Samsung ML-1630 Service Manual

ML-1630

ML-1630/XFA

Basic Model : ML-1630

SERVICE Manual

DIGITAL LASER PRINT |

The keynote of Product |

Slim Size Laser Printer (ML-1630/ML-1630S)

- Printing Speed : 16PPM(A4), 17PPM(Ltr) - Interface : USB 2.0

- Paper Input Capacity : 100 sheets - Paper Output Capacity : 30 sheets - Engine Life : 50,000 Pages

- Toner : Initial(1K) / Sales(2K)

ML-1630

Contents

1.Precautions

1.1Safety Warning

1-1

1-1

1.2Caution for safety

1-2

1-2

1.3ESD Precautions

1-5

1-5

2.Product specification and feature

2.1Product Specifications

2-1

2-1

2.1.1Product Overview

2-1

2-1

2.1.2Specifications

2-1

2-1

2.1.3Model Comparison Table

2-4

2-4

2.1.4ACCESSORY

2-6

2-6

2.2Summary of Product

2-7

2-7

2.2.1Printer Components

2-7

2-7

2.2.2System Layout

2-13

2-13

2.2.3System Description

2-14

2-14

2.2.4S/W Descriptions

2-21

2-21

3.Disassembly

3.1General Precautions on Disassembly

3-1

3-1

3.2Cover Unit

3-2

3-2

3.3Cassette

3-6

3-6

3.4LSU Unit

3-8

3-8

3.5 Drive Unit |

3-9 |

3.6Main Board

3-10

3-10

3.7HVPS Board

3-11

3-11

3.8SMPS Board

3-12

3-12

3.9Fuser Unit

3-13

3-13

Continued

3.10Transfer Roller

3-14

3-14

4.Adjustment and Troubleshooting

4.1Alignment and Adjustments

4-1

4-1

4.1.1Control Panel

4-1

4-1

4.1.2Status of OP Panel

4-2

4-2

4.1.3Manu Map

4-9

4-9

4.1.4Report Printing Condition

4-11

4-11

4.1.5Table. Periodic Images according to Rollers

4-11

4-11

4.1.6Paper Path and Jam Error Solution

4-12

4-12

4.1.7Error Messages

4-19

4-19

4.2Troubleshooting

4-20

4-20

4.2.1Procedure of Checkig the Symptoms

4-20

4-20

4.2.2The cause and solution of image quality

4-21

4-21

4.2.3 |

The cause and solution of the paper feeding |

4-33 |

4.2.4 |

The cause and solution of the malfunction |

4-39 |

5.Exploded Views & Parts List

5.1Main

5-2

5-2

5.2Cover Top

5-4

5-4

5.3Cover Lower

5-6

5-6

5.4Frame Upper

5-8

5-8

5.5Frame Lower

5-10

5-10

5.6Main Drive

5-14

5-14

5.7Fuser

5-16

5-16

5.8Cassette

5-18

5-18

Continued

6.System Diagram

6.1Block Diagram

6-1

6-1

6.2Connection Diagram

6-2

6-2

7.Reference information

7.1Tool for Troubleshooting

7-1

7-1

7.2Acronyms and Abbreviations

7-2

7-2

7.3Select a location for the printer

7-4

7-4

7.4Sample Tests Patterns

7-5

7-5

7.5Parts Life Cycle Maintenance Table

7-6

7-6

7.5.1Parts Life Cycle Maintenance Table

7-6

7-6

7.5.2Toner Cartridge Criterion

7-6

7-6

7.6Model Information

7-7

7-7

7.6.1Understanding for Model Code

7-7

7-7

7.6.2 Understanding Material Code & Name |

7-8 |

7.6.3 F/W Upgrade Method

7-8

7-8

1 Precautions

1. Precautions

The cautions below are items needed to keep in mind when maintaining and servicing.

Please read carefully and keep the contents in mind to prevent accidents while servicing and to prevent the machine from getting damaged.

1.1 Safety Warning

(1) Request service by qualified service person.

Service for this machine must be performed by a Qualified service person. It is dangerous if unqualified service personnel or users try to fix the machine.

(2) Do not rebuild.

Do not attach or change parts discretionary. Do not dissemble, fix of rebuilt it. If so, printer will abnormally work and electric shock or fire may occur.

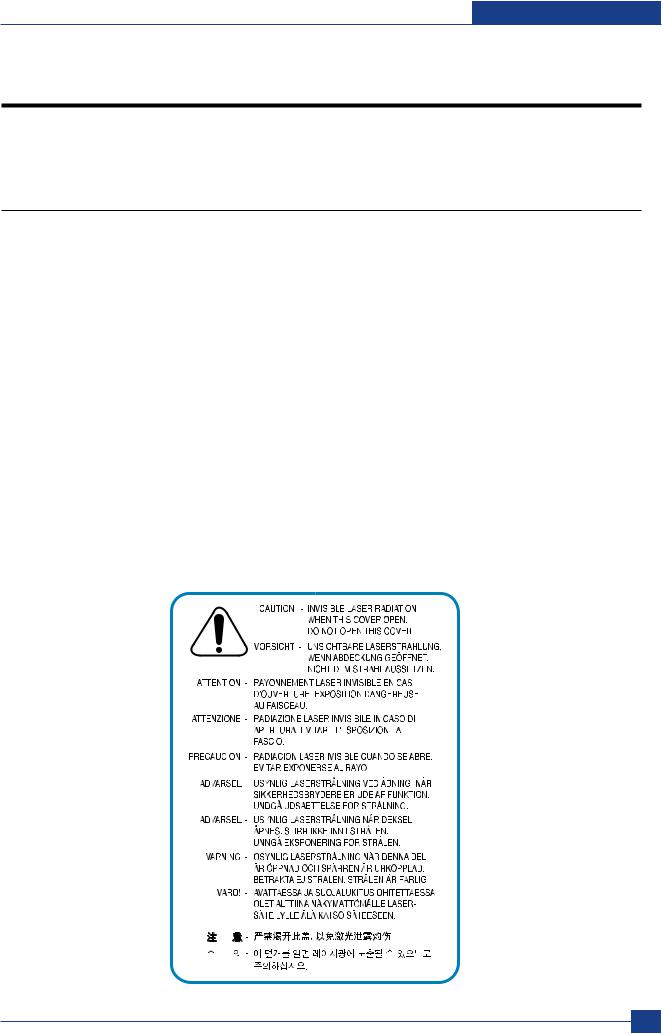

(3) Laser Safety Statement

The Printer is certified in the U.S. to conform to the requirements of DHHS 21 CFR, chapter 1 Subchapter J for Class 1(1) laser products, and elsewhere, is certified as a Class I laser product conforming to the requirements of IEC 825.

Class I laser products are not considered to be hazardous. The laser system and printer are designed so there is never any human access to laser radiation above a Class I level during normal operation, user maintenance, or prescribed service condition.

Warning >> Never operate or service the printer with the protective cover removed from Laser/Scanner assembly. The reflected beam, although invisible, can damage your eyes. When using this product, these basic safety precautions should always be followed to reduce risk of fire, electric shock, and injury to persons.

Samsung Electronics |

Service Manual |

1-1 |

|

||

|

|

Precautions

1.2 Caution for safety

1.2.1 Noxious Material Precaution

The toner in a printer cartridge contains a chemical material, which may harm human body if it is swallowed. Please keep children out of reach of the toner cartridge.

1.2.2 Electric Shock or fire Precaution

It is possible to get electric shock or burn by fire if you don't fallow the instructions of the manual.

(1)Use exact voltage. Please use an exact voltage and wall socket. If not, a fire or an electric leakage can be caused.

(2)Use authorized power cord. Do use the power cord supplied with PRINTER. A fire can happen when over current flows in the power cord.

(3)Do not insert many cords in an outlet. A fire can be occurred due to flow over current in an outlet.

(4)Do not put water or extraneous matter in the PRINTER. Please do not put water, other liquid, pin, clip, etc. It can cause a fire, electric shock, or malfunction. If this occurs, turn off the power and remove the power plug from outlet immediately.

(5)Do not touch the power plug with wet hand. When servicing, remove the power plug from outlet. Do not insert or take off it with wet hand. Electric shock can be occurr.

(6)Caution when inserting or taking off the power plug. The power plug has to be inserted completely. If not, a fire can be caused due to poor contact. When taking off the power plug, grip the plug and take it off. If grip the line and pull over, it could be damaged. A fire or electric shock could happen.

(7)Management of power cord. Do not bend, twist, or bind it and place other materials on it. Do not fix with staples. If the power cord gets damaged, a fire or electric shock can happen. A damaged power cord must be replaced immediately. Do not repair the damaged part and reuse it. A repaired part with plastic tape can be cause a fire or electric shock. Do not spread chemicals on the power cord. Do not spread insecticide on the power cord. A fire or electric shock can be happen due to thinner(weak) cover of the power cord.

(8)Check whether the power outlet and the power plug are damaged, pressed, chopped, or blazing fire or not. When such inferiorities are found, repair it immediately. Do not make it pressed or chopped when moving the machine.

(9)Caution when there is thundering or lightning, and being flash of lightening. It causes a fire or electric shock. Take the power plug off there is thunder. Do not touch cable and device when thundering and flash of lightening.

(10)Avoid the place where is moisture or has dust. Do not install the printer where lots of dust or around humidifier. A fire can occurred. A plug part need to clean well with dried fabric to remove dust. If water drops are dripped on the place covered with dust, a fire can occurred.

(11)Avoid direct sunlight. Do not install the printer near window where direct contacts to the sunlight. If the machine contacts sunlight long time, the machine cannot work properly because inner temperature of the machine is getting hotter. A fire can occur.

(12)Turn off the power and take off the plug when smoke, strange smell, or sound from the machine. If you keep using it, a fire can be occurred.

(13)Do not insert steel or metal piece inside/outside of the machine. Do not put steel or metal piece into a ventilator. An electric shock could happened.

1-2 Service Manual

Samsung Electronics

Precautions

1.2.3 Handling Precautions

If you ignore this information, you could harm machine and could be damaged.

(1)Do not install it on different levels, or slanted floor.

Please confirm whether it is balanced or not after installation. If it is unbalanced, an accident can be happened due to the machine falling over.

(2)Be careful not to insert a finger or hair in the rotating unit.

Be careful not to insert a finger of hair in the rotating unit (motor, fan, paper feeding part, etc) while the machine is operating. Once it happens, you could be harmed.

(3)Do not place a pot containing water/chemical or small metals. If they got caught into the inner side of machine, a fire or electric shock can be occurred.

(4)Do not install it where lots of moisture or dust exists or where raindrop reaches. A fire or electric shock can be caused.

(5)Do not place a candlelight, burning cigarette, and etc. on the machine. Do not install it near to heater. A fire can be occurred.

1.2.4 Assembly/Disassembly precaution

When replacing parts, do it very carefully. Memorize the location of each cable before replace parts for reconnecting it afterwards. Do memorize. Please perform the steps below before replace or disassembly the parts.

(1)Check the contents stored in the memory. All the information will be erased after replacing main board. The information needed to keep has to be written down.

(2)Before servicing or replacing electric parts, take off a plug.

(3)Take off printer cables and power cord connected to printer.

(4)Do use formal parts and same standardized goods when replacing parts.Must check the product name, part cord, rated voltage, rated current, operating temperature, etc.

(5)Do not give an over-force when release or tighten up the plastic parts.

(6)Be careful not to drop the small parts such as screws in the printer.

(7)Be careful not to change the location of small parts such as screws when assembling and disassembling.

(8)Do remove dust or foreign matters completely to prevent fire of tracking, short, or etc.

(9)After finished repair, check the assembling state whether it is same as before the repair or not.

Samsung Electronics |

Service Manual |

1-3 |

|

||

|

|

Precautions

1.3 ESD Precautions

Certain semiconductor devices can be easily damaged by static electricity. Such components are commonly called “Electrostatically Sensitive (ES) Devices”, or ESDs. Examples of typical ESDs are: integrated circuits, some field effect transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help reduce the incidence of component damage caused by static electricity.

Caution >>Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

1.Immediately before handling a semiconductor component or semiconductor-equipped assembly, drain off any electrostatic charge on your body by touching a known earth ground. Alternatively, employ a commercially available wrist strap device, which should be removed for your personal safety reasons prior to applying power to the unit under test.

2.After removing an electrical assembly equipped with ESDs, place the assembly on a conductive surface, such as aluminum or copper foil, or conductive foam, to prevent electrostatic charge buildup in the vicinity of the assembly.

3.Use only a grounded tip soldering iron to solder or desolder ESDs.

4.Use only an “anti-static” solder removal device. Some solder removal devices not classified as “anti-static” can generate electrical charges sufficient to damage ESDs.

5.Do not use Freon-propelled chemicals. When sprayed, these can generate electrical charges sufficient to damage ESDs.

6.Do not remove a replacement ESD from its protective packaging until immediately before installing it. Most replacement ESDs are packaged with all leads shorted together by conductive foam, aluminum foil, or a comparable conductive material.

7.Immediately before removing the protective shorting material from the leads of a replacement ESD, touch the protective material to the chassis or circuit assembly into which the device will be installed.

8.Maintain continuous electrical contact between the ESD and the assembly into which it will be installed, until completely plugged or soldered into the circuit.

9.Minimize bodily motions when handling unpackaged replacement ESDs. Normal motions, such as the brushing together of clothing fabric and lifting one’s foot from a carpeted floor, can generate static electricity sufficient to damage an ESD.

1-4 Service Manual

Samsung Electronics

Product specification and feature

22. Product specification and feature

2.1 Product Specifications

2.1.1 Product Overview

- 16ppm (A4) / 17ppm (Ltr.) - USB 2.0

- 100 sheet cassette tray - Up to 600 x 600 dpi

- Low Noise System ( 45dB )

- Noiseless Paper-path for Slim Size Feeding System

- Two Lamp Fusing System

2.1.2Specifications

Product Specifications are subject to change without notice. See below for product specifications.

Product Specifications are subject to change without notice. See below for product specifications.

2.1.2.1 General Spec.

NO |

|

SPEC. |

ML-1630 |

1 |

|

SIZE(WxDxH) |

332*375*120mm |

2 |

NOISE |

WARMING UP |

43dBA |

|

|

READY |

38dBA |

|

|

PRINTING/COPYING |

45dBA |

3 |

WEIGHT |

NET(Inc. CRU) |

6.4kg |

|

|

GROSS(Inc. PACKING) |

7.8kg |

|

|

|

|

Samsung Electronics |

Service Manual |

2-1 |

|

||

|

|

Product specification and feature

Item |

Specifications and Description |

|

|

Paper input capacity a |

100 multi-pages for plain paper (20 lb bond, 75 g/m 2 ) |

|

|

Paper output capacity |

30 sheets (face up) |

Consumables |

1-piece print cartridge system |

|

|

Power rating |

AC 110 - 127 V or AC 220 - 240 V |

|

See the Rating label on the machine for the correct voltage, frequency (hertz) and |

|

type of current for your machine. |

Power consumption |

Average operation mode: Less than 350 W |

|

Sleep mode: Less than 8.12 W |

|

Power off mode: 0 W |

Noise level b |

Standby mode: Less than 38 dBA |

|

|

Operating environment |

Temperature: 10 °C to 32 °C (50 ° F to 89.6 ° F ) |

|

Humidity: 20% to 80% RH |

Display |

Blue LED Module (65EA Dots) |

Toner cartridge yield c |

Standard Yield: Average cartridge yield 2,000 standard pages. |

|

(Ships with 1,000 pages Starter/Standard Toner Cartridge) |

|

** Declared yield value in accordance with ISO/IEC 19752. |

Memory |

8 MB (Non-extendable) |

External dimension (W x D x H) |

332 x 370 x 120mm (13.1 x 14.6 x 4.7 inches) |

Weight |

6.4 Kg (14.1 lbs) (including consumables) |

Package weight |

Paper: 1.1 Kg (2.431 lbs) |

|

Plastic: 0.271 Kg (0.60 lbs) |

|

|

Duty cycle |

Monthly print volume: Up to 4,000 pages |

|

|

2-2 Service Manual

Samsung Electronics

Product specification and feature

2.1.2.2 Printer Spec.

|

Item |

ML-1630 |

Remark |

Overview |

Function |

|

|

|

|

|

|

Speed (Mono) |

Up to 16 ppm in A4(17 ppm in Letter) |

|

|

|

|

|

|

|

First Print Out Time (Mono) |

15 seconds(From Cold Start) |

|

|

Resolution |

600 x 600 dpi |

|

|

Emulation |

SPL (Samsung Printer Language) |

|

|

|

|

|

|

Duplex |

N/A |

|

|

|

|

|

Paper Handling |

Input Capacity and Types |

100-sheet Auto sliding Cassette |

|

|

Output Capacity and Types |

30 sheets, Face-Up |

|

|

|

|

|

|

Media Size |

A4, A5, A6, Letter, Executive,ISO B5, JIS B5 |

|

|

|

|

|

|

Media Type |

Plain,Thin,Thick,Bond,OHP,Label,Cardstock |

|

General |

Processor |

Samsung 150 Mhz |

|

|

Memory / Storage |

8MB |

|

|

|

|

|

|

OS Compatibility |

Windows 2000/XP(32/64 bit)/2003 Server/Vista |

|

|

|

|

|

|

Interface |

Hi-Speed USB 2.0 |

|

|

Noise Level |

Less than 45 dBA (Printing) |

|

|

|

|

|

|

Duty Cycle, Monthly |

Up to 5,000 pages |

|

|

|

|

|

|

Dimension (W x D x H) |

332 x 375 x 121.5 mm |

|

|

|

|

|

|

Weight |

5.5kg |

|

Consumables |

Yield |

Average Cartridge Yield 2,000 standard pages. |

|

|

|

(Ships with 1,000 pages Starter Toner Cartridge) |

|

|

Type |

Single Cartridge |

|

|

|

|

|

|

Model Code |

ML-D1630 |

|

|

|

|

|

Maintenance

Maintenance

Items |

Yield (Average) |

|

|

Transfer roller |

Approx. 50,000 pages |

|

|

Fuser unit |

Approx. 50,000 pages |

|

|

Paper feed roller |

Approx. 50,000 pages |

|

|

Samsung Electronics |

Service Manual |

2-3 |

|

||

|

|

Product specification and feature

2.1.3 Model Comparison Table

Model (SEC)

Model (SEC)

Laser MFP SCX-4500 |

Laser Printer ML-1630 |

General |

Size (W*D*H) |

332*420*164mm |

320*358*115mm |

|

Input Capacity |

100 sheets |

|

|

Output Capacity |

30 sheets |

|

|

|

|

|

|

Engine Life |

50,000 sheets |

|

|

Toner |

2K (Initial 1K) |

|

|

Interface |

USB 2.0 |

|

|

Dimension (W x D x H) |

Max 45 dBA |

|

|

|

|

|

Printer |

Speed |

16ppm(A4) |

|

|

|

|

|

|

FPOT |

Less than 15 sec (from cold start) |

Less than 10 sec (from cold start) |

|

|

|

|

Copy |

Resolution |

600 dpi |

X |

|

Speed |

16cpm(A4) |

X |

Scan |

Resolution |

600 dpi |

X |

|

Scan Module |

Color CIS |

X |

Mech Comparison (SCX-4500/ML-1630)

Mech Comparison (SCX-4500/ML-1630)

UNIT |

Part |

Logan |

Swan |

|

|

SCX-4500 |

ML-1630 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-4 Service Manual

Samsung Electronics

Product specification and feature

Competitor Model

Competitor Model

|

ITEM |

ML-1630 |

Brother |

HP |

|

|

|

HL-2040 |

LJ-1020 |

|

|

|

|

|

General |

Size (W*D*H) |

320*358*115mm |

371*361*165mm |

370*242*209mm |

|

|

|

|

|

|

Interface |

USB 2.0 |

USB 2.0, Parallel |

USB 2.0 |

Printing |

Noise |

Max 45 dBA |

- |

- |

|

|

|

|

|

|

Speed |

16 ppm(A4) |

20 ppm(A4) |

14 ppm(A4) |

|

FPOT |

Less than 10 sec |

Less than 10 sec |

Less than 10 sec |

Paper |

Input Capacity |

100 sheets |

250 sheets |

150 sheets |

|

|

|

|

|

|

Output |

Face Up |

Face Down |

Face Up |

|

Output Capacity |

30 sheets |

100 sheets |

150 sheets |

|

|

|

|

|

Life |

Engine |

50,000 Pages |

- |

- |

|

Toner |

2K |

1.5K/2.5K (Drum 12K) |

2K |

|

|

|

|

|

Samsung Electronics |

Service Manual |

2-5 |

|

||

|

|

Product specification and feature

2.1.4 ACCESSORY

No. |

Item |

Code |

Quantity |

1 |

INA-ACESSORY |

JC99-02061D |

- |

2 |

PE-BAG |

6902-000809 |

1 |

3 |

LABEL(P)-BLANK 90*25 |

JC68-01584A |

1 |

4 |

COVER PAPER |

JC61-02123A |

1 |

5 |

POWER CORD |

3903-000042 |

1 |

6 |

USB Cable |

JC39-00001A |

1 |

7 |

Driver-CD |

JC46-00348A |

1 |

8 |

MANUAL-(CARD)WARRANTY CARD |

JC68-00690A |

1 |

9 |

MANUAL-SERVICE CARD |

JC68-00421A |

1 |

|

|

|

|

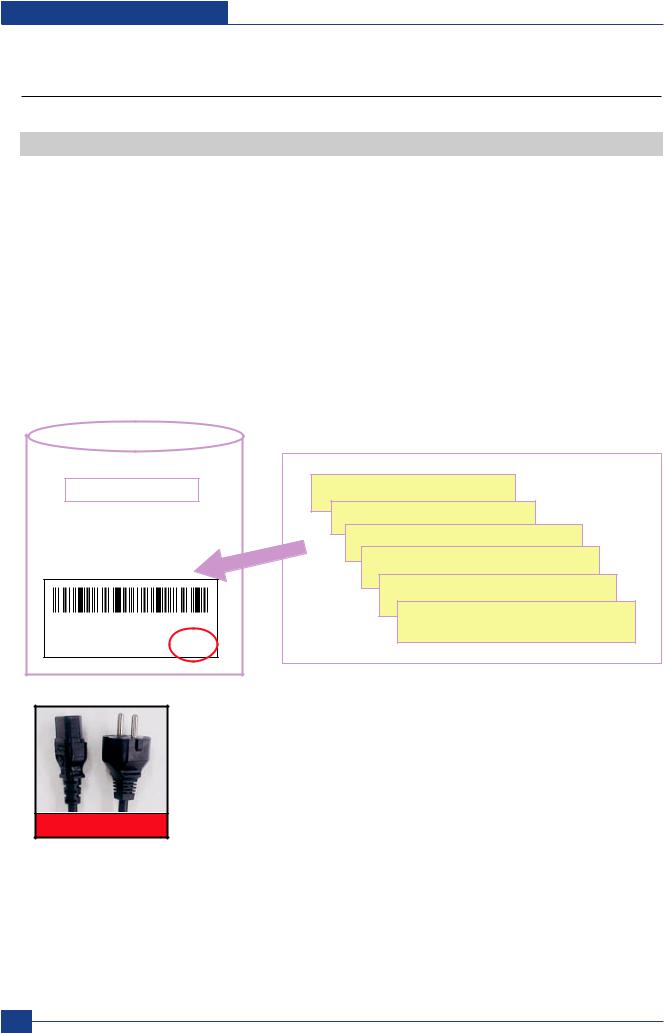

ACCESSORY BAG |

|

KRA1JC99-02061D C100X8C0028 |

|

SCX-4500/XEV |

ED:?? |

|

|

1 COVER PAPER |

2 POWER CORD |

3 USB Cable |

4 Driver-CD |

5 MANUAL-(CARD)WARRANTY CARD |

6 MANUAL-SERVICE CARD |

3903-000042

2-6 Service Manual

Samsung Electronics

Product specification and feature

2.2 Summary of Product

This chapter describes the functions and operating principal of the main component.

2.2.1 Printer Components

2.2.1.1 Front View

1

4

2

3

4

5

6

7

8

9

1 |

control panel |

6 |

tray open button |

2 |

top cover |

7 |

top cover lever |

3 |

output tray |

8 |

print cartridge |

4 |

output support |

9 |

inner cover |

5tray

Samsung Electronics |

Service Manual |

2-7 |

|

||

|

|

Product specification and feature

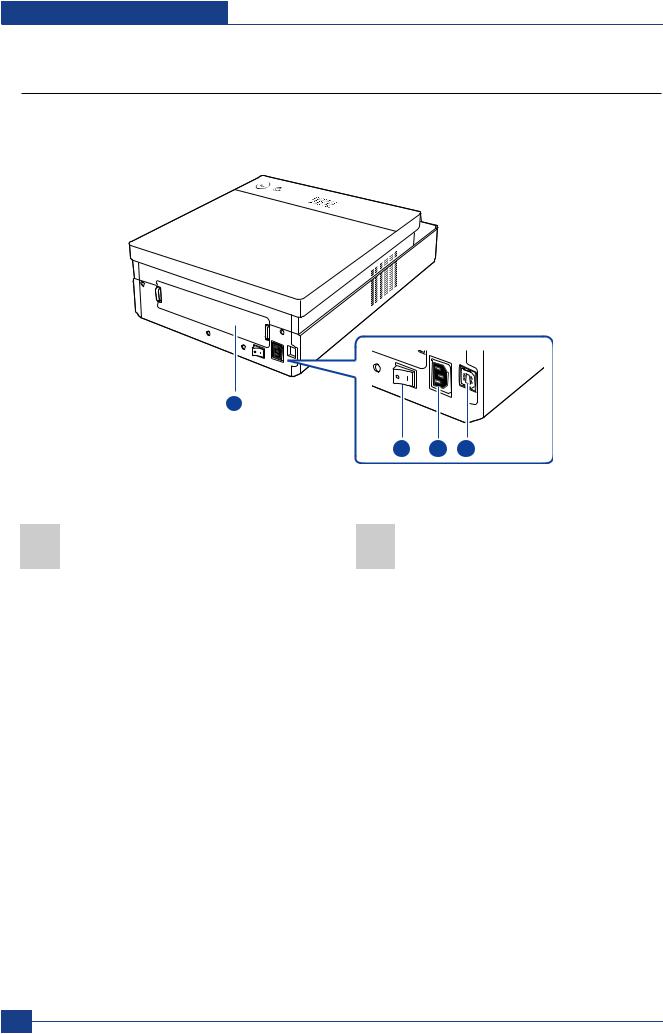

2.2.1.2 Rear View

1

2 3 4

1 |

rear cover |

3 |

power receptacle |

2 |

power switch |

4 |

USB port |

|

|

|

|

2-8 Service Manual

Samsung Electronics

Product specification and feature

2.2.1.2(a) Feeding Section

Feeding Method : Universal Cassette Type

Feeding Method : Universal Cassette Type

Feeding Standard : Center Loading

Feeding Standard : Center Loading

Feeding Capacity : Cassette 100 Sheets(75g/

Feeding Capacity : Cassette 100 Sheets(75g/ , 20lb Paper Standard)

, 20lb Paper Standard)

Cassette 1 Sheet(Paper, OHP, etc.)

Paper Detecting Sensor : Photo Sensor

Paper Detecting Sensor : Photo Sensor

Paper Size Sensor : N/A

Paper Size Sensor : N/A

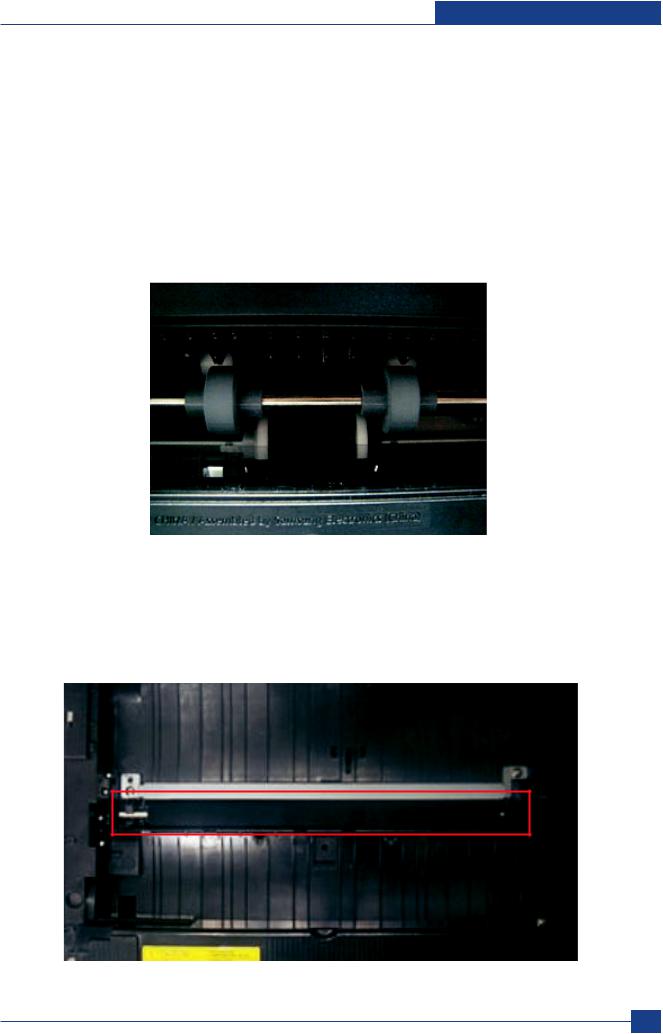

2.2.1.2(b) Transfer Ass'y

Life Span : Print over 50,000 Sheets(in 15~30

Life Span : Print over 50,000 Sheets(in 15~30 )

)

Transfer roller

Samsung Electronics |

Service Manual |

2-9 |

|

||

|

|

Product specification and feature

2.2.1.2(c) Driver Ass'y

By driving the motor, it supplies power to the feeding unit, the fusing unit, and the distributing unit.

By driving the motor, it supplies power to the feeding unit, the fusing unit, and the distributing unit.

In ML-1630 Series, latch gear is used for an easy jam removal at gear drv fuser

In ML-1630 Series, latch gear is used for an easy jam removal at gear drv fuser

2.2.1.2(d) Fuser Ass'y

Halogen Lamp - Control the Fusing Temperature by Heating

Halogen Lamp - Control the Fusing Temperature by Heating

Thermostat - Temperature Intercepting Device, Open 170 c (Receptacle type)

Thermostat - Temperature Intercepting Device, Open 170 c (Receptacle type)

Heat Roller - Teflon Coating

Heat Roller - Teflon Coating

Pressure Roller - Silicon, the Same as one of Oriole (ML-2571N)

Pressure Roller - Silicon, the Same as one of Oriole (ML-2571N)

Thermistor - Temperature Detecting Sensor

Thermistor - Temperature Detecting Sensor

2-10 Service Manual

Samsung Electronics

Product specification and feature

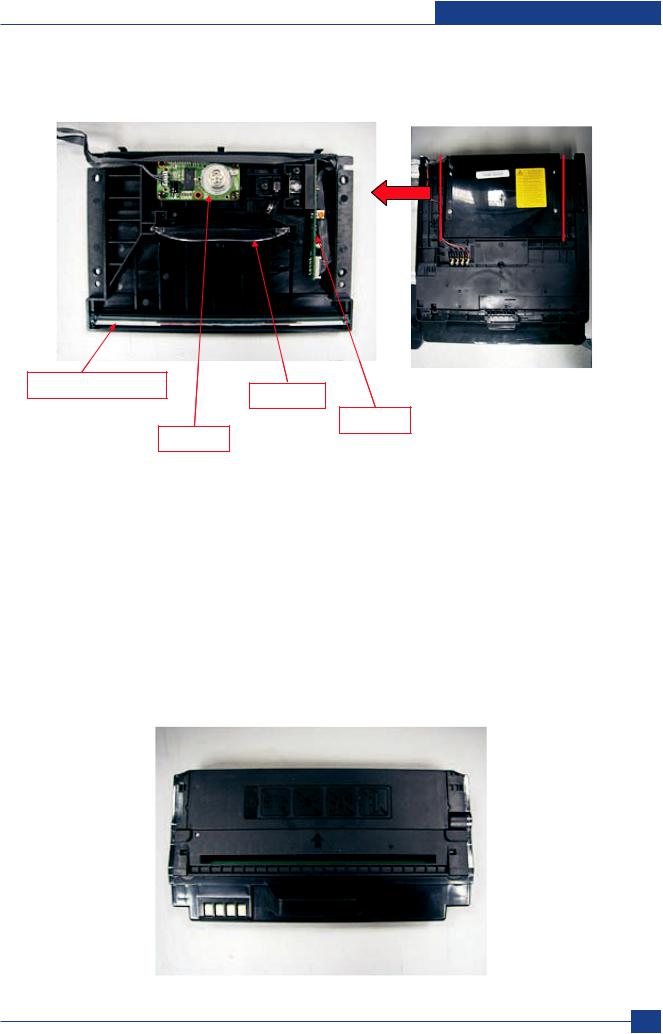

2.2.1.2(e) LSU(Laser Scanner Unit)

Reflection mirror

F -Lens

-Lens

LD PCB

P/Motor

2.2.1.2(f) Toner Cartridge

Developing Method : Non-magnetic 1 element contacting method

Developing Method : Non-magnetic 1 element contacting method

Toner : Non-magnetic 1 element shatter type toner

Toner : Non-magnetic 1 element shatter type toner

Toner remaining amount detecting sensor : None

Toner remaining amount detecting sensor : None

The life span of toner : 2,000 Sheets(ISO 19752 Standard Pattern)

The life span of toner : 2,000 Sheets(ISO 19752 Standard Pattern)

OPC Cleaning : Collect the toner by using electric static + FILM OPC

OPC Cleaning : Collect the toner by using electric static + FILM OPC

Management of disused toner : Collect the toner by using electric static (Non-Cleaner type)

Management of disused toner : Collect the toner by using electric static (Non-Cleaner type)

OPC Drum protecting Shutter : None

OPC Drum protecting Shutter : None

Service Manual 2-11

Samsung Electronics

Product specification and feature

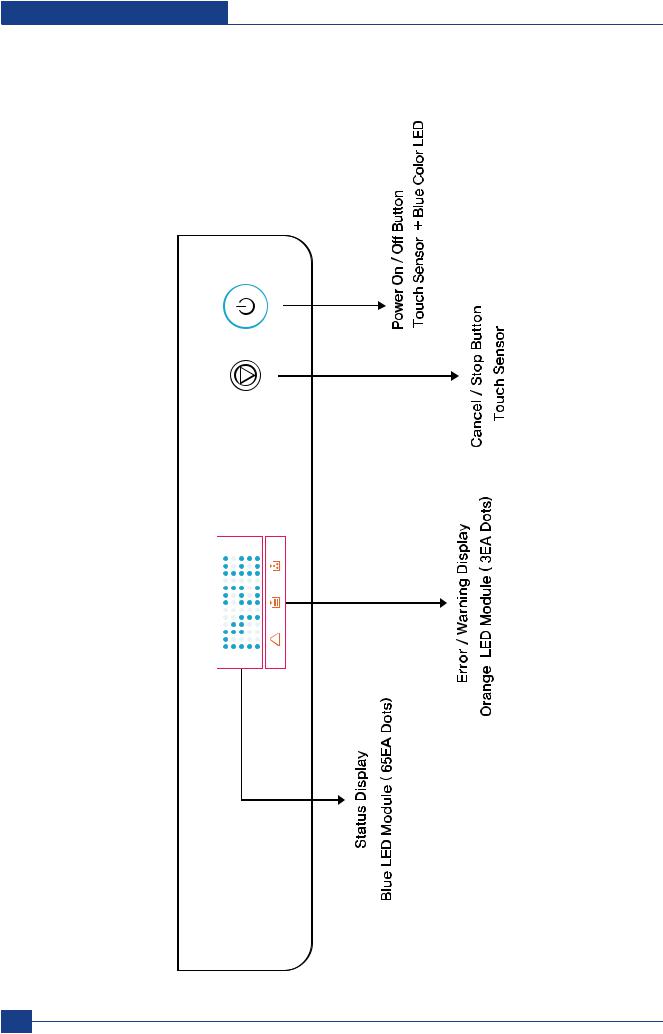

2.2.1.2(g) Panel Part

2-12 Service Manual

Samsung Electronics

Product specification and feature

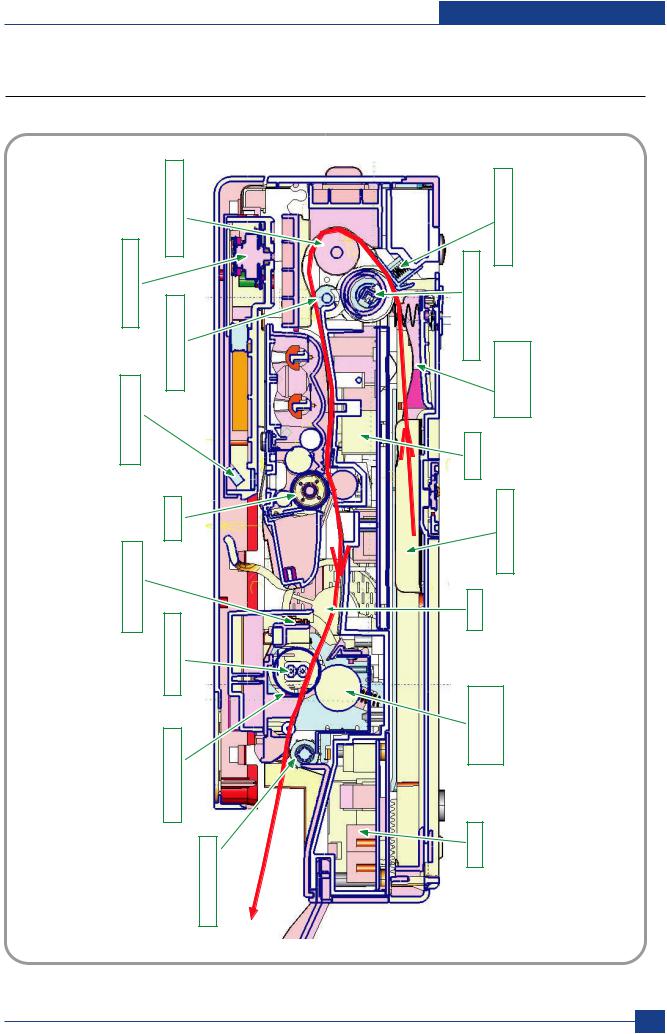

2.2.2 System Layout

MIRROR LSU MOTOR |

REGI. ROLLER FEED ROLLER |

PICK-UP ROLLER |

KNOCK-UP HOLDER PAD |

PLATE |

LSU |

|

SMPS |

|

|

|

OPC |

|

ADJUST |

|

THERMOSTAT |

LAMP |

FAN |

CST |

|

|

DUAL |

PRESSURE |

|

|

|

ROLLER |

ROLLER |

|

|

|

HEAT |

|

|

|

|

ROLLER |

HVPS |

|

|

|

EXIT |

|

|

|

Service Manual 2-13

Samsung Electronics

Product specification and feature

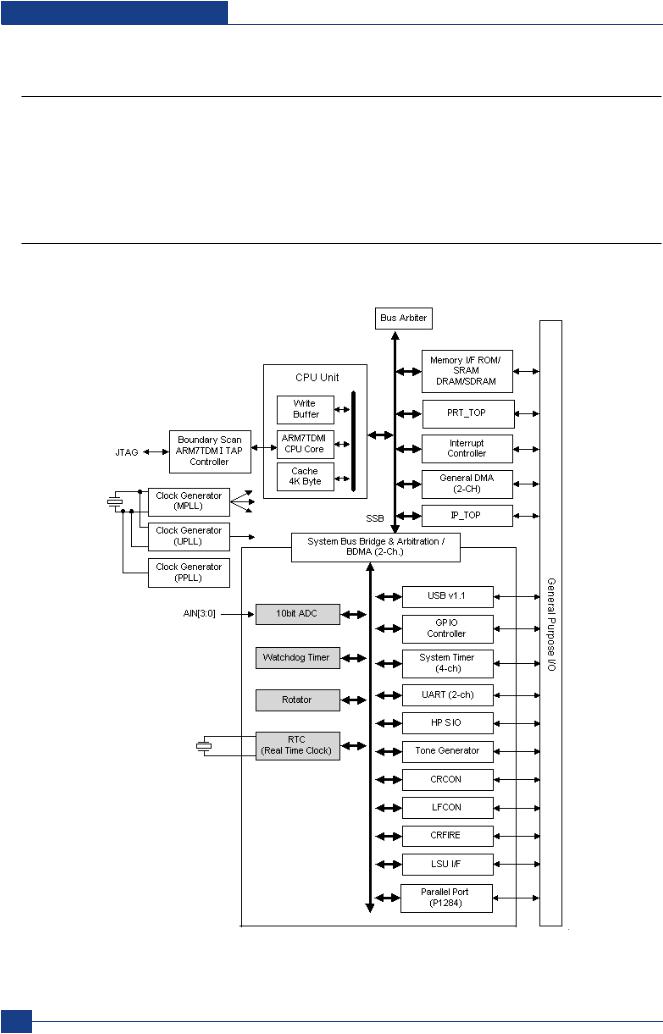

2.2.3 System Description

ML-1630 is roughly made up Main Controller and Operation Panel, SMPS/HVPS part and Engine Part. Main Controller uses Chorus2 for its ASIC, which is on chip micro controller and is composed of 1Mbyte Flash

memory and 8Mbyte SDRAM to control 16Bit Bus. Chorus2 is operated by 66MHz Bus Clock thru internal PLL of 12MHz system Clock.

2.2.3.1 System Structure

2-14 Service Manual

Samsung Electronics

Product specification and feature

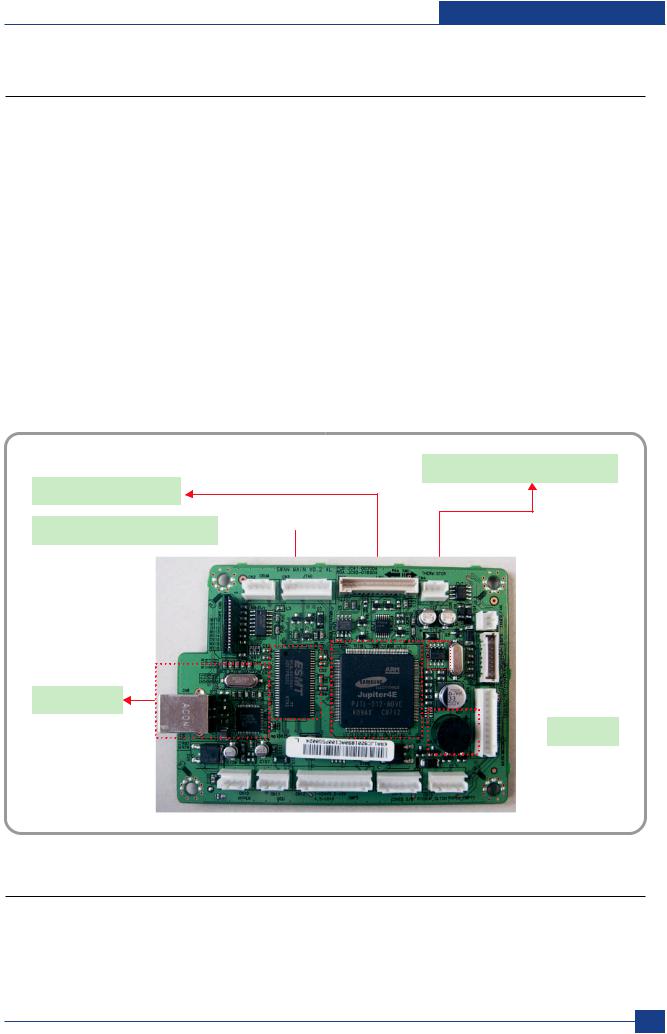

2.2.3.2 Main Controller

ML-1630 is consisted of ASIC(CPU), scan part and print part and Bus Control. I/O Handling, each driver, and PC interface are working controlled by the CPU.

Main Controller has full capability on Main Board. There are 2 major functions in the CPU which are Controller ASIC and Image Processor.

1)CPU : 16Bit RISC Processor, Chrous II for printers and MFPs is used and controls the system operating each operation block by system program in Flash Memory.

2)Flash Memory : saves system program and each parameter used in system, and downloads the system program by

PC Interface.

-Memory : 1 Mbyte

-Access Time : 70 nsec

3)SDRAM : used by Print Buffer while printing, Scan Buffer while scanning, and System Working Memory.

-Memory : 8 Mbyte

-Access Time : 75 nsec

Main Clock and SSCG

CPU - Jupiter4e

SDRAM - 8MB * 1EA

USB 2.0

Buzzer

Buzzer

2.2.3.3 Motor Contorller

Bi-polar Motor is controlled by L6219 Motor Drive IC and is controlled by the output signal of Scan Motor Controller.

Service Manual 2-15

Samsung Electronics

Product specification and feature

2.2.3.4 Panel Part

It adapts CY8C21434 Touch IC interfaces through UART and PT6169 LED Driver IC controls 65 LED matrix and 11 key LEDs.

Touch Sensor IC - TS02N

2.2.3.5 Engine H/W configuration

1) Main Board

Main Board is consist of Engine and Controller on the one-Board.

Main board interfaces PC and communicates with Image Scan and LCD of OPE Panel. Video data comes out from LSU. it senses and controls motor driving, Fuser high voltage, and sensors.

2-16 Service Manual

Samsung Electronics

Product specification and feature

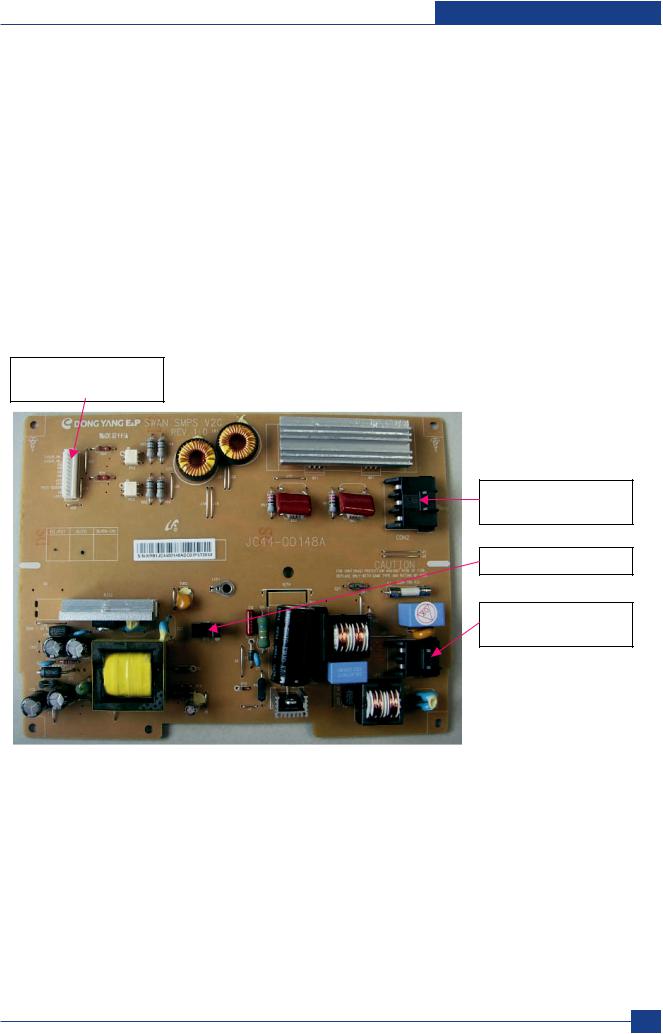

2) SMPS Board

It is consisted of the SMPS part, which supplies the DC power for driving the system, and the AC heater Controller, which supplies the power to fuser.

SMPS has two output channels. Which are 5V and +24V

- AC Input

Input Rated Voltage : AC 110V ~ 127V(V1) , AC 220V ~ 240V(V2)

Input Rated Voltage : AC 110V ~ 127V(V1) , AC 220V ~ 240V(V2)

Input Voltage fluctuating range : AC 99V ~ 135V / AC 198V ~ 255V

Input Voltage fluctuating range : AC 99V ~ 135V / AC 198V ~ 255V

Rated Frequency : 50/60 Hz

Rated Frequency : 50/60 Hz

Frequency Fluctuating range : 47~53Hz(50Hz) , 57~63Hz (60Hz)

Frequency Fluctuating range : 47~53Hz(50Hz) , 57~63Hz (60Hz)

Input Current : Under 4.0Arms / 2.5Arms

Input Current : Under 4.0Arms / 2.5Arms

(But, the status when lamp is off or rated voltage is inputted/outputted )

Main < - > SMPS

Connector

Heat Lamp1, 2

Connector

Paper Feed Sensor

AC Input

Connector

Service Manual 2-17

Samsung Electronics

Product specification and feature

- Rated Output Power

NO |

Items |

CH1 |

CH2 |

Remarks |

1 |

CHANNEL |

+5V |

+24.0V |

|

2 |

CONNECTOR PIN |

CON 2 |

CON 2 |

|

|

|

5V PIN: 2 |

24V PIN: 7, 8 |

|

|

|

GND PIN: 3, 4 |

GND PIN: 5, 6 |

|

3 |

Rated Output |

+5V 5% (4.75 5.25V) |

+24V-10/+15% (21.6 |

27.6V) |

4 |

Max. Output current |

1.0 A |

2.5 A |

|

|

|

|

|

|

5 |

Peak Loading current |

1.3 A |

2.6 A |

1ms |

6 |

RIPPLE NOISE Voltage |

150mVp-p or less |

500mVp-p or less |

|

7 |

Maximum output |

5W |

36W |

|

8 |

Peak output |

7.5W |

60W |

1ms |

9Protection for loading

|

shortage and overflowing |

- |

|

- |

|

|

|

current |

|

|

|

|

|

- Consumption Power |

|

|

|

|

||

|

|

|

|

|

|

|

NO |

Item |

|

CH1 (+5V) |

CH2 (24V) |

|

System |

1 |

Stand-By |

|

0.8 A |

0.4 A |

|

AVG : 70 Wh |

2 |

PRINTING |

|

1.0 A |

1.5 A |

|

AVG : 320 Wh |

3 |

Sleep-Mode |

|

0.3A |

0.25A |

|

AVG : 10 Wh |

|

|

|

|

|

|

|

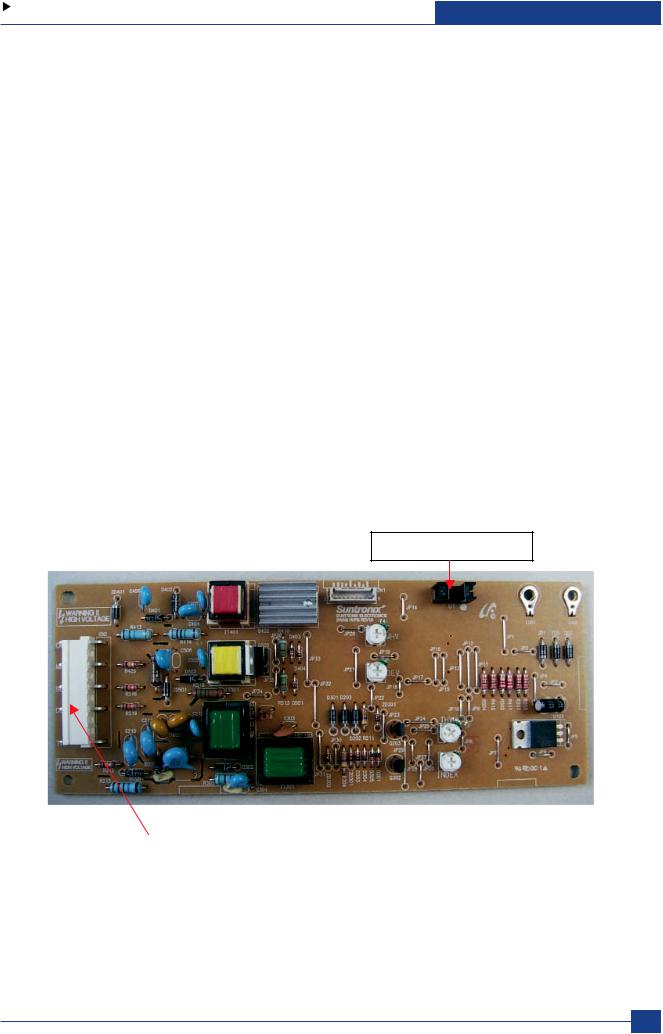

3) HVPS Board

The HVPS part takes the 24V and outputs the high voltage for THV/MHV/BIAS, and the outputted high voltage is supplied to the toner, OPC cartridge, and transfer roller.

Transfer High Voltage (THV+)

Transfer High Voltage (THV+)

-Input Voltage : 24 V DC  15%

15%

-Out Voltage : Max +5.0KV  3

3

-Input Voltage Variation :  3 % below(Variation 21.6V

3 % below(Variation 21.6V 26.4V)

26.4V)

-Out Voltage Rising Time : 100 ms Max

-Out Voltage Falling Time : 100 ms Max

-Transfer Variation Voltage on Environment Variation : +400V ~ 5 KV

-Control Method on environment : THV-PWM ACTIVE, transfer Active signal, of environment sensing voltage is input and get feed back current, and recalculate it to resistance .

-Control method on transfer output voltage : It is controlled by changing its duty of THVPWM Signal as follows.

Charge Voltage (MHV)

Charge Voltage (MHV)

-Input Voltage : 24 V DC  15%

15%

-Out Voltage : -1.2KV ~ -1.8KV DC  3%

3%

-Out Voltage Rising Time : 50 ms Max

-Out Voltage Falling Time : 50 ms Max

2-18 Service Manual

Samsung Electronics

Product specification and feature

-Out Voltage Range : 30 M ~ 1000 M

~ 1000 M

-Output Control Signal(MHV-PWM) : CPU is HV output when PWM is Low

Developing Voltage (DEV)

Developing Voltage (DEV)

-Input Voltage : 24 V DC  15%

15%

-Output Voltage : -220V ~ -450V DC  3%

3%

-Output Voltage Fluctuation range : PWM Control

-Input contrast of the output stability degree :  3 % or less

3 % or less

-Loading contrast :  3 % or less

3 % or less

-Output Voltage Rising Time : 50 ms Max

-Output Voltage Falling Time : 50 ms Max

-Output Loading range : 10M ~ 1000 M

~ 1000 M

-Output Control Signal (BIAS-PWM) : the CPU output is HV output when PWM is low.

Supply

Supply

-Output Voltage : -420 V ~ -650V DC  3% (ZENER using, DEV )

3% (ZENER using, DEV )

-Input contrast of the output stability degree : under  3 %

3 %

-Loading contrast :  3 % or less

3 % or less

-Output Voltage Rising Time : 50 ms Max

-Output Voltage Falling Time : 50 ms Max

-Output Loading range : 10 M ~ 1000 M

~ 1000 M

-Output Control Signal (BIAS-PWM) : the CPU is HV output when PWM is low.

Paper Exit Sensor

OPC |

- 100 V |

|

Main < - > HVPS |

|

|

|

|

|

Connector |

|

|

MHV |

- 1300 V |

||||

|

|

|

|||

|

HVPS board supply high voltage for developing Process. |

||||

|

|

|

|||

SUP |

- 730 V |

||||

|

High Voltage controlled by PWM signal from CPU. |

||||

|

|

|

|||

DEV |

- 430 V |

|

Paper Exit Sensor exists on HVPS. |

||

|

|

|

|

|

|

HV |

+1,300 V |

|

|

|

|

|

|

|

|

|

|

Service Manual 2-19

Samsung Electronics

Product specification and feature

4) FUSER AC POWER CONTROL

Fuser(HEAT LAMP) gets heat from AC power. The AV power controls the switch with the Triac, a semiconductor switch. The 'ON/OFF control' is operated when the gate of the Triac is turned on/off by Phototriac (insulting part).

In other words, the AC Controller is passive circuit, so it turns the heater on/off with taking signal from engine controller. When the 'HEATER ON' signal is turned on at engine, the LED of Photo Triac takes the voltage and flashes.

From the flashing light, the Triac part (light receiving part) takes the voltage, and the voltage is supplied to the gate of Triac and flows into the Triac. As a result, the AC current flows in the heat lamp, and heat is occurred. On the other hand, when the signal is off, the photo triac is off, the voltage is cut off at the gate of Triac, the Triac becomes off, and then the heat lamp is turned off.

-Triac feature :16A, 600V SWITCHING

-Phototriac Coupler

2-20 Service Manual

Samsung Electronics

Product specification and feature

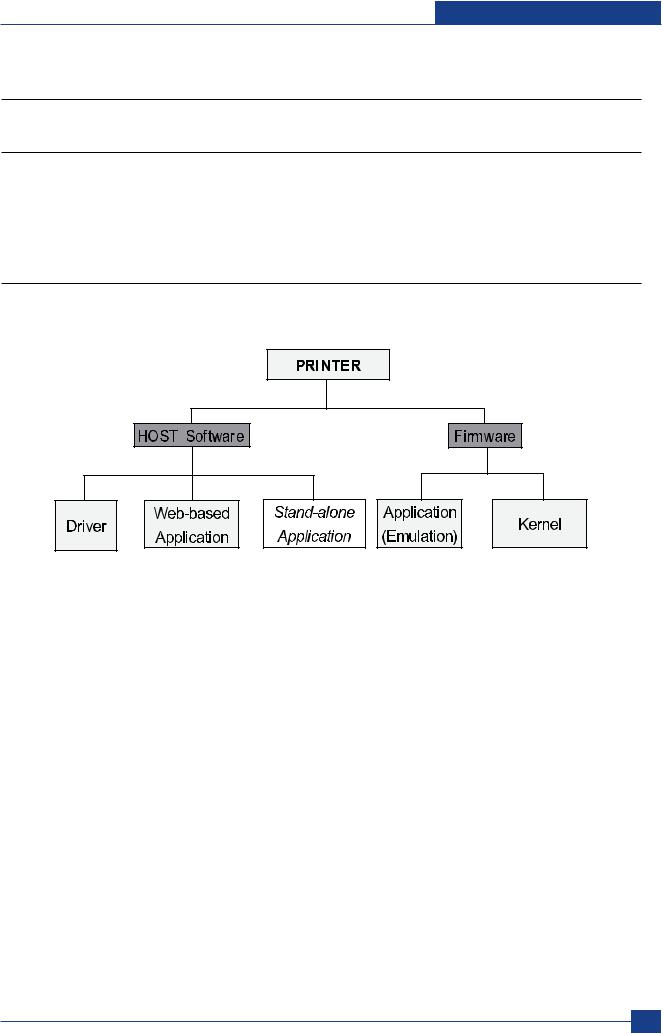

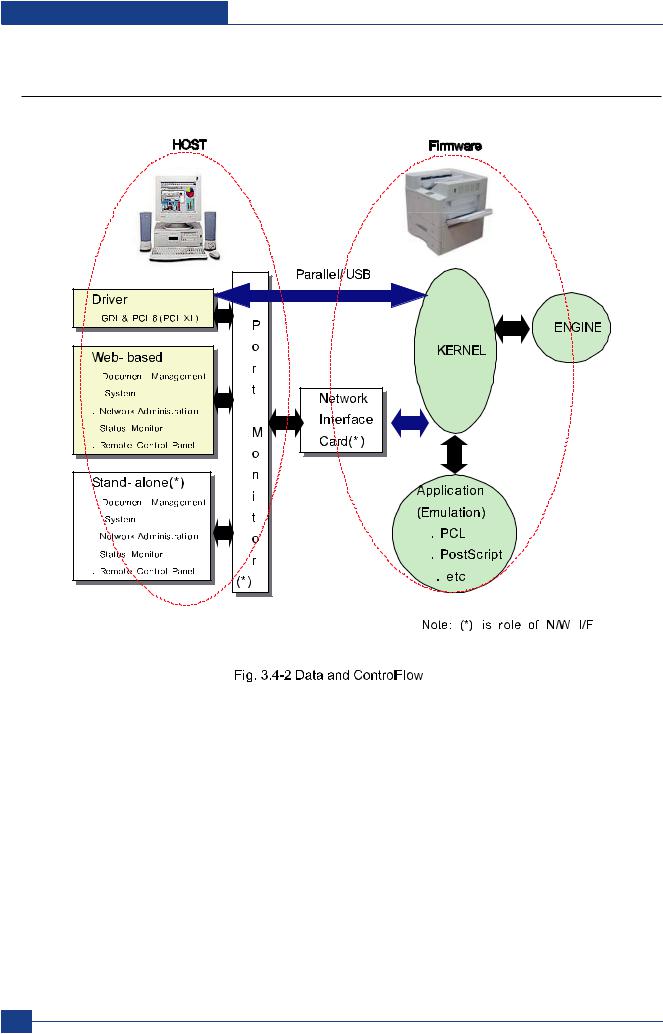

2.2.4 S/W Descriptions

2.2.4.1 Overview

The software of Swan system is constructed with

1)Host Software part that the application software operated in Window and Web Environment, and

2)Firmware parts that is a Embedded software controls printing job.

2.2.4.2 Architecture

Host Software is made up of

1.Graphic User Interface that offers the various editing functions to user in Host,

2.Driver that translates the received document to a Printing Command language which printer can understand and transfers data to spooler,

3.Stand-alone Application that offers the various printing application, DMS(Document Management System), RCP(Remote Control Panel), Printer Status Monitor, Network Management in Window system,

4.Web-based-Application that offers the same functions as Stand-alone Application and RDC(Remote Diagnosis Control) in Web environment.

Firmware is made up of

1.Application (Emulation) translates the data received from Host to a printing language (PCL, PS, GDI, etc)

2.Kernel is in control of the Control flow and printing job.

Service Manual 2-21

Samsung Electronics

Product specification and feature

2.2.4.3 Data and Control Flow

The above Block Diagram is explained that:

Host Side is made up of

1.Driver that is Windows application software translate printed data to one of printer language and create spooler file,

2.Web-based Application that offer a various printer additional functions, management of printing job, printer administration, Status monitor to monitoring the printer status by real time in Web, independent environment on OS.

3.Stand-alone Application that is a similar Window software as same as above 2,

4.Port Monitor that manages the network communication between spooler and Network Interface Card, or various additional application and Network Interface Card,(this is, at first, make communication logical port, manage the data, transfer them from spooler to network port, and offer the result of printing).

2-22 Service Manual

Samsung Electronics

Loading...

Loading...