Page 1

Operating Instructions

ND 287

English (en)

11/2013

Page 2

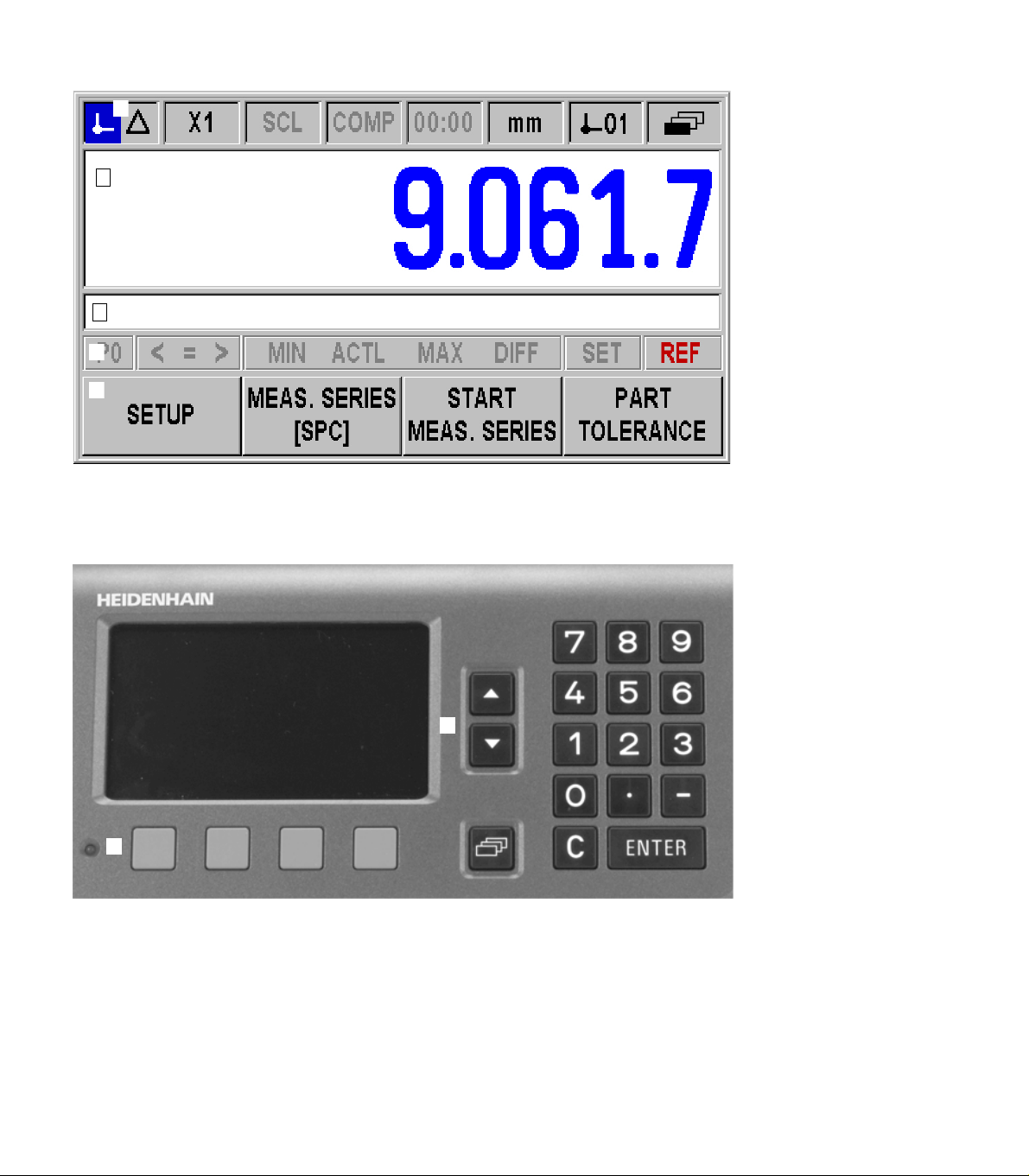

ND 287 screen

12345

7

6

ND 287 front panel

Page 3

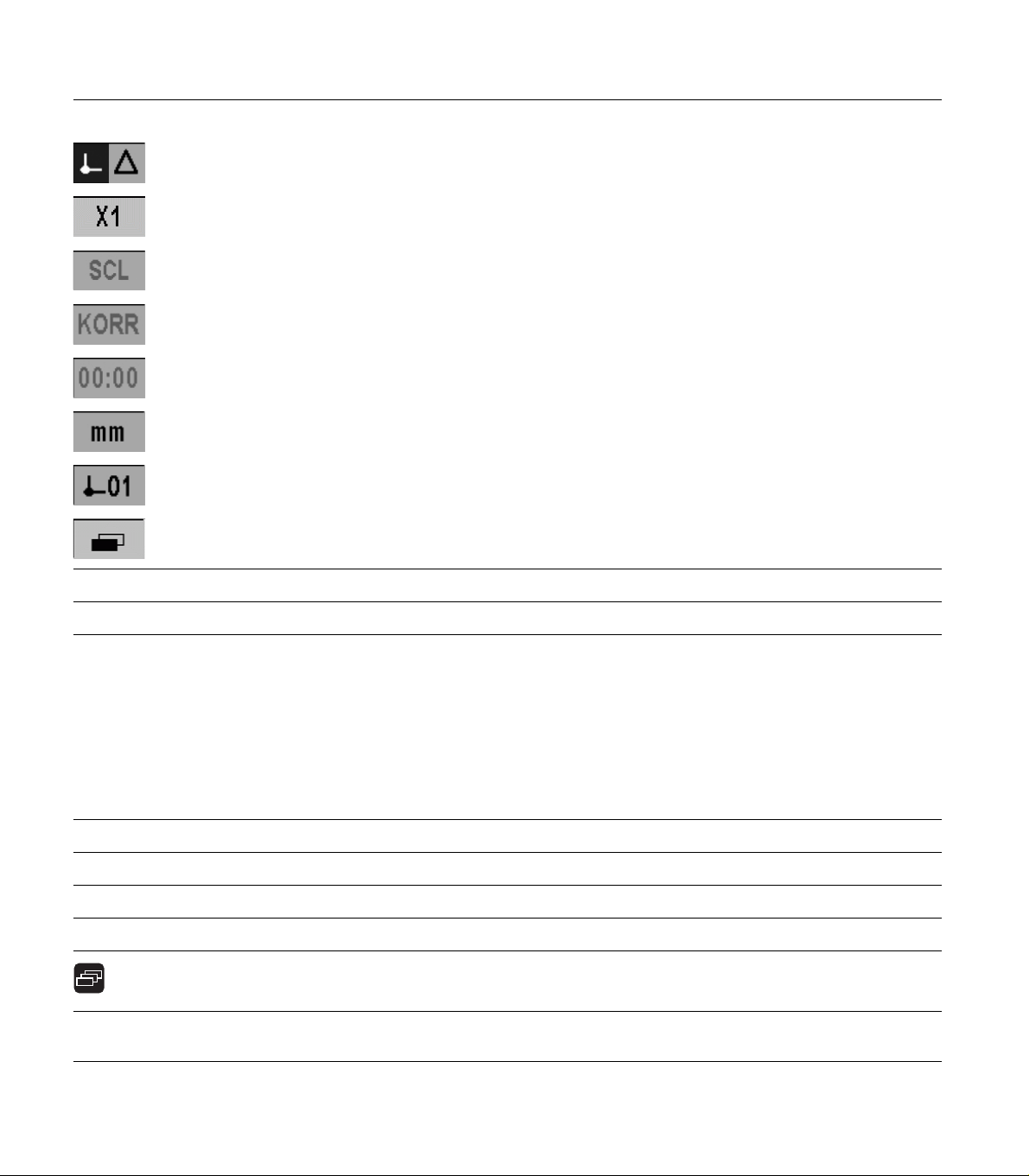

Controls and displays

1 Status bar

Current operating mode: Actual Value, Distance-To-Go

Current display mode for input X1, X2 or coupled axes X1:X2

SCL shown in black: Scaling factor is active

COMP shown in black: Error compensation or axis-error compensation is active for the currently displayed axis

or coupled axes.

Elapsed time of running stopwatch: If the stopwatch is stopped, the box appears dimmed.

mm, inch, DEG, DMS or rad: Currently active unit of measure

Currently active datum: The ND 287 allows you to work with two different datums.

Indicates the soft-key page (soft-key row) you are currently on.

2 Position display: Current position value (length or angle), or other measured value

3 Message line for displaying information, errors or warnings

4 Status display:

<• / = / >: The first three symbols become effective when tolerance checking and sorting mode is activated.

MIN, ACTL or MAX and DIFF: Minimum, current or maximum measured value of a series of measurements,

or difference between minimum and maximum measured value.

SET: If you enter a new value during datum setting, the SET symbol will start flashing.

REF: The REF symbol is flashing until the reference mark evaluation for the displayed axis has been

completed (if an incremental encoder is connected).

P0-P9: Selected part is displayed for the sorting and tolerance checking mode.

5 and 6 Soft keys and soft-key buttons for executing functions

1,2,3,4... Numeric input keys

ENTER Use the ENTER key to confirm your entry or to return to the previous screen.

C Use the C key to clear an entry, acknowledge an error message or return to the previous screen.

The NAVIGATION key moves through the soft-key pages (soft-key rows).

7 Use the UP or DOWN arrow key to move between fields within a form or menu items (parameters) within a

menu.

Page 4

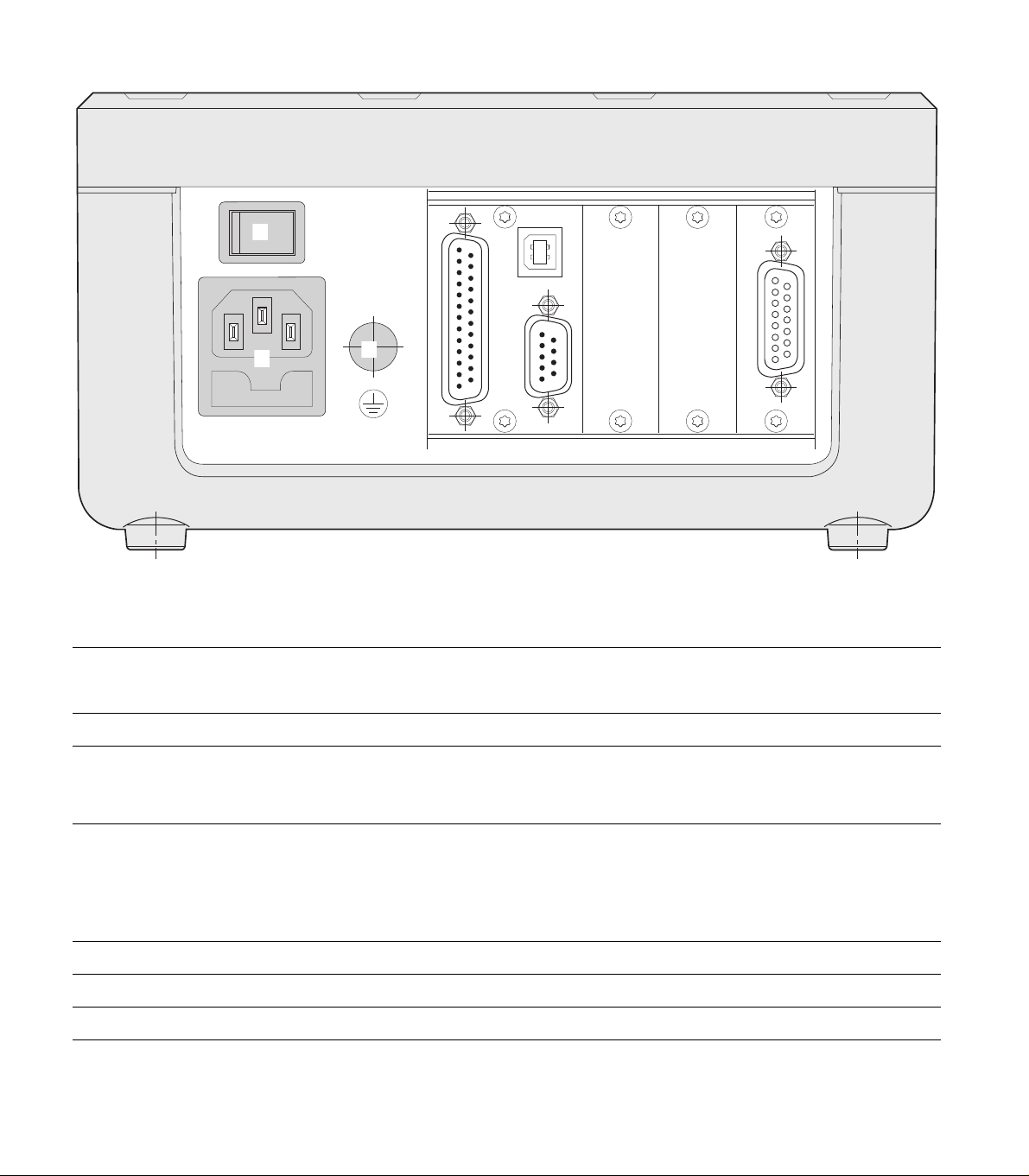

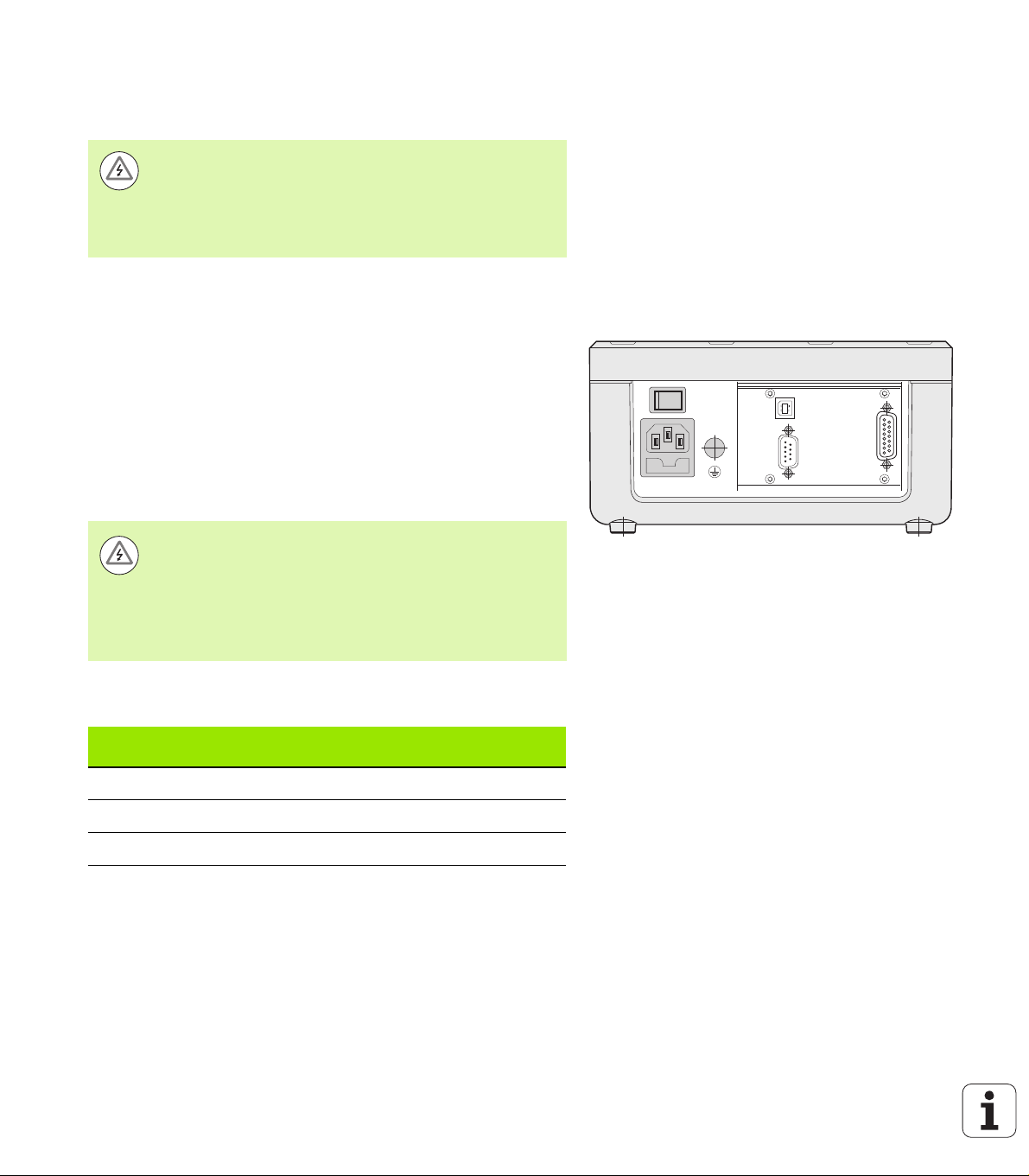

ND 287 rear panel

X1

X2

X26(X27)

X32/X31

X41

123

Connections

1 Power switch

2 Power connection with fuse

3 Ground (protective earthing)

X1 Encoder module for connecting a HEIDENHAIN encoder with 11 µApp, 1 Vpp or EnDat interface (purely

serial)

Option: Analog module for connecting an analog sensor

X2 Optional:

Encoder module for connecting a HEIDENHAIN encoder with 11 µApp, 1 Vpp

for a second axis or

Analog module for connecting an analog sensor, primarily a temperature sensor for axis-error

compensation

X26 (X27) Option: Ethernet module (100baseT) for network connection via TCP/IP protocol

X32/X31 Two serial ports for data transfer: RS-232-C/V.24 (X31) and USB Type B (UART, X32)

X41 Switching inputs and outputs at D-sub connection

or EnDat 2.1/2.2 interface

Page 5

Introduction

Software version

The software version is shown on the power-up screen of the ND 287.

This manual describes the functions that are available in

the ND 287 and the installation of the units.

Symbols within notes

Every note is marked with a symbol on the left indicating to the

operator the type and/or potential severity of the note.

General information

e. g. on the behavior of the ND 287.

Refer to accompanying documents

e.g. when a special tool is required for a function.

Danger to the operator, workpiece or internal

components

e.g. danger of collision

Introduction

Electrical hazard

e. g. danger of electrical shock when opening a housing.

The ND 287 must be prepared by a qualified and

authorized technician to perform this function.

Fonts

The chart below shows how the different variables (soft keys, hard

keys, forms and form fields) are represented within the text of this

manual:

Soft keys – SETUP soft key

Hard keys – ENTER hard key

Menus and forms – UNITS OF MEASURE form

Parameters and input fields – ANGULAR field

Data in fields - ON, OFF

ND 287 5

Page 6

Page 7

I Working with the ND 287 position display unit ..... 13

I – 1 ND 287 position display unit ..... 14

I – 2 Fundamentals of positioning ..... 16

Datums ..... 16

Actual position, nominal position and distance-to-go ..... 17

Absolute workpiece positions ..... 18

Incremental workpiece positions ..... 18

Incremental position encoders ..... 19

Absolute position encoders ..... 19

Reference marks ..... 20

I – 3 Basic functions of the ND 287 ..... 21

ND 287 power-up ..... 21

Reference mark evaluation ..... 22

Working without reference mark evaluation ..... 22

ND 287 shutdown ..... 22

Standard screen layout ..... 23

Soft-key functions on the standard screen ..... 25

Axis display mode ..... 27

Data input ..... 27

Integrated help system ..... 28

Data input forms ..... 29

Instruction box messages ..... 29

Error messages ..... 29

I – 4 Job Setup ..... 30

Operating modes ..... 30

Datum setting ..... 31

Setting the display value for one axis or for two axes in the X1 or X2 display mode ..... 31

Setting the display value for two axes in display mode X1:X2 (applies to X1+X2, X1-X2, f(X1,X2)) ..... 32

Calling the JOB SETUP menu ..... 33

Unit of measure ..... 34

Scaling factor ..... 35

Value for datum point ..... 36

Stopwatch ..... 36

Console adjustment ..... 37

Language ..... 37

Switching signals ..... 38

Measured-value output ..... 39

Function of external inputs ..... 40

Compensation using a reference part ..... 41

ND 287 7

Page 8

I – 5 Series of measurements and statistical process control ..... 42

Functions ..... 42

Switching between series of measurements and SPC mode ..... 42

Calling the SERIES OF MEASUREMENTS menu ..... 43

Analysis of series of measurements ..... 43

Setting up a series of measurements ..... 44

Defining the display for a series of measurements ..... 46

Setting the position or speed display ..... 47

Defining the record mode ..... 47

Starting and stopping a series of measurements ..... 48

Calling the SPC menu ..... 49

SPC analysis ..... 49

Setting up SPC ..... 52

Samples ..... 52

Tolerances ..... 53

Control limits ..... 54

Statistical distribution ..... 55

Measured value recording ..... 55

Deleting SPC statistics ..... 55

Starting and stopping SPC ..... 56

I – 6 Sorting and tolerance checking ..... 58

Sorting function ..... 58

Defining the sorting parameters and part tolerances ..... 59

I – 7 Error messages ..... 60

Overview ..... 60

8

Page 9

II Installation, specifications ..... 63

II – 1 Installation and electrical connection ..... 64

Items supplied ..... 64

Optional accessories ..... 64

Mounting ..... 65

Environmental conditions ..... 65

Mounting location ..... 65

ND 287 – Mounting and installation ..... 65

Electromagnetic compatibility/

CE compliance ..... 66

Electrical connection ..... 67

Electrical requirements ..... 67

Wiring the power connector ..... 67

Grounding ..... 67

Preventative maintenance or repair ..... 68

Connecting the encoders ..... 68

D-sub connection X1/X2 (15-pin, female) for the following input signals ..... 68

Optional: Analog module with ±10 V interface at input X1 or X2 for connecting an analog sensor ..... 69

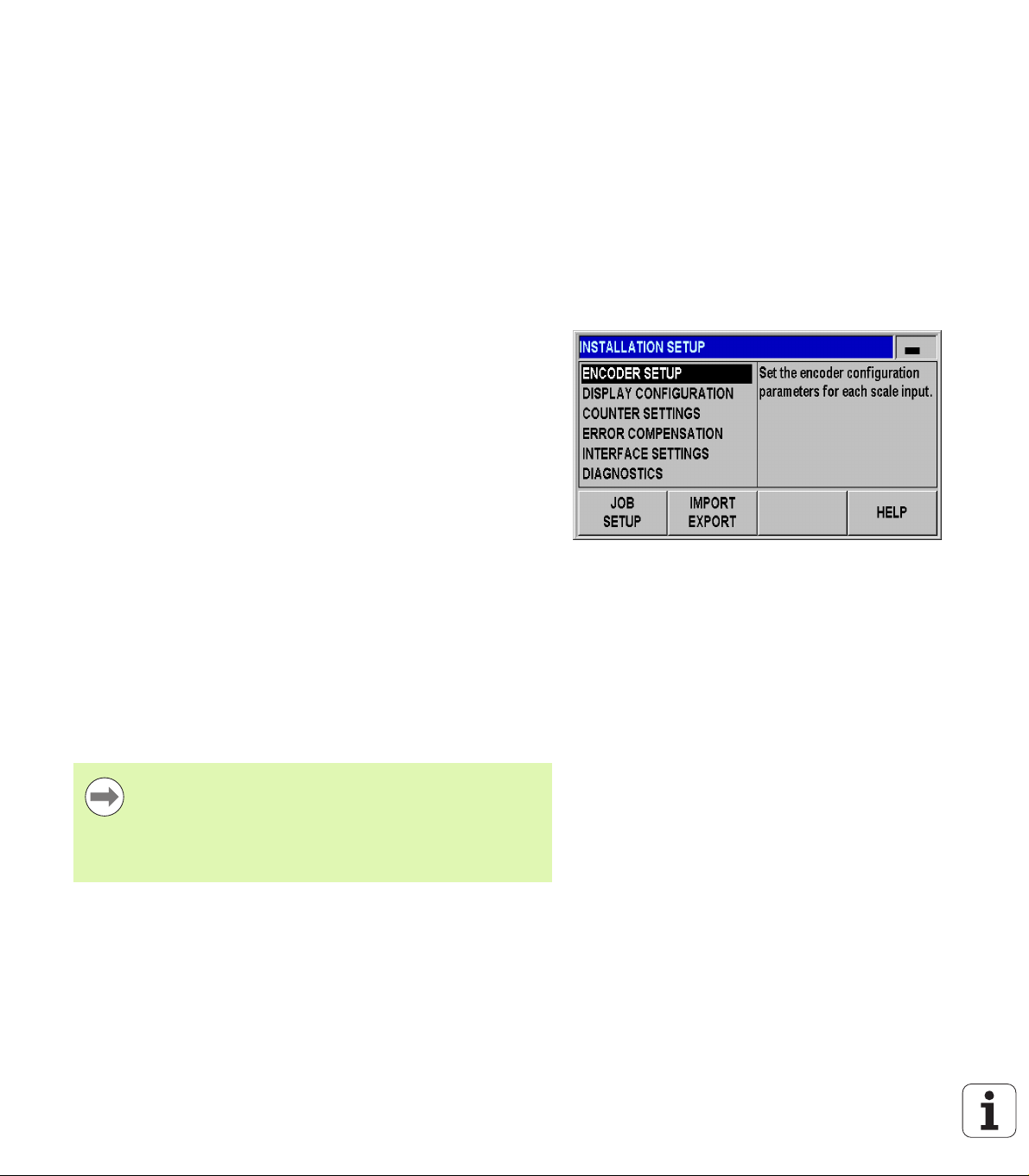

II – 2 Installation Setup ..... 70

INSTALLATION SETUP menu ..... 70

Setting up the encoder ..... 71

Incremental linear encoder ..... 72

Incremental rotary encoder ..... 73

Absolute encoder ..... 74

Using an absolute multiturn rotary encoder as a linear encoder ..... 74

Analog sensor with ±10 V interface, preferably a temperature sensor ..... 75

Configuring the display ..... 76

Linear encoder ..... 76

Rotary encoder ..... 76

Analog sensor for compensation ..... 76

Counter settings ..... 77

Setting the display modes of the axes ..... 78

Formula for coupled position ..... 78

Error compensation ..... 79

Linear error compensation (not for rotary encoders) ..... 80

Non-linear error compensation ..... 81

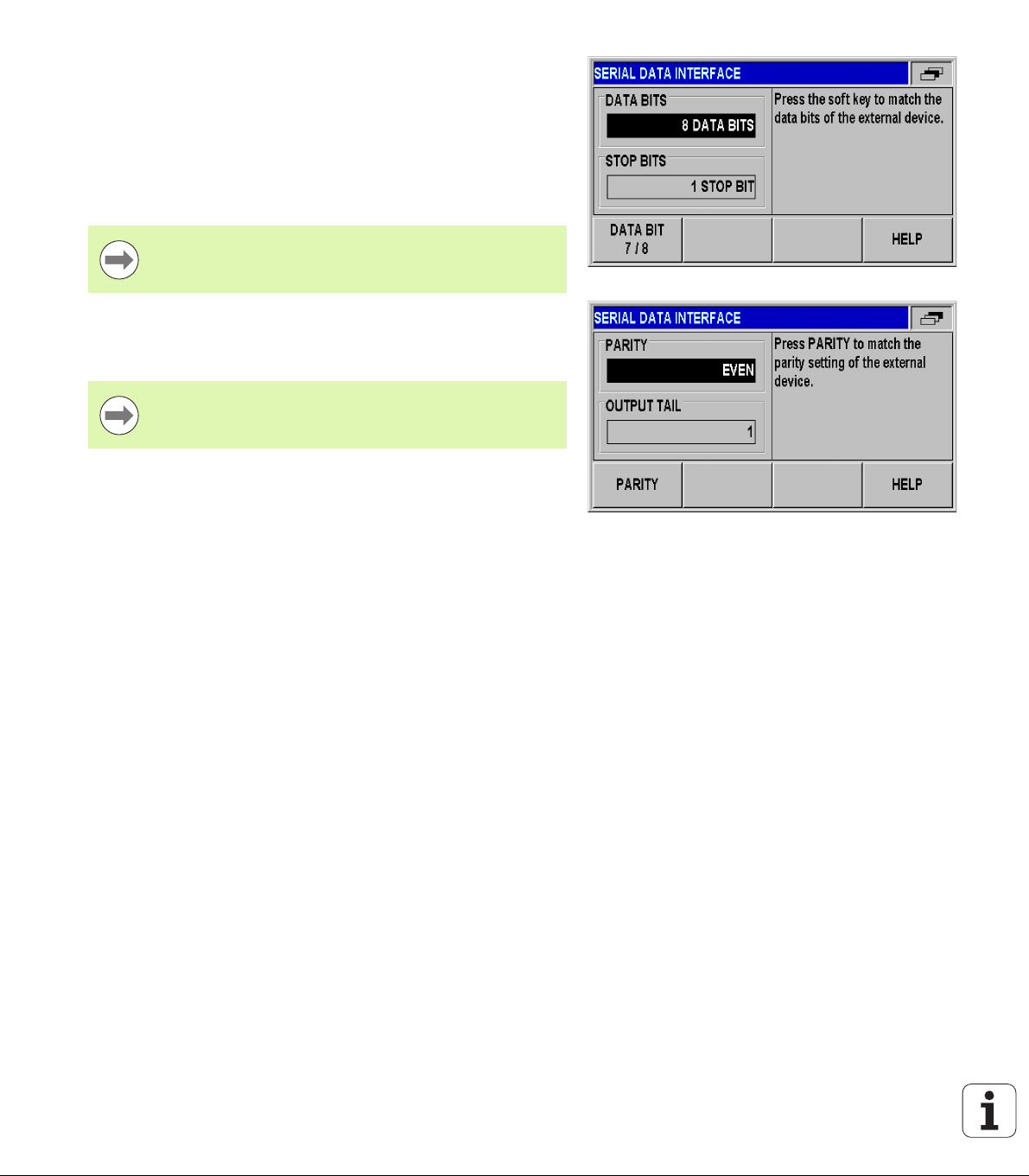

Setting up the serial port ..... 85

Setting up the data interface ..... 85

Diagnostics ..... 87

Keypad test ..... 87

Display test ..... 87

Encoder test ..... 88

Power supply ..... 90

Switching inputs test ..... 91

Switching outputs test ..... 92

ND 287 9

Page 10

II – 3 Switching inputs and outputs ..... 93

Switching inputs at D-sub connection X41 ..... 93

Input signals ..... 94

Signal level of inputs ..... 94

Ignoring the reference mark signals ..... 94

Switching outputs at D-sub connection X41 ..... 95

Output signals ..... 95

Signal level of outputs ..... 95

Trigger limits ..... 96

Sorting limits ..... 97

Trigger signal for error ..... 97

Zero crossover ..... 97

II – 4 Encoder parameters ..... 98

Table values ..... 98

HEIDENHAIN linear encoders ..... 98

HEIDENHAIN rotary encoders ..... 99

II – 5 Data interface ..... 100

Data communication ..... 100

Serial data transfer with the Import or Export function ..... 101

Data transfer from the ND 287 to a printer ..... 101

Data transfer from the ND 287 to a PC ..... 101

Importing data into the ND 287 from a PC ..... 102

Data format ..... 102

Control characters ..... 102

Software update (firmware update) installation ..... 103

Wiring the connecting cable ..... 104

USB Type B (UART), socket as per IEC 61076-3-108 ..... 105

External operation via RS-232-C/V.24 or USB interface ..... 106

Key commands ..... 106

Description of key commands ..... 107

Key is pressed (TXXXX commands) ..... 108

Output of screen contents (AXXXX commands) ..... 108

Execute function (FXXXX commands) ..... 112

Execute special function (SXXXX commands) ..... 112

10

Page 11

II – 6 Measured value output ..... 113

Alternatives for starting measured value output ..... 113

Measured value output after a trigger signal ..... 113

Propagation times ..... 113

Duration of measured value transfer ..... 113

Measured-value output via the serial data interface X31 or X32 ..... 114

Propagation times ..... 114

Duration of measured value transfer ..... 115

Example: Data sequence during measured-value output ..... 115

II – 7 Input and output of parameter list and error compensation table ..... 116

Text file ..... 116

Output format of the parameter list ..... 117

First line ..... 117

Second line ..... 117

Subsequent lines for the individual parameters ..... 117

Last line ..... 117

Examples of parameter lists ..... 118

ND 287 with rotary encoder connected to input X1 ..... 118

ND 287 with two rotary encoders connected to inputs X1 and X2 (optional) ..... 123

Output format of the error compensation table ..... 128

First line ..... 128

Second line ..... 128

Third line ..... 128

Fourth line (only if second axis input is available, optional) ..... 129

Fifth line ..... 129

Sixth line ..... 129

Seventh line ..... 130

Subsequent lines for further compensation values ..... 130

Last line ..... 130

Examples of error compensation tables ..... 131

ND 287 with linear encoder connected to input X1 ..... 131

ND 287 with two linear encoders connected to inputs X1 and X2 (optional) ..... 133

ND 287 with rotary encoder connected to input X1 ..... 135

II – 8 Specifications for ..... 137

ND 287 ..... 137

II – 9 Dimensions ..... 140

ND 287 ..... 140

II – 10 Accessories ..... 141

ID numbers for accessories ..... 141

Mounting the input assemblies ..... 142

Mounting base for installation in 19-inch electrical cabinet ..... 143

ND 287 11

Page 12

12

Page 13

Working with the ND 287 position display unit

ND 287 13

Page 14

I – 1 ND 287 position display unit

The ND 287 position display unit from HEIDENHAIN is designed for

measuring devices, adjustment and testing equipment, automated

tasks, as well as infeed and positioning tasks with up to two axes that

can be moved manually.

Linear/angular/rotary encoders, length gauges or analog sensors can

be connected to the ND 287. The ND 287 features two slots for the

connection of modular input assemblies:

An encoder module for connecting an incremental photoelectrical

HEIDENHAIN encoder with sinusoidal 11 µApp, 1 Vpp signals or an

absolute HEIDENHAIN encoder with bidirectional EnDat interface

(purely serial) is a standard item supplied with the position display

unit.

Optional modules that can be easily adapted to the ND's

requirements:

Second encoder module for connecting a HEIDENHAIN encoder

with 11 µApp, 1 Vpp or EnDat interface (purely serial) or

Analog module for connecting an analog sensor with ±10 V

interface, primarily a temperature sensor for axis-error

I – 1 ND 287 position display unit

compensation

Sorting and tolerance checking function with capacity for saving

the tolerances of 10 parts

The following functions are available on the ND 287:

Multilingual user guidance: Language can be selected by the user

REF reference-mark evaluation for distance-coded or single

reference marks

Display of position value (length or angle), traversing speed for

series of measurements or other measured values from analog

sensors

Distance-To-Go or Actual Value operating mode

Two datums

Scaling factor

Stopwatch

Reset or Preset function, also through external signal

Linear or non-linear error compensation for axis-error

compensation

Switching inputs and outputs

Fig. I.1 ND 287

14 I Working with the ND 287 position display unit

Page 15

Series of measurements:

Sorting measured values and finding the Minimum, Maximum,

Sum, Difference or a definable coupled position value.

Displaying the sorting results in order to intervene, if necessary.

Memory capacity for series of measurements: Up to 10 000

measured values per axis.

Analysis of series of measurements: Arithmetical mean value,

standard deviation, graphical representation of all measured

values with minimum, maximum and mean value of the series of

measurements.

Measured-value acquisition by external signal or selectable

sampling interval, or by pressing the ENTER key.

Statistical Process Control (SPC):

Calculation of arithmetical mean value, standard deviation and

range. Displaying graphs or histograms with symmetrical or

asymmetrical density function.

Process capability indices c

mean value, standard deviation and range.

Measured-value acquisition by external signal or by pressing the

ENTER key.

FIFO memory capacity: Up to 1000 measured values.

There are two serial ports for transmitting measured values,

compensation values or configuration parameters to a PC or printer:

The data can be transferred via the RS 232-C/V.24 or the USB Type

B (UART) interface. It is also possible to download software via the

serial interface.

Diagnostic functions for testing the encoder, the keyboard, the

screen, the supply voltage and the switching inputs/outputs.

On the ND 287, one measured value can be displayed in large

characters on the screen at any one time. If two encoders are

connected to the ND, you can switch the display from the position

value supplied by the first encoder to the position value supplied by

the second encoder, or to a defined coupled position value.

The integrated help system provides information and assistance in

any situation.

and cpk, quality control charts for

p

I – 1 ND 287 position display unit

ND 287 15

Page 16

I – 2 Fundamentals of positioning

?

Z

?

?

?

?

0

Z

10

20

30

40

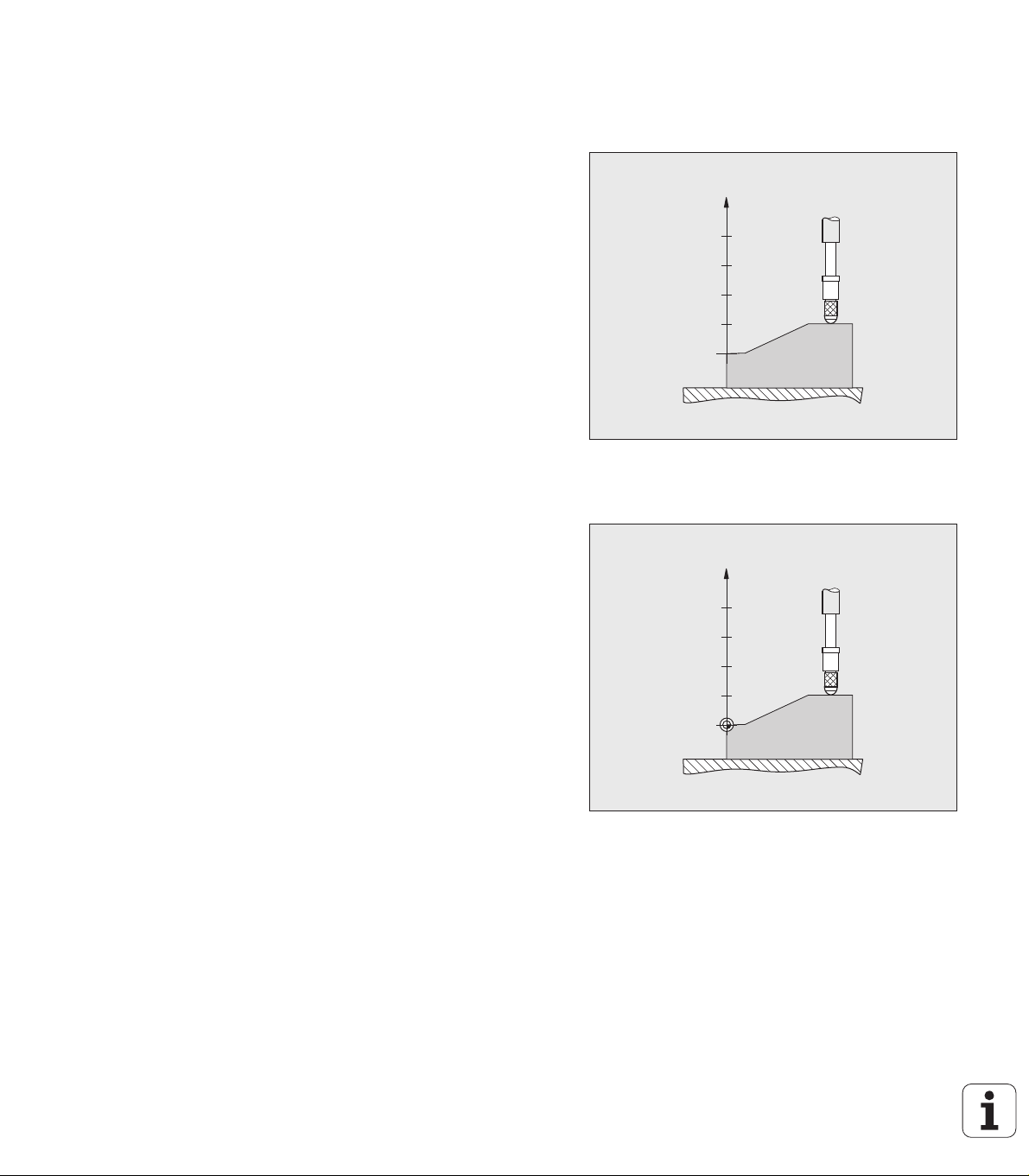

Datums

The workpiece drawing identifies a certain point on the workpiece

(usually a corner) as the absolute datum and perhaps one or more

other points as relative datums.

The datum setting procedure establishes these points as the origin of

the absolute or relative coordinate systems. The workpiece, which is

aligned with the machine axes, is moved to a certain position relative

to the length gauge and the display is set either to zero or to another

appropriate value.

I – 2 Fundamentals of positioning

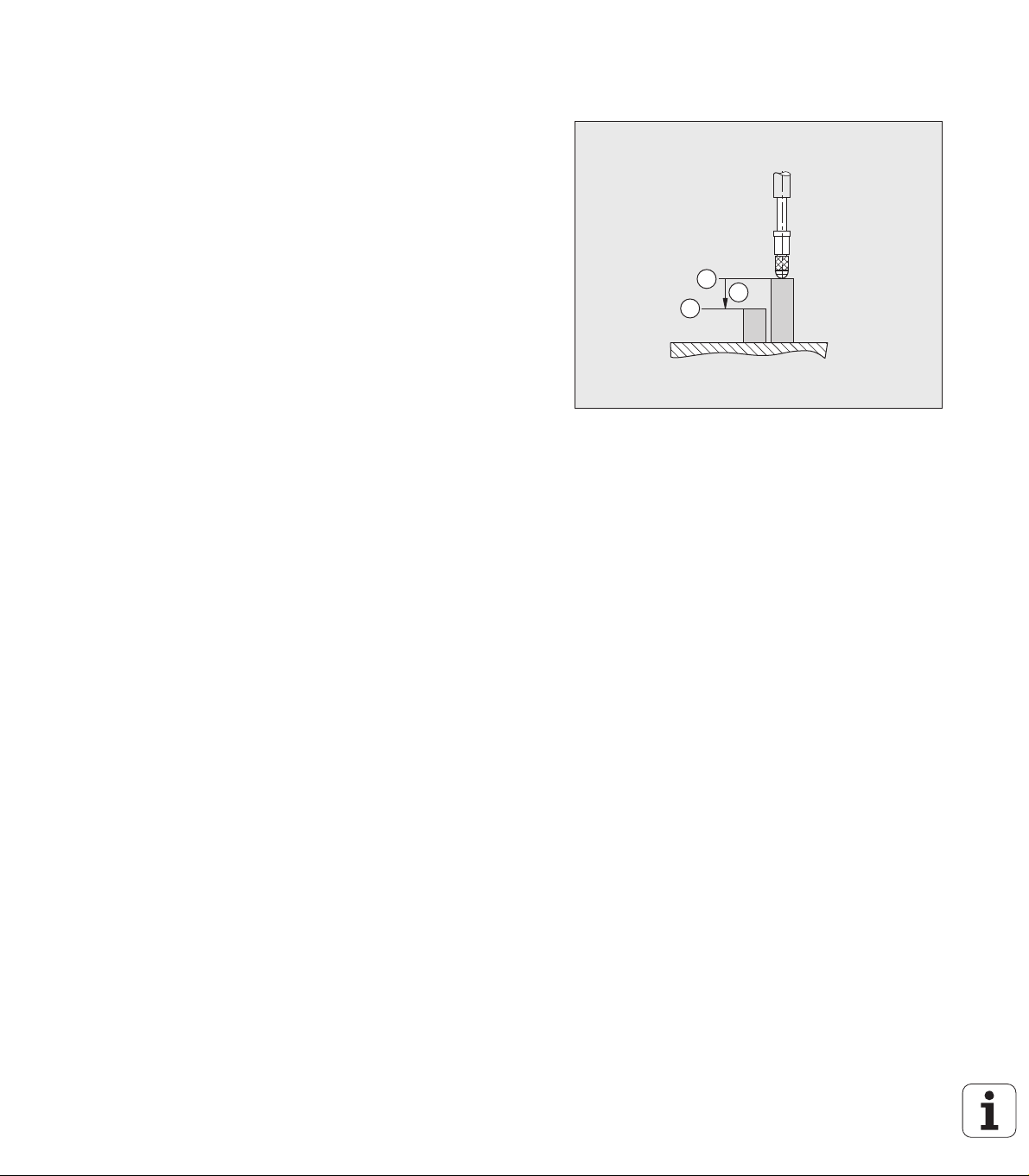

Fig. I.2 Length gauge without datum setting:

Unknown assignment of measured values

to positions

Fig. I.3 Length gauge with datum setting: Known

assignment of measured values to positions

16 I Working with the ND 287 position display unit

Page 17

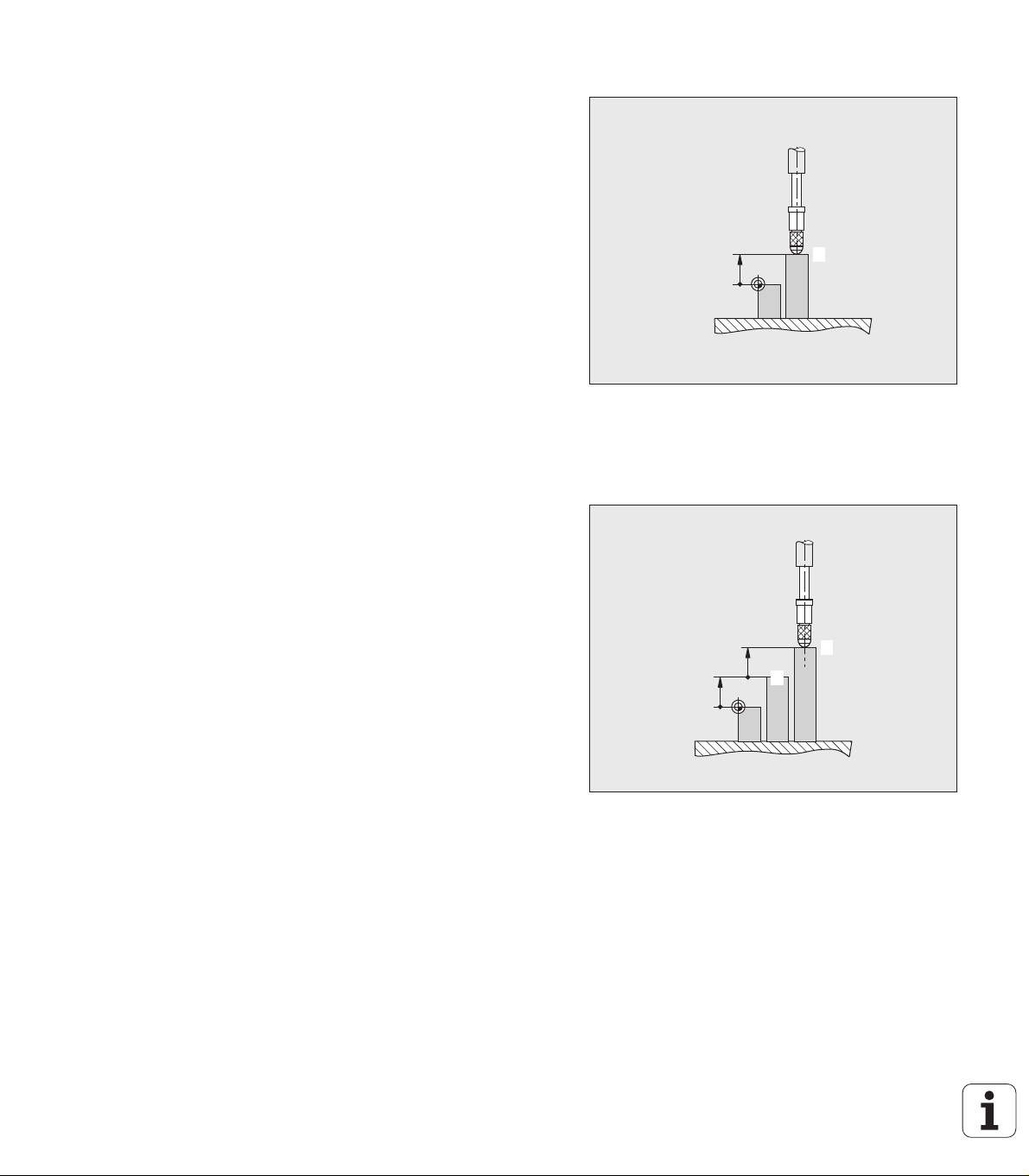

Actual position, nominal position and

R

I

S

distance-to-go

The position of the length gauge at any given moment is called the

actual position, while the position that the length gauge is to move

to is called the nominal position. The distance from the nominal

position to the actual position is called the distance-to-go (see Fig.

I.4).

Fig. I.4 Nominal position S, actual position I and

distance-to-go R

I – 2 Fundamentals of positioning

ND 287 17

Page 18

Absolute workpiece positions

0

20

1

0

10

10

2

3

Each position on the workpiece is uniquely identified by its absolute

coordinates (see Fig. I.5).

Example: Absolute coordinates of position 1: Z = 20 mm

If you are drilling or milling a workpiece according to a workpiece

drawing with absolute coordinates, you are moving the tool or length

gauge to the value of the coordinates.

Incremental workpiece positions

I – 2 Fundamentals of positioning

A position can also be referenced to the preceding nominal position.

For this, the relative datum must be set to the preceding nominal

position. Such coordinates are referred to as incremental

coordinates (increment = increase). They are also called incremental

or chain dimensions (since the positions are defined as a chain of

dimensions). Incremental coordinates are identified by a preceding I.

Example: Incremental coordinate of position 3 referenced to position

2 see Fig. I.6.

Absolute coordinate of position 2: Z = 10 mm

Incremental coordinates of position 3: IZ = 10 mm

If you are drilling or milling a workpiece according to a workpiece

drawing with incremental coordinates, you are moving the tool or

length gauge by the value of the coordinates.

Fig. I.5 Position 1: definition through absolute

coordinates

Fig. I.6 Position 3: definition through incremental

coordinates

18 I Working with the ND 287 position display unit

Page 19

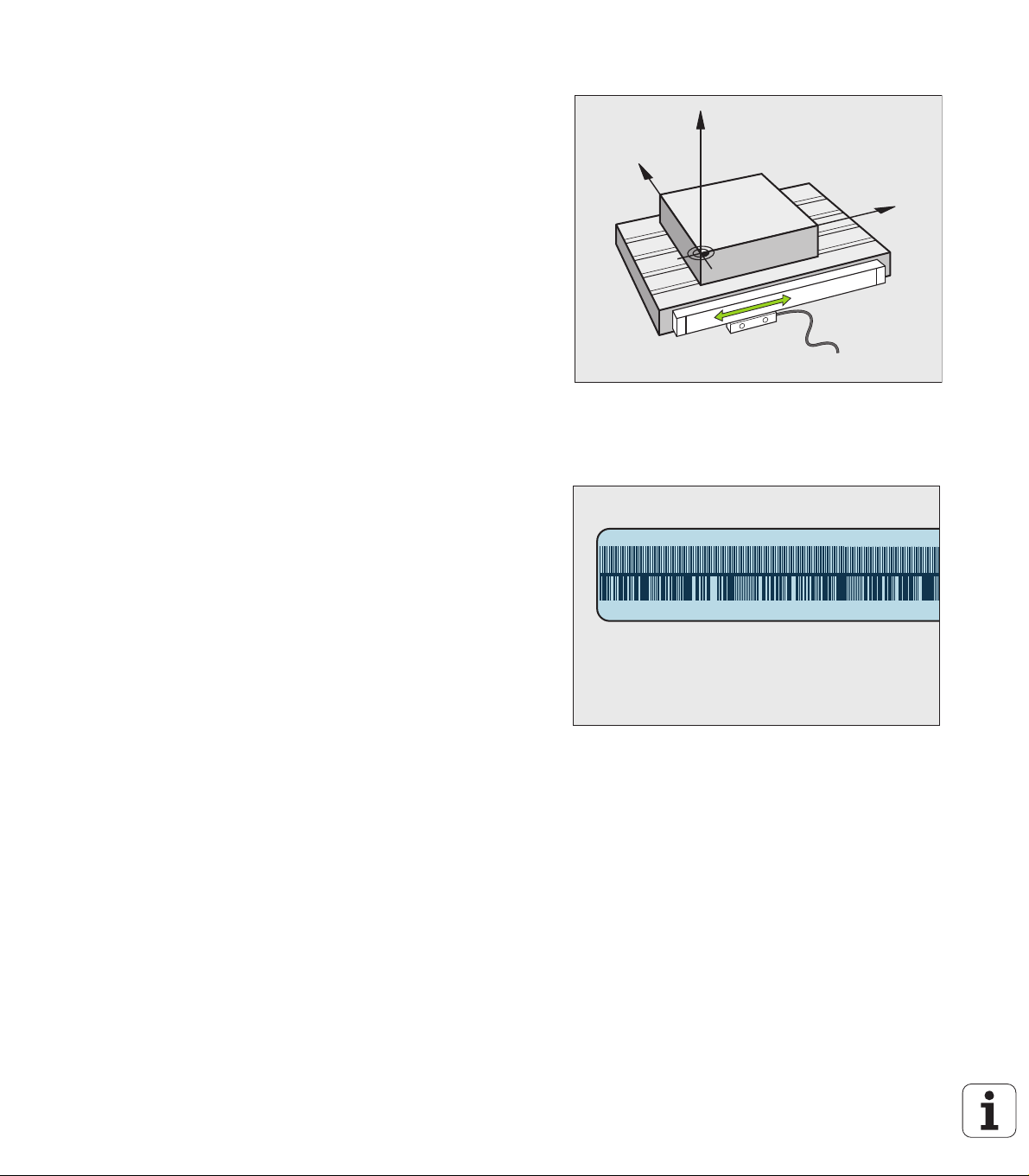

Incremental position encoders

Y

X

Z

Incremental linear and rotary encoders from HEIDENHAIN convert the

movements of, for example, a length gauge into electrical signals. A

position display unit, such as the ND 287, constantly evaluates these

signals and calculates the actual positions of the length gauge, which

it displays as a numerical value on the screen.

If there is a power interruption, the calculated position will no longer

correspond to the actual position of the length gauge. When power is

restored, you can re-establish this relationship with the aid of the

reference marks on the position encoders and the ND 287's reference

mark evaluation feature.

Absolute position encoders

Fig. I.7 Linear position encoder, here for the X axis

Absolute linear and angle encoders from HEIDENHAIN transmit the

absolute position value to the position display unit immediately after

switch-on. This way the assignment of the actual position to the

position of, for example, a length gauge is re-established directly after

switch-on.

The encoder reads the absolute position information directly from the

scale graduation (see Fig. I.8), and transmits it serially to the position

display unit via the bidirectional EnDat interface.

I – 2 Fundamentals of positioning

Fig. I.8 Scale grating for absolute position encoders

ND 287 19

Page 20

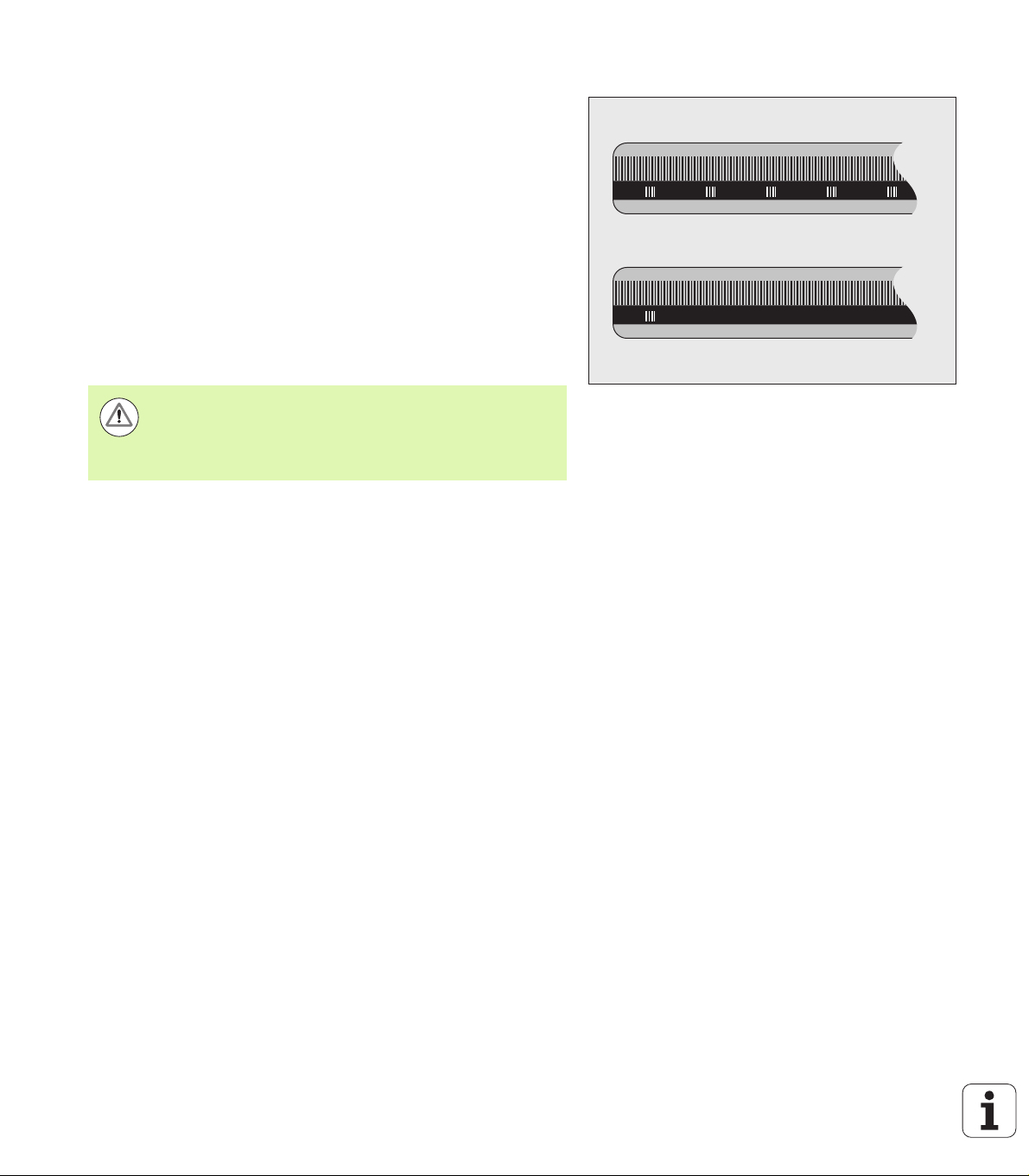

Reference marks

Encoders normally contain one or more reference marks (see Fig. I.9)

which the ND 287's reference mark evaluation feature uses to reestablish datum positions after a power interruption. There are two

main options available for reference marks: fixed and distance-coded.

Encoders with distance-coded reference marks have marks

separated by a specific encryption pattern that allows the ND 287 to

use any two pair of marks along the length of the encoder to reestablish the prior datums. This configuration means that the operator

only has to travel a very short distance, anywhere along the encoder,

to re-establish the datums when the ND 287 is turned back on.

Encoders with fixed reference marks have one or more marks on

fixed intervals. To re-establish the datums correctly, it is necessary to

use the same exact reference mark, during the reference mark

evaluation routine, that was used when the datum was first

established.

Danger to workpiece!

The established datums cannot be restored from one

power cycle to the next if the reference marks were not

crossed before the datums were set.

I – 2 Fundamentals of positioning

Fig. I.9 Linear scales – with distance-coded

reference marks (upper illustration) and one

reference mark (lower illustration)

20 I Working with the ND 287 position display unit

Page 21

I – 3 Basic functions of the ND 287

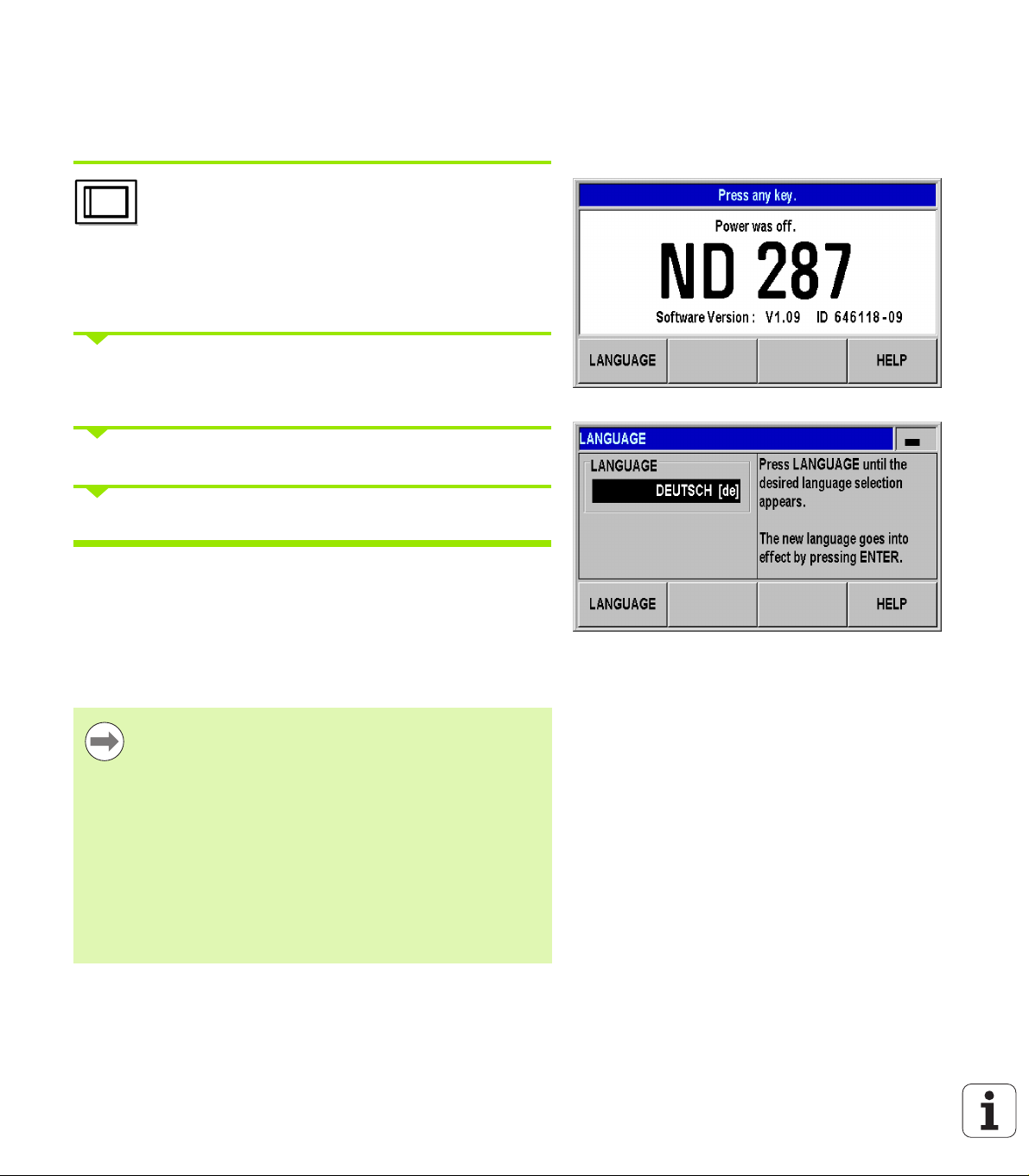

ND 287 power-up

Switch on the ND 287. The power switch is located

on the back of the ND. After switching the ND 287 on,

or after a power failure, the power-up screen will

appear (see Fig. I.10). The green LED on the front

panel lights up. The power-up screen shows the

position display unit model as well as the ID and

version number of the currently installed software.

Press the LANGUAGE soft key if you want to change the

conversational language (see Fig. I.11). Press ENTER to confirm your

selection.

Press the HELP soft key to call the integrated help system.

Fig. I.10 Power-up screen

Press any key to call the standard screen.

Your ND 287 is now ready for operation in the Actual Value operating

mode. If an incremental encoder is connected to the ND, the REF

symbol is flashing. At this point the reference mark evaluation should

be completed (see "Reference mark evaluation" on page 22).

If an absolute encoder is connected to the ND, the encoder

automatically transmits the absolute position value to the position

display unit.

If necessary, you can change the language later, see

"Language" on page 37.

To update your software version (firmware version), see

"Software update (firmware update) installation" on page

103.

The idle time after which the ND activates the screen

saver can be defined (factory default setting: 120 min,

see "Console adjustment" on page 37). The red LED on

the front panel lights up. To reactivate the screen, press

any key or move the encoder.

You can deactivate the power-up screen in order to

display the standard screen immediately after power up

(see "Counter settings" on page 77).

I – 3 Basic functions of the ND 287

Fig. I.11 Selecting the language

ND 287 21

Page 22

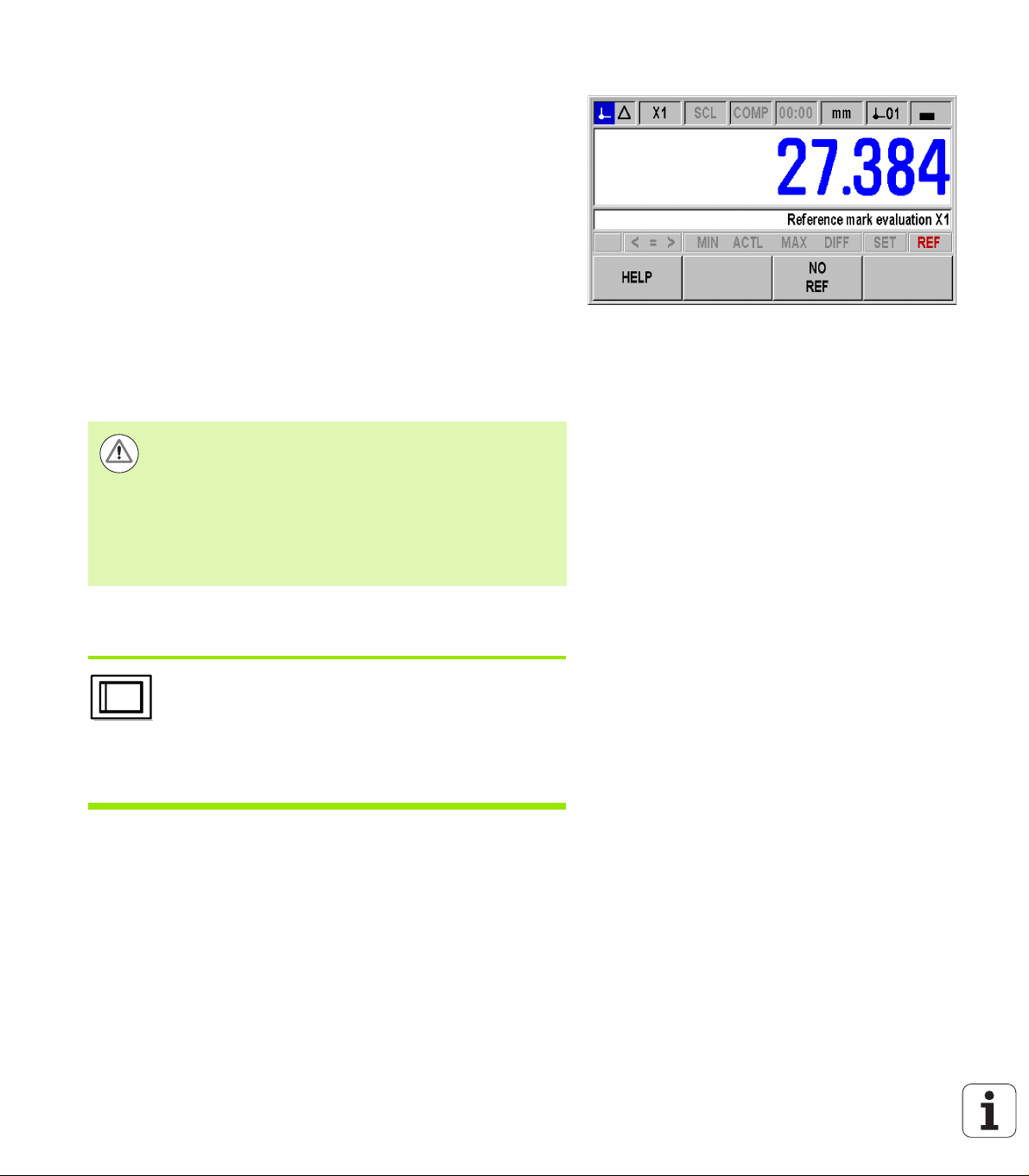

Reference mark evaluation

The ND 287's REF reference mark evaluation feature automatically reestablishes the relationship between axis-slide or length gauge

positions and display values that you last defined by setting the datum.

Reference mark evaluation if an incremental encoder is connected

(see Fig. I.12):

If the REF symbol is flashing, cross over the reference marks.

The REF mark evaluation feature determines the correct display

value and the REF symbol stops flashing.

Working without reference mark evaluation

Press the NO REF soft key to exit the reference mark evaluation

routine and continue.

In order to activate the reference mark evaluation feature at a later

time, you can apply an external signal to pin 25 at connection X41

(see "Setting up the encoder" on page 71), or you can switch the

ND 287 off and then back on.

Danger to workpiece!

If an encoder is set up without reference marks, or if the

I – 3 Basic functions of the ND 287

reference marks have not been crossed over, then the

REF indicator will appear dimmed, and datums set from

any axis will be lost once power is turned off. This means

that it is not possible to re-establish the relationship

between axis slide positions and display values after a

power interruption (switch-off).

Fig. I.12 Screen for establishing reference marks

ND 287 shutdown

Switch off the ND 287. The measured values of a

series of measurements will not be retained on a

power cycle. The parameter settings, the error

compensation tables or measured values that have

been saved during statistical process control will stay

in memory.

22 I Working with the ND 287 position display unit

Page 23

Standard screen layout

1

432

5

In addition to displaying position information, the ND 287 standard

screen also displays information on settings and operating modes at

any time (see Fig. I.13). The standard screen is divided into the

following areas:

1 Status bar

Current operating mode: Actual Value,

Distance-To-Go.

X1, X2 or X1:X2: Current display mode of axis or coupled axes.

SCL shown in black: Scale factor is active.

COMP shown in black: The error compensation or axis-error

compensation is active for the currently displayed axis or

coupled axes.

Elapsed time of running stopwatch: If the stopwatch is

stopped, the box appears dimmed.

MM, INCH, DEG, DMS or RAD: Currently active unit of

measure.

Currently active datum: The ND 287 allows you to work with

two different datums.

Indicates the soft-key page (soft-key row) you are currently on.

2 Position display

Length display:

Current axis value with algebraic sign.

Angle display:

Current angle value with algebraic sign and unit of measure for

display values in degrees, minutes or seconds.

When displaying the traversing speed in the series of

measurements mode, the ND 287 shows the unit of speed in

lowercase at the left edge of the screen.

3 Message line

The message line provides information on the required data

input or procedures, which is intended to support you in using

the position display unit.

If errors or warnings occur, they show up in red letters in the

message line. Acknowledge the message with the C key.

At the left edge of the message line the ND 287 displays a

measured-value counter in the series of measurements mode,

and a sample counter in the SPC mode.

If you have activated axis-error compensation with a

temperature sensor, the ND shows the value measured by the

temperature sensor at the left edge of the message line.

If a multiturn rotary encoder is connected, the ND shows the

number of revolutions at the right edge of the message line.

Fig. I.13 Standard screen

I – 3 Basic functions of the ND 287

ND 287 23

Page 24

4 Status display

5 Soft keys

I – 3 Basic functions of the ND 287

P0-P9: The symbol for the selected part becomes active once

you have activated the sorting and tolerance checking mode.

< / = / >: The first three symbols become active once you have

activated the tolerance checking and sorting mode, as well as

during Statistical Process Control (SPC). The symbols are

shown in red if the current value is less than the lower sorting

limit or greater than the upper sorting limit. Green indicates that

the value is within the two sorting limits.

MIN, ACTL or MAX and DIFF: The symbols are only active,

while a series of measurements is running. They indicate the

display mode you have selected.

Set: If you enter a new value during datum setting, the SET

symbol will start flashing.

REF: The REF symbol is flashing in red until the reference mark

evaluation for the displayed axis has been completed (if an

incremental encoder is connected).

The NAVIGATION key (shown at left) allows you to move

through the three pages of selectable soft-key functions.

Press the corresponding soft key directly below each soft

key label to execute the soft-key function. The soft-key

assignment varies depending on the ND's operating

mode.

24 I Working with the ND 287 position display unit

Page 25

Soft-key functions on the standard screen

There are three pages (rows) of soft-key functions. Use the

NAVIGATION key (shown at left) to move through the pages.

The page indicator in the status bar shows the number of

pages. The darkened page indicates the page you are currently

on. This manual provides more information about each soft key

on the pages indicated in the table below.

Soft key page 1:

Soft key Function Page

SETUP Opens the JOB SETUP menu and

provides access to the

INSTALLATION SETUP soft key.

Page 30

Fig. I.14 Page indicator

MEAS.

SERIES

START MEAS.

SERIES

SPC Opens the SPC menu. Page 49

START

SPC

PART

TOLERANCE

Soft key page 2:

Soft key Function Page

HELP Calls the integrated help system. Page 28

PRINT Transmits the current measured

Distance-to-goonSwitches the display between

MM

inch

DEG

DMS

rad

Opens the SERIES OF

MEASUREMENTS menu.

Starts a series of measurements. Page 48

Starts the SPC function. Page 56

Opens the SELECT PART menu. Page 58

value to a connected PC or printer

via the serial interface.

operating modes Actual Value/

Distance-To-Go.

Switches the position display

(length or angle) to the displayed

unit of measure. The selected unit

of measure is shown in the status

bar.

Page 42

Page 113

Page 30

Page 34

I – 3 Basic functions of the ND 287

Soft key page 3:

ND 287 25

Page 26

Soft key Function Page

X1

[X2]

DATUM Switches the datum (see datum display in the status bar). Page 31, Page 36,

This function is only available if the ND is configured for two axes:

Switches the display mode in the status bar (X1, X2, X1:X2) and the display

value.

The upper axis designation indicates the displayed axis, here X1. The lower

axis designation in brackets (here, X2) appears in the respective field if you

press the soft key again. Press the soft key repeatedly for the following

display values: X1, X2, X1+X2, X1-X2 and formula f(X1, X2).

Page 27, Page 77

I – 3 Basic functions of the ND 287

PRESET Sets the axis value to the preset value for the datum.

If a coupled position X1:X2 is active, the ND sets X1 to the preset value for

the datum and resets X2 to zero..

RESET Actual Value mode: Resets the selected datum of the displayed axis to zero.

MEASURE

REF. PART

If a coupled position is active, the ND resets the selected datum for both axes

to zero.

Distance-To-Go mode: Resets the distance-to-go for the displayed axis to

zero. If a coupled position is active, the ND resets the distance-to-go for both

axes to zero.

Display the measured values of a reference part: If temperature compensation

using a reference part is activated, the ND 287 displays the actual measured

temperature value on the left side of the message line, and the entered nominal

dimension of the reference part on the right side.

Page 31

Page 31

Page 41

26 I Working with the ND 287 position display unit

Page 27

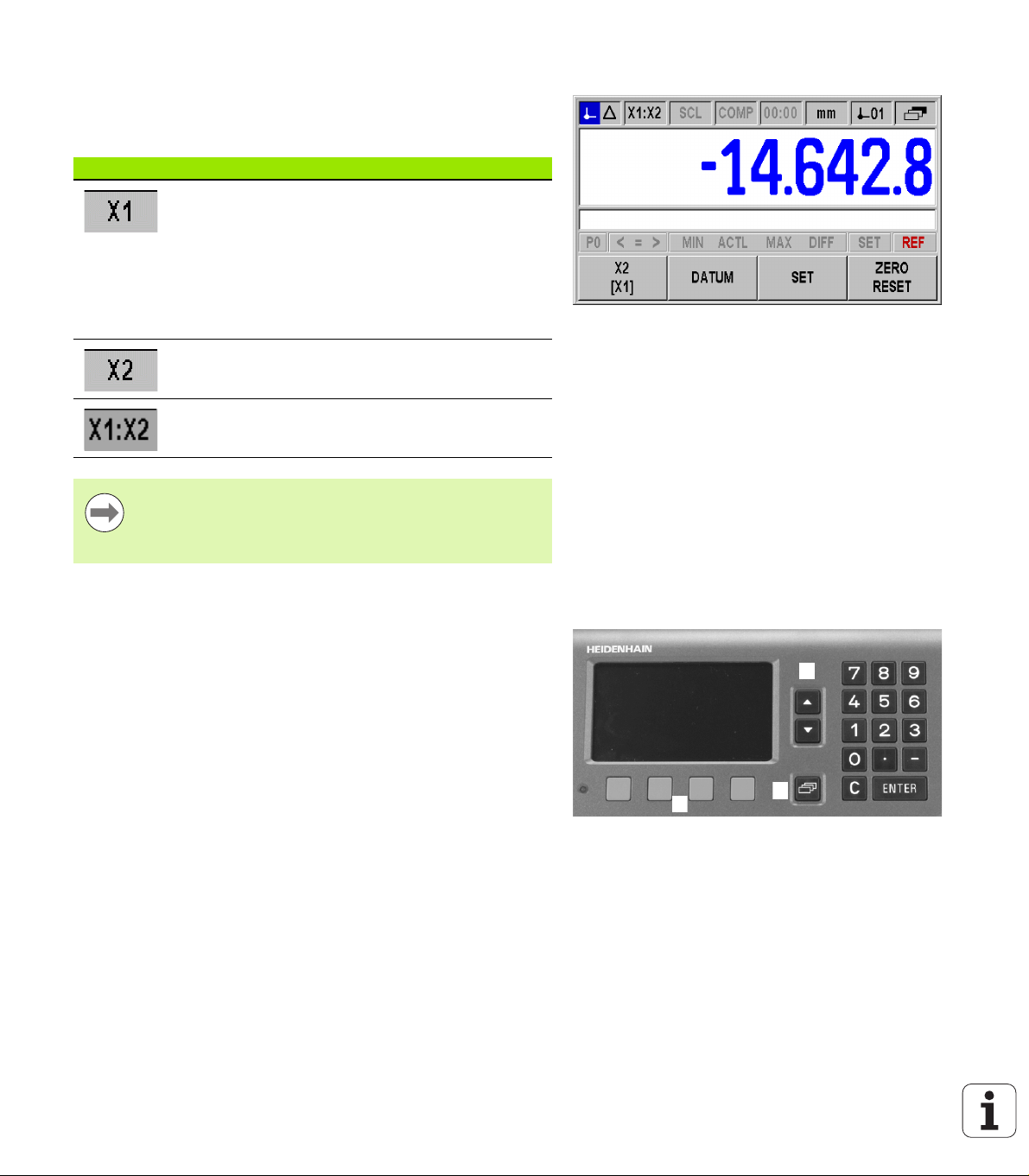

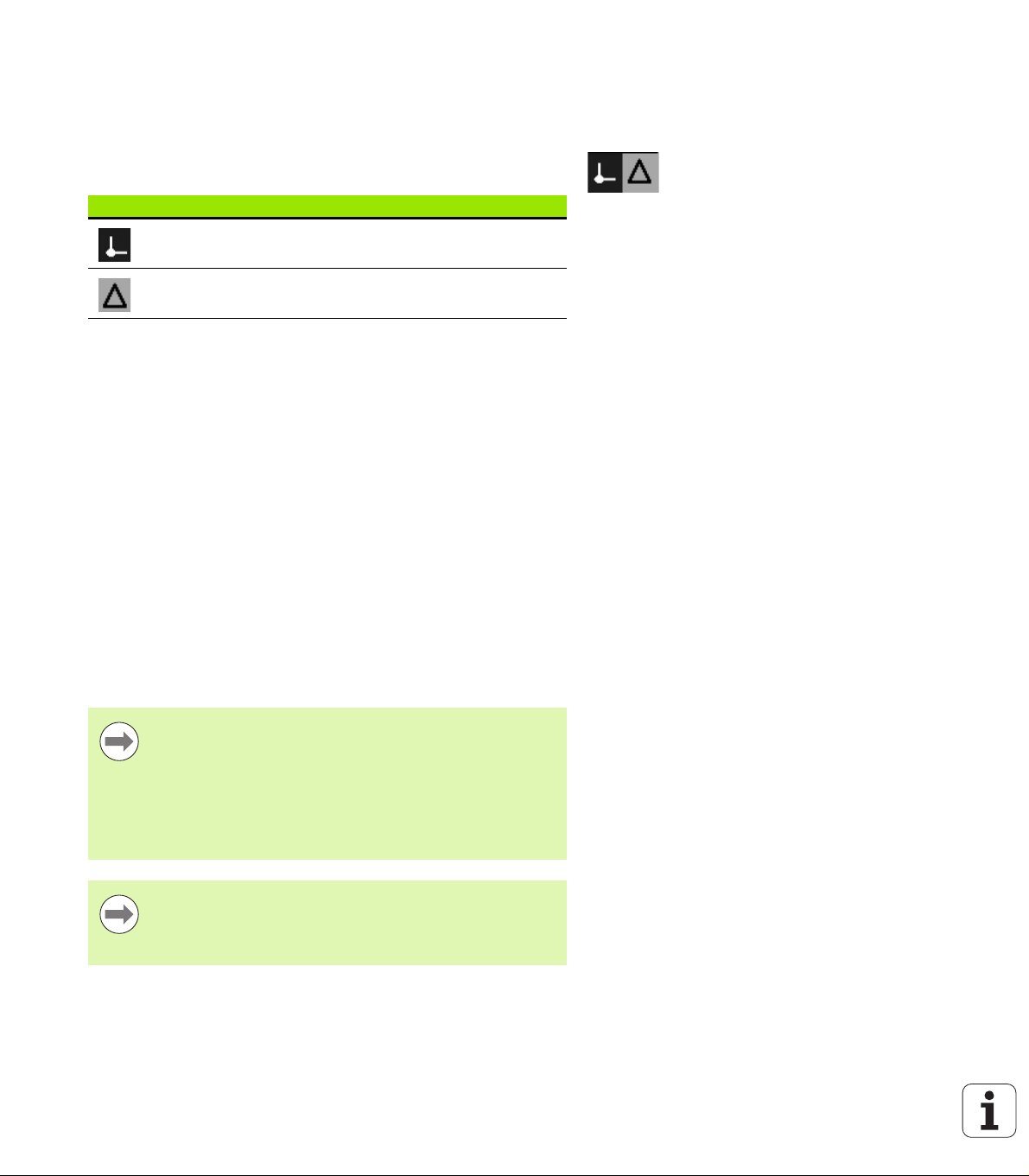

Axis display mode

123

Press the X1-X2 [f(X1,X2)] soft key to select the desired display mode

and the corresponding display value (see "Soft-key functions on the

standard screen" on page 25):

Status bar Function

Display mode of axis X1 or input X1

If an analog sensor is connected to

input X2 and the ENCODER TYPE

field under Encoder Setup is set to

COMPENSATION, (see "Setting up

the encoder" on page 71) the ND 287

behaves in the same way as a singleaxis display unit (only X1).

Display mode of axis X2 or input X2

Display mode for both axes: Display for

X1+X2, X1-X2 or f(X1,X2).

Fig. I.15 Standard screen with soft-key page 3

If you want to enter a formula for (X1,X2), select the

formula editor, see "Counter settings" on page 77. There

you can also define the possible display modes of the

axes.

Data input

Use the keypad to enter numeric values within each field.

The ENTER key will confirm the entry within a field and return to the

previous screen.

Press the C key to clear entries, acknowledge error messages or

return to the previous screen.

Soft-key labels 1 show the various operating and parameter-setting

functions. These functions are selected by pressing the

corresponding soft key directly below each soft key label. The

soft-key functions are usually arranged in up to three soft-key pages.

Use the NAVIGATION key 2 to move through the soft-key pages

(see below).

The NAVIGATION key 2 moves through the pages of available

soft-key functions. The current page will be highlighted in the status

bar at the top of the screen.

Use the UP or DOWN arrow key 3 to move between fields within a

form or menu items (parameters) of a menu. The orientation of the

cursor is such that it will return to the top once it has reached the

bottom of the menu.

I – 3 Basic functions of the ND 287

Fig. I.16 Data input

ND 287 27

Page 28

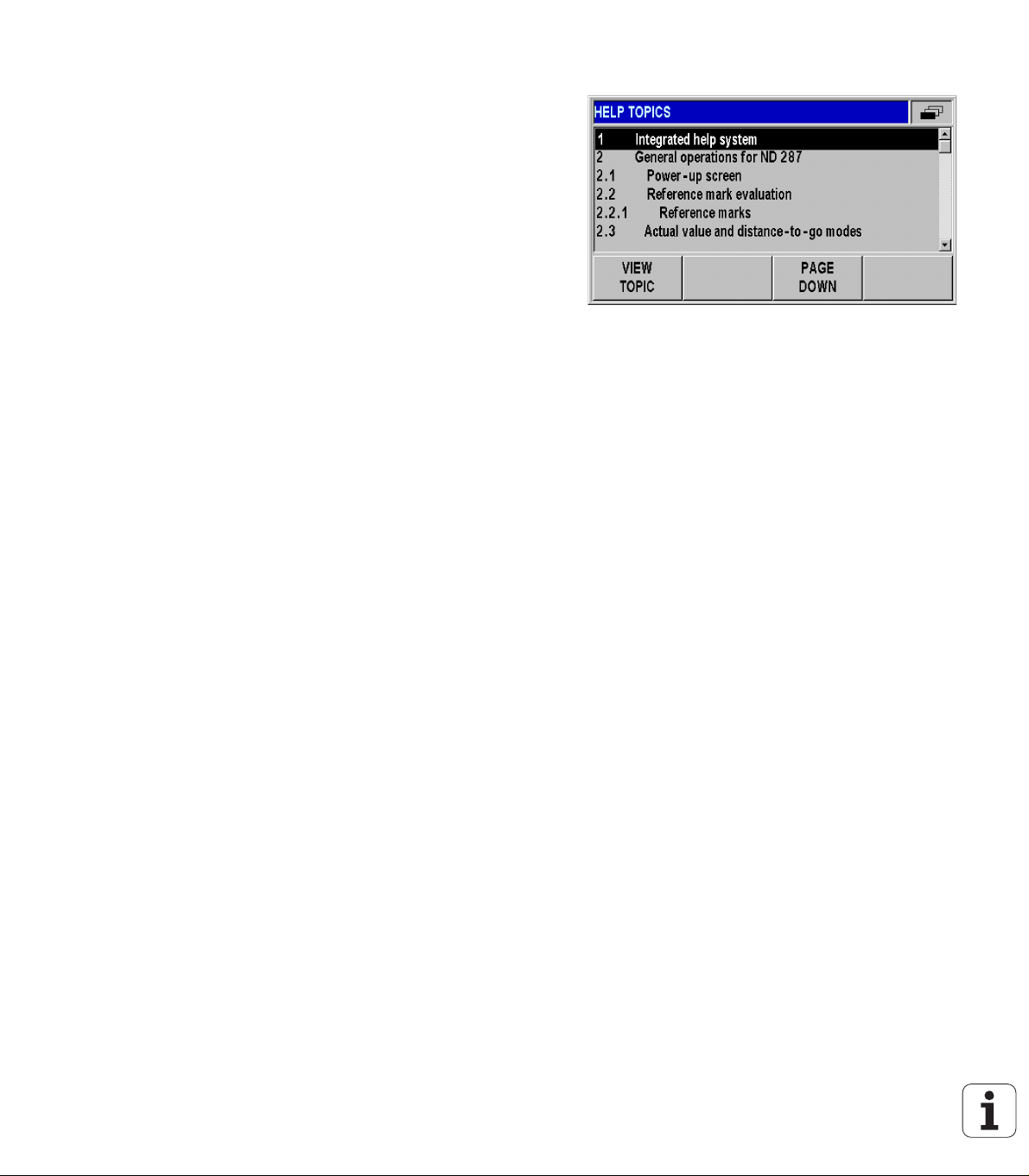

Integrated help system

The integrated help system provides appropriate information and

assistance in any situation (see Fig. I.17).

To call the integrated help system:

Press the HELP soft key.

Information relevant to the current operation will be displayed.

Use the UP or DOWN arrow keys or the PAGE UP or DOWN soft

keys if the explanation is spread over more than one screen page.

To view information on another topic:

Press the LIST OF TOPICS soft key to view the index of the help

topics.

Press the PART 1/[PART 2] soft key to call the extended help, which

is available in exceptional cases.

Press the UP or DOWN arrow key or the PAGE UP or PAGE DOWN

soft key to scroll through the index.

Press the VIEW TOPIC soft key or the ENTER key to select the item

you need.

To leave the integrated help system:

Press the C key. The ND will return to the screen from which you

I – 3 Basic functions of the ND 287

called the help system.

Fig. I.17 Integrated help system

28 I Working with the ND 287 position display unit

Page 29

Data input forms

Information required for various operational functions and setup

parameters is entered through a data input form. These forms will

appear after selecting features that require any additional information.

Each form provides specific fields for entering the required

information.

To confirm the changes:

Press the ENTER key.

To ignore the changes and return to the previous screen:

Press the C key.

Instruction box messages

Whenever a menu or form is open, an instruction box will also open

immediately to the right of it (see Fig. I.18). This message box will

provide information to the operator on what the chosen function does

and present instructions on the available options.

I – 3 Basic functions of the ND 287

Fig. I.18 Example of instruction box messages

Error messages

If an error occurs while you are working with the ND, the message will

appear on the display and provide an explanation of what caused the

error.

To acknowledge the error message:

Press the C key.

If a new error occurs before the last error has been

acknowledged, the last error that has occurred will be

displayed. After the last error has been acknowledged, the

previous error will be displayed again. The ND always

stores the last error of each error category for

acknowledgment (see "Error messages" on page 60).

ND 287 29

Page 30

I – 4 Job Setup

Operating modes

The ND 287 has two operating modes: Actual Value and Distance-

To-Go.

Status bar Function

I – 4 Job Setup

In the Actual Value operating mode, the ND 287 always displays the

current actual position of the length gauge, relative to the active

datum. In this mode, all moves are done by traveling until the display

matches the nominal position that is required.

The Distance-To-Go feature enables you to approach nominal

positions simply by traversing to display value zero. Proceed as

follows:

Press the DELTA MODE ON soft key to switch the operating mode

(see "Soft-key functions on the standard screen" on page 25): The

display value is zero.

Use the numeric keys to enter the nominal position you want to

move to and confirm with the ENTER key: The distance-to-go is

displayed.

Traverse the axis until the display value is zero.

If required, enter the next nominal position and confirm with the

ENTER key: Traverse the axis until the display value is zero.

To leave the Distance-To-Go operating mode: Press the DELTA

MODE OFF soft key.

Shows current actual position

Displays current distance from the

nominal position

Fig. I.19 Actual Value symbol (highlighted) in the

status display

Algebraic sign of distance-to-go:

The distance-to-go has a positive sign if the axis

direction from the actual towards the nominal position is

negative.

The distance-to-go has a negative sign if the axis

direction from the actual towards the nominal position is

positive.

In the Distance-To-Go operating mode, the switching

outputs A1 (pin 15) and A2 (pin 16) have a different

function (see "Switching outputs at D-sub connection

X41" on page 95).

30 I Working with the ND 287 position display unit

Page 31

Datum setting

The datum setting procedure assigns the matching display value to a

known position. With the ND 287 position display unit, you can set

two separate datum points.

During operation, you can reset the display value of the axis to zero, or

preset it to a defined or new value.

With RESET, you set the current datum to zero at the

current position for that axis:

If the Actual Value mode is active, the display value is

zero.

If the Distance-To-Go mode is active, the distance

remaining to the position of the new datum is displayed.

Setting the display value for one axis or for two axes in the X1 or X2 display mode

Select soft-key page 3 on the standard screen.

Select display mode X1 or X2 (see "Axis display mode" on page 27).

If necessary, press the DATUM soft key to select the datum you

want to set.

To reset the display value to zero, press the RESET soft key or apply

a signal to pin 2 of connection X41. As an alternative, you can use

the numeric keys to enter the number zero and press ENTER to

confirm your entry.

You can also set any desired display value by entering the new value

with the numeric keypad. As a result, the SET symbol in the status

display starts flashing in red. Press the ENTER key to confirm the

entered numerical value.

To set the display value to the preset value for the datum point (see

"Value for datum point" on page 36), press the PRESET soft key. As

an alternative, you can apply a signal to pin 3 of connection X41.

I – 4 Job Setup

Fig. I.20 Standard screen with soft-key page 3

ND 287 31

Page 32

Setting the display value for two axes in display mode X1:X2 (applies to X1+X2, X1-X2, f(X1,X2))

Select soft-key page 3 on the standard screen.

Select display mode X1:X2 (see "Axis display mode" on page 27).

If necessary, press the DATUM soft key to select the datum you

want to set.

To reset the display value of both axes to zero, press the RESET

soft key or apply a signal to pin 2 of connection X41. As an

alternative, you can use the numeric keys to enter the number zero

I – 4 Job Setup

and press ENTER to confirm your entry. Depending on the formula

programmed for the coupled position, the display value does not

necessarily need to be zero.

You can also set axis X1 to any desired display value by entering the

new value with the numeric keypad. As a result, the SET symbol in

the status display starts flashing in red. Press the ENTER key to

confirm the entered numerical value. The display value of axis X2 is

automatically reset to the value zero.

To set axis X1 to the preset value for the datum point (see "Value for

datum point" on page 36), press the PRESET soft key. The display

value of axis X2 is automatically reset to the value zero. As an

alternative, you can apply a signal to pin 3 of connection X41.

Fig. I.21 Standard screen with soft-key page 3

Fig. I.22 Sum or difference display

32 I Working with the ND 287 position display unit

Page 33

Calling the JOB SETUP menu

The ND 287 offers two categories for setting up operating

parameters: JOB SETUP and INSTALLATION SETUP.

The JOB SETUP parameters are used to accommodate specific

machining requirements for each job.

The INSTALLATION SETUP menu is used to establish encoder,

display and communication parameters (see "INSTALLATION

SETUP menu" on page 70).

To call the JOB SETUP menu:

Press the SETUP soft key to open the JOB SETUP menu.

When in the JOB SETUP menu, the following soft keys will be

available (see Fig. I.23):

INSTALLATION SETUP

Press to begin accessing the INSTALLATION SETUP parameters

(see "INSTALLATION SETUP menu" on page 70).

IMPORT/EXPORT

Operating parameter information can be imported or exported over

the serial port. (See "Serial data transfer with the Import or Export

function" on page 101). Press this soft key to call the two following

soft keys:

Press IMPORT to download operating parameters from a PC.

Press EXPORT to upload the current operating parameters to a PC.

To exit, press the C key.

HELP

This soft key will open on-line help.

Press the NAVIGATION key to move through the pages of menu

parameters. To view and change menu parameters, use the UP/

DOWN arrow key to highlight the parameter of interest and press the

ENTER key.

On the following pages you will find more information on the menu

parameters.

I – 4 Job Setup

Fig. I.23 JOB SETUP menu

Fig. I.24 JOB SETUP menu

ND 287 33

Page 34

Unit of measure

The UNITS OF MEASURE form is used to specify the preferred display

units and formats for linear and angular measurements. The ND 287

powers up with these settings in effect.

In the LINEAR field, define the unit of measure for linear

measurement:

In the JOB SETUP menu, select UNITS and press the ENTER key to

open the form.

I – 4 Job Setup

Use the MM/INCH soft key to switch between MM and INCHES.

This can be performed in either Actual Value or Distance-To-Go

mode.

In the ANGULAR field, define the format and input mode for angles.

Press the ANGLE soft key to switch between DECIMAL DEGREES,

RADIANS and DMS (degrees/minutes/seconds).

The defined unit of measure is shown in the status bar on the standard

screen.

Fig. I.25 Unit of measure

34 I Working with the ND 287 position display unit

Page 35

Scaling factor

The scaling factor is used to scale the part up or down. All encoder

movements are multiplied by the scaling factor.

A scaling factor of 1.0 creates a part with the exact size as

dimensioned on the print.

A scaling factor > 1 enlarges the workpiece.

A scaling factor < 1 reduces the workpiece.

To define the scaling factor:

In the JOB SETUP menu, select SCALE FACTOR and press the

ENTER key to open the form.

The ON/OFF soft key is used to disable the current scaling factors.

Use the numeric keys to enter a number greater than zero if a

scaling factor is active. The number range is 0.100000 to 10.000000.

When the scaling factor is a value other than 1, the scaling symbol

SCL is shown in black in the status bar.

The settings for the scaling factor will be retained on a power cycle.

I – 4 Job Setup

Mirror: A scaling factor of –1.00 will produce a mirror

image of the part. You can both mirror and scale a part

at the same time.

Fig. I.26 Scaling factor

ND 287 35

Page 36

Value for datum point

This form is used to set a value for a datum point (see Fig. I.27).

In the JOB SETUP menu, select VALUE FOR DATUM POINT and

press the ENTER key to open the form.

Enter the value and press ENTER to confirm your entry.

If you want to set the display value to this value, press the PRESET

soft key on the standard screen (see "Datum setting" on page 31) or

activate pin 3 at D-sub connection X41 (see "Switching inputs at D-

I – 4 Job Setup

sub connection X41" on page 93).

Stopwatch

The stopwatch shows the hours (h), minutes (m), seconds (s). It

operates like a stop watch showing elapsed time. The clock starts

timing from 0:00:00.

The ELAPSED TIME field shows the total accumulated time from each

interval (see Fig. I.28).

In the JOB SETUP menu, select STOPWATCH and press the ENTER

key to open the form.

Press the START/STOP soft key. The ND 287 shows the status field

RUNNING and the elapsed time. Press it again to stop time from

elapsing.

Press the RESET soft key to reset the elapsed time. Resetting will

stop the clock if it is running (STOPPED).

Fig. I.27 Value for datum point

Fig. I.28 Stopwatch

All stopwatch functions (START, STOP, and RESET) are

applied immediately.

The status bar shows minutes and seconds for an

elapsed time of less than 1 hour. Hours and minutes are

shown for a time of 1 hour or more.

36 I Working with the ND 287 position display unit

Page 37

Console adjustment

You can adjust the brightness of the ND 287's LCD display (see Fig.

I.29):

In the JOB SETUP menu, select CONSOLE ADJUSTMENT and

press the ENTER key to open the form.

Press the DECREASE or INCREASE soft key to adjust the

brightness to your requirements.

The DISPLAY SAVER setting is the amount of time the system is

idle before the LCD is turned off. The idle time may be set from 30

to 120 minutes. The display saver can be disabled during the current

power cycle by pressing the DISABLE soft key.

I – 4 Job Setup

You can also use the UP or DOWN arrow key to adjust the

LCD's brightness directly on the screen.

Language

The ND 287 supports multiple languages. To change the language:

In the JOB SETUP menu, select LANGUAGE and press the ENTER

key to open the form.

Press the LANGUAGE soft key until the desired language appears in

the LANGUAGE field.

Press ENTER to confirm your selection.

Fig. I.29 Console adjustment

Fig. I.30 Language

ND 287 37

Page 38

Switching signals

Danger to internal components!

The power supply of external circuits must comply with

EN 50178 requirements for low voltage electrical

separation.

Connect inductive loads only with a quenching diode

parallel to the inductance.

I – 4 Job Setup

Danger to internal components!

Use only shielded cables and connect the shield to the

connector housing.

In the JOB SETUP menu, use the DOWN arrow key to select

SWITCHING SIGNALS, and press the ENTER key to open the form.

Press the ON/OFF soft key to activate/deactivate the trigger points.

Using the numeric keys, enter the desired trigger limits A1 and A2.

When the trigger limits defined by parameter are reached, the

corresponding output becomes active. Output A1 represents pin 15

at D-sub connection X41, and output A2 represents pin 16:

Pin 15 remains active as long as the measured value is greater than

or equal to A1.

Pin 16 remains active as long as the measured value is greater than

or equal to A2.

A separate output is available for trigger point zero. If the display value

is zero, the position display unit always activates pin 14 at D-sub

connection X41. The minimum signal duration is 180 ms.

The ND 287 constantly monitors the measuring signal, the input

frequency, the data output, etc., and displays errors in the message

line. If errors occur that seriously influence measurement or data

output, the ND activates the switching output at pin 19. The output

remains active until the error has been acknowledged. This makes it

possible to monitor proper function during automated processes.

Fig. I.31 Switching signals

In the Distance-To-Go operating mode, the switching

outputs A1 (pin 15) and A2 (pin 16) have a different

function (see "Switching outputs at D-sub connection

X41" on page 95).

38 I Working with the ND 287 position display unit

Page 39

Measured-value output

1

2

3

4

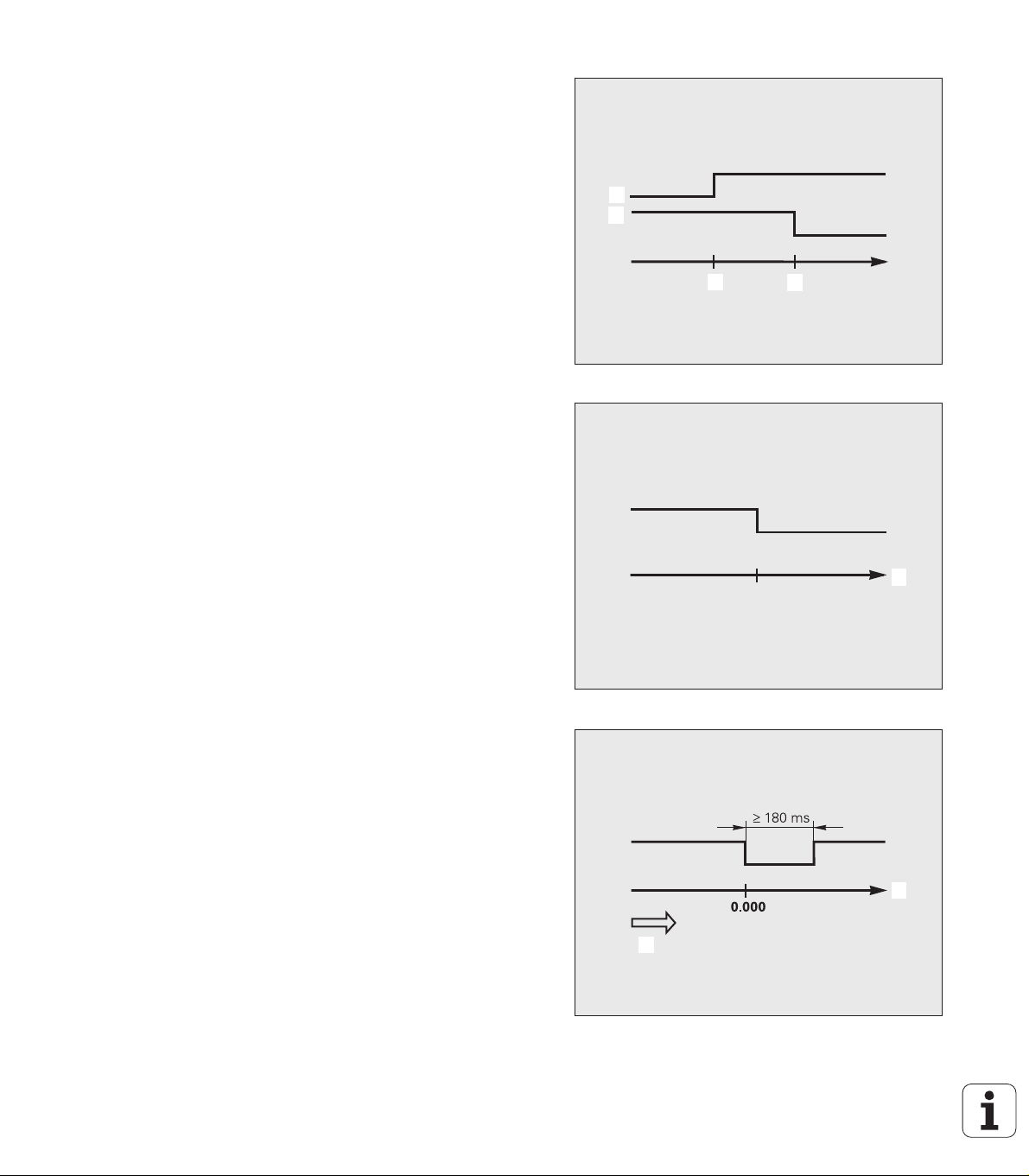

With the measured value output feature, the current display values

can be transmitted over the serial port. Output of the current display

values is activated via a switching signal at D-sub connection X41,

the command CTRL B, or the PRINT soft key (see "Measured value

output" on page 113).

The effect the signal for measured value output has on the display

value on the screen can be defined as follows:

In the JOB SETUP menu, select MEASURED VALUE OUTPUT and

press the ENTER key to open the form.

Press the DISPLAY FREEZE soft key. Three different settings are

available:

CONCURRENT DISPLAY: The display is not stopped during

measured value output. The display value is the current measured

value.

FROZEN/CONCURRENT DISPLAY: The display is stopped during

measured value output and remains stopped while the switching

input is active.

FROZEN DISPLAY: The display is stopped, but is updated by

every measured value output.

The following figure illustrates the different settings for measured

value output.

I – 4 Job Setup

Fig. I.32 Measured-value output

1 Position

2 Latch signal

3 Frozen display

4 Frozen/concurrent display

For more information on measured value output, refer to Page 113.

ND 287 39

Page 40

Function of external inputs

Danger to internal components!

The power supply of external circuits must comply with

EN 50178 requirements for low voltage electrical

separation.

Connect inductive loads only with a quenching diode

parallel to the inductance.

I – 4 Job Setup

Danger to internal components!

Use only shielded cables and connect the shield to the

connector housing.

The function for hiding possible display modes of the axes

(see page 78) is always active.

Use FUNCTION EXT. INPUTS in the JOB SETUP menu to determine

the ND 287's reaction to the external inputs at connection X41 (see

"Switching inputs at D-sub connection X41" on page 93).

In the JOB SETUP menu, select FUNCTION EXT. INPUTS and press

the ENTER key to open the form.

Press the VERSION soft key. Two different versions are available:

VERSION 1: You can externally activate the minimum/

maximum measurement for measurement series if the signal

at pin 6 remains permanently LOW. The SELECT DISPLAY soft

key for selecting the display mode becomes ineffective. Pin 7

sets the display to MIN, pin 8 to MAX and pin 9 to DIFF. The

display can only be set to ACTL if either none of the pins 7, 8 or 9

or more than one of the pins carries a signal. A signal (pulse) at

pin 5 starts a new series of measurements if the signal at pin 6

is permanently LOW.

VERSION 2: If pins 5, 6, 7, 8 or 9 are activated, the display modes

are switched to operation with two axes. Pin 6 switches to

axis X1, pin 7 to axis X2, pin 8 to the sum of the two axes X1+X2,

pin 9 to the difference between the two axes X1-X2 and pin 5

switches to the definable relationship between the two axes

f(X1,X2), see "Formula for coupled position" on page 78.

An overview of the switching inputs and outputs is provided on

Page 93.

Fig. I.33 External inputs function

40 I Working with the ND 287 position display unit

Page 41

Compensation using a reference part

Select the REFERENCE PART COMP. menu item to activate

temperature compensation using a reference part. Prerequisites:

A temperature sensor is connected to encoder input X2.

For the temperature sensor, you have set the ENCODER TYPE field

in the ENCODER SETUP menu to COMPENSATION and entered

the following encoder parameters, see "Setting up the encoder",

page 71:

Calibration pair of values

Correct thermal expansion coefficient

Reference temperature

The compensation value C is calculated as follows:

C = ND * E * (T - T_r)

ND: Nominal dimension of reference part

E: Expansion coefficient

T: Temperature currently being measured

T_r: Reference temperature

To activate the compensation:

In the JOB SETUP menu, select REFERENCE PART COMP. and

press the ENTER key to open the form.

Enter the known nominal dimension of the reference part in the

NOMINAL DIMENSION field.

Press the ON/OFF soft key to activate the temperature

compensation using a reference part in the MEASURE REF. PART

field.

To measure the reference part:

Press the MEASURE REF. PART soft key in the 3rd soft key row of

the standard screen. The ND 287 displays the current temperature

value on the left side of the message line, and the entered nominal

dimension of the reference part on the right side.

Insert your reference part and press either the ZERO soft key or the

NOMINAL DIMENSION soft key, depending on whether you want

to display the test objects' deviations from zero or from the nominal

dimension.

I – 4 Job Setup

Fig. I.34 Compensation using a reference part

ND 287 41

Page 42

I – 5 Series of measurements and

statistical process control

Functions

In addition to displaying measured values, the ND 287 can record and

evaluate measured values as a series of measurements, and can

perform Statistical Process Control (SPC).

You can record series of measurements with up to 10000 measured

process control

values per connected axis. The recording of the measured values

can be initiated manually, externally or according to time. After the

series of measurements has been recorded, you can immediately

evaluate it on the ND 287 and display it as a table or a graph. The

measured values can also be exported.

For statistical process control, the ND 287 can store up to 1000

measured values in a non-volatile FIFO memory. After the required

parameters have been defined and SPC has been started, samples of

the measured values to be monitored are recorded. After a sufficient

number of measured values has been recorded, the measured values

accumulated so far can be evaluated. In addition to displaying the

measured values, basic statistical data and a histogram, the ND 287

can also calculate and display the process capability indices Cp and

Cpk as well as various quality control charts. For fundamentals on

quality capability characteristics, refer to ISO 21747.

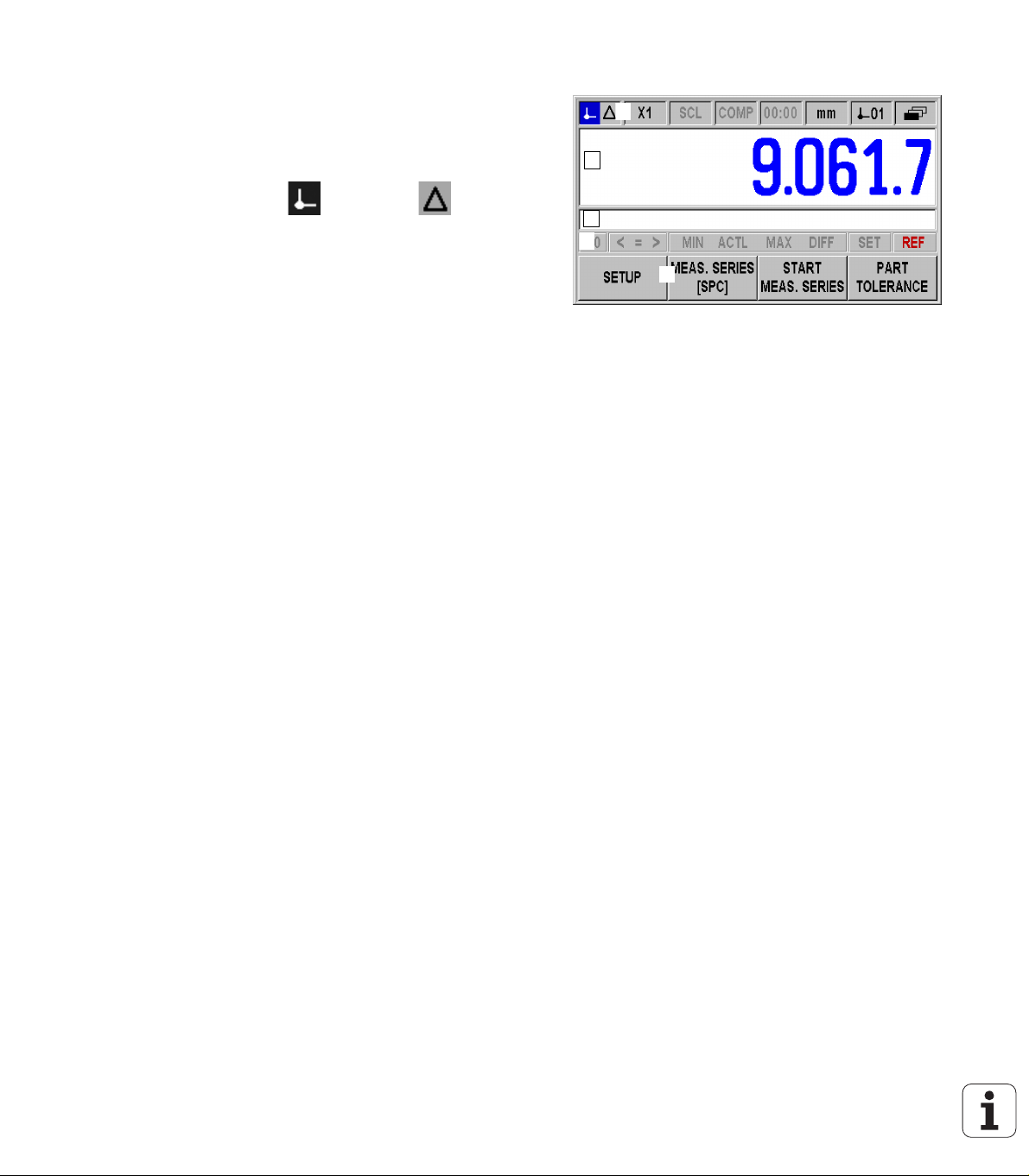

Switching between series of measurements and SPC mode

I – 5 Series of measurements and statistical

To switch between the MEAS. SERIES and SPC mode:

Press the MEAS. SERIES [SPC] or SPC [MEAS. SERIES] soft key

(depending on which of the two soft keys is displayed) in the first

soft-key row of the standard screen.

This opens the SERIES OF MEASUREMENTS or SPC -

STATISTICAL PROCESS CONTROL menu.

To switch the mode, press the MEAS. SERIES [SPC] or SPC [MEAS.

SERIES] soft key.

Fig. I.35 Measurement Series [SPC] mode

42 I Working with the ND 287 position display unit

Page 43

Calling the SERIES OF MEASUREMENTS menu

All parameters required for a series of measurements and the

possibility of analyzing a previously recorded series of measurements

are provided by the SERIES OF MEASUREMENTS menu.

To call the SERIES OF MEASUREMENTS menu, press the MEAS.

SERIES [SPC] soft key in the first soft-key row of the standard

screen.

Use the MEAS. SERIES ANALYSIS, MEAS. SERIES SETUP, MEAS.

SERIES DISPLAY , RECORD MODE and POS / SPEED DISPLAY

parameters to define further settings.

In the following sections you will find more detailed information on the

menu parameters.

Analysis of series of measurements

The ND 287 provides the following possibilities for analyzing the

recorded series of measurements:

Call the SERIES OF MEASUREMENTS menu.

Select MEAS. SERIES ANALYSIS. This opens an overview of the

statistical data of the series of measurements: Number of

measured values, maximum and minimum measured value,

difference (MAX-MIN, also referred to as range), mean value and

standard deviation.

If you have recorded the measured values of both axes, you can

switch between the measured-value analyses of the two axes with

the X1 [X2] soft key.

Press the EXPORT soft key to transfer the recorded data to a PC.

Press the GRAPH soft key to call a graphic display of all measured

values, including the minimum, maximum and mean values of the

measurement series. If the sorting and tolerance checking mode is

active, the ND 287 also enters the sorting limits into the graph.

Press the MEASURED VALUES soft key to open a table with all

recorded values. The measured values are listed in table format

(24 measured values per page). If the sorting and tolerance checking

mode is active, all measured values that are outside the sorting

limits are displayed in red in the table.

Use the PAGE UP or PAGE DOWN key to scroll through the table

one page at a time.

Press the STATISTICAL DATA soft key to return to the overview of

statistical data.

Fig. I.36 SERIES OF MEASUREMENTS menu

Fig. I.37 Statistical data of series of measurements

Fig. I.38 Diagram

process control

I – 5 Series of measurements and statistical

ND 287 43

Page 44

Setting up a series of measurements

To define the parameters of the series of measurements:

Call the SERIES OF MEASUREMENTS menu.

Select MEAS. SERIES SETUP.

In the RECORD MEAS. VALUES field, activate or deactivate

measured-value recording for a series of measurements.

In the RECORD field, select the trigger for recording the measured

values of a series of measurements. Press the RECORD soft key to

select one of the following possibilities:

process control

Sampling interval

External signal at connection X41 (pin 22 or 23)

ENTER key

Press the DOWN arrow key or the NAVIGATION key to display

further parameters.

The ND 287 can store a maximum of 10000 measured

values per axis. The measured values recorded in a series

of measurements will only be retained in memory until

power is switched off.

If you have selected EXTERNAL SIGNAL or ENTER key, another

parameter needs to be defined:

In the NO. MEAS. VALUES field, you enter the number of measured

values for the series of measurements. If you enter the value zero,

the ND deactivates the RECORD MEASURED VALUES function.

Fig. I.39 Setting up a series of measurements

Fig. I.40 Setting up a series of measurements

I – 5 Series of measurements and statistical

44 I Working with the ND 287 position display unit

Page 45

If you have selected SAMPLING INTERVAL, the two following

parameters in the second soft-key row are available for the exact

definition of the interval:

In the TIME SLOT field, define the duration of the series of

measurements in hours/minutes/seconds. Use the ← and → soft

keys to move from hours to minutes and seconds, and vice versa.

Use the numeric keys to enter the desired value. The maximum

possible duration of a measurement series is 999 hours, 59

minutes and 59 seconds.

In the SAMPLING INTERVAL field, enter the amount of time until a

measured value is recorded. Press the DECREASE or INCREASE

soft key to decrease or increase the value shown in the field: 20 ms

to 80 ms in increments of 20 ms, 100 ms to 900 ms in increments

of 100 ms, 1 s to 9 s in increments of 1 s and 10 s to 50 s in

increments of 10 s, 1 min to 9 min in increments of 1 min and

10 min to 30 min in increments of 10 min.

On the basis of the settings you defined for the sampling interval,

the ND 287 calculates the number of measured values for the series

of measurements and displays it in the NO. MEAS. VALUES field.

The measured values can be sorted and the sorting result

can be displayed in color during the series of

measurements to enable you to intervene, if required (see

"Sorting and tolerance checking" on page 58).

process control

Fig. I.41 Setting up a series of measurements

ND 287 45

I – 5 Series of measurements and statistical

Page 46

Defining the display for a series of

DIFF

MAX

MIN

ACTL

2e = r

MAX

r

MIN

e = DIFF

2

r

MAX

r

MIN

e

measurements

In the SERIES OF MEASUREMENTS menu, select MEAS. SERIES

DISPLAY. Then press the DISPLAY MEAS. SER. soft key to select the

value to be displayed while a series of measurements is being

performed:

ACTL DISPLAY: Current measured value is displayed.

MIN DISPLAY: Minimum value of a series of measurements is

displayed.

process control

MAX DISPLAY: Maximum value of a series of measurements is

displayed.

DIFF DISPLAY: Difference MAX - MIN (i. e. the range) is displayed.

Fig. I.42 Display for series of measurements

I – 5 Series of measurements and statistical

46 I Working with the ND 287 position display unit

Fig. I.43 MIN, MAX and DIFF of a curved surface

Fig. I.44 Series of measurements for determining

eccentricity

Page 47

Setting the position or speed display

In the series of measurements mode the ND 287 can also display the

traversing speed of the axes.

In the MEAS. SERIES menu, select the POS / SPEED DISPLAY

menu item.

Select the desired axis and press the POSITION [SPEED] soft key to

activate the speed display. After you have started the series of

measurements, the traversing speed of the axis is displayed and

recorded. You can also display and record the MIN, ACTL, MAX and

DIFF values of the traversing speed.

The speed unit is displayed in lowercase at the left edge of the axis

display. You can choose between mm/min, ipm or rpm.

The value is always displayed with one decimal place.

Defining the record mode

The ND 287 can record different types of measured values:

In the MEAS. SERIES menu, select the RECORD MODE menu

item.

Press the RECORD MEAS. SERIES soft key to select the mode of

recording:

ACTL DISPLAY: Current measured value is recorded.

MIN DISPLAY: Minimum values of a series of measurements are

recorded.

MAX DISPLAY: Maximum values of a series of measurements are

recorded.

DIFF DISPLAY: Differences MAX - MIN (i. e. the ranges) are

recorded.

Fig. I.45 POS / SPEED DISPLAY

Fig. I.46 Mode of recording

process control

I – 5 Series of measurements and statistical

ND 287 47

Page 48

Starting and stopping a series of measurements

Select the first soft-key page of the standard screen.

Press the START MEAS. SERIES soft key to start a series of

measurements. If the START SPC soft key is displayed on the

screen, press the SPC [MEAS. SERIES] soft key to open the SPC

menu, and then press the SPC [MEAS. SERIES] soft key to switch

to the SERIES OF MEASUREMENTS mode (see "Switching

between series of measurements and SPC mode" on page 42). If

the ND 287 is configured for two axes and the display mode X1:X2

is not active, then the ND records the values for both axes

process control

simultaneously after the series of measurements has been started.

The ND can store up to 10000 values per axis. The measured-value

counter is shown on the left side of the message line. It shows the

number of the current value being measured and the total number

of values to be measured, e.g. 0/50.

If required, you can switch the display mode during the series of

measurements by pressing the SELECT DISPLAY soft key (see

"Defining the display for a series of measurements" on page 46). The

currently active display mode is highlighted in the status display:

MIN, ACTL, MAX or DIFF.

You can stop the current series of measurements at any time by

pressing the STOP MEAS. SERIES soft key. When the defined

number of measured values has been reached, the ND stops the

series of measurements automatically.

The DYNAMIC RESET soft key appears only if you use the ENTER

key or an external signal for saving and if you have selected the MIN,

MAX or DIFF recording mode. If you press this soft key, the MIN,

MAX and DIFF values are reset to zero.

All parameters required for a series of measurements and the

possibility of analyzing a previously recorded series of measurements

I – 5 Series of measurements and statistical

are provided by the SERIES OF MEASUREMENTS menu.

Fig. I.47 Standard screen with soft-key page 1

Fig. I.48 Series of measurements has been started

When a series of measurements is started, the MIN/

MAX/DIFF memory is automatically reset, and the

measured values of the last recorded series of

measurements are deleted.

A new series of measurements cannot be started until

the current series of measurements has been

concluded.

48 I Working with the ND 287 position display unit

Page 49

Calling the SPC menu

x

All parameters required for Statistical Process Control (SPC) and the

possibility of analyzing the current or completed SPC are provided by

the SPC menu.

To call the SPC menu, press the SPC [MEAS. SERIES] soft key in the

first soft-key row of the standard screen.

Use the SPC ANALYSIS, SPC SETUP and DELETE STATISTIC

parameters to define further settings.

In the following sections you will find more detailed information on the

menu parameters.

SPC analysis

The ND 287 provides the following possibilities for analyzing the

measured values recorded during statistical process control:

Call the SPC menu.

Select SPC ANALYSIS. This opens an overview of the SPC data:

Number of measured values, minimum and maximum measured

values, difference MAX-MIN, mean value and standard deviation.

This data is based on the measured values from the FIFO memory.

At the upper right of the screen the ND displays the sample

counter x/y z, as well as the selected part and the selected axis or

coupled position, e.g. 1/5 51. x is the number of the measurement

that is currently being performed for the current sample (the total

number of measurements to be performed for each sample is

indicated in DATA PER SAMPLE), y is the number of measured

values per sample (indicated in DATA PER SAMPLE), and z is the

total number of measurements that have been recorded so far

(maximum of z = product of x multiplied by y). You can call the

analysis function immediately after switching the ND 287 on. The

number of recorded values depends on the sample settings you

have defined for SPC (see "Samples" on page 52).

Press the EXPORT soft key to transfer the recorded data to a PC.

Press the MEASURED VALUES soft key to open a table with all

recorded values. The measured values are listed in table format

(24 measured values per page).

Use the PAGE UP or PAGE DOWN key to scroll through the table

one page at a time.

Press the leftmost soft key to toggle through all evaluated diagram

types: Graph, histogram, control chart , control chart s and control

chart r. Press the C key to return to the SPC menu.

process control

Fig. I.49 SPC menu

I – 5 Series of measurements and statistical

Fig. I.50 SPC data

ND 287 49

Page 50

Press the GRAPH soft key to call a graphic display of all measured

xxxxx

xxx

values, including the lower tolerance limit LT, upper tolerance limit

UT, nominal value (mean tolerance value) NV and the mean

value . The graph shows the last 30 measured values. Use the

⇐ and soft keys to scroll the graph forward or backward by 25

measured values at a time.

Press the HISTOGRAM soft key to display a histogram of the

measured values. The histogram sorts all recorded values into 10

classes. The histogram also shows the lower tolerance limit LT, the

upper tolerance limit UT, the nominal value (mean tolerance value)

NV and the mean value . When a sufficient number of measured

process control

values (at least half of the product of NUMBER OF SAMPLES

multiplied by DATA PER SAMPLE) is available after SPC has been

restarted, the ND 287 also draws the probability density curve in

the histogram. The ND 287 calculates the process capability

indices c

These values can be used to estimate the reliability of the process

within the defined specifications.

Press the CONTROL CHART soft key to display the control chart

for the mean value ( chart). The mean value of each sample is

entered in this control chart. The control chart shows up to 30 of the

last values. Use the ⇐ and soft keys to scroll the graph forward

or backward by 25 measured values at a time. The control chart also

shows the lower control limit for the mean value LCL , the upper

control limit for the mean value UCL and the mean value of all

measured values . The violation of lower or upper control limit

and the position of the individual mean values are important for the

analysis of this control chart. For example, it is interesting to check

whether a trend or run is visible. For more information, please refer

to appropriate technical literature or ISO 21747.

and cpk and displays them to the right of the histogram.

p

Fig. I.51 Graph

Fig. I.52 Histogram

I – 5 Series of measurements and statistical

Fig. I.53 Control chart

50 I Working with the ND 287 position display unit

Page 51

Press the CONTROL CHART s soft key to display the control chart

s

srr

for standard deviation s (s chart). The standard deviation s of each

sample is entered in this control chart. The control chart shows up

to 30 of the last values. Use the ⇐ and soft keys to scroll the

graph forward or backward by 25 measured values at a time. The

control chart also shows the upper control limit for the standard

deviation UCL s, and the mean value of the standard deviations .

The ND also shows the calculated value .

Press the CONTROL CHART r soft key to display the chart r. The

range r is the difference between the smallest and the largest value

of a sample. It is a measure of the statistical spread of the process.

The chart shows up to 30 of the last values. Use the ⇐ and soft

keys to scroll the graph forward or backward by 25 measured values

at a time. The control chart also shows the upper control limit for the

range UCL r,, and the mean value of the ranges . The ND also

shows the calculated value .

Press the SPC ANALYSIS soft key to return to the overview of

statistical data.

process control

Fig. I.54 Control chart s

Fig. I.55 Control chart r

ND 287 51

I – 5 Series of measurements and statistical

Page 52

Setting up SPC

Call the SPC SETUP submenu to define the SPC parameters:

Call the SPC menu.

Select SPC SETUP. This opens the SPC SETUP submenu. The

following parameters for setting up SPC are available:

SAMPLES

TOLERANCES

CONTROL LIMITS

process control

STATISTICAL DISTRIBUTION

MEASURED VALUE RECORDING

In the following sections you will find more detailed information on the

menu parameters.

Samples

In the sample parameters, you define the total number

of measured values for statistical process control

If you edit the values entered, the ND displays a

warning. In order to save the changes, the ND must

clear the data stored in the FIFO memory. Press the

ENTER key to confirm, or press the C key to cancel.

To call the SAMPLES form:

In the SPC SETUP submenu, select SAMPLES and press the

ENTER key to open the form.

Use the numeric keys to enter the desired value in the NUMBER OF

I – 5 Series of measurements and statistical

SAMPLES field, and press the ENTER key to confirm. A minimum

of two and a maximum of 100 samples are allowed.

Use the numeric keys to enter the number of measured values per

sample in the DATA PER SAMPLE field. Press the ENTER key to

confirm your entry. A minimum of three and a maximum of ten

measured values per sample are allowed.

If you edit the values entered, the ND displays a warning. In order

to save the changes, the ND must clear the data stored in the

FIFO memory. Press the ENTER key to confirm, or press the C key

to cancel.

Fig. I.56 SPC SETUP submenu

Fig. I.57 Samples

52 I Working with the ND 287 position display unit

Page 53

Tolerances

If you edit the values entered, the ND displays a warning.

In order to save the changes, the ND must clear the

data stored in the FIFO memory. Press the ENTER key

to confirm, or press the C key to cancel.

In the TOLERANCES form, you define the tolerance limits for

statistical process control:

In the SPC SETUP submenu, select TOLERANCES and press the

ENTER key to open the form.

The currently selected part (P0-P9) is displayed at the upper right.

You can also change the tolerances for the selected part in the

SELECT PART form that is opened by pressing the PART

TOLERANCE soft key on the standard screen.

Use the numeric keys to enter the values for the lower tolerance

limit, the nominal value and the upper tolerance limit in the

LOWER LIMIT, NOMINAL VALUE and UPPER LIMIT fields. The