Mitsubishi Electronics PEA-RP250 WHA User Manual

Air-Conditioners

INDOOR UNIT

PEA-RP250 WHA

GB

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

3

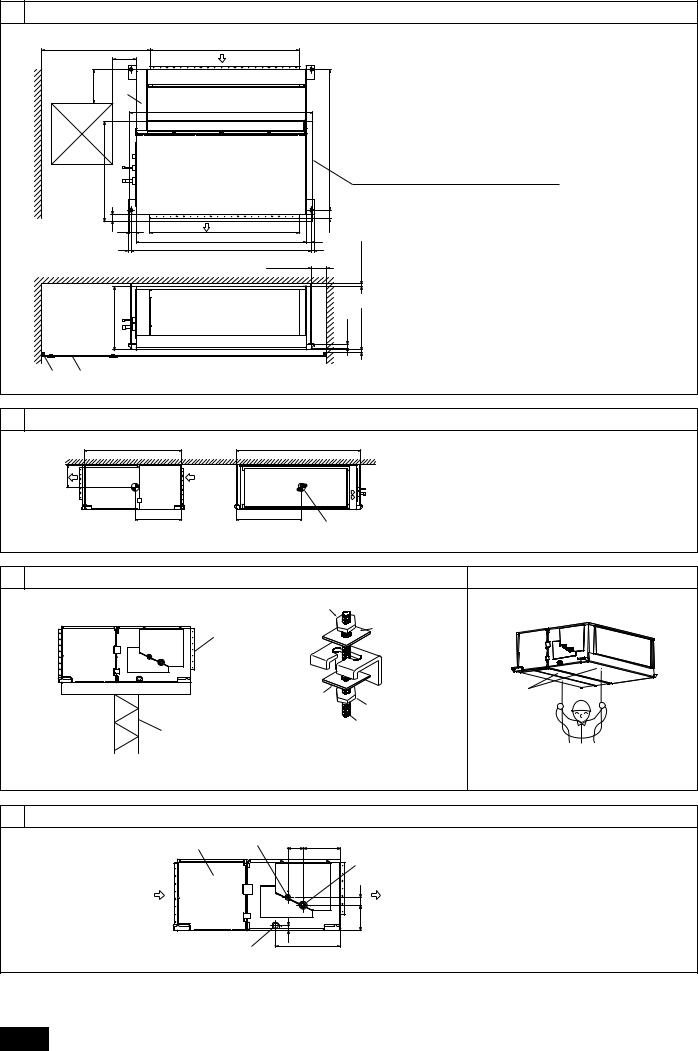

[Fig. 3.2.1]

800

|

150~200 |

|

~300 |

B |

|

200 |

||

|

450

A

730

50 |

50 |

|

|

|

23 |

470

EA

1100

C

1350

D 1100 1250 1324

3.2

1034

60

37

23

more than 100

Keep the service space for the maintenance from the bottom when the heat exchanger is cleaned.

|

more than 20 |

|

1030± |

20 |

|

thanmore |

A Access door |

|

|

|

B Electrical parts box

C Air inlet

DAir outlet

ECeiling surface

4 |

|

4.1 |

[Fig. 4.1.1] |

1034 |

1324 |

235 |

|

|

|

494 |

701 |

A

A Center of gravity

5 |

5.1 |

[Fig. 5.1.1] |

[Fig. 5.1.2] C |

|

D |

|

A |

|

D |

|

C |

B |

E |

|

|

|

C Nuts (field supply) |

A Unit body |

D Washers (accessory) |

B Lifting machine |

E M10 hanging bolt (field supply) |

5.3

[Fig. 5.3.1]

A

A Indoor unit’s bottom surface

6 |

|

|

|

6.2 |

|

[Fig. 6.2.1] |

D |

B |

|

100 244 |

|

|

|

|

|

C |

|

|

|

|

|

52 |

|

A |

|

|

|

165 |

F |

|

|

|

|

|

|

|

|

|

30 |

424 |

|

|

|

|

|

|

E

A Air inlet |

B Refrigerant piping (liquid) |

||

C |

Refrigerant piping (gas) |

D |

Control box |

E |

Drain pipe |

F |

Air outlet |

2

7 |

7.1 |

[Fig. 7.1.1] |

[Fig. 7.1.2] |

A Cut here

B Remove brazed cap

[Fig. 7.1.3]

A

B

C

E

D M P

D M P

N

G  O

O

F

I  M

M

J  H

H

K

|

20 |

E |

|

|

|

|

|

20 |

|

Q |

R |

|

|

|

K

L

L

20

20 J

A

A

A Cool by a wet cloth

AThermal insulation tubing (small)

BCaution:

Pull out the thermal insulation on the refrigerant piping at the site, braze the piping, and replace the insulation in its original position.

Take care to ensure that condensation does not form on exposed copper piping.

CRefrigerant piping (liquid)

DRefrigerant piping (gas)

EMain body

FThermal insulation tubing (large)

GSite refrigerant piping

HEnsure that there are no gaps between the insulation and the main body.

IThermal insulation tubing (small) (supplied) 1

JTies (large) (supplied) 4

KEnsure that there is no gap here. Place join upwards.

LThermal insulation tubing (medium) (supplied) 2

MThermal insulation

NPull

OFlared pipe end

PWrap with damp cloth

QReturn to original position

REnsure that there is no gap here.

7.2

[Fig. 7.2.1]

|

C |

C |

C |

A Downward slope 1/100 or more |

|

|

|

E |

B Drain hose (Accessory) |

A |

|

|

C Indoor unit |

|

|

|

|

||

B |

1 |

|

|

D Collective piping |

|

|

|

|

|

|

D |

|

2 |

E Maximize this length to approx. 10 cm |

|

|

|

[Fig. 7.2.2]

|

|

I |

|

A |

B |

F |

G |

|

5 |

25 |

H |

|

D |

E |

|

C

AIndoor unit

BInsulation pipe (short) (accessory)

CTie band (accessory)

DBand fixing part

EInsertion margin

FDrain hose (accessory)

GDrain pipe (O.D. ø32 PVC TUBE, field supply)

HInsulating material (field supply)

IMax.145 ± 5 mm

3

8

[Fig. 8.0.1]

|

D |

|

|

D C |

C |

|

|

|

|

B |

|

|

|

|

A |

I |

|

|

H |

|

E G |

F |

||

|

|

|

||

|

A Air inlet |

B Air filter (supplied at site) |

|

|

|

C Duct |

D Canvas duct |

|

|

|

E Access door |

F Ceiling |

|

|

GEnsure sufficient length to prevent short cycling

H Air outlet I Keep duct-work length 850 mm or more

9 |

9.1 |

|

|

|

9.2 |

|

[Fig. 9.1.1] |

|

[Fig. 9.2.1] |

|

B |

A |

|

|

|

|

|

|

||

|

|

|

|

M1M2 |

M1M2 S 1 |

2 |

|

|

|

TB3 |

|

TB5 |

TB15 |

|

|

|

|

|

|

A Terminal block for indoor |

A |

B |

|

|

|

|

transmission cable |

|

|

|

|

|

|

B Terminal block for outdoor |

|

C |

|

|

|

|

transmission cable |

|

|

|

|

|

C Remote controller |

|

|

|

|

|

|

|

|

|

|

[Fig. 9.2.2] |

|

|

|

|

|

|

|

|

B |

|

C |

A Switch 16 A |

|

D |

|

2 |

|

|

|

|

A |

|

|||

B Overcurrent protection 16 A |

|

|

1 |

|

||

|

|

|

|

|||

C Indoor unit |

|

|

|

S |

|

|

|

|

|

M2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M1 |

|

A Non-polarized |

|

|

|

|

DC10~13V |

B TB15 |

|

|

|

|

|

|

C |

|

|

|

|

N |

|

C Remote Controller |

|

|

|

L |

A |

B |

||

|

|

|

|

|||

|

|

|

1 |

2 |

D TB5 |

|

|

|

|

|

|||

|

|

|

|

|

|

|

4

Loading...

Loading...