Hitachi AX-F100-WUN, AX-F100-W, AX-F100-E, AX-F100-EBS Service Manual

SERVICE MANUAL

MANUEL D'ENTRETIEN

WARTUNGSHANDBUCH

CAUTION:

Beforeservicing this chassis, itisimportantthat the servicetechnician read the“Safe ty

Precautions”and“ProductSafetyNotices”inthisservicemanual.

SM0100

AXF100E

AXF100EBS

AXF100UC

AXF100W

AXF100WUN

Data contained within this Service

manual is subject to alteration for

improvement.

ATTENTION:

Avantd’effectuerl’entretienduchâassis,letechniciendoitlireles«Précautionsdesécurité»

etles«Noticesdesécuritéduproduit»présentésdansleprésentmanuel.

VORSICHT:

VorÖffnendesGehäuseshatderService-Ingenieurdie„Sicherheitshinweise“und„Hinweise

zurProduktsicherheit“indiesemWartungshandbuchzulesen.

Les données fournies dans le présent

manueld’entretienpeuventfairel’objet

demodificationsenvuedeperfectionner

leproduit.

Die in diesem Wartungshandbuch

enthaltenenSpezifikationenkönnensich

zwecksVerbesserungenändern.

CONTENTS

SPECIFICATIONS...............................................................................................................................................3

SERVICE POINTS..............................................................................................................................................4

WIRING DIAGRAM.............................................................................................................................................8

PRINTED WIRING BOARD...............................................................................................................................9

CIRCUIT DIAGRAM...........................................................................................................................................17

BLOCK DIAGRAM.............................................................................................................................................29

EXPLODED VIEW.............................................................................................................................................31

REPLACEMENT PARTS LIST..........................................................................................................................35

SPECIFICATIONSANDPARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

MINI COMPONENT HI-FI SYSTEM

September 2000

ENGLISH

SAFETY PRECAUTIONS

WARNING: The following precautions must be observed.

ALL PRODUCTS

Before any service is performed on the chassis an

isolation transformer should be inserted between the

power line and the product.

1. When replacing the chassis in the cabinet, ensure

all the protective devices are put back in place.

2. When service is required, observe the original

lead dressing. Extra precaution should be taken to

ensure correct lead dressing in any high voltage

circuitry area.

3. Many electrical and mechanical parts in

HITACHI products have special safety related

characteristics. These characteristics are often not

evident from visual inspection, nor can the

protection afforded by them necessarily be

obtained by using replacement components rated

for higher voltage, wattage, etc. Replacement

parts which have these special safety

characteristics are identified by marking with a

on the schematics and the replacement parts

list.

The use of a substitute replacement component

that does not have the same safety characteristics

as the HITACHI recommended replacement one,

shown in the parts list, may create electrical

shock, fire, X-radiation, or other hazards.

4. Always replace original spacers and maintain lead

lengths. Furthermore, where a short circuit has

occurred, replace those components that indicate

evidence of overheating.

5. Insulation resistance should not be less than 2M

ohms at 500V DC between the main poles and

any accessible metal parts.

6. No flashover or breakdown should occur during

the dielectric strength test, applying 3kV AC or

4.25kV DC for two seconds between the main

poles and accessible metal parts.

7. Before returning a serviced product to the

customer, the service technician must thoroughly

test the unit to be certain that it is completely safe

to operate without danger of electrical shock. The

service technician must make sure that no

protective device built into the instrument by the

manufacturer has become defective, or

inadvertently damaged during servicing.

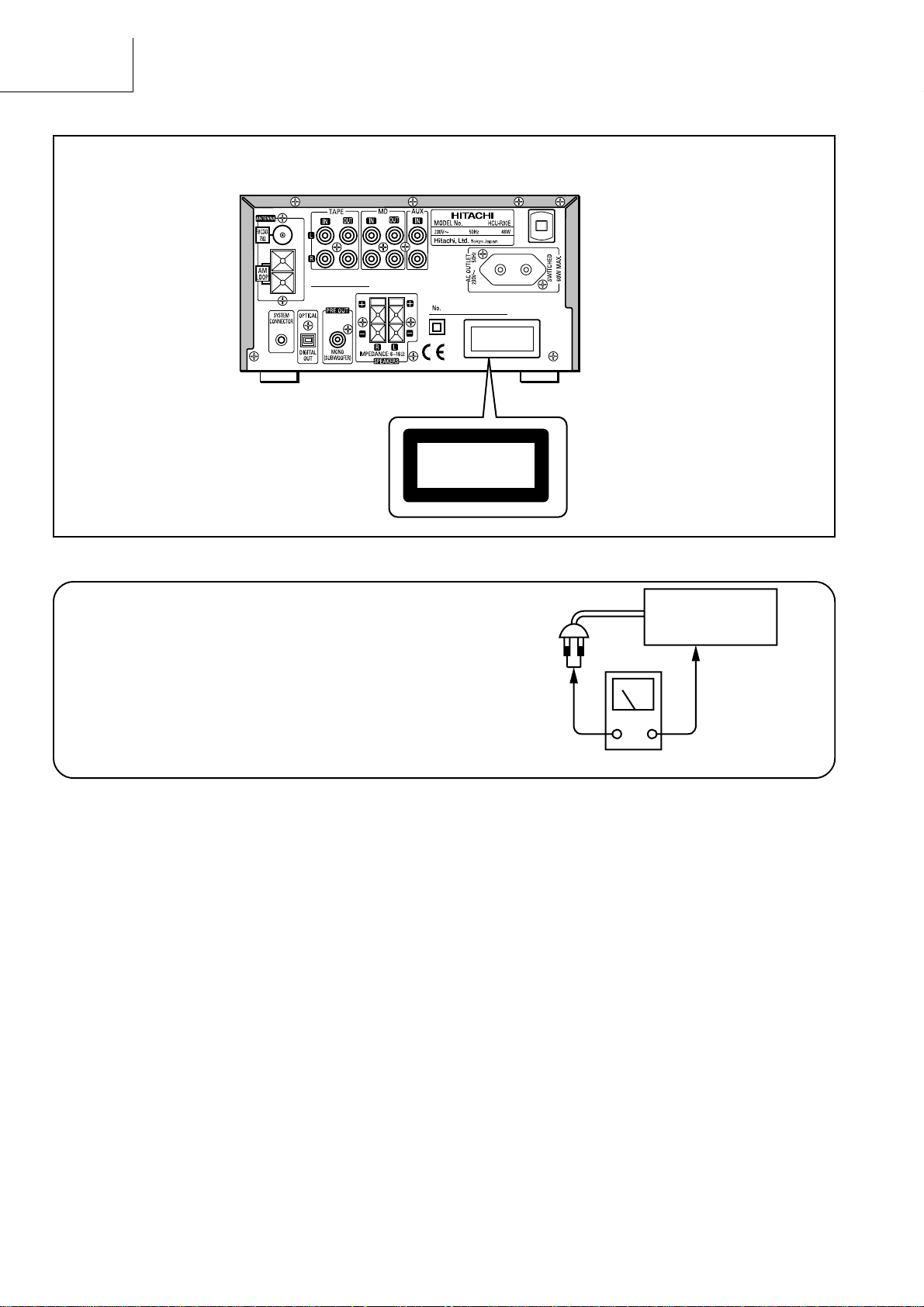

CE MARK

1. HITACHI products may contain the CE mark on

the rating plate indicating that the product

contains parts that have been specifically

approved to provide electromagnetic

compatibility to designated levels.

2. When replacing any part in this product, please

use only the correct part itemised in the parts list

to ensure this standard is maintained, and take

care to replace lead dressing to its original state,

as this can have a bearing on the electromagnetic

radiation/immunity.

PICTURE TUBE

1. The line output stage can develop voltages in

excess of 25kV; if the E.H.T. cap is required to be

removed, discharge the anode to chassis via a

high value resistor, prior to its removal from the

picture tube.

2. High voltage should always be kept at the rated

value of the chassis and no higher. Operating at

higher voltages may cause a failure of the picture

tube or high voltage supply, and also, under

certain circumstances could produce X-radiation

levels moderately in excess of design levels. The

high voltage must not, under any circumstances,

exceed 29kV on the chassis (except for projection

Televisions).

3. The primary source of X-radiation in the product

is the picture tube. The picture tube utilised for

the above mentioned function in this chassis is

specially constructed to limit X-radiation. For

continued X-radiation protection, replace tube

with the same type as the original HITACHI

approved type

4. Keep the picture tube away from the body while

handling. Do not install, remove, or handle the

picture tube in any manner unless shatterproof

goggles are worn. People not so equipped should

be kept away while picture tubes are handled

LASERS

If the product contains a laser avoid direct exposure to

the beam when the cover is open or when interlocks are

defeated or have failed.

AX-F100

• The caution labels on laser usage • Notices de précautions d’emploi du laser

CLASS 1 LASER PRODUCT

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

CLASS 1 LASER PRODUCT

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

Check that exposed parts are acceptably insulated from

the supply circuit before returning the repaired instrument

to the customer.

• Checking method

Measure the resistance value between the both poles of

attachment cup (Power supply plug) and the exposed

parts (Parts such as Knob, Cover, etc. where the customer is easy to touch.) and check that the resistance

value is 500 kohms or more.

INSTRUMENT

(Exposed part)

Insulation tester (DC 500V)

2

SAFETY PRECAUTIONS

The following precautions should be observed when servicing.

1. Since many parts in the unit have special safety-related characteristics, always use genuine Hitachis replacement

parts. Especially critical parts in the power circuit block should not be replaced with other makers. Critical parts

are marked with in the circuit diagram.

2. Before returning a repaired unit to the customer, the service technician must thoroughly test the unit to ascertain

that it is completely safe to operate without danger of electrical shock.

SPECIFICATIONS• SPECIFICATIONS

RECEIVER SECTION

Tuner Range : FM: 87.5 - 108.0 MHz (0.1 MHz step) UC

: FM: 87.50 - 108.00 MHz (0.05 MHz step) E, EBS, W, WUN

: MW: 520 - 1,710 kHz (10 kHz step) UC, W, WUN

: MW: 522 - 1,611 kHz (9 kHz step) E, EBS, W, WUN

: LW: 153 - 281 kHz (1 kHz step) E, EBS

CD SECTION

Sampling Frequency : 44.1 kHz

Laser : Semiconductor laser

AX-F100

TIMER SECTION

System : Digital Quartz Clock

Display Format : 24-hour cycle E, EBS, W, WUN

12-hour cycle UC

Timer Accuracy : Within 60 seconds at monthly rate in normal room temperature

GENERAL SPECIFICATIONS

Power Supply : AC 110 - 127 V/220 - 240 V, 50/60 Hz W, WUN

: AC 120 V, 60 Hz UC

: AC 230 V, 50 Hz E, EBS

Power Consumption : 48 W (ECO-ON mode: less than 1 W) E, EBS, W, WUN

: 1.1 A include AC outlet (ECO-ON mode: less than 1 W) UC

Rated Output Power : 30 W + 30 W (6 ohms, THD 10%)

Inputs/Outputs : MD, TAPE, AUX, Optical Digital Out, Pre out, Headphone, System Connector

SPEAKER SECTION

System : 2 Way Bass Reflex Speaker System

Speaker Unit : Woofer: 10 cm ∞ 1, Tweeter: 5 cm ∞ 1

Impedance : 6 ohms

DIMENSIONS

HCU-R30 Unit : 210 (W) ∞ 120 (H) ∞ 325 (D) mm

Speaker Unit : 150 (W) ∞ 275 (H) ∞ 227 (D) mm

WEIGHT

HCU-R30 Unit : 4.4 kg

Speaker Unit : 3.0 kg (1 speaker)

ACCESSORY SUPPLIED : FM Antenna, AM LOOP Antenna,

Remote Control (RB-AXF3), Battery,

Edison plug adapter (For W, WUN only)

* Specifications are subject to change for performance improvement without notice.

3

AX-F100

SERVICE POINTS

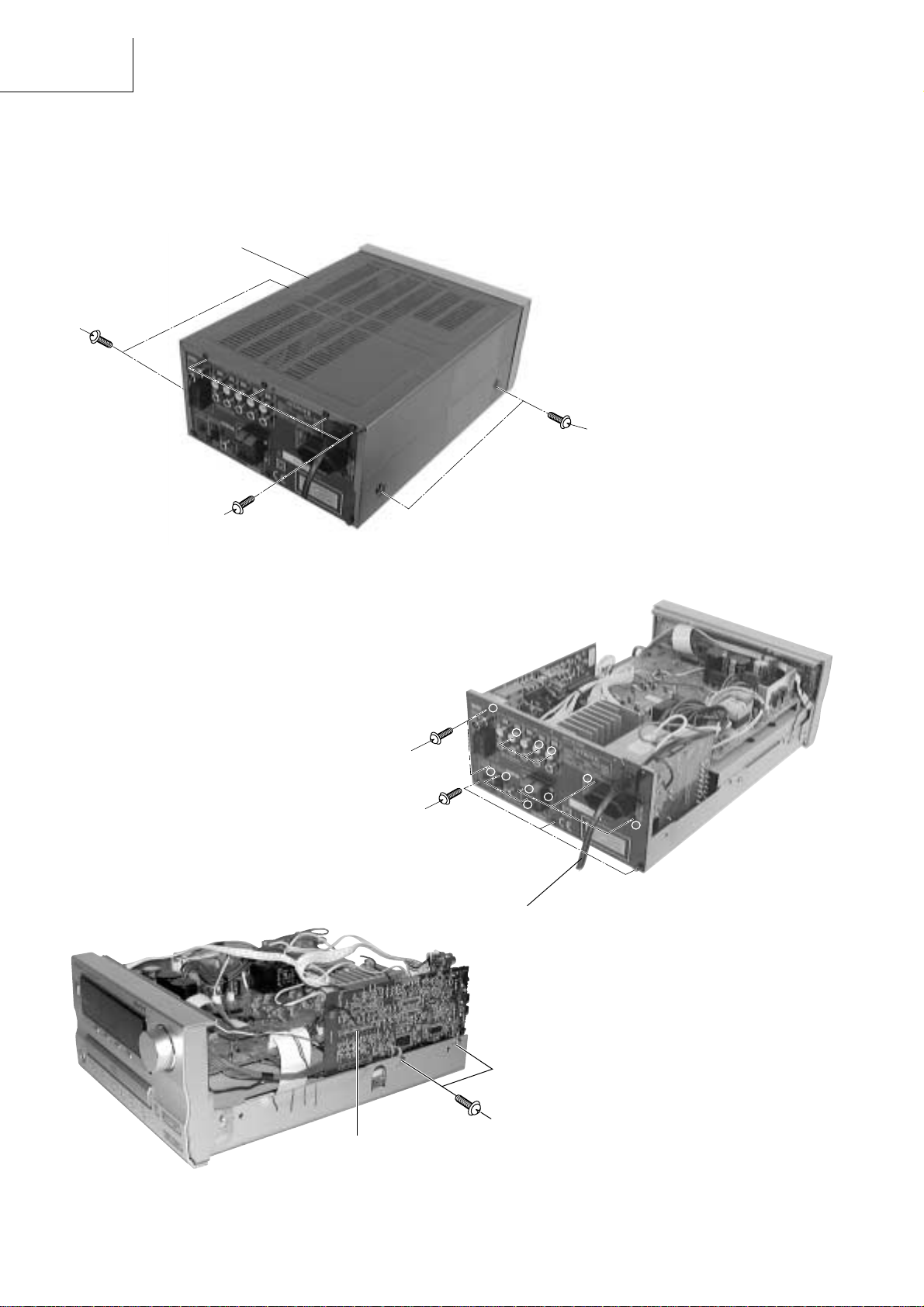

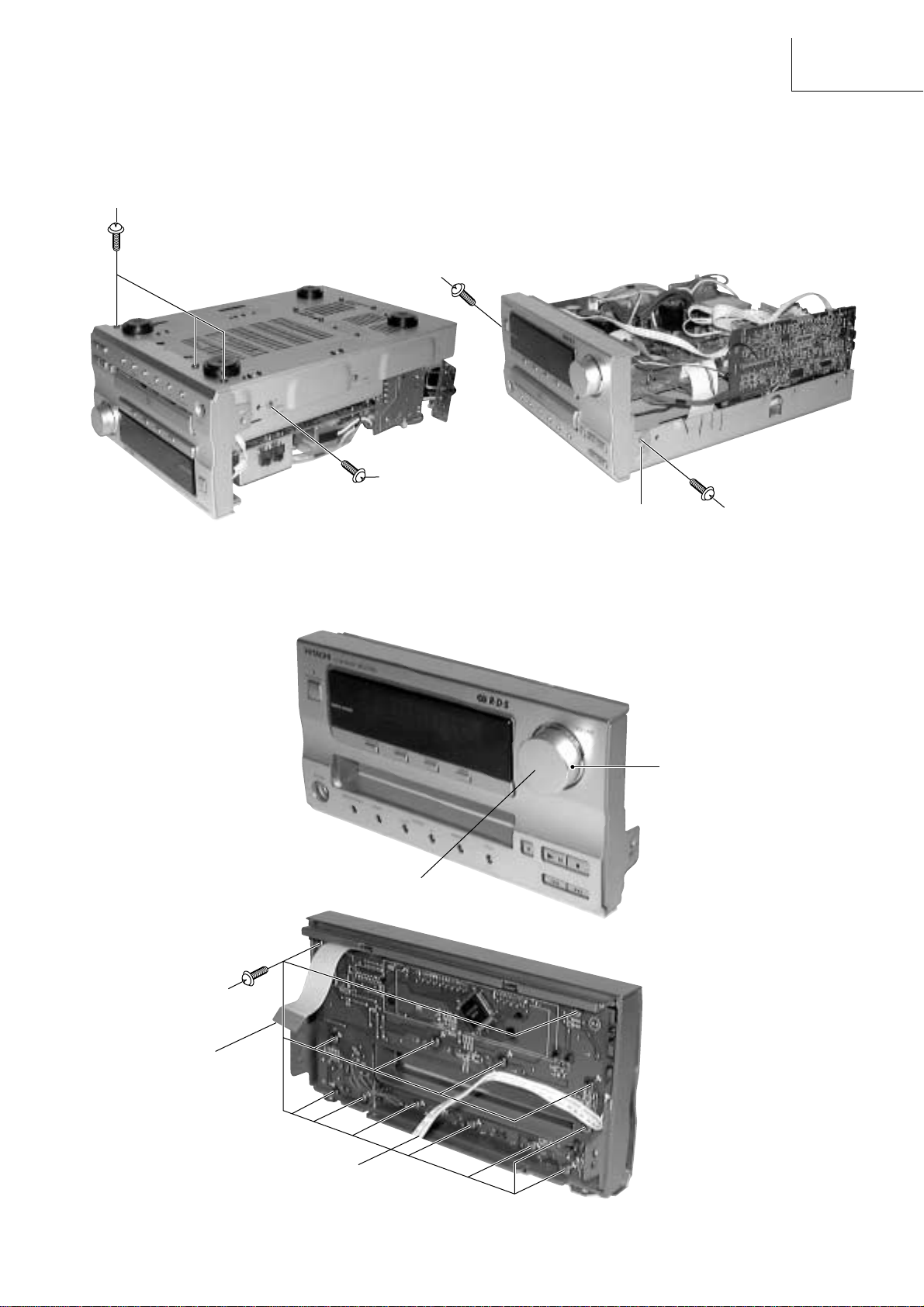

1. Removal of Top Cover

(1) Remove 4 screws 1 from each side.

(2) Remove 4 screws 2 from the rear plate.

Top cover

1

1

2

Fig. 1

3. Removal of Tuner P.W.B Board

(1) Remove 2 screws 5.

(2) Pull the tuner P.W.B gently to detach from

connector A of the main PCB.

2. Removal of Rear Plate and Power Cord

(1) Remove 11 screws 3 and 4 from the rear plate.

(2) Detach the power cord.

1

3

4

4

2

3

Power cord

5

9

7

8

10

6

11

Fig. 2

Fig. 3

5

Connector A

4

4. Removal of Front Panel

(1) Detach connector B & C (Refer to Fig. 5-2)

(2) Remove 3 screws 6 from base of front panel.

(3) Remove 1 screw 7 from each side and screw 8.

(4) Release the claw of the Inner panel from each side.

6

7

8

Fig. 4-1

Claw

AX-F100

Fig. 4-2

7

5. Removal of Front P.W.B Board

(1) Remove the volume knob to detach the nut.

(2) Remove 13 screws 9.

Fig. 5-1

Volume knob

9

Nut

Connector B

Fig. 5-2

Connector C

5

AX-F100

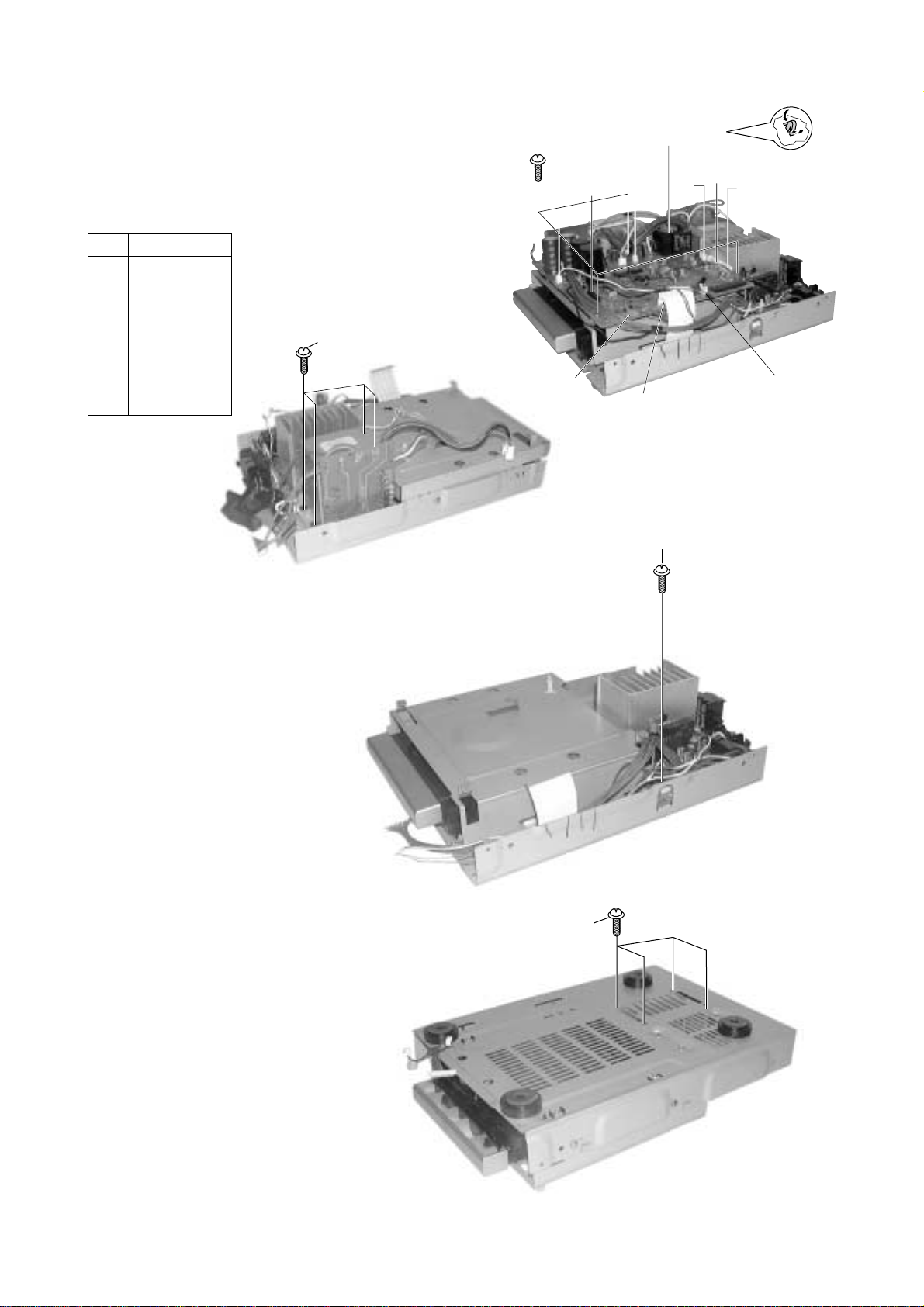

6. Removal of Main P.W.B Board and Power Transformer

(1) Detach the connector D to K.

(2) Remove 4 screws ! from base of the plate and 4

screws ".

(3) Press and push downwards the P.W.B. support.

(4) Gently pull the main P.W.B. upwards and remove

the Power Transformer.

No. CONNECTOR

D CN702

E CN701

F PG301

G PG302

H PG501

I PG601

J CN501

K PG505

L PG602

"

!

K

D

P.W.B. Support

I

J

E

H

G

F

Fig. 6-1

L

7. Removal of Amp P.W.B. Board

(1) Remove 1 screw #.

(2) Remove 4 screws $ from base of chassis.

Fig. 6-2

#

Fig. 7-1

$

6

Fig. 7-2

8. Removal of P.W.B. Holder

(1) Remove 3 screws % to detach the P.W.B. Holder.

AX-F100

%

%

Fig. 8

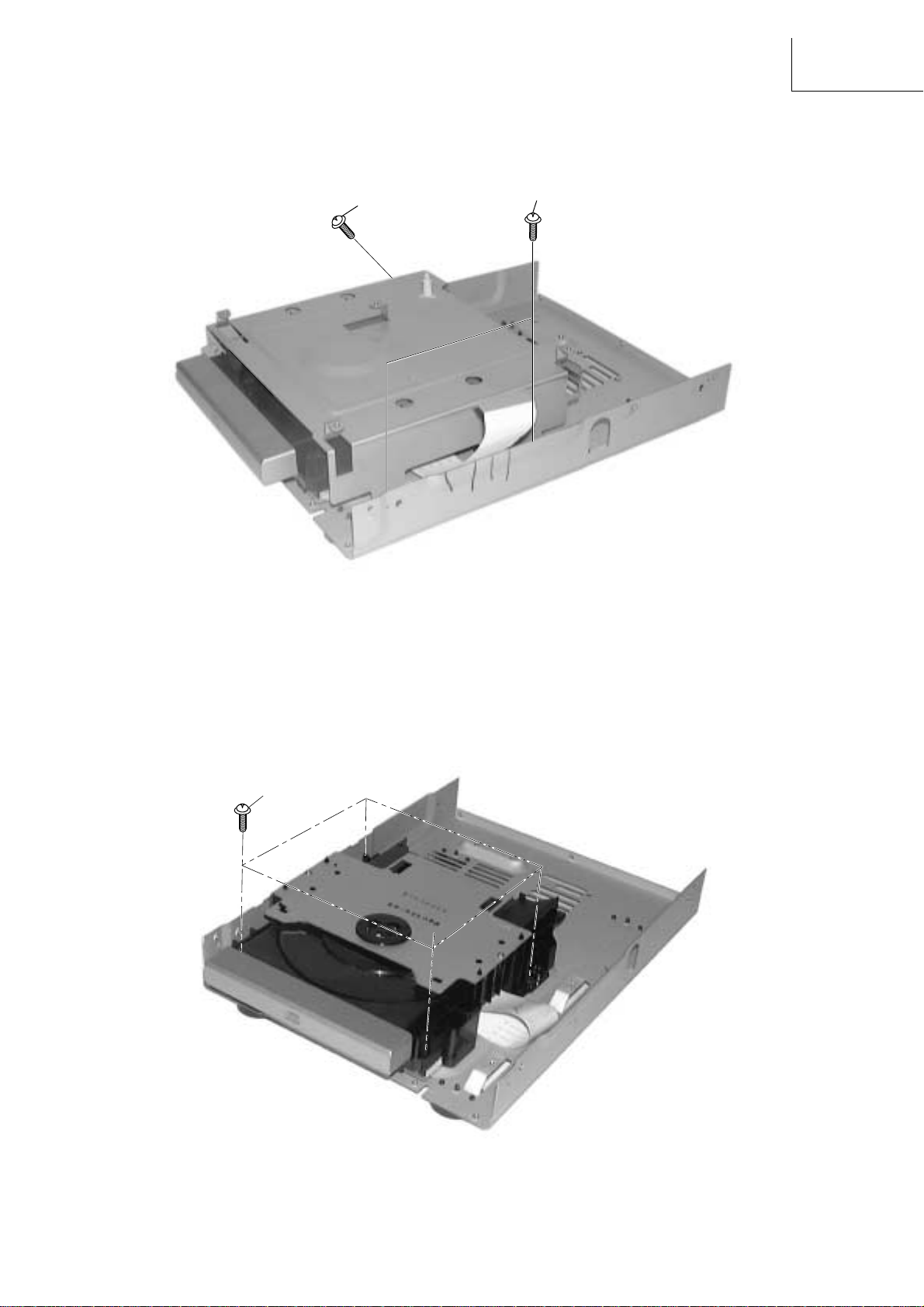

9. Removal of CD Mechanism Assembly

(1) Remove 4 screws & and pull up the CD mechanism.

&

Fig. 9

7

Loading...

Loading...