Hitachi C 12RSH, C 12LSH User Manual

Slide Compound Miter Saw Model C 12LSH • C 12RSH

Handling instructions

Note:

Before using this Electric Power Tool, carefully read through these HANDLING INSTRUCTIONS to ensure efficient, safe operation. It is recommended that these INSTRUCTIONS be kept readily available as an important reference when using this power tool.

GENERAL OPERATIONAL PRECAUTIONS

WARNING! When using electric tools, basic safety precautions should always be followed to reduce the risk of fire, electric shock and personal injury, including the following.

Read all these instructions before operating this product and save these instructions.

For safe operations:

1.Keep work area clean. Cluttered areas and benches invite injuries.

2.Consider work area environment. Do not expose power tools to rain. Do not use power tools in damp or wet locations. Keep work area well lit.

Do not use power tools where there is risk to cause fire or explosion.

3.Guard against electric shock. Avoid body contact with earthed or grounded surfaces (e.g. pipes, radiators, ranges, refrigerators).

4.Keep children and infirm persons away. Do not let visitors touch the tool or extension cord. All visitors should be kept away from work area.

5.Store idle tools. When not in use, tools should be stored in a dry, high or locked up place, out of reach of children and infirm persons.

6.Do not force the tool. It will do the job better and safer at the rate for which it was intended.

7.Use the right tool. Do not force small tools or attachments to do the job of a heavy duty tool. Do not use tools for purposes not intended; for example, do not use circular saw to cut tree limbs or logs.

8.Dress properly. Do not wear loose clothing or jewelry, they can be caught in moving parts. Rubber gloves and non-skid footwear are recommended when working outdoors. Wear protecting hair covering to contain long hair.

9.Use eye protection. Also use face or dust mask if the cutting operation is dusty.

10.Connect dust extraction equipment.

Cutting operation by this slide compound miter saw may produce considerable amount of dust from extraction duct on fixed guard.

(Dust material: Wood or Aluminium)

If devices are provided for the connection of dust extraction and collection facilities ensure these are connected and properly used.

11.Do not abuse the cord. Never carry the tool by the cord or yank it to disconnect it from the receptacle. Keep the cord away from heat, oil and sharp edges.

12.Secure work. Use clamps or a vise to hold the work. It is safer than using your hand and it frees both hands to operate tool.

13.Do not overreach. Keep proper footing and balance at all times.

14.Maintain tools with care. Keep cutting tools sharp and clean for better and safer performance. Follow instructions for lubrication and changing accessories. Inspect tool cords periodically and if damaged, have it repaired by authorized service center. Inspect extension cords periodically and replace, if damaged. Keep handles dry, clean, and free from oil and grease.

15.Disconnect tools. When not in use, before servicing, and when changing accessories such as blades, bits and cutters.

16.Remove adjusting keys and wrenches. Form the habit of checking to see that keys and adjusting wrenches are removed from the tool before turning it on.

17.Avoid unintentional starting. Do not carry a pluggedin tool with a finger on the switch. Ensure switch is off when plugging in.

18.Use outdoor extension leads. When tool is used outdoors, use only extension cords intended for outdoor use.

19.Stay alert. Watch what you are doing. Use common sense. Do not operate tool when you are tired.

20.Check damaged parts. Before further use of the tool, a guard or other part that is damaged should be carefully checked to determine that it will operate properly and perform its intended function. Check for alignment of moving parts, free running of moving parts, breakage of parts, mounting and any other conditions that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced by an authorized service center unless otherwise indicated in this handling instructions. Have defective switches replaced by an authorized service center. Do not use the tool if the switch does not turn it on and off.

21.Warning

The use of any accessory or attachment, other than those recommended in this handling instructions, may present a risk of personal injury.

22.Have your tool repaired by a qualified person. This electric tool is in accordance with the relevant safety requirements. Repairs should only be carried out by qualified persons using original spare parts. Otherwise this may result in considerable danger to the user.

PRECAUTIONS ON USING SLIDE COMPOUND MITER SAW

1.Keep the floor area around the machine level. Well maintained and free of loose materials e.g. chips and cut-offs.

2.Provide adequate general or localized lighting.

3.Do not use power tools for applications other than those specified in the handling instructions.

4.Repairing must be done only by authorized service facility. Manufacturer is not responsible for any damages and injuries due to the repair by the unauthorized persons as well as the mishandling of the tool.

5.To ensure the designed operational integrity of power tools, do not remove installed covers or screws.

6.Do not touch movable parts or accessories unless the power source has been disconnected.

7.Use your tool at lower input than specified on the nameplate; otherwise, the finish may be spoiled and working efficiency reduced due to motor overload.

8.Do not wipe plastic parts with solvent. Solvents such as gasoline, thinner, benzine, carbon tetrachloride, alcohol, may damage and crack plastic parts. Do not wipe them with such solvent. Clean plastic parts with a soft cloth lightly dampened with soapy water.

9.Use only original HITACHI replacement parts.

10.This tool should only be disassembled for replacement of carbon brushes.

2

11.The exploded assembly drawing on this handling instructions should be used only for authorized service facility.

12.Never cut ferrous metals or masonry.

13.Adequate general or localized lighting is provided. Stock and finished workpieces are located close to the operators normal working position.

14.Wear suitable personal protective equipment when necessary, this could include:

Hearing protection to reduce the risk of induced hearing loss.

Eye protection to reduce the risk of injuring an eye. Respiratory protection to reduce the risk of inhalation of harmful dust.

Gloves for handling saw blades (saw blades shall be carried in a holder wherever practicable) and rough material.

15.The operator is adequately trained in the use, adjustment and operation of the machine.

16.Refrain from removing any cut-offs or other parts of the workpiece from the cutting area whilst the machine is running and the saw head is not in the rest position.

17.Never use the slide compound miter saw with its lower guard locked in the open position.

18.Ensure that the lower guard moves smoothly.

19.Do not use the saw without guards in position, in good working order and properly maintained.

20.Use correctly sharpened saw blades. Observe the maximum speed marked on the saw blade.

21.Do not use saw blades which are damaged or deformed.

22.Do not use saw blades manufactured from high speed steel.

23.Use only saw blades recommended by HITACHI.

40.Review this Manual and familiarize yourself with the safety rules and operating instructions for this POWER TOOL before attempting to use it.

41.Always confirm that the POWER TOOL is clean before using it.

42.Always wear snug-fitting clothing, non-skid footwear (preferably with steel toes) and eye protection when operating the POWER TOOL.

43.Always handle the POWER TOOL carefully. If the POWER TOOL falls or strikes against a hard object, it might become deformed or cracked or sustain other damage.

44.Always cease operating the saw at once, if you notice any abnormality whatsoever.

45.Always confirm that all components are mounted properly and securely before using the tool.

46.When replacing the saw blade, always confirm that the rpm rating of the new blade is correct for use on this tool.

47.Always shut off the power and wait for the saw blade to completely stop rotating before undertaking any maintenance or adjustments.

48.During slide cutting, always push the saw blade away from the operator.

49.During miter or bevel cutting, always wait for the rotation of the blade to stop completely before lifting the saw blade.

50.Always make a trial run first before attempting any new use of the saw.

51.Always handle the saw blade with care when dismounting and mounting it.

52.Always confirm that the workpiece is free of nails or other foreign objects before beginning a cut.

53.Always keep your hands out of the path of the saw blade.

24.The saw blades should be from 290 mm to 305 mm 54. Always confirm that the lower guards are in the

external diameter ranges.

25.Select the correct saw blade for the material to be cut.

26.Never operate the slide compound miter saw with the saw blade turned upward or to the side.

27.Ensure that the workpiece is free of foreign matter such as nails.

28.Replace the table insert when worn.

29.Do not use the saw to cut other than aluminium, wood or similar materials.

30.Do not use the saw to cut other materials than those recommended by the manufacturer.

31.Blade replacement procedure, including the method for repositioning and a warning that this must be carried out correctly.

32.Connect the slide compound miter saw to a dust collecting device when sawing wood.

33.Take care when slotting.

34.When transporting or carrying the tool, do not grasp the holder. Grasp the handle instead of the holder.

35.Start cutting only after motor revolution reaches maximum speed.

36.Promptly cut OFF the switch when abnormality observed.

37.Shut off power and wait for saw blade to stop before servicing or adjusting tool.

38.During a miter or bevel cut the blade should not be lifted until it has stopped rotation completely.

39.Take all the possibility of residual risks in cutting operation into your consideration, such as the laser radiation to your eyes, the inadvertent access to moving parts on slide mechanical parts on machine and so on.

proper places before using the saw.

55.Always confirm that the lower guards do not obstruct the sliding motion of the saw before attempting slide cutting.

56.Inspect the tool power cords periodically.

57.Always confirm that the motor air vents are fully open before using the tool.

58.Always wait until the motor has reached full speed before starting a cut.

59.Never use the POWER TOOL for applications not specified in the instruction manual.

60.Never operate the tool while wearing loose clothing, a necktie or jewelry, or while your hair is uncovered, to protect against getting caught in the moving machinery.

61.Never remove any safety devices or blade guards; use of the tool without them would be hazardous.

62.Never lock the lower guards; always confirm that it slides smoothly before using the tool.

63.Never damage the power cord of the tool.

64.Never attempt to move a plugged-in POWER TOOL while your finger is on the starting switch.

65.Never use the POWER TOOL near flammable liquids or gases because sparking can cause an explosion.

66.Never clean plastic components with solvents because the plastic may dissolve.

67.Never raise the saw blade from the workpiece until it has first come to a complete stop.

68.When slide cutting, never pull the handle toward the operator, since this could cause the saw blade to kick up from the workpiece. Always push the

handle away from the operator in a single, smooth

motion. |

3 |

|

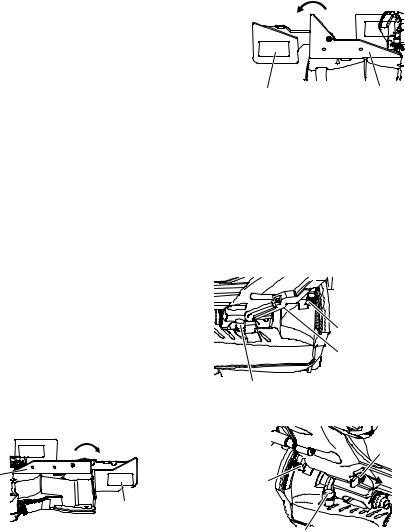

NAME OF PARTS

Digital display Motor Nameplate (only C12LSH)

Dust bag

Locking pin

Hinge

Holder (A)

Clamp lever

Sub cover

Laser marker

Knob (B) Indicator

(For right bevel scale)

Set pin (A)

Sub fence (B)

Vise assembly

Fence (B)

Base

5 mm machine screw

Belt cover

Spindle lock

Adjuster (For laser marker) Guard

Knob (A)

Indicator (For left bevel scale)

Lever (A) Gear case

Motor head

Fig. 1

Lever (A)

Trigger switch

|

Handle |

|

Spindle cover |

|

Washer (B) |

|

Rotation |

|

direction |

|

Lower guard |

|

Saw blade |

|

Sub fence (A) |

|

Fence (A) |

|

Table insert |

|

5 mm machine |

|

screw |

|

Turntable |

|

Side handle |

Indicator |

Lever |

(For miter scale) |

|

Switch (For laser marker) (Only C12LSH)

Slide securing knob (A)

Switch (For laser marker)(Only C12RSH)

Slide Securing Knob (B)

Holder

Fig. 2

4

SPECIFICATIONS

Item |

Model |

C 12LSH / C 12RSH |

Motor |

Type |

Series commutator motor |

|

Power source |

Single-phase AC 50Hz |

|

Voltage (Volts) |

(230V, 240V) |

|

Power input |

1520 W (For New Zealand : 1600 W) |

Laser Marker |

Maximum output |

Po<3mW CLASS II Laser Product |

|

(lambda) |

654 nm |

|

Laser medium |

Laser Diode |

Digital Display (Only Model C12LSH) |

Precision ±0.5° |

|

Applicable |

|

Outside Dia. 305 mm |

saw blade |

|

Hole Dia. 25.4 mm |

No load speed |

|

4000/min (For New Zealand : 3800/min) |

Max. |

|

Head |

Turntable |

Max. sawing dimension |

|

sawing |

Miter |

0 |

0 |

Max. Height |

107 mm |

dimension |

|

|

|

Max. Width |

312 mm |

|

|

|

or |

|

|

|

|

|

|

|

|

|

|

|

* |

Max. Height |

120 mm |

|

|

|

|

Max. Width |

260 mm |

|

|

|

With aux. board |

25 mm |

|

|

|

0 |

Left 45° |

Max. Height |

107 mm |

|

|

|

or |

Max. Width |

220 mm |

|

|

|

Right 45° |

or |

|

|

|

|

* |

Max. Height |

120 mm |

|

|

|

|

Max. Width |

180 mm |

|

|

|

With aux. board |

25 mm |

|

|

|

0 |

Right 57° |

Max. Height |

107 mm |

|

|

|

|

Max. Width |

170 mm |

|

|

|

|

or |

|

|

|

|

* |

Max. Height |

120 mm |

|

|

|

|

Max. Width |

130 mm |

|

|

|

With aux. board |

25 mm |

|

|

Bevel |

Left 45° |

0 |

Max. Height |

70 mm |

|

|

|

|

Max. Width |

312 mm |

|

|

|

|

or |

|

|

|

|

* |

Max. Height |

75 mm |

|

|

|

|

Max. Width |

260 mm |

|

|

|

With aux. board |

25 mm |

|

|

|

Rigth 45° |

0 |

Max. Height |

45 mm |

|

|

|

|

Max. Width |

312 mm |

|

|

|

|

or |

|

|

|

|

* |

Max. Height |

50 mm |

|

|

|

|

Max. Width |

260 mm |

|

|

|

With aux. board |

25 mm |

|

|

Compound |

Left 45° |

Left 45° |

Max. Height |

70 mm |

|

|

|

|

Max. Width |

220 mm |

|

|

|

|

or |

|

|

|

|

* |

Max. Height |

75 mm |

|

|

|

|

Max. Width |

180 mm |

|

|

|

With aux. board |

25 mm |

|

|

|

Left 45° |

Right 31° |

Max. Height |

70 mm |

|

|

|

|

Max. Width |

265 mm |

|

|

|

|

or |

|

|

|

|

* |

Max. Height |

75 mm |

|

|

|

|

Max. Width |

220 mm |

|

|

|

With aux. board |

25 mm |

|

|

|

Right 45° |

Right 45° |

Max. Height |

45 mm |

|

|

|

|

Max. Width |

220 mm |

|

|

|

|

or |

|

|

|

|

* |

Max. Height |

50 mm |

|

|

|

|

Max. Width |

180 mm |

|

|

|

With aux. board |

25 mm |

|

|

|

Right 45° |

Left 31° |

Max. Height |

45 mm |

|

|

|

|

Max. Width |

265 mm |

|

|

|

|

or |

|

|

|

|

* |

Max. Height |

50 mm |

|

|

|

|

Max. Width |

220 mm |

|

|

|

With aux. board |

25 mm |

|

Miter sawing range |

|

Left 0° – 46° Right 0° – 57° |

|

|

|

Bevel sawing range |

|

Left 0° – 45° Right 0° – 45° |

|

|

|

Compound sawing range |

Left (Bevel) 0° – 45°, Left (Miter) 0° – 45°, Right (Miter) 0° – 31° |

|

|||

|

|

Right (Bevel) 0° – 45°, Right (Miter) 0° – 45°, Left (Miter) 0° – 31° |

|

||

Net weight |

|

C12LSH 30 kg C12RSH 29 kg |

|

|

|

Cord |

|

2 Conductor type cable 1.8 m |

|

|

|

5

When cutting the workpiece which has the dimension of “*” there might be some possibility of the lower end of the circular saw to touch with the workpiece, even if the motor head is located at the lower limit position. Pay attention when cutting the workpiece. For further details, refer to “PRACTICAL APPLICATIONS” on page 13. Mount the auxiliary board on the fence surface (Refer ( ) the thickness of auxiliary board). Refer to "5. Cutting large workpieces" on page 14 (Fig. 31).

STANDARD ACCESSORIES

1 |

2 |

3 |

45

Fig. 3

1 305 mm TCT Saw blade (1 piece) (For wood)

2Dust bag (1 piece)

For how to use, refer to page 19.

3Vise Assembly w/knob bolt (1 piece) For how to use, refer to page 13.

4 17 mm BOX wrench (1 piece)

5 Holder (1 piece)

For how to use, refer this page. 6 Washer (C) (Only For Australia)

OPTIONAL ACCESSORIES...sold separately

1 Extension Holder and Stopper

2Crown molding Vise Ass’y

(Include Crown molding Stopper (L))

3 Crown molding Stopper (L)

4 Crown molding Stopper (R)

NOTE

Accessories are subject to change without any obligation on the part of the HITACHI.

APPLICATIONS

Wood and aluminum sash.

PREPARATION BEFORE OPERATION

Make the following preparations before operating the power tool:

1. Installation

281mm |

256mm |

9 mm

3 holes

244 mm 281 mm

Base 8mm bolt

25 mm thick bench

Work bench |

8 mm nut |

Fig. 4

Attach the power tool to a level, horizontal work bench in accordance with Fig. 4.

Select 8 mm diameter bolts suitable in length for the thickness of the work bench.

Bolt length should be at least 40 mm plus the thickness of the work bench.

For example, use 65 mm or larger bolts for a 25 mm thick work bench.

The holder attached to the rear of the base helps stabilize the power tool.

Holder adjustment:

Loosen the 6 mm bolt with the 10 mm box wrench. Adjust the holder until its bottom surface contacts the work bench surface.

After adjustment, firmly tighten the 6 mm bolt.

6 mm Bolt

Move Holder

Adjust the holder until its bottom surface contacts the work bench surface.

Fig. 5

6

2.Releasing the locking pin

When the power tool is prepared for shipping, its main parts are secured by a locking pin.

Move the handle slightly so that the locking pin can be disengaged.

Handle

Locking pin

Pull

Fig. 6

NOTE

Lowering the handle slightly will enable you to disengage the locking pin more easily and safely. The lock position of the locking pin is for carrying and storage only.

3.Installing the dust bag, holder, stopper and vises

(The holder and stopper are optional accessories.) Attach the dust bag and vise assembly as indicated in Fig. 1 and Fig. 2.

BEFORE USING

1. Make sure the power source is appropriate for the tool.

WARNING

Never connect the power tool unless the available AC power source is of the same voltage as that specified on the nameplate of the tool.

Never connect this power tool to a DC power source.

2.Make sure the trigger switch is turned OFF. WARNING

If the power cord is connected to the power source with the trigger switch turned ON the power tool will start suddenly and can cause a serious accident.

3.Check the saw blade for visible defects.

Confirm that the saw blade is free of cracks or other visible damage.

4.Confirm that the saw blade is attached securely to the power tool.

Using the supplied 17 mm box wrench, tighten the 10 mm bolt on the saw blade spindle to secure the saw blade.

For details, see Fig. 55-a, Fig. 55-b, Fig. 55-c and Fig. 55-d in the section on “SAW BLADE MOUNTING AND DISMOUNTING”.

5.Check to see that the lower guard operates smoothly CAUTION

This slide compound miter saw is equipped with a saw head lock as safety device.

To lower the saw head to cut, the lock must be released by pressing the lever (A) with your thumb.

(1) When you push down the handle while pushing the lever (A), check that the lower guard revolves smoothly (Fig. 7).

(2)Next, check that the lower guard returns to the original position when the handle is raised.

Lever (A)

Handle

Lower guard

Fig. 7

6.Confirm the position of the spindle lock before using the tool.

After installing the saw blade, confirm that the spindle lock has been returned to the retract position before using the power tool (see Fig. 2).

7.Check the lower limit position of the Saw Blade.

Although it was adjusted before shipment, carefully check the height of the saw blade. Confirm that the saw blade can be lowered 9 mm to 11 mm below the table insert. For details, see the section on “Checking the saw blade lower limit position”.

8.Check the Power Receptacle.

To prevent overheating, accidental stopping or intermittent operation, confirm that the power cord plug fits properly in the electrical receptacle and does not fall out after it is inserted. Repair or replace the receptacle if it is faulty.

9.Confirm the tool’s power cord is not damaged.

Repair or replace the power cord if an inspection indicates that it is damaged

AFTER CONNECTING THE POWER PLUG TO AN APPROPRIATE AC POWER SOURCE, CHECK THE OPERATION OF THE TOOL AS FOLLOWS:

10.Trial Run

After confirming that no one is standing behind, the power tool start and confirm that no operating abnormalities exist before attempting a cutting operation.

11.Inspect the rotating stability of the saw blade.

For precise cutting, rotate the saw blade and check for deflection to confirm that the blade is not noticeably unstable; otherwise vibrations might occur and cause an accident.

7

BEFORE CUTTING

1.Cutting a groove on the guard

Holder (A) has a guard (see Fig. 8) into which a groove must be cut.

Loosen the 6 mm knob bolt to retract the guard slightly. After placing a suitable wooden piece to sit on the fence and the table surfaces, fix it with the vise assembly.

After the switch has been turned on and the saw blade has reached maximum speed, slowly lower the handle to cut a groove on the guard.

Handle |

|

Saw blade |

Holder (A) |

Vise assembly |

|

Fence (B) |

6 mm knob bolt |

|

Guard |

Workpiece |

|

Fig. 8 |

Fence (A) |

CAUTION

Do not cut the groove too quickly; otherwise the guard might become damaged.

2. Positioning the table insert

5 mm machine Workpiece |

Saw blade |

screw |

|

|

Table insert |

[Right angle cutting]

Fig. 9-a

5 mm machine |

Workpiece |

Saw blade |

|

screw |

|||

|

|

||

|

|

Table insert |

[Left bevel angle cutting]

Fig. 9-b

Saw blade Workpiece 5 mm machine screw

Table insert

[Right bevel angle cutting]

Fig. 9-c

Table inserts are installed on the turntable. When shipping the tool from the factory, the table inserts are so fixed that the saw blade does not contact them. The burr of the bottom surface of the workpiece is remarkably reduced, if the table insert is fixed so that the gap between the side surface of the table insert and the saw blade will be minimum. Before using the tool, eliminate this gap in accordance with the following procedure.

(1)Right angle cutting

Loosen the three 5 mm machine screws, then secure the left side table insert and temporarily tighten the 5

mmmachine screws of both ends. Then fix a workpiece (about 200 mm wide) with the vise assembly and cut it off. After aligning the cutting surface with the edge of the table insert, securely tighten the 5 mm machine screws of both ends. Remove the workpiece and securely tighten the 5 mm center machine screw. Adjust the right hand table insert in the same way.

(2)Left and right bevel angle cutting

Adjust the table insert in the manner shown in Fig. 9-

band Fig. 9-c following the same procedure for right angle cutting.

CAUTION

After adjusting the table insert for right angle cutting, the table insert will be cut to some extent if it is used for bevel angle cutting.

When bevel cutting operation is required, adjust the table insert for bevel angle cutting.

3. Checking the saw blade lower limit position

8 mm depth

Gear case adjustment

Gear case adjustment

bolt

Hinge

Saw blade

Saw blade

Turntable

Fig. 10-a

Turn

8 mm depth adjustment

bolt

Gear case

Hinge

Fig. 10-b

Check that the saw blade can be lowered 9 mm to 11 mm below the table insert as shown in Fig. 10-a. When you replace a saw blade with a new one, adjust the lower limit position so that the saw blade will not cut the turntable or complete cutting cannot be done. To adjust the lower limit position of the saw blade, follow the procedure (1) indicated below. (Fig. 10-b) Furthermore, when changing the position of a 8 mm depth adjustment bolt that serves as a lower limit position stopper of the saw blade.

8

(1)Turn the 8 mm depth adjustment bolt, change the height where the bolt head and the hinge contacts, and adjust the lower limit position of the saw blade.

NOTE

Confirm that the saw blade is adjusted so that it will not cut into the turntable.

4. Lower limit position of saw blade when cutting a large workpiece

NOTE

When cutting a workpiece exceeding 107 mm in height in right-angle cutting or 70 mm in left bevel angle cutting or 45 mm in right bevel angle cutting, adjust the lower limit position so that the base of the motor head (see Fig. 10-a) will not come in contact with the workpiece.

To adjust the lower limit position of the saw blade, follow the procedure (1) shown in Fig. 10-a.

(1)Lower the motor head, and turn the 8 mm depth adjustment bolt and make adjustments so that there can be a clearance of 2 mm to 3 mm between the lower limit position of the motor head and the top of the workpiece at the saw blade's lower limit position where the head of the 8 mm depth adjustment bolt

contacts the hinge.

5. Confirmation for use of sub fence (A) WARNING

In the case of right bevel cutting, turn the sub fence

(A) clockwise. Unless it is turned clockwise, the main body or saw blade may contact the sub fence (A), resulting in an injury.

This power tool is equipped with a sub fence (A).

In the case of direct angle cutting and left bevel angle cutting, use the sub fence (A). Then, you can realize stable cutting of the material with a wide back face.

In the case of right bevel cutting, raise the sub fence

(A) up as illustrated in Fig. 11 and then turn it clockwise.

Left bevel angle cutting |

|

|

Direct angle cutting |

Turn |

Right bevel angle |

|

||

|

|

|

|

|

cutting |

Fence (A) |

|

|

|

|

Sub fence (A) |

Fig. 11

6. Confirmation for use of sub fence (B) WARNING

In the case of left bevel cutting, turn the sub fence (B) counterclockwise. Unless it is turned counterclockwise, the main body or saw blade may contact the sub fence (B), resulting in an injury.

This power tool is equipped with a sub fence (B). In the case of direct angle cutting and right bevel angle cutting, use the sub fence (B). Then, you can realize stable cutting of the material with a wide back face. In the case of left bevel cutting, raise the sub fence (B) up as illustrated in Fig.12 and turn it counterclockwise.

Left bevel angle |

Turn Right bevel angle cutting |

|

Direct angle cutting |

||

cutting |

||

|

Sub fence (B) |

Fence (B) |

Fig. 12

7.Oblique angle

Before the power tool is shipped from the factory, it is adjusted for 0°, right angle, left 45° bevel cutting angle and right 45° bevel cutting angle with the 8 mm set screw, 8 mm bolt (A) and 8 mm bolt (B).

When changing the adjustment, change the height of the 8 mm set screw, 8 mm bolt (A), or 8 mm bolt (B) by turning them.

When changing the bevel angle to the right 45°, pull the set pin (A) on the direction shown in Fig. 13-b and incline the motor head to the right.

When adjusting the motor head to 0°, always return the set pin (A) to its initial position as shown in Fig. 13-b.

Indicator

(For left bevel scale)

8 mm set screw (Stopper for 0° not

shown)

8 mm bolt (B)

(Stopper for right 45° bevel angle)

|

Fig. 13-a |

|

|

Set pin (A) |

|

Indicator |

Pull |

|

(For right |

||

|

||

bevel scale) |

|

8 mm bolt (A)

(Stopper for left 45° bevel angle)

Fig. 13-b

8. Securing the workpiece WARNING

Always clamp or vise to secure the workpiece to the fence; otherwise the workpiece might be thrust from the table and cause bodily harm.

9

9.Installing the holders ... (Optional accessory)

The holders help keep longer workpieces stable and in place during the cutting operation.

(1)As indicated in Fig. 14, use a steel square for aligning the upper edge of the holders with the base surface. Loosen the 6 mm wing nut. Turn a height adjustment bolt 6 mm, and adjust the height of the holder.

(2)After adjustment, firmly tighten the 6 mm wing nut and fasten the holder with the 6 mm knob bolt (optional accessory). If the length of Height Adjustment Bolt 6 mm is insufficient, spread a thin plate beneath. Make sure the end of Height Adjustment Bolt 6 mm does not protrude from the holder.

6 mm knob bolt (Optional accessory)

Steel square Holder  (Optional

(Optional

accessory)

accessory)

6 mm wing nut |

Base surface |

|

(Optional accessory) |

Height adjustment bolt 6 mm |

|

(Optional accessory) |

|

Fig. 14 |

10.Stopper for precision cutting ... (Stopper and holder are optional accessory)

The stopper facilitates continuous precision cutting in lengths of 285 mm to 450 mm.

To install the stopper, attach it to the holder with the 6 mm knob bolt as shown in Fig. 15.

Workpiece Stopper (Optional accessory)

Holder (Optional accessory)

6 mm knob bolt |

Move |

(Optional accessory) |

|

Fig. |

15 |

11. Using an ink line

(1)Right angle cutting

Loosen the 6 mm knob bolt and contact the tip of the guard with the workpiece.

Aligning the ink line on the workpiece with the groove of the guard, the workpiece is cut on the ink line (Fig. 16).

Saw blade groove |

6 mm knob |

|

bolt |

Marking (pre-marked) Guard Workpiece

Fig. 16

(2)Miter cutting and compound cutting (Miter cutting + bevel cutting)

Upon lowering the motor section, the lower guard is raised and the saw blade appears.

Align the ink line with the saw blade (Fig. 17).

Move the

guard

guard

backward

backward

Sub fence (B)

Lower guard

6 mm knob bolt

Marking

(pre-marked)

Fig. 17

CAUTION

In some arrangements when the turntable is rotated, the guard projects from the fence surface. Loosen the 6 mm knob bolt and push the guard to the retracted position. Never lift the lower guard while the saw blade is rotating. When cutting at an angle to the right or more, please slide the guard to the rear. The guard and sub-fence (A) and sub-fence (B) will not only make contact and adversely affect cutting accuracy, this could also result in damage to the guard.

12. Position adjustment of laser line WARNING

*Make sure before plugging the power plug into the receptacle that the main body and the laser marker are turned off.

*Exercise utmost caution in handling a switch trigger for the position adjustment of the laser line, as the power plug is plugged into the receptacle during operation.

If the switch trigger is pulled inadvertently, the saw blade can rotate and result in unexpected accidents.

*Do not remove the laser marker to be used for other

purposes.

CAUTION

Fig. 18

10

Loading...

Loading...