Hitachi C 8FSHE, C 8FSE User Manual

|

|

LIST Nos. |

|

|

|

|

C 8FSE: E948 |

|

|

|

|

C 8FSHE: E949 |

|

|

|

|

Feb. 2008 |

|

|

PRODUCT NAME |

|

|

|

|

Hitachi Slide Compound Miter Saw |

|

|||

Models |

C 8FSE, C 8FSHE |

|

||

MARKETING OBJECTIVE |

|

C |

||

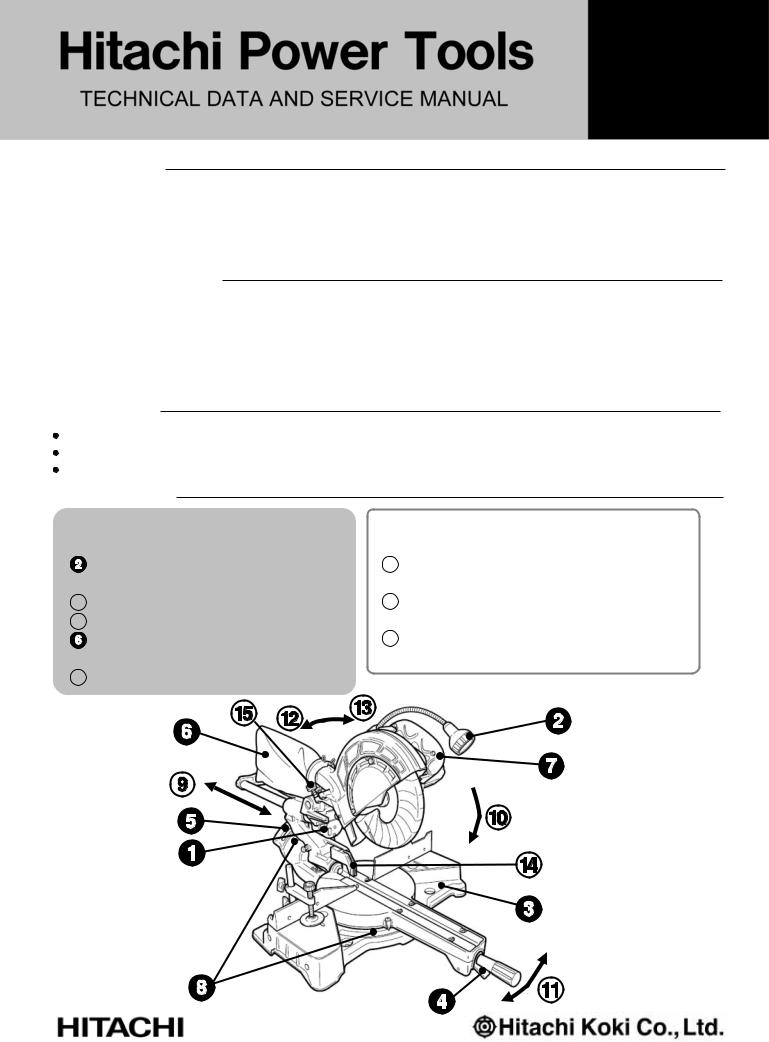

The new slide compound miter saws Models C 8FSE and C 8FSHE are developed to bring to the European |

||||

|

||||

market at the prices as low as the competitors’ products. The Model C 8FSHE is equipped with a laser marker |

|

|||

for easier alignment with the ink line and an LED light to illuminate the working surface brightly. In addition, the |

|

|||

Model C 8FSE that is mostly the same as the Model C 8FSHE except that it is not equipped with the laser |

|

|||

marker and the LED light is introduced in tandem with the Model C 8FSHE. With the new Models C 8FSE and |

|

|||

C 8FSHE, we aim to enhance the share of the Hitachi slide compound miter saw series. |

|

|||

APPLICATIONS |

|

|

|

|

Cutting various types of wood workpieces |

|

|

||

Cutting workpieces of plywood, decoration panels, soft fiberboards and hard boards |

|

|||

Cutting aluminum sashes |

|

|

||

SELLING POINTS |

|

|

||

[ NEW FEATURES ] |

<Same features as the conventional models> |

|

||

Laser marker (Only the Model C 8FSHE)

Laser marker (Only the Model C 8FSHE)

LED light (Only the Model C 8FSHE)

Lightweight

Lightweight

Positive angle stoppers

Positive angle stoppers

Bevel cutting range: Left 48° to right 5°

Bevel cutting range: Left 48° to right 5°

High dust collecting performance

Soft grip handle

Soft grip handle  Legible scale

Legible scale

Slide cutting

Slide cutting

Press cutting

Press cutting

Miter cutting

Miter cutting

Right and left bevel cutting

Right and left bevel cutting

Compound miter and left bevel cutting

Compound miter and left bevel cutting

Splinter guard, also serving for cut alignment

Splinter guard, also serving for cut alignment

Groove cutting

Groove cutting

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT.

C 8FSHE

International Sales Division

REMARK:

For more information about HANDLING INSTRUCTIONS, visit our website at:

http://www.hitachi-koki.com/manual_view_export/

Throughout this TECHNICAL DATA AND SERVICE MANUAL, a symbol(s) is(are) used in the place of company name(s) and model name(s) of our competitor(s). The symbol(s) utilized here is(are) as follows:

Symbols Utilized |

|

Competitors |

|

Company Name |

|

Model Name |

|

|

|

||

P1 |

DEWALT |

|

DW707 |

P2 |

DEWALT |

|

DW777 |

P3 |

DEWALT |

|

DW712 |

B |

BOSCH |

|

GCM8S |

|

CONTENTS |

|

|

|

Page |

SELLING POINT DESCRIPTIONS ----------------------------------------------------------------------------------------- |

1 |

|

SPECIFICATIONS -------------------------------------------------------------------------------------------------------------- |

6 |

|

1. |

Specifications -------------------------------------------------------------------------------------------------------------------------------- |

6 |

COMPARISONS WITH SIMILAR PRODUCTS-------------------------------------------------------------------------- |

8 |

|

1. |

Specification comparisons ------------------------------------------------------------------------------------------------------------- |

8 |

PRECAUTIONS IN SALES PROMOTION------------------------------------------------------------------------------ |

12 |

|

1. |

Safety instructions ----------------------------------------------------------------------------------------------------------------------- |

12 |

2. |

Precautions requiring particular attention during sales promotion ------------------------------------------ |

15 |

ADJUSTMENT AND OPERATIONAL PRECAUTIONS------------------------------------------------------------- |

16 |

|

1. |

Confirmation of saw blade lower limit position -------------------------------------------------------------------------- |

16 |

2. |

Confirmation for use of sub fence (Optional accessory) ---------------------------------------------------------- |

16 |

3. |

Position adjustment of laser line (Only the Model the C 8FSHE) -------------------------------------------- |

17 |

4. |

How to use the vise assembly --------------------------------------------------------------------------------------------------- |

18 |

5. |

Adjustment of table insert position --------------------------------------------------------------------------------------------- |

18 |

6. |

Cutting operation ------------------------------------------------------------------------------------------------------------------------- |

19 |

ADJUSTMENT OF COMPONENTS ------------------------------------------------------------------------------------- |

24 |

|

1. |

Bevel angle adjustment -------------------------------------------------------------------------------------------------------------- |

24 |

2. |

Ball bushing (Linear bearing) ----------------------------------------------------------------------------------------------------- |

24 |

PACKING |

----------------------------------------------------------------------------------------------------------------------- |

25 |

REPAIR GUIDE---------------------------------------------------------------------------------------------------------------- |

26 |

|

1. ---------------------------------------------------------------------------- |

Precautions in disassembly and reassembly |

26 |

2. ----------------------------------------------------------------------------------------------------------------- |

Troubleshooting guide |

43 |

STANDARD --------------------------------------------------------------------REPAIR TIME (UNIT) SCHEDULES |

48 |

|

Assembly diagram for C 8FSHE |

|

|

Assembly diagram for C 8FSE |

|

|

SELLING POINT DESCRIPTIONS

Laser marker (Only the Model C 8FSHE)

Laser marker (Only the Model C 8FSHE)

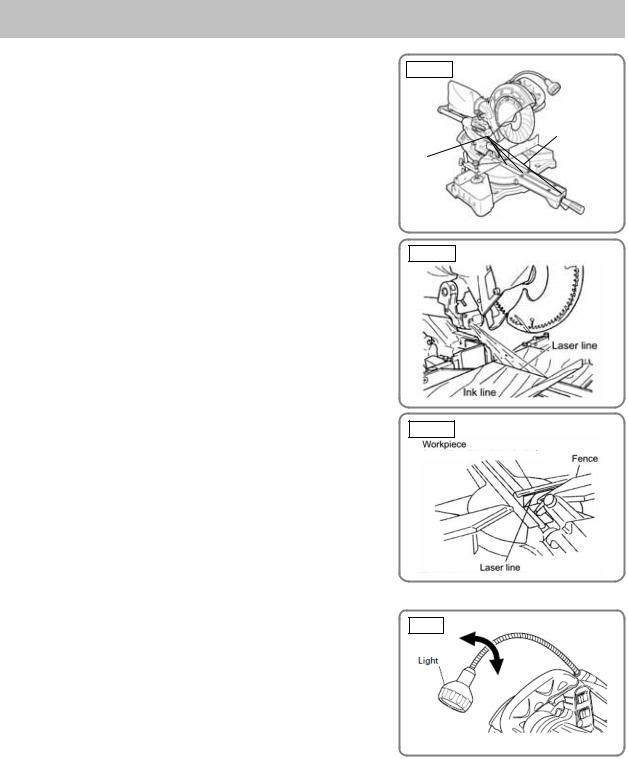

Use the laser marker for aligning with the ink line on the workpiece.

(1)Cutting position can be properly adjusted by aligning the positioning ink line with the laser line. There is no need to make a long ink line on the workpiece.

(2)There is no need to lower the motor head to align with the ink line because the laser marker makes a laser line on the workpiece. In addition, cutting position can be easily adjusted because the operator can hold the workpiece with both hands to move.

(3)Cutting position can be easily adjusted because the laser line can be aligned with an optionally angled ink line.

(4)Even the workpieces such as crown moldings and base boards that have decorative surfaces and are difficult to be made an ink line can be cut just by aligning the laser line with the ink line on the fence side. The laser line is adjusted to the width of the saw blade at the time of factory shipment. Depending upon the user's cutting choice, the laser line can be aligned with the left side of the cutting width (saw blade) or the ink line on the right side. Adjust the position of the laser line according to "Position adjustment of laser line" on page 17.

LED light (Only the Model C 8FSHE)

LED light (Only the Model C 8FSHE)

The Model C 8FSHE is equipped with an LED light to light up over a table brightly. The two LEDs incorporated in it light up the materials and the point of the saw blade brightly. The LED light can freely move at the time of right and left bevel cutting because the support is flexible. Therefore, it lights up the materials and the point of the saw blade brightly at any time.

Fig. 1-a

Laser beam

Laser marker

Fig. 1-b

Fig. 1-c

(molding, base board, etc.)

Fig. 2

Lightweight

Lightweight

The Model C 8FSE is most lightweight (14 kg) in the class of 8” (216 mm) slide compound miter saws because the reinforcement rib of the table is placed in the most suitable position.

-1-

Positive angle stoppers

Positive angle stoppers

The Models C 8FSE and C 8FSHE have positive angle stoppers in the turn table at the right and the left of the 0° center setting, at 15°, 22.5°, 31.6° and 45° settings. Thanks to the positive angle stoppers, positioning can be done more securely than the ball index method utilized in the current Model C 8FB2. In addition, a lever is provided at the lower tip of the turn table to secure or release the positive angle stoppers.

Adjustment of the turn table and positioning can be easily done while holding the side handle.

Bevel cutting range: Left 48° to right 5°

Bevel cutting range: Left 48° to right 5°

Possible range of bevel cutting is from left 48 degrees to right 5 degrees. By the simple operation of the set pin, you can set the position of the right angle and left 45 degrees.

In addition, setting to approximately 30 degrees and 33.9 degrees for crown molding cutting can be done by this set pin.

Fig. 3

Fig. 4

Set pin

High dust collecting performance

High dust collecting performance

The dust collecting performance of the Models C 8FSE and C 8FSHE are remarkably higher than the other models thanks to the adoption of new dust guide and gear case.

|

|

Table 1 |

|

|

|

(%) |

|

Cutting |

Maker |

HITACHI |

|

|

|

||

method |

Model |

C 8FSE |

|

C 8FB2 |

P1 and P2 |

P3 |

B |

|

C 8FSHE |

|

|

|

|

||

|

|

|

|

|

|

|

|

Press cutting *1 |

|

75.0 |

|

25.0 |

5.9 |

31.3 |

62.2 |

(Size of the workpiece: |

|

|

|||||

60 mm x 60 mm (2-3/8” x 2-3/8”)) |

|

|

|

|

|

|

|

Slide cutting *2 |

|

|

|

|

|

|

|

(Size of the workpiece: |

|

80.0 |

|

45.0 |

11.0 |

72.3 |

74.5 |

30 mm x 150 mm (1-3/16” x 5-29/32”)) |

|

|

|

|

|

|

|

*1: This is a method to cut a workpiece by shaking the motor head.

*2: This is a method to cut a workpiece by sliding the motor head from the front. The dust collecting performance is obtained from the following formula:

Weight of sawdust accumulated in the dust bag (g) x 100 Weight of all sawdust during cutting (g)

Soft grip handle

Soft grip handle

The handles are widely covered with soft-touch elastomer (rubber-like soft resin).

It is slip-resistant and securely fits in the palm of a hand even if the gripping hand sweats.

Legible scale

Legible scale

The Models C 8FSE and C 8FSHE have legibly labeled angle scale and bevel scale while the current Model C 8FB2 has the scale printed on the die casting.

-2-

Slide cutting

Slide cutting

|

|

|

Table 2 |

|

Unit: mm (inch) |

|

Max. |

Maker |

HITACHI |

|

|

|

|

Model |

|

|

|

|||

|

|

P1 and P2 |

P3 |

B |

||

cutting |

|

C 8FSE |

C 8FB2 |

|||

|

|

|

|

|||

dimension |

|

C 8FSHE |

|

|

|

|

|

|

|

|

|

||

|

|

65 x 312 |

|

|

|

|

Height x Width |

(2-9/16” x 12-1/4”) |

65 x 305 |

|

|

|

|

75 x 262 |

(2-9/16” x 12”) |

60 x 270 |

70 x 300 |

60 x 270 |

||

(H x W) |

(2-15/16” x 10-5/6”) |

75 x 265 |

(2-3/8” x 10-3/8”) |

(2-3/4” x 11-13/16”) |

(2-3/8” x 10-3/8”) |

|

|

|

with aux. board |

(2-15/16” x 10-7/16”) |

|

|

|

|

|

width 30 (1-3/16”) |

|

|

|

|

|

|

|

|

|

|

|

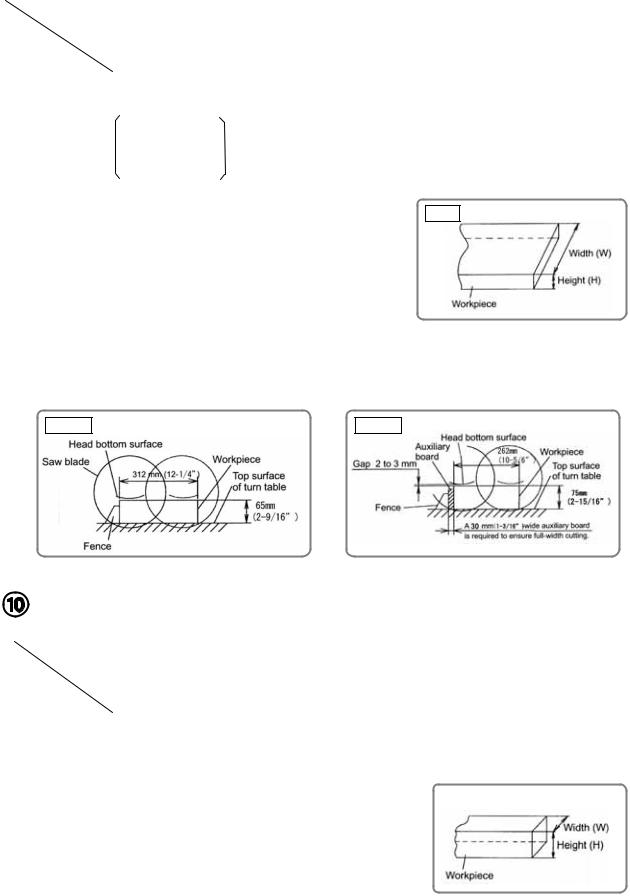

Workpieces as wide as shown in Table 2 can be cut with the motor head sliding. The lower limit position of the saw blade is factory-

adjusted so that workpieces up to 65 mm (2-9/16") high and 312 mm (12-1/4") wide can be cut as shown in Fig. 6-a. When cutting a workpiece of 75 mm (2-15/16") in height as indicated in [ ] in Table 2, adjust the saw so that there is a clearance of 2 to 3 mm (3/32" to 1/8") between the bottom surface of the head and the top surface of the

workpiece at the lower limit position of the saw blade as shown in Fig. 6-b. (See the Instruction Manual "Lower limit position of saw blade when cutting a large workpiece.")

Please note that, when cutting in this position, it is necessary to use an auxiliary board of 30 mm (1-3/16") wide so that the workpiece on the fence side can be cut fully in width.

Fig. 6-a |

Fig. 6-b |

Press cutting

|

|

|

|

Table 3 |

|

|

|

|

Unit: mm (inch) |

|

|

|

|

|

|

|

|

|

|

|

Max. |

Maker |

HITACHI |

|

|

|

|

|

|

|

Model |

|

|

|

|

|

|||

|

|

|

P1 and P2 |

|

|

P3 |

B |

||

|

cutting |

|

C 8FSE |

C 8FB2 |

|

|

|||

|

|

|

|

|

|

|

|||

|

dimension |

C 8FSHE |

|

|

|

|

|

||

|

|

|

|

|

|

|

|||

|

Height x Width |

65 x 65 |

65 x 65 |

60 x 60 |

|

70 x 40 |

60 x 68 |

||

|

(H x W) |

(2-9/16” x 2-9/16”) |

(2-9/16” x 2-9/16”) |

(2-3/8” x 2-3/8”) |

|

(2-3/4” x 1-9/16”) |

(2-3/8” x 2-11/16”) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Press cutting with the head swiveling enables cutting square |

Fig. 7 |

|

|||||||

|

|

|

|

||||||

workpieces as large as shown in Table 3 in a single sawing |

|

|

|

|

|

||||

operation. It is convenient for cutting narrow workpieces (Fig. 7). |

|

|

|

|

|||||

-3-

Miter cutting

Miter cutting

|

|

|

Table 4 |

|

|

Unit: mm (inch) |

|

Max. |

Maker |

HITACHI |

|

|

|

||

Model |

|

|

|

||||

|

|

P1 and P2 |

P3 |

B |

|||

cutting |

|

C 8FSE |

|

||||

|

C 8FB2 |

|

|

|

|||

dimension |

C 8FSHE |

|

|

|

|||

|

|

|

|

||||

Right and |

65 x 220 |

|

|

|

|

||

(2-9/16” x 8-21/32”) |

|

|

|

|

|||

left 45° |

75 x 185 |

65 x 220 |

60 x 190 |

70 x 212 |

60 x 190 |

||

Height x Width |

(2-15/16” x 7-1/4”) |

(2-9/16” x 8-21/32”) |

(2-3/8” x 7-15/32”) |

(2-3/4” x 6-11/32”) (2-3/8” x 7-15/32”) |

|||

(H x W) |

with aux. board |

|

|

|

|

||

|

|

width 20 (13/16”) |

|

|

|

|

|

|

|

65 x 170 |

|

|

|

|

|

Right 57° |

(2-9/16” x 6-11/16”) |

|

|

|

|

||

75 x 140 |

65 x 175 |

|

70 x 160 |

60 x 155 |

|||

Height x Width |

- |

||||||

(2-15/16” x 5-1/2”) |

(2-9/16” x 6-7/8”) |

(2-3/4” x 6-5/16”) |

(2-3/8” x 6-3/32”) |

||||

|

|||||||

(H x W) |

with aux. board |

|

|

|

|

||

|

|

width 20 (13/16”) |

|

|

|

|

|

Wide workpieces as wide as shown in Table 4 can be cut |

|

|

Fig. 8 |

||

by swiveling the turn table (right and left). |

||

|

The maximum cutting dimensions in [ ] in Table 4 are those obtained by adjusting the lower limit position of the saw blade indicated in Fig. 6-b, also with an auxiliary board.

Right and left bevel cutting

|

|

|

Table 5 |

|

Unit: mm (inch) |

||

Max. |

Maker |

HITACHI |

|

|

|

||

Model |

|

|

|

||||

|

|

P1 and P2 |

P3 |

B |

|||

cutting |

|

C 8FSE |

C 8FB2 |

||||

|

|

|

|

||||

dimension |

C 8FSHE |

|

|

|

|||

|

|

|

|

||||

|

|

45 x 312 |

|

|

|

|

|

Left 45° |

(1-25/32” x 12-1/4”) |

|

|

|

|

||

50 x 252 |

45 x 305 |

48 x 270 |

50 x 300 |

42 x 270 |

|||

Height x Width |

|||||||

(1-15/16” x 9-15/16”) |

(1-25/32” x 12”) |

(1-7/8” x 10-3/8”) |

(1-15/16” x 11-13/16”) |

(1-21/32” x 10-3/8”) |

|||

(H x W) |

with aux. board |

|

|

|

|

||

|

|

width 30 (1-3/16”) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60 x 312 |

|

|

|

|

|

Right 5° |

(2-9/16” x 12-1/4”) |

|

|

|

|

||

70 x 252 |

|

|

|

|

|||

Height x Width |

- |

- |

- |

- |

|||

(2-3/4” x 9-15/16”) |

|||||||

(H x W) |

with aux. board |

|

|

|

|

||

|

|

width 30 (1-3/16”) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 9

-4-

Compound miter and bevel cutting

|

|

|

Table 6 |

|

Unit: mm (inch) |

||

Max. |

Maker |

HITACHI |

|

|

|

||

Model |

|

|

|

||||

|

|

P1 and P2 |

P3 |

B |

|||

cutting |

C 8FSE |

C 8FB2 |

|||||

|

|

|

|||||

dimension |

C 8FSHE |

|

|

|

|||

|

|

|

|

||||

Miter left/right |

45 x 220 |

|

|

|

|

||

|

45° |

(1-25/32” x 8-21/32”) |

|

|

|

|

|

|

50 x 170 |

45 x 220 |

48 x 190 |

50 x 212 |

42 x 190 |

||

Bevel left 45° |

|||||||

(1-15/16” x 6-11/16”) |

(1-25/32” x 8-21/32”) |

(1-7/8” x 7-15/32”) |

(1-15/16”x6-11/32”) |

(1-21/32”x7-15/32”) |

|||

Height x Width |

with aux. board |

|

|

|

|

||

(H x W) |

width 30(1-3/16”) |

|

|

|

|

||

|

|

|

|

|

|

||

Miter left/right |

60 x 220 |

|

|

|

|

||

|

45° |

|

|

|

|

||

|

(2-9/16” x 8-21/32”) |

|

|

|

|

||

Bevel right |

70 x 170 |

- |

- |

- |

- |

||

|

45° |

(2-3/4” x 6-11/16”) |

|||||

|

|

|

|

|

|||

Height x Width |

with aux. board |

|

|

|

|

||

(H x W) |

width 30(1-3/16”) |

|

|

|

|

||

By turning the turn table to the left or right and inclining the saw blade section (head) to the left or right, the Models C 8FSE and C 8FSHE are capable of compound cutting (bevel and miter, see Figs. 10-a and 10-b) of workpieces with the maximum dimensions shown in Table 6.

Fig. 10-a |

Fig. 10-b |

Splinter guard, also serving for cut alignment

Splinter guard, also serving for cut alignment

When cutting the ends of a workpiece, splinters may drop on the saw blade and be cut into pieces. The Models C 8FSE and C 8FSHE are equipped with a splinter guard to prevent such splinter cutting.

(Refer to "SELLING POINTS  .") Safe cutting is also ensured in bevel cutting because the splinter guard is tilted with the saw blade.

.") Safe cutting is also ensured in bevel cutting because the splinter guard is tilted with the saw blade.

Groove cutting

Groove cutting

The Models C 8FSE and C 8FSHE can cut grooves at desired depth by adjusting the 6-mm depth adjustment bolt manually. (Refer to "Groove cutting procedures" described in the Instruction Manual for details.)

NOTE: The Models C 8FSE and C 8FSHE cannot cut grooves at constant depth unless the saw blade slides in parallel with the base surface.

|

|

|

|

|

|

|

|

|

|

Fig. |

11-a |

|

6 mm depth adjustment bolt |

|

Fig. |

11-b |

|

|

|

|

|

|

|

|

|||||

Slide |

direction |

|

Slide direction |

|

|||||

|

|

|

|

||||||

|

|

|

|

|

|

|

|||

|

|

|

|

Saw blade |

|

|

|

Saw blade |

|

|

|

|

|

Workpiece |

|

|

|

Workpiece |

|

|

|

|

Base surface |

Groove |

|

|

Base surface |

Groove |

|

|

|

|

[Model C 8FSE/C 8FSHE] |

|

|

[Model P1 and P2] |

|

||

-5-

|

|

|

|

|

SPECIFICATIONS |

|

|||||

1. Specifications |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Model |

|

|

|

|

|

|

C 8FSE/C 8FSHE |

|

||

|

|

0°(Right angle) |

65 mm x 312 mm (2-9/16” x 12-1/4”), |

|

|||||||

|

|

75 mm x 262 mm (2-15/16” x 10-5/6”) (with aux. board 30 mm (1-3/16”)) |

|||||||||

|

|

|

|

|

|||||||

|

|

|

|

Left/right 45° |

65 mm x 220 mm (2-9/16” x 8-21/32”), |

|

|||||

|

|

Miter |

|

75 mm x 185 mm (2-15/16” x 7-1/4”) (with aux. board 20 mm (13/16”)) |

|||||||

|

Maximum |

Right 57° |

65 mm x 170 mm (2-9/16” x 6-11/16”), |

|

|||||||

|

|

|

|

||||||||

|

|

|

75 mm x 140 mm (2-15/16” x 5-1/2”) (with aux. board 20 mm (13/16”)) |

||||||||

|

cutting |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

dimensions |

|

|

Left 45° |

45 mm x 312 mm (1-25/32” x 12-1/4”), |

|

|||||

|

Height x |

|

|

50 mm x 252 mm (1-15/16” x 9-15/16”) (with aux. board 30 mm (1-3/16”)) |

|||||||

|

Bevel |

|

|||||||||

|

Width |

|

|

|

|

|

|

|

|

||

|

|

60 mm x 312 mm (2-3/8” x 12-1/4”), |

|

||||||||

|

mm (inch) |

|

|

Right 5° |

|

||||||

|

|

|

|

|

70 mm x 252 mm (2-3/4” x 9-15/16”) (with aux. board 30 mm (1-3/16”)) |

||||||

|

|

Miter left/right 45°+ |

45 mm x 220 mm (1-25/32” x 8-21/32”), |

|

|||||||

|

|

bevel left 45° |

50 mm x 170 mm (1-15/16” x 6-11/16”) (with aux. board 30 mm (1-3/16”)) |

||||||||

|

|

Miter left/right 45°+ |

60 mm x 220 mm (2-3/8” x 8-21/32”), |

|

|||||||

|

|

bevel right 5° |

70 mm x 170 mm (2-3/4” x 6-11/16”) (with aux. board 30 mm (1-3/16”)) |

||||||||

|

Miter cutting ranges |

Left 0° - 45°, Right 0° - 57° |

|

||||||||

|

Bevel cutting ranges |

Left 0° - 48°, Right 0° - 5° |

|

||||||||

|

Compound (miter + bevel) |

Miter left 45° to right 45° + left bevel 0° to 45° |

|

||||||||

|

cutting ranges |

Miter left 45° to right 45° + right bevel 0° to 5° |

|

||||||||

|

|

|

|

|

|

||||||

|

Angle stopper positions |

0°, Right/left 15°, 22.5°, 31.6° and 45° |

|

||||||||

|

Applicable saw blade |

216 mm (8-1/2") external dia. |

|

||||||||

|

Saw blade bore |

U.S.A./Canada |

|

|

Europe/Australia |

|

|

Others |

|||

|

15.9 mm (5/8”) |

|

|

30 mm (1-11/64”) |

|

|

25.4 mm (1”) |

||||

|

|

|

|

|

|

|

|

|

|||

|

External diameter of applicable |

200 mm to 220 mm (7-7/8" to 8-21/32") |

|||||||||

|

saw blades |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Lower guard lock |

U.S.A./Canada |

|

|

Europe/Australia |

|

Others |

||||

|

Not provided |

|

|

Provided |

|

Not provided |

|||||

|

|

|

|

|

|

|

|

||||

|

Laser marker |

Maximum output |

< 1 mW (CLASS II) |

|

|||||||

|

(Only the |

|

Wave length |

400 nm to 700 nm |

|

|

|

|

|

|

|

|

Model |

|

|

|

|

|

|

|

|||

|

|

Laser medium |

Laser diode |

|

|

|

|

|

|

||

|

C 8FSHE) |

|

|

|

|

|

|

|

|||

|

Power source type and voltage |

AC single phase 50/60 Hz, 110 V, 120 V, 220 V to 240 V |

|||||||||

|

Type of motor |

AC single phase commutator series motor |

|

||||||||

|

Full-load current |

110 V: 10 A, 120 V: 9.2 A, 220 V: 5 A, 230 V: 4.8 A, 240 V: 4.6 A |

|

||||||||

|

No-load rotation speed |

5,500 min-1 |

|

|

|

|

|

|

|||

|

Max. output |

|

|

|

Approx. 2,100 W |

|

|

|

|

|

|

|

Main unit dimensions |

555 mm x 790 mm x 485 mm (21-27/32" x 31-3/32" x 19-3/32") |

|

||||||||

|

(Width x depth x height) |

|

|||||||||

|

|

|

|

|

|

|

|

||||

|

Weight |

|

|

|

C 8FSE 14 kg (31 lbs.) |

C 8FSHE 14.5 kg (32 lbs.) |

|

||||

|

Coating |

|

|

|

Gunmetallic silver |

|

|

|

|

|

|

|

Packaging |

|

|

|

Corrugated cardboard box |

|

|||||

|

Cord |

|

|

|

Type: 2-conductor cabtire cable Length: 1.8 m (6 ft) |

||||||

-6-

|

· 216 mm (8-1/2") TCT saw blade (15.9 mm (5/8”) bore, NT24, |

|

|

Code No. 998840 for USA/CAN) --------------------- |

for wood cutting |

|

· 216 mm (8-1/2") TCT saw blade (30 mm (1-11/64”) bore, NT24, |

|

|

Code No. 998859 for Europe/AUS) ----------------- |

for wood cutting |

|

· 216 mm (8-1/2") TCT saw blade (25.4 mm (1”) bore, NT24, |

|

|

Code No. 998858 for others) ------------------------- |

for wood cutting |

Standard accessories |

· Dust bag |

|

|

· Vise ass’y |

|

|

· 10 mm box wrench |

|

|

· Holder |

|

|

· Side handle |

|

|

· Sub fence (for USA/CAN) |

|

|

|

|

|

· 216 mm (8-1/2") TCT saw blade (15.9 mm (5/8”) bore, NT36, |

|

|

Code No. 998860 for USA/CAN) ------------------- |

for wood cutting |

|

· 216 mm (8-1/2") TCT saw blade (30 mm (1-11/64”) bore, NT36, |

|

|

Code No. 998861 for Europe/AUS) --------------- |

for wood cutting |

|

· 216 mm (8-1/2") TCT saw blade (25.4 mm (1”) bore, NT36, |

|

|

Code No. 996210 for others) ----------------------- |

for wood cutting |

|

· 216 mm (8-1/2") TCT saw blade (15.9 mm (5/8”) bore, NT60, |

|

|

Code No. 998862 for USA/CAN) ---------- |

for aluminum sash cutting |

|

· 216 mm (8-1/2") TCT saw blade (30 mm (1-11/64”) bore, NT60, |

|

Optional accessories |

Code No. 998863 for Europe/AUS) ------ |

for aluminum sash cutting |

|

· 216 mm (8-1/2") TCT saw blade (25.4 mm (1”) bore, NT60, |

|

|

Code No. 996288 for other) ---------------- |

for aluminum sash cutting |

|

· Extension holder and stopper (Code No. 321553) |

|

|

· Crown molding vise ass’y (Code No. 329782) |

|

|

(Including crown molding stopper (L)) |

|

|

· Crown molding stopper (L) (Code No. 321374) |

|

|

· Crown molding stopper (R) (Code No. 321373) |

|

|

· Sub fence ass’y (Code No. 329464) |

|

|

|

|

-7-

COMPARISONS WITH SIMILAR PRODUCTS

1. Specification comparisons

[For Europe and others (Except for the U.S.A and Canada)]

|

|

|

|

|

(Superior specifications: |

|

) |

|

|

|

|

|

|

|

|

|

|

Maker |

HITACHI |

P1 |

P2 |

B |

|

|||

Model name |

C 8FSE/C 8FSHE |

|

||||||

|

|

|

|

|

||||

|

0 (Right angle) |

65 x 312 (2-9/16” x 12-1/4”) |

60 x 270 |

60 x 270 |

60 x 270 |

|

||

|

75 x 262 (2-15/16” x 10-5/6”) |

|

||||||

|

|

|

(with aux. board 30 (1-3/16”)) |

(2-3/8” x 10-3/8”) |

(2-3/8” x 10-3/8”) |

(2-3/8” x 10-3/8”) |

|

|

|

|

|

|

|

|

|

|

|

(inch) |

|

|

|

|

|

|

|

|

|

Left/right 45° |

65 x 220 (2-9/16” x 8-21/32”) |

60 x 190 |

60 x 190 |

60 x 190 |

|

||

mm |

|

75 x 185 (2-15/16” x 7-1/4”) |

(2-3/8” x 7-15/32”) |

(2-3/8” x 7-15/32”) |

(2-3/8” x 7-15/32”) |

|||

Miter |

|

(with aux. board 20 (13/16”)) |

||||||

|

|

|

|

|

|

|

||

Width |

|

|

|

|

|

|

|

|

Right 57° |

65 x 170 (2-9/16” x 6-11/16”) |

- |

- |

60 x 155 |

|

|||

|

|

|||||||

|

|

|

|

|

||||

x |

|

75 x 140 (2-15/16” x 5-1/2”) |

(2-3/8” x 6-3/32”) |

|

||||

Height |

|

|

(with aux. board 20 (13/16”)) |

|

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

45 x 312 (1-25/32” x 12-1/4”) |

48 x 270 |

48 x 270 |

42 x 270 |

|

||

dimensions: |

|

Left 45° |

|

|||||

|

50 x 252 (1-15/16” x 9-15/16”) |

|

||||||

|

|

60 x 312 (2-3/8” x 12-1/4”) |

(1-7/8” x 10-3/8”) |

(1-7/8” x 10-3/8”) |

(1-21/32” x 10-3/8”) |

|||

|

Bevel |

|

(with aux. board 30 (1-3/16”)) |

|

|

|

|

|

cutting |

Right 5° |

70 x 252 (2-3/4” x 9-15/16”) |

- |

- |

- |

|

|

|

|

|

|

||||||

|

|

(with aux. board 30 (1-3/16”)) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Maximum |

|

|

|

|

(1-7/8” x 7-15/32”) |

|

||

bevel left 45° |

(with aux. board 30 (1-3/16”)) |

(1-7/8” x 7-15/32”) |

(1-21/32” x 7-15/32”) |

|||||

|

Miter left/right 45°+ |

45 x 220 (1-25/32” x 8-21/32”) |

48 x 190 |

48 x 190 |

42 x 190 |

|

||

|

|

|

50 x 170 (1-15/16” x 6-11/16”) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Miter left/right 45°+ |

60 x 220 (2-3/8” x 8-21/32”) |

- |

- |

|

|

|

|

|

70 x 170 (2-3/4” x 6-11/16”) |

- |

|

|

||||

|

bevel right 5° |

|

|

|||||

|

(with aux. board 30 (1-3/16”)) |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Groove cutting width |

Possible |

|

|

Possible |

|

|||

(with bolt height |

Impossible |

Impossible |

(with screw height |

|||||

|

|

|

adjustment) |

|

|

adjustment) |

|

|

|

|

|

|

|

|

|

|

|

Miter cutting ranges |

Left 0° - 45° |

Left 0° - 50° |

Left 0° - 50° |

Left 0° - 50° |

|

|||

Right 0° - 57° |

Right 0° - 50° |

Right 0° - 50° |

Right 0° - 58° |

|

||||

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

Bevel cutting ranges |

Left 0° - 48° |

Left 0° - 48° |

Left 0° - 48° |

Left 0° - 45° |

|

|||

Right 0° - 5° |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Miter left and right |

|

|

|

|

|

Compound |

0° - 45° |

Miter left and right |

Miter left and right |

Miter left and right |

||||

Bevel left 0° - 45° |

||||||||

(miter + bevel) |

|

0° - 45° |

0° - 45° |

0° - 45° |

|

|

||

|

|

|

||||||

cutting ranges |

Miter left and right |

Bevel left 0° - 45° |

Bevel left 0° - 45° |

Bevel left 0° - 45° |

||||

|

|

|

0° - 45° |

|

|

|

|

|

|

|

|

Bevel right 0° - 5° |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Angle stopper positions |

0°, Right/left 15°, 22.5°, |

0°, Right/left 15°, |

0°, Right/left 15°, |

0°, Right/left 15°, |

|

|||

31.6° , 45° |

22.5°, 30°, 45°, 50° |

22.5°, 30°, 45°, 50° |

22.5°, 30°, 45° |

|

||||

|

|

|

|

|||||

|

|

|

|

|

|

|

||

Saw blade external |

|

|

|

|

|

|

||

diameter mm (inch) |

216 (8-1/2") (24P) |

216 (8-1/2") (24P) |

216 (8-1/2") |

216 (8-1/2") (24P) |

||||

(No. of teeth) |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

-8- |

|

|

|

|

Maker |

HITACHI |

|

P1 |

|

P2 |

|

B |

|

|

Model name |

C8FSE/C8FSHE |

|

|

|

|

||||

|

|

|

|

|

|

|

|||

Laser marker |

Provided |

|

Not provided |

|

Not provided |

|

Provided |

|

|

Laser output |

< 1 mW |

|

- |

|

- |

|

< 1 mW |

|

|

Light |

Provided (2 LEDs) |

Not provided |

|

Not provided |

|

Provided |

|

||

Motor |

Full-load current (A) |

230 V - 4.8 A |

|

230 V - 5.6 A |

|

230 V |

|

230 V - 6.1 A |

|

No-load revolution |

5,500 |

|

6,700 |

|

6,300 |

|

5,000 |

|

|

|

|

|

|

|

|||||

|

(min-1) |

|

|

|

|

||||

Insulation structure |

Double insulation |

|

Double insulation |

Double insulation |

Double insulation |

||||

Splinter guard |

Provided |

|

Provided |

|

Not provided |

|

Not provided |

|

|

Type of angle stopper |

Positive stopper |

|

Positive stopper |

Positive stopper |

Positive stopper |

||||

Sub fence |

Not provided (Option) |

Not provided |

|

Provided |

|

Not provided |

|

||

|

|

|

|

|

|

|

|

|

|

Capacity of dust bag (l) |

2 |

|

- |

|

|

|

2 |

|

|

Main unit dimensions |

555 x 790 x 485 |

|

460 x 560 x 590 |

|

460 x 560 x 590 |

|

450 x 610 x 510 |

|

|

[Width x Depth x Height] |

(21-27/32" x 31-3/32" |

|

(18-1/8” x 22-1/16” |

|

(18-1/8” x 22-1/16” |

|

(17-23/32” x 24” |

|

|

mm (inch) |

x 19-3/32") |

|

x 23-7/32”) |

|

x 23-7/32”) |

|

x 20-3/32”) |

|

|

|

|

|

|

|

|

|

|

|

|

Product weight kg (lbs.) |

C 8FSE: 14 (31) |

|

14.5 (32) |

|

14 (31) |

|

15 (33.1) |

|

|

C 8FSHE: 14.5 (32) |

|

|

|

||||||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||

|

|

· 216 mm (8-1/2") TCT |

|

· 216 mm (8-1/2") TCT |

· 216 mm (8-1/2") TCT |

· 216 mm (8-1/2") |

|

||

|

|

saw blade (NT24) |

|

saw blade (NT24) |

|

saw blade |

|

TCT saw blade |

|

|

|

for wood cutting------- |

1 |

for wood cutting --- |

1 |

for wood cutting--- |

1 |

(NT24) --------- |

1 |

|

|

· Dust bag -------------- |

1 |

· Hex. bar wrench -- |

2 |

· Hex. bar wrench -- |

2 |

· Vise ass’y ------ |

1 |

Standard accessories |

· Vise ass’y ------------ |

1 |

· Fence insert------- |

1 |

· Dust bag ---------- |

1 |

· Hex. bar wrench |

|

|

· 10 mm box wrench |

1 |

|

|

· Dust extraction |

|

|

1 |

||

|

|

|

|

|

----------------- |

||||

|

|

· Holder ---------------- |

1 |

|

|

nozzles ----------- |

2 |

|

|

|

|

· Sub fence------------- |

1 |

|

|

|

|

|

|

|

|

(for USA/CAN) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

· Extension holder and |

|

· Legstand |

|

· Legstand |

|

· Extension bars |

|

|

|

stopper |

|

· Vise ass’y |

|

· Vise ass’y |

|

· 216 mm (8-1/2") |

|

|

|

· Crown molding vise |

|

· Roller table |

|

· Roller table |

|

TCT saw blade |

|

|

|

ass’y (Including crown |

|

· Length stop for short |

· Length stop for short |

(NT48) |

|

||

Optional accessories |

molding stopper (L)) |

|

workpieces |

|

workpieces |

|

|

|

|

· Crown molding |

|

|

|

· Dust extraction tubes |

|

|

|||

|

|

|

|

|

|

|

|||

|

|

stopper (L) |

|

|

|

· Three-way connector |

|

|

|

|

|

· Crown molding |

|

|

|

|

|

|

|

|

|

stopper (R) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-9-

[For the U.S.A and Canada]

|

|

|

|

(Superior specifications: |

|

) |

|

|

|

|

|

|

|

|

|

Maker |

HITACHI |

P3 |

|

||||

Model name |

C 8FSE/C 8FSHE |

C 8FB2 |

|

||||

|

|

|

|||||

|

0° (Right angle) |

65 x 312 (2-9/16” x 12-1/4”) |

65 x 305 (2-9/16” x 12”) |

70 x 300 |

|

||

|

75 x 262 (2-15/16” x 10-5/6”) |

|

|||||

|

75 x 265 (2-15/16” x 10-7/16”) |

(2-3/4” x 11-13/16”) |

|

||||

|

|

|

(with aux. board 30 (1-3/16”)) |

|

|||

|

|

|

|

|

|

|

|

(inch) |

|

|

|

|

|

|

|

|

Left/right 45° |

65 x 220 (2-9/16” x 8-21/32”) |

65 x 220 |

70 x 212 |

|

||

|

|

|

|||||

|

|

75 x 185 (2-15/16” x 7-1/4”) |

|

||||

mm |

|

(2-9/16” x 8-21/32”) |

(2-3/4” x 6-11/32”) |

|

|||

|

|

(with aux. board 20 (13/16”)) |

|

||||

Miter |

|

|

|

|

|

||

|

|

|

|

|

|

||

Width |

|

|

|

|

|

|

|

Right 57° |

65 x 170 (2-9/16” x 6-11/16”) |

65 x 175 |

70 x 160 |

|

|||

|

|

||||||

|

|

|

|

|

|

||

x |

|

75 x 140 (2-15/16” x 5-1/2”) |

(2-9/16” x 6-7/8”) |

(2-3/4” x 6-5/16”) |

|

||

Height |

|

|

(with aux. board 20 (13/16”)) |

|

|||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

45 x 312 (1-25/32” x 12-1/4”) |

45 x 305 |

50 x 300 |

|

||

dimensions: |

|

Left 45° |

|

||||

|

60 x 312 (2-3/8” x 12-1/4”) |

|

|||||

|

|

50 x 252 (1-15/16” x 9-15/16”) |

(1-25/32” x 12”) |

(1-15/16” x 11-13/16”) |

|

||

|

|

|

(with aux. board 30 (1-3/16”)) |

|

|||

|

Bevel |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

cutting |

Right 5° |

70 x 252 (2-3/4” x 9-15/16”) |

- |

- |

|

|

|

|

|

|

|||||

|

|

(with aux. board 30 (1-3/16”)) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Maximum |

|

|

|

|

|

|

|

bevel left 45° |

(with aux. board 30 (1-3/16”)) |

(1-25/32” x 8-21/32”) |

(1-15/16” x 6-11/32”) |

|

|||

|

Miter left/right 45°+ |

45 x 220 (1-25/32” x 8-21/32”) |

45 x 220 |

50 x 212 |

|

||

|

50 x 170 (1-15/16” x 6-11/16”) |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Miter left/right 45°+ |

60 x 220 (2-3/8” x 8-21/32”) |

|

|

|

|

|

|

70 x 170 (2-3/4” x 6-11/16”) |

- |

- |

|

|

||

|

bevel right 5° |

|

|

||||

|

(with aux. board 30 (1-3/16”)) |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Groove cutting width |

Possible |

Possible |

Possible |

|

|||

(with screw height |

(with screw height |

|

|||||

(with bolt height adjustment) |

|

||||||

|

|

|

adjustment) |

adjustment) |

|

||

|

|

|

|

|

|

|

|

Miter cutting ranges |

Left 0° - 45° |

Left 0° - 45° |

Left 0° - 50° |

|

|||

Right 0° - 57° |

Right 0° - 57° |

Right 0° - 60° |

|

||||

|

|

|

|

||||

|

|

|

|

|

|

|

|

Bevel cutting ranges |

Left 0° - 48° |

Left 0° - 45° |

Left 0° - 48° |

|

|||

Right 0° - 5° |

Right 0° - 2° |

|

|||||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Miter left and right |

|

|

|

|

Compound |

0° - 45° |

Miter left and right |

Miter left and right |

|

|||

Bevel left 0° - 45° |

|

||||||

(miter + bevel) |

|

0° - 45° |

0° - 45° |

|

|

||

|

|

|

|||||

cutting ranges |

Miter left and right |

Bevel left 0° - 45° |

Bevel left 0° - 45° |

|

|||

|

|

|

0° - 45° |

|

|

|

|

|

|

|

Bevel right 0° - 5° |

|

|

|

|

|

|

|

|

|

|

|

|

Angle stopper positions |

0°, Right/left 15°, 22.5°, |

0°, Right/left 15°, 22.5°, |

0°, Right/left 10°,15°, 22.5°, |

|

|||

31.6°, 45°, |

|

|

|||||

31.6° , 45° |

31.6°, 35.3°, 45° |

|

|

||||

|

|

|

Left 50°, Right 60° |

|

|||

|

|

|

|

|

|

||

|

|

|

|

|

|

||

Saw blade external |

|

|

|

|

|

||

diameter mm (inch) |

216 (8-1/2") (24P) |

216 (8-1/2") (24P) |

216 (8-1/2") (30P) |

|

|||

(No. of teeth) |

|

|

|

|

|

||

-10-

Maker |

HITACHI |

|

|

P3 |

|

|||

Model name |

C 8FSE/C 8FSHE |

|

C 8FB2 |

|

|

|

||

|

|

|

|

|

||||

Laser marker |

Provided |

|

Not provided |

|

|

Not provided |

|

|

Laser output |

< 1 mW |

|

- |

|

- |

|

||

Light |

Provided (2 LEDs) |

|

Not provided |

|

|

Not provided |

|

|

Motor |

Full-load current (A) |

120 V – 9.2 A |

|

115 V – 9.5 A |

|

|

120 V - 15 A |

|

No-load revolution |

5,500 |

|

4,900 |

|

5,400 |

|

||

|

|

|

|

|||||

|

(min-1) |

|

|

|

||||

Insulation structure |

Double insulation |

|

Double insulation |

|

|

Double insulation |

|

|

Splinter guard |

Provided |

|

Provided |

|

|

Not provided |

|

|

|

|

|

(Option) |

|

||||

|

|

|

|

|

|

|

|

|

Type of angle stopper |

Positive stopper |

|

Ball index |

|

|

Positive stopper |

|

|

Sub fence |

Provided |

|

Not provided |

|

|

Provided |

|

|

|

|

|

|

|

|

|

||

Capacity of dust bag (l) |

2 |

|

2 |

|

- |

|

||

|

|

|

|

|

|

|

|

|

Main unit dimensions |

555 x 790 x 485 |

|

520 x 755 x 500 |

|

|

580 x 720 x 555 |

|

|

[Width x Depth x Height] |

(21-27/32" x 31-3/32" |

|

(20-15/32” x 29-23/32” |

|

|

(22-27/32” x 28-11/32” |

|

|

mm (inch) |

x 19-3/32") |

|

x 19-11/16”) |

|

|

x 21-27/32”) |

|

|

|

|

|

|

|

|

|

|

|

Product weight kg (lbs.) |

C 8FSE: 14 (31) |

|

17.5 (38.6) |

|

19.5 (43) |

|

||

C 8FSHE: 14.5 (32) |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

· 216 mm (8-1/2") TCT |

|

· 216 mm (8-1/2") TCT |

|

|

· 216 mm (8-1/2") |

|

|

|

saw blade (NT24) |

|

|

|

|

||

|

|

|

saw blade (NT24) |

|

|

TCT saw blade |

|

|

|

|

for wood cutting |

1 |

|

|

|

||

|

|

for wood cutting |

1 |

|

(NT30) |

1 |

||

|

|

· Dust bag |

1 |

|

||||

|

|

· Dust bag |

1 |

|

· Blade spanner |

1 |

||

Standard accessories |

· Vise ass’y |

1 |

|

|||||

· 10 mm box wrench. |

1 |

|

|

|

||||

· 10 mm box wrench |

1 |

|

|

|

||||

|

|

· Vise ass’y |

1 |

|

|

|

||

|

|

· Holder |

1 |

|

|

|

||

|

|

· Slide fence ass’y |

1 |

|

|

|

||

|

|

· Sub fence |

1 |

|

|

|

||

|

|

|

|

|

|

|

||

|

|

(for USA/CAN) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

· Extension holder and |

|

· Stopper |

|

|

· Legstand |

|

|

|

stopper |

|

· 216 mm (8-1/2") TCT |

|

|

· Fence insert |

|

|

|

· Crown molding vise |

|

saw blade (NT36) |

|

|

· Dust extraction kit |

|

|

|

ass’y (Including crown |

|

for wood cutting |

|

|

· Carrying strap |

|

Optional accessories |

molding stopper (L)) |

|

· 216 mm (8-1/2") TCT |

|

|

|

|

|

· Crown molding |

|

saw blade (NT60) |

|

|

|

|

||

|

|

stopper (L) |

|

for wood cutting |

|

|

|

|

|

|

· Crown molding |

|

· 216 mm (8-1/2") TCT |

|

|

|

|

|

|

stopper (R) |

|

saw blade (NT60) |

|

|

|

|

|

|

|

|

for aluminum cutting |

|

|

|

|

|

|

|

|

|

|

|

|

|

-11-

PRECAUTIONS IN SALES PROMOTION

1. Safety instructions

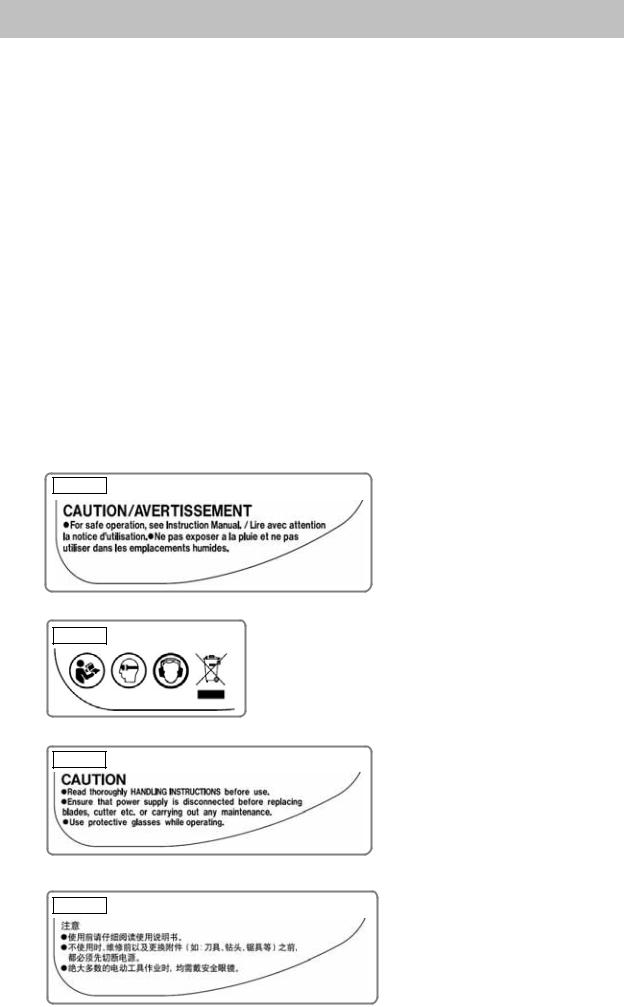

In the interest of promoting the safest and most efficient use of the Models C 8FSE and C 8FSHE Slide Compound Miter Saws by all of our customers, it is very important that at the time of sale the salesperson carefully ensures that the buyer seriously recognizes the importance of the contents of the Instruction Manual, and fully understands the meaning of the precautions listed on the Warning Labels, Warning Signs and Caution Labels attached to each machine.

A. Instruction manual

Although every effort is made in each step of design, manufacture and inspection to provide protection against safety hazards, the dangers inherent in the use of any slide compound miter saw cannot be completely eliminated. Accordingly, general precautions and suggestions for the use of electric power tools, and specific precautions and suggestions for the use of the slide compound miter saw are listed in the Instruction Manual to enhance the safe, efficient use of the tool by the customer. Salespersons must be thoroughly familiar with the contents of the Instruction Manual to be able to offer appropriate guidance to the customer during sales promotion.

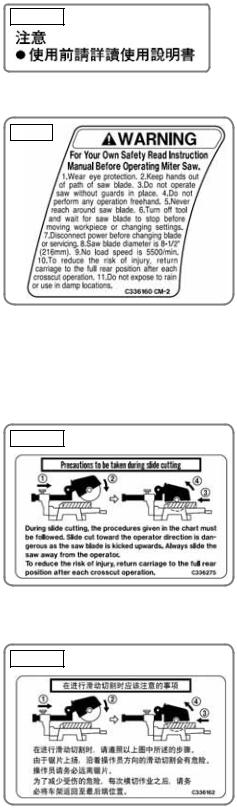

B. Warning labels and caution labels

(1) Precautions on the name plate

Each of the Models C 8FSE and C 8FSHE is furnished with a Name Plate that lists the following precautions. For the U.S.A. and Canada

Fig. 12-a

For Europe

Fig. 12-b

For Australia and Asia

Fig. 12-c

For China

Fig. 12-d

-12-

For Taiwan

Fig. 12-e

(2) Warning label (A) (for the U.S.A. and Canada)

Fig. 13

Warning label (A) specified by the UL is affixed on the left side of the gear case.

Please instruct users to strictly observe the 11 items of precautions in warning label (A) shown above.

(3) Caution labels (A) and (B) (at the front of the base)

·Caution label (A) (at the front of the base)

For the U.S.A., Canada, Europe, Australia and Asia

Fig. 14-a

·Caution label (B) (at the front of the base) For China

Fig. 14-b

-13-

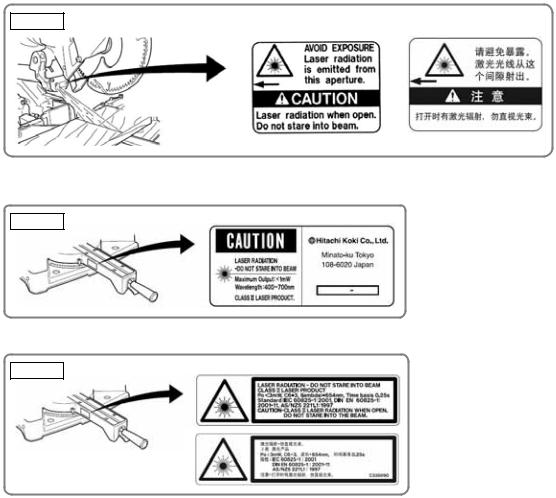

(4)Caution label (J) (at the front of the hinge) and caution labels (C) and (E) (at the front left of the turn table) (only the Model C 8FSHE)

Do not stare into laser beam. If your eye is exposed directly to the laser beam, it can be hurt. Caution

label (J) and caution labels (C) and (E) are adhered to each machine to comply with the standards for the safe use of laser equipment.

· Caution label (J) (at the front of the hinge) (only the Model C 8FSHE)

Fig. 15-a

·Caution labels (C) and (E) (at the front left of the turn table) (only the Model C 8FSHE) For the U.S.A. and Canada

Fig. 15-b

For Europe, Australia, China and Asia

Fig. 15-c

C. Relative standards

Standards, regulations and guidelines for the safe use of laser equipment [The U.S.A.] FDA CDRH 21 CFR

[AUS/NZL] AS/NZS 2211.1: 2001 [Europe] EN 60825-1: 2001-11

D. Laser marker (only the Model C 8FSHE)

The Model C 8FSHE is equipped with the laser marker that complies with the Class II requirements of the standard specified in "Relative standards." The Class II laser is defined as follows:

·The laser power is low and it is safe by the protective measures such as blinking.

However, it is dangerous if the operator’s eyes are exposed directly to the laser for a protracted period.

·The operator can use the laser equipment without particular training and instruction.

·The amount of light exposure (output) is 1 mW or less at the position where the operator can be exposed to the laser radiation during operation. (This is in the case of the U.S.A. The measuring methods and the output values are different depending on the standards.)

The saw blade unit prevents access of the operator’s eye to the laser-emitting aperture less than 65 mm. In addition, the amount of light exposure (output) is 1 mW or less (about 0.4 mW) at this position. Thus the Model C 8FSHE satisfies the Class II requirements adequately. There is no ill effect on the operator’s body if looking at the laser line on the workpiece during operation.

-14-

CAUTION: (1) Be sure to disconnect the power cord plug from the receptacle before removing the laser marker for repair. If it is unavoidable to check the operation of the removed laser marker with the power turned on, face the laser emitting aperture to the ground to show the laser line on the ground.

(2) Laser radiation when open. DO NOT STARE INTO BEAM OR VIEW DIRECTLY WITH OPTICAL INSTRUMENTS.

The life span of the laser marker in the Model C 8FSHE is about 3,600 hours. (About 3 years: 5 hours of use/day x 240 days/year)

2. Precautions requiring particular attention during sales promotion

A. Ambient illuminance and visibility of laser line (only the Model C 8FSHE)

The visibility of the laser line on the workpiece changes depending on the brightness of the working environment. Instruct the customer to consider the brightness of the working environment when using the laser marker referring to the following table.

Table 7 Ambient illuminance and visibility of laser line

Illuminance (lux) |

3000 or more |

3000 or more |

3000 - 2500 |

800 - 600 |

300 - 200 |

150 - 80 |

30 or less |

|

|

|

Under direct |

Shaded area |

Cloudy |

Shaded area |

Just before |

|

|

|

|

the sunset in |

|

|

||||

|

Outdoor |

sunlight of fine |

in cloudy |

- |

|

|||

|

in fine weather |

weather |

cloudy |

|

||||

|

|

weather |

weather |

|

|

|||

Ambient |

|

|

|

weather |

|

|

||

|

|

|

|

|

|

Ink line is |

||

|

|

|

|

|

|

Near the |

||

conditions |

|

|

|

|

Near the |

|

||

|

|

|

|

|

window |

invisible. |

||

(reference) |

|

|

Near the |

Indoor under |

window |

Indoor under |

||

Indoor |

- |

under cloudy |

|

|||||

|

window under |

under |

cloudy |

|

||||

|

fine weather |

weather, just |

|

|||||

|

|

|

fine weather |

cloudy |

weather |

|

||

|

|

|

|

before the |

|

|||

|

|

|

|

|

weather |

|

|

|

|

|

|

|

|

|

sunset |

|

|

|

|

|

|

|

|

|

|

|

Laser |

line |

Invisible |

Visible |

Visible |

Visible |

Visible |

Glaring |

Glaring |

(The working environment where the illuminance is 200 luxes or less is dark and difficult to operate the Model C 8FSHE.)

The laser line is invisible under direct sunlight of fine weather. Prepare a shaded area or relocate to a shaded area to operate the Model C 8FSHE.

When a laser line is dazzling, please light up the laser line with a LED light. You can watch a laser line if you do so.

B. Precautions concerning brake

The Models C 8FSE and C 8FSHE are equipped with a "brake" that stops running when the switch is turned off. Normally the operation is stopped in 5 - 6 seconds when the switch is turned off. If it takes 10 seconds or more to stop, absolutely avoid further use of this machine. In this event, ensure that your customers bring this machine in their local Hitachi power tools dealer or Hitachi power tools center for servicing.

(1)Be sure to use the carbon brushes dedicated to the Models C 8FSE and C 8FSHE (110 V to 120 V: Code No. 999021, 220 V to 240 V: Code No. 999001). Use of other carbon brushes will adversely affect the brake performance.

(2)If the brake should fail to work, check the carbon brushes. Replace the carbon brushes with new ones if their length is shorter than 6 mm. If the brake still does not work, replace the armature ass’y.

-15-

ADJUSTMENT AND OPERATIONAL PRECAUTIONS

1. Confirmation of saw blade lower limit position

The lower limit of the saw blade cutting depth is factory-adjusted so that when the saw blade is fully lowered, its cutting edge is 10 to 11 mm (13/32" to 7/16") below the upper surface of the turn table in order to cut workpieces completely without cutting the bottom of the turn table groove. Lower the saw blade and check that it stops at the correct position (Fig. 16-a).

When changing the position of the 8 mm depth adjustment bolt that serves as the lower limit position stopper of the saw blade, perform the following steps.

(1)Make the tip of the 8 mm depth adjustment bolt contact with the hinge.

(2)Turn the 8 mm depth adjustment bolt with a 13-mm wrench to adjust the lower limit position of the saw blade (Fig. 16-c).

CAUTION: Perform the adjustment carefully to ensure that the saw blade does not cut into the turn table.

Fig. 16-a |

Fig. 16-b |

8 mm depth adjustment bolt

Turn table

Fig. 16-c

8 mm depth adjustment bolt

2. Confirmation for use of sub fence (Optional accessory)

The sub fence is optionally available (located at the front right of the base). Use the sub fence for miter cutting and right bevel cutting. The sub fence supports the workpiece widely for stable cutting. In the case of left bevel cutting, raise the sub fence as illustrated in Fig. 17 and turn it counterclockwise.

*For the U.S.A. and Canada, the Models C 8FSHE and C8FSE are equipped with the sub fence as a standard accessory.

Fig. 17

Sub fence

NOTE: Mount the sub fence as follows.

Insert the flat-head screw M6 into fence (B) and mount the sub fence and the plate. Then tighten the nylon nut M6 with the attached 10-mm box wrench so that the sub fence can turn smoothly.

WARNING: In the case of left bevel cutting, turn the sub fence counterclockwise. Otherwise the main body or the saw blade may contact the sub fence resulting in an injury. Be sure to instruct the customers to turn the sub fence counterclockwise in the case of left bevel cutting.

-16-

3. Position adjustment of laser line (Only the Model C 8FSHE)

The laser line is adjusted to the width of the saw blade at the time of factory shipment. Depending upon the cutting choice, align the laser line with the left side of the cutting width (saw blade) or the right side according to the following procedure.

First, make a right-angle ink line on the workpiece that is about 20 mm (25/32") in height and 150 mm (5-29/32") in width.

To cut the right side of the ink line with the saw blade as shown in Fig. 18, align the left side of the saw blade with the ink line on the workpiece and make a groove of about 5 mm deep on the workpiece to the middle. Hold the grooved workpiece by the vise as it is and do not move it. (For grooving work, refer to the Instruction Manual "Groove cutting procedures.")

Light up the laser marker. Turn the adjuster to align the laser line with the ink line. (Turning the adjuster clockwise will shift the laser line position to the right and turning counterclockwise will shift to the left.) (Fig. 19)

Thus the cutting position matches the laser line position. Align the ink line on the workpiece with the laser line. When aligning the ink line, slide the workpiece little by little and secure it by vise at a position where the laser line overlaps with the ink line (Fig. 20). Work on the grooving again and check the position of the laser line. When the ink line and the laser line are overlapped, the strength and weakness of light will change, resulting in a stable cutting operation because you can easily discern the conformity of lines. This ensures the minimum cutting errors.

WARNING:

Fig. 18

Fig. 19

Vise assembly

Fig. 20

•Make sure before plugging the power plug into the receptacle that the main body and the laser marker are turned off.

•Exercise utmost caution in handling a switch trigger for the position adjustment of the laser line, as the power plug is plugged into the receptacle during operation. If the switch trigger is pulled inadvertently, the saw blade can rotate and result in unexpected accidents.

•Do not remove the laser marker to be used for other purposes.

CAUTION:

•Laser radiation - Do not stare into beam.

•Laser radiation on work table - Do not stare into beam.

If your eye is exposed directly to the laser beam, it can be hurt.

•Do not dismantle it.

•Do not give strong impact to the laser marker (main body of tool); otherwise, the position of a laser line can go out of order, resulting in the damage of the laser marker as well as a shortened service life.

•Keep the laser marker lit only during a cutting operation. Prolonged lighting of the laser marker can result in a shortened service life.

NOTE:

•Perform cutting by overlapping the ink line with the laser line. When the ink line and the laser line are overlapped, the strength and weakness of light will change, resulting in a stable cutting operation because you can easily discern the conformity of lines. This ensures the minimum cutting errors.

•In outdoor or near-the-window operations, it may become difficult to observe the laser line due to the sunlight. Under such circumstances, move to a place that is not directly under the sunlight and engage in the operation.

•Do not tug on the cord behind the motor head or hook your finger, wood and the like around it; otherwise, the cord may come off and the laser marker may not be lit up.

Instruct the above precautions on the laser marker to the customers.

-17-

4. How to use the vise assembly

(1)The vise assembly can be mounted on either the left fence (fence (B)) or the right fence (fence (A)) by loosening 6 mm wing bolt (A).

(2)The screw holder can be raised or lowered according to the height of the workpiece by loosening 6 mm wing bolt (B). After the adjustment, firmly tighten 6 mm wing bolt (B) and fix the screw holder.

(3)Turn the upper knob and securely fix the workpiece in position (Fig. 21).

Fig. 21

6 mm wing bolt (B)

6 mm wing bolt (A)

WARNING: Always firmly clamp or vise to secure the workpiece to the fence; otherwise the workpiece might be thrust from the table and cause bodily harm.

CAUTION: Always confirm that the motor head does not contact the vise assembly when it is lowered for cutting. If there is any danger that it may do so, loosen 6 mm wing bolt (B) and move the vise assembly to a position where it will not contact the saw blade.

5. Adjustment of table insert position

The table inserts are installed on the turn table. When the machine is shipped from the factory, the table inserts are positioned so that there is no chance that the saw blade will come in contact with either side of the saw blade slot even if the machine is used for 45° bevel cutting. Before operating the machine, adjust the position of the table inserts so that the sides of the saw blade align with the edges of the table inserts according to the following procedure.

First, loosen the three 6-mm machine screws that fasten the table inserts, and temporarily tighten the two outside screws (front and back). Next, clamp a workpiece (about 200 mm (7-7/8") wide) with the vise assembly and cut the workpiece. Align the cutting surfaces with the table inserts as shown in Figs. 22-a and b, and securely tighten the front and back 6-mm machine screws. Finally, remove the workpiece and securely tighten the middle 6-mm machine screw.

If adjustment is done as described, workpieces can be cut precisely by aligning the appropriate side edge of the table inserts with the ink line on the workpiece. Adjust the table inserts as necessary for the type of cutting desired (right-angle or left bevel cutting).

Fig. 22-a |

|

|

|

Fig. 22-b |

|

|

|

|

|

|

|||||

6 mm |

|

6 mm |

|||||

machine |

|

|

|

machine |

|

||

|

|||||||

screw |

|

|

|

screw |

|

|

|

Saw blade |

|

Saw blade |

|||||

|

|

||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

-18-

Loading...

Loading...