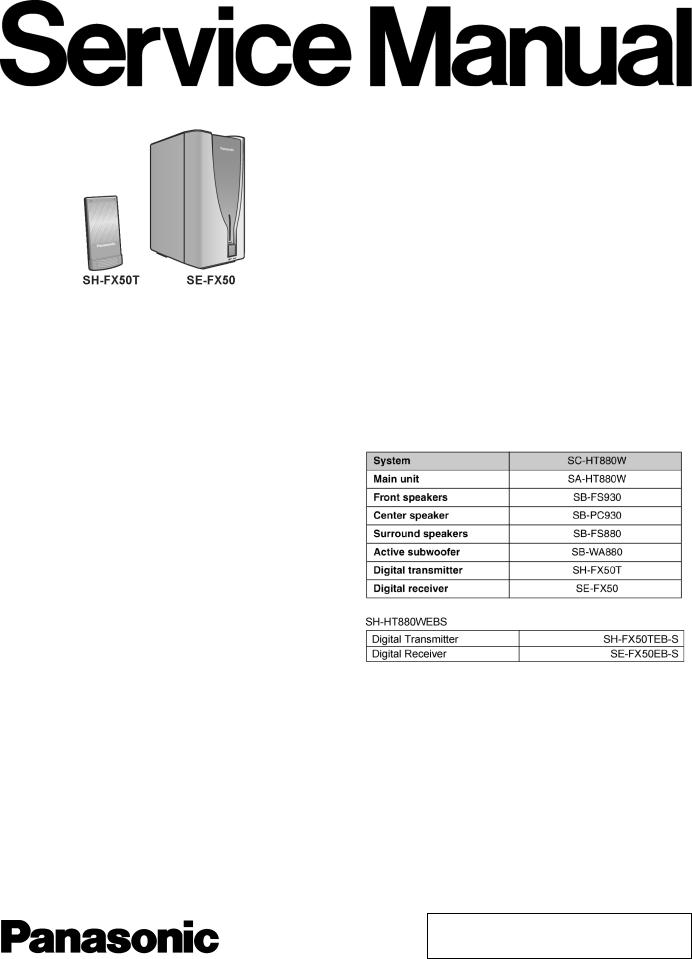

Panasonic SEFX-50-EB, SHFX-50-TEB, SHHT-880-WEB Service manual

Specification

n AMPLIFIER SECTION (For digital receiver)

RMS Output Power

Surround Ch 70 W per channel (4Ω), 1 kHz, 10 % THD

DIN Output Power

Surround Ch 45 W per channel (4Ω), 1 kHz, 1 % THD

n GENERAL (For digital transmitter and receiver)

Power supply |

AC 230 - 240 V, 50Hz |

Power consumption |

|

Digital transmitter |

0.3 W |

Digital receiver |

35 W |

Dimensions (W x H x D) |

|

Digital transmitter |

97 mm x 47.5 mm x 8.5 mm |

Digital receiver |

103 mm x 215 mm x 178 mm |

Mass |

|

Digital transmitter |

0.03 kg |

Digital receiver |

2.3 kg |

Wireless module |

|

Frequency range |

2.402 - 2.480 GHz |

No. of channels |

79 |

Bandwidth/Channel |

1 MHz |

RF Output Power |

13 dBm (Max) |

RF Output Impedance |

50 Ω |

ORDER NO. MD0504154C2

Digital Transmitter & Receiver

SH-HT880WEB

SH-FX50TEB

SE-FX50EB

Colour

(S)..........Silver Type

Type of emissions |

|

Data rate |

1 Mbps |

Operating temperature range |

+5 °C to +35 °C |

Operating humidity range |

5 % to 90 % RH (no |

|

condensation) |

Notes:

1.Specifications are subject to change without notice. Mass and dimensions are approximate

2.Total harmonic distortion is measured by a digital spectrum analyzer

© 2005 Matsushita Electric Industrial Co. Ltd.. All rights reserved. Unauthorized copying and distribution is a violation of law.

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

CONTENTS

|

Page |

|

|

Page |

|

1 |

Safety Precautions |

3 |

|

10.2. RECEIVER MODULE BLOCK |

36 |

|

1.1. GENERAL GUIDELINES |

3 |

|

10.3. TRANSMITTER MODULE BLOCK |

38 |

2 |

Caution for AC Mains Lead |

4 |

11 |

Notes of Schematic Diagram |

40 |

3 |

Handling the Lead-free Solder |

5 |

12 |

Schematic Diagram |

41 |

|

3.1. About lead free solder (PbF) |

5 |

|

12.1. DIGITAL AMP CIRCUIT, TRANSFORMER CIRCUIT, LED |

|

4 |

Before Repair and Adjustment (Digital Receiver SE-FX50) |

5 |

|

CIRCUIT and SWITCH CIRCUIT |

41 |

5 |

Protection Circuitry |

5 |

|

12.2. RECEIVER MODULE CIRCUIT |

43 |

6 |

Using of Digital Receiver Unit (SE-FX50) |

6 |

|

12.3. TRANSMITTER MODULE CIRCUIT |

46 |

|

6.1. Below is tips on using the digital receiver |

6 |

13 |

Printed Circuit Board |

49 |

|

6.2. Tips for using Digital Transmitter (SH-FX50T) |

7 |

|

13.1. DIGITAL AMP P.C.B |

49 |

7 |

Technical Information (New Features) |

8 |

|

13.2. TRANSFORMER P.C.B, LED P.C.B and SWITCH P.C.B |

|

|

7.1. RF Wireless Audio Transceiver |

8 |

|

|

50 |

|

7.2. Detail Block Diagram (Receiver module) |

9 |

|

13.3. RECEIVER MODULE P.C.B |

51 |

|

7.3. Class-D Amplifier |

13 |

|

13.4. TRANSMITTER MODULE P.C.B |

52 |

8 |

TX & RX Module P.C.B. |

17 |

14 |

Wiring Connection Diagram |

53 |

|

8.1. TX and RX Inspection Layout |

17 |

15 |

Illustration of ICs, Transistors and Diodes |

54 |

|

8.2. List of RF components |

18 |

16 |

Terminal Function Of IC |

55 |

|

8.3. RF Transmit Power Test |

19 |

|

16.1. IC2 (M9Z000000013): IC RF |

55 |

|

8.4. Receiver Sensitivity |

22 |

17 |

Voltage Measurement |

56 |

|

8.5. Program ID |

25 |

|

17.1. DIGITAL AMP P.C.B. |

56 |

|

8.6. Testing of link between transmitter & receiver |

28 |

|

17.2. TRANSFORMER P.C.B. |

56 |

9 |

Assembling & Disassembling |

29 |

18 |

Parts Location and Replacement Parts List |

57 |

|

9.1. Disassembly flow chart |

29 |

|

18.1. Cabinet |

58 |

|

9.2. P.C.B. Positions |

30 |

|

18.2. Module Kit Unit (For Service Parts Replacement) |

61 |

|

9.3. Disassembly & Assembly Procedures |

31 |

|

18.3. Electrical Part List (SE-FX50) |

62 |

|

9.4. Service Positions (Digital Receiver SE-FX50) |

34 |

|

18.4. Electrical Part List (SH-FX50T) |

65 |

10 |

Block Diagram |

35 |

|

18.5. Packing Materials & Accessories Parts List |

67 |

|

10.1. POWER BLOCK |

35 |

|

18.6. Packaging |

67 |

2

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

1 Safety Precautions

1.1.GENERAL GUIDELINES

1.When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or damaged by the short circuit.

2.After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly installed.

3.After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

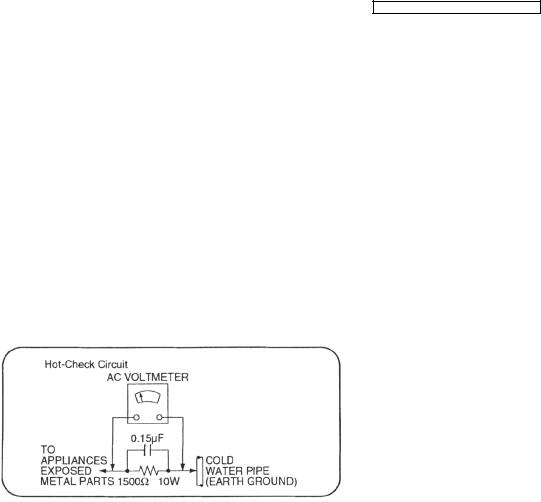

1.1.1.LEAKAGE CURRENT COLD CHECK

1.Unplug the AC cord and connect a jumper between the two prongs on the plug.

2.Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each exposed metallic cabinet part on the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the chassis, the reading should be between 1MΩ and 5.2Ω.

When the exposed metal does not have a return path to the chassis, the reading must be  .

.

Fig. 1

1.1.2.LEAKAGE CURRENT HOT CHECK (See Figure 1.)

1.Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2.Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15µF capacitors, between each exposed metallic part on the set and a good earth ground such as a water pipe, as shown in Figure 1.

3.Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4.Check each exposed metallic part, and measure the voltage at each point.

5.Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6.The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent) may be used to make the hot checks, leakage current must not exceed 1/2 milliamp. In case a measurement is outside of the limits specified, there is a possibility of a shock hazard, and the equipment should be repaired and rechecked before it is returned to the customer.

3

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

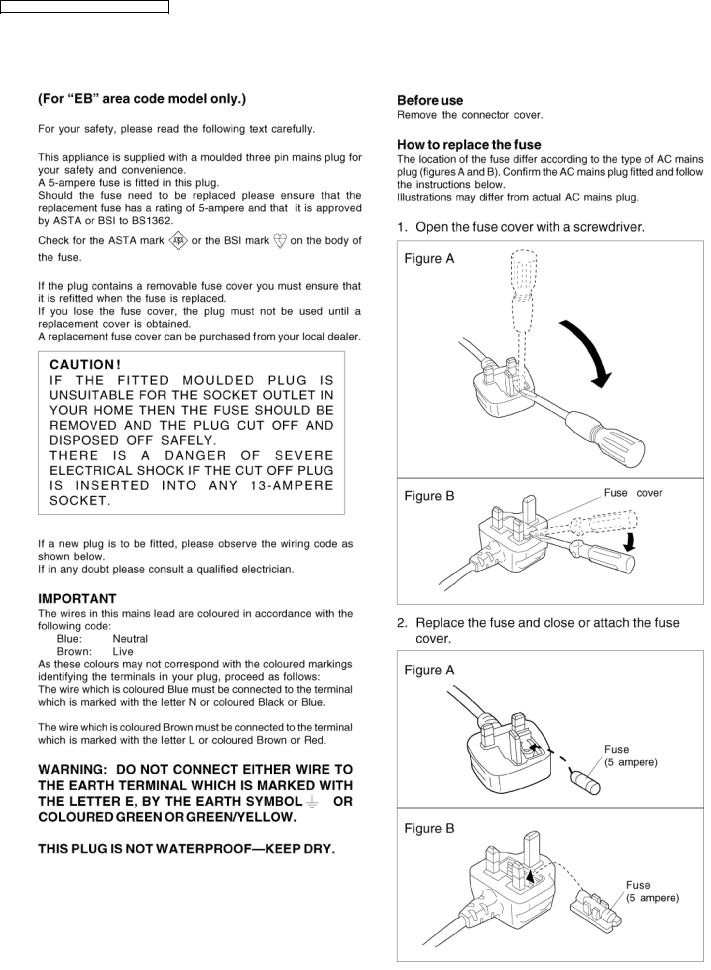

2 Caution for AC Mains Lead

4

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

3 Handling the Lead-free Solder

3.1.About lead free solder (PbF)

Distinction of PbF P.C.B. :

P.C.B.s (manufactured) using lead free solder will have a PbF stamp on the P.C.B.

Caution:

·Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 - 70°F (30 - 40°C) higher. Please use a high temperature soldering iron. In case of the soldering iron with temperature control, please set it to 700 ± 20°F (370 ± 10°C).

·Pb free solder will tend to splash when heated too high (about 1100°F/600°C).

·When soldering or unsoldering, please completely remove all of the solder on the pins or solder area, and be sure to heat the soldering points with the Pb free solder until it melts enough.

4 Before Repair and Adjustment (Digital Receiver SE-FX50)

Disconnect AC power, discharge Power Supply Capacitors C5903, C5904, C5920 and C5926 through a 10 Ω, 1 W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices. After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consumption at AC 230 - 240V, 50Hz in NO SIGNAL mode should be ~248 mA.

5 Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

·No sound is heard when the power is turned on.

·Stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are “shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1.Turn off the power.

2.Determine the cause of the problem and correct it.

3.Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

5

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

6Using of Digital Receiver Unit (SE-FX50)

·This model can be equipped with the digital transmitter and receiver to enjoy surround sound wirelessly.

6.1.Below is tips on using the digital receiver

Special Note:

This unit is equipped with auto-off function (Relay will turn off the power after 1 minute to reduce power consumption).

6

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

6.2.Tips for using Digital Transmitter (SH-FX50T)

7

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

7 Technical Information (New Features)

7.1.RF Wireless Audio Transceiver

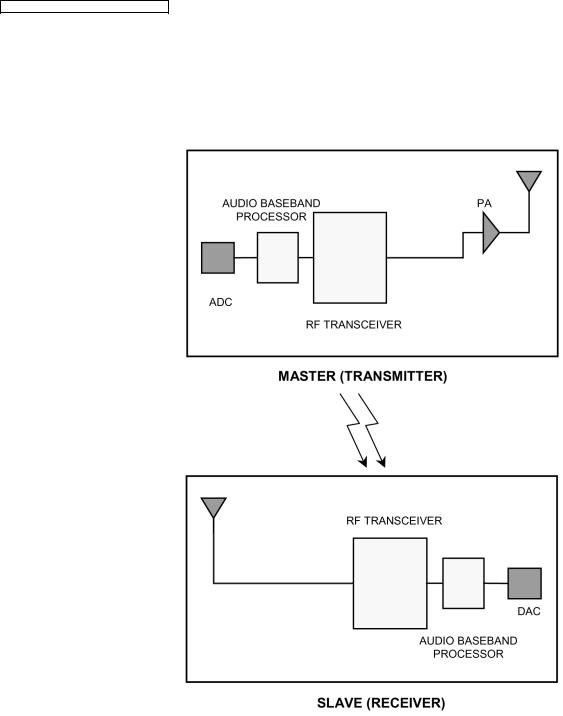

7.1.1.Block Diagram

7.1.2.Definition

1.ADC : Analog-to-Digital Converter

2.Transceiver : Transmitter-Receiver Device

3.PA : Power Amplifier

4.DAC : Digital-to-Analog Converter

7.1.3.Features

·Crystal Clear CD Quality Stereo Sound

·Highly Robust Forward Error Correction

·44.1KHz / 48KHz sampling frequency

·Adaptive Frequency Hopping System

·Range (open space) : 100m

·Low power consumption

·SNR (for left / right channel analog interface) : 80 dB

·THD : 0.2%

·Compact : 40mm x 80mm

8

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

7.2.Detail Block Diagram (Receiver module)

9

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

7.2.1.Operation

RF signal transmission and reception:

During the receive process, the radio signal is taken from a pair of balanced RF I/O pins that feed into the low noise amplifier (LNA). Direct I/Q down conversion and on-chip filtering send the processed I/Q data to the analog-to-digital converter before processing by the GFSK (Gaussian Frequency Shift Keying) demodulator. Within the demodulator, data detection and timing recovery circuits convert the data for transfer to an external device. The transmit process operates in a similar fashion in reverse order.

The transmitted signal is GFSK (Gaussian Frequency Shift Keying) modulated data that is amplified on the chip to yield a radiated output of 0dBm. A power control signal for an external amplifier is provided.

The audio baseband processor (DWM3100) is a digital audio processor IC encompassing apt-XTM audio compress/decompress algorithm for wireless transmission of crystal-clear CD quality audio data.

For digital transmission the analog audio signals are sampled at 48kHz and converted to 1.536Mbps digital data through an external 16-bit stereo audio codec. The digitized data are apt-XTM 4:1 compressed to 384Kbps stream data for efficient transmission. Redundancy bits for forward error correction (FEC), synchronization flags, and control signals for time-division duplexing (TDD) are appended to form data frames for error-free transmission.

In the receiver(Slave), synchronization flags and control data are first detected from the input stream. FEC decoder corrects any errors that may have been introduced during the transmission and produces error-free compressed audio data. The compressed audio is decompressed into 16-bit stereo PCM audio data through digital signal processing blocks. External audio codec converts the PCM data to 2-channel (left and right) analog audio signals.

The Tx/Rx controller is in charge of several functions such as radio channel setup, frequency hopping for interference reduction and generation of control signal for TDD and external RF chip.

In audio mode, the transmitter(Master) can send additional 16Kbps digital data simultaneously with stereo audio data.

How much time delay to transmit audio in wireless?

Audio compression and decompression requires about 3ms. Total time delay can be calculated as follows: Total delay time = audio compression time + transmitter operating time + receiver operating time + audio decompression time. Total delay time is approximately 12.2ms.

What is the power consumption?

The 2.4GHz RF module consumes about 45mA (max 65mA) for the transmitter and 55mA (max 71mA) for the receiver. The EEPROM consumes about 1mA while the baseband IC consumes about 20mA.The total power consumption is 66mA (max 86mA) for the transmitter and 76mA (max 92mA) for the receiver.

10

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

Does the system support any mode to save power consumption?

Yes, it has POWER SAVING SCAN mode. When the communication link is lost, the slave starts scanning procedure to re-establish the link. If the slave cannot find the master within a certain amount of time (info stored in EEPROM), the slave automatically goes into power saving scan mode.

How does the system handle interference from other 2.4GHz RF devices?

It adopts Adaptive Frequency Hopping Spread Spectrum (AHSS) technology to avoid interference.

How does the system handle interference from other 2.4GHz RF devices?

The system supports 3 types of Spread Spectrum. These are

1.FHSS - Frequency Hopping Spread Spectrum

2.AHSS - Adaptive Frequency Hopping Spread Spectrum

3.Fixed Channel Mode

FHSS refers to the conventional 79 channels (or 23 dependent on the country) hopping of Bluetooth. Devices using such hopping method receives a lot of interference from other devices that use 2.4GHz range frequency such as WLAN and other Bluetooth devices. FHSS, being built to avoid interfering with other devices, rather interferes a lot with devices that has high output power using 2.4GHz frequency range and with other FHSS devices.During initialization, system scans 79 channels (or 23) and selects the clear, non-interfered and reliable channel and starts the communication between master and slave. During the channel link, the channel becomes unreliable and the error detection from FEC block exceeds the preset error threshold value, the system executes scanning, as in initialization, and reselects new clear and reliable channel.

FHSS and AHSS can be selected by setting appropriate parameters on the EEPROM.

In Fixed Channel mode, 4 frequency levels can be selected (2.410GHz, 2.430GHz, 2.450GHz and 2.470GHz)

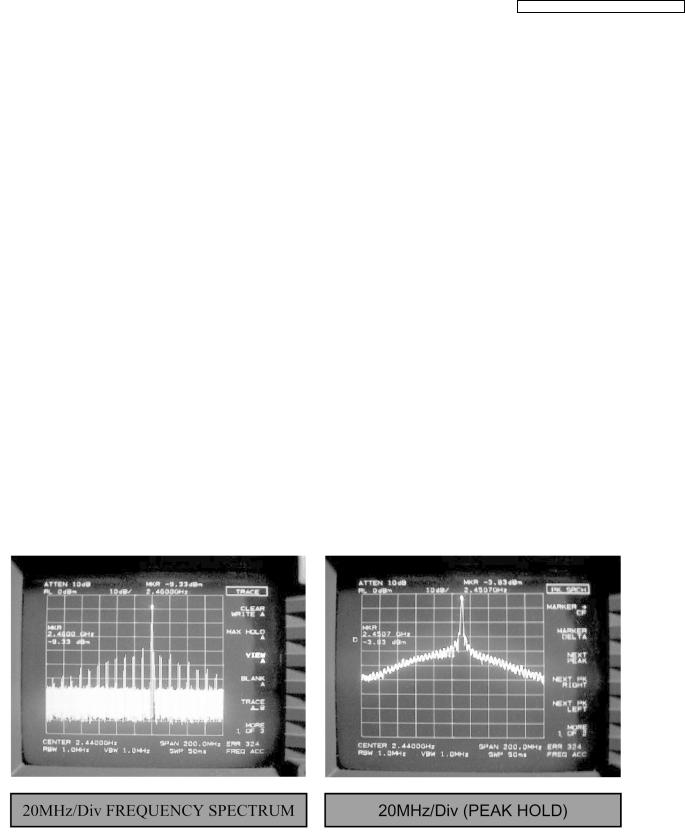

Spectrum distribution characteristic of 2.4GHz RF signal

11

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

Spectrum distribution characteristic of 2.4GHz RF signal

How can Master or Slave setting be selected? By software or hardware?

It can be selected by external control pin.

How long does it take to transmit single packet?

To establish communication channel properly, hopping frequency and Syncword of each packet should be determined by Device ID(Identification). Device ID is unique value of each device, master and slaves. Only master and slaves with same Device ID can communicate each other. Device ID can be set manually in case selected master and slaves do not communicate together. This procedure is *Device ID set*. Device ID set procedure occurs when master and slave devices boot simultaneously with ID_SET=1. In this procedure, the slave can figure out the Device ID of the master and store it in external EEPROM.When ID_SET is established, S5G3000 performs ID send/scan to send Device ID of master to slave before general page operation. In normal mode, communication is accomplished by going into page state directly without ID send/scan.

How can the Master and Slave units be paired to prevent mix-up?

It takes 2.5ms.

12

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

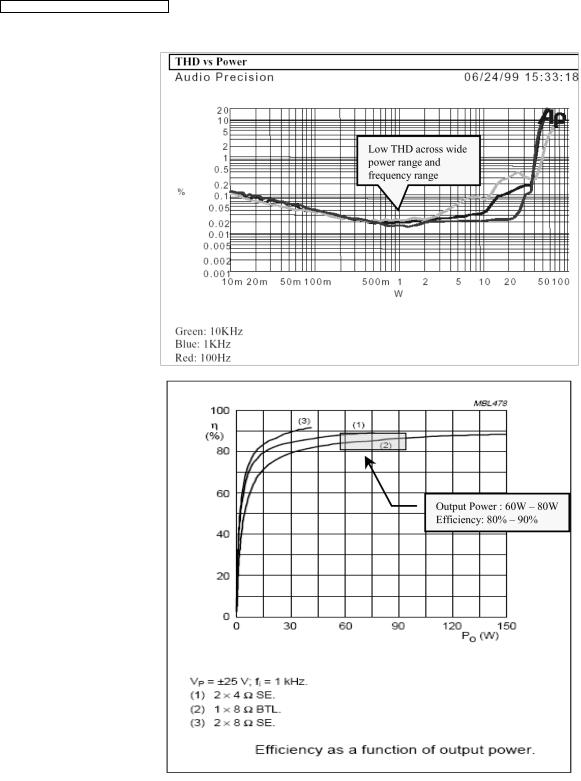

7.3.Class-D Amplifier

7.3.1.How are digital amplifiers different?

A digital amplifier incorporates a switching output stage that operates according to a principle known as pulse width modulation (PWM). In contrast to the low-frequency control signal used in a conventional analog amplifier output stage, the switching output stage of a digital amplifier is controlled by a high-frequency digital signal. The high-frequency digital signal is a PWM signal, in which the music is modulated into a fixed-frequency carrier signal. In a digital amplifier, the modulation process is based on a digital pulse code modulated (PCM) representation of the music signal (or other signal that needs amplification) from a CD player, a DVD player, or some other device.

BLOCK DIAGRAM OF TYPICAL ANALOG INPUT CLASS-D AMPLIFIER

7.3.2.What are the advantages of digital amplification technology?

·High power efficiency, i.e., smaller heat sinks and/or no fan required

·Compact (reduced PCB area)

·Low weight (reduced transformer size)

·Good sound quality (low signal distortion/THD)

7.3.3.Why is the digital amplifier so efficient?

A class-D amplifier is one in which the output transistors are operated as switches. When a transistor is off, the current through it is zero. When it is on, the voltage across it is small, ideally zero. In each case, the power dissipation is very low.

7.3.4.Does the “D” in class-D mean DIGITAL?

No. This is not correct because the operation of the class-D amplifier is based on analog principles. There is no digital coding of the signal. Before the advent of the class-D amplifier, the standard classes were class-A, class-AB, class-B, and class-C. The “D” is simply the next letter in the alphabet after “C.” Indeed, the earliest work on class-D amplifiers involved vacuum tubes and can be traced to the early 1950s.

13

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

7.3.5.What are the potential problems of a Class-D amplifier based system?

The two most common issues of class-D amp system are AM interference and EMI.The switching frequency of class-D ranges from 300kHz to 450kHz typically 315kHz. The harmonics of such switching frequency will fall into the AM band of 600kHz to 1710kHz. To avoid interference, it is recommended to have a variable switching frequency adjustment circuit [usually known as beatproofing in PSG). Systems without AM tuner are not required to have such circuitry.

14

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

Class-D amp systems are basically switching systems. As such, it is prone to EMI. EMI issues can be rectified through proper grounding techniques and proper components layout. It is quite common to see ferrite beads, capacitors and inductors on these systems.

Another issue would be interchannel modulation. This problem would only arise if each channel is using different switching frequency. It would create an amplified “beat” that can be heard from speakers.

7.3.6.Other issues should we be aware of ?

The class-D amplifier IC is limited to only +/- 30volts power supply. This system uses a linear power source to supply power to the module. These linear power supplies are unregulated (i.e. voltage is not fixed). Therefore we have to implement a voltage limiter circuit that would limit the maximum voltage of +/-27volts. It is also imperative that the power supply voltages are almost balanced.

Also, the class-D amplifier IC is configured as single-ended connection. It means one of the outputs is a signal while the other is connected to ground. With this configuration, this Class D amplifiers will deliver energy back to the power supply. We refer to this phenomenon as “Supply pumping effect”. Supply pumping effect is more evident on very low frequencies. It is recommended to have enough buffer on the supply rails to limit the supply pumping effect.It is also advised not to use any type of speakers for testing. There is an output filter that needs to be matched with the intended speaker. A normal resistive load may be used.

7.3.7.Actual Class-D amplifier IC information

Part number: C1BA00000407 (TDA8920BJ)

Block diagram:

15

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

IC Package Information

Soldering Information

Wave Soldering/Dipping: The maximum permissible temperature of the solder is 260 C; solder at this temperature must not be in contact with the joints for more than 5 seconds. The total contact time of successive solder waves must not exceed 5 seconds.Manual Soldering: If the temperature of the soldering iron bit is less than 300 C it may remain in contact for up to 10 seconds. If the bit temperature is between 300 and 400 C, contact may be up to 5 seconds.

16

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

8 TX & RX Module P.C.B.

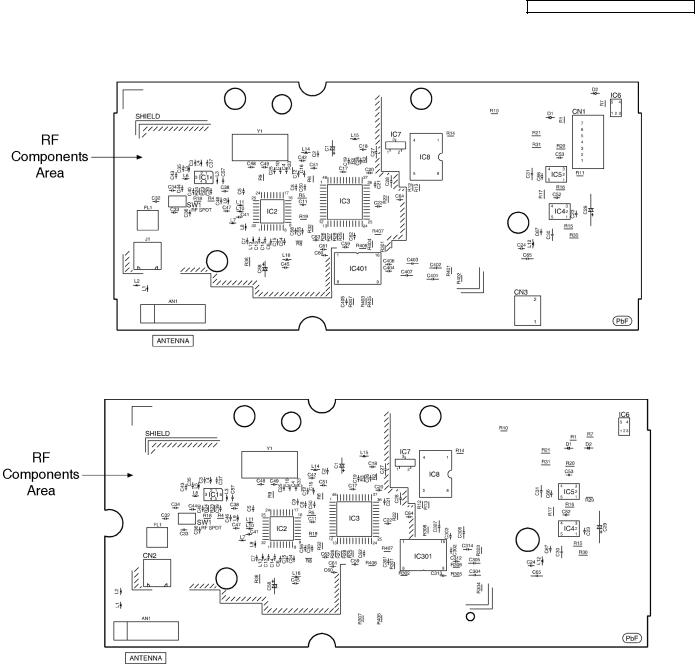

8.1.TX and RX Inspection Layout

· The following processes is required when

1.EEPROM IC was replaced due to fault.

2.Replacement of RF components (Refer to section 8.2 for list of RF components.)

17

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

8.1.1.TX and RX Inspection Process

Below is a list equipments & softwares needed:

1.Test jig (For component level repair & replacement) [M]

2.Frequency spectrum analyser (3 GHZ Range: Recommend)

3.Personal computer (Hyper Terminal)

4.Load EEPROM_I.O. exe (EEPROM / FIRMWARE DOWNLOADING) [M]

5.Program IDI.O. exe (ID programming)

6.Service jig Part no: (RFKZFX50PP-S) [M]

Note:

Item 1 to 5 as mentioned applies during component level repair. Item 6 is used for purpose of verification the functionality of TX & RX.

Step 1: EEPROM Download

To download Parameters & Status into the Registers of Baseband IC. (IC3 - DWM3100)

Step 2: Receiver Sensitivity

To ensure the communication distance between master & slave of at least 100m. (Ref to BER test at section 8.4)

Step 3: Device ID Programming

To program into both the Master (Transmitter Module) & Slave (Receiver Module) an unique number so as not to interfere with the communication between one unit with another.

Note:

For ID No. please refer to indication on the modules P.C.B. (Ref to section 13.3 and 13.4)

Step 4: Transmitter RF Output Test

To ensure the Transmitting Power is within 11 to 16dBM (At center freq = 2.441GHZ, Span = 100MHZ, Ref Level = +25dBM)

Step 5: Audio Frequency Response Measurement

To ensure the frequency response of the unit as below:

8.2.List of RF components

Below is the list of RF components that need special care (handling) during replacement of parts:

·AN1 - chip dielectric antenna

·J1 - Microwave coaxial connector

·FL1 - LC Filter

·IC2 - RF Transceiver

·IC1 - RF Power Amplifier

·IC3 - Audio Processor IC

·SW1 - RF switch

Note:

Please refer to electrical partlist (section 18.3. and 18.4.) for part no. For location of these components, please refer to section 13.1.

18

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

8.2.1.Component Layer side A (Receiver Module P.C.B.)

8.2.2.Component Layer side A (Transmitter Module P.C.B.)

8.3.RF Transmit Power Test

Note:

This test is carried out & necessary for component level repair / replacement.

8.3.1.Procedure

Step 1 : Put PCB properly on the inspection jig and connect RF cable into the PCB.

19

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

Step 2 : Select EEPROM programming icon.

Step 3 : On the switch and according to the PCB BLOCK NO select slave (A) or master (B) module.

Step 4 : Follow the reset information, press reset button.

20

SH-HT880WEB / SH-FX50TEB / SE-FX50EB

Step 5 : Press ´Test´ icon

Step 6 : When the ´max_hold´ info shown, press max_hold´ button on the spectrum analyzer, then press ´OK´ icon.

Step 7 : Base on the Fail or Pass information on the spectrum analyzer to judge PCB condition.

Step 8 : OFF the switch, take out the PCB from jig and put marking.

21

Loading...

Loading...