

|

|

|

|

|

|

* Refer to the NOTE: |

|

|

4 |

Sintered bearing |

|

|

|

|

|

|

|

Lubricate when an |

Silicon oil |

|

|

|

|

|

|

|

|

|

|

|

abnormal sound is |

|

|

|

|

|

|

|

|

|

|

|

|

heard. |

|

|

|

5 |

Sensor |

|

{ |

{ |

{ |

{ |

{ |

{ |

|

Clean by air |

|

|

6 |

Edge binding stapler |

|

Replacement reference: Replace the unit after 500K of staple. |

|

||||||

|

|

7 |

Center binding stapler |

|

Replacement reference: Replace the unit after 200K of staple. |

|

||||||

|

|

8 |

Punch |

|

Replacement reference: Replace the unit after 1,000K of panch. |

|

||||||

1 |

|

9 |

Drag roller |

|

S |

S |

S |

S |

S |

S |

|

|

NOTE: Discharge brush cleaning

Wipe the brush with wet cloth with a small amount of water. (Recommend)

Handle the brush carefully.

MX-FNX6 MAINTENANCE LIST 2 – 1

[3] MECHANISM

1.Composition layout

(* In the figure: For the MX-FNX7 only)

|

Proof branch |

Proof tray |

pawl |

|

Punch unit |

Tray |

|

assembly |

|

* Center binding |

Staple branch |

pawl |

|

stapler |

Pre-stack |

|

|

* Folding plate |

branch pawl |

|

|

* Folding roller |

Pre-stack tray |

|

|

|

Edge binding |

|

stapler |

* Tray |

|

paper folding |

|

section |

|

1)Proof branch, staple branch

The paper path is selected between the path to the proof tray and the path to the upper tray depending on presence of sort or staple.

2)Proof tray

When the sort mode and the staple mode are not selected, copy paper is discharged to this tray.

3)Tray assembly

This tray lifts up or moves down in the sort mode depending on the copy discharge quantity (the number of copy sets).

4)Tray paper folding section (The MX-FNX7 only)

Center binding copy is discharged to this tray in the sort mode.

5)Pre-stack section

The first page of the second or later sets is switch-back transported and kept in standby, and fed together with the second page to the staple tray.

6)Center binding staple section (The MX-FNX7 only)

Sheets of copy paper are aligned by the alignment roller and the jogger fence, performing stapling.

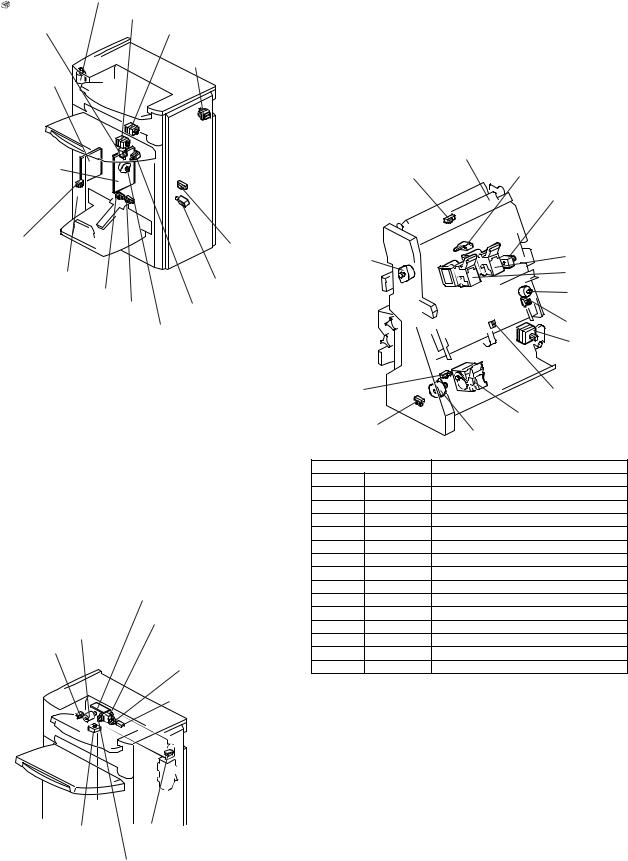

2. Electric parts layout

SOL2

S7

M4

SOL1 |

M2 |

S10 |

|

||

|

|

M19 |

S11 |

|

S1 |

M18 |

|

S5 |

S9 |

S8 |

S12 |

|

S6 |

Tray upper limit |

|

|

|

SW |

M10 |

S13 |

Signal name |

Parts name |

|

M2 |

UPTRS_M |

Upper transport motor |

M4 |

EXIT_M |

Paper exit motor |

M10 |

STRLVI_M |

Return roller oscillation motor |

M18 |

SFT_M |

Shift motor |

M19 |

EXGPLT_M |

Paper exit guide plate open/close motor |

S1 |

FINENT |

Inlet sensor |

S5 |

SFTROLHP |

Shift HP sensor |

S6 |

UPTRYEXT |

Shift tray paper exit sensor |

S7 |

EXGPLTHP |

Paper exit guide plate HP sensor |

S8 |

UTRPHNST |

Staple mode paper surface detection |

S9 |

UTRPHSTP |

Shift mode paper surface detection |

S10 |

PRFTRYEX |

Proof tray paper exit sensor |

S11 |

PRFTRYFL |

Proof tray full sensor |

S12 |

UPTRYLMT |

Shift mode rear edge detection |

S13 |

STKROLHP |

Oscillation return roller HP sensor |

SOL1 |

UPJCTG_S |

Proof branch pawl SOL |

SOL2 |

LOJCTG_S |

Staple branch pawl SOL |

- |

- |

Tray upper limit SW |

MX-FNX6 MECHANISM 3 – 1

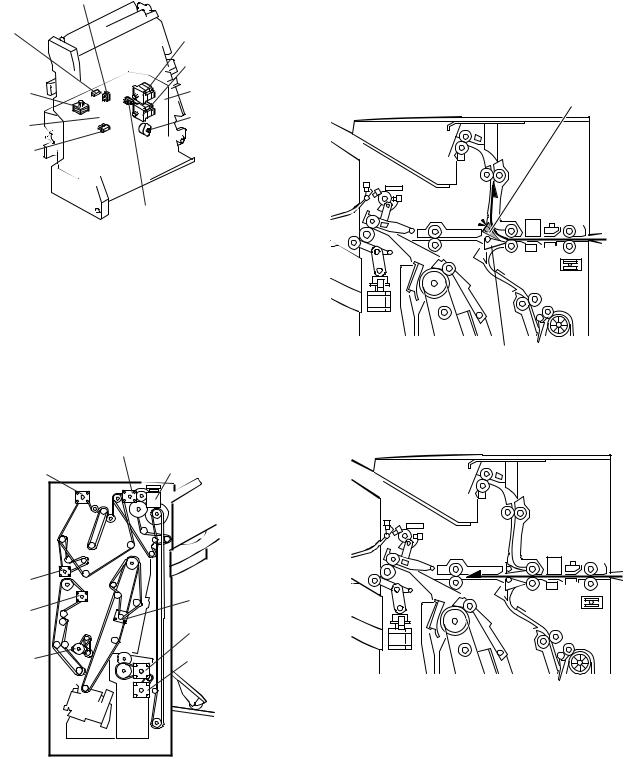

M21

M3

* SOL5 |

M1 |

PCB: STP: |

Door SW |

|

|

Control plate |

|

PCB: Main:

Control plate

* S19

S2

S20

|

|

* S34 |

SOL4 |

|

|

|

|

|

|

* S33 |

SOL3 |

* MX-FNX7 only |

M14 |

|

|

|

|

||

|

|

||

Signal name |

Parts name |

||

M1 |

ENT_M |

Inlet motor |

|

M3 |

LOTRS_M |

Lower transport motor |

|

M14 |

POP_M |

Beating roller drive motor |

|

M21 |

TRYLFT_M |

Tray up/down motor |

|

S2 |

PSTRYEXT |

Staple paper exit sensor |

|

S19 |

UPTRFLSD |

Full sensor: Center binding (*) |

|

S20 |

UPTRFLNS |

Full sensor: Without center binding |

|

S33 |

SDLFLLR |

Center binding tray full sensor (*) |

|

S34 |

SDLFLLF |

Center binding tray full sensor (*) |

|

SOL3 |

POS_S |

Beating SOL |

|

SOL4 |

TEGPRS_S |

Rear edge holding SOL |

|

SOL5 |

SDLPRS_S |

Center binding holding SOL (*) |

|

- |

- |

PCB: STP: Control plate |

|

- |

- |

PCB: Main: Control plate |

|

- |

- |

Door SW |

|

PCB: Punch: Control plate

M7

M24

S24

S22

S3

Signal name |

Parts name |

|

M7 |

STSMOV_M |

Horizontal resist detection sensor shift motor |

M9 |

PNCHMV_M |

Punch shift motor |

M24 |

PNCH_M |

Punch drive motor |

S21 |

PNCHMVHP |

Punch shift HP sensor |

S22 |

PAPPOSHP |

Horizontal resist detection HP sensor |

S24 |

PNCHENC |

Punch HP sensor |

S3 |

PAPPOS |

Horizontal resist detection sensor |

S4 |

PNCHHPFL |

Punch dust full sensor |

- |

- |

PCB: Punch: Control plate |

|

|

* S27 |

|

*S32 |

S16 |

|

|

M5 |

* M17 |

* M23 |

|

|

|

* M22 |

|

|

M15 |

|

|

S15 |

|

|

M6 |

S18 |

|

S14 |

|

|

M20 |

|

S17 |

M13 |

|

|

|

Signal name |

Parts name |

|

M5 |

BLT_M |

Discharge motor |

M6 |

STPMV_M |

Stapler shift motor |

M13 |

STPROT_M |

Stapler slant motor |

M15 |

JOG_M |

Jogger motor |

M17 |

BDJCTG_M |

Bundle branch open/close (*) |

M20 |

STPMOV_M |

Stapler |

M22 |

SDLSTF_M |

Center binding stapler (*) |

M23 |

SDLSTR_M |

Center binding stapler (*) |

S14 |

STPTRPAP |

Stapler tray paper presence sensor |

S15 |

JOGHPS |

Jogger HP sensor |

S16 |

BLTHPS |

Discharge pawl HP sensor |

S17 |

CONSTPHP |

Stapler shift HP sensor |

S18 |

STPROTHP |

Stapler slant HP sensor |

S27 |

STJCTGHP |

Bundle branch open/close HP (*) |

S32 |

STKPRST |

Lead edge detection sensor (*) |

M9 S4

S21

MX-FNX6 MECHANISM 3 – 2

|

* S25 |

* S31 |

* M12 |

|

|

|

* M11 |

* M8 |

* S29 |

* S26 |

* M16 |

|

|

* S28 |

|

|

|

* S30 |

* MX-FNX7 only |

|

|

|

|

|

Signal name |

Parts name |

|

M8 |

DRRLVI_M |

Drive roller oscillation motor (*) |

M11 |

FLDPLT_M |

Folding plate drive motor (*) |

M12 |

FLDROL_M |

Folding roller motor (*) |

M16 |

TALFNC_M |

Rear edge fence motor (*) |

S25 |

CLPROLHP |

Drive roller HP sensor (*) |

S26 |

FLDUNENT |

Reach sensor (*) |

S28 |

FLDBTMHP |

Rear edge fence HP sensor (*) |

S29 |

FLDPLTHP |

Folding plate HP sensor (*) |

S30 |

FLDCMHP |

Folding HP sensor (*) |

S31 |

FLDUNEXT |

Folding pass sensor (*) |

3. Drive layout

|

M4 |

M2 |

M21 |

|

|

M1 |

|

|

M5 |

M3 |

|

|

* M12 |

M14 |

* M11 |

* MX-FNX7 only |

|

Signal name |

Parts name |

|

M1 |

ENT_M |

Inlet motor |

M2 |

UPTRS_M |

Upper transport motor |

M3 |

LOTRS_M |

Lower transport motor |

M4 |

EXIT_M |

Paper exit motor |

M5 |

BLT_M |

Discharge motor |

M11 |

FLDPLT_M |

Folding plate drive motor (*) |

M12 |

FLDROL_M |

Folding roller motor (*) |

M14 |

POP_M |

Beating roller drive motor |

M21 |

TRYLFT_M |

Tray up/down motor |

4. Branch mechanism

1)Paper is branched to the three directions by the proof branch pawl and the staple branch pawl.

2)In the proof mode, when discharging to the proof tray, copy paper is transported to the proof tray by the proof branch pawl.

When in the proof mode:

Staple branch pawl

Proof branch pawl

3)In the shift mode, the proof branch pawl and the staple branch pawl do not operate, and copy paper is transported to the shift tray.

In the shift mode:

MX-FNX6 MECHANISM 3 – 3

4)In the staple mode, the staple branch pawl operates to transport copy paper to the staple section.

In the staple mode:

Staple branch pawl

5. Pre-stack mechanism

Four sheets can be discharged with max. three sheets of pre-stack. In the example below, descriptions are made on discharge of three sheets with two sheets of pre-stack.

1) Stapling the first set is performed.

2nd sheet of 2nd set

1st sheet of 2nd set

Bundle of 1st set

2)The first sheet of the second set is switch-back transported to the pre-stack tray.

Pre-stack tray

3)The first sheet of the second set is transported from the prestack tray. At the same time, transport of the second sheet of the second set is started.

4)Transport of the first sheet of the second set is completed. At the same time, the rear edge of the second sheet of the second set passes the branch pawl.

Pre-stack Branch pawl

5)The first sheet and the second sheet of the second set are switch-back transported together to the pre-stack tray.

6)Stapling of the first set is completed. At the same time, the first sheet and the second sheet of the second set are transported together from the pre-stack. Transport of the third sheet of the second set is also started.

3rd sheet of 2nd set

MX-FNX6 MECHANISM 3 – 4

Loading...

Loading...