Hitachi CC14ST User Manual [ru]

Cut-O Machine Profil kesme

Відрізна машина Oтрезная машина

CC 14ST

Read through carefully and understand these instructions before use. Aleti kullanmadan önce bu kılavuzu iyice okuyun ve talimatları anlayın.

Будьласка, прочитайтеінструкціїіперевірте себе, чивсезрозуміло, першніжкористуватисяприладом. Внимательно прочтите данную инструкцию по эксплуатации прежде чем пользоваться инструментом.

Handling instructions

Kullanım talimatları

lнструкціїщодоповодженнязпристроєм

Инструкция по эксплуатации

1 |

|

|

4 |

|

2 |

|

|

|

|

|

|

4 |

|

||

|

|

|

|

|

|

|

|

|

|

2 |

5 |

|

|

8 |

|

|

|

|

|

|

|

|

|

|

e |

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

r |

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

7 g |

w |

|

|

|

|

|

|

|

y |

q |

|

|

|

|

3 |

|

|

4 |

|

|

5 |

|

|

|

|

^ |

|

0 |

q |

w |

|

# |

|

|

|

|

||

! |

$ |

|

|

|

|

||

|

% |

|

( |

|

|||

|

|

|

|

|

|

||

|

|

|

|

|

|

t |

|

|

|

* |

7 |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

& |

|

* |

|

|

|

0 |

# |

|

|

) |

r |

|

@ |

|

|

|

|||

|

|

@ |

@ |

y |

|||

|

|

|

|

||||

|

|

|

|

|

|

|

|

6 |

q |

|

7 |

|

|

8 |

|

|

|

|

|

|

|

7 |

|

|

w |

|

|

|

|

|

|

|

|

|

|

|

|

* |

|

|

|

e |

|

|

|

||

|

|

|

|

|

|

||

) |

|

|

q |

* |

|

7 |

35 mm 70 mm |

|

y |

|

r |

|

|

q |

|

|

|

|

|

|

|

||

9 |

|

|

10 |

|

|

11 |

|

|

|

|

|

|

|

s |

|

|

|

|

w |

i |

|

|

|

|

|

|

|

|

q |

|

|

t |

|

|

|

o |

|

|

|

u |

|

y |

u |

p |

|

|

|

|

|

|

|

|

a |

|

|

|

|

|

|

|

|

|

|

2

12 |

d |

6 |

13 |

|

5 |

f |

|

|

|

g |

14 |

|

h |

j |

|

|

18 mm |

6 mm |

|

3

|

English |

Türkçe |

Український |

Pyccкий |

1 |

Wheel cover |

Disk kapağı |

Крышка диска |

Крышка диска |

2 |

Lower guard (A) |

Alt koruyucu (A) |

Нижня напрямна (A) |

Нижнее защитное |

приспособление (A) |

||||

3 |

Lower guard (B) |

Alt koruyucu (B) |

Нижня напрямна (B) |

Нижнее защитное |

приспособление (B) |

||||

4 |

Handle |

Kol |

Рукоятка |

Рукоятка |

5 |

Carrying handle |

Taşıma kolu |

Ручка для перенесення |

Рукоятка для переноски |

6 |

Spark chute |

Kıvılcım oluğu |

Iскровий жолоб |

Искровой желоб |

7 |

Hex. bar wrench |

Altıgen çubuk lokma |

Гайковий ключ у вигляді |

Гаечный ключ в виде |

anahtarı |

шестигранного стрижня |

шестигранного стержня |

||

8 |

Switch |

Anahtar |

Перемикач |

Переключатель |

9 |

Motor |

Motor |

Двигун |

Двигатель |

0 |

Cut-o wheel |

Profil Kesme diski |

Відрізний диск |

Отрезной диск |

! |

Stopper |

Durdurucu |

Стопор |

Стопор |

@ |

Wheel washer |

Disk pulu |

Шайба диска |

Дисковая шайба |

# |

Stopper pin |

Stoper pimi |

Стопорний штифт |

Стопорный штырь |

$ |

Hole of wheel washer |

Dik pulu deliği |

Отвір у шайбі диска |

Отверстие дисковой |

шайбы |

||||

% |

Cut-o wheel spindle |

Profil kesme diski mili |

Шпиндель відрізного |

Отрезной дисковый |

диска |

шпиндель |

|||

^ |

Sleeve |

Rakor |

Втулка |

Втулка |

& |

O-ring |

O-halka |

Кільце ущільнення |

Уплотнительное кольцо |

* |

10 mm bolt |

10 mm cıvata |

10 мм болти |

10 мм болты |

( |

Washer (A) |

Pul (A) |

Шайба (A) |

Шайба (A) |

) |

Workpiece material |

İş parçası malzeme |

Матеріал робочої |

Материал рабочей |

заготовки |

заготовки |

|||

q |

Vise (B) |

Mengene (B) |

Затискні пристрої (В) |

Зажимное |

приспособление (В) |

||||

w |

Vise (A) |

Mengene (A) |

Затискні пристрої (А) |

Зажимное |

приспособление (А) |

||||

e |

Clutch |

Kavrama kolu |

Муфта |

Муфта |

r |

Screw handle |

Vidalı kol |

Рукоятка гвинта |

Рукоятка винта |

t |

Long workpiece material |

Uzun iş parçası malzeme |

Довга робоча заготовка |

Длинное рабочее |

изделие |

||||

y |

Base |

Taban |

Основа |

Основание |

u |

Block |

Blok |

Блок |

Блок |

i |

Dimension of workpiece |

Üzerinde çalışılacak |

Розмір заготовки для |

Размер заготовки для |

|

to be cut |

malzemenin boyutları |

відрізання |

отрезания |

o |

Square block |

Kare blok |

Квадратний блок |

Квадратный блок |

p |

Dimension of square block |

Kare blok ebadı |

Розміри квадратного |

Размеры квадратного |

блока |

блока |

|||

a |

Lock nut |

Kilit somunu |

Контргайка |

Зажимная гайка |

s |

Stopper bolt |

Stoper cıvatası |

Стопорний болт |

Стопорный болт |

d |

Screw |

Vida |

Гвинт |

Винт |

f |

Chain hook |

Zincir kancası |

Гачок для ланцюга |

Цепной крюк |

g |

Chain |

Zincir |

Ланцюг |

Цепь |

h |

Carbon brush |

Kömür |

Вугільна щітка |

Угольная щетка |

j |

Wear limit |

Aşınma sınırı |

Межа зносу |

Предел износа |

4

|

|

|

|

|

English |

Türkçe |

Український |

Pyccкий |

|

|

|

|

|

Symbols |

Simgeler |

Символи |

Символы |

|

|

|

|

|

WARNING |

DİKKAT |

ПОПЕРЕДЖЕННЯ |

ПРЕДУПРЕЖДЕНИЕ |

|

|

|

|

|

The following show |

Aşağıda, bu alet için |

Тут показані символи, |

Ниже приведены |

|

|

|

|

|

symbols used for the |

kullanılan simgeler |

використані в |

символы, |

|

|

|

|

|

machine. Be sure that |

gösterilmiştir. Aleti |

керівництві. Будь |

используемые для |

|

|

|

|

|

you understand their |

kullanmadan önce bu |

ласка, переконайтеся, |

машины. Перед |

|

|

|

|

|

meaning before use. |

simgelerin ne anlama |

що правильно |

началом работы |

|

|

|

|

|

|

geldiğini anladığınızdan |

розумієте їхнє |

обязательно убедитесь |

|

|

|

|

|

|

emin olun. |

значення. |

в том, что Вы |

|

|

|

|

|

|

|

|

понимаете их значение. |

|

|

|

|

|

Read all safety |

Tüm güvenlik |

Прочитайте всі |

Прочтите все правила |

|

|

|

|

|

warnings and all |

uyarılarını ve tüm |

правила безпеки та |

безопасности и |

|

|

|

|

|

instructions. |

talimatları okuyun. |

вказівки. |

инструкции. |

|

|

|

|

|

Failure to follow the |

Uyarılara ve talimatlara |

Невиконання цих |

Не выполнение правил |

|

|

|

|

|

warnings and instructions |

uyulmaması elektrik |

правил та інструкцій |

и инструкций может |

|

|

|

|

|

may result in electric |

çarpmasına, yangına ve/ |

може призвести до |

привести к поражению |

|

|

|

|

|

shock, fire and/or serious |

veya ciddi yaralanmaya |

удару струмом, пожежі |

электрическим |

|

|

|

|

|

injury. |

neden olabilir. |

та/або серйозної |

током, пожару и/или |

|

|

|

|

|

|

|

травми. |

серьезной травме. |

|

|

|

|

|

Always wear eye |

Daima koruyucu gözlük |

Завжди носіть захисні |

Всегда надевайте |

|

|

|

|

|

protection. |

takın. |

окуляри. |

средства защиты глаз. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Only for EU countries |

Sadece AB ülkeleri için |

Лише для країн ЄС НЕ |

Только для стран |

|

|

|

|

|

Do not dispose of |

Elektrikli el aletlerini |

викидайте електричні |

ЕС Не выкидывайте |

|

|

|

|

|

electric tools together |

evdeki çöp kutusuna |

інструменти із |

электроприборы |

|

|

|

|

|

with household waste |

atmayınız! |

побутовими відходами! |

вместе с обоычным |

|

|

|

|

|

material! |

Kullanılmış elektrikli |

Згідно Європейської |

мусором! |

|

|

|

|

|

In observance of |

aletleri, elektrik ve |

Директиви 2002/96/EC |

В соответствии |

|

|

|

|

|

European Directive |

elektronikli eski cihazlar |

про відходи |

с европейской |

|

|

|

|

|

2002/96/EC on |

hakkındaki 2002/96/EC |

електронного |

директивой 2002/96/ЕС |

|

|

|

|

|

waste electrical and |

Avrupa yönergelerine |

та електричного |

об утилизации старых |

|

|

|

|

|

electronic equipment |

göre ve bu yönergeler |

виробництва і її |

электрических и |

|

|

|

|

|

||||

|

|

|

|

|

and its implementation |

ulusal hukuk kurallarına |

запровадження згідно |

электронных приборов |

|

|

|

|

|

in accordance with |

göre uyarlanarak, ayrı |

місцевих законів, |

и в соответствии с |

|

|

|

|

|

national law, electric |

olarak toplanmalı ve |

електроінструменти, |

местными законами |

|

|

|

|

|

tools that have reached |

çevre şartlarına uygun |

які відслужили |

электроприборы, |

|

|

|

|

|

the end of their life |

bir şekilde tekrar |

робочий строк слід |

бывщие в |

|

|

|

|

|

must be collected |

değerlendirmeye |

утилізувати окремо і |

эксплуатации, должны |

|

|

|

|

|

separately and returned |

gönderilmelidir. |

повертати до установ, |

утилизовываться |

|

|

|

|

|

to an environmentally |

|

що займаються |

отдельно безопасным |

|

|

|

|

|

compatible recycling |

|

екологічною |

для окружающей среды |

|

|

|

|

|

facility. |

|

переробкою брухту. |

способом. |

5

English

(Original instructions)

GENERAL OPERATIONAL PRECAUTIONS

WARNING! When using electric tools, basic safety precautions should always be followed to reduce the risk of fire, electric shock and personal injury, including the following.

Read all these instructions before operating this product and save these instructions.

For safe operations:

1. Keep work area clean. Cluttered areas and benches invite injuries.

2. Consider work area environment. Do not expose power tools to rain. Do not use power tools in damp or wet locations. Keep work area well lit.

Do not use power tools where there is risk to cause fire or explosion.

3. Guard against electric shock. Avoid body contact with earthed or grounded surfaces (e.g. pipes, radiators, ranges, refrigerators).

4. Keep children and infirm persons away. Do not let visitors touch the tool or extension cord. All visitors should be kept away from work area.

5. Store idle tools. When not in use, tools should be stored in a dry, high or locked up place, out of reach of children and infirm persons.

6. Do not force the tool. It will do the job better and safer at the rate for which it was intended.

7. Use the right tool. Do not force small tools or attachments to do the job of a heavy duty tool. Do not use tools for purposes not intended; for example, do not use circular saw to cut tree limbs or logs.

8. Dress properly. Do not wear loose clothing or jewelry, they can be caught in moving parts. Rubber gloves and non-skid footwear are recommended when working outdoors. Wear protecting hair covering to contain long hair.

9. Use eye protection. Also use face or dust mask if the cutting operation is dusty.

10. Connect dust extraction equipment.

If devices are provided for the connection of dust extraction and collection facilities ensure these are connected and properly used.

11. Do not abuse the cord. Never carry the tool by the cord or yank it to disconnect it from the receptacle. Keep the cord away from heat, oil and sharp edges.

12. Secure work. Use clamps or a vise to hold the work. It is safer than using your hand and it frees both hands to operate tool.

13. Do not overreach. Keep proper footing and balance at all times.

14. Maintain tools with care. Keep cutting tools sharp and clean for better and safer performance. Follow instructions for lubrication and changing accessories. Inspect tool cords periodically and if damaged, have it repaired by authorized service center. Inspect extension cords periodically and replace, if damaged. Keep handles dry, clean, and free from oil and grease.

15. Disconnect tools. When not in use, before servicing, and when changing accessories such as blades, bits and cutters.

16. Remove adjusting keys and wrenches. Form the habit of checking to see that keys and adjusting wrenches are removed from the tool before turning it on.

17. Avoid unintentional starting. Do not carry a plugged-in tool with a finger on the switch. Ensure switch is o when plugging in.

18.Use outdoor extension leads. When tool is used outdoors, use only extension cords intended for outdoor use.

19.Stay alert. Watch what you are doing. Use common sense. Do not operate tool when you are tired.

20.Check damaged parts. Before further use of the tool, a guard or other part that is damaged should be carefully checked to determine that it will operate properly and perform its intended function. Check for alignment of moving parts, free running of moving parts, breakage of parts, mounting and any other conditions that may a ect its operation. A guard or other part that is damaged should be properly repaired or replaced by an authorized service center unless otherwise indicated in this handling instructions. Have defective switches replaced by an authorized service center. Do not use the tool if the switch does not turn it on and o .

21.Warning

The use of any accessory or attachment, other than those recommended in this handling instructions, may present a risk of personal injury.

22.Have your tool repaired by a qualified person.

This electric tool is in accordance with the relevant safety requirements. Repairs should only be carried out by qualified persons using original spare parts. Otherwise this may result in considerable danger to the user.

PRECAUTIONS ON USING CUT-OFF MACHINE

1.Inspect the cutting wheel before use, do not use chipped or otherwise defect cutting wheels. Always make a trial run before use to confirm that the Cut-o Machine does not involve abnormalities.

2.Use the normal cut-o wheel on its normal working surface.

3.Guard against cut-o sparks.

4.Properly replace the cut-o wheel.

5.Always pay attention that the cut-o wheel clamping parts are never impaired. Defective parts will cause damage to the cut-o wheel.

6.Ensure that the workpiece is free of foreign matter such as nails.

7.Use only cutting wheels recommended by the manufacturer which have a marked speed equal to or greater than the speed marked on the nameplate of the machine.

8.Abrasive wheels shall be stored and handled with care in accordance with manufacturer’s instructions.

9.Ensure that mounted wheel are fitted in accordance with the manufacture’s instructions.

10.Do never use the machine without the guard in place.

11.Do not saw blade.

12.Do not use the machine in explosive atmospheres and environments where sparks could fire, explosion etc.

6

English

SPECIFICATIONS

Voltage (by areas)*1 |

|

|

|

(220 V, 230 V, 240 V) |

|||||||||

Power Input*1 |

|

|

|

|

|

2200 W |

|||||||

|

|

A |

|

|

|

|

A |

|

|

|

|

|

B |

Shape of material |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

||

Max. cutting dimensions*2 to be cut |

|

|

|

A |

|

|

|

|

|

||||

|

|

||||||||||||

Height × width |

|

|

|

|

|

|

|

|

|

|

A × B |

||

|

|

|

|

|

|

|

|

|

|

||||

A

A

A

|

|

Cutting angle 0° |

120 mm |

115 mm |

90 mm × 200 mm |

130 mm |

|

|

Cutting angle 45° |

115 mm |

104 mm |

110 mm × 104 mm |

100 mm |

Cut-o wheel |

ø355 × ø25.4 × 4 mm (Reinforced resinoid cut-o wheel) |

|||||

No-load Speed |

|

|

3800 min-1 |

|

||

Max. working peripheral speed |

|

4800 m/min |

|

|||

Weight |

|

|

17.0 kg |

|

||

*1 |

Be sure to check the nameplate on product as it is subject to change by areas. |

|

||||

*2 |

The maximum cutting dimensions are the permissible cutting dimensions when the cut-o wheel is not remarkably worn |

|||||

|

by cutting material. |

|

|

|

|

|

STANDARD ACCESSORIES |

|

|

(1) |

Cut-o wheel................................................................. |

1 |

(2) |

Hex. bar wrench............................................................ |

1 |

APPLICATIONS

Cutting of various metallic materials such as pipes, round bars and shaped steel.

PRIOR TO OPERATION

1.Power source

Ensure that the power source to be utilized conforms to the power requirements specified on the product nameplate.

2.Power switch

Ensure that the power switch is in the OFF position. If the plug is connected to a receptacle while the power switch is in the ON position, the power tool will start operating immediately, which could cause a serious accident.

3.Extension cord

When the work area is removed from the power source, use an extension cord of su cient thickness and rated capacity. The extension cord should be kept as short as practicable.

4.Install the machine on a level flat place, and keep it in a stable condition. Prior to shipping, the equipment is subjected to a rigid factory inspection to prevent electric shocks during operation.

5.Since movable portions are secured by tension of a chain while in transit, remove the chain from the chain hook by slightly depressing the switch handle.

6.Ascertain that all cut-o wheels are in perfect condition, and do not display scars and cracks.

7.Although they have been fully clamped at the factory prior to delivery, reclamp the clamping nuts securely for safety.

8.Possible accidents such as a cracked cut-o wheel is prevented by this protective cover (wheel cover). Although it has been fully clamped at the factory prior to delivery, securely reclamp the mounting screws for safety.

9.When replacing the cut-o wheel, ensure that the replacement cutting wheel has a designed circumferential speed in excess of 4800 m/min.

10.Ensure that the bar spanner used for tightening or removing the cut-o wheel is not attached to the machine.

11.Check that the work piece is properly supported. Ensure that the material is securely fastened with the vise. If it is not, a serious accident could be caused if the material comes loose or the cut-o wheel breaks during operation.

12.Ensure that the abrasive wheel is correctly fitted and tightened before use and run the machine at no-load for 30 seconds in safe position, stop immediately if there is a considerable vibration or if other defects are detected. If this condition occurs, check the machine to determine the cause.

13.Rotate the cut-o wheel to inspect any facial deflection. A heavy deflection will cause the cut-o wheel to shift.

14.Ensure that ventilation openings are kept clear when working in dusty conditions. If it should become necessary to clear dust, first disconnect the machine from the mains supply.

CUTTING PROCEDURES

CAUTION

It is dangerous to remove or install the workpiece while the cut-o wheel turning.

1. Operating the switch

Power will be turned on when the switch is pulled, and turned o when released. (Fig.2)

2. Cutting

(1) Rotate the cut-o wheel, gently press down the handle, and bring the cut-o wheel close to the cutting material.

(2) When the cut-o wheel contacts the cutting material, gently press down the handle further and start cutting.

(3) When cutting (or designated slotting) is completed, raise the handle and restore it to its original position.

(4) At the termination of each cutting process, turn OFF the switch to stop rotation and proceed with the subsequent cutting job.

7

English

CAUTION

It does not necessarily cut rapidly when putting more force on the handle.

Too much force on the handle will put excessive pressure on the motor and reduce its capacity.

Do not fail to switch OFF the switch after operation is completed and pull the plug out.

MOUNTING AND DISMOUNTING THE CUT-OFF WHEEL

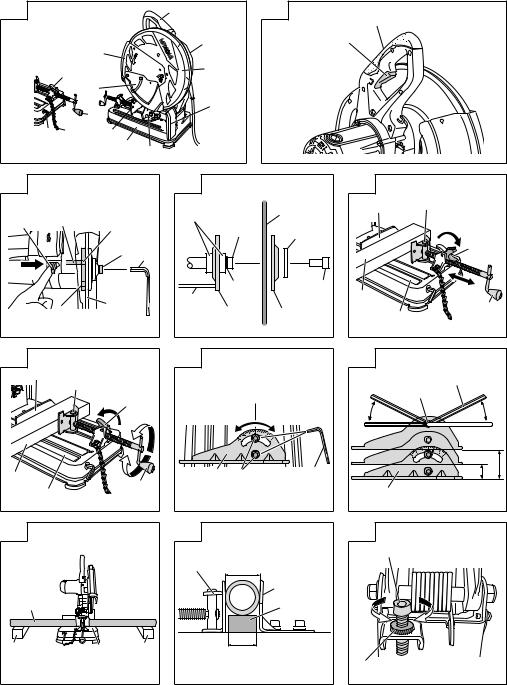

1. Dismounting the cut-o wheel (Fig. 3 and 4)

(1) Raise lower gurd (A) and lower gurd (B).

Press down on the stopper pin to bring it into contact with the wheel washer.

Rotate the cut-o wheel, pass the stopper pin through the hole on the wheel washer and then remove the M10 bolt with the hexagonal bar wrench supplied.

(2) Remove the bolt, washer (A), and the wheel washer and detach the cut-o wheel. (Fig. 4)

CAUTION

Do not remove the O-ring or sleeve from the cut-o wheel spindle.

2. Mounting the cut-o wheel

Throughly remove dust from the wheel washers and bolt then mount the wheel by following the dismounting procedures in reverse order. Return lower gurd (A) and lower gurd (B) to its original position.

CAUTION

Confirm that the stopper which was used for installation and removal of the cut-o wheel has returned to the retract position.

HOW TO OPERATE

1. Procedure for fixing the cutting material (Fig. 5 and 6)

Place the workpiece material between vise (A) and vise (B), raise the clutch and push the screw handle to bring vise (A) lightly into contact with the workpiece material, as shown in Fig. 5.

Then, turn the clutch down, and securely fix the workpiece material in position by turning the screw handle. When the cutting job is completed, turn the screw handle 2 or 3 times to loosen the vise (A), and remove the workpiece material, as shown in Fig. 6.

CAUTION

Never remove or install a workpiece material while the cut-o wheel is rotating, to avoid personal injury.

2. Cutting at angles (Fig. 7)

(1) The machine permits cutting at angles of 0° or 45°.

(2) Loosen the two M10 hexagon socket head bolts on the vice (B), then set the working surface on the vice-jaw at any angles of 0°, 30°, or 45°. Upon completion of setting, securely tighten the two 10 mm bolts.

3. Moving the stationary vise-jaw (Fig. 8)

The vise opening is set at the maximum of 165 mm when shipped from the factory. In case an opening of more than 165 mm is required, move the vise to the position shown by the chain line after unscrewing the two bolts. The maximum opening can be set in two steps 200 mm and 235 mm. When the cutting material is excessively wide, the vise can be e ectively used by repositioning the stationary side of the vise-jaws.

4. Cutting long workpiece materials (Fig.9)

Make sure you place both ends of long workpiece materials on blocks that are the same height as the base to stabilize it prior to beginning work.

5. How to use square block (Fig. 10)

When the cut-o wheel has a reduced outer diameter, insert between the vise (A) and (B) a square block slightly smaller than the dimension of workpiece being cut to use the cut-o wheel economically.

6. Adjusting the cutting depth (Fig. 11)

When the cut-o wheel has a reduced outer diameter, change the height of the stopper bolt to adjust the cutting depth. Adjustments are made by loosening the lock nut and rotating the stopper bolt. When finished, retighten the lock nut to fix the stopper bolt in place.

It is possible to eradicate splinters depending on the material.

CAUTION

○ Make sure the height of the stopper bolt is readjusted when the cut-o wheel is replaced.

○ If the stopper bolt is too low, there is a chance that the cut-o wheel will cut into the base.

7. Adjusting the spark sheet (Fig.12)

Loosen the screw holding the spark sheet in place with a phillips screwdriver to adjust the angle.

Change the angle in accordance with the prevalent environment and the work required to adjust the direction in which the sparks fly.

8. Transporting the unit (Fig.13)

When moving the unit, attach the chain hook onto the chain and grip the carrying handle to carry it.

MAINTENANCE AND INSPECTION

CAUTION

Be sure to switch o and pull o the plug from the power outlet before inspection and maintenance.

1. Replacing a cut-o wheel

When the cut-o wheel has already become dull while continually using, the unnecessary load is got from the motor. Consequently, redress or replace a dull cut-o wheel to ensure grinding e ciency.

2. Inspecting the carbon brushes (Fig. 14)

The Motor employs carbon brushes which are consumable parts. When they become worn to or near the “wear limit”, it could result in motor trouble. When an auto-stop carbon brush is equipped, the motor will stop automatically. At that time, replace both carbon brushes with new ones shown in the figure. In addition, always keep carbon brushes clean and ensure that they slide freely within the brush holders.

3. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that they are properly tightened. Should any of the screws be loose, retighten them immediately. Failure to do so could result in serious hazard.

4. Replacing supply cord

If the replacement of the supply cord is necessary, it has to be done by Hitachi Authorized Service Center to avoid a safety hazard.

5. Lubrication

Supply oil in the following oil supply points once a month so as to keep the machine workable for a long time.

Oil supply points.

○ Rotary part of shaft ○ Rotary part of vise ○ Slide way of vise (A)

6. Cleaning

Wipe o chip and waste adhered to the machine with a cloth or the like time to time. Be careful not to make the motor portion wet with oil or water.

8

7. Service parts list CAUTION

Repair, modification and inspection of Hitachi Power Tools must be carried out by a Hitachi Authorized Service Center.

This Parts List will be helpful if presented with the tool to the Hitachi Authorized Service Center when requesting repair or other maintenance.

In the operation and maintenance of power tools, the safety regulations and standards prescribed in each country must be observed.

MODIFICATIONS

Hitachi Power Tools are constantly being improved and modified to incorporate the latest technological advancements.

Accordingly, some parts may be changed without prior notice.

GUARANTEE

We guarantee Hitachi Power Tools in accordance with statutory/country specific regulation. This guarantee does not cover defects or damage due to misuse, abuse, or normal wear and tear. In case of complaint, please send the Power Tool, undismantled, with the GUARANTEE CERTIFICATE found at the end of this Handling instruction, to a Hitachi Authorized Service Center.

NOTE

Due to HITACHI’s continuing program of research and development, the specifications herein are subject to change without prior notice.

Information concerning airborne noise and vibration

The measured values were determined according to EN61029.

The typical A-weighted sound pressure level: 95 dB (A). The typical A-weighied sound power level: 108 dB (A).

Wear hearing protection.

Vibration total values (triax vector sum) determined according to EN61029.

Cutting steel bar: a

Vibration emission value h = 5.0 m/s2

Uncertainty K = 1.5 m/s2

The declared vibration total value has been measured in accordance with a standard test method and may be used for comparing one tool with another.

It may also be used in a preliminary assessment of exposure.

WARNING

○ The vibration emission value during actual use of the power tool can di er from the declared value depending on the ways in which the tool is used.

○ Identify safety measures to protect the operator that are based on an estimation of exposure in the actual conditions of use (taking account of all parts of the operating cycle such as the times when the tool is switched o and when it is running idle in addition to the trigger time).

English

●Information about power supply system of nominal voltage 230 V~

Under unfavorable mains conditions, this power tool may cause transient voltage drops or interfering voltage fluctuations.

This power tool is intended for the connection to a power supply system with a maximum permissible system impedance ZMAX of 0.14 Ohm at the interface point (power service box) of the user’s supply.

The user has to ensure that this power tool is connected only to a power supply system which fulfills the requirement above.

If necessary, the user can ask the public power supply company for the system impedance at the interface point.

●Information about power supply system of nominal voltage 230 V~

This tool should be used only if it is connected to a 16 A Fuse with gl disconnection characteristic.

9

Türkçe

(Asıl talimatların çevirisi)

KULLANIMLA ÓLGÓLÓ GENEL ÖNLEMLER

DÓKKAT! Elektrikli el aletleri kullanılırken, elektrik çarpması, yaralanma ve yangına karßı korunmak üzere aßaåıdaki temel güvenlik önlemlerine uyulmalıdır.

Aleti kullanmadan önce bu kılavuzu okuyun ve talimatlara uyun.

Güvenli bir kullanım için:

1.Çalıßma ortamını temiz tutun. Daåınık ve düzensiz alanlar yaralanmaya yol açabilir.

2.Çalıßma yapılan ortamın çevresine dikkat edin. Aleti yaåmura maruz bırakmayın, rutubetli veya ıslak yerlerde kullanmayın. Çalıßma alanının iyi bir ßekilde aydınlatılmasını saålayın. Elektrikli el aletlerini yangın veya patlama tehlikesi olan ortamlarda kullanmayın.

3.Elektrik çarpmasına karßı korunun. Topraklanmıß yüzeylerle (borular, radyatörler, fırınlar, buzdolapları gibi) temastan kaçının.

4.Çocukları uzak tutun. Baßkalarının alete veya uzatma kablosuna dokunmalarına izin vermeyin. Çalıßanların haricindeki kißilerin çalıßma sahasından uzak tutulması gerekir.

5.Kullanılmayan aletleri çocukların ulaßamayacaåı kuru, yüksek bir yere kaldırın veya kilitli bir yerde saklayın.

6.Aleti zorlamayın. En iyi ve güvenilir sonucun aletin tasarlandıåı ßekilde kullanılmasından elde edileceåini unutmayın.

7.Doåru aleti kullandıåınızdan emin olun. Küçük bir aleti aåır bir iß için zorlamayın. Hiçbir aleti amacı dıßında kullanmayın. (Örneåin dairesel testereyi aåaç kesmek için kullanmak gibi.)

8.Çalıßma giysilerinize dikkat edin. Bol giysiler ve takılar gibi aletin hareketli parçalarına kapılabilecek giysiler giymeyin. Açık alanlarda çalıßırken lastik eldiven ve kaymayan ayakkabıların kullanılması tavsiye edilir. Ayrıca uzun saçları içine alan koruyucu baßlık kullanın.

9.Koruyucu gözlük kullanın. Eåer toz çıkaran bir çalıßma yapıyorsanız, yüz ya da toz maskesi kullanın.

10.Toz toplama teçhizatı kullanın.

Toz toplama baålantısı için gerekli teçhizat ve baålantı araçları saålanmıßsa, bunların baålı olduåundan ve doåru ßekilde kullanıldıåından emin olun.

11.Kabloyu yanlıß yerlerde kullanmayın. Aleti asla kablosundan tutarak taßımayın veya hızla prizden çekmeyin. Kabloyu kesici cisimlerden, sıcak yüzeylerden ve yaådan uzak tutun.

12.Güvenli bir ßekilde çalıßın. Óßi elinizle deåil, kıskaç veya mengene kullanarak tutun. Bu, ellerinizi kullanmanızdan daha güvenlidir; ayrıca boßta kalan iki elinizi de aleti çalıßtırmak için kullanabilirsiniz.

13.Fazla uzanmayın. Ayaklarınızın konumuna ve dengenize her zaman dikkat edin.

14.Aletleri korumaya özen gösterin. Daha yüksek performans elde etmek ve güvenliåiniz için aletleri keskin ve temiz tutun. Yaålama ve aksesuar deåißimlerinde talimatlara uyun. Kabloları düzenli olarak kontrol edin ve zarar görmüß olanları yetkili servislerde tamir ettirin. Uzatma kablolarını da düzenli aralıklarla kontrol edip hasarlı olan varsa deåißtirin. Tutma kollarını kuru, temiz ve yaåsız tutun.

15.Kullanmadıåınız zamanlarda; bıçak, keski gibi aksesuar deåißimlerinde ve tamirat öncesi aletin elektrik baålantısını kesin.

16.Aleti çalıßtırmadan önce ayar anahtarlarının çıkartılmıß olup olmadıåını kontrol etmeyi alıßkanlık haline getirin. Çıkartılmamıßsa çıkarın.

17.Aletin istek dıßı çalıßmasını engelleyin. Elektrik baålantısı olan aleti parmaåınız ßalter üzerinde olduåu halde taßımayın. Fißi takmadan aletin kapalı olduåuna emin olun.

18.Açık alandaki çalıßmalar için sadece açık alana özel uzatma kablosu kullanın.

19.Daima tetikte olun. Ne yaptıåınızın farkında olun ve duyarlı olun. Aleti yorgunken çalıßtırmayın.

20.Aletinizin hasarlı olup olmadıåını kontrol edin. Aletle yeni bir iße baßlamadan önce; koruyucu tertibatların veya hafif hasarlı parçaların ißlevlerini kusursuz ve usulüne uygun bir biçimde yerine getirip getirmediklerini kontrol edin. Hareketli parçaların hizalı olup olmadıåını, sıkıßıp sıkıßmadıklarını veya hasarlı olup olmadıklarını kontrol edin. Kullanım kılavuzunda baßka türlü belirtilmemißse; hasar görmüß koruyucu tertibat ve parçalar bir yetkili servis tarafından usulüne uygun olarak onarılmalı veya deåißtirilmelidir. Hasarlı ßalterler de yetkili servis tarafından yenilenmelidir. Íalterlerin kapama/açma ißlevini yerine getirmediåi bir aleti kullanmayın.

21.Dikkat

Bu talimatlarda belirtilenler dıßında aksesuarların veya parçaların kullanılması, yaralanmalara yol açabilir.

22.Aletin yalnızca vasıflı bir kißi tarafından tamir edilmesini saålayın. Bu elektrikli alet, ilgili güvenlik gerekliliklerine uygundur. Tamiratlar yalnızca yetkili servis tarafından orijinal yedek parçalar kullanılarak yapılmalıdır. Aksi halde kullanıcı açısından büyük tehlikeler doåabilir.

PROFÓL KESME MAKÓNASÓNÓ KULLANÓRKEN DÓKKAT EDÓLECEK HUSUSLAR

1.Kullanmadan önce kesme diskini kontrol edin, yıpranmıß ve bozuk kesme disklerini kullanmayın. Kullanmadan önce mutlaka bir deneme yaparak makinada herhangi bir anormallik olup olmadıåını kontrol edin.

2.Normal profil kesme diskini, uygun normal yüzeylerde tatbik edin.

3.Kesme esnasında olußacak kıvılcımlara karßı kendinizi koruyun.

4.Profil kesme diskini deåißtirirken düzgün yerleßtirin.

5.Kesme diskinin baålantı parçalarının aßınmamıß ve saålam olmasına her zaman özen gösterin. Bozuk baålantı parçaları kesme diskine zarar verir.

6.Çalıßtıåınız yüzeyde, çivi gibi yabancı maddelerin olmadıåına emin olun.

7.Sadece üretici firma tarafından önerilen kesme disklerini kullanınız. Kullanacaåınız diskin makinada belirtilen hıza eßit veya daha yüksek hıza göre ayarlanmıß olması gerekmektedir.

8.Zımparalama diski, üretici kılavuzunda belirtildiåi ßekilde saklanmalı ve dikkatle kullanılmalıdır.

9.Diskin, üretici kılavuzunda belirtildiåi ßekilde yuvasına takılmıß olduåundan emin olunuz.

10.Koruma parçası üzerinde takılı olmadan makinayı asla kullanmayınız.

11.Bıçaåı bilemeyin.

12.Makinayı, patlayıcı ortamlarda ve kıvılcım olußabilecek ortamlarda kullanmayın.

10

Loading...

Loading...