Page 1

Quick Reference Guide

Kurzanleitung

Guide d‘initiation rapide

快速使用指南

クイックリファレンスガイド

ND 287

Mai 2009

Page 2

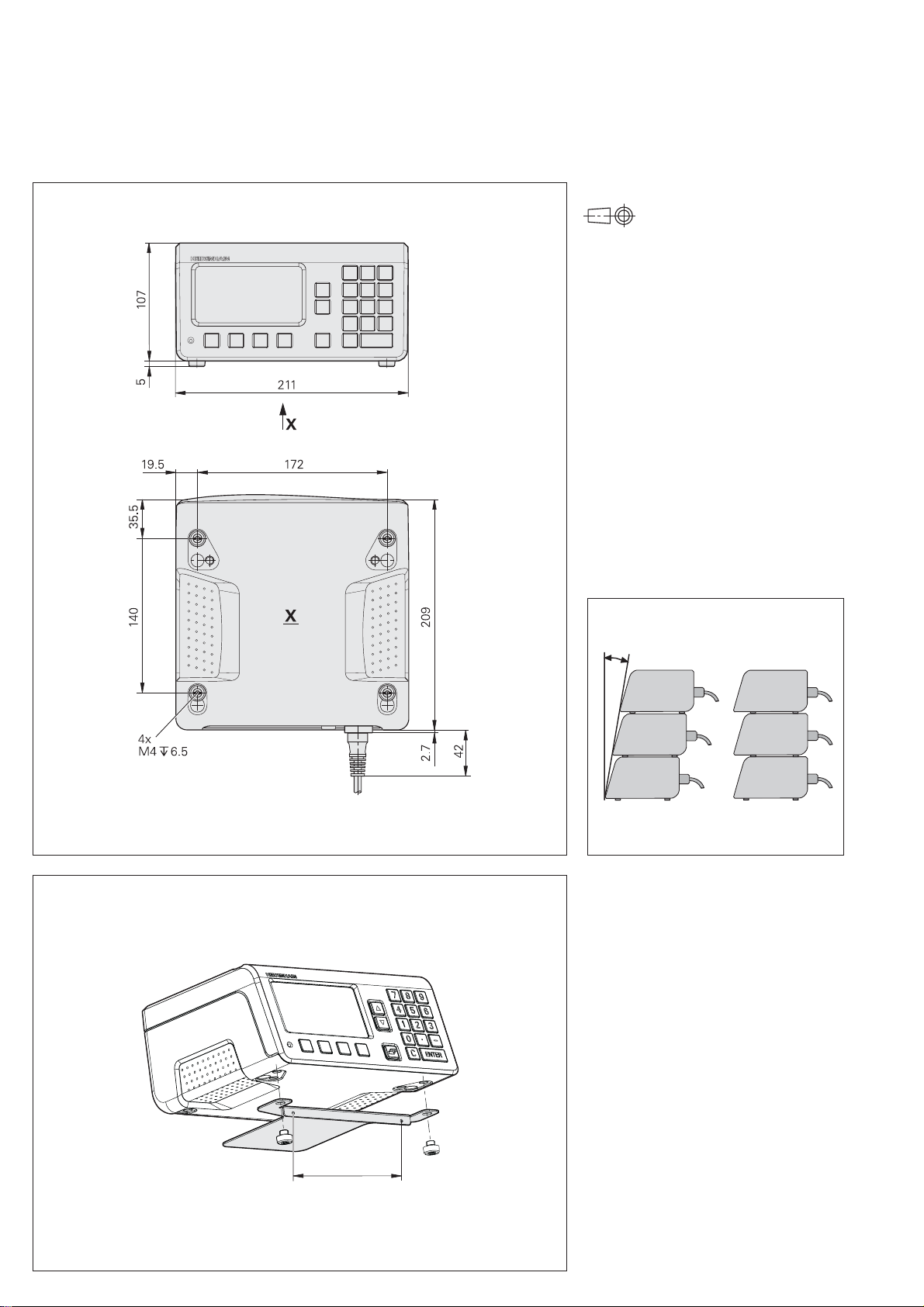

ND 287

mm

Tolerancing ISO 8015

ISO 2768 - m H

< 6 mm: ±0.2 mm

10°

127

ID 654 020-01

Page 3

ND 287

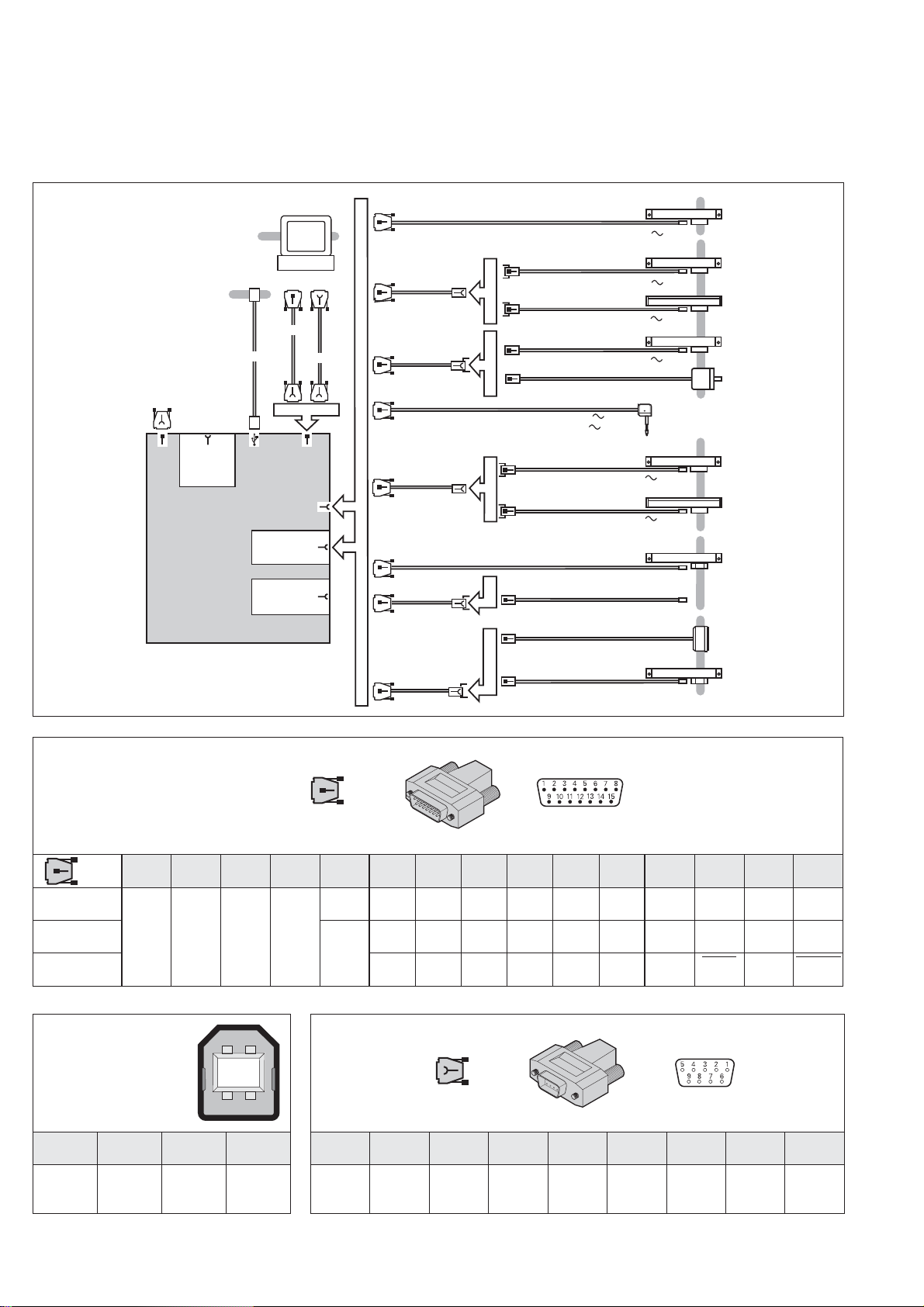

1 2 3 X41 X32 X31 X1

Page 4

ND 287

Switching inputs/outputs

315 650-06

2)

X41

Ethernet

module

654 019-01

X26

ND 280

ND 287

2)

only for ND 287

3)

Option, only for ND 287

5m

354 770-xx

3)

USB

Typ B

X2

X2

20m

X32

2. Encoder

module

654 017-01

654 018-01

25-pin 9-pin

368 017-xx

9-pin

V.24/

RS-232-C

oder

Analog module

PC

366 964-xx

X31

X1

3)

3)

15-pin

309 784-xx

310 196-xx

653 231-xx

524 599-xx

324 544-xx

12-pin

12-pin

LS 303:

LS 603:

9-pin

619 884-xx

8-pin

17-pin

387 287-xxLS:

344 228-xx

LS:

344 451-xx MSS

310 127-xx

LB:

310 126-xx MSS

360 645-xxLS:

310 125-xx

310 124-xx MSS

310 573-xx

310 731-xx MSS

533 661-xx

533 631-xx

11 µA

1)

1)

1 V

9m

1 V

PP

30m

1 V

PP

1 V

PP

1 V

PP

PP

PP

1)

11 µA

1)

11 µA

LC x83

EnDat

1m

EnDat

LC x83

EnDat

30m

PP

PP

20m

30m

X1

» 1 V

PP

» 11 µA

EnDat / / / / / / DATA

X32

USB (Type B; UART)

1234

V

CC

+ 5 V

412210619311147513815

UPSensor

U

PP

P

0 V Sensor

0 V

/A+A–B+B–R+R–/ / / /

Inside

I

I

I

I

I

1+

1–

2+

2–

I

0+

0–

////

shield

12

43

X31

V.24/RS-232-C

123456789

D– D+ GND

/ RXD TXD DTR Signal

DSR RTS CTS /

GND

DATA CLOCK CLOCK

Page 5

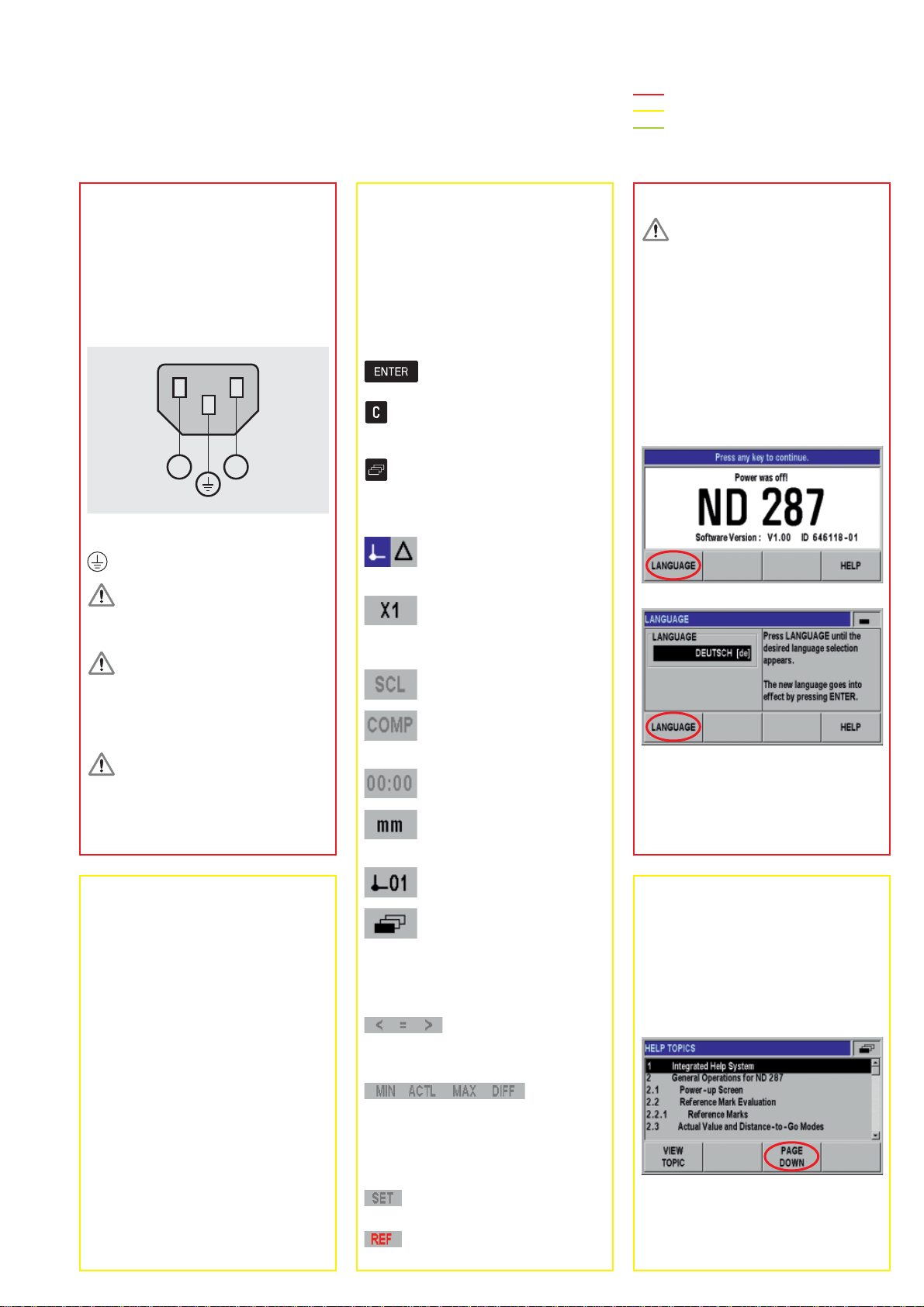

ND 287

Setup

For detailed description, see www.heidenhain.de

Before Switch-On

Electrical connection

Line voltage 100 - 240 Vac

Power frequency 50 - 60 Hz (± 2 Hz)

Power consumption † 30 W

Line fuse 2 x T500 mA

Wiring the power connector

L N

L: Phase (brown)

N: Neutral (blue)

: Grounding conductor (yellow/green)

Caution: Changes to the power

cable may be made only by an

electrical technician.

Danger of electrical shock!

Do not open the unit.•

The protective ground connection •

must never be interrupted, not even if

a network adapter is used.

Danger to internal components

Do not engage or disengage any •

connecting elements while the unit is

under power.

Use only original fuses.•

Connections

Power switch

1

2 Power connection with fuse

3 Ground (protective ground)

X1 Encoder input for HEIDENHAIN

encoder with 11-µApp, 1-Vpp or

EnDat-2.2 interface

X2 Optional input: Input for encoder

module or analog module

X26 Optional interface: Installation of

Ethernet module (100BaseT)

X31 RS-232-C/V.24 interface

X32 USB Type B (UART) interface

X41 Switching inputs/outputs

Controls and Displays

Position display

1.

2. Soft keys for functions

3. Message line for displaying

information, error messages, and

information on samples or temperature

Confi rms an entry and returns

to the previous screen.

Deletes an entry, acknowledges

an error message, or returns

to the previous screen.

Moves through the soft-key

pages.

4. Status bar

Operating mode: Actual Value

(active) – Distance-To-Go

(selectable by soft key)

Input: X1 (active), X2, X1 + X2,

X1 – X2, f(X1;X2) (selectable

by soft key if a module is

connected to the 2nd input)

Scale factor (inactive; can be

activated via Job Setup)

Error compensation (inactive;

can be activated via Installation

Setup)

Stopwatch (inactive; can be

activated via Job Setup)

Unit of measure: mm (active),

inch, DEG, DMS or rad

(selectable by soft key)

Datum point 1 (active) or 2

(selectable by soft key)

Soft-key page (page 1 active,

3 pages are available, use the

navigation key to move

through the pages)

5. Status display

(greater than, within,

less than the tolerance limit)

active in sorting and tolerance

checking mode

(minimum,

actual, maximum measured

value, and difference between

MIN and MAX) if MEAS.

SERIES mode is active

(selectable by soft key)

Datum setting (fl ashes when a

value is entered)

Reference-mark evaluation

(active)

Very important

Please note

For your information

Initial Operation

The position display unit must be

set up properly during initial operation,

or when an encoder is exchanged.

Only this way the unit can be adapted

to the encoder requirements in order

to ensure that the movements are

displayed correctly.

Power Up

1. Connect the components.

2. Connect the ND to the network.

3. Press the power switch to switch the

ND on. The initial screen appears:

4. Select the language.

Press the soft key repeatedly until the

proper language appears. Press the

HELP soft key to call the integrated

help system in your language. The help

system provides support for all further

entries and functions.

Integrated Help System

Press the HELP soft key to call the

integrated help system. It provides

information and assistance (in the

language of your country) for the current

operation in any situation.

Press the LIST OF TOPICS soft key to

view information on any topic.

Use the PAGE UP/DOWN soft keys to

scroll one page up or down, and the

arrow keys to move one line up or

down. Press the C key to return to the

previous screen.

1

Page 6

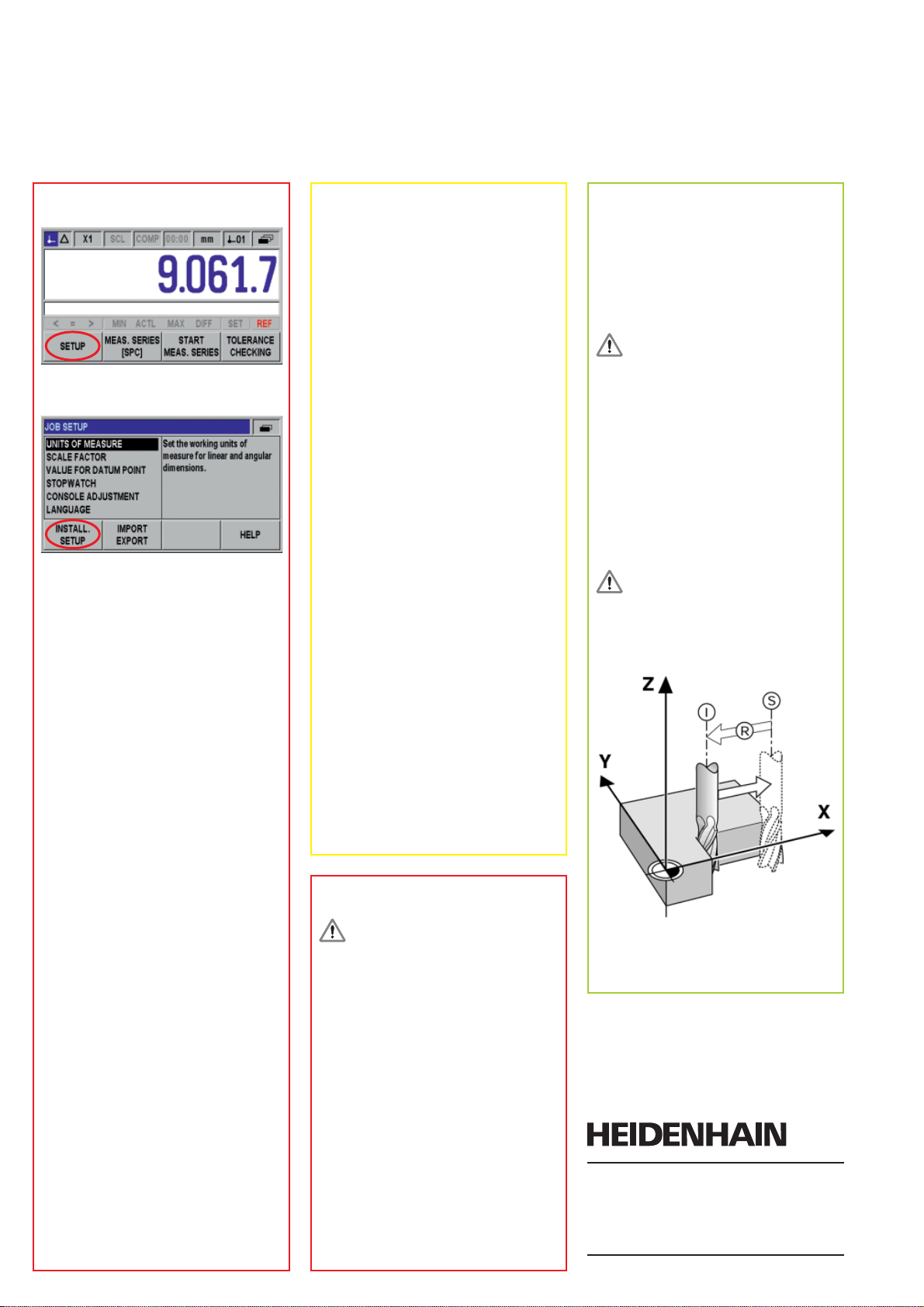

ND 287

Setup

For detailed description, see www.heidenhain.de

Installation Setup

1. Press the soft key shown in the

fi gure above.

2. Press the soft key shown in the fi gure

above and enter the passcode 95148.

Operating Parameters

Important parameters are in bold type.

1. Encoder Setup

Encoder Type• (linear, rotary).

Encoder Signal: Automatically •

determined.

Signal Period:• Depends on the

encoder.

Reference Mark:• Depends on the

encoder.

External REF (as required).•

Count Direction:• Select the proper

count direction.

Error Monitor (as required).•

Job Setup

Press the SETUP soft key to open the

menu.

1. Units

Select mm or inches, or degrees/minutes/

seconds (DMS), decimal degrees (DEG)

or rad (display in status bar).

2. Scale Factor

Deactivate the scale factor, or select the

desired scale factor (display in status bar).

3. Value for Datum Point

Enter numerical value for datum setting

over switching input or with PRESET

soft key.

4. Stopwatch

Start the stopwatch (elapsed time is

displayed in status bar).

5. Console Adjustment

Select the brightness and activate the

display saver.

6. Language

Select the proper conversational

language.

7. Switching Signals

Enter the trigger limits.

8. Measured Value Output (Display

Freeze)

Select the display mode for measured

value output (concurrent, frozen, or frozen/

concurrent display).

9. Function of External Inputs

Select the function of the external

inputs.

Functions

REF Reference Mark Evaluation

The ND 287's REF reference mark

evaluation feature automatically

re-establishes the relationship between

axis-slide or measuring-probe positions

and display values that you last defi ned

by setting the datum.

If you do not use the REF feature,

the datums will be lost once the ND is

switched off.

Actual Value/Distance-To-Go

In the Actual Value operating mode, the

ND always displays the current actual

position of the encoder, relative to the

active datum.

In the Distance-To-Go operating mode,

you enter the desired nominal position

and simply traverse to the display value

zero.

The distance-to-go is displayed with

a reversed algebraic sign. For example,

the distance-to-go has a positive sign if

the axis direction from the actual towards

the nominal position is negative.

2. Display Confi guration

Set the display resolution.•

3. Counter Settings

In the Application fi eld, select 1 Axis •

or 2 Axes (only with optional encoder

module or analog module). Two axes

can be coupled through mathematical

functions.

Lock or release the keypad.•

Second decimal point (after 3 decimal •

places).

Reset all parameters to factory default •

settings.

4. Error Compensation

Error Compensation:• Select OFF,

Linear or Non-linear, and enter the

data.

5. Interface Settings

As required.

6. Diagnostics

As required.

2

Before starting a measurement

Ensure that the distance or angle

actually traversed matches the displayed

value and direction. Deviations may be

due to the following causes:

Signal period•

Counting direction •

Error compensation•

Scale factor•

Application (1 axis or 2 axes; formula •

for coupled position)

Distance-to-go display•

I: Actual position

S: Nominal position

R: Distance-to-go

DR. JOHANNES HEIDENHAIN GmbH

Dr.-Johannes-Heidenhain-Straße 5

83301 Traunreut, Germany

{ +49 (8669) 31-0

| +49 (8669) 5061

E-mail: info@heidenhain.de

www.heidenhain.de

Page 7

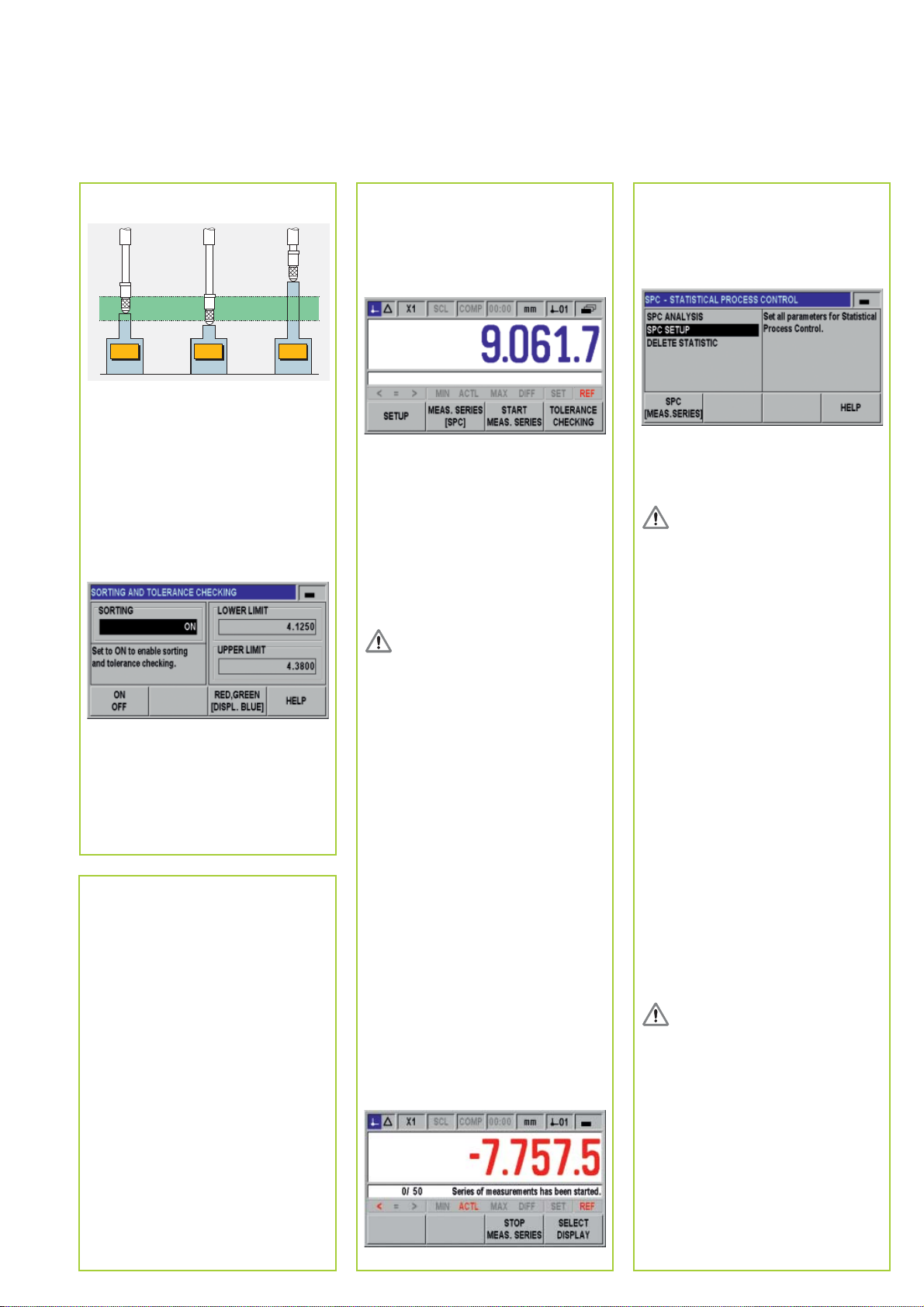

Sorting and Tolerance Checking

Measurement Series

SPC Statistical Process Control

=

= >

To sort the parts, the ND 287 compares

the displayed value with an upper or lower

sorting limit, and displays the sorting

result in color in the status display as a

value or with one of the symbols < = >.

In addition, a corresponding signal is

available at switching output X41. Press

the TOLERANCE CHECKING soft key to

open the form for defi ning the sorting

parameters and the sorting limits.

The sorting and tolerance checking

function is always effective for the

currently displayed value, also when

measurement series, minimum/

maximum display, SPC or coupled

positions are active.

<

Display Freeze

In order to read the display in spite of

quickly changing values, the display can

be frozen. The position value is counted

internally until a new display value is

called. You can freeze the display through

a switching signal "Output measured

value" to X41, the CTRL B command, or

by pressing the PRINT soft key.

The MEASURED VALUE OUTPUT

parameter in the Job Setup menu offers

the following possibilities for settings:

Concurrent Display•

The display value always matches the

measured value.

Frozen Display•

The display remains stopped, but is

updated by every measured value

output.

Frozen/Con. Display•

The display is only stopped during

measured value output.

The ND 287 can store measurement

series with up to 10 000 measured

values. They can be evaluated internally

or they can be read out in a block.

Setup Series of Measurements

Measured-value recording through the •

ENTER key, an external signal or

sampling intervals.

Number of measured values.•

Defi nition of sampling intervals (20 ms •

to 60 s) and time slot.

Start Measurement Series

By pressing START MEAS. SERIES. •

By sending an external signal to X41.•

Switching-off the ND or starting a

new measurement series deletes the

values of the previously recorded

measurement series.

Stop Measurement Series

Automatic stop when the defi ned •

number of measured values is reached.

By pressing STOP MEAS. SERIES. •

Measurement Series Analysis

The measurement series can be

displayed as

Statistical data•

Diagram•

Measured value table •

Export Measured Values

Press the EXPORT soft key to start

transmission of the measured value table.

Minimum/Maximum Display

During the measurement series you can

press the SELECT DISPLAY soft key to

switch from the actual value display

(ACTL) to the display of the minimum

value (MIN), the maximum value (MAX)

or the difference between minimum and

maximum value (DIFF).

For Statistical Process Control, the

ND 287 can store up to 1 000 measured

values in a non-volatile FIFO memory.

SPC Setup

Number of samples and data per •

sample.

If you change these values, the

data in the FIFO memory will be

deleted.

Upper and lower tolerance limits •

(same as sorting limits) and nominal

value.

Control limits for control charts.•

Distribution (symmetrical, left-hand or •

right-hand limit).

Measured-value recording through the •

ENTER key or an external signal.

Record SPC Values

Press the START SPC soft key to start •

data acquisition for SPC.

Press the STOP SPC soft key to •

interrupt the SPC function. The

ND 287 is then available for other

measuring tasks.

Press the START SPC soft key to •

restart measurement of the defi ned

number of samples.

The sample counter in the message •

line indicates the number of the

current sample being measured, the

number of the measurements

performed and the total number of

samples to be measured.

Before starting a new SPC

measurement, select DELETE

STATISTIC to delete old SPC values

from the FIFO memory.

SPC Analysis

While the data is being measured, the

ND can display the current status as

Statistical data•

Graph (for the last 30 values)•

Histogram with 10 classes •

Control chart for • average value x,

standard deviation s and range r

(difference between maximum and

minimum value) of a sample

3

Page 8

ND 287

Functions

For detailed description, see

www.heidenhain.de

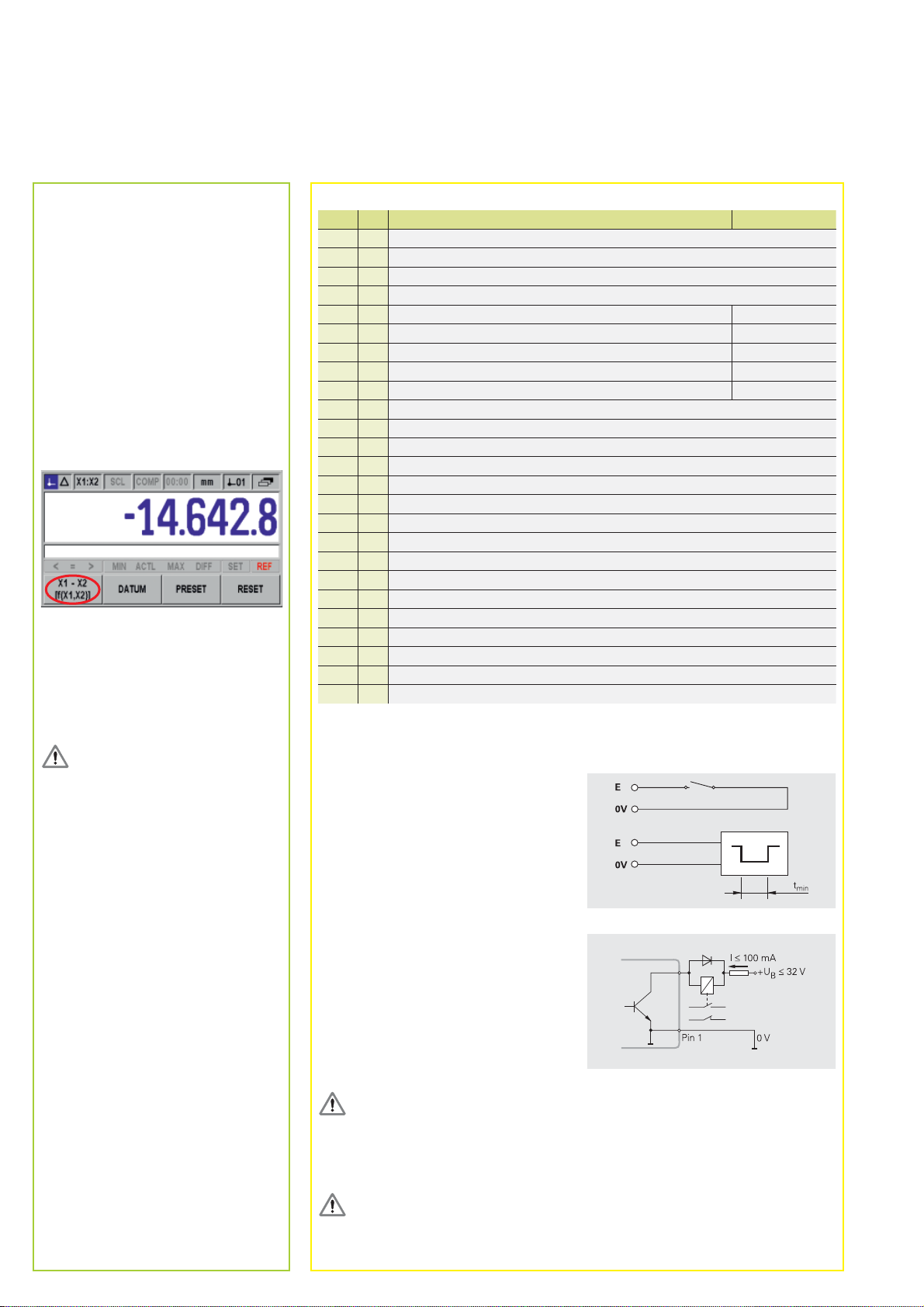

Axis Coupling

Input X2 is available for an additional

input assembly (option). Possible options:

Encoder module for connecting a •

second encoder

Analog module for connecting an •

analog sensor with ± 10 V

Descriptions are included with the

modules.

X1 and X2 can be displayed separately

or they can be coupled through

mathematical functions. You can switch

the display by soft key or through a

switching input at any time.

The following axis displays are possible:

Input X1•

Input X2•

Sum of X1 and X2•

Difference between X1 and X2•

Any function for coupling X1 and X2•

Switching I/O

Pin Layout

PIN Version 1 Version 2

1

2 I

3 I

4 I

5 I

6 I

7 I

8 I

9 I

10

11

12

13

14 O

15 O

16 O

17 O

18 O

19 O

20

21

22 I

23 I

24 I

25 I

I: Switching input; O: Switching output

Version 1 or 2 can be selected in Function External Inputs in the Job Setup menu.

0 V

Reset, clear error message

Set the datum

Ignore reference mark signals (input X1)

Start measurement series f(X1,X2) display

Select display value for meas. series externally X1 display

Display the minimum value (MIN) of the meas. series X2 display

Display the maximum value (MAX) of the meas. series X1+X2 display

Display the difference MAX-MIN of the meas. series X1-X2 display

0 V

Free

Do not assign

Do not assign

Display value is zero

Measured value is greater than or equal to trigger limit A1

Measured value is greater than or equal to trigger limit A2

Measured value is less than the lower sorting limit

Measured value is greater than the upper sorting limit

Error

Free

Free

Measured value output (pulse)

Measured value output (contact)

Ignore reference mark signals (input X2, optional)

Activate or deactivate REF mode

Special features of coupled

positions

If PRESET is used, X1 is set to the •

value entered, and X2 is set to zero.

If RESET is used, a value other than •

zero may be displayed depending on

the programmed formula (e.g.: 5 if

"X1 + X2 + 5").

The values of the currently active axis •

display are used for SPC.

If two axes are coupled, the fi ner of •

the two display resolutions will be

used.

If axis values are used as divisors, •

division by zero or display overfl ow

may cause a temporary error

message.

If an analog sensor is connected to •

input X2 and the ENCODER TYPE

fi eld under Encoder Setup, Input X2 is

set to COMPENSATION, the ND 287

behaves in the same way as a

single-axis display unit.

If COMPENSATION is selected, the •

formula for axis-error compensation is

determined automatically. You only

enter the coeffi cient of expansion and

the reference temperature.

Switching Inputs

The switching input E is active

when a Low signal U

(contact or pulse to 0 V).

Signal level

– 0.5 V † U

3.9 V † U

t

‡ 30 ms

min

† 0.9 V at IL † 6 mA

L

† 15.0 V

H

is applied

L

Switching Outputs

The ND 287 features open-collector

outputs that switch to 0 V (= active Low).

Delay of signal output:

t

† 20 ms

D

Signal level

U

† 0.4 V at IL † 100 mA

L

U

† 32 V at IH † 10 µA

H

Danger to internal components!

The power supply of external circuits must comply with EN 50• 178 requirements for

low voltage electrical separation.

Connect inductive loads only with a • quenching diode parallel to the inductance.

Use only shielded cables.• Connect the shield to the connector housing.

In the Distance-To-Go operating mode, the switching outputs A1 (pin 15) and A2

(pin 16) are based on switching ranges.

Contact

Pulse

4

Page 9

ND 287

Einrichten

Ausführliche Beschreibung siehe www.heidenhain.de

Vor dem Einschalten

Elektrischer Anschluss

Netzspannung 100 bis 240 V~

Netzfrequenz 50 bis 60 Hz

(± 2 Hz)

Leistungs aufnahme † 30 W

Netzsicherung 2 x T500 mA

Anschluss des Netzsteckers

L N

L: Phase (braun)

N: Nullleiter (blau)

: Schutzleiter (gelb/grün)

Achtung: Änderungen am Netz-

kabel nur durch Elektrofachkraft!

Stromschlaggefahr!

Gerät nicht öffnen.•

Schutzleiter darf nie unterbrochen •

sein, auch nicht bei Anschluss über

Netzadapter.

Gefahr für interne Bauteile

Steckverbindungen nur bei ausge-•

schaltetem Gerät herstellen oder lösen.

Nur Originalsicherungen verwenden.•

Anschlüsse

Netzschalter

1

2 Netzanschluss mit Sicherung

3 Erdungsanschluss

(Schutzerdung)

X1 Messgeräte-Eingang für

HEIDENHAIN-Messgerät mit

11-µAss-, 1-Vss- oder

EnDat-2.2-Schnittstelle

X2 Option Eingang: Einbau eines

Messgeräte-Moduls oder eines

Analog-Moduls

X26 Option Schnittstelle: Einbau

eines Ethernet-Moduls

(100BaseT)

X31 Schnittstelle V.24/RS-232-C

X32 Schnittstelle USB Typ B (UART)

X41 Schaltein-/ausgänge

Anzeige- und Bedienelemente

Positionsanzeige

1.

2. Softkeys für Funktionen

3. Hinweiszeile für Hinweise, Stich-

probenanzeige, Temperatur, Fehlermeldungen

4. Statusleiste

5. Statusanzeige

im Klassiermodus aktiv

aktueller, maximaler Mess-

Bestätigen der Eingabe und

Rückkehr zum vorherigen Bildschirm

Löschen des Eintrags, Quittie-

ren der Fehlermeldung oder

Rückkehr zum vorherigen Bildschirm

Umschalten der Softkey-

Ebenen

Betriebsart: Istweg (aktiv) –

Restweg (umschalten über

Softkey)

Eingangsanzeige: X1 (aktiv),

X2, X1 + X2, X1 – X2, f(X1;X2)

(umschalten über Softkey,

wenn 2. Eingang bestückt ist)

Skalierfaktor (inaktiv; aktivie-

ren über BEARBEITUNG EINRICHTEN)

Fehlerkorrektur (inaktiv; akti-

vieren über SYSTEM EINRICHTEN)

Stoppuhr (inaktiv; aktivieren

über BEARBEITUNG EINRICHTEN)

Maßeinheit: mm (aktiv), inch,

GRD, GMS oder rad (umschalten über Softkey)

Bezugspunkt 1 (aktiv) oder 2

(umschalten über Softkey)

Softkey-Ebene (Ebene 1 aktiv,

3 vorhanden; umschalten über

Taste)

(über, in, unter Toleranz)

(minimaler,

wert und Differenz aus MIN

und MAX) bei Messreihe aktiv

(umschalten über Softkey)

Bezugspunkt setzen (blinkt bei

Eingabe eines Wertes)

Referenzmarkenauswertung

(aktiv)

unbedingt beachten

wichtig

informativ

Erstinbetriebnahme

Bei Erstinbetriebnahme und

Messgeräte-Wechsel ist es zwingend

notwendig, die Positionsanzeige einzurichten. Erst damit wird sie an das

Messgerät angepasst und die Bewegungen werden richtig angezeigt.

Gerät einschalten

1. Komponenten anschließen

2. ND an Netz anschließen

3. ND über Netzschalter einschalten.

Es erscheint der Start-Bildschirm:

4. Sprache wählen

Softkey solange betätigen, bis Ihre Landessprache erscheint. Jetzt steht Ihnen

für alle weiteren Eingaben und Funktionen unter der Softkey HILFE das inte-

grierte Hilfe-System in Ihrer Sprache

zur Verfügung.

Integriertes Hilfesystem

Das integrierte Hilfesystem rufen Sie mit

den Softkey HILFE auf. Es liefert Ihnen

in Ihrer Landessprache in jeder Situation

die passenden Informationen zum aktuellen Vorgang.

Über den Softkey THEMENLISTE können Sie beliebige Themen anzeigen.

Mit den Softkeys BILD NACH UNTEN

bzw. BILD NACH OBEN blättern Sie seitenweise, mit den Pfeiltasten zeilenweise. Über die Taste C kehren Sie wieder

zum Ausgangsbildschirm zurück.

1

Page 10

ND 287

Einrichten

Ausführliche Beschreibung siehe www.heidenhain.de

System einrichten

1. Softkey betätigen

2. Softkey betätigen und Schlüsselzahl

95148 eingeben.

Bearbeitung einrichten

Öffnen des Menüs über den Softkey

EINRICHTEN

1. Maßeinheit

mm oder inch bzw. Grad/Minuten/Sekunden (GMS), Dezimalgrad (GRD) oder

rad wählen (Anzeige in Status leiste)

2. Maßfaktor

Ausschalten oder Faktor wählen (Anzeige in Statusleiste)

3. Wert für Bezugspunkt

Für externes Setzen über Schalteingang

oder schnelles Setzen über Tastatur.

4. Stoppuhr

Starten (Anzeige in Statusleiste)

5. Bildschirm anpassen

Helligkeit wählen und Bildschirmschoner

aktivieren

Funktionen

Referenzmarkenauswertung

REF

Mit der Referenzmarkenauswertung

REF ermittelt der ND 287 automatisch

wieder die Zuordnung zwischen der

Achsschlitten- oder Messtaster-Position

und dem Anzeigewert, die Sie zuletzt

vor dem Ausschalten festgelegt haben.

Wenn Sie ohne REF arbeiten,

gehen mit dem Ausschalten der ND die

gesetzten Bezugspunkte verloren.

Istwert-/Restweg-Anzeige

In der Betriebsart Istwert zeigt der ND

immer die aktuelle Ist-Position des

Messgeräts bezogen auf den aktiven

Bezugspunkt an.

In der Betriebsart Restweg tippen Sie

die gewünschte Zielposition ein und verfahren dann den restlichen Weg einfach

auf den Anzeigewert 0.

Die Betriebsparameter

Wichtige Parameter sind fett gestellt.

1. Messgerät defi nieren

Messgeräte-Typ wählen• (Längen-,

Winkelmessgerät)

Messgeräte-Signal: wird automatisch •

erkannt und eingetragen

Signalperiode• abhängig vom Mess-

gerät

Referenzmarke• abhängig vom Mess-

gerät

Externes REF (nach Bedarf)•

Zählrichtung• wählen

Fehlerüberwachung (nach Bedarf)•

6. Sprache

Dialogsprache nachträglich ändern

7. Schaltsignale

Eingabe der Schaltgrenzen

8. Messwert-Ausgabe (Anzeige-Stopp)

Auswahl für Anzeigestopp (mitlaufende,

gestoppte oder gestoppte/mitlaufende

Anzeige)

9. Funktion externer Eingänge

Umstellen der Funktionalität der externen Eingänge

2. Anzeige konfi gurieren

Anzeigeschritt festlegen•

3. Anwendung einstellen

Anwendung 1 Achse oder 2 Achsen •

(nur bei optionalem Messgeräte-Modul oder Analog-Modul) zwei Achsen

können über mathematische Funktionen miteinander verknüpft werden.

Tastatursperre•

Dezimalpunkt (zusätzlich nach 3 Stel-•

len)

Rücksetzen in Auslieferungszustand•

4. Fehlerkorrektur

Fehlerkorrektur• wählen (aus, linear,

nichtlinear) und Werte eingeben

Vor dem Messen

Vergleichen Sie vor dem Messen,

ob der tatsächlich verfahrene Weg

bzw. Winkel in Größe und Richtung mit

der Anzeige übereinstimmt. Überprüfen

Sie als mögliche Ursachen für Abweichungen:

Signalperiode•

Zählrichtung •

Fehlerkorrektur•

Maßfaktor•

Anwendung •

(eine oder zwei Achsen;

Funktion für Achsverknüpfung)

Restweg-Anzeige•

5. Schnittstelle einrichten

Nach Bedarf

6. Diagnose

Nach Bedarf

2

Der Restweg wird mit umgekehrten

Vorzeichen angezeigt. So hat z.B. der

Restweg ein positives Vorzeichen beim

Verfahren in negativer Achsrichtung.

I: Istposition

S: Sollposition

R: Restweg

DR. JOHANNES HEIDENHAIN GmbH

Dr.-Johannes-Heidenhain-Straße 5

83301 Traunreut, Germany

{ +49 (8669) 31-0

| +49 (8669) 5061

E-mail: info@heidenhain.de

www.heidenhain.de

Page 11

Klassieren

=

Messreihen

Die ND 287 speichert Messreihen mit

bis zu 10 000 Messwerten. Sie können

intern ausgewertet oder in einem Block

ausgelesen werden.

Statistische Prozessregelung

SPC

Für die statistische Prozessregelung

verfügt die ND 287 über einen span-

nungsausfallsicheren FIFO-Speicher

für bis zu 1 000 Messwerte.

= >

Beim Klassieren vergleicht die ND 287

den angezeigten Wert mit einer oberen

und unteren Klassiergrenze und zeigt

das Klassierresultat als farbigen Anzeigewert bzw. über die Symbole < = > in der

Statusanzeige an. Zusätzlich liegt ein

entsprechendes Signal am Schaltausgang X41 an. Das Fenster zum Defi nieren der Klassierparameter und Klassiergrenzen öffnen Sie über den Softkey

KLASSIEREN.

Die Klassierfunktion wirkt auf den je-

weils angezeigten Wert, auch bei Messreihen, Minimum/Maximum-Anzeige,

SPC und Achskopplungen.

Anzeige-Stopp

Um die Anzeige auch bei sich schnell ändernden Messwerten sicher abzulesen,

kann sie angehalten werden. Der interne

Zähler läuft weiter. Der Anzeigestopp

wird ausgelöst durch das Schaltsignal

„Messwert ausgeben“ an X41, den Befehl Control B oder Drücken des Softkeys PRINT.

Im Parameter MESSWERT-AUSGABE in

„Bearbeitung einrichten“ haben sie folgende Einstellmöglichkeiten:

Mitlaufende Anzeige•

Anzeige entspricht immer dem Messwert

Gestoppte Anzeige•

Anzeige bleibt angehalten und mit jedem Befehl aktualisiert

Gestoppt/mitlaufende Anzeige•

Anzeige bleibt nur für die Dauer des

Befehls gestoppt

<

Messreihe einrichten

Einspeichern der Messwerte (über •

Taste ENTER, externes Signal oder

zeitgesteuerte Abtastintervalle)

Anzahl der Messwerte•

Defi nition der Abtastintervalle (20 ms •

bis 60 s) und des Zeitfensters

Messreihe starten

über Softkey MESSREIHE STARTEN •

über externes Signal an X41.•

Ausschalten der ND oder Starten

einer Messreihe löscht die Werte der

vorher aufgenommenen Messreihe.

Messreihe beenden

automatisch, wenn die festgelegte •

Anzahl der Messwerte erreicht ist

über Softkey MESSREIHE BEENDEN •

Messreihe auswerten

Darstellung der Messreihe als

Statistische Daten•

Diagramm•

Messwert-Tabelle •

Messwerte exportieren

Mit dem Softkey EXPORT starten Sie

die Übertragung der Messwerttabelle

Minimum/Maximum-Anzeige

Während die Messreihe läuft, kann die

Anzeige über ANZEIGE WÄHLEN vom

aktuellen Messwertes ACTL auch auf

das Minimum MIN, das Maximum

MAX oder die Differenz DIFF daraus

umgestellt werden.

SPC einrichten

Anzahl der Stichproben und Anzahl •

der Werte pro Stichprobe

Mit Ändern dieser Werte werden

die Daten im FIFO-Speicher gelöscht

Obere und untere Toleranzgrenze •

(entspricht den Klassiergrenzen) sowie das Sollmaß

Eingriffsgrenzen für Regelkarten•

Verteilungsart (symmetrisch oder ein-•

seitig)

Einspeichern der Messwerte (über •

Taste ENTER oder externes Signal)

SPC-Daten erfassen

Mit Softkey SPC STARTEN eine neue •

Datenerfassung beginnen.

Der Softkey SPC BEENDEN unter-•

bricht die SPC-Funktion. Die ND 287

steht für andere Messaufgaben zur

Verfügung

Mit Softkey SPC STARTEN beginnen •

Sie immer wieder eine Stichprobenmessung bis zur festgelegte Anzahl

Der Stichprobenzähler in der Hinweis-•

zeile zeigt die Nummer der Messung

in der aktuellen Stichprobe, die Anzahl

der bisherigen Messungen sowie die

Gesamtzahl der Messungen

Vor neuer SPC mit Befehl STATISTK LÖSCHEN alte SPC-Werte aus

dem FIFO-Speicher löschen.

SPC auswerten

Bereits während der Datenerfassung

zeigt die ND den aktuellen Stand als

Statistische Daten•

Werteverlauf der letzten 30 Werte•

Histogramm mit 10 Klassen •

Regelkarten für • Mittelwert x, Stan-

dardabweichung s und Spannweite r (Differenz aus größtem und

kleinsten Wert) einer Stichprobe.

3

Page 12

ND 287

Funktionen

Ausführliche Beschreibung siehe

www.heidenhain.de

Achskopplung

Der Steckplatz X2 ist für eine zusätzliche

Eingangsbaugruppe (Option) vorgesehen.

Verwendbar sind

Messgeräte-Modul zum Anschluss •

eines zweiten Messgeräts

Analog-Modul zum Anschluss eines •

analogen Sensors mit ± 10 V.

Beschreibungen liegen den Modulen

bei.

X1 und X2 sind können einzeln angezeigt werden und über mathematischen

Funktionen miteinander gekoppelt werden. Die Anzeige ist jederzeit per Softkey

oder Schalteingang umschaltbar

Folgende Anzeigen sind möglich:

Eingang X1•

Eingang X2•

Summe aus X1 und X2•

Differenz aus X1 und X2•

Beliebige Funktion aus X1 und X2•

Schaltein-/ausgänge

Steckerbelegung

PIN Version 1 Version 2

1

2 I

3 I

4 I

5 I

6 I

7 I

8 I

9 I

10

11

12

13

14 O

15 O

16 O

17 O

18 O

19 O

20

21

22 I

23 I

24 I

25 I

I: Schalteingang; O: Schaltausgang

Die Version 1 bzw. 2 ist unter „Funktion externer Eingänge“ in „Bearbeitung einrichten“

wählbar.

0 V

Nullen, Fehlermeldung löschen

Bezugspunkt setzen

Referenzmarkensignale ignorieren (Eingang X1)

Messreihe starten Anzeige f(X1,X2)

Anzeigewert bei Messreihe extern wählen Anzeige X1

Minimum MIN der Messreihe anzeigen Anzeige X2

Maximum MAX der Messreihe anzeigen Anzeige X1+X2

Differenz MAX-MIN der Messreihe anzeigen Anzeige X1-X2

0 V

Frei

Nicht belegen.

Nicht belegen.

Anzeige ist 0

Messwert ist größer oder gleich Schaltgrenze A1

Messwert ist größer oder gleich Schaltgrenze A2

Messwert ist kleiner als Klassieruntergrenze

Messwert ist größer als Klassierobergrenze

Fehler

Frei

Frei

Messwert ausgeben (Impuls-Ansteuerung)

Messwert ausgeben (Kontaktschluss)

Referenzmarkensignale ignorieren (Eingang X2, optional).

REF-Betrieb abschalten oder aktivieren

Besonderheiten bei Achskopp-

lungen

Beim SETZEN wird X1 auf den einge-•

stellten Wert gesetzt und X2 auf 0

Beim NULLEN kann – abhängig von •

der programmierten Formel – ein von

0 abweichender Wert angezeigt wer-

den (z.B.: 5 bei „X1 + X2 + 5“)

Für SPC werden die Werte der aktuell •

eingestellten Anzeige verwendet

Sind für die Messgeräte unterschied-•

liche Anzeigeschritte eingestellt, wird

hier der feinere verwendet.

Werden Achswerte als Divisor ver-•

wendet, kann es bei Division durch 0

bzw. Überlauf des Anzeigewertes

kurzzeitig zu einer Fehlermeldung

kommen.

Bei Anschluss eines analogen Sensors •

am Eingang X2 und Wahl des Mess-

geräte-Typs KOMPENSATION verhält

sich die ND 287 wie eine Ein-Achs-

Anzeige.

Bei KOMPENSATION ist die Formel •

zur Achsfehlerkompensation fest hin-

terlegt. Sie geben lediglich Ausdeh-

nungskoeffi zient und Bezugstempera-

tur ein

Schalteingange

Der Schalteingang E ist jeweils aktiv,

wenn ein Low-Signal U

(Kontakt oder Impuls gegen 0 V)

Signalpegel

– 0,5 V † U

3,9 V † U

t

‡ 30 ms

min

† 0,9 V bei IL † 6 mA

L

† 15,0 V

H

anliegt

L

Schaltausgänge

Die ND 287 hat Open-Collector-Ausgänge,

die gegen 0 V (= aktiv Low) durchschalten.

Verzögerung bis zur Signalausgabe:

t

† 20 ms

V

Signalpegel

U

† 0,4 V bei IL † 100 mA

L

U

† 32 V bei IH † 10 µA

H

Gefahr für interne Bauteile!

Die Spannung externer Stromkreise muss einer • Funktionskleinspannung mit

sicherer Trennung nach EN 50 178 entsprechen!

Induktive Lasten nur mit • Löschdiode parallel zur Induktivität anschließen!

Nur abgeschirmte Kabel verwenden!• Schirm auf Steckergehäuse legen.

In der Betriebsart Restweg wirken die Schaltausgänge A1 (Pin 15) und A2

(Pin 16) als Abschaltbereiche.

Kontakt

Impuls

4

Page 13

ND 287

Confi guration

Description détaillée cf. www.heidenhain.de

Avant la mise sous tension

Raccordement électrique

Tension d‘alimentation 100 à 240 V~

Fréquence secteur 50 à 60 Hz

(± 2 Hz)

Consommation † 30 W

Fusibles 2 x T500 mA

Raccordement de la prise secteur

L N

L: Phase (braun)

N: Conducteur neutre (bleu)

: Conducteur terre (jaune/vert)

Attention: Modifi cations câble

secteur seulement par professionnel!

Risque de décharge électrique!

Ne pas ouvrir l‘appareil.•

Ne pas couper le conducteur de terre, y •

com pris avec raccordement via un adaptateur secteur.

Danger pour composants internes

Ne brancher/débrancher connecteurs •

qu‘après mise hors-tension de l‘appareil.

N‘utiliser que des fusibles d‘origine.•

Raccordement

Commutateur d‘alimentation

1

2 Raccordement secteur avec

fusible

3 Mise à la terre (terre de

protection)

X1 Entrée système de mesure

pour système de mesure

HEIDENHAIN avec interface

11 µAcc, 1 Vcc ou EnDat-2.2

X2 Option entrée: Montage d‘un

mo dule pour système de mesure ou d‘un module analogique

X26 Option interface: Montage d‘un

module Ethernet (100BaseT)

X31 Interface V.24/RS-232-C

X32 Interface USB type B (UART)

X41 Entrées/sorties à commutation

Affi chage et éléments de

commande

Affi chage de position

1.

2. Softkeys pour les fonctions

3. Ligne de remarques pour remarques,

affi chage d‘échantillons, de la température, des messages d‘erreur

Validation de l‘introduction et

retour à l‘écran précédent

Effacer la valeur, acquitter le

message d‘erreur ou retour à

l‘écran précédent

Changer de barre de softkeys

4. Barre d‘état

Mode: Valeur effective (actif) –

Chemin restant (commutation

par softkey)

Affi chage entrée: X1 (actif),

X2, X1 + X2, X1 – X2, f(X1;X2)

(commutation par softkey si

2ème entrée raccordée)

Facteur échelle (inactiv;

activation avec PARAMETRER

USINAGE)

Correction d‘erreurs (inactive;

activer avec PARAMETRER

SYSTEME)

Chronomètre (inactif;

activer avec PARAMETRER

USINAGE)

Unité de mesure: mm (active),

inch, GRD, GMS ou rad

(commutation par softkey)

Point d‘origine 1 (actif) ou 2

(commutation par softkey)

Barres de softkeys (barre 1

active, 3 en tout; commutation

par touche)

5. Affi chage d‘état

(au dessus, dans, en

dessous de la tolérance)

actif en mode Classifi cation

(valeur de

mesure min., actuelle, max. et

différence entre MIN et MAX)

d‘un cycle de mesure actif

(commutation par softkey

Initialisation du point d‘origine

(clignote lors de l‘introduction

d‘une valeur)

Exploitation des marques de

référence (active)

à respecter absolument

important

à titre d‘information

Première mise en route

A la première mise en route et

pour changer de système de mesure,

confi gurer impérativement la visualisation de cotes. Nécessaire pour l‘adapter au système de mesure et affi cher

correctement les déplacements.

Mettre l‘appareil sous tension

1. Raccorder les éléments

2. Raccorder le ND au secteur

3. Mettre le ND sous tension (commu-

tateur). L‘écran de démarrage s‘affi che:

4. Sélectionner la langue

Appuyer sur la softkey jusqu‘à ce que

votre langue s‘affi che. Vous disposez

maintenant avec la softkey AIDE du sys-

tème d‘aide intégrée dans votre langue

pour introduire toutes les données et

pour toutes les fonctions.

Système d‘aide intégrée

Vous appelez le système d‘aide intégrée

avec la softkey AIDE. Quelle que soit la

situation, il vous renseigne dans votre

langue sur l‘étape en cours.

Avec la softkey LISTE DES RUBRIQUES,

vous pouvez affi cher tous les thèmes

que vous désirez.

Avec les softkeys PAGE ARRIERE ou

PAGE AVANT, feuilletez page à page et

avec les touches fl échées, passez d‘une

ligne à une autre. Avec la touche C,

retournez à l‘écran précédent.

1

Page 14

ND 287

Confi guration

Description détaillée cf. www.heidenhain.de

Paramétrer le système

1. Appuyer sur la softkey

2. Appuyer sur la softkey et introduire le

code 95148.

Paramétrer l‘usinage

Ouvrir menu avec softkey PARAMETRES

1. Unité de mesure

Sélectionner mm ou pouces ou degrés/

minutes/secondes (DMS), degré décimal

(GRD) ou rad (affi chage sur la barre d‘état)

2. Facteur échelle

Désactiver ou sélectionner le facteur

échelle (affi chage sur la barre d‘état)

3. Valeur pour le point d‘origine

pour initialisation externe via l’entrée à

commutation ou rapide avec le clavier.

4. Chronomètre

Start (affi chage sur la barre d‘état)

5. Réglages de l‘écran

Choisir la luminosité et activer

l‘économiseur d‘écran

Fonctions

Exploitation des marques de

référence REF

Grâce à l’exploitation des marques de

référence REF, le ND 287 rétablit automatiquement les relations entre la position du chariot ou du palpeur de mesure

et la valeur d’affi chage que vous aviez

défi nie avant la mise hors tension.

Si vous travaillez sans REF, les

points d‘origine initialisés sont perdus

lorsque le ND est mis hors tension.

Valeur effective/Chemin restant

En mode Valeur effective, le ND 287

affi che toujours la position effective du

système de mesure par rapport au point

d’origine actif.

En mode Chemin restant, vous introduisez la position-cible et parcourez simplement la course restante jusqu‘à la valeur

d‘affi chage 0.

Paramètres de fonctionnement

Principaux paramètres en caractères gras.

1. Défi nir le système de mesure

Sélectionner le • type de système de

mesure (linéaire, angulaire)

Signal du système de mesure: Il est •

détecté et inscrit automatiquement

Période de signal• en fonction du

système de mesure

Marque de référence• en fonction du

système de mesure

REF externe (si nécessaire)•

Sélectionner le • sens de comptage

Contrôle d‘erreurs (si nécessaire)•

2. Paramétrer l‘affi chage

Défi nir la résolution d‘affi chage•

3. Confi gurer le compteur

Application 1 axe ou 2 axes (seulement •

avec module système de mesure

optionnel ou module analogique).

Deux axes peuvent être couplés par

des fonctions mathématiques.

Verrouillage du clavier•

Autre point décimal (après 3 digits) •

Réinitialisation à la confi guration usine•

4. Correction d‘erreurs

Sélectionner • la correction d‘erreurs

(OFF, linéaire, non-linéaire) et introduire les valeurs

5. Confi gurer l‘interface

Si nécessaire

6. Diagnostic

Si nécessaire

2

6. Langue

Modifi er après-coup la langue du dialogue

7. Signaux de commutation

Introduction des limites de commutation

8. Sortie de la valeur mesurée (arrêt

de l‘affi chage)

Sélection de l‘arrêt de l‘affi chage (simultané, arrêt ou arrêt/affi chage simultané)

9. Fonction des entrées externes

Commutation de la fonctionnalité des

entrées externes

Avant la mesure

Avant la mesure, vérifi ez si la

course réellement parcourue (ou l‘angle)

correspond bien à l‘affi chage au niveau

de la valeur et de la direction. S‘il y a une

différence, vérifi ez les causes possibles:

Période de signal•

Sens de comptage •

Correction d‘erreurs•

Facteur échelle•

Application •

(un ou deux axes;

fonction de couplage d‘axes)

Affi chage Chemin restant•

Le chemin restant est affi ché avec

le signe inversé. Par exemple, le signe

du chemin restant est positif pour un déplacement dans le sens négatif.

I: Position effective

S: Position nominale

R: Chemin restant

HEIDENHAIN FRANCE sarl

2 avenue de la Cristallerie

92310 Sèvres, France

{ 0141 143000

| 0141 143030

E-Mail: info@heidenhain.fr

www.heidenhain.fr

Page 15

Classifi cation

=

Cycles de mesure

Le ND 287 enregistre des cycles de

mesure pouvant comporter jusqu‘à

10 000 valeurs de mesure. Ils peuvent

être traités en interne ou importés en

bloc.

Maîtrise Statistique des

Procédés SPC

Pour la Maîtrise Statistique des Procédés SPC, le ND 287 dispose d‘une mémoire FIFO non volatile capable d‘enre-

gistrer jusqu‘à 1 000 valeurs de mesure.

= >

En mode Classifi cation, le ND 287

compare la valeur affi chée à une limite

supérieure ou inférieure de classifi cation

et affi che le résultat de la classifi cation

avec une valeur en couleur et aussi avec

les sym boles < = > sur la barre d’état.

Un signal adéquat est émis sur la sortie

à commutation X41. Avec la softkey

CLASSIF., vous ouvrez la fenêtre pour

introduire les paramètres et limites de

classifi cation.

La fonction de classifi cation agit sur la

valeur affi chée, y compris pour les

cycles de mesure, l‘affi chage Minimum/

Maximum, le contrôle SPC et le

couplage d‘axes.

<

Arrêt de l‘affi chage

On peut stopper l‘affi chage pour lire les

valeurs de mesure qui changent rapidement. Le compteur interne conti nue à

tourner. L’arrêt de l’affi chage est déclenché par le signal de commutation „sortie

valeur de mesure“ sur X41, la commande

Control B ou la softkey PRINT.

Possibilités de réglage dans le paramètre SORTIE VALEUR MESURE sous „Paramétrer usinage“:

Affi chage simultané•

L‘affi chage correspond toujours à la

valeur de mesure actuelle

Arrêt affi chage•

L‘affi chage est gelé et actualisé à

chaque nouvelle instruction

Arrêt/affi chage simultané•

L‘affi chage ne s‘arrête que pendant la

durée de l‘instruction

Paramétrer un cycle de mesure

Enregistrement des valeurs mesurées •

(avec touche ENTER, signal externe

ou intervalles de palpage paramétrés)

Nombre de valeurs de mesure•

Défi nition des intervalles de palpage •

(20 ms à 60 s) et de la fenêtre de durée

Lancer le cycle de mesure

avec la softkey LANCER CYCLE MES •

avec signal externe sur X41.•

La mise hors tension du ND ou le

lancement d‘un cycle de mesure efface

les valeurs du précédent cycle de mesure.

Arrêter le cycle de mesure

automatiquement lorsque le nombre •

de valeurs de mesure défi ni est atteint

avec la softkey FERMER CYCLE MES. •

Analyse du cycle de mesure

Affi chage du cycle de mesure avec

données statistiques•

diagramme•

tableau des valeurs de mesure •

Exporter les valeurs de mesure

Lancer le transfert du tableau des valeurs

de mesure avec la softkey EXPORT

Affi chage Minimum/Maximum

Pendant le cycle de mesure, avec

SELECTION AFFICHAGE, vous pouvez

commuter de la valeur de mesure ACTL

vers la valeur MIN, la valeur MAX ou la

différence DIFF.

Paramétrer la SPC

Nombre d‘échantillons et nombre de •

valeurs par échantillon

Une modifi cation de ces valeurs

efface les données de la mémoire FIFO

Tolérance supérieure et tolérance infé-•

rieure (limites de classifi cation) et cible

Limites de contrôle pour cartes de •

contrôle

Type de répartition (symétrique ou •

limitation d‘un côté)

Enregistrement des valeurs de mesure •

(touche ENTER ou signal externe)

Enregistrer les données SPC

Lancer nouvel enregistrement avec la •

softkey LANCER SPC.

La softkey FERMER SPC ferme la fonc-•

tion SPC. Le ND 287 est disponible

pour d’autres opérations de mesure

Avec la softkey LANCER SPC, vous •

lancez toujours une nouvelle mesure

d‘échantillon jusqu‘au nombre défi ni

Le compteur d‘échantillons sur la ligne •

des remarques affi che le numéro de

la mesure dans l‘échantillon actuel, le

nombre de mesures effectuées et le

nombre total de mesures

Avant une nouvelle SPC, effacer

les anciennes valeurs de la mémoire

FIFO avec EFFACER STATISTIQUES.

Analyse SPC

Pendant l‘enregistrement des données,

le ND affi che l‘état actuel sous forme de

données statistiques•

courbe des 30 dernières valeurs•

histogramme avec 10 classes•

cartes de contrôle pour • valeur mo-

yenne x, écart type s et étendue r

(différence entre la valeur min. et la

valeur max.) d‘un échantillon.

3

Page 16

ND 287

Fonctions

Description détaillée cf.

www.heidenhain.de

Couplage des axes

L‘entrée X2 est prévue pour un module

d‘entrée supplémentaire (option).

Possibilités:

Module pour raccordement d‘un •

deuxième système de mesure

Module analogique pour le raccorde-•

ment d’un capteur analogique ± 10 V.

Descriptions fournies avec les modules.

X1 et X2 peuvent être affi chés séparément ou couplés par des fonctions

mathématiques. L‘affi chage est commutable à tout moment par softkey ou

entrée à commutation

Affi chages possibles:

Entrée X1•

Entrée X2•

Somme de X1 et X2•

Différence de X1 et X2•

N‘importe quelle fonction de X1 et X2•

Entrées/sorties à commutation

Distribution des plots

Plot Version 1 Version 2

1

2 I

3 I

4 I

5 I

6 I

7 I

8 I

9 I

10

11

12

13

14 O

15 O

16 O

17 O

18 O

19 O

20

21

22 I

23 I

24 I

25 I

I: Entrée à commutation; O: Sortie à commutation

Sélectionner la version 1 ou 2 sous „Fonction entrées externes“ dans „Paramétrer usinage“.

0 V

Remise à zéro, effacer le message d’erreur

Initialisation du point d’origine

Ignorer les signaux de référence (entrée X1)

Lancer le cycle de mesure Affi chage f(X1,X2)

Sélection ext. d‘une valeur pour un cycle de mesure Affi chage X1

Affi cher la valeur MIN du cycle de mesure Affi chage X2

Affi cher la valeur MAX du cycle de mesure Affi chage X1+X2

Affi cher la différence MAX-MIN du cycle de mesure Affi chage X1-X2

0 V

Libre

Ne pas raccorder.

Ne pas raccorder.

Affi chage égal à 0

Valeur de mesure supérieure ou égale à la limite de commutation A1

Valeur de mesure supérieure ou égale à la limite de commutation A2

Valeur de mesure inférieure à la limite inférieure de classifi cation

Valeur de mesure supérieure à la limite supérieure de classifi cation

Erreur

Libre

Libre

Sortie de la valeur de mesure (commande par impulsion)

Sortie de la valeur de mesure (fermeture de contact)

Ignorer les signaux de référence (entrée X2, option).

Désactiver ou activer le mode REF

Particularités du couplage d‘axes

Avec INIT, X1 est initialisé à la valeur •

présélectionnée et X2 à la valeur 0

Avec RAZ, on peut affi cher – selon la •

formule programmée – une valeur

différente de 0 (par ex.: 5 avec

„X1 + X2 + 5“)

Les valeurs de l‘affi chage actuel sont •

utilisées pour la SPC

Si différentes résolutions d‘affi chage •

sont confi gurées pour les systèmes

de mesure, la plus fi ne est utilisée ici.

Si des valeurs d‘axes sont utilisées en •

tant que diviseur, il peut en résulter

brièvement une division par 0 ou un

dépassement de la valeur affi chée et

donc un message d‘erreur.

Si vous raccordez un capteur analo-•

gique sur l’entrée X2 et sélectionnez

pour type de système de mesure

COM PENSATION, le ND 287 se

comporte alors comme un compteur

un axe.

Avec COMPENSATION, la formule de •

compensation des défauts des axes

est défi nie. Il vous suffi t d‘introduire le

coeffi cient de dilatation et la température de référence

Entrées à commutation

L’entrée à commutation E est active

lorsqu’un signal Low U

(contact ou impulsion à 0 V)

Amplitude du signal

– 0,5 V † U

3,9 V † U

t

‡ 30 ms

min

† 0,9 V pour IL † 6 mA

L

† 15,0 V

H

est appliqué

L

Contact

Impulsion

Sorties à commutation

Le ND 287 est équipé de sorties collecteur

ouvert commutées à 0 V (= Low actif).

Retard jusqu‘à l‘émission du signal:

t

† 20 ms

V

Amplitude du signal

U

† 0,4 V pour IL † 100 mA

L

U

† 32 V pour IH † 10 µA

H

Danger pour composants internes!

La tension de circuits de courant externes doit correspondre à une • basse tension de

fonctionnement avec séparation galvanique d’après EN 50 178!

Ne raccorder les charges inductives qu’avec une • diode lumineuse en parallèle à

l’inductivité!

Utiliser uniquement du câble blindé!• Relier le blindage au carter de la prise.

En mode Chemin restant, les sorties à commutation A1 (plot 15) et A2 (plot 16)

agissent comme plages de décommutation.

4

Page 17

ND 287

设置

更多信息,请访问www.heidenhain.de

开机前

电气连接

线电压 100 - 240 Vac

电源频率 50 - 60 Hz (± 2 Hz)

功耗 † 30 W

电路保险丝 2 x T500 mA

电源插头连线

L N

L: 相线(棕色)

N: 中性线(蓝色)

: 地线接头(黄色/绿色)

小心: 只允许电气技术人员改动

动力电缆。

有电危险!

严禁打开外壳。•

严禁断开保护地线的连接,包括未连•

接网络适配器时。

可能损坏内部零件

数显装置带电时,严禁连接任何连接•

件或断开其连接。

只允许使用原配保险丝。•

控制和显示

位置显示

1.

2. 功能软键

3. 信息行用于显示提示信息、出错信息

和样本或温度信息

确认输入信息和返回上页。

删除输入信息,确认出错信息

或返回上页。

软键翻页。

4. 状态栏

操作模式: 实际值(有效) -

待移动距离(用软键选择)

输入: X1(有效),X2,X1

+ X2,X1 – X2,f(X1;X2)(如

有一个模块连接在第2个输入

接口处,可用软键选择)

缩放系数(未使用;可通过“

任务设置”激活)

误差补偿(未使用;可通过“

系统设置”激活)

计时表(未使用;可通过“任

务设置”激活)

尺寸单位: mm(激活)

,inch,DEG,DMS或RAD(

可通过软键选择)

非常重要

请注意

提示信息

第一次使用

第一次使用该数显装置或更换编码

器时,必须正确设置该数显装置。 只有

这样数显装置才能适应编码器要求,使

其正确显示位移量。

开机启动

1. 连接各部件。

2. 将ND数显装置接入电网。

3. 按下ND数显装置的电源开关,开

启。 显示初始化页:

4. 选择语言。

重复按下该软键直到显示所需语言。 按

下“帮助”软键调用所选语言的在线帮

助系统。 帮助系统为操作人员提供输入

信息和操作的帮助。

连接

电源开关

1

2 连接电路保险丝

3 接地(防护性接地)

X1 编码器输入接口,海德汉编码器

输入接口11-μApp,1-Vpp或

EnDat-2.2

X2 选装输入接口: 编码器模块或模

拟信号模块的输入接口

X26 选装接口: 安装以太网模块

(100BaseT)

X31 RS-232-C/V.24接口

X32 USB的B型(UART)接口

X41 开关量输入/输出

原点1(有效)或原点2(可通

过软键选择)

软键页(页1有效,共3页,用

浏览键翻页)

5. 状态显示

(大于公差极限,

在公差范围内,小于公差极

限)用于分类和公差检查模式

(最小值,

实际值,最大测量值,最小值

与最大值之差)如果“测量值

序列”模式有效(用软键选

择)

原点设置(输入值时,闪亮)

参考点计算(有效)

在线帮助系统

按下“帮助”软键调用在线帮助系统。

在线帮助系统可在任何情况下为操作人

员提供与当前操作有关的信息和帮助

(用所选语言)。

按下“主题列表”软键查看任何一个主

题信息。

用“上页/下页”软键向前或向后翻页,

用箭头键向上或向下移动一行。 按

下“C”键返回上页。

1

Page 18

ND 287

设置

更多信息,请访问www.heidenhain.de

系统设置

1. 按下上图中的所需软键。

2. 按下上图中的所需软键并输入密码

95148。

工作参数

重要参数用粗体表示。

1. 编码器设置

编码器类型• (直线,旋转)。

编码器信号: 自动确定。•

信号周期:• 取决于编码器。

参考点:• 取决于编码器。

外部参考点REF(根据需要)。•

计数方向:• 选择适当计数方向。

错误监视器(根据需要)。•

2. 显示配置

设置显示分辨率。•

任务设置

按下“设置”软键打开菜单。

1. 单位

选择毫米或英寸,或度分秒(DMS),

小数度(DEG)或弧度(在状态栏显

示)。

2. 缩放系数

取消缩放系数或选择所需缩放系数(在

状态栏显示)。

3. 原点值

输入数值,用于通过开关量输入接口或

用“预设点”软键设置原点。

4. 计时表

启动计时表(在状态栏显示已用时

间)。

5. 面板调整

选择亮度和开启显示器待机空闲时间。

6. 语言

选择所需对话语言。

7. 开关量信号

输入触发极限值。

8. 测量值输出(显示冻结)

选择测量值输出显示模式(并行,冻结

或冻结/并行显示)。

9. 外部输入功能

选择外部输入功能。

功能

REF参考点计算

ND 287的REF参考点计算功能可以自动

用上个设置的原点恢复机床轴位置与显

示值的对应关系。

如果不用REF功能,ND数显装置

关机后将丢失原点。

实际值/待移动距离

ND数显装置的实际值操作模式仅显示编

码器相对当前原点的当前实际位置值。

在待移动距离操作模式中,输入名义位

置值,然后只需移动到显示值为零处。

待移动距离显示值的代数符号相

反。 例如,如果由实际位置向名义位置

的轴方向是负方向,待移动距离用正

号。

I: 实际位置

S: 名义位置

R: 待移动距离

3. 计数器设置

选择“应用”字段•

的“1轴”或“2轴”(仅限选配编码

器模块或模拟量模块)。 两个轴可通

过算术运算合并显示。

锁定或释放键盘。•

第二小数点(3个小数位后)。 •

复位所有参数为工厂默认设置值。•

4. 误差补偿

误差补偿:• 选择“关闭”,“线

性”或“非线性”,并输入数据。

5. 接口设置

根据需要。

6. 诊断

根据需要。

2

开始测量前

确保实际运动的距离或角度与显示

值和显示方向相符。 以下原因可能导致

偏差:

信号周期•

计数方向•

误差补偿•

缩放系数•

应用(1轴或2轴;连接轴位置的公•

式)

待移动距离显示•

DR. JOHANNES HEIDENHAIN GmbH

Dr.-Johannes-Heidenhain-Straße 5

83301 Traunreut, Germany

{ +49 (8669) 31-0

| +49 (8669) 5061

E-mail: info@heidenhain.de

www.heidenhain.de

Page 19

分类和公差检查

测量值序列

SPC统计过程控制

=

= >

为对零件进行分类,ND 287比较显示值

与分类极限值的上限和下限,并在状态

栏用不同颜色显示分类结果,用数值或

用“< = >”符号显示。 此外,还为开

关量输出接口X41提供相应信号。 按

下“公差检查”软键打开分类参数和分

类极限值的定义窗体。

<

ND 287的测量值序列可保存10 000个测

量值。 这些测量值可用于内部计算,也

可被分段读取。

设置测量值序列

测量值通过“ENTER”键,外部信号•

或取样间隔时间启动记录。

测量值数量。•

取样间隔时间定义(20 ms至60 s)和•

时间间隔。

开始测量值序列

按下“开始测量值序列”。 •

使外部信号发至X41接口。•

将ND数显装置关机或开始一个新

测量值序列将删除原记录的测量值序

列。

在统计过程控制中,ND 287的非易失

FIFO存储器可保存1 000个测量值。

SPC设置

采样数量和每个样本的数据。 •

如需修改这些值,FIFO存储器中

的值将被删除。

公差上限和下限(等于分类极限值)•

和名义值。

控制图表的控制极限值。•

分布(对称,左极限值或右极限•

值)。

测量值通过“ENTER”键或外部信号•

启动记录。

分类和公差检查功能对当前显示值一定

有效,此外也适用于测量值序列,最小

值/最大值显示,SPC或连接轴位置模式

有效时。

显示冻结

为读取快速变化的显示值,可以冻结显

示值。 位置值在系统内部进行连续计算

直到要求刷新显示值时。 可通过连接至

X41的“输出测量值”开关量信号冻结

显示值,也可通过“CTRL B”指令或按

下“打印”软键冻结。

通过“任务设置”菜单中“测量值输

出”参数进行以下定义:

并行显示• 显示值一定为测量值。

冻结显示• 显示值保持不变,但在每次

输出测量值时更新显示。

冻结/连续显示• 输出测量值期间显示值

保持不变。

停止测量值序列

达到定义的测量值数量时,自动停•

止。

按下“停止测量值序列”。 •

测量值序列分析

测量值序列的显示形式有

统计数据•

图形•

测量值表 •

导出测量值

按下“导出”软键开始传输测量值表。

最小值/最大值显示

在测量值序列执行期间,按下“选择显

示”软键使实际值显示(ACTL)切换为

最小值显示(MIN),最大值显示(

MAX)或最小值与最大值之差(

DIFF)。

记录SPC值

按下“开始SPC”软键将使SPC开始•

获取数据。

按下“停止SPC”软键中断SPC功•

能。 然后,ND 287可用于其他测量任

务。

按下“开始SPC”软键重新执行定义•

数量的采样测量过程。

信息行中的样本计数器显示当前进行•

的测量采样数和被测样本总数。

开始进行新SPC测量前,按下“删

除统计数据”删除FIFO存储器中的原有

SPC值。

SPC分析

测量数据期间,ND数显装置显示当前状

态为

统计数据•

图形(最后30个测量值)•

10个等级的柱状图 •

样本的• 平均值x,标准方差s和范

围 r(最大值与最小值之差)的控制

图表

3

Page 20

ND 287

功能

更多信息,请访问www.heidenhain.de

轴连接

输入接口X2是一个附加的输入套件(选

装)。 可选:

连接第二个编码器模块•

模拟模块,连接± 10 V模拟传感器•

其说明,参见相应模块。

X1和X2可分别显示,也可以通过算术运

算合并显示。 如需切换显示方式,可随

时用软键或开关量输入接口。

支持以下轴显示:

输入接口X1•

输入接口X2•

X1与X2之和•

X1与X2之差•

X1与X2连接轴的任何函数关系•

切换I/O

针脚编号

针脚 版本1 版本2

1

2 I

3 I

4 I

5 I

6 I

7 I

8 I

9 I

10

11

12

13

14 O

15 O

16 O

17 O

18 O

19 O

20

21

22 I

23 I

24 I

25 I

I: 开关量输入;O: 开关量输出

可在“任务设置”菜单的“外部输入功能”中选择“版本1”或“版本2”。

0 V

复位,清除出错信息

设置原点

忽略参考点信号(输入接口X1)

开始测量值序列 f(X1,X2)显示

外部选择测量值序列的显示值 X1显示

显示测量值序列的最小值(MIN) X2显示

显示测量值序列的最大值(MAX) X1+X2显示

测量值序列最大与最小值之差 X1-X2显示

0 V

空

未分配

未分配

显示值为零

显示值大于或等于触发器极限值A1

显示值大于或等于触发器极限值A2

测量值小于分类下限

测量值大于分类上限

错误

空

空

测量值输出(脉冲)

测量值输出(接触)

忽略参考点信号(输入接口X2,选装)

激活或取消REF模式

连接轴位置的特殊功能

如果用“预设点”,将X1设置为输入•

值,将X2设置为零。

如果用“复位”功能,根据编程公式•

可显示任何非零值(例如: 5,如

果“X1 + X2 + 5”)。

当前有效轴显示的测量值用于SPC功•

能。

如将两个轴连接在一起,将用其中显•

示分辨率最细的。

如果轴值被用作除数,被零除或显示•

溢出时将临时显示出错信息。

如果连接模拟传感器至输入接口•

X2和“编码器设置”的“编码器类

型”字段中,“输入接口X2”设置

为“补偿”,ND 287的工作方式将与

单轴数显装置相同。

如果未选择“补偿”功能,系统自动•

确定轴误差补偿公式。 只能输入热膨

胀系数和基准温度。

开关量输入信号

开关量输入接口E有效,

如果用低电平信号U

(接触或脉冲至0 V)。

信号电平

- 0.5 V † U

3.9 V † U

t

‡ 30 ms

min

L

H

L

† 0.9 V,IL † 6 mA

† 15.0 V

开关量输出

ND 287数显装置提供集电极开路输出信号,

使输出电平为0 V(= 低电平有效)。

输出信号的延迟:

t

† 20 ms

D

信号电平

U

† 0.4 V , IL † 100 mA

L

U

† 32 V , IH † 10 μA

H

可能损坏内部零件!

外部电路的供电技术条件必须符合EN 50• 178低压电气隔离要求。

传导式负载的连接只能为电感与• 灭弧二极管并联连接。

仅允许使用屏蔽电缆。• 将屏蔽层连接至外壳。

接触

脉冲

在待移动距离操作模式中,开关量输出A1(针脚15)和A2(针脚16)以开关量

范围为基础。

4

Page 21

ND 287

設定

詳細は弊社ホームページ www.heidenhain.co.jp を参照ください。

電源投入前

電気的接続

電源電圧

商用電源周波数

消費電力

ヒュー ズ

電気接続配線

100 - 240 Vac

50 - 60 Hz (± 2 Hz)

† 30 W

2 x T500 mA

L N

L:

フェーズ (茶

N:

ニュートラル (青

:

グランド (黄/緑

注意 :電源ケーブルを変更する際に

は電気知識の豊富な技術者が行ってくだ

さい。

電気的ショックに注意

•

本体のカバーを開けないこと

•

ネットワークケーブルを接続していなく

ても必ずアースは接続してください。

内部コンポーネントに影 響します

•

製品の通電中にコネクタを外すもしく

は接続しないでください。

•

オリジナルのヒューズをご使用くださ

い。

)

)

)

!

接続

電源投入

1

ヒューズ

2

アース

3

11-µApp, 1-Vpp

X1

EnDat-2.2

もったハイデンハインのエンコー

ダ用の入力端子

入力端子(オプション)エンコー

X2

ダ モ ジュー ル用 もしくは ア ナ ログ

モジュール用

インターフェース用 : イーサーネッ

X26

トのモジュール

RS-232-C/V.24

X31

USB

X32

フェース

外部入出力スイッチ

X41

インターフェースを

(100BaseT)

Type B (UART)

または

インターフェース

インター

操作および表示

位置表示

1.

機能用ソフトキー

2.

表示内容、エラー情報およびサンプ

3.

ルまたは温度情報の表示

入力の確認および全画面へ戻

る

入力の取り消し、エラーの確認

または全画面へ戻る

ソフトキーを使用するページ

の移動

ステータス

4.

操作モード: 現在値 (デフォル

) –

ト

残り距離 (ソフトキーに

よる選 択

: X1 (

入力

+ X2, X1 – X2, f(X1;X2) (

ションモジュールを使用した場

合、ソフトキーで選択可能

スケーリング係数 (デフォルト

無効; ジョブ設定にて有効にで

)

きる

エラー補正機能 (デフォルト

無効; システム設定にて活用

)

可能

ストップ ウォッチ (デフォルト

;

無効

できる

表示単位

インチ、度、度分秒およびラ

ジアンはソフトキーで選択可

)

能

基準点

フトキーにて選択可能

ソフトキーによるページ選択

(1

ページがデフォルト表示、

3

全

ページが表示可能、ナビ

ゲーションキーにてページ選

択可能

ステータス表 示

5.

(

公差上限以上) 選別公差確認

モードで有効化可能

在値、最大値または最大最

小の際) 連続計測モードが有

効の際(ソフトキーによる選択

)

可能

基準値の設定 (入力時には点

)

滅

参照マーク (有効

)

デフォルト

ジョブ設定にて有効に

)

: mm (

1 (

有効) または

)

公差下限以下、公差内、

), X2, X1

オプ

デフォルト、

2 (

)

(

最小、現

)

)

-

-

ソ

重要

注意

参考

初期動作

初期設定時またはエンコーダ交換

時にはデジタル 表 示 カウンタを正しく設 定

して下さい。正しく設定されていないと正

常に動作しない場合があります。

立ち上げ

エンコーダの接続

1.

デジタル表示カウンタとネットワーク

2.

との接続

ND 287

3.

期画面が表示される

言語設定

4.

-

ソフトキーを押し言語を設定する(日本

語-

選択言語でヘルプが表示されます。この

ヘルプ機能はすべての機能と入力項目に

関してサポートしております。

の電源スイッチを入れ、初

Nihongo) HELP

ソフトキーを押すと

内蔵されたヘルプ機能システム

HELP

ソフトキーはND287に内蔵され

ているヘルプ機能を呼び出すことができ

ます。内容は設定された言語で情報や

サポートをどの画面からも見ることがで

きます。

LIST OF TOPICS

てのトピックスをリストにできます。

PAGE UP/DOWN

クロー ル することができ、 矢印 キ ーで一

行ずつカーソルを移動できます。C キー

にて元の画面に戻ります。

のソフトキーではすべ

ソフトキーで画面をス

1

Page 22

ND 287

設定

詳細は弊社ホームページ www.heidenhain.co.jp を参照ください。

システム設 定

上記の画面で赤丸のソフトキーを押し

1.

てください。

上記の画面で赤丸のソフトキーを押し

2.

てパスワード

い。

95148

を入力して下さ

操作パラメータ

重要なパラメータは太字で下記表示しま

した。

エンコーダ の 定 義

1.

• (

エンコーダタイプ

• :

エンコーダの信号の種類

•

信号周期

•

参照マーク

• (

外部参照マーク

•

計測方向

• (

エラーの監視

画面の調整

2.

•

表示画面の解像度の設定

設定

3.

• 1

アプリケーションの設定では

くは 2 軸 (オプションのエンコーダモ

ジュールもしくは アナログ モジュール

を使用した場合) が選択できます。

軸仕様では数式を使用して2軸の数値

の合成、計算が可能です。

•

キーボードのロックもしくはロック解

除の設定

3 •

桁ごとの区切りのための点の設定

•

工場出荷時のデフォルトの設定へリ

セットする

エラー補正

4.

•

エラー補正

非線形エラー補正および数値の入力

の選択

インターフェースの 設 定

5.

必要な場合

診断機能

6.

必要な場合

:

:

リニ ア、 ロータリ

自動認識

エンコーダへ依存する

:

エンコーダへ依存する

オプション

計測方向の選択

必要に応じて

:

向こう、線形エラー補正、

)

)

)

軸もし

2

2

加工設定

SETUP

ソフトキーを押し、メニューを 開く

単位

1.

インチ、度分秒または度、ラジアンを選

択(ステータスバーに表示されます。

スケーリング係数

2.

スケーリング係数の無効または必要な

係数値の選択 (ステータスバーに表示さ

)

れます

基準点の値

3.

基準点の数値を外部スイッチもしくは

PRESET

4.

ストップウォッチの計測開始 (経過時間

はステータスバーに表示されます

5.

画面の輝度やスクリーンセーバーなどの

調整、設定

6.

言語の選択、設定

7.

トリガー信号の入力

8.

測定値の出力のための画面のモード選

択 (固定するしないなど

9.

外部入力の機能の選択

ソフトキーにより入力

ストップ ウォッチ

画面の調整

言語

スイッチ信号

計測値の出力 (画面固定

外部入力の機能

計測を始める前に

移動距離または回転角度が表示

されている値、方向と一致しているかど

うか確認下さい。もし異なっている場合、

下記の可能性が考えられます。

•

信号周期

•

計測方向

•

エラー補正

•

スケーリング係数

• (1

アプリケーション

2

軸の位置値の計算

•

残り距離の表示

)

)

)

軸 または2 軸、

)

機能

REF

参照マークの評価

ND 287

と最後の設定した基準点の関係を自動

的に回復する機能です。

)

合は停電時などで電源が遮断されるとそ

の位置関係を失ってしまいます。

現在値/ 残り距 離

操作モードで現在値設定をすると、

ND 287

からの距離を表示します。

操作モードで残り距離 設定を行い、希望

する位置を入力すると、単純に表示がゼ

ロになる位置まで移動することになりま

す。

になっています。たとえば、残り距離設

定で正の符号の場合、現在値から到達

希望位置まで負の方向に動かす必要が

あります。

I:

S:

R:

DR. JOHANNES HEIDENHAIN GmbH

Dr.-Johannes-Heidenhain-Straße 5

83301 Traunreut, Germany

{ +49 (8669) 31-0

| +49 (8669) 5061

E-mail: info@heidenhain.de

www.heidenhain.de

の参照マーク評価機能は現在値

REF

もし

残り距離設定では正負の符号が逆

現在値

到達希望位置

残り距離

自動を設定していない場

はエンコーダの現在値、基準値

Page 23

選別および公差確認

=

連続測定

ND 287

までの測定値を保存できます。連続測定

の記録後は、それをすぐに

価することもエキス ポ ートすることもでき

ます。

では、連続測定最大

10 000

ND 287

個

で評

SPC

統計的工程管理手法

統計的工程管理において、

1 000

個の測定値を不揮発性メモリ

(

FIFO)

に保存できます。

ND 287 は

= >

部品の選別に関して、

値と選別の上限、下限を比較し、その

結果をステータス部に色と数値もしくは

< = >

の記号を表示します。さらに、ス

イッチ信号出力

応した信号が出力されます。公差確認の

ソフトキーにて選別のパラメータおよび

選別限界を設定することができます。

選別と公差確認機能は現在表示されて

いる数値に対して常に有効です。その一

方、連続測定の場合、最大、最小の表示、

SPC や2

ことが可能です。

軸の計算に対しても有効にする

<

ND 287

X41

から選別結果に対

は測定

画面固定

素早く切り替わる画面上の数字を読む代

わりに、画面を固定することが可能です。

測定値は次の数値を呼び出すまで、カウ

ンター内部で計測しております。画面固

定の場合には

しくはソフトキー " 印刷 "によって固定

することができます。

計測値の出力は加工設定のメニューで

下記の項目が設定できます。

•

同時進行での表示

表示された値は常に計測値と一致して

います。

•

画面固定

画面は固定されますが、常に新しい測

定値が外部へ出力される際に更新され

ます。

•

画面の固定/同時進行の切り替え

画面は計測値を外部へ出力中のみ固

定されます。

X41

より計測値の出力も

連続測定の設定

• ENTER

連続測定は

しくはサンプリング時間によって行う

ことが で きます。

•

測定数

• (20 ms 〜 60 s)

サンプリング時間

は連続計測時間を定義することによっ

て決定します。

連続測定の開始

•

連続測定の開始を押す。

X41 •

へ外部信号を送ることによっても

開始します。

カウンターの電源を落としたり、新

しい連続測定を開始すると、それまでの

保存されたデータは消去されます。

連続計測の終了

•

あらかじめ設定された計測回数に達す

ると自動的に終了します。

•

または、連続測定の終了のキーを押

すことで終了できます。

連続計測の評価

連続計測は統計データ、グラフもしくは

表の形で表示できます。

計測データの外部出力

エキスポートのソフトキーを押すことで

測定値が転送されます。

キー、外部信号も

また

最大最小表示

連続計測中に表示選択のソフトキーを押

すことで現在値

および最大値

(

)

の差異

できます。

DIFF

(ACTL)

から最小値

(

)

MAX

および最大最小

の表示に切り替えることが

(

MIN

SPC

の設定

•

サンプル数およびサンプルあたり

データ数

発性メモリ

があります。

• (

上限値、下限値

および標準値

•

工程管理図の管理限界

• (

測定値の分布

右側の限界

ENTER •

て測定値は保存できます。

SPC

SPC •

開始ソフトキーにて行います。

SPC •

します。その結果、カウンターは他の

機能を使用することができるのです。

• SPC

再度、

定義されたサンプル数の計測を再開し

ます。

•

メッセージラインの サンプルカウンタ

は、現在測定中のサンプル番号、計

測終了した回数、設定した測定回数を

表しています。

発性メモリ

削除するために統計の削除キーを押し

て下さい。

)

SPC

データを測定中に

タ、直 近30個のデータのグラフおよ

び10個のクラスタ分けされたヒストグラ

ム、

ます。

もしこの設定を変更するには不揮

(FIFO)

の中を消去する必要

選別限界と同じく)

対称性、左側および

)

キーもしくは外部信号によっ

値の保存

のためのデータの取得は

SPC

機能は

新しい

の分析

X-R、X-

(FIFO)

の停止キーにて中断

の開始を押すと、すでに

SPC

の計測を 行う前 に不揮

の中の古い

ND 287

σなどの管理図を表示でき

SPC

SPC

値を

は統計デー

の

3

Page 24

ND 287

機能

詳細は弊社ホームページ

www.heidenhain.co.jp を参照ください。

2

軸のデータの計算

入力スロット

軸を接続することができます。

• 2

つまり、

可能なのです。

± 10 V •

はアナログモジュールを使用すること

で可能となります。

以下の記述はモジュールを使った場合の

内容も含まれています。

X1

および

くは算術計算を行った結果の表示が可能

です。ソフトキーもしくは外部入力によっ

て切り替 え可能です。

以下の表示が可能です。

X1 •

X2 •

X1 •

X1 •

• X1

それ以外の

• X1

プリセットキーを 使うと、

れた値に設定され、

されます。

•

リセットキーを使用すると、入力さ

れた数式によりますが、ゼロ以外

の数字が表示されます。(たとえば

X1 + X2 + 5

示されます。

• SPC

現状有効になっている軸の値が

に使用されます。

• 2

もし

2

つの軸の内分解能の細かい分解能

の表示が採用されます。

•

表示される値に割り算が使用されてい

る場合、ゼロでの割り算もしくは表示

がオーバーフローした場合にはエラー

表示となります。

• X2

アナログセンサーが

ンコーダの設定のエンコーダのタイ

プで

ND 287

•

補正が選択された場合、自動的に補

正の数式がセットされますので、傾き

と基準温度を入力するだけで使用でき

ます。

X2

にはオプションで付加

個目のエンコーダの接続が

のアナログ信号をもったセンサ

X2

のデータは別々に表示もし

の値

の値

X2

と

の和

X2

と

の差

X2

と

の合成

合成位置の特徴

は入力さ

X2

はゼロに設定

が入力さえた場合5が表

)

軸の値が合成されている場合、

に接続されエ

X2

が補正とセットされた場合、

は 1 軸表示となります。

I/O の切り替え

ピンレイアウト

PIN Version 1 Version 2

1

2 I

3 I

4 I

5 I

6 I

7 I

8 I

9 I

10

11

12

13

14 O

15 O

16 O

17 O

18 O

19 O

20

21

22 I

23 I

24 I

25 I

I: 外部入力; O: 外部出力

バ ー ジョン 1 もしくは バ ージョン 2 は加工設定メニューの外部入力機能で選択できます。

外部入力

UL

を入力すると外部入力E が有効

(

接点またはパルスを

信号レベル

– 0.5 V † U

3.9 V † U

t

‡ 30 ms

min

外部出力

ND 287 は0V

Low)

出力信号の遅延

t

† 20 ms

D

信号レベル

U

† 0.4 V

L

U

† 32 V

H

• EN 50 178

外部回路の電源は

ればなりません。

リレ ー 回 路 に 並 列 に な るよう• サージ吸収用ダイオードをつなげて下さい。

外部シールドのあるケーブルを使用して下さい。• シールドはコネクターハウジングへ接

続下さい。

0 V

ゼロ セット、エラーメッセージの削除

基準点の設定

リファレンスマーク信号を無視する (X1)

X1,X2の値の算術計算した値を連続測定値のX1の値の表示表示f(X1,X2)

外部より連続測定の表示値のX1の値の表示 表示X1

連続測定の最小値の表示 表示X2

連続測定の最大値の表示 表示X1+X2

連続測定の最大値と最少値の差の表示 表示X1-X2

0 V

空き

使用せず

使用せず

表示を ゼロとする

測定値がスイッチ限界A1 より大きい または同じ

測定値がスイッチ限界A2 より大きい または同じ

測定値が選別下限より小さい

測定値が選別上限より大きい

エラー

空き

空き

測定値の出力 (パルス)

測定値の出力 (接点)

リファレンスマーク信号を無視する (X2 オプション)

REF を有効もしくは無効

† 0.9 V の時 IL † 6 mA

L

† 15.0 V

H

へ 切り替えること(アクティブ

でオープンコレクター出力が可能です。

:

IL † 100 mA

の時

IH † 10 µA

の時

内部部品に関する注意

残り距 離 表示モードでは、スイッチ出力

スイッチングの範囲を基本としています。

0 V へ).

!

で要求されている低電圧からの分離を満たしていなけ

A1 (

ピン番号

15) と A2 (

ピン番号

Contact

Pulse

16)

は

4

Page 25

DR. JOHANNES HEIDENHAIN GmbH

Dr.-Johannes-Heidenhain-Straße 5

83301 Traunreut, Germany

{ +49 (8669) 31-0

| +49 (8669) 5061

E-mail: info@heidenhain.de

Technical support | +49 (8669) 32-1000

Measuring systems { +49 (8669) 31-3104

E-mail: service.ms-support@heidenhain.de

TNC support { +49 (8669) 31-3101

E-mail: service.nc-support@heidenhain.de

NC programming { +49 (8669) 31-3103

E-mail: service.nc-pgm@heidenhain.de

PLC programming { +49 (8669) 31-3102

E-mail: service.plc@heidenhain.de

Lathe controls { +49 (8669) 31-3105

E-mail: service.lathe-support@heidenhain.de

www.heidenhain.de

Page 26

DR. JOHANNES HEIDENHAIN GmbH

Dr.-Johannes-Heidenhain-Straße 5

83301 Traunreut, Germany

{ +49 (8669) 31-0

| +49 (8669) 5061

E-mail: info@heidenhain.de

www.heidenhain.de

DE HEIDENHAIN Technisches Büro Nord

12681 Berlin, Deutschland

{ (030) 54705-240

E-Mail: tbn@heidenhain.de

HEIDENHAIN Technisches Büro Mitte

08468 Heinsdorfergrund, Deutschland

{ (03765) 69544

E-Mail: tbm@heidenhain.de

HEIDENHAIN Technisches Büro West

44379 Dortmund, Deutschland

{ (0231) 618083-0

E-Mail: tbw@heidenhain.de

HEIDENHAIN Technisches Büro Südwest

70771 Leinfelden-Echterdingen, Deutschland

{ (0711) 993395-0

E-Mail: tbsw@heidenhain.de

HEIDENHAIN Technisches Büro Südost

83301 Traunreut, Deutschland

{ (08669) 31-1345

E-Mail: tbso@heidenhain.de

AR NAKASE SRL.

B1653AOX Villa Ballester, Argentina

{ +54 (11) 47684242

E-mail: nakase@nakase.com

AT HEIDENHAIN Techn. Büro Österreich

83301 Traunreut, Germany

{ +49 (8669) 31-1337

E-mail: tba@heidenhain.de

AU FCR Motion Technology Pty. Ltd

Laverton North 3026, Australia

{ +61 (3) 93626800

E-mail: vicsales@fcrmotion.com

BE HEIDENHAIN NV/SA

1760 Roosdaal, Belgium

{ +32 (54) 343158

E-mail: sales@heidenhain.be

BG ESD Bulgaria Ltd.

Sofi a 1172, Bulgaria

{ +359 (2) 9632949

E-mail: info@esd.bg

BR DIADUR Indústria e Comércio Ltda.

04763-070 – São Paulo – SP, Brazil

{ +55 (11) 5696-6777

E-mail: diadur@diadur.com.br

BY Belarus − RU

CA HEIDENHAIN CORPORATION

Mississauga, Ontario L5T2N2, Canada

{ +1 (905) 670-8900

E-mail: info@heidenhain.com

CH HEIDENHAIN (SCHWEIZ) AG

8603 Schwerzenbach, Switzerland

{ +41 (44) 8062727

E-mail: verkauf@heidenhain.ch

CN DR. JOHANNES HEIDENHAIN

(CHINA) Co., Ltd.

Beijing 101312, China

{ +86 10-80420000

E-mail: sales@heidenhain.com.cn

CS Serbia and Montenegro − BG

CZ HEIDENHAIN s.r.o.

106 00 Praha 10, Czech Republic

{ +420 272658131

E-mail: heidenhain@heidenhain.cz

DK TP TEKNIK A/S

2670 Greve, Denmark

{ +45 (70) 100966

E-mail: tp-gruppen@tp-gruppen.dk

ES FARRESA ELECTRONICA S.A.

08028 Barcelona, Spain

{ +34 934092491

E-mail: farresa@farresa.es

FI HEIDENHAIN Scandinavia AB

02770 Espoo, Finland

{ +358 (9) 8676476

E-mail: info@heidenhain.fi

FR HEIDENHAIN FRANCE sarl

92310 Sèvres, France

{ +33 0141143000

E-mail: info@heidenhain.fr

GB HEIDENHAIN (G.B.) Limited

Burgess Hill RH15 9RD, United Kingdom

{ +44 (1444) 247711

E-mail: sales@heidenhain.co.uk

GR MB Milionis Vassilis

17341 Athens, Greece

{ +30 (210) 9336607

E-mail: bmilioni@otenet.gr

HK HEIDENHAIN LTD

Kowloon, Hong Kong

{ +852 27591920

E-mail: service@heidenhain.com.hk

HR Croatia − SL

HU HEIDENHAIN Kereskedelmi Képviselet

1239 Budapest, Hungary

{ +36 (1) 4210952

E-mail: info@heidenhain.hu

ID PT Servitama Era Toolsindo

Jakarta 13930, Indonesia

{ +62 (21) 46834111

E-mail: ptset@group.gts.co.id

IL NEUMO VARGUS MARKETING LTD.

Tel Aviv 61570, Israel

{ +972 (3) 5373275