HONDA HF2315SBE User Manual

Realizzazione: EDIPROM / bergamo - PRINTED IN ITALY

TONDEUSE AUTOPORTEE

LAWN-TRACTOR

RASENTRAKTOR

MINITRACTOR CORTADOR DE CESPED

TRATTORINO RASAERBA

ZITMAAIER

HF2315SBE

HF2315HME

HF2415SBE

HF2417HME

HF2417HTE

HF2620HME

HF2620HTE

MANUEL D’UTILISATION

OPERATOR’S MANUAL

GEBRAUCHSANWEISUNG

MANUAL DE INSTRUCCIONES

MANUALE DI ISTRUZIONI

GEBRUIKERSHANDLEIDING

Honda Europe Power Equipment S.A.

Pôle 45 - Rue des Châtaigniers CG71505090H4 FR EN DE ES IT NL 451401 ORMES - FRANCE

INTRODUCTION |

EN 1 |

INTRODUCTION

Dear Customer,

thank-you for having chosen one of our products. We hope that you will get complete satisfaction from using your new lawn-tractor and that it will fully meet all your expectations.

This manual has been compiled in order that you may get to know your machine and to be able to use it safely and efficiently. Don’t forget that it forms an integral part of the machine, so keep it handy so that it can be consulted at any time, and pass it on to the purchaser if you resell the machine.

This new machine of yours has been designed and made in line with current regulations, and is safe and reliable if used for cutting and collecting grass exactly following the instructions given in this manual (proper usage). Using the machine in any other way or ignoring the instructions for safe usage, maintenance and repair is considered "incorrect usage" which will invalidate the guarantee, and the manufacturer will decline all responsibility, placing the blame with the user for damage or injury to himself or others in such cases.

Since the product is continually being improved, you may find slight differences between your machine and the descriptions contained in this manual. Certain modifications can be made to the machine without prior warning and without the obligation to update the manual, although the essential safety and function characteristics will remain unaltered. In case of any doubts, do not hesitate to contact your Dealer. And now enjoy your work!

AFTER-SALES SERVICE

This manual gives all the necessary instructions for using the machine and the basic maintenance that may be carried out by the user.

Contact your Dealer for operations not described in this manual.

EN 2 |

TABLE OF CONTENTS |

||

TABLE OF CONTENTS |

|

||

1. |

SAFETY REGULATIONS ............................................................................... |

3 |

|

|

Regulations for using the machine safely |

|

|

2. |

IDENTIFICATION OF THE MACHINE AND COMPONENTS ........................ |

7 |

|

|

Explanations on how to identify the machine and its main components |

|

|

3. |

UNPACKING AND ASSEMBLY ..................................................................... |

9 |

|

|

Explanations on how to remove the packing and on how to assemble separat- |

||

|

ed parts |

|

|

4. |

CONTROLS AND INSTRUMENTS .............................................................. |

15 |

|

|

Position and functions of all the controls |

|

|

5. |

HOW TO USE THE MACHINE ...................................................................... |

22 |

|

|

Provides indications for working efficiently and safely |

|

|

|

5.1 |

Safety recommendations ........................................................................ |

22 |

|

5.2 |

Why the safety devices cut in ................................................................. |

22 |

|

5.3 |

Preliminary operations before starting work ........................................... |

24 |

|

5.4 |

Using the machine .................................................................................. |

27 |

|

5.5 |

Using on slopes ...................................................................................... |

35 |

|

5.6 |

Transporting ............................................................................................ |

36 |

|

5.7 |

Advice on how to obtain a good cut ....................................................... |

36 |

|

5.8 |

Summary of the main operations to be carried out in various conditions |

.... 37 |

6. |

MAINTENANCE ............................................................................................ |

39 |

|

|

All the information for maintaining the machine in peak efficiency |

|

|

|

6.1 |

Safety recommendations ........................................................................ |

39 |

|

6.2 |

Routine maintenance .............................................................................. |

39 |

|

6.3 |

Checks and adjustments ........................................................................ |

44 |

|

6.4 |

Dismantling and renewing parts ............................................................. |

52 |

7. |

TROUBLESHOOTING .................................................................................. |

59 |

|

|

A help in quickly resolving any problems |

|

|

8. |

ACCESSORIES ON REQUEST ................................................................... |

62 |

|

|

A description of the accessories available for particular types of work |

|

|

9. |

SPECIFICATIONS ......................................................................................... |

63 |

|

|

A summary of the main specifications of your machine |

|

|

10. ALPHABETICAL INDEX ............................................................................ |

64 |

||

|

Where information can be found |

|

|

SAFETY REGULATIONS |

EN 3 |

1.SAFETY REGULATIONS

1.1 HOW TO READ THE MANUAL

Some paragraphs in the manual containing information of particular importance for safety and operation are highlighted at various levels of emphasis, and signify the following:

NOTE |

or |

IMPORTANT |

These give details or further informa- |

|

|

tion on what has already been said, and aim to prevent damage to the machine.

–type of transmission: with mechanical gear-change or with hydrostatic continuous speed adjustment;

–blade engagement system, manual, pneumatic or electromagnetic clutch;

–special equipment and/or accessories.

The symbol highlights all differences in usage and is followed by the indication of the version to which it refers.

The symbol “ ” makes a reference to another part of the manual where further information or clarification can be found.

NOTE |

Whenever a reference is made to a position on the machine |

|

“front”, “back”, “left” or “right” hand side, this is determined by facing the direction of forward travel.

IMPORTANT For all usage and maintenance operations on the battery which are not described in this manual, consult the relevant manual which form an integral part of all the documentation supplied with the machine.

EN 4 |

SAFETY REGULATIONS |

1.2SAFETY REGULATIONS

(read carefully before using the machine)

A) TRAINING

1)Read the instructions carefully. Be familiar with the controls and the proper use of the equipment.

2)Never allow children or people unfamiliar with these instructions to use the lawnmower. Local regulations can restrict the age of the operator.

3)Never mow while people, especially children, or pets are nearby.

4)Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people or their property.

5)Do not carry passengers.

6)All drivers should seek and obtain professional and practical instruction. Such instruction should emphasise:

– the need for care and concentration when working with ride-on machines;

– control of a ride-on machine sliding on a slope will not be regained by the application of the brake. The main reasons for loss of control are:

– insufficient wheel grip;

– being driven too fast;

– inadequate braking;

– the type of machine is unsuitable for its task;

– lack of awareness of the effect of ground conditions, especially slopes;

– incorrect hitching and load distribution.

B) PREPARATION

1)While mowing, always wear substantial footwear and long trousers. Do not operate the equipment when barefoot or wearing open sandals.

2)Thoroughly inspect the area where the equipment is to be used and remove all objects which can be thrown by the machine.

3)DANGER! Petrol is highly flammable:

–store fuel in containers specifically designed for this purpose;

–refuel outdoors only and do not smoke while refuelling;

–add fuel before starting the engine. Never remove the cap of the fuel tank or add petrol while the engine is running or when the engine is hot;

–If petrol is spilled, do not attempt to start the engine but move the machine away from the area of spillage and avoid creating any source of ignition until the petrol vapours have dissipated;

–replace all fuel tank and container caps securely.

4)Replace faulty silencers.

5)Before using, always visually inspect to see that the blades, blade bolts and cutter assembly are not worn or damaged. Replace worn or damaged blades and bolts in sets to preserve balance.

6)On multi-bladed machines, take care as rotating one blade can cause other blades to rotate.

C) OPERATION

1) Do not operate the engine in a confined space where dangerous carbon monoxide

SAFETY REGULATIONS |

EN 5 |

fumes can collect.

2)Mow only in daylight or good artificial light.

3)Before attempting to start the engine, disengage all blade attachment clutches and shift into neutral.

4)Do not use on slopes of more than 10° (17%).

5)Remember there is no such thing as a “safe” slope. Travel on grass slopes requires particular care. To guard against overturning:

– do not stop or start suddenly when going up or downhill;

– engage the clutch slowly and always keep the machine in gear, especially when travelling downhill;

– machine speeds should be kept low on slopes and during tight turns;

– stay alert for humps and hollows and other hidden hazards;

– never mow across the face of the slope.

6)Use care when pulling loads or using heavy equipment:

– use only approved drawbar hitch points;

– limit loads to those you can safely control;

– do not turn sharply. Use care when reversing;

7) Stop the blades rotating before crossing surfaces other than grass.

8) Never operate the machine with defective guards, or without safety protective devices in place.

9) Do not change the engine governor settings or overspeed the engine. Operating the engine at excessive speed can increase the hazard of personal injury.

10) Before leaving the operator’s position:

– disengage the power take-off and lower the attachments;

– change into neutral and set the parking brake;

– stop the engine and remove the key.

11)Disengage drive to attachments, stop the engine and remove the ignition key:

– before clearing blockages or unclogging chutes;

– before cleaning, checking or working on the machine;

– after striking a foreign object. Inspect the machine for damage and make repairs before restarting and operating the equipment;

– If the machine starts to vibrate abnormally (check immediately).

12)Disengage drive to blades when transporting or not in use.

13)Stop the engine and disengage drive to the attachment:

–before refuelling;

–before removing the grass catcher.

14) Reduce the throttle setting during engine run-out and, if the engine is provided with a shut-off valve, turn the fuel off at the conclusion of mowing.

D) MAINTENANCE AND STORAGE

1)Keep all nuts, bolts and screws tight to be sure the equipment is in safe working condition.

2)Never store the equipment with petrol in the tank inside a building where fumes may reach an open flame or spark.

3)Allow the engine to cool before storing in any enclosure.

4)To reduce the fire hazard, keep the engine, silencer, battery compartment and petrol storage area free of grass, leaves, or excessive grease.

5)Check the grass catcher frequently for wear or deterioration.

6)Replace worn or damaged parts for safety.

7)If the fuel tank has to be drained, this should be done outdoors.

8)On multi-bladed machines, take care as rotating one blade can cause other blades to rotate.

9)When the machine is to be stored or left unattended, lower the cutting deck.

EN 6 |

SAFETY REGULATIONS |

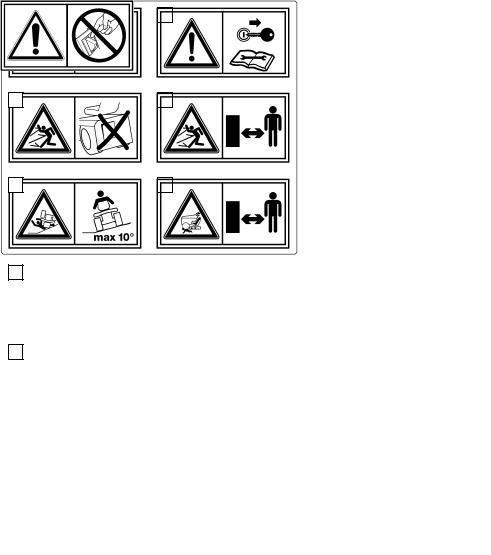

1.3 SAFETY DECALS

Your machine must be used with care. Therefore, decals have been placed on the machine, to remind you pictorially of the main precautions to take during use. These decals are to be considered an integral part of the machine.

If a decal should fall off or become illegible, contact your Dealer to replace it. Their meaning is explained below.

1

3

5

7

8

|

1 = Warning: Read the instruc- |

|

2 |

||

tions before operating this |

||

|

machine. |

|

|

2 = Warning: Disconnect the |

|

|

ignition key and read the instruc- |

|

|

tions before carrying out any |

|

|

repair or maintenance work. |

|

4 |

||

|

3 = Danger! Ejected objects: |

|

|

Do not operate without either the |

|

|

stone-guard or grass-catcher in |

|

|

place. |

|

|

|

|

6 |

4 = Danger! Ejected objects: |

|

|

||

|

Keep bystanders away. |

|

|

5 = Danger! Machine rollover: |

|

|

Do not use this machine on |

|

|

slopes greater then 10°. |

6 = Danger! Dismemberment: Make sure that children stay clear of the machine all the time when engine is running.

7 = Danger of cutting yourself. Blades in movement. Do not put hands or feet near or under the opening of the cutting plate.

8 = Warning: Do not manipulate the microswitch.

1.4 REGULATIONS FOR TOWING

A kit for towing a small trailer is available on request. This accessory is to be fitted as per the instructions provided. When using, do not exceed the recommended drawbar loads stated on the decal and follow the safety instructions, ( 1.2, C-6).

IDENTIFICATION OF THE MACHINE AND COMPONENTS |

EN 7 |

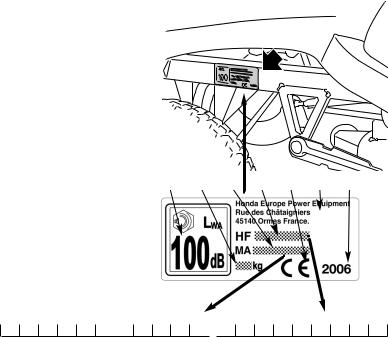

2.IDENTIFICATION OF THE MACHINE AND COMPONENTS

2.1 IDENTIFICATION OF THE MACHINE

The plate located on the left side of the main frame has the essential data of each machine.

The serial number (5) must be quoted when you require technical assistance or spare parts.

1. |

Acoustic power level according to direc- |

|

|

|

|

|

|

|

|

tive 2000/14/EEC |

|

|

|

|

|

|

|

2. |

Conformity mark according to directive |

1 |

6 |

5 |

4 |

2 |

7 |

3 |

|

98/37/EEC |

|||||||

|

|

|

|

|

|

|

|

|

3. Year of manufacture |

|

|

|

|

|

|

|

|

4. Type of machine |

|

|

|

|

|

|

|

|

5. Serial number |

|

|

|

|

|

|

|

|

6. Weight in kg |

|

|

|

|

|

|

|

|

7. |

Name and address of Manufacturer |

|

|

|

|

|

|

|

M A _ _ _ _  _ _ _ _ _

_ _ _ _ _

H F 2 _ _ _ _ _ E

H F 2 _ _ _ _ _ E

Note your |

Write your |

machine serial number here |

machine’s model here. |

HOW TO RECOGNIZE YOUR MACHINE

Preparation, use and maintenance of a range of machines with many differing features are described in this manual. It is therefore important to clearly identify your machine’s model in order to following all of the information regarding it.

Your machine’s model is indicated on the “identification label” in point 4 and is composed of a series of letters and numbers.

In the following pages of this manual, the model or models to which operations refer are indicated beforehand. The absence of any indication means it is valid for all models.

EN 8 |

IDENTIFICATION OF THE MACHINE AND COMPONENTS |

2.2 IDENTIFICATION OF MAIN COMPONENTS

Various main components can be seen on the machine, and these have the following functions:

1.Cutting deck: this is the guard enclosing the rotating blades.

2.Blades: these are what cut the grass. The wings at the ends help convey the cut grass towards the collector channel.

3.Collector channel: this is the part connecting the cutting deck to the grasscatcher.

4.Grass-catcher: as well as collecting the grass cuttings, this is also a safety element in that it stops any objects drawn up by the blades from being thrown outside of the machine.

5.Stone-guard or deflector (available as optional part): this can be fitted in place of the grass-catcher and prevents objects drawn up by the blades from being thrown outside of the machine.

6.Engine: this moves the blades and drives the wheels.

7.Battery: provides the energy for starting the engine. Its specifications and regulations for use are described in a specific manual.

8.Driver seat: this is where the machine operator sits. It has a sensor for detecting the presence of the operator which is a safety device.

9.Decals for regulations and safety: give reminders on the main provisions for working safely, each of which is explained in chapter 1.

10.Inspection hatch: for access to make several adjustments.

4 |

8 |

9 |

10 |

7 |

6 |

5

3 |

2 |

1 |

UNPACKING AND ASSEMBLY |

EN 9 |

3.UNPACKING AND ASSEMBLY

For storage and transport reasons, some components of the machine are not directly installed in the factory, but have to be assembled after their removal from the packing. Final assembly is carried out by following these simple instructions.

IMPORTANT The machine is supplied without engine oil or fuel. Before starting up the engine, fill with oil and fuel following the instructions.

3.1 UNPACKING

When unpacking the machine, take care to gather all individual parts and fittings, and do not damage the cutting deck when taking the machine off the base pallet. The packing contents:

–the machine;

–the steering wheel;

–the seat;

–the front bumper (if fitted);

–the grass-catcher brackets;

–the grass-catcher components;

–the battery charger;

–an envelope containing:

–the operator’s manuals and documents,

–the nuts and bolts including a pin for blocking the steering wheel,

–2 starter keys and a spare 10 A fuse.

NOTE |

To prevent damaging the cutting deck when getting the ma- |

|

chine down from the pallet, take it to the maximum height ( 4.6) and be very careful. In the hydrostatic drive models, to get the machine off the pallet and to move it more easily, put the drive disengage lever in position «B» ( 4.34).

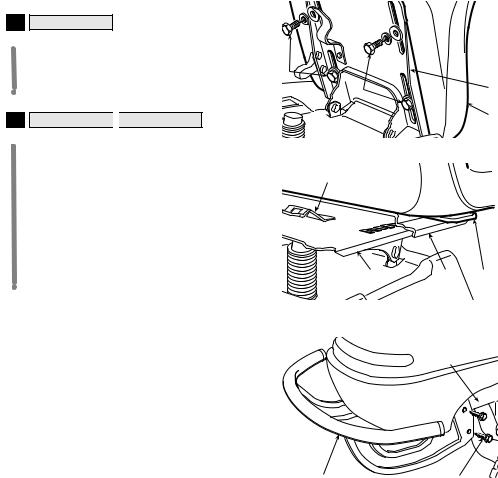

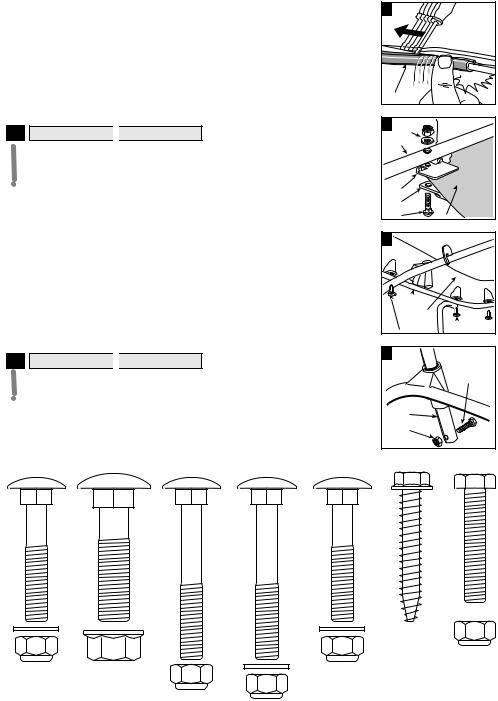

3.2 FITTING THE STEERING WHEEL

1

Put the machine on a flat surface and straighten up the front wheels.

Fit the steering wheel (1) onto the pro- |

|

truding shaft (2) with the spokes directed |

|

towards the seat. |

|

Line up the hole in the steering wheel hub |

3 |

EN 10 |

UNPACKING AND ASSEMBLY |

with the hole in the shaft and insert the pin supplied (3) using a hammer, ensuring that the end comes completely through to the opposite side.

NOTE |

To avoid damaging the steering wheel, use a punch of the |

|

same size to push the pin in the last part.

3.3 FITTING THE SEAT

HF2•••◊BE

Mount the seat (1) on the plate (2) using

the screws (3). |

3 |

|

HF2•••◊ME

HF2•••◊TE

HF2•••◊TE

Raise the adjustment lever (3) and fit the seat (1) in the slide (2), introducing it from the steering wheel’s side, till the seat engages in one of the 6 positions.

At this point the seat is engaged and cannot be removed unless the lever (4) is pressed, freeing it from its retainer.

3.4 FRONT BUMPER ASSEMBLY (if fitted)

Fit the front bumper (1) on the lower part of the frame (2) using the four screws (3).

3.5 CONNECTING THE BATTERY

3 |

2 |

|

1 |

4

2 |

1 |

3 |

2

1 |

3 |

The battery (1) is situated behind the engine and is held in place by an elastic strap (2). Unhook the elastic strap (2), remove the battery and its protective cover

(3) and pour the electrolytic solution (4) (Acid not supplied: specific gravity 1,280

UNPACKING AND ASSEMBLY |

EN 11 |

or 31,5° Baumé) until the indicated level is reached, distrib- |

3 |

uting it evenly among the six elements. |

|

6 |

|

Close the six caps |

|

|

(5) which are includ- |

|

|

|

|

|

|

|

|

ed and begin charg- |

|

|

|

ing the battery. |

4 |

|

|

Remount the bat- |

|

|

|

|

|

|

|

tery on the ma- |

|

1 |

|

chine. |

|

|

The elastic strap (2) |

|

|

|

|

|

|

2 |

7 |

shoud be placed |

|

behind the filling |

|

||

|

|

|

caps (5) of the battery. Connect the red cable (6) to first the positive terminal (+)

then the black cable (7) to the negative terminal (–) using 5

the supplied screws as indicated.

the supplied screws as indicated.

Grease the terminals with silicon grease, making sure that

Grease the terminals with silicon grease, making sure that

the protective cap of the red cable (6) is positioned correctly.

IMPORTANT After having activated the battery, continue charging it completely. Contact your Dealer who has all of the proper equipment available. The battery charger supplied is NOT able to carry out the first charging of the battery after it has been activated..

IMPORTANT To prevent the safety device in the electronics card from cutting in, never start the engine until the battery is fully charged!

Battery acid is corrosive and a pollutant. When handling, use protective gloves and dispose of properly following current regulations.

Battery acid is corrosive and a pollutant. When handling, use protective gloves and dispose of properly following current regulations.

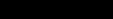

3.6GRASS-CATCHER SUPPORT ASSEMBLY

Fit the two brackets (1) on the rear plate (2), using for each bracket three screws

(3) which are supplied, as shown, without fully tightening the nuts (4).

4

1

3 |

2 |

The supports (1) must be mounted so that

EN 12 |

UNPACKING AND ASSEMBLY |

the wings (1a) are turned inwards.

Hook the upper part of the grass-catcher frame (5) onto the brackets and centre it up with the rear plate (2).

Adjust the position of the two brackets (1) to the stop (6) so that, when turning the grass-catcher frame, the pin (7) slots into the seat (8) correctly.

Check again that the frame (5) is properly centred with the rear plate (2) and that it rotates correctly, as shown above, and then fully tighten the screws (3) and the nuts (4).

5

1a

|

1 |

2 |

6 |

|

|

|

8 |

|

1 |

7 |

5 |

|

|

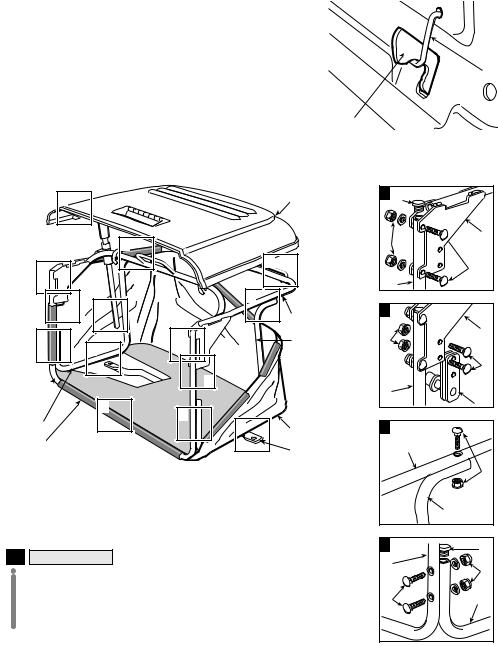

3.7 ASSEMBLING THE LEVERS FOR TIPPING THE GRASS-CATCHER

HF2•••HTE

Position the lever axle (1) in the notch of the two plates (2) and attach them on the internal side of the grass-catch- er supports (3), using the included screws (4) in the sequence shown.

Connect the end of the rod (5) of the lifting piston to the lever (6) with the pin

(7) and attach the two snap rings (8).

Before attaching the grass-catcher to its supports, make sure that the tipping lever moves properly.

4 3 1 4 3

4

4

1 |

2 |

8 |

7 |

5 |

|

6 |

|

|

8 |

UNPACKING AND ASSEMBLY |

EN 13 |

3.8 REMOVAL OF THE STOP FROM THE HOOKING PAWL OF THE GRASSCATCHER

For transport purposes, the pawl (1) hooking the grass-catcher is held onto the rear plate by a stop

(2). This stop must be removed before fitting the

grass-catcher brackets, and is not to be subse- |

2 |

|

|

quently used. |

|

|

1 |

3.9 GRASS-CATCHER ASSEMBLY |

|

H

19

C

C

A |

G

B

D

F |

2

E

7

12

17

H

C |

1 |

A |

7 |

B |

D |

11 |

F |

|

|

15 |

A) Join the upper part of the frame (1) to the front component (2) using the supplied screws and nuts (3) as shown. Fit the two rubber caps (4) into the holes in the tube of front frame (2).

HF2•••HTE

B)Before fully tightening the nuts (3), insert the two supports (5) between the plates of the upper frame (1) with the rollers turned inwards. Fasten them with the screws and nuts (6) and then fully tighten the nuts (3).

A |

4 |

|

1 |

3 |

|

|

3 |

|

2 |

B |

|

6 |

1 |

|

|

|

6 |

2 |

5 |

|

|

C |

|

|

1 |

|

8 |

|

7 |

D |

10 |

2 |

9 |

|

|

9 |

7 |

|

C-D) Attach the two side elements (7), using the screws and nuts (8 and 9) as

EN 14 |

UNPACKING AND ASSEMBLY |

shown. Fit the two rubber caps (10) into the holes in the two E side elements (7).

E) Insert the frame in the canvas cover (11) making sure it is correctly positioned on the base perimeter. Hook the plastic profiles (12) onto the frame tubes with the aid of a screw-dri- 12 ver (13).

13

13

|

K |

A |

|

CL |

|

HF2•••SBE

HF2•••HME

HF2•••HME

F)Place the plate (14) between the canvas and the lower part of the frame’s right side element (7a), lining up the holes.

F)Attach the stiffening bar (15) under the frame with screws and nuts (16) keeping the flat part turned towards the canvas.

G)Using the six screws (18), attach the cover (17) to the frame’s upper part (1).

HF2•••SBE

HF2•••HME

HF2•••HME

H)Insert the emptying lever (19) in its position and put in the limit stop screw (20) with its nut (21).

F |

16 |

|

|

|

|

7a |

|

|

14 |

|

|

15 |

|

|

16 |

11 |

|

G |

|

|

1  17

17

18 18

H

20

19

21

3 |

6 |

8 |

9 |

16 |

18 |

20 - 21 |

(x 4) |

(x 4) |

(x 2) |

(x 4) |

(x 2) |

|

(x 6) |

CONTROLS AND INSTRUMENTS |

EN 15 |

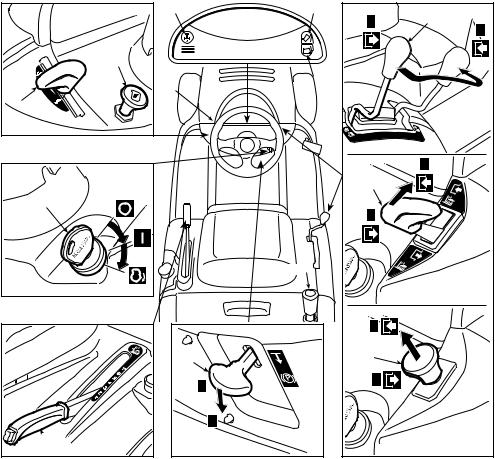

4.CONTROLS AND INSTRUMENTS

4.1STEERING WHEEL

Turns the front wheels.

4.2CHOKE CONTROL

This enriches the mixture so must only be used for the time necessary when starting from cold.

4.3 ACCELERATOR LEVER

Regulates the engine's r.p.m. The positions are indicated on the plate and corre-

4.7 |

4.9.2 |

4.8.1 |

|

A |

|

|

B |

|

|

|

|

4.2 |

4.9.3 |

|

|

|

|

4.1 |

|

|

4.3 |

|

|

|

|

B |

|

4.8.2 |

|

4.4 |

A |

|

|

|

4.9.1

|

|

B |

4.5 |

|

4.8.3 |

|

|

|

|

A |

A |

|

|

|

|

|

B |

4.6

4.6

EN 16 |

CONTROLS AND INSTRUMENTS |

spond to: |

|

«SLOW» |

for minimum engine speed |

«FAST» |

for maximum engine speed |

–When moving from one area to another, put the lever in a position between «SLOW» and «FAST».

–When cutting, go to the «FAST» position.

4.4 KEY IGNITION SWITCH

This key operated control has three positions:

«OFF» |

everything is switched off; |

«ON» |

activates all parts; |

«START» |

engages the starter motor. |

On being released at the «START» position, the key will automatically return to «ON».

4.5 PARKING BRAKE LEVER

This lever is to stop the machine from moving when it has been parked. There are two positions:

«A» = Brake off

«B» = Brake engaged

–The brake is engaged by fully pressing the pedal (4.21 or 4.31) and moving the lever to position «B». When you take your foot off the pedal it will be blocked in the down position.

–In models which include it, a pilot lamp will warn that the “brake is engaged” (4.10.d).

–To disengage the parking brake, press the pedal (4.21 or 4.31). The lever will return to position «A».

4.6 CUTTING HEIGHT ADJUSTING LEVER

There are seven positions for this lever, shown as "1" to "7" on the label, which

CONTROLS AND INSTRUMENTS |

EN 17 |

correspond to just as many cutting heights. Their values are indicated in the “Specifications table” ( Chapter 9).

–To go from one height to another, press the release button at the end of the lever.

4.7 PUSH-BUTTON FOR REVERSE MOWING

By keeping the push-button pressed, it is possible to engage the reverse gear and go backwards even with the blades engaged, without causing the engine to stop.

4.8 BLADE ENGAGEMENT AND BRAKE CONTROL |

|

|

|

HF2•••SBE |

A |

4.8.1 |

|

B |

|||

|

The lever (4.8.1) has two positions, as shown on the label and correspond to:

«A» = Blades disengaged

«A» = Blades disengaged

«B» = Blades engaged

«B» = Blades engaged

HF2315HME

HF2417◊••

HF2417◊••

The lever (4.8.2) inserts the blades with a pneumatic clutch and has two positions, as shown on the label. They correspond to:

«A» = Blades disengaged

«A» = Blades disengaged

«B» = Blades engaged

«B» = Blades engaged

– The “Blades engaged” condition is indicated by a  pilot lamp (4.10.c).

pilot lamp (4.10.c).

4.8.2

A

B

HF2620◊••

The mushroom switch (4.8.3) is for engaging the |

B |

||

blades by an electromagnetic clutch: |

4.8.3 |

||

«A» Pressed |

= Blades disengaged |

||

A |

|||

«B» Pulled |

= Blades engaged |

||

|

|||

– The “Blades engaged” condition is indicated by a  pilot lamp (4.10.c).

pilot lamp (4.10.c).

EN 18 |

CONTROLS AND INSTRUMENTS |

–If the blades are engaged when safety conditions have not been complied with, the engine shuts down and cannot be restarted ( 5.2).

–On disengaging the blades (position "A"), a brake is simultaneously activated which stops their rotation in few seconds.

–It is possible to engage the blades in reverse only by pressing push-button 4.7.

4.9 CONTROL FOR TIPPING GRASS-CATCHER

HF2•••SBE

HF2•••HME

HF2•••HME

The grass-catcher may be tipped to empty by pulling the lever (4.9.1), which can be extracted from its housing.

The grass-catcher may be tipped to empty by pulling the lever (4.9.1), which can be extracted from its housing.

HF2•••HTE

The grass-catcher may be emptied by pressing the pushbutton (4.9.2), keeping it pressed until the control motor stops.

The grass-catcher returns to the working position by pressing the push-button (4.9.3), keeping it pressed until the pawl hooks into place and the control motor stops.

4.9.1

4.9.2

4.9.2

4.9.3

4.9.3

4.10 INDICATOR LIGHTS AND SOUND WARNINGS ON THE DASHBOARD

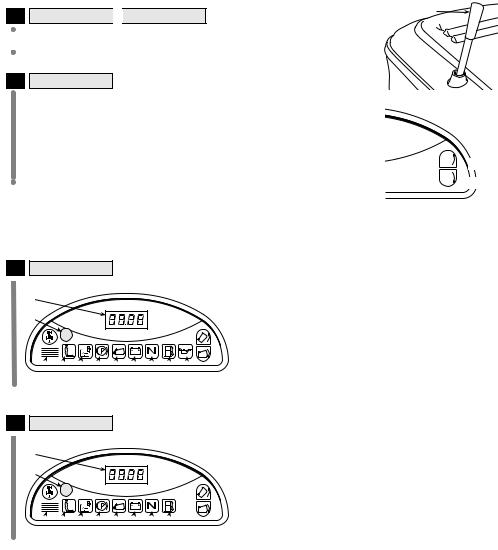

HF2620HTE

a

l

m

m b

b  c

c  d

d  e

e  f

f  g

g  h

h  j

j

HF2417HTE

a l

m

m b

b  c

c  d

d  e

e  f

f  g

g  h

h

a)The display comes on when the key is inserted (4.4):

–it indicates the battery voltage in the «ON» position, before starting the engine;

–it indicates the engine’s total operation time in the «ON» position, with the engine started;

–a blinking decimal point (.) indicates that the counter is working.

The warning lights come on when the key is in the «ON» position and stay on simultaneously for approximately 2 seconds (in combination with an intermittent warning sound) to indicate proper functioning.

CONTROLS AND INSTRUMENTS |

EN 19 |

HF2620HME

l

m

m b

b  c

c  d

d  e

e  f

f  g

g  h

h  j

j

HF2315HME

HF2417HME

HF2417HME

l

m

m b

b  c

c  d

d  e

e  f

f  g

g  h

h

HF2315SBE

HF2415SBE

HF2415SBE

m |

k |

Afterwards, when a warning light comes on, it indicates:

b) seat without operator;

c)

blades engaged;

blades engaged;

d) parking brake engaged;

parking brake engaged;

e)  missing grass-catcher or stoneguard;

missing grass-catcher or stoneguard;

f)  insufficient battery recharge; look for the causes in chapter 7 of this manual;

insufficient battery recharge; look for the causes in chapter 7 of this manual;

g)  transmission in “neutral” position.

transmission in “neutral” position.

h)  low fuel: it means that approx. 1.5 liters are left in the tank, which is enough for 30-40 minutes of normal work;

low fuel: it means that approx. 1.5 liters are left in the tank, which is enough for 30-40 minutes of normal work;

j)  problems with the engine’s lubrication: turn the engine off immediately and check the oil level ( 5.3.3). If the problem persists, contact your Dealer.

problems with the engine’s lubrication: turn the engine off immediately and check the oil level ( 5.3.3). If the problem persists, contact your Dealer.

k)  This warning light comes on when the key (4.4) is in the «ON» position and always stays on while operating.

This warning light comes on when the key (4.4) is in the «ON» position and always stays on while operating.

–If it blinks, it means that the engine cannot be started ( 5.2).

l)The sensor located inside the dashboard turns on the headlights automatically (in models where included) after approximately few of darkness and turns them off after few seconds of light.

–To avoid unnecessary use of them, keep the area near the sensor clean and do not place rags or objects on the dashboard.

m)There are two types of sound warnings:

–continuous the electronic card’s protection device has cut in;

–intermittent warning that the grass-catcher is full.

Loading...

Loading...