Mitsubishi Electronics PAR-U02MEDA User Manual

CITY MULTI Control System

Smart ME Controller PAR-U02MEDA

Installation Manual

Prior to use, thoroughly read the instructions in this manual to use the product correctly.

Retain this manual for future reference.

Make sure that the CD-ROM, this manual, and Simple Operation Manual are passed on to

any future users.

To ensure safety and proper operation of the remote controller, the remote controller should

only be installed by qualified personnel.

For distribution to dealers and contractors

English

– 1 –

Chapter 1. Installation

This installation manual describes how to install the Smart ME Controller for use with Mitsubishi

Building Air Conditioning System, direct expansion type CITY MULTI air conditioner indoor units (“-A”

type and later).

Please be sure to read this installation manual and Instruction Book that are supplied with the Remote

Controller before proceeding with the installation. Failure to follow the instructions may result in

equipment damage.

For information on how to wire and install the air conditioning units, refer to the Air Conditioner

Installation Manual.

After the installation, hand over this manual to users.

Smart ME Controller is a type of ME Remote Controllers, sometimes simply referred to as ME Remote

Controller.

• Read the following safety precautions prior to installation.

• Observe these precautions carefully to ensure safety.

• After reading this manual, pass it on to the end user to retain for future reference.

• Keep this manual for future reference and refer to it as necessary. This manual should be made

available to those who repair or relocate the controller. Make sure that the manual is passed on to

any future users.

WARNING

1 Safety Precautions

WARNING

Indicates a risk of death or serious injury.

CAUTION

Indicates a risk of serious injury or structural damage.

General precautions

All electric work must be performed by qualified personnel.

Do not install the unit in a place where large amounts of

oil, steam, organic solvents, or corrosive gases, such

as sulfuric gas, are present or where acidic/alkaline

solutions or sprays are used frequently. These

substances can compromise the performance of the

unit or cause certain components of the unit to corrode,

which can result in electric shock, malfunctions,

smoke, or fire.

To reduce the risk of shorting, current leakage, electric

shock, malfunctions, smoke, or fire, do not wash the

controller with water or any other liquid.

To reduce the risk of electric shock, malfunctions,

smoke or fire, do not operate the switches or touch

other electrical parts with wet hands.

To reduce the risk of injury or electric shock, before

spraying a chemical around the controller, stop the

operation and cover the controller.

To reduce the risk of injury or electric shock, stop the

operation and switch off the power supply before

cleaning, maintaining, or inspecting the controller.

Properly install all required covers to keep moisture

and dust out of the controller. Dust accumulation and

water can cause electric shock, smoke, or fire.

To reduce the risk of injury, keep children away while

installing, inspecting, or repairing the controller.

– 2 –

CAUTION

WARNING

CAUTION

WARNING

CAUTION

Precautions during installation

Precautions during wiring

To reduce the risk of fire or explosion, do not place

flammable materials or use flammable sprays around

the controller.

To reduce the risk of damage to the controller, do not

directly spray insecticide or other flammable sprays on

the controller.

To reduce the risk of electric shock or malfunctions, do

not touch the touch panel with a pointy or sharp object.

To reduce the risk of injury and electric shock, avoid

contact with sharp edges of certain parts.

To avoid injury from broken glass, do not apply

excessive force on the glass parts.

To reduce the risk of injury, wear protective gear when

working on the controller.

Do not directly stare at the LED light, as this may

damage your eyes.

Do not install the controller where there is a risk of

leaking flammable gas. If flammable gas accumulates

around the controller, it may ignite and cause a fire or

explosion.

Properly dispose of the packing materials. Plastic bags

pose suffocation hazard to children.

Take appropriate safety measures against earthquakes

to prevent the controller from causing injury.

To prevent injury, install the controller on a flat surface

strong enough to support its weight.

To reduce the risk of shorting, current leakage, electric

shock, malfunctions, smoke, or fire, do not install the

controller in a place exposed to water or in a

condensing environment.

Controller must be installed by qualified personnel

according to the instructions detailed in the Installation

Manual.

Improper installation may result in electric shock or fire.

When attaching the cover and the top casing to the

bottom casing, push it until it they click into place. If

they are not properly locked into place, they may fall,

causing personal injury, controller damage, or

malfunctions.

To reduce the risk of damage to the controller,

malfunctions, smoke, or fire, do not connect the power

cable to the signal terminal block.

Properly secure the cables in place and provide

adequate slack in the cables so as not to stress the

terminals. Improperly connected cables may break,

overheat, and cause smoke or fire.

To reduce the risk of injury or electric shock, switch off

the main power before performing electrical work.

All electric work must be performed by a qualified

electrician according to the local regulations,

standards, and the instructions detailed in the

Installation Manual. Capacity shortage to the power

supply circuit or improper installation may result in

malfunction, electric shock, smoke, or fire.

To reduce the risk of current leakage, overheating,

smoke, or fire, use properly rated cables with adequate

current carrying capacity.

To reduce the risk of electric shock, shorting, or

malfunctions, keep wire pieces and sheath shavings

out of the terminal block.

To reduce the risk of shorting, current leakage, electric

shock, or malfunctions, keep the cables out of contact

with controller edges.

To reduce the risk of electric shock, malfunctions, or

fire, seal the gap between the cables and cable access

holes with putty.

– 3 –

WARNING

CAUTION

The CD-ROM that is supplied with Smart ME Controller

The CD-ROM that is supplied with the Smart ME Controller contains an Installation Manual and

Instruction Book.

Each document is in PDF format.

Viewing documents requires a computer with Adobe

®

Reader

®

or Adobe

®

Acrobat

®

installed.

Precautions for moving or repairing the controller

Additional precautions

WARNING

The CD-ROM can only be played on a CD-drive or a DVD-drive. Do not attempt to play the

CD-ROM on an audio CD player as this may damage your ears and/or speakers.

“Adobe

®

Reader

®

” and “Adobe

®

Acrobat

®

” are registered trademarks of Adobe Systems Incorporated.

The controller should be repaired or moved only by

qualified personnel.

Do not disassemble or modify the controller.

Improper installation or repair may cause injury, electric

shock, or fire.

To reduce the risk of shorting, electric shock, fire, or

malfunction, do not touch the circuit board with tools or

with your hands, and do not allow dust to accumulate

on the circuit board.

To avoid damage to the controller, use appropriate

tools to install, inspect, or repair the controller.

This controller is designed for exclusive use with the

Building Management System by Mitsubishi Electric.

The use of this controller for with other systems or for

other purposes may cause malfunctions.

Take appropriate measures against electrical noise

interference when installing the air conditioners in

hospitals or facilities with radio communication

capabilities. Inverter, high-frequency medical, or

wireless communication equipment as well as power

generators may cause the air conditioning system to

malfunction. Air conditioning system may also

adversely affect the operation of these types of

equipment by creating electrical noise.

To avoid malfunctions, do not bundle power cables and

signal cables together, or place them in the same

metallic conduit.

To prevent malfunctions, do not remove the protective

film or the circuit board from the casing.

To avoid damage to the controller, do not overtighten

the screws.

Use a flat-head screwdriver with a blade width of 4-5.5 mm

(5/32-7/32 in). The use of a screwdriver with a narrower or

wider blade tip may damage the controller casing.

To prevent damage to the controller casing, do not

force the driver to turn with its tip inserted in the slot.

To avoid discoloration, do not use benzene, thinner, or

chemical rag to clean the controller. To clean the

controller, wipe with a soft cloth soaked in water with

mild detergent, wipe off the detergent with a wet cloth,

and wipe off water with a dry cloth.

To avoid damage to the controller, provide protection

against static electricity.

Do not use solderless terminals to connect cables to

the terminal block.

Solderless terminals may come in contact with the

circuit board and cause malfunctions or damage the

controller cover.

To avoid damage to the controller, do not make holes

on the controller cover.

To avoid deformation and malfunction, do not install

the remote controller in direct sunlight or where the

ambient temperature may exceed 40ºC (104ºF) or

drop below 0ºC (32ºF).

Do not install the controller on the control panel door.

Vibrations or shocks to the controller may damage the

controller or cause the controller to fall.

Hold the cables in place with clamps to prevent undue

force from being applied to the terminal block and

causing cable breakage.

To prevent cable breakage and malfunctions, do not

hang the top controller casing hang by the cable.

– 4 –

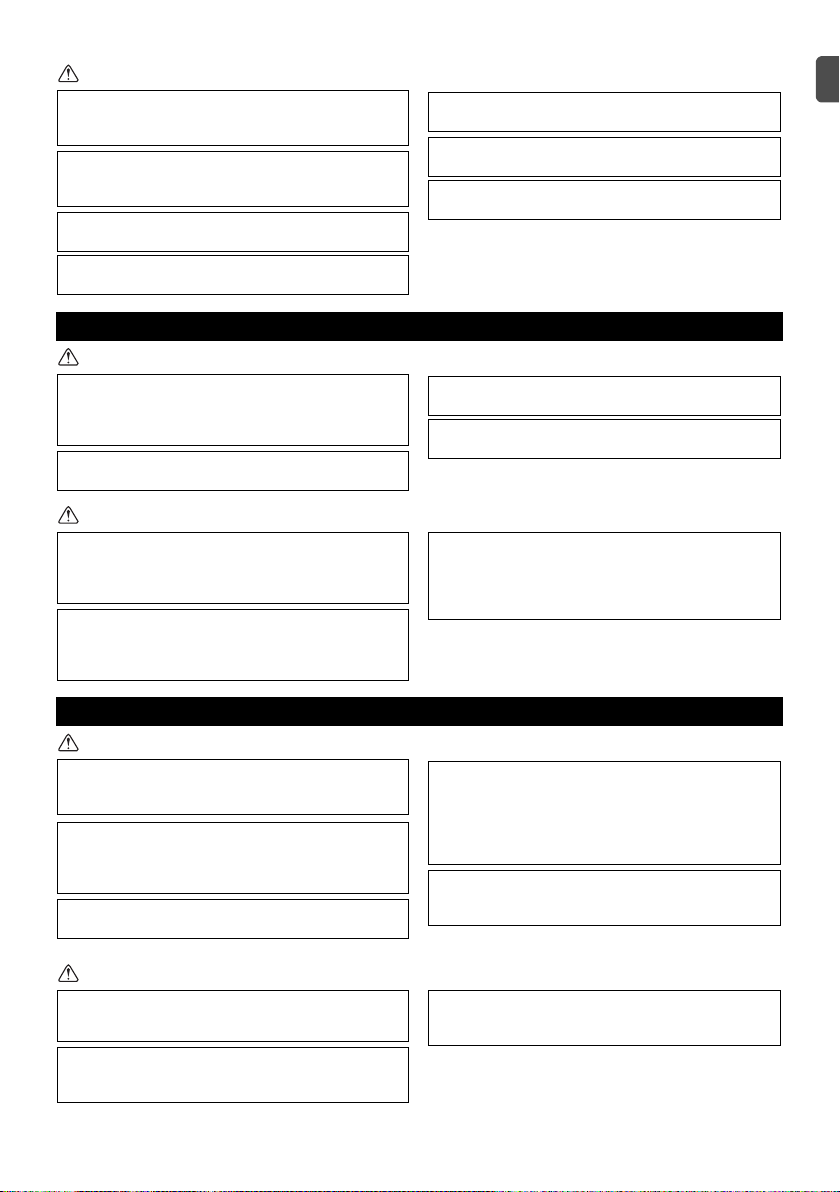

The following parts are included in the box.

(1) Field-supplied parts

(2) Required tools

• Flat-tip screwdriver (Width: 4-5.5 mm (5/32-7/32 in))

• Knife or nipper

• Miscellaneous tools

2 Component names and supplied parts

*1 The front cover is already installed on the top case at

factory shipment.

*2 ISO metric screw thread

*3 Remote controller cable is not included.

3 Field-supplied parts/Required tools

Parts name Qty. Notes

Double switch box 1

Not required for direct wall installationThin metal conduit As needed

Locknut and bushing As needed

Cable cover As needed Required for routing remote controller cable along a wall

Putty As needed

Molly anchor As needed

Remote controller cable

(0.3 mm² (AWG 22) 2-core

sheathed cable)

As needed

If the remote controller cable exceeds 10 m (32 ft), use an

electric wire that meets the following specification.

CVVS: 1.25 mm

2

(standard AWG 16) or equivalent

CPEVS: ø1.2 mm (standard AWG 16) or equivalent

Parts name Qty.

Remote controller (front cover) *1 1

Remote controller (top case) *1 1

Remote controller (bottom case) 1

Roundhead cross slot screws M4×30 *2 4

Wood screw 4.1×16 *2

(for direct wall installation)

4

Installation Manual (this manual) 1

Simple Operation Manual 1

CD-ROM

(Installation Manual, Instruction Book)

1

Bottom case

Front cover

Top case

– 5 –

*1 The power consumption coefticient of the Smart ME Controller is “0.5” and that of a ME Remote Controller

(PAR-F27MEA) is “0.25”.

If the number of Smart ME Controllers is high and the total power supply they require exceeds the outdoor unit's

ability to supply power, a Transmission booster (PAC-SF46EPA) will be required.

*1: "7" for the P200 and P250 models

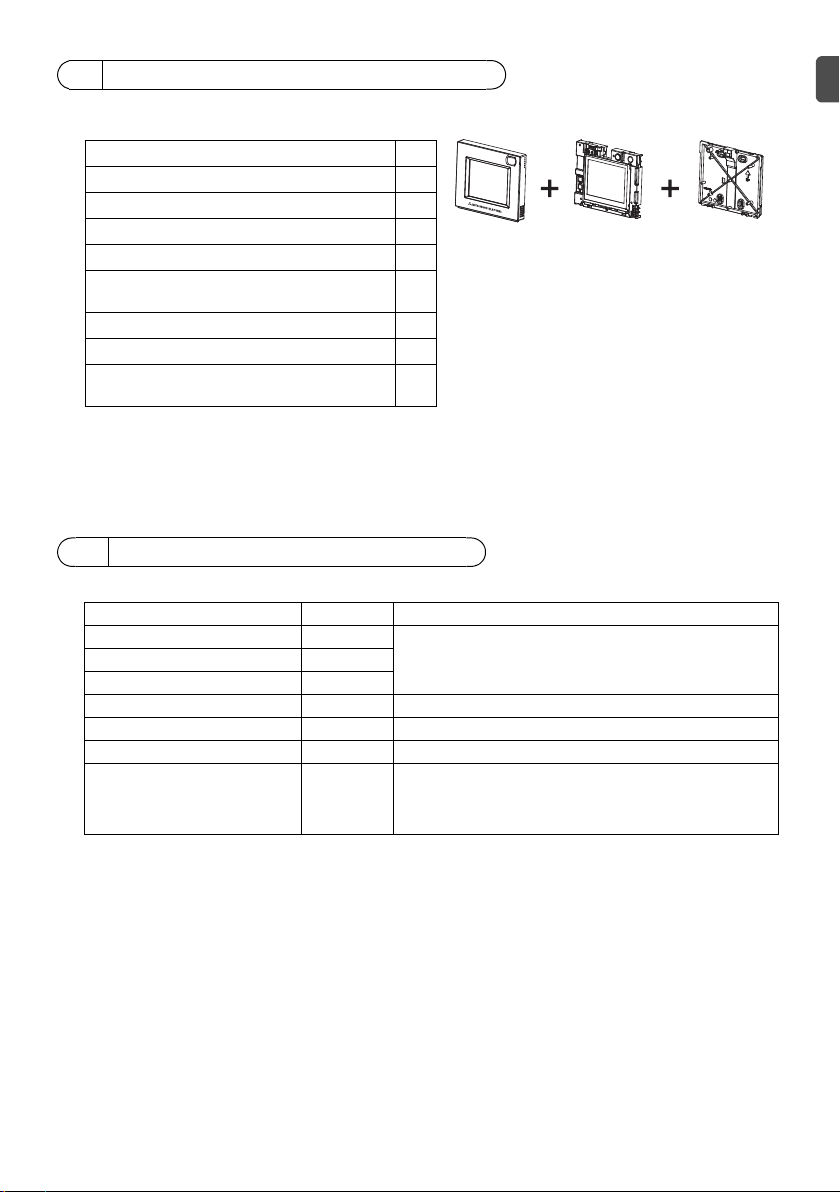

(1) Wiring from the remote controller

• Connect to TB5 (terminal block for indoor-outdoor transmission cable) on any indoor unit in same

M-NET system.

• The terminal block has no polarity. Connect to the terminals M1 and M2.

(2) Operating in a group (Groups 01, 02, 03, and 04)

• Assign the lowest address to the main indoor unit in the group.

The remote controller address should be set to a number that equals the main indoor unit address

plus 100.

(3) Up to two remote controllers (main and sub) can be connected to an indoor unit or a group of

indoor units.

• Connect the main and sub remote controllers in the same way as described in (1) above.

• Be sure to set the main and sub remote controller addresses.

The sub remote controller address should be set to a number that equals the main indoor unit

address plus 150.

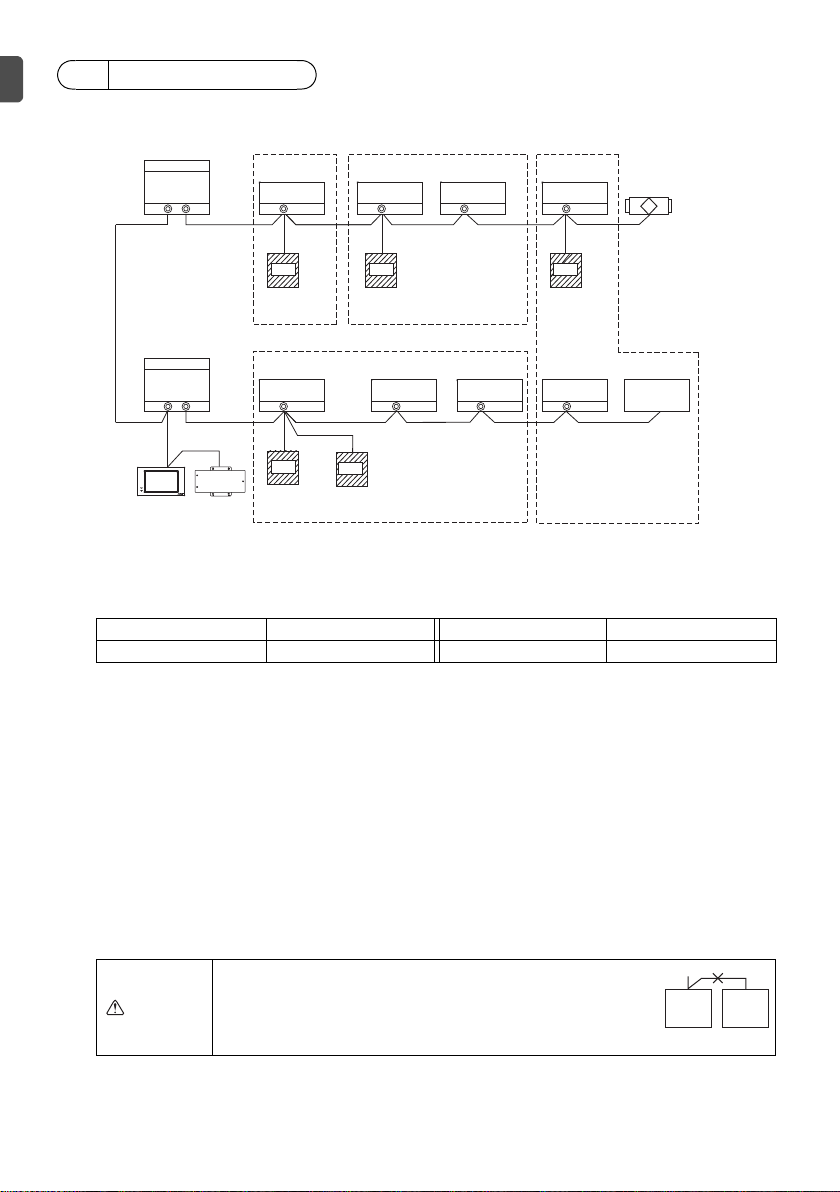

4 System diagram

Outdoor unit Transmission booster Indoor unit Smart ME Controller

32 25 1

(*1)

0.5

CAUTION

- Remote controllers cannot be wired together. Only one

cable can be connected to the remote controller terminal

block.

- The ME remote controller and MA remote controller

cannot be connected in the same group.

051

TB7 TB3 TB5

001

TB5

002

TB5

003

TB5

004

101 102 104

056

TB7 TB3 TB5

009

TB5

008

TB5

007

TB5

006

107

157

CENTRALIZED CONTROLLER AG-150A

201

000

Outdoor unit

Smart ME

Controller *1

Indoor unit

Indoor unit

Smart ME

Controller

Indoor unit

Indoor unit

Smart ME

Controller

Indoor unit

Smart ME

Controller

Smart ME

Controller

Indoor unit

Indoor unit

Indoor unit

Outdoor unit

Centralized

controller

Power supply

unit

LOSSNAY unit

005

Advanced HVAC

CONTROLLER (AHC)

Group 01

Group 02

Group 03

Group 04

Main

remote

controller

Sub

remote

controller

– 6 –

This remote controller is for the wall installation. It can be installed either in the switch box or directly

on the wall. When performing direct wall installation, cables can be thread through either back or top

of the remote controller.

(1) Selecting an installation site

Install the remote controller (switch box) on the site where the following conditions are met.

(a) A flat surface

(b) A place where the remote controller can measure the accurate room temperature and humidity

Sensors to monitor the room temperature are on the indoor unit and on the remote controller.

When the room temperature is monitored with the sensor on the remote controller, the main

remote controller monitors the room temperature. When using the sensor on the remote controller,

follow the instructions below.

• To monitor the accurate room temperature and humidity, install the remote controller away from

direct sunlight, heat sources, and the supply air outlet of the air conditioner.

• Install the remote controller in a location that allows the sensor to measure the representative

room temperature and humidity.

• Install the remote controller where no wires are routed around the temperature sensor on the

controller or where no obstacles block the air inlet, otherwise the sensor cannot measure accurate

room temperature and humidity.

• After the controller has been exposed to high humidity (above 80%RH) for 60 hours, the humidity

detection value will be offset by 3%RH.

When the ambient humidity drops below 80%RH, the offset will be gradually cancelled.

• Do not install the controller where it is exposed to high concentration of acid, alkaline, or volatile

organic compounds.

• If exposed to cigarette smoke for a long time, the humidity detection value will be offset.

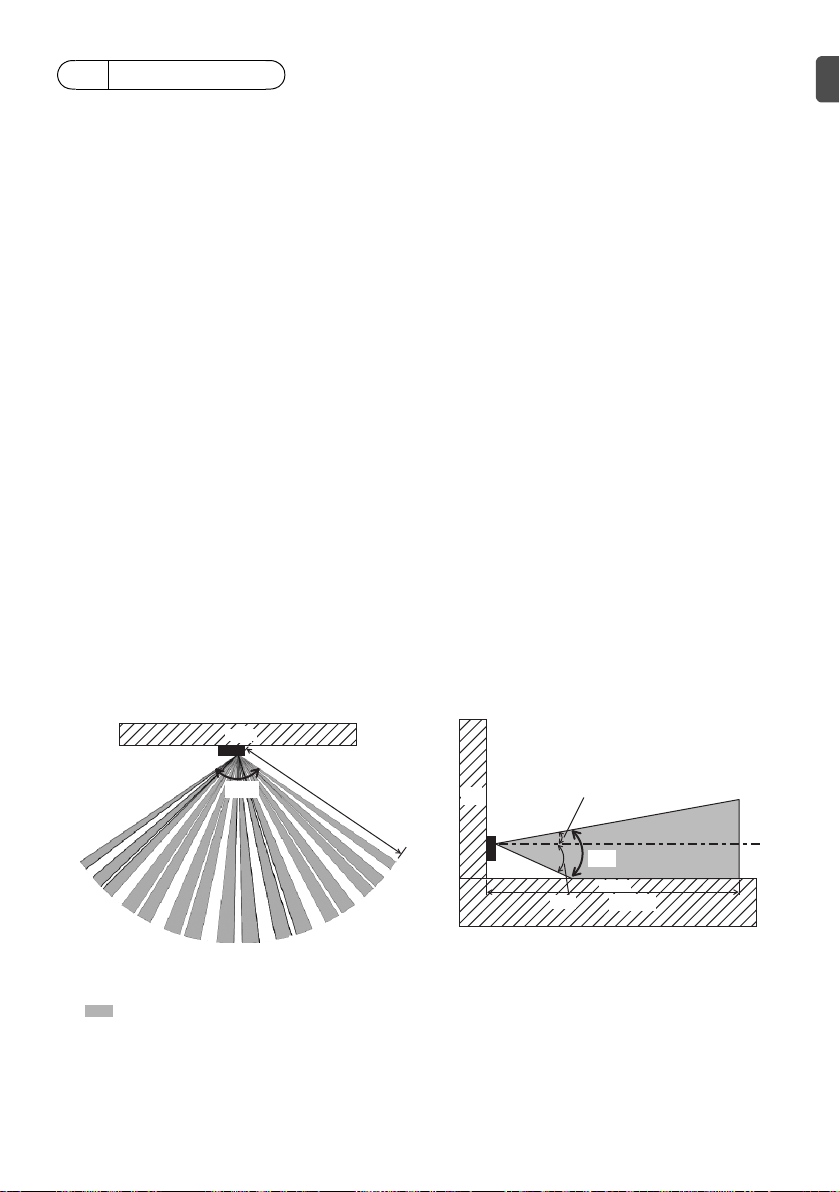

(c) Install the remote controller where occupancy and brightness can be properly detected.

The remote controller has an occupancy sensor and a brightness sensor.

Each sensor has a sensor-detection zone.

• Install the remote controller where the coverage area covers the appropriate area in the room.

The maximum distance the sensor can detect occupancy is approximately 10 m (32 ft).

: Detection area

* As an inherent characteristic of the occupancy sensor, it is more sensitive to movements across

the area indicated by

■ than to movements straight toward the sensor.

5How To Install

Occupancy sensor

Horizontal direction Vertical direction

110°

Remote

controller

Wall

10 m

Figure 1

31°

11°

20°

Remote

controller

Floor

Wall

10 m

Figure 2

– 7 –

Occupancy sensor detects occupancy based on the temperature difference between the occupant

and its surroundings.

To be precise, to enhance the sensitivity of the sensor to occupant movements, the occupancy

sensor is designed to detect the changes in the amount of infrared light emitted from an object in

the detection zone, including human bodies.

The occupancy sensor will not detect occupancy if no movements exist.

The sensor also becomes less sensitive to occupancy when the temperature difference between

the occupant and its surroundings is small.

• Select the installation location carefully to avoid false detection.

Factors that contribute to false detection by the occupancy sensor

• Direct sunlight to the remote controller

• Supply air directed straight toward the remote controller

• Fireplace in the detection zone

• Portable heater (e.g., oscillating electric heater) in the detection zone

• Excessive vibrations or large impact inflicted on the remote controller

• Strong electrical noise

• Movements of small animals, such as cats and dogs

Handling precautions

• Keep the lens scratch-free.

• Do not place adhesive tape or labels over the lens.

• Use a soft cloth to clean the lens.

Brightness sensor

Horizontal direction Vertical direction

44°

Remote

controller

Wall

Figure 3

44°

22°

22°

Remote

controller

Floor

Wall

Figure 4

Do not install the controller in a place where

the difference between the remote controller

surface temperature and the actual room

temperature will be great.

If the temperature difference is too high,

room temperature may not be adequately

controlled.

To avoid deformation and malfunction, do

not install the remote controller in direct

sunlight, where the ambient temperature

may rise above 40ºC (104°F) or drop below

0ºC (32°F), or where the relative humidity

may rise above 90% or drops below 20%.

To reduce the risk of malfunctions, do not

install the controller in a place where water

or oil may come into contact with the

controller, or in a condensing or corrosive

environments.

Do not install the remote controller directly

onto electrically conductive objects such as

metal plate that has not been painted.

To use the Energy Saving Assist function in

a system with both main and sub remote

controllers, activate the function only on the

remote controller whose coverage area is

the largest.

Important

Loading...

Loading...