Hitachi 917 User manual

S

Operator's Manual

BM/Hitachi 917

V 2.1 – Operator's Manual

BM/Hitachi 917

The contents of this manual, including all drawings and tables, are the property of BOEHRINGER MANNHEIM GmbH. They may not be copied or duplicated without prior written consent, or used in whole or in parts for the manufacture or sale of items.

BOEHRINGER MANNHEIM GmbH reserves the right to make changes to their manual without being obliged to give notice of this.

No responsibility is accepted by BOEHRINGER MANNHEIM GmbH for any errors this manual may contain.

This manual describes the BM/Hitachi 917 Software Version 2.

Version |

Published |

Software affected |

V 1.0 |

January 1995 |

V 1.03 |

V 2.0 |

June 1996 |

V 2 |

V 2.1 |

March 1997 |

V 2 |

First Edition – March, 1997

Boehringer Mannheim GmbH, Mannheim

Production: |

P. Hirn, D.H. Jung, B. Koroknay, J. Lutzke, I. Reinhardt, J. Westera |

Layout: |

Scriptor Dokumentations Service GmbH, Bielefeld |

V 2.1 – Operator's Manual

Contents

Contents

V 2.1 – Operator's Manual |

1 |

BM/Hitachi 917

0. |

Potential Hazards and Safety Precautions |

0-1 |

|

1. |

Introduction |

1-1 |

|

1.1 |

Manual Outline |

1-2 |

|

2. |

Daily Routine |

2-1 |

|

2.1 |

Introduction |

2-2 |

|

2.2 |

Daily Maintenance - Outline |

2-3 |

|

2.3 |

System Start |

2-6 |

|

|

2.3.1 |

Introduction |

2-6 |

|

2.3.2 |

Power On |

2-6 |

|

2.3.3 |

Automatic Start Procedure |

2-7 |

|

2.3.4. |

Log On/Log Off |

2-8 |

2.4 |

Daily Start Up |

2-10 |

|

|

2.4.1 |

Checking the Reagents REQUIREMENTS Screen |

2-11 |

|

2.4.2 |

Reconstituting Calibrators and Controls |

2-13 |

|

2.4.3 |

Air Purge (Photometric System) |

2-15 |

|

2.4.4 |

ISE Prime, Conditioning, Calibration |

2-16 |

2.5 |

Calibration Test Selection |

2-18 |

|

|

2.5.1 |

Automatic Calibration |

2-18 |

|

2.5.2 |

Manual Control Test Selection (from Sample Disk 2) |

2-24 |

2.6 |

Initiate Run with Routine Patient Test Selections |

2-25 |

|

|

2.6.1 |

Routine Patient Test Selection |

2-25 |

|

2.6.2 |

Initiate Run Procedure |

2-29 |

|

2.6.3 |

Entering Non-Barcoded or Unreadable Barcoded Samples |

|

|

|

(in the Barcode Mode) |

2-34 |

2.7 |

Sample Tracking |

2-36 |

|

2.8 |

Measurement of Additional Routine Samples |

2-37 |

|

2.9 |

STAT Test Selections |

2-38 |

|

2 |

V 2.1 – Operator's Manual |

|

|

|

Contents |

2.10 |

Processing of Rerun Samples |

2-41 |

|

|

2.10.1 |

Automatic Rerun |

2-42 |

|

2.10.2 |

Manual Rerun |

2-43 |

2.11 |

Adding Reagent During a Run |

2-45 |

|

2.12 |

Patient Reports |

2-47 |

|

|

2.12.1 Selecting the Patient Report Format for Real Time Printing |

2-47 |

|

|

2.12.2 Printing Patient Reports in Batch |

2-48 |

|

2.13 |

Data Management |

2-49 |

|

|

2.13.1 |

Reviewing Data |

2-49 |

|

2.13.2 |

Editing Data |

2-50 |

|

2.13.3 |

Deleting Functions |

2-55 |

2.14 |

Quality Control Procedures |

2-58 |

|

|

2.14.1 Selecting Controls for Real Time QC |

2-59 |

|

|

2.14.2 |

Individual QC List |

2-60 |

|

2.14.3 Setting of Controls in the Individual QC Chart |

2-61 |

|

2.14.4Validation of Individual QC with Real Time QC

|

|

(Rejection of Single Test Couplings) |

2-63 |

2.15 |

QC File Maintenance |

2-65 |

|

|

2.15.1 |

Accumulate QC Data |

2-65 |

|

2.15.1 |

Deleting QC Data |

2-66 |

|

2.15.3 |

Cumulative QC List |

2-67 |

|

2.15.4 Validation of Cumulative QC |

2-68 |

|

|

2.15.5 Printing the Cumulative QC List and Chart |

2-69 |

|

|

2.15.6 Deleting the Cumulative QC |

2-70 |

|

2.16 |

System Shutdown |

2-71 |

|

|

2.16.1 |

Instrument Shutdown |

2-71 |

|

2.16.2 |

Activating the SLEEP Mode |

2-72 |

V 2.1 – Operator's Manual |

3 |

BM/Hitachi 917

3. |

Maintenance and Daily Care |

3-1 |

|

3.1 |

Introduction |

3-2 |

|

|

3.1.1 |

Necessary Material and Safety Precautions |

3-2 |

|

3.1.2 |

Automatic System Cleaning (Daily) |

3-5 |

|

3.1.3 |

ERGO Console Cleaning |

3-6 |

|

3.1.4 |

Maintenance and Care Schedule |

3-7 |

3.2 |

Daily System Maintenance |

3-9 |

|

|

3.2.1 |

Emptying the Waste Container |

3-9 |

|

3.2.2 |

Checking/Replacing the Detergent |

3-10 |

|

3.2.3 |

Checking the Detergent/Replenishing the Bottles |

3-12 |

|

3.2.4 |

Cleaning the Reagent Probes and Sample Probe |

3-13 |

|

3.2.5 |

Cleaning the Stirring Unit |

3-14 |

|

3.2.6 |

Checking the Paper Supply |

3-15 |

|

3.2.7 |

Cleaning the Instrument Surfaces |

3-15 |

|

3.2.8 |

Cleaning the Nozzles of the Cell Rinse Unit |

3-15 |

|

3.2.9 |

Priming, Conditioning and Calibrating the ISE Unit |

3-16 |

|

3.2.10 |

Cleaning the ISE Unit with ISE Wash Solution |

3-17 |

|

3.2.11 |

Checking the Temperature of the Incubation Bath |

3-17 |

|

3.2.12 Performing a Photometer Check |

3-18 |

|

3.3 |

Weekly System Maintenance |

3-19 |

|

|

3.3.1 |

Cleaning the Reaction Cells |

3-19 |

|

3.3.2 |

Performing the Cell Blank Measurement |

3-20 |

3.3.3Cleaning the Rinse Bath for the Sample Probe, Reagent Probes,

|

and the Stirring Paddle |

3-21 |

3.4 Monthly System Maintenance |

3-22 |

|

3.4.1 |

Replacing the Reaction Cell Segments |

3-22 |

3.4.2 |

Cleaning the Incubation Bath and the Incubation Bath Drain Filter |

3-24 |

3.4.3 |

Cleaning the Inside of the Sample and Reagent Disks |

3-28 |

3.4.4 |

Cleaning the Air Filter |

3-30 |

3.4.5 |

Replacing the ISE Pinch Valve Tubing |

3-32 |

4 |

V 2.1 – Operator's Manual |

|

|

|

Contents |

3.5 |

Quarterly System Maintenance |

3-33 |

|

|

3.5.1 |

Cleaning the Inlet Water Filter |

3-33 |

|

3.5.2 |

Replacing the Syringe Seals |

3-34 |

3.6 Six Monthly System Maintenance |

3-42 |

||

|

3.6.1 |

Replacing the ISE Reference Electrode |

3-42 |

|

3.6.2 |

Replacing the Teflon Block (Nozzle Tip) |

3-44 |

3.7 Analyzer Maintenance As Required |

3-45 |

||

|

3.7.1 |

Emptying the Vacuum Tank |

3-45 |

|

3.7.2 |

Replacing the Photometer Lamp |

3-47 |

|

3.7.3 |

Cleaning/Replacing Clogged Probes |

3-52 |

|

3.7.4 |

Checking the Alignments |

3-54 |

|

3.7.5 |

Cleaning Clogged Rinse Nozzles |

3-63 |

|

3.7.6 |

Replacing the Stirring Paddles |

3-65 |

|

3.7.7 |

Replacing the ISE Measurement Electrodes (Na+, K+, Cl-) |

3-67 |

3.8 |

Printer Maintenance |

3-70 |

|

|

3.8.1 |

Start-Up |

3-70 |

|

3.8.2 |

Replacing the Ink Ribbon Cartridge |

3-71 |

|

3.8.3 |

Loading Continuous-Feed Paper |

3-74 |

|

3.8.4 |

Inserting Single Sheets |

3-78 |

|

3.8.5 |

Setting the Paper Thickness |

3-80 |

V 2.1 – Operator's Manual |

5 |

BM/Hitachi 917

4. |

Operation Support |

4-1 |

|

4.1 Adding a New Application |

4-2 |

||

|

4.1.1 |

Loading New Applications from Disk |

4-3 |

|

4.1.2 |

Loading New Applications from a Barsheet |

4-5 |

|

4.1.3 |

Adding of User-Definable Applications (901 to 905) |

4-9 |

|

4.1.4 |

Key Setting |

4-11 |

|

4.1.5 |

Assigning the Print Order |

4-12 |

|

4.1.6 |

Reagent Registration |

4-13 |

|

4.1.7. |

Programming Preset K Factors for Assays |

4-13 |

4.2 |

Loading of a Serum Index Application |

4-14 |

|

4.3 |

Special Wash Programming |

4-16 |

|

|

4.3.1 |

Reagent Probe Wash |

4-16 |

|

4.3.2 |

Sample Probe Wash |

4-19 |

|

4.3.3 |

Cell Wash |

4-22 |

4.4 |

Calculated and Compensated Tests |

4-25 |

|

|

4.4.1 |

Calculated Tests |

4-25 |

|

4.4.2 |

Compensated Tests |

4-30 |

4.5 |

Loading Calibrator Information |

4-33 |

|

|

4.5.1 |

Manual Setting of Calibrator |

4-33 |

|

4.5.2 |

Loading Calibrator Setpoints from a Barsheet |

4-34 |

|

4.5.3 |

Assigning a Calibrator Position |

4-35 |

|

4.5.4 |

Deleting a Calibrator |

4-36 |

|

4.5.5 |

Deleting a Calibrator Position |

4-37 |

4.6 |

Loading Control Information |

4-38 |

|

|

4.6.1 |

Manual Setting of Controls |

4-38 |

|

4.6.2 |

Loading Control Setpoints from a Barsheet |

4-40 |

|

4.6.3 |

Assigning a Control Position |

4-42 |

|

4.6.4 |

Deleting a Control |

4-43 |

|

4.6.5 |

Deleting a Control Position |

4-44 |

|

4.6.6 |

Activating Controls |

4-45 |

|

4.6.7 |

Assigning Key Settings for Controls |

4-46 |

|

4.6.8 |

Manual Control Test Selections (Sample Disk 2) |

4-47 |

|

4.6.9 |

Setting Controls for the QC |

4-48 |

6 |

V 2.1 – Operator's Manual |

|

|

|

Contents |

4.7 |

Defining Profiles |

4-50 |

|

|

4.7.1 |

Adding a Profile |

4-50 |

|

4.7.2 |

Deleting a Profile / Deleting a Test from a Profile |

4-52 |

|

4.7.3 |

Default Profiles |

4-54 |

4.8 |

Operator-ID / Password Management |

4-55 |

|

|

4.8.1 |

Assigning an Operator ID |

4-56 |

|

4.8.2 |

Delete Operator ID |

4-57 |

|

4.8.3 |

Password Registration |

4-58 |

4.9 |

Disk Management |

4-59 |

|

4.9.1Writing System Parameters (Application Settings) on a Floppy

|

Disk |

4-59 |

4.9.2 |

Reading System Parameters from a Floppy Disk |

4-60 |

4.9.3 |

Formatting a Floppy Disk |

4-61 |

4.9.4 |

Archive Data |

4-62 |

4.9.5 |

Saving QC Data |

4-63 |

4.10 Define Maintenance Frequency and Maintenance Item |

4-64 |

|

4.10.1 |

Defining the Maintenance Frequency |

4-64 |

4.10.2 |

Defining the Maintenance Item |

4-66 |

V 2.1 – Operator's Manual |

7 |

BM/Hitachi 917

5. |

Printouts |

5-1 |

|

5.1 |

MEASUREMENT DATA Printout |

5-2 |

|

|

5.1.1 |

REPORT Format |

5-2 |

|

5.1.2 |

MONITOR Format |

5-5 |

5.2 |

REACTION MONITOR Printout |

5-6 |

|

5.3 |

REQUISITION LIST Printout |

5-8 |

|

|

5.3.1 |

Requisition List Without Sample Barcode |

5-8 |

|

5.3.2 |

Requisition List With Sample Barcode |

5-9 |

5.4 |

RERUN LIST Printout |

5-10 |

|

5.5 |

PRECISION CHECK Printout |

5-12 |

|

5.6 |

PROFILING LIST Printout |

5-13 |

|

5.7 |

SYSTEM REQUIREMENTS Printout |

5-14 |

|

5.8 |

REAGENT STATUS Printout |

5-15 |

|

5.9 |

CALIBRATION MONITOR Printout |

5-17 |

|

|

5.9.1 |

CALIBRATION MONITOR Photometry |

5-18 |

|

5.9.2 |

CALIBRATION MONITOR ISE |

5-22 |

5.10 |

REACTION MONITOR Printout |

5-23 |

|

|

5.10.1 The Primary and Secondary Wavelengths Option |

5-24 |

|

|

5.10.2 The Primary Minus Secondary Wavelengths Option |

5-25 |

|

5.11 |

CALIBRATOR LOAD LIST Printout |

5-26 |

|

5.12 |

CALIBRATION TRACE Printout |

5-27 |

|

|

5.12.1 |

CALIBRATION TRACE Photometry, Rate |

5-28 |

|

5.12.2 CALIBRATION TRACE Photometry, Endpoint |

5-30 |

|

|

5.12.3 |

CALIBRATION TRACE ISE |

5-31 |

5.13 |

INDIVIDUAL QC CHART Printout |

5-32 |

|

5.14 |

INDIVIDUAL QC LIST Printout |

5-34 |

|

5.15 |

CUMULATIVE QC CHART Printout |

5-35 |

|

5.16 |

CUMULATIVE QC LIST Printout |

5-37 |

|

5.17 |

ALARM TRACE Printout |

5-38 |

|

|

5.17.1 |

DAILY ALARM TRACE |

5-38 |

|

5.17.2 |

CUMULATIVE ALARM TRACE |

5-39 |

8 |

V 2.1 – Operator's Manual |

|

|

|

Contents |

5.18 |

SYSTEM COMMUNICATION TRACE Printout |

5-40 |

|

5.19 |

OPERATOR ID TRACE Printout |

5-42 |

|

5.20 |

CUMULATIVE OPERATION LIST Printout |

5-43 |

|

5.21 |

MAINTENANCE REPORT Printout |

5-45 |

|

5.22 |

REPORT EXAMPLE Printout |

5-46 |

|

|

5.22.1 |

Setting ONE REPORT/PAGE |

5-47 |

|

5.22.2 |

Setting TWO REPORTS/PAGE |

5-49 |

5.23 |

CELL BLANK MEASUREMENT Printout |

5-51 |

|

5.24 |

PHOTOMETER CHECK Printout |

5-52 |

|

5.25 |

CELL BLANK MEASUREMENT Printout |

5-53 |

|

5.26 |

PRINTER CHECK Printout |

5-55 |

|

5.27 |

BARCODE READER CHECK Printout |

5-56 |

|

5.28 |

ISE CHECK Printout |

5-57 |

|

5.29 |

HD CHECK Printout |

5-59 |

|

5.30 |

FD CHECK Printout |

5-61 |

|

V 2.1 – Operator's Manual |

9 |

BM/Hitachi 917

6. |

Troubleshooting |

6-1 |

|

6.1 |

Overview |

|

6-2 |

6.2 |

General Troubleshooting Strategy |

6-6 |

|

|

6.2.1 |

Troubleshooting Conditions at power up |

6-8 |

|

6.2.2 |

Test troubleshooting |

6-9 |

|

6.2.3 |

Preparation of reagents, calibrators, controls |

6-10 |

|

6.2.4 |

High test results |

6-11 |

|

6.2.5 |

Low test results |

6-12 |

|

6.2.6 |

Erratic test results |

6-13 |

|

6.2.7 |

Problems with a single sample or control |

6-15 |

|

6.2.8 |

Problems with a single test |

6-16 |

|

6.2.9 |

Problems with tests with one calibration set point |

6-17 |

|

6.2.10 |

Problems with all tests with more than one calibration set point |

6-18 |

|

6.2.11 |

Problems with multiple tests (photometrics only) |

6-19 |

|

6.2.12 |

Problems with all tests, including ISEs |

6-20 |

6.2.13Problems with ISE, all results are erratic,

|

excessive air in sipper syringe |

6-21 |

6.2.14 |

Erratic ISE results |

6-22 |

6.2.15 |

Problems with ISE, high internal standard values |

6-24 |

6.2.16 |

Problems with low sodium, potassium and chloride values |

6-25 |

6.2.17 Problems with a biased enzymes |

6-26 |

|

6.3 Data Alarms |

6-27 |

|

6.3.1 |

Calculation disabled |

6-27 |

6.3.2 |

Absorbance over |

6-28 |

6.3.3 |

Absorbance maximum over (non-linear calibration) |

6-29 |

6.3.4 |

ADC abnormal |

6-29 |

6.3.5 |

Calculation test error |

6-30 |

6.3.6 |

Calibration result abnormal |

6-30 |

6.3.7 |

Calibration error |

6-31 |

6.3.8 |

Cell blank abnormal |

6-32 |

6.3.9 |

Test-to-test compensation error |

6-33 |

6.3.10 |

Test-to-test compensation disabled |

6-34 |

6.3.11 |

Duplicate error |

6-34 |

6.3.12 |

Edited test |

6-36 |

6.3.13 |

Outside of reference value |

6-36 |

10 |

V 2.1 – Operator's Manual |

|

|

Contents |

6.3.14 Internal standard concentration abnormal |

6-37 |

|

6.3.15 |

Level error |

6-38 |

6.3.16 Technical value limit over |

6-40 |

|

6.3.17 Reaction limit over at all points (Limt0) |

6-41 |

|

6.3.18 Reaction limit over at 1 point (Limt1) |

6-42 |

|

6.3.19 Reaction limit over (Limt2) |

6-43 |

|

6.3.20 |

Linearity abnormal (Lin.) |

6-44 |

6.3.21 |

Linearity abnormal (Lin.8) |

6-46 |

6.3.22 |

ISE Preparation abnormal |

6-48 |

6.3.23 |

Noise error |

6-49 |

6.3.24 |

Overflow |

6-50 |

6.3.25 |

Prozone error |

6-50 |

6.3.26 |

QC error 1 |

6-51 |

6.3.27 |

QC error 2 |

6-52 |

6.3.28 |

Random error |

6-53 |

6.3.29 |

Reagent short |

6-54 |

6.3.30 Value outside repeat limit |

6-55 |

|

6.3.31 |

Sample value abnormal |

6-55 |

6.3.32 |

Sample short |

6-56 |

6.3.33 |

SD error |

6-57 |

6.3.34 |

Sensitivity error |

6-58 |

6.3.35 |

Slope abnormal |

6-59 |

6.3.36 |

Standard error |

6-60 |

6.3.37 |

Systematic error 1 |

6-61 |

6.3.38 |

Systematic error 2 |

6-62 |

6.3.39 |

Systematic error 3 |

6-63 |

6.3.40 |

Systematic error 4 |

6-64 |

6.3.41 |

Systematic error 5 |

6-65 |

6.3.42 |

Systematic error 6 |

6-66 |

6.3.43 Standard 1 absorbance abnormal |

6-67 |

|

7.Appendix

A.1 |

Glossary |

A-2 |

A.2 |

Index |

A-13 |

V 2.1 – Operator's Manual |

11 |

BM/Hitachi 917

12 |

V 2.1 – Operator's Manual |

Potential Hazards and Safety Precautions

0. Potential Hazards and Safety Precautions

V 2.1 – Operator's Manual |

0 - 1 |

BM/Hitachi 917

Safety Warnings

Before putting the analyzer into operation, you should become acquainted with all precautions and regulations concerning the handling of the analyzers electrical and mechanical components in order to rule out any potentially hazardous situations to yourself and your colleagues.

All safety warnings that the operator must consider in this manual are classified as below. Acquaint yourself with the following labels and pictures.

WARNING

WARNING

If these instructions are not strictly adhered to, there is a risk of fatal injury e.g. from power supplies or infection.

CAUTION

CAUTION

If these instructions are not strictly adhered to, there is an increased risk of injury and/or serious functional disruptions to the analyzer.

ATTENTION

Identifies all other situations where increased attention is necessary (e.g. to avoid damage to the analyzer).

Note

Indicates information to be considered e.g. remarks, etc.

is the international symbol for caution

0 - 2 |

V 2.1 – Operator's Manual |

Potential Hazards and Safety Precautions

Safety Precautions

WARNING

WARNING

Electrical Safety

Never open the back or side panels when the analyzer is connected to the mains supply (wall socket)! Pull the plug out beforehand!

You can receive an electric shock by touching supply-carrying components.

CAUTION

Flammable and Explosive Materials

Avoid using flammable materials around the analyzer.

Electrical sparks can cause fires and explosions.

CAUTION

Analyzer in Operation

Never touch the sample pipetter, reagent pipetters, stirrer, rinse units and all other moving components when the analyzer is operating.

There is a risk of injury from the moving components and the analyzer can also be damaged.

WARNING

Photometer Lamp

Never look for long periods into the light of the photometer lamp without eye protection.

If this warning is not heeded, damage to the eyes can occur. Wear darkened protective goggles to protect yourself from ultra violet light, when you must look at the light transmitted from the photometer lamp for long periods.

V 2.1 – Operator's Manual |

0 - 3 |

BM/Hitachi 917

WARNiNG

Samples

1.Avoid direct contact with samples that contain bacteria or are potentially infectious.

If sample material comes in contact with the analyzer surface, clean it up immediately with a towel.

2.Ensure that the sample contains no fibrin clots, dust or other insoluble contaminations.

If the sample contains insoluble material, false results can be produced. This applies especially when fibrin clots block the sample pipetter.

CAUTION

Liquid Waste

1.Potentially infectious waste must be disposed of according to the legal regulations.

There is a risk of contamination from potentially infectious waste.

2.Contact the manufacturer of the reagent, if you require more information about its environmental compatibility.

CAUTION

Correctness/Precision of the Measurements

To ensure that the analyzer operates correctly, controls must be measured and the functions must be monitored.

Erroneous measurements can lead to a false diagnosis resulting in an incorrect therapy that puts the patient at risk.

0 - 4 |

V 2.1 – Operator's Manual |

Potential Hazards and Safety Precautions

Safety Precautions During Operation

CAUTION

CAUTION

Correct Usage

1.The analyzer was designed for clinical-chemical analyses, electrolyte analyses, immunological tests and medical analyses using water-soluble samples and reagents.

Comply with the manufacturer regulations of the reagent when using the tests on the analyzer.

2.If reagents are used other than those developed by Boehringer Mannheim, then Boehringer Mannheim guarantees the technical specifications of the analyzer but takes no responsibility for the measured results.

CAUTION

Operator Qualifications

1.The operation of the analyzer should only be performed under the control of a qualified person, who has taken part in a recognized training from Boehringer Mannheim.

2.For clinical tests, the analyzer should only be controlled by a practitioner or a laboratory doctor.

CAUTION

Operation and Maintenance

1.The operation and maintenance of the analyzer may only be performed according to the described procedures. No other components other than those specified may be touched.

2.Never open the screwed down analyzer covers when the analyzer is connected to a power supply. Contact with the circuit boards can damage the electronic components.

V 2.1 – Operator's Manual |

0 - 5 |

BM/Hitachi 917

3.Never touch the sample pipetter, reagent pipetter, stirrer, rinse units and all other moving components of the analyzer when it is in operation.

If this precaution is not adhered to, damage or interruption to the analyzer can occur.

4.Never touch the reaction disk, sample disk and reagent disk when they are rotating. If this precaution is not adhered to, damage or interruption to the analyzer can occur.

CAUTION

Environment Conditions (Installation Conditions)

Consider the specified installation conditions. If the analyzer is to be located somewhere else, contact Boerhinger Mannheim customer support.

CAUTION

Limitations for Samples and Reagents

1.The reaction cells, sample cups and the tubing for liquid waste are not impervious to organic solutions. Never use organic solutions.

2.Never use samples or reagents that can stick to the sample probe, reagent probes or the reaction cells. This also applies to samples and reagents that may block the sample probe or reagent probes. False measurements may be produced.

CAUTION

Loading Samples and Reagents

Only load samples and reagents into the intended positions on the analyzer. Spilt samples and reagents can cause disruptions to the analyzer. Only load reagents when the analyzer is in the "stand-by" mode, or when the reagent stop function permits loading.

If this precaution is not adhered to, damage or interruption to the analyzer can occur.

0 - 6 |

V 2.1 – Operator's Manual |

Potential Hazards and Safety Precautions

CAUTION

Analyzer Cover

The analyzer cover should always be closed during operation. Only open the cover to load samples, etc.

CAUTION

Sample Disk

Never load new samples or change the sample disk when the LEDs, indicating that the disk is rotating, are lit or blinking.

LED 1 indicates that sample disk 1 is rotating.

LED 2 indicates that sample disk 2 is rotating.

If this precaution is not adhered to, the analyzer can be damaged.

CAUTION

Reaction Disk

1.Never touch the reaction disk when the analyzer is operating.

2.Always follow the corresponding instructions when removing, loading or replacing the reaction disk or the reaction cell segments.

If this precaution is not adhered to, damage or interruption to the analyzer can occur.

CAUTION

Reagent Disk

Only open the reagent disk cover in order to replace reagents.

If this precaution is not adhered to, the cooling can be affected thus causing the reagents to expire. Opening the cover during an analysis causes an analyzer alarm.

V 2.1 – Operator's Manual |

0 - 7 |

BM/Hitachi 917

CAUTION

Reaction Cells

If a reaction cell dries out after use, cracks can occur and contaminations may not be able to be removed. Therefore, the reaction cells must be stored after use in deionized water. If the analyzer is not going to be used for more than three days, the reaction cells must be removed from the reaction disk and must be stored in a 2% solution of Hitergent.

CAUTION

Switching the Analyzer On

Never switch the analyzer off and then immediately back on. Wait at least 30 seconds before switching back on.

If this is not adhered to, the analyzer may be damaged.

CAUTION

Handling Detergents

Never touch detergents with bare fingers, this can cause skin damage. Wear rubber gloves when handling detergents.

CAUTION

Photometer Lamp

Do not touch the hot lamp or lamp housing, there is a risk of burns.

CAUTION

Stirrer

Do not bend the stirring paddle. Bent stirring paddles can cause false measurements.

0 - 8 |

V 2.1 – Operator's Manual |

Manual Outline

1. Introduction

V 2.1 – Operator's Manual |

1 - 1 |

BM/Hitachi 917

1.1 Manual Outline

The Operator’s Manual is a part of the documentation for the analyzer BM/Hitachi 917, which additionally includes the volume System Description and the Short Guide.

The volume Operator’s Manual offers a detailed overview of all processes concerned with the daily operation and those processes required fro the daily routine of the analyzer.

–In chapter 0 potentially hazardous sources are brought to light as well as safety notes and precautionary measures.

–Chapter 2 provides detailed information about the daily routine on the analyzer.

–Procedures for analyzer care and maintenance are described in detail in chapter 3.

–Chapter 4 deals with operation support that could be useful when tuning the analyzer to the laboratory requirements.

–In chapter 5 all printouts are described that can be requested from the analyzer.

–The 6th and last chapter describes errors and what measures must be taken to cure them.

–The Appendix consists of a Glossary and an Index, allowing you quick access to any required information.

1 - 2 |

V 2.1 – Operator's Manual |

Introduction

2. Daily Routine

V 2.1 – Operator's Manual |

2 - 1 |

BM/Hitachi 917

2.1 Introduction

In this chapter you find a description how the daily routine is prepared, performed and shut down. Step by step you will get to know how to switch on the analyzer, how to access the menus, how to determine the type and number of samples, how to allocate tests, how to start the analysis, and how to obtain results at the end of the analysis.

Your service person at Boehringer Mannheim

Name:

Address:

Tel.:

Fax.:

2 - 2 |

V 2.1 – Operator's Manual |

Daily Maintenance - Outline

2.2 Daily Maintenance - Outline

Perform all daily operational checks prior to beginning the first run of the day. Each daily operational check should be logged on the MAINTENANCE LOG sub menu. Default daily maintenance items include:

1.Empty waste container

2.Check / replace cell detergent supply

3.Check / replace detergent supplies (1D1 - 2D3)

4.Check W1/W2 positions on sample disk 2

5.Clean sample and reagent probes

6.Clean stirrer paddles

7.Check paper supplies

8.Clean instrument surfaces

9.Clean cell rinse unit nozzles

10.Wash ISE unit with ISE Wash Solution (in position W2)

11.ISE prime/condition/calibrate

12.Check incubation bath temperature

13.Perform photometer check

14.Update Maintenance Log

V 2.1 – Operator's Manual |

2 - 3 |

BM/Hitachi 917

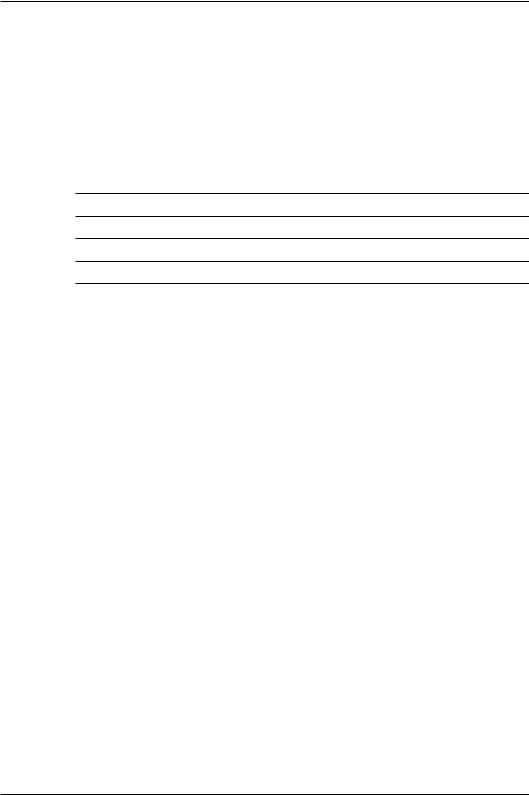

The following table displays an overview of the above maintenance procedures. More detailed information can be found in chapter 3 Maintenance and Daily Care of the Operator's Manual.

No. |

Maintenance Item |

Material required |

Note Details |

Page |

1 |

Empty waste |

disinfecting solu- |

Content of the waste container is |

3-9 |

|

container |

tion, water for |

potentially hazardous. Wear |

|

|

|

rinsing, paper |

disposable gloves. |

|

|

|

towels |

|

|

2 |

Check / replace cell |

Detergent 1 |

Place both tube filters in the first |

3-10 |

|

detergent supply |

(NaOH-D) |

NaOH-D bottle. Execute a Cell |

|

|

|

|

detergent prime, before running |

|

|

|

|

analysis. |

|

3 |

Check / replace |

fresh detergent |

Hitergent is used for position |

3-12 |

|

detergent supplies |

|

1D1 and 2D1. |

|

|

(1D1 - 2D3) |

|

|

|

|

|

|

NaOH-D (70 mL bottle) is used |

|

|

|

|

for position 1D2 and 2D2. |

|

|

|

|

Detergent for additional rinsing is |

|

|

|

|

used for position 1D3 and 2D3. |

|

4 |

Check W1, W2 |

NaOH-D |

NaOH-D is used for position W1. |

3-5 |

|

position on sample |

|

|

|

|

disk 2 |

ISE wash solution |

ISE wash solution is used for |

|

|

|

|

position W2. |

|

5 |

Clean sample and |

alcohol, lint-free |

Switch off the instrument to |

3-13 |

|

reagent probes |

cloth |

move the pipettors. |

|

6 |

Clean stirrer |

alcohol, lint-free |

Switch off the instrument to |

3-14 |

|

paddles |

cloth |

move the stirrer paddles. |

|

7 |

Check paper supply |

printer paper |

Load new printer paper, if |

3-15 |

|

|

|

necessary. |

|

8 |

Clean instrument |

disinfecting |

Clean all surfaces with a lint-free |

3-15 |

|

surfaces |

solution, water, |

cloth and water or disinfecting |

|

|

|

lint-free cloth |

solution, if needed. |

|

9 |

Clean nozzles of the |

alcohol, lint-free |

Instrument must be in Standby |

3-15 |

|

cell rinse unit |

cloth |

or OFF. |

|

2 - 4 |

V 2.1 – Operator's Manual |

Daily Maintenance - Outline

No. |

Maintenance Item |

Material required |

10 |

Wash ISE Unit with |

ISE wash solution |

|

ISE wash solution (in |

|

|

position W2) |

|

11 ISE prime/condition/ ISE reagents, calibration human sample,

calibrators

12Check incubation bath temperature

13Perform photometer check

14Update Maintenance log

Note Details |

Page |

ISE maintenance has to be |

3-17 |

performed once a day. Ensure |

|

that ISE conditioning and |

|

calibration are performed prior to |

|

the start of the next routine. |

|

Perform an ISE prime and |

3-16 |

calibration once a day. |

|

Check the incubation bath |

3-17 |

temperature displayed on the |

|

SAMPLE TRACKING global |

|

menu screen (Tolerance: 37°C ± |

|

0.2 °C) |

|

Check that the results do not |

3-18 |

exceed 16000 |

|

in the MAINTE LOG sub menu |

|

(MAINT/UTILITY main menu) |

|

V 2.1 – Operator's Manual |

2 - 5 |

BM/Hitachi 917

2.3 System Start

2.3.1 Introduction

There are two ways to start the routine operation - by pressing the main switch of the analyzer (POWER ON) on the right side of the front panel, or by waking up the instrument from the SLEEP mode.

2.3.2 Power On

1.If necessary, turn on the external water supply and open the tap, before starting the daily routine operation.

2.Switch on the analyzer using the main switch (on the right side of the front panel). The computer, screen, and the printer are also switched on, if the main switches of these components are permanently left in the ON position.

2 - 6 |

V 2.1 – Operator's Manual |

Loading...

Loading...