Page 1

User’s Manual

ND 281

Measure d V alue Displays

English (en)

10/2002

B

Page 2

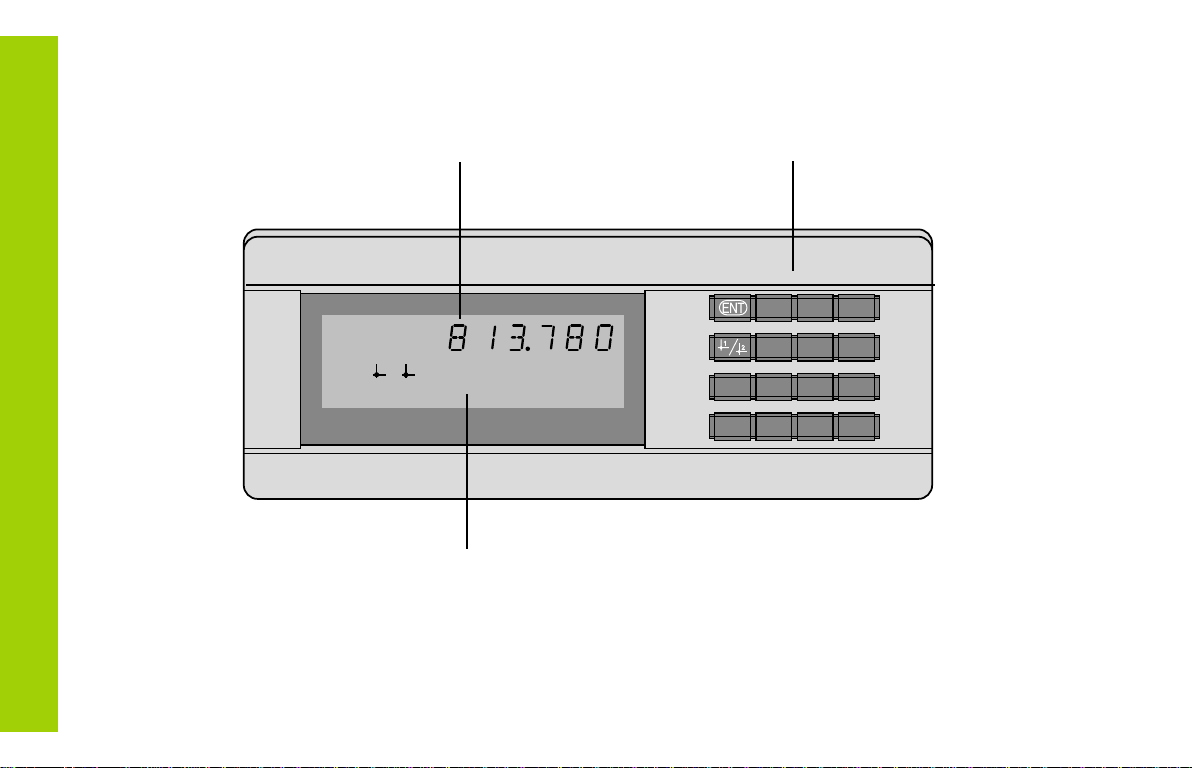

Display of actual value and input

(9 decades with algebraic sign)

REF SET START PRINT inch

=

<>

21

MIN ACTL MAX DIFF

HEIDENHAIN

Status display with indicators

Numeric keypad

with decimal point

789

456

MOD

123

.

0

CL

2

Page 3

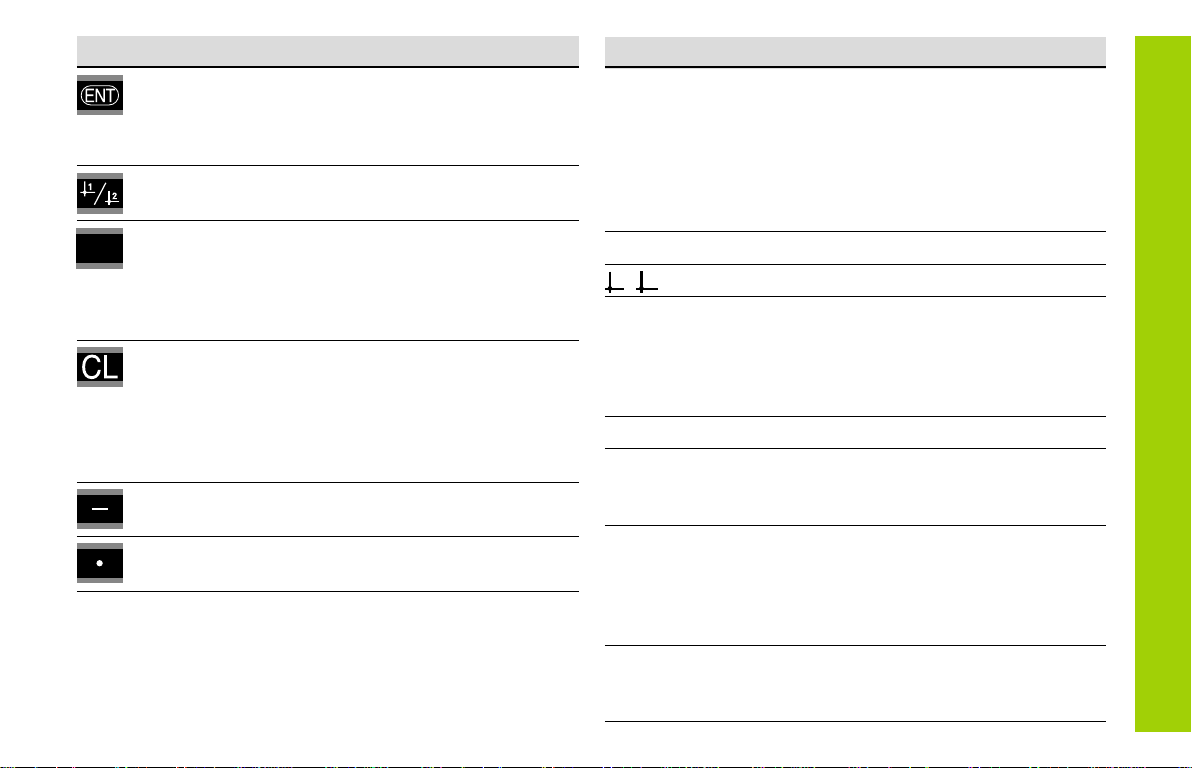

Key Function

• Set datum

• Transfer input value

• Set display to value from P79 (P80!)

• Leave parameter list

• Select datum

• Page backwards in parameter list

MOD

• Select parameter after switch-on

• Page forward in parameter list

• Start series of measurements

• Switch display for measurement series

• Start measured value output “PRINT”

• Delete entry

• Set display to zero (P80!)

• CL plus MOD: select parameter list

• CL plus number: select parameter

• Delete parameter input and show

parameter number

• Algebraic sign

• Reduce parameter value

• Decimal point

• Increase parameter value

1)

Only in linear measurement mode.

Indicator Meaning

REF If the decimal point is also blinking:

Display is waiting for reference mark

traversing. If decimal point is not blinking:

Reference mark has been traversed—display

stores datum points in nonvolatile memory

Blinking: display is waiting for ENT or

CL to be depressed

inch Position values in inches

1)

1 / 2 Selected datum point

1)

PRINT "Linear measurement”

Blinking: Display is waiting for ENT to

be pressed for data output

“Angular measurement”

Measured value output with MOD key

SET Blinking: Display is waiting for input values

< / = / > Sorting and tolerance checking:

measured value smaller than lower limit /

within the limits / greater than upper limit

/

MAX / Series of measurements: Minimum /

MIN

DIFF / ACTL

1)

maximum / greatest difference (MAX–MIN) /

current measured value

Blinking: Confirm selection or deselect

function

START

1)

Series of measurements is running

Blinking: Display is waiting for signal to

start series of measurements

3

Page 4

Items supplied with ND 281 B

ND 281 B Measured value display unit,

benchtop model

Encoder input

11 µAPP/1 V

Power cord 3 m (9.9 ft)

User's Manual ND 281B

Items Supplied

Adhesive plug-in feet For stacking ND 281B units

PP

This manual is for the ND 281 B measured value

display with the following software number or higher:

349 797-04

Id. Nr. 344 996-xx

The software number is indicated on a label onthe

4

rear panel.

Page 5

Contents

Working with the ND Display Units

Encoders 6

Reference Mar ks 7

Switch-On, Tr aversing the Reference Marks 8

Datum Setting 9

Finding Minimum and Maximum Values

Sorting and Tolerance Checking 13

Measured Value Output 14

Display Freeze 15

Error Messages 16

1)

Only in linear measurement mode

1)

10

Installation and Specifications

Rear Panel, Accessories 17

Mounting 19

Pow er Connection 20

Linear/Angular Measuring Modes 21

Operating Par ameters 22

List of Operating Parameters 24

Linear Encoders 28

Angle Encoders 33

Multipoint Axis Error Compensation 34

Switching Inputs and Outputs EXT (X41) 38

Locking the Keypad 43

Displaying the Software Version 44

Distance-to-Go Mode 45

RS-232-C/V.24 Data Interface (X31) 46

Input/Output of Parameter and 51

Compensation-V alue Lists

Output Format of the Parameter List 53

Output Format of the Compensation-Value Table 57

Remote Operation over the RS-232-C/V.24 60

Data Interface

Specifications 63

Dimensions 64

Contents

5

Page 6

Position Encoders

The ND 281 B display unit is designed for use with photoelectrical linear or angular encoders with sinusoidal signals:

primarily for HEIDENHAIN MT length gauges.

When shipped by HEIDENHAIN, the display units are set to the

linear measurement mode.

You can switch between the linear and angular modes by

Position Encoders

entering the code number 41 52 63 (see “Linear/Angular

Measurement Modes”).

On the back of the display you will find two flange sockets for

connecting the encoder: X1 for encoders with 11 µA

dal current signals and X2 for 1 V

Before shipping, HEIDENHAIN activates the encoder connection X1 for 11 µA

P02 you can activate the encoder input that matches your

encoder (see “Operating Parameters”).

sinusoidal current signals. With parameter

PP

sinusoidal voltage signals.

PP

sinusoi-

PP

6

Page 7

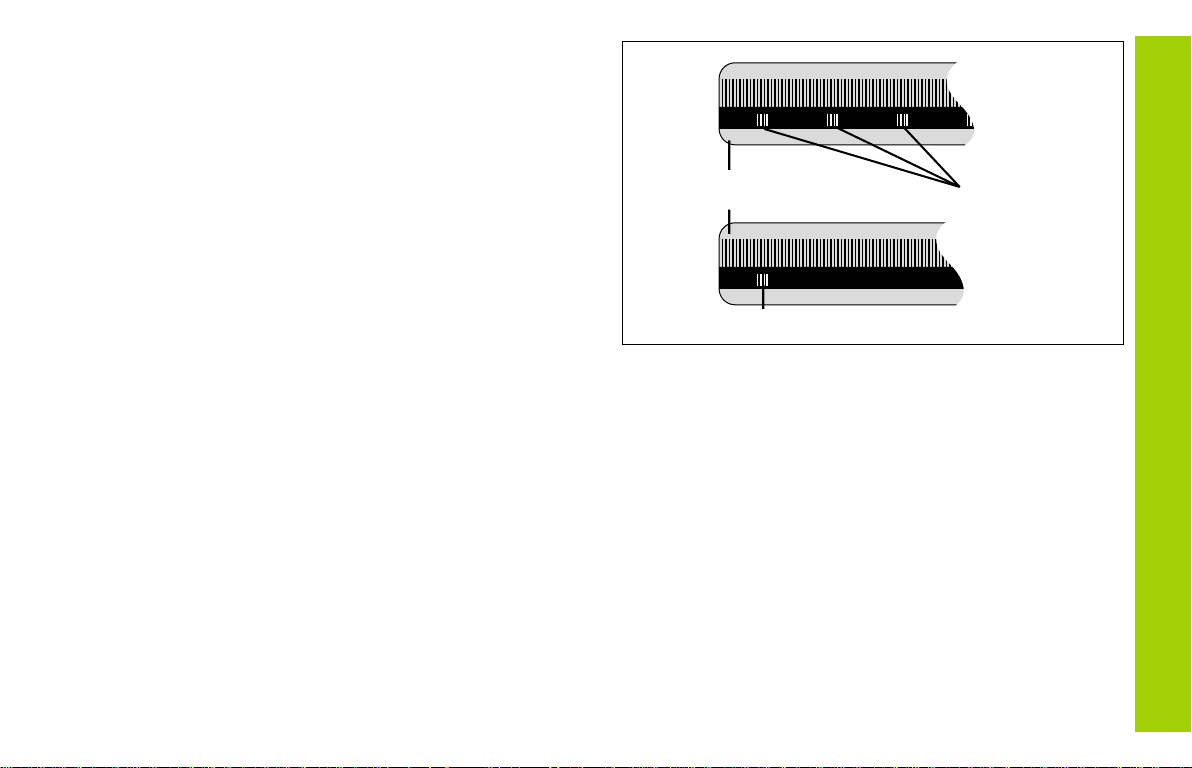

Reference Marks

The MT length gauges have one reference mark. The scales of

other photoelectric linear or angular encoders can contain one

reference mark or many

distance-coded

reference marks.

If there is an interruption of power, the relationship between the

position of the length gauge and the displayed position value is

lost. The reference marks on the position encoders and the REF

reference mark evaluation feature enable the display unit to

quickly reestablish this relationship again when the power is

restored.

When a reference mark is crossed over, a signal is generated

which identifies that position as a reference point. At the same

time, the display unit restores the relationship between length

gauge position and display values which you last defined by

setting the datum.

To restore the datum on scales with distance-coded reference

marks, you only need to traverse a maximum of 20 mm for

linear encoders, and 10° or 20° for angle encoders, depending

on the model.

Scale in Distance-coded

linear encoder reference marks

Reference Marks

Reference mark

Reference marks on linear encoders

7

Page 8

Switch-On, Traversing the Reference Marks

REF mode

ä

0

ENT...CL

5 , 6 9 7

Switch-On, Traversing the Reference Marks

For automation purposes, crossing over the reference marks

and the display ENT ... CL can be disabled with parameter P82.

Turn on the power.

1

(Switch located on rear panel.)

• ND 281 B appears for two seconds.

• ENT ... CL

• REF indicator starts blinking.

Switch-on the reference mark evaluation

function.

• The position value that was last

assigned to the reference mark

position is displayed.

• REF indicator lights.

• Decimal point starts blinking.

Cross over the reference mark.

Move the plunger until the display starts

counting and the decimal point stops blink-

Û

ing. The display is now ready for operation.

1)

appears.

Crossing over the reference marks automatically switches the

display to REF mode: The last assignment of display values to

length gauge positions is stored in nonvolatile memory.

1)

Press the CL key if you choose not to traverse the reference

marks. Note that, in this case, the relationship between

length gauge position and display value will be lost if the

power is interrupted or if the unit is switched off.

8

Page 9

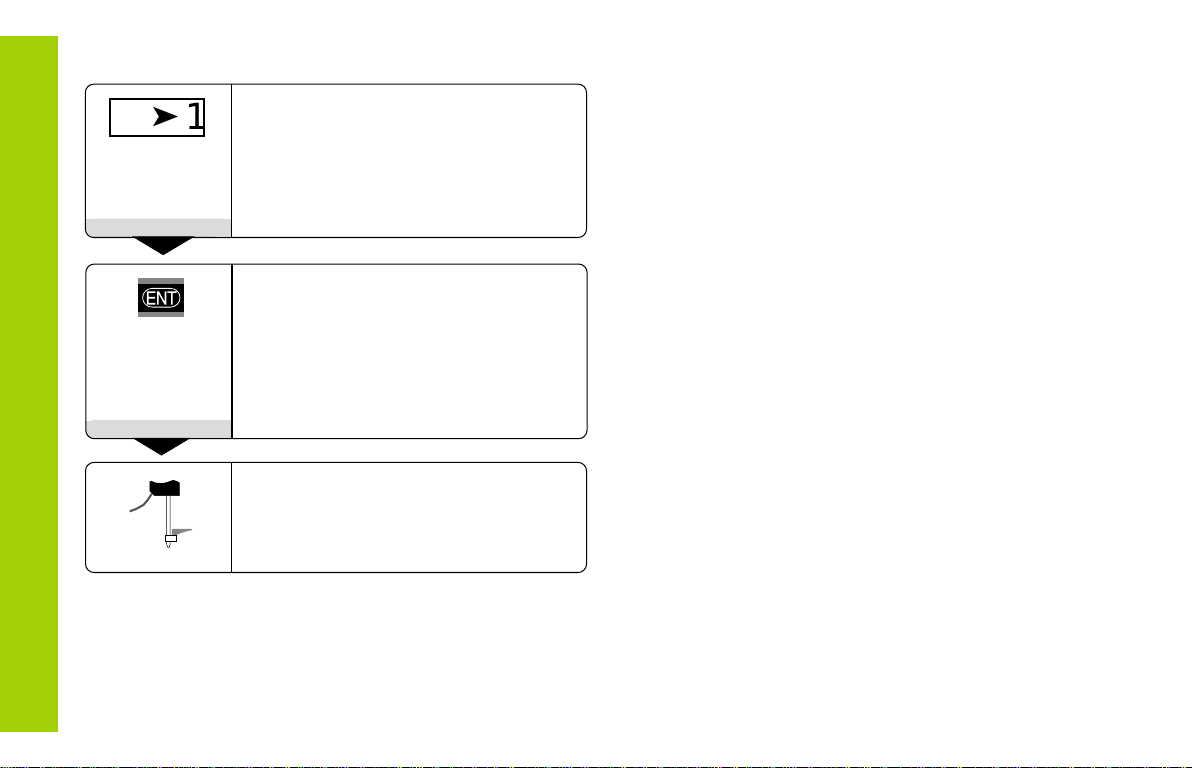

Datum Setting

The datum setting procedure assigns a display value to a

known position. With the ND 200 series, you can set two

separate datum points.

There are several ways to set the datum:

• Enter a numerical value, or

• Transfer a value from an operating parameter

(see P79, P80), or

• By external signal

Select datum 1 or 2.

Enter a numerical value (here, 5).

5

You can switch between datums 1 and 2 as desired. Datum 2

can be used, for example, for working with incremental dimensions.

When you switch back to datum 1, the display unit resumes

display of the encoder's actual position.

SET starts blinking.

Confirm the entered numerical value.

Z

?

?

?

?

?

Without datum setting: unknown assignment of measured

values to positions

Datum Setting

After datum setting: Assignment of measured values to

positions

9

Page 10

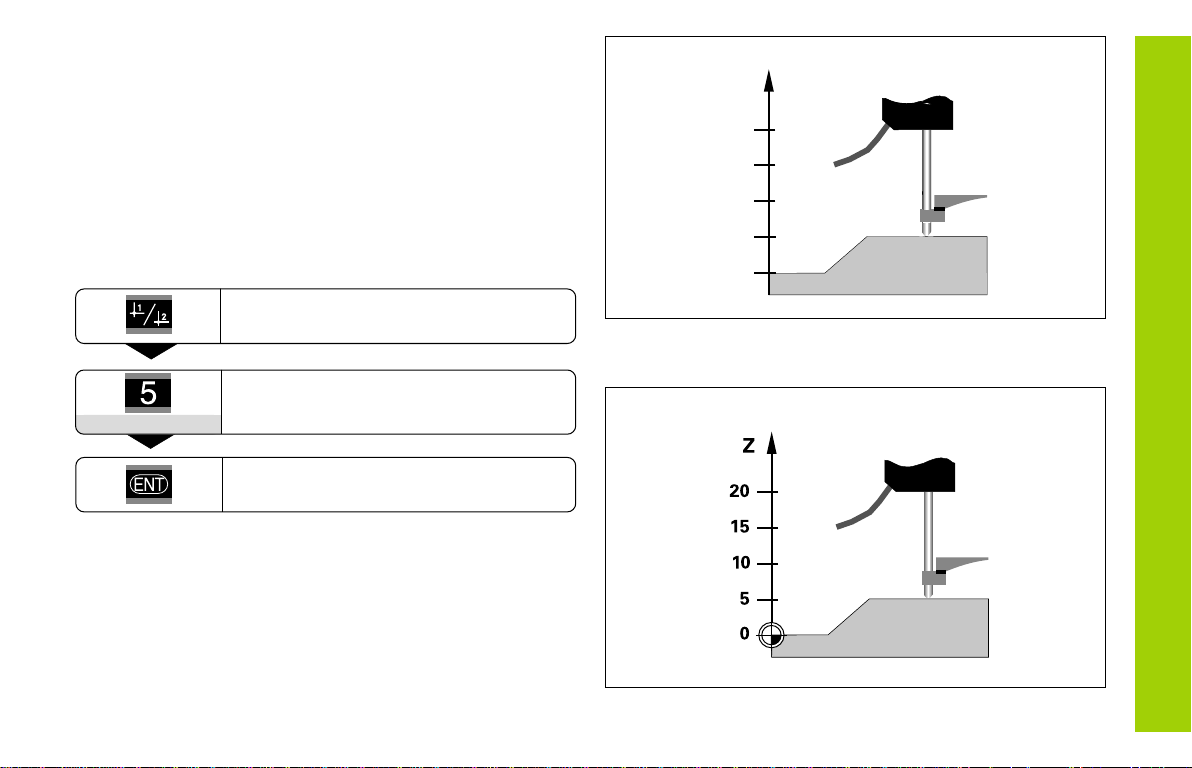

Finding Minimum and Maximum Values from a

Series of Measurements

After a series of measurements has been started, the display

transfers the first measured value to the memory for minimum

and maximum values. Every 0.55 ms, the display compares the

current measured value with the memory contents: A new

value is stored if it is greater than the stored maximum value or

smaller than the stored minimum value. At the same time, the

display calculates and stores the difference DIFF between the

current MIN and MAX values.

Display Meaning

MIN Minimum value from the series of measurements

MAX Maximum value from the series of measurements

DIFF Difference MAX – MIN

ACTL Current measured value

Starting the measurement series and selecting the display

Finding Minimum and Maximum Values

You can start the series of measurements either by pressing

MOD and selecting the desired display—as described on the

following pages—or by external signal over the switching

inputs at the D-sub connection EXT (X41, see “Switching

Inputs and Outputs”).

1)

MAX

ACTL

Series of measurements: The MIN, MAX and DIFF values of an

uneven surface

DIFF

MIN

10

When a series of measurements is started, the internal MIN/

MAX/DIFF memory is reset.

1)

Only in the linear measurement mode.

Example: Measurement series for determining eccentricity

e

Page 11

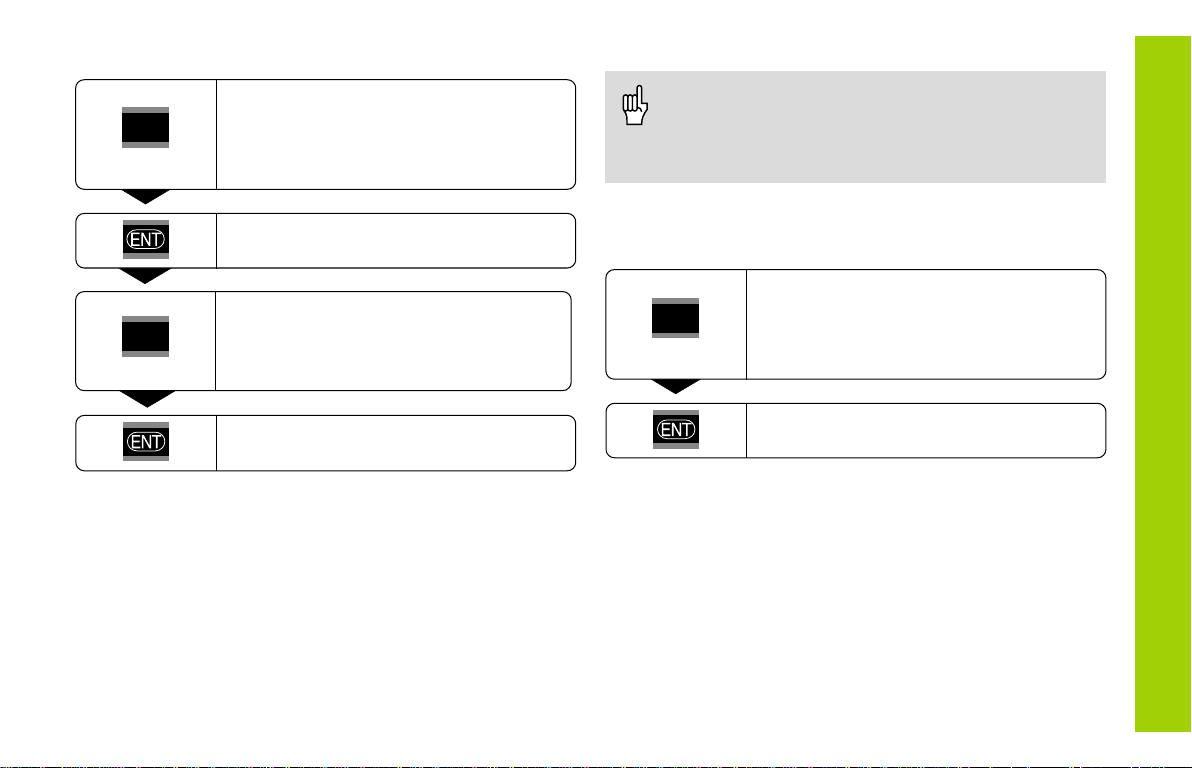

Starting a series of measurements

Switching between MIN, MAX, DIFF and ACTL displays

Repeatedly

MOD

MAX

Repeatedly

Select the display for a series of measurements.

The selected indicator starts blinking

(here, MAX).

Confirm selection.

... until the START indicator starts blinking.

MOD

START

Start the series of measurements.

Indicator preselection

Press MOD to start the series of measurements and select

the display with the indicators.

Operating parameter P86 allows you to define which indicator

is displayed first when MOD is pressed.

It is not possible to switch between the displays as

described below if the switching input for external

control of the series of measurements (pin 6 on

D-sub connection EXT) is active.

As an alternative, you can select the display with operating

parameter P21 (see "Operating Parameters").

Repeatedly

MOD

MIN

The display now shows the smallest value measured during the

current series of measurements.

Select the new display of a series of

measurements.

The selected indicator starts blinking

(here, MIN).

Confirm the change.

Finding Minimum and Maximum Values

11

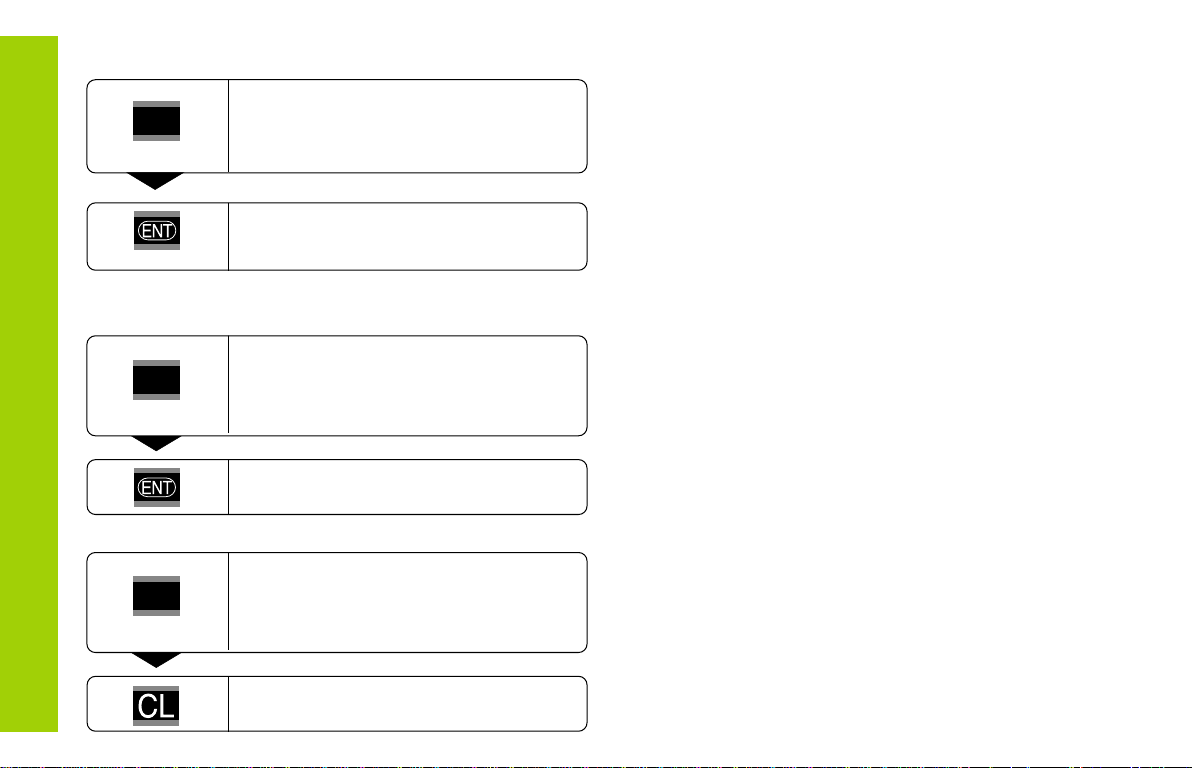

Page 12

Starting a new series of measurements

Repeatedly

MOD

START

Ending a series of measurements

Repeatedly

MOD

Select the indicator START.

The START indicator starts blinking.

Start a new series of measurements.

Select the active indicator (MIN, ACTL,

MAX, DIFF).

The indicator that lit up last starts blinking.

End the series of measurements.

Finding Minimum and Maximum Values

or

Repeatedly

MOD

START

Select the indicator START.

The START indicator starts blinking.

12

End the series of measurements.

Page 13

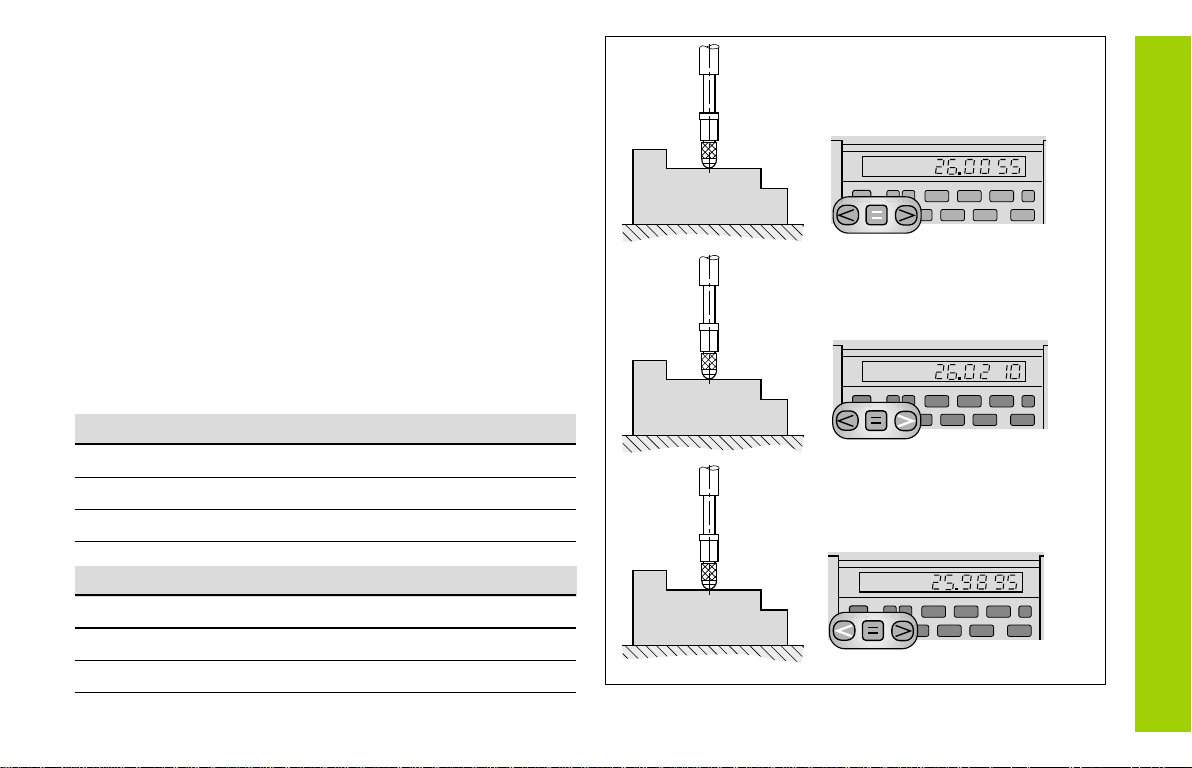

Sorting and Tolerance Checking

In the sorting and tolerance checking mode, the display unit

compares the displayed value with the programmed upper and

lower sorting limits. The sorting and tolerance checking mode is

enabled and disabled with operating parameter P17.

Entering sorting limits

Sorting limits are entered in operating parameters P18 and P19

(see operating parameters).

Sorting signals

The indicators and switching outputs at D-sub connection EXT

(see section on X41) sort the display value into one of three

classes.

Display Meaning

= Measured value is within sorting limits

< Measured value is smaller than lower sorting limit

> Measured value is greater than upper sorting limit

Operating parameters for sorting and tolerance checking

P17 CLASS Sorting ON/OFF

P18 L.CLASS. Lower sorting limit

P19 U.CLASS. Upper sorting limit

Part 1

Part 2

Part 3

Example: Upper sorting limit = 26.02 mm

Lower sorting limit = 26.00 mm

Accept

Sorting and Tolerance Checking

Rework

Reject

13

Page 14

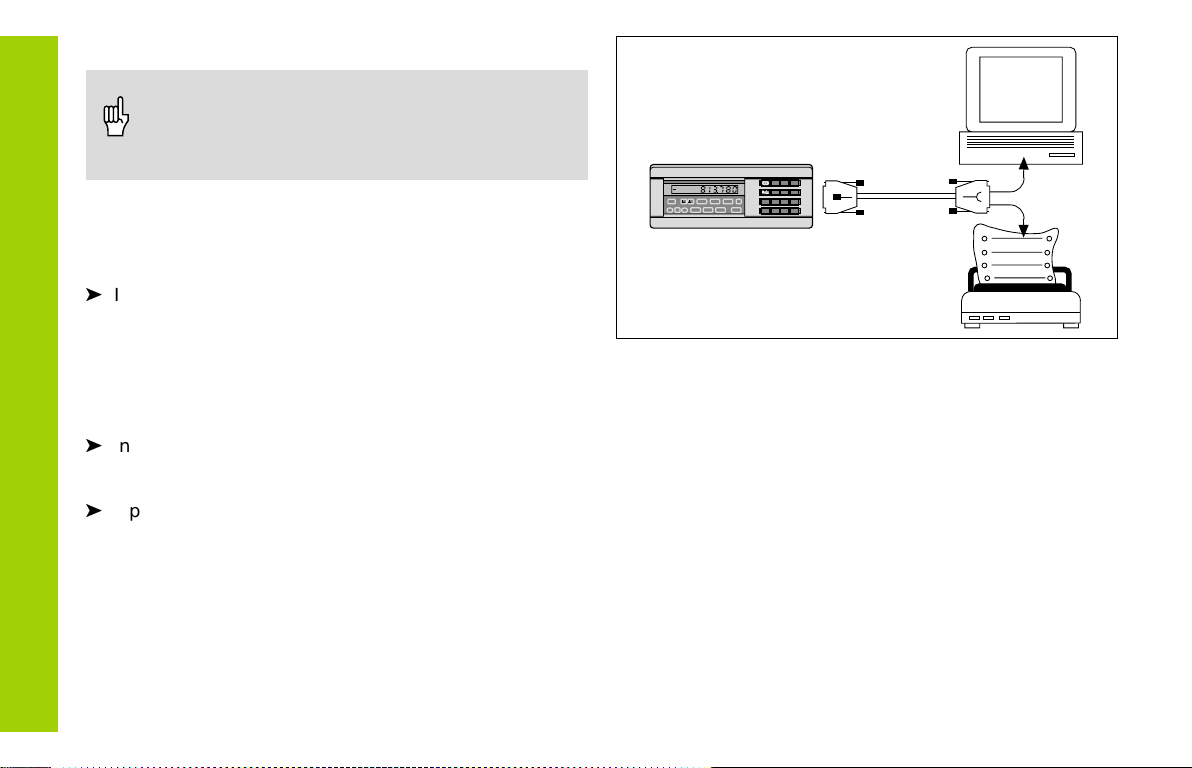

Measured Value Output

For technical information on the RS-232-C/V.24

data interface (X31), information on the data

format, etc., see the chapter “RS-232-C/V.24

Data Interface (X31).”

Measured values can be transmitted over the RS-232-C/V.24

interface (X31), for example to a printer or PC.

There are several ways to start measured value output:

ä

In the linear measurement mode:

Measured Value Output

Press MOD repeatedly until the PRINT indicator starts

blinking, then start measured value output with ENT.

In the angular measurement mode:

Press the MOD key (this feature can be disabled with

operating parameter 86).

or

ä

Input the command STX (Ctrl B) over the RXD input of the

RS-232-C/V.24 interface (X31);

or

ä

Input a signal for measured data output (Pulse or Contact)

at the D-sub connection EXT (X41).

PC

START PRINT

MOD

in.

123

0.–CL

REF21SET

=

<>

HEIDENHAIN

MIN ACTL MAX DIFF

789

456

The RS-232-C/V.24 interface (X31) enables you to connect a

printer or a PC to your display unit

14

Page 15

Display Freeze

With the latch command, the display can be stopped for any

period of time. The internal counter remains active. Parameter

P23 selects the “display freeze” mode and offers three

settings:

• Concurrent display, no display freeze—the display value

is the current measured value.

• Frozen display—display value is frozen and is updated with

each signal for measured value output.

• Frozen/concurrent display—display remains frozen as

long as the latch signal is present; after the signal, the

display resumes continuous display of the current measured values.

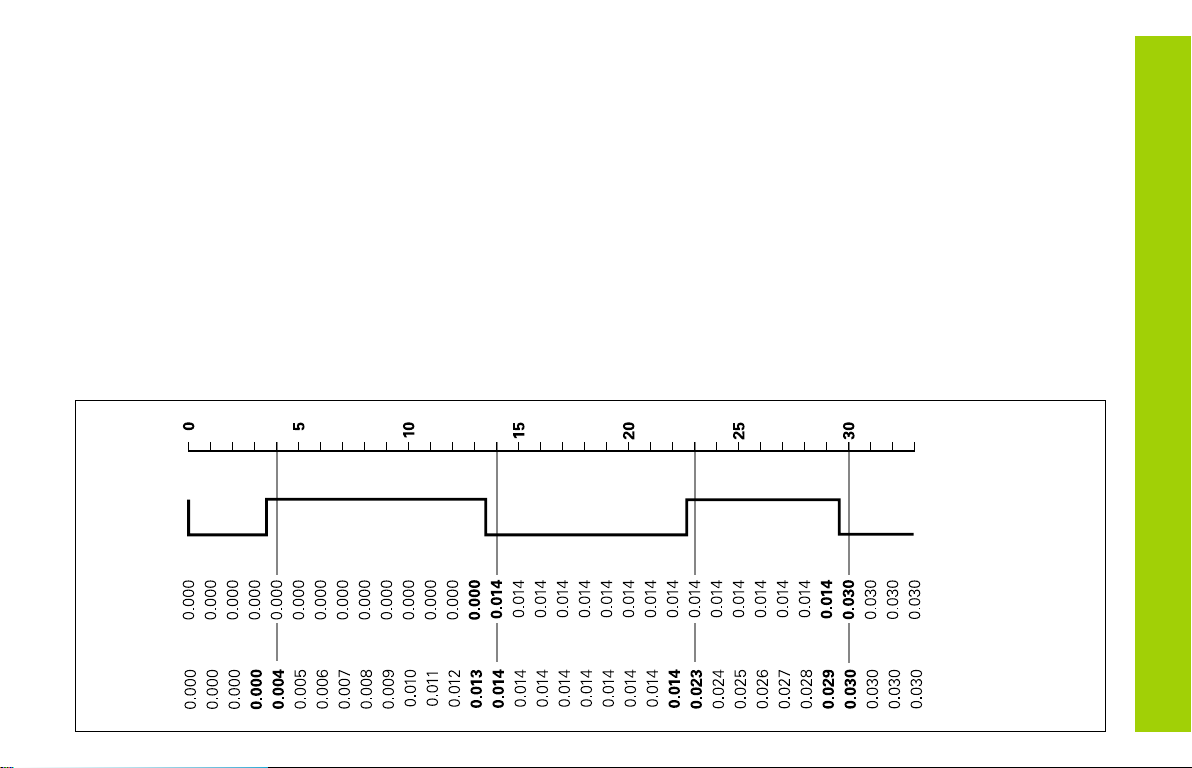

Position

Latch

signal

Frozen

display

Display Freeze

Frozen/

concurrent

display

15

Page 16

Error Messages

Display Effect/Cause

RS232 FAST Command for measured value

output followed too quickly by

another.

1)

SIGNAL Encoder signal is too weak.

Error Messages

The scale may be contaminated.

DSR.MISSING The connected device has not sent

a DSR signal.

1)

REF. ERR. The spacing of the reference marks

as defined in P43 is not the actual

spacing.

1)

FORMAT ERR. Data format, baud rate, etc. do not

1)

match.

FREQUENCY Input frequency too high for encoder

input. Traversing speed may be

too fast.

1)

MEMORY ERR. Checksum error: Check the datum,

operating parameters and compensation values for multipoint axis

error compensation. If this error

recurs, contact your service

agency!

1)

These errors are important for the attached device. The

error signal (pin 19) at D-sub connection EXT is active.

Display Effect/Cause

REC. ERROR Error during reception of param-

eter and compensation-value lists.

Other Error displays

If “OVERFLOW” appears, the measured value is too large or

1)

too small:

ä

Set a new datum.

or

ä

Traverse back.

If all sorting signals light up, the upper sorting limit is smaller

than the lower limit:

ä

Change operating parameters P18 and/or P19.

To clear error messages:

Once you have removed the cause of the error:

ä

Clear the error message with the CL key.

16

Page 17

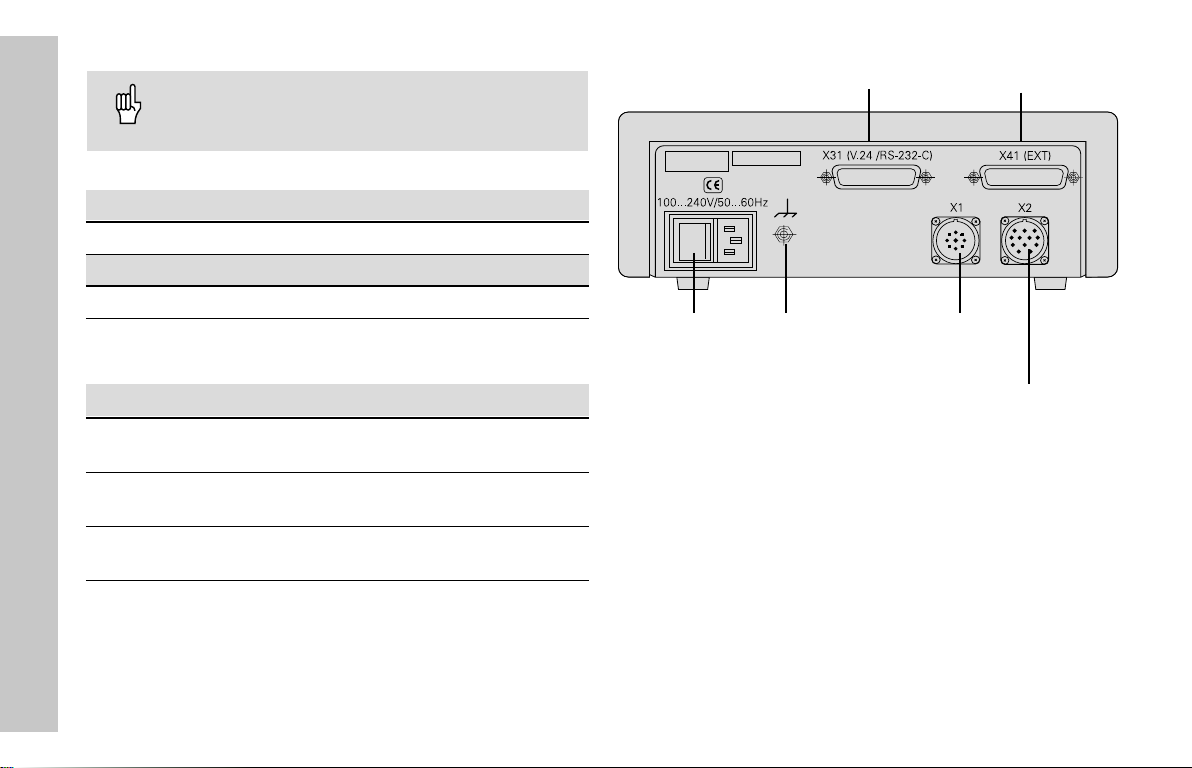

Rear Panel

Ports X1, X2, X31 and X41 comply with the

recommendations in EN 50178 for separation

from line power.

Encoder input X1

HEIDENHAIN flange socket 9-pin

Input signals 11 µA

Maximum encoder cable length 30 m (98.5 ft)

Maximum input frequency 100 kHz

Encoder input X2

HEIDENHAIN flange socket 12-pin

Input signals 1 V

Maximum encoder cable length 60 m (197 ft)

Maximum input frequency 500 kHz

PP

Rear Panel, Accessories

PP

17

Page 18

Rear Panel

Ports X1, X2, X31 and X41 comply with the

recommendations in EN 50178 for separation

from line power.

RS-232-C/V.24 data interface (X31)

25-pin D-sub connection (female)

Switching inputs and outputs EXT (X41)

25-pin D-sub connection (male)

Rear Panel, Accessories

Accessories

Connecting elements

Connector (female) 25-pin for D-sub connection X41

Id. Nr. 249 154 ZY

Connector (male) 25-pin for D-sub connection X31

Id. Nr. 245 739 ZY

Data interface cable, 3 m (9.9 ft), 25-pin for D-sub con-

complete nection X31, Id. Nr. 274 545-01

Power switch

Data interface

Ground

connection

Input X1 for one

HEIDENHAIN

encoder

11 µA

PP

D-sub

connection

Input X2 for one

HEIDENHAIN

encoder

1 V

PP

18

Page 19

Mounting

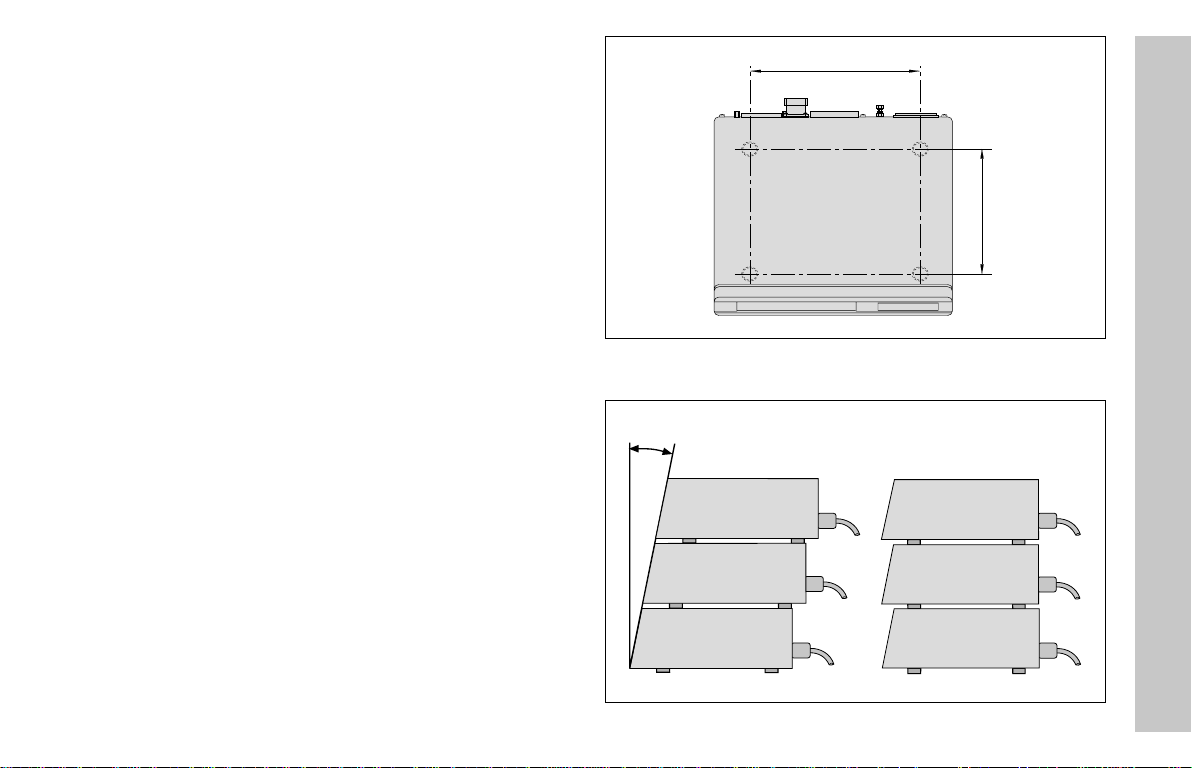

You can fasten the ND 281 B from below by using M4 screws

(see illustration at right).

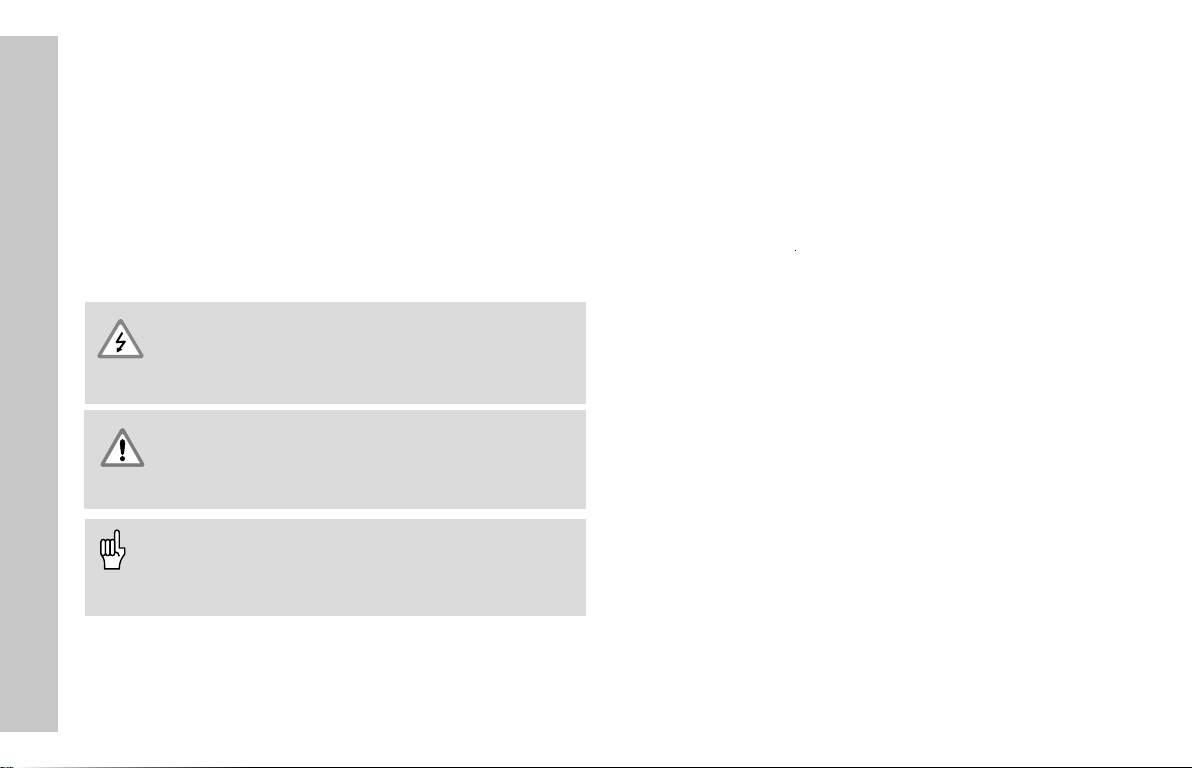

ND 281 B display units are stackable. Adhesive plug-in feet

(supplied with your unit) prevent the stacked units from being

moved out of place.

172 ± 0.2

6.77 ± .008"

Hole positions for mounting the ND display unit

15°

140 ± 0.2

5.51 ± .008"

Mounting

Alternatives of stacking the display units

19

Page 20

Power Connection

The rear panel of the ND 281 B contains a connecting jack for

a power cord with Euro connector (power cord supplied with

the delivery).

Minimum cross section of the power cord: 0.75 mm

Power supply: 100 Vac to 240 Vac (–15% to +10%)

Power supply: 50 Hz to 60 Hz (± 2 Hz)

Power Connection

A voltage selector is therefore not necessary.

Danger of electrical shock!

Unplug the power cord before opening the

housing. Connect the grounding conductor.

Do not interrupt the grounding conductor.

Danger to internal components!

Do not engage or disengage any connections

while the unit is under power. Use only original

replacement fuses.

To increase noise immunity, connect the ground

terminal on the rear panel to the central ground

point of the machine.

(Minimum cross-section: 6 mm

20

2

2

)

Page 21

Linear/Angular Measuring Modes

You can select the linear measuring mode or angular

measuring mode by entering the code number 41 52 63:

➤ Select the user parameter P00 CODE

(see "Operating Parameters").

➤ Enter the code number 41 52 63.

➤ Confirm your entry with ENT.

➤ With the “.” or “–” key, select the ND LENGTH or

ND ANGLE mode, respectively.

➤ Confirm your selection with ENT.

➤ The display unit resets itself.

➤ For further procedure, see “Switch-On, Traversing the

Reference Marks.”

Linear/Angular Measuring Modes

21

Page 22

Operating Parameters

Operating parameters allow you to modify the operating

characteristics of your ND display unit and define the

evaluation of the encoder signals.

Operating parameters are designated by:

• The letter P,

• A two-digit parameter number, and

• An abbreviation.

Example: P01 INCH

Operating Parameters

The factory settings of the operating parameters are

indicated in the parameter list (see “List of Operating

Parameters”) in boldface type.

Parameters consist of “user parameters” and “protected

operating parameters,” which can only be accessed by

entering a code number.

User parameters

User parameters are operating parameters that can be

changed without entering the code number:

P00 to P30, P50, P51, P79, P86, P98

The functions of the individual user parameters are detailed in

the list of operating parameters (see “List of Operating

Parameters”).

To access a user parameter ...

... after switching on the display:

While ENT ... CL is

displayed:

Display first user parameter.

MOD

... during operation:

Together:

Display first user parameter.

MOD

To go directly to a user parameter:

Together:

Press and hold CL while entering the first

digit of the parameter number (here, 1).

Enter the second digit of the parameter

number (here, 9).

The display shows the selected user

parameter.

22

Page 23

Code number for changing protected operating

parameters

If you wish to change protected operating parameters, you

must first enter the code number 9 51 48:

ä

Select the user parameter P00 CODE.

ä

Enter the code number 9 51 48.

ä

Confirm entry with ENT.

Parameter P30 appears on the display. By paging through the

list of operating parameters you can display—and, if

necessary, change—each protected operating parameter and,

of course, each user parameter.

Once you have entered the code number, the

protected operating parameters remain accessible

until the display unit is switched off.

Functions for changing the operating parameters

Function Key

Page forward

in the list of operating parameters

Page backward

in the list of operating parameters

Reduce parameter value

Increase parameter value

Correct entry and

display parameter designations

Confirm change or numerical entry,

exit the list of operating parameters

A changed parameter is stored as soon as you

• Exit the list of operating parameters

or

• Page forward or backward after the change.

MOD

Operating Parameters

23

Page 24

List of Operating Parameters

Parameter Settings / Function

P00 CODE Enter a code number:

9 51 48: To change the protected

operating parameters

41 52 63: To select the linear or angular

measurement mode

10 52 96: Multipoint axis error

compensation

24 65 84: To lock the keyboard

66 55 44: To show the software version

24 65 82: Distance-to-go display

48 61 53: Input and output of parameter

and compensation-value lists

P01 Units of measurement

List of Operating Parameters

Display in millimeters MM

Display in inches INCH

P02 X1/X2 Select an encoder input

Signals at X1 11 µAPP

Signals at X2 1 VPP

P08 DISPL. Display mode

Decimal degrees DEC. DEGREE

Deg., minutes, seconds DEG.MIN.SEC.

Parameter Settings / Function

P09 ANGLE Angle display

2)

+/- 180° +/- 180 DEG.

+/-

¥

ENDLESS

360° 360 DEG.

P11 SCL Scaling factor

1)

Scaling factor off SCALING OFF

Scaling factor on SCALNG. ON

P12 SCL Scaling factor

1)

Enter a numerical value

0.100000 < P12 < 9.999999

1)

Default setting: 1.000000

P17 CLASS Sorting and tolerance checking

Sorting and tol. checking ON CLASS ON

Sorting and tol. checking OFF CLASS OFF

P18 L.CLASS Lower limit for sorting

P19 U.CLASS Upper limit for sorting

2)

P21 SERIES Display for series of measurements

1)

OFF MIN MAX ACTL DIFF

24

1)

Only in linear measurement mode.

2)

Only in angular measurement mode.

Page 25

Parameter Settings/ Function

P23 DISPL. Display stop for measured value output

Concurrent display, no display freeze;

the display value is the current actual

value DISPL. ACTL.

Frozen display; hold display until next

measured value output DISPL. HOLD

Frozen/concurrent display; freeze display

as long as Pulse/Contact for measured

value output is present DISPL. STOP

P30 DIR Counting direction

Positive counting direction with

positive direction of traverse DIRECT. POS

Negative counting direction with

positive direction of traverse DIRECT. NEG

1)

P31 S. PER. Signal period

of encoder

0.000 000 01 < P31 < 99 999.9999

Default setting: 10 µm

P33 COUNT Counting mode

1)

0-1-2-3-4-5-6-7-8-9 COUNT 0-1

0-2-4-6-8 COUNT 0-2

0-5 COUNT 0-5

P36 SP/R Signal periods per revolution

2)

1 < P36 < 999 999

Default setting: 36 000

Parameter Settings/ Function

P37 STEP Counting mode

2)

0-1-2-3-4-5-6-7-8-9 COUNT 0-1

0-2-4-6-8 COUNT 0-2

0-5 COUNT 0-5

P38 DEC. Decimal places

3)

1 / 2 / 3 / 4 / 5 / 6

(up to 8 for inch display)

P40 COMP. Select encoder compensation

No compensation COMP. OFF

Multipoint: up to 64 compensation points for

linear encoders, up to 72 for angle encoders

(fixed spacing of 5 deg.) COMP. MULTI

Linear compensation COMP. LIN

1)

Only in linear measurement mode.

2)

Only in angular measurement mode.

3)

Depends on signal period (P31) and unit of measure (P01)

List of Operating Parameters

1)

25

Page 26

Parameter Settings / Function

P41 L.COMP. Linear error compensation

– 99 999.9 < P41 < + 99 999.9 [µm/m]

Default setting: 0

Example: Find input value for P41

Displayed measuring length .............L

= 620.000 mm

d

Actual length (measured, e.g.

with the VM 101 comparator

system from HEIDENHAIN) ..............L

= 619.877 mm

a

Length difference .............................DL = L

Compensation factor k (= P41):

k = DL / Ld = – 123 µm / 0.62 m .......k = – 198.4 [µm/m]

P42 BACKLASH Backlash compensation

List of Operating Parameters

Input range (mm): +9.999 to -9.999

Default setting: 0.000

= no backlash compensation

During a change in direction, the mechanical

play between the encoder and table, the socalled backlash, can cause error.

Positive backlash: The rotary encoder moves

before the table, therefore the display value

is too high (positive value input).

Negative backlash: The rotary encoder

moves after the table, therefore the display

value is too low (negative value input).

1)

– Ld = – 123 µm

a

1)

Parameter Settings / Function

P43 REF Reference marks

One reference mark SINGLE REF.

Distance-coded with 500 • SP

(SP: signal period) 500 SP

Distance-coded with 1000 • SP

(e.g. for HEIDENHAIN LS ...C) 1000 SP

Distance-coded with 2000 • SP 2000 SP

Distance-coded with 5000 • SP 5000 SP

P44 REF Reference mark evaluation

Evaluate the reference mark REF. ON

Do not evaluate the reference

mark REF. OFF

P45 ALARM Encoder monitoring

No monitoring ALARM OFF

Monitor the frequency FREQUENCY

Monitor contamination CONTAMINAT.

Contamination + frequency FRQ. + CONT.

P50 RS232 Baud rate

110 / 150 / 300 / 600 / 1200 /

2400 / 4800 / 9600 / 19 200 /

38 400 baud

26

1)

Only in linear measurement mode.

Page 27

Parameter Settings / Function

P51 RS232 Additional blank lines

during data output BK LINE 1

0 £ P51 £ÿ99

Default setting: 1

P62 A1 Trigger limit 1

P63 A2 Trigger limit 2

P79 PRESET Value for datum point

Enter numerical value for

datum setting over switching input

or with ENT key

P80 ENT-CL Set display

No zero reset/Set with

CL/ENT CL-ENT OFF

Zero reset with CL

setting disabled with ENT CL......ON

Zero reset with CL and set with

ENT to value selected in P79 CL-ENT ON

P82 DISPL.ON Message after switch-on

ENT...CL message MESSAGE ON

No message MESSG. OFF

P85 EXT.REF External REF

REF over D-sub port EXT EXT.REF ON

No REF over D-sub port EXT EXT.REF OFF

Parameter Settings / Function

P86 MOD In the linear measurement mode

First indicator after pressing MOD

START PRINT

MIN ACTL MAX DIFF

In the angular measurement mode

PRINT via MOD disabled PRINT OFF

PRINT via MOD enabled PRINT ON

P98 LANGUA. Conversational language

German LANGUAGE DE

English LANGUAGE EN

French LANGUAGE FR

Italian LANGUAGE IT

Dutch LANGUAGE NL

Spanish LANGUAGE ES

Danish LANGUAGE DA

Swedish LANGUAGE SV

Finnish LANGUAGE FI

Czech LANGUAGE CS

Polish LANGUAGE PL

Hungarian LANGUAGE HU

Portuguese LANGUAGE PT

List of Operating Parameters

27

Page 28

Linear Encoders

The ND 281 B display unit is designed for use together with

photoelectrical encoders with sinusoidal signals—11 µA

1V

.

PP

Display step with linear encoders

You can select a specific display step by adapting the

Linear Encoders

following operating parameters:

• Signal period (P31)

• Counting mode (P33)

• Decimal places (P38)

Example

Linear encoder with a signal period of 10 µm

Desired display step................. 0.000 5 mm

Signal period (P31) ................... 10

Counting mode (P33) ............... 5

Decimal places (P38)................ 4

The following tables will help you select the appropriate

parameter settings.

PP

or

28

Page 29

Recommended parameter setting s f or HEIDENHAIN linear encoders w it h 11 µA

Model

P 31 P 43

CT

MT xx01

LIP 401A/401R

LF 103/103C

LF 401/401C

LIF 101/101C

LIP 501/501C

LIP 101

MT xx 10 Single 0.0005

LS 303/303C

LS 603/603C

2

4

20 Single/1000 0.01

Reference

marks

Signal

period

in µm

Single 0.0005

Single

Single/5000 0.001

Single

Millimeters

Display

step

in mm

0.0002

0.0001

0.00005

Recommd. only for LIP 401

0.00002

0.00001

0.000005

0.0005

0.0002

0.0001

0.00005

Recommd. only for LIP 101

0.00002

0.00001

0.0002

0.0001

0.005

P 33 P 38

5

2

1

5

2

1

5

1

5

2

1

5

2

1

5

2

1

1

5

Count.

mode

4

4

4

5

5

5

6

3

4

4

4

5

5

5

4

4

4

2

3

Decimal

places

Inches

Display

step

in inches

0.00002

0.00001

0.000005

0.000002

0.000001

0.0000005

0.0000002

0.00005

0.00002

0.00001

0.000005

0.000002

0.000001

0.0000005 1 5

0.00002

0.00001

0.000005

0.0005

0.0002

signals

PP

Count.

mode

P 33 P 38

2

1

5

2

1

5

2

5

2

1

5

2

2

1

5

5

2

5

5

6

6

6

7

7

5

5

5

6

6

6

7

5

5

6

4

4

Decimal

places

Linear Encoders

29

Page 30

Recommd. parameter settings for HEIDENHAIN linear encoders with 11 µAPP signals (continued)

Model

Linear Encoders

LS 106/106C

LS 406/406C

LS 706/706C

ST 1201

LB 302/302C

LIDA 10x/10xC

LB 301/301C 100 Single/1000 0.005

LIM 501 10240 Single 0.1

Reference

marks

Signal

period

in µm

P 31 P 43

20

40 Single/2000

Single/1000

-

Millimet er s

Display

step

in mm

0.001

0.0005

0.005

0.002

0.001

0.0005

Recommd. only for LB 302

0.0002

0.0001

0.002

0.001

0.01

0.05

P 33 P 38

1

5

5

2

1

5

2

1

5

2

1

1

1

5

Count.

mode

3

4

3

3

3

4

4

4

3

3

3

1

2

2

Inches

Display

step

in inches

Decimal

places

0.00005

0.00002

0.0002

0.0001

0.00005

0.00002

0.000001

0.0000005 1 5

0.0002

0.0001

0.00005

0.005

0.0005

0.002

P 33 P 38

5

2

2

1

5

2

2

1

5

5

5

2

Count.

mode

Decimal

places

5

5

4

4

5

5

5

6

4

4

5

3

4

3

30

Page 31

Recommended parameter settings for HEIDENHAIN linear encoders with 1 VPP signals

Model

P 31 P 43

LIP 382 0.128 - 0.000002

MT xx81

LIP 481A/481R

LF 183/183C

LF 481/481C

LIF 181/181C

LIP 581/581C

VM 182

LS 186/186C

LS 486/486C

ST 1281

2 Single

4

20

Reference

marks

Signal

period

in µm

Single/5000 0.001

-

Single/1000 0.001

-

Millimeters

Display

step

in mm

0.000001 2 1

0.0005

0.0002

0.0001

0.00005

Recommd. only for LIP 481 X

0.00002

0.00001

0.000005

0.0005

0.0002

0.0001

0.00005

Recommd. only for VM 182

0.00002

0.00001

0.0005

P 33 P 38

5

2

1

5

2

1

5

1

5

2

1

5

2

1

1

5

Count.

mode

Decimal

6

6

4

4

4

5

5

5

6

3

4

4

4

5

5

5

3

4

places

Inches

Display

step

in inches

0.0000001

0.0000000

5

0.00002

0.00001

0.000005

0.000002

0.000001

0.0000005

0.0000002

0.00005

0.00002

0.00001

0.000005

0.000002

0.000001

0.0000005 1 5

0.00005

0.00002 5 2

Count.

mode

P 33 P 38

1

5

2

1

5

2

1

5

2

5

2

1

5

2

Decimal

places

7

8

5

5

6

6

6

7

7

5

5

5

6

6

6

7

5

5

Linear Encoders

31

Page 32

Recommended parameter settings for HEIDENHAIN linear encoders with 1 VPP signals (continued)

Model

Linear Encoders

LB 382/382C

LIDA 18x/18xC

LB 381/381C 100 Single/1000 0.005

Reference

marks

Signal

period

in µm

P 31 P 43

40 Single/2000

Millimeters

Display

step

in mm

0.005

0.002

0.001

0.0005

Recommd. only for LB 382

0.0002

0.0001

0.002

0.001

P 33 P 38

5

2

1

5

2

1

5

2

1

Count.

mode

3

3

3

4

4

4

3

3

3

Inches

Display

step

in inches

Decimal

places

0.0002

0.0001

0.00005

0.00002

0.00001

0.000005 1 5

0.0002

0.0001

0.00005

Count.

P 33 P 38

2

1

5

2

2

1

5

mode

Decimal

places

4

4

5

5

5

6

4

4

5

32

Page 33

Recommended paramet e r settings for HEIDENHAIN angle encoders with 11 µA

Model

Signal

P36

ROD 450 /

ROD 456 / ROD 486

/ ROD 1080

ROD 250 C / ROD 280 C

RON 255 C / RON 285 C

ROD 250 C / ROD 280 C

ROD 255 C / RON 285 C

ROD 700 C / ROD 780 C

RON 705 C / RON 785 C

RON 706 C / RON 786 C

RON 905 / 36 000 One Single 0.0001° 1 4

ROD 800 C / ROD 880 C

ROD 806 C / ROD 886 C

Convert decimal degrees into degrees, minutes, seconds

1 degree (1°) = 60 minutes (60'); 1 minute (1') = 60 seconds (60")

1 second (1") »ÿ0.000278°

3600 One Single

9000

18 000

36 000

periods per

revolution

Reference

marks

Dist.coded

Dist.coded

Dist.coded

Display

step

Count.

P43

0.01°

0.005°

0.001°

500

1000

1000 0.0001° 1 4

0.005°

0.001° 5 1

0.001°

0.0005°

0.0001°

P37 P38

/ 1 VPP signals

PP

mode

1

5

1

1

5

1

Decimal

places

3

3

3

3

3

4

4

Angle Encoders

33

Page 34

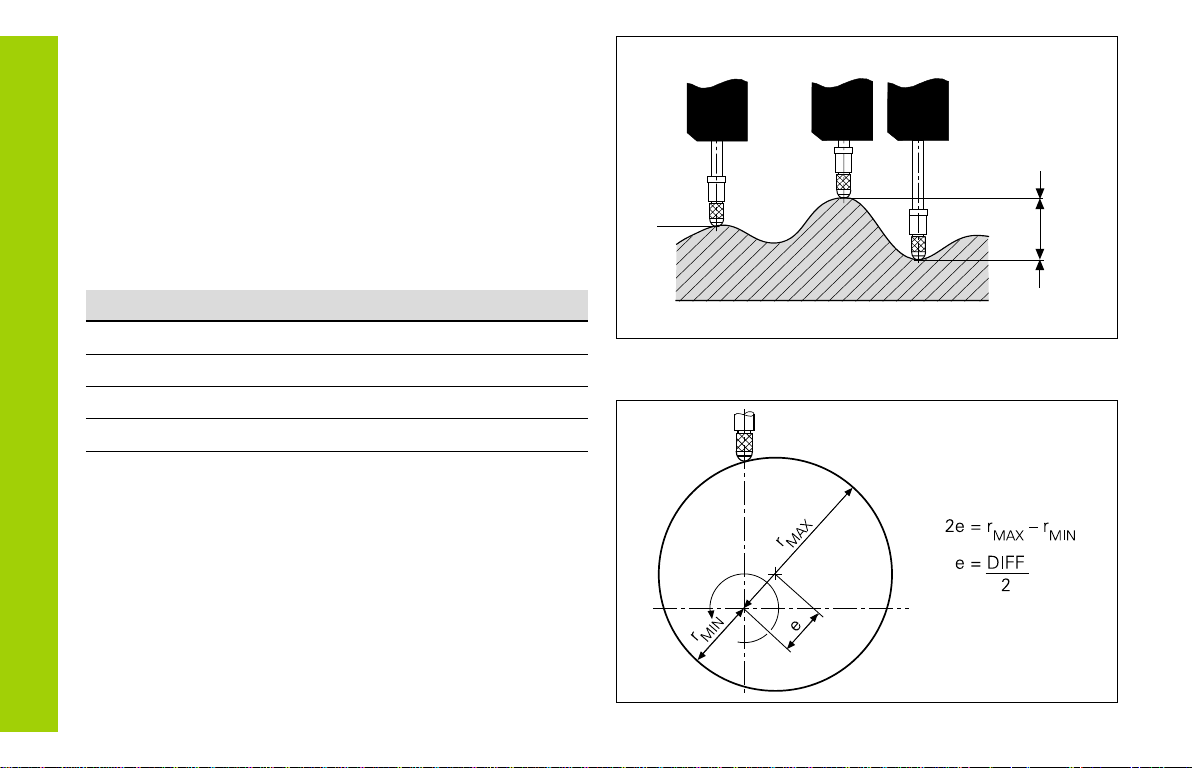

Multipoint Axis Error Compensation

If you want to use the multipoint axis error

compensation feature, you must:

• Activate the feature with operating parameter

40 (see “Operating Parameters”),

• Traverse the reference marks after switching

on the display unit,

• Enter a compensation value table.

Your machine may have a nonlinear axis error due to factors

such as axis sag or leadscrew errors. Such deviations are

usually measured with a comparator measuring system (such

as the HEIDENHAIN VM 101).

In the linear measurement mode:

You can make a compensation value table with 64

compensation values.

In the angular measurement mode:

You can make a compensation value table with 72

Multipoint Axis Error Compensation

compensation points (point spacing: 5 degrees). The datum is

the reference point.

You select the compensation table through P00 CODE and by

entering the code number 10 52 96 (see "Operating

Parameters").

Ascertaining the compensation values

To ascertain the compensation values (e.g. with a VM 101)

you must select the compensation table and then press the

“–” key to select the REF display.

34

The letter “R” at the left of the display indicates that the

displayed position value is given with respect to the reference

mark. If “R” blinks, you must traverse the reference mark.

Entries in the compensation value table

• Datum

1)

:

Here you enter the point at which the compensation is to

begin. This point indicates the absolute distance to the

reference point.

Do not change the datum after measuring the axis

error and before entering the axis error into the

compensation table.

• Spacing of the compensation points

1)

:

The spacing of the compensation points is expressed as:

Spacing = 2 x [µm].

Enter the value of the exponent

x

in into the compensation

value table.

Minimum input value: 6 (= 0.064 mm)

Maximum input value: 20 (= 1048.576 mm)

Example: 900 mm traverse with 15 compensation points

==> 60.000 mm spacing between points.

Nearest power of two: 2

16

= 65.536 mm (see

“Table for determining the point spacing”)

Input value in the table: 16

• Compensation value:

You enter the measured compensation value (in millimeters) for the displayed compensation point. Compensation point 0 always has the value 0 and cannot be changed.

1)

Only in the linear measurement mode

Page 35

Table for determining the point spacing

Exponent Point spacing

in mm in inches

6 0.064 0.0025“

7 0.128 0.0050“

8 0.256 0.0100“

9 0.512 0.0200“

10 1.024 0.0403“

11 2.048 0.0806“

12 4.096 0.1612“

13 8.192 0.3225“

14 16.384 0.6450“

15 32.768 1.290“

16 65.536 2.580“

17 131.072 5.160“

18 262.144 10.32“

19 524.288 20.64“

20 1048.576 41.28“

Multipoint Axis Error Compensation

35

Page 36

Selecting the compensation table, entering an axis correction

together

with

Select the operating parameters.

MOD

Select P00 CODE.

P00 CODE

Enter the code number 10 52 96,

confirm with ENT.

DATUM (shown for approx. two seconds)

MOD

Multipoint Axis Error Compensation

SPACING

1)

Enter the active datum for the error on

the axis to be corrected, e.g. 27 mm.

Press MOD to select the next input box.

Enter the spacing of the compensation

points on the axis to be corrected, for

4 x

MOD

example 210 mm (equals 1.024 mm).

Press MOD four times to select COMP.

NR. 01. (You cannot enter values in the

POS. NR. 00, COMP. NR. 00 and POS.

NR. 01 boxes.)

36

COMP. NR. 01

Enter the associated compensation value,

e.g. 0.01 mm. Press MOD twice to

2 x

MOD

select COMP. NR. 02. (You cannot enter

any values in the POS. NR. 02 box).

COMP. NR. 02

Enter all further compensation points.

If you want so select a compensation

2 x

MOD

point directly, press CL and

simultaneously enter the desired

1)

compensation point number.

Conclude entry.

1)

Only in the linear measurement mode

1)

For "angle measurement": Datum = reference point

1)

Point separation: 5 degrees

Page 37

Deleting a compensation value table

together

with

P00 CODE

DATUM

DELETE

Select the operating parameters.

MOD

Select P00 CODE.

Enter the code number 10 52 96,

confirm with ENT.

Select the “delete” function.

Confirm with ENT or cancel with CL.

Exit the compensation table mode.

Multipoint Axis Error Compensation

37

Page 38

Switching Inputs and Outputs EXT (X41)

Inputs at D-sub connection EXT (X41)

Danger to internal components!

Voltage sources for external circuitry must conform

to the recommendations in EN 50178 for lowvoltage electrical separation. Connect inductive

loads only with a quenching diode parallel to the

inductance.

Only use shielded cables!

Connect the shield to the connector housing.

Outputs at D-sub connection EXT (X41)

Pin Function

14 Display value is zero

15 Measured value ³ trigger limit A1 (P62)

16 Measured value ³ trigger limit A2 (P63)

Switching Inputs and Outputs EXT (X41)

17 Measured value < lower sorting limit (P18)

18 Measured value > upper sorting limit (P19)

19 Error (see “Error Messages”)

38

1)

Only in the linear measurement mode

Pin Function

1, 10 0 V

2 Reset display to zero, clear error message

3 Set display to the value selected in P79

4 Ignore reference mark signals

5 Start series of measurements

1)

6 Externally select display value for series of

measurements

1)

7 Display MIN value of series of measurements

8 Display MAX value of series of measurements

9 Display difference MAX – MIN

1)

22 Pulse: Transmit measured value

23 Contact: Transmit measured value

25 Enable or disable REF mode

(current REF status is changed)

12, 13, 24

11, 20, 21

Do not assign

Vacant

Special case: Display current measured value ACTL

If you wish to display the current measured value ACTL of a

series of measurements, note for inputs 7, 8 and 9:

Either none or more than one of these inputs must be active.

1)

1)

Page 39

Inputs

Outputs

Input signals

Internal pull-up resistor 1 kW, active with low level

Trigger by making contact against 0 V or

by low-level signal over TTL logic device

Delay for set/zero reset: td £ 2ms

Minimum pulse duration for all signals: t

³ 30 ms

min

Signal level of inputs

Status Level

High + 3.9 V £ U £ + 15 V

Low – 0.5 V £ U £ + 0.9 V; I £ 6 mA

E

0V

E

0V

t

min

t

min

³ÿ30 ms

Output signals

"Open collector" outputs, active with low level

Delay until signal output: td £ 30 ms

Signal duration of zero signal, trigger limit A1, A2: t0 ³ 180 ms

Signal level of outputs

Status Level

High U £ + 32 V; I £ 10 µA

Low U £ + 0.4 V; I £ 100 mA

I ≤ 100 mA

+ UB ≤ 32 V

C

B

U

CE

E

Pin 1.10

0 V

Switching Inputs and Outputs EXT (X41)

39

Page 40

Setting and zero resetting the display

With an external signal, you can set the display to the value

selected in parameter P79 (pin 3) or reset each axis to zero (pin 2).

Enabling and disabling REF mode

Operating parameter P85 allows you to activate the input

(pin 25) which will be used for setting the display externally to

REF mode when the unit is switched on or when the power is

restored after an interruption. The next signal deactivates REF

mode again (switchover function).

Ignoring reference mark signals

If this input (pin 4) is active, the display will ignore all

Switching Inputs EXT (X41)

reference mark signals. A typical application of this function is

for measuring lengths with a rotary encoder and spindle; in

this case, a cam switch releases the reference mark signal at

a preset position.

40

Externally selecting MIN/MAX

Starting a series of measurements

Switching the display between MIN/MAX/DIFF/ACTL

You can activate the operating mode for finding minimum and

maximum values from a series of measurements with an

external signal (pin 6, low-level signal must be present

continuously). The setting selected with MOD or operating

parameter P21 is disabled. You can switch to MIN/MAX/DIFF/

ACTL display (pins 7, 8, 9, low-level signal must be present

continuously) and START (pin 5, Pulse) of a new series of

measurements only by external signal over the switching

inputs.

1)

1)

Only in linear measurement mode.

Page 41

Switching signals

As soon as the trigger points defined in parameters are

reached, the corresponding outputs (pins 15, 16) are

activated. You can set up to two trigger points. The switching

point “zero” has a separate output (see “Zero crossover”).

Signals for sorting and tolerance checking

If the sorting limits defined in parameters are exceeded, the

corresponding outputs (pins 17, 18) are activated.

Output

Switching point

Measured value < lower sorting limit

Path

Signals Operating parameters Pin

Switching signals P62, switching limit 1 15

P63, switching limit 2 16

Sorting signals P18, lower sorting limit 17

P19, upper sorting limit 18

Zero crossover

The display value “zero” activates the corresponding output

(pin 14). Minimum signal duration is 180 ms.

Measured value > upper

sorting limit

Lower limit Upper limit

Path

Weg

Path

5

Pin 15

(A1)

t

d

t

v

t

t

d

v

Time curve of signal at pin 15 for trigger limit (A1) = 5 mm , td £

t

t

30 ms

Switching Outputs EXT (X41)

41

Page 42

Switching signal for errors

The display unit permanently monitors functions such as

measuring signal, input frequency, and data output, and

displays an error message if it detects an error.

If errors occur that seriously influence measurement or data

output, the display unit activates a switching output. This

feature allows monitoring of automated processes.

Switching Outputs EXT (X41)

ERROR xx

Error

42

Page 43

Locking the Keypad

You can lock or release the keypad by entering the code

number 24 65 84:

➤ Select the user parameter P00 CODE (see “Operating

Parameters”).

➤ Enter the code number 24 65 84.

➤ Confirm the entry with ENT.

➤ With the “•” or “–” key, select KEYS ON or

KEYS OFF.

➤ Confirm your selection with ENT.

If the keypad is locked, you can only select the datum or

select P00 CODE over the MOD key.

Locking the Keypad

43

Page 44

Displaying the Software Version

To display the software version of the display unit, enter the

code number 66 55 44:

➤ Select the user parameter P00 CODE.

➤ Enter the code number 66 55 44.

➤ Confirm your entry with ENT.

➤ The display unit shows the software number.

➤ With the “–” key you can switch the display to the date of

issue.

➤ To exit the software version display mode, press ENT.

Displaying the Software Version

44

Page 45

Distance-to-Go Mode

1)

Function of switching outputs A1 and A2

Normally, the display shows the actual position of the encoder. However, it is often more helpful to display the remaining distance to an entered nominal position—especially

when you are using the display unit for machine tools and automation purposes. You can then position simply by traversing

to display value zero.

You can access the distance-to-go display by entering the

code number 24 65 82.

Display Meaning

DELTA ON Distance-to-go display active

DELTA OFF Distance-to-go display not active

“Traversing to zero” with distance-to-go display

ä

Select datum point 2.

ä

Enter the nominal position.

➤ Move the axis until the display value is zero.

In the distance-to-go mode, switching outputs A1 (pin 15) and

A2 (pin 16) have a different function: they are symmetrical to

the display value zero. For example, if a switching point of

10 mm is entered in P62, output A1 switches at both +10 mm

and –10 mm. The figure below shows output signal A1 when

approaching zero from the negative direction.

t

d1

t

d2

Time curve of a signal for switching limit (A1) = 10 mm,

t

£

d1

30 ms, t

d2

£

180 ms

Distance-to-Go Mode

1)

Only in linear measurement mode

45

Page 46

RS-232-C/V.24 Data Interface (X31)

The RS-232-C/V.24 interface (X31) of your display unit enables

you to transmit measured data in ASCII format, for example to

a printer or PC.

Connecting cable

You can use a connecting cable with full wiring (figure at upper

right) or simplified wiring (below right). A cable with full wiring

is available from HEIDENHAIN.

Data transmission cable for RS-232-C/V.24

D-sub (male) 25-pin/D-sub (female) 25-pin

Id. Nr. 274 545-..

On this type of cable, pin 6 and pin 8 are additionally connected

over a jumper.

Data transmission cable for RS-232-C/V.24

D-sub (male) 25-pin/D-sub (female) 9-pin

Id. Nr. 368 017-..

RS-232-C/V.24 Data Interface (X31)

Maximum cable length: 20 m (66 ft)

25 pol. 25 pol.

Data transmission cable 25-pin/25-pin

(full wiring)

25 pol. 25 pol.

Data transmission cable 25-pin/25-pin

(simplified wiring)

46

25 pol. 9 pol.

Data transmission cable 25-pin/9-pin

Page 47

Pin layout RS-232-C/V.24 (X31)

Data format and control characters

Pin Signal Assignment

1 CHASSIS GND Chassis ground

2 TXD Transmitted data

3 RXD Received data

4 RTS Request to send

5 CTS Clear to send

6 DSR Data set ready

7 SIGN. GND Signal ground

8 to 19 –

Not assigned

20 DTR Data terminal ready

21 to 25 –

Not assigned

Levels for TXD and RXD

Logic level Voltage level

Active – 3 V to – 15 V

Not active + 3V to +15 V

Levels for RTS, CTS, DSR and DTR

Logic level Voltage level

Active + 3 V to + 15 V

Not active – 3V to – 15 V

Data format 1 start bit

7 data bits

Even parity bit

2 stop bits

Control characters Call measured value: STX (Ctrl B)

Interrupt DC3 (Ctrl S)

Continue DC1 (Ctrl Q)

Interrogate error message: ENQ (Ctrl E)

Example: Data sequence during measured value output

Measured value = – 5.23 mm

The measured value is within the sorting limits ( = ) and is the

current value ( A ) of a series of measurements.

Measured value output

- 5 . 2 3 = A < C R > < L F >

123456 7 8

1

Algebraic sign

2

Numerical value with decimal point (10 characters on

the whole, leading zeros are output as blank spaces.)

(Angle measurement “min, sec” up to 3 dec. spaces.)

3

Blank space

4

Unit: Blank space = mm; " = inch; ? = fault

5

Sorting status (<, >, =; ? if P18 > P19)

or blank space

6

Series of measurements

(S = MIN; A = ACTL; G = MAX; D = DIFF)

or blank space

7

CR (carriage return)

8

LF (line feed)

RS-232-C/V.24 Data Interface (X31)

47

Page 48

Operating parameters for measured value output

Parameter Function

P50 RS232 Baud rate

P51 RS232 Number of additional blank lines for

measured value output

Display freeze during measured value output

In operating parameter P23, you can specify how the

measured value output signal will affect the display unit.

Display freeze during measured value output P23

Concurrent display, no display freeze: The

display value is the current measured value DISPL. ACTL.

Frozen display: Display is stopped

RS-232-C/V.24 Data Interface (X31)

(frozen) and updated by every

measured value output signal DISPL. HOLD

Frozen/concurrent display: Display is

frozen as long as a measured value output

signal is present DISPL. STOP

Measured value output via PRINT function

In the linear measurement mode, press MOD repeatedly

until the PRINT indicator starts blinking.

Start the measured value output with ENT.

In the angular measurement mode, press MOD (this feature

can be disabled with operating parameter 86).

Duration of measured value transfer

187 + (11 • number of blank lines)

t

= [s]

D

Indicator preselection (linear measurement mode)

Operating parameter P86 allows you to define which indicator

is displayed first when MOD is pressed.

baud rate

48

Page 49

Measured value output after signal through the “Contact”

or “Pulse” inputs

To start measured value output through the EXT interface

(X41), you can either:

ä

Close the “Contact” input (pin 23 on X41) against 0 V,

for example with a simple switch (make contact);

or

ä

Close the “Pulse” input (pin 22 on X41) against 0 V,

for example by triggering the input with a TTL logic

device (such as SN74LSxx).

Characteristic times for measured value output

EXT(X41)

Pin 23

Pin 1(0V)

EXT(X41)

Pin 22

Pin 1(0V)

Process Time

Minimum duration of “Contact” signal te ³ 7 ms

Minimum duration of “Pulse” signal te ³

1.5 µs

Storage delay after “Contact” t1 £ 5 ms

Storage delay after “Pulse” t1 £ 1 µs

Measured value output after t2 £

Regeneration time t3 ³

57 ms

0

Duration of measured value transfer

187 + (11 • number of blank lines)

= [s]

t

D

baud rate

Triggering the “Contact” and “Pulse” inputs at D-sub

connection EXT (X41)

t

e

t

1

t

2

t

D

t

e

t

3

Signal transit times for measured value output after “Pulse”

or “Contact”

RS-232-C/V.24 Data Interface (X31)

49

Page 50

t

1

t

2

Ctrl B

t

D

t

3

Ctrl B

Measured value output with CTRL B

If the display unit receives the control character STX (Ctrl B)

over the RS-232-C/V.24 interface, it transmits the current

measured value back over the interface. Ctrl B is received

over the RXD line of the interface and the measured values

are transferred over the TXD line.

The measured values can be received and saved using a

terminal program (e.g. HyperTerminal, which is a component

of Windows

®

).

The basic program at the upper right shows the fundamental

structure of a program for measured value output.

10 L%=18

20 CLS

30 PRINT "V.24/RS-232-C"

40 OPEN "COM1:9600,E,7" AS#1

50 PRINT #1, CHR$ (2);

60 IF INKEY$<>""THEN 130

70 C%=LOC(1)

80 IF C%<L%THEN 60

90 X$=INPUT$(L%,#1)

100 LOCATE 9,1

110 PRINT X$;

120 GOTO 50

130 END

Characteristic times for measured value output

Process Time

Storage after t1 £ 1ms

RS-232-C/V.24 Data Interface (X31)

Measured value output after t2 £ 50 ms

Regeneration time t3 ³ 0

These times are prolonged if functions are active

(for example, series of measurements with DIFF

value display).

Duration of measured value transfer

187 + (11 • number of blank lines)

baud rate

50

tD = [s]

BASIC program for measured value output with “Ctrl B”

Propagation times for measured value output after “Ctrl B”

Page 51

Input/Output of Parameter and Compensation-Value

Lists

Calling the "data transfer" function:

together

with

Select the operating parameters.

MOD

Select P00 CODE.

REC. PARAM.

If

reqd.

or

The display unit is ready to receive a

parameter list over the RS-232-C/V.24

interface. After successful reception of the

parameter list, the display unit resets itself

and restarts. Continue in the data transfer

menu with the decimal point key.

P00 CODE

Enter the code number 48 61 53 and

confirm with ENT.

Data transfer function:

TRANSFER

Continue with ENT.

SEND PARAM.

If

reqd.

or

Press the ENT key if you want to transmit

the parameter list over the RS-232-C/V.24

interface. After transmission, return to the

beginning ("TRANSFER") to transmit or

receive further lists. Press the decimal

point key to continue in the data tranfer

menu.

SEND COMP.

If

reqd.

or

REC. COMP.

If

reqd.

or

With the ENT key, you transmit the

compensation value list over the RS-232-C/

V.24 interface. After transmission, return to

the beginning ("TRANSFER") to transmit or

receive more lists. Continue in the data

transfer menu with the decimal point key.

The display unit is ready to receive a

parameter list over the RS-232-C/V.24

interface. After successful reception, return

to the beginning ("TRANSFER") to transmit or

receive more lists. Continue in the data

transfer menu with the decimal point key.

Exit the data transfer function.

Input/Output of Parameter and Compensation-Value Lists

51

Page 52

Note on the input/output of parameter and

compensation-value lists

With a terminal program (e.g. HyperTerminal, included with

Windows

unit over the RS-232-C/V.24 interface as text files and save

them on your PC. Each list must be saved as a separate text

file. You can then use the terminal program to transmit the

text files back to the display unit .

If you wish, you can edit the text files with a text editor and

change the parameter values, for example. However, this

requires knowledge of the different output formats of the lists

(see following pages). When receiving lists, the display unit

expects the same list structure as used for the output.

When receiving lists, the display unit first waits for the starting

character < * >. The receiving mode ends as soon as the

display unit has received the final character < * >.

The lists received are first checked for the type of display unit

(line 2 of output list). The receiving display unit accepts only

lists prepared by the same type of display unit. Furthermore,

the list is checked for completeness. Lists that contain, for

example, too many or too few parameters are ignored. If an

error occurs, the following error message appears:

REC. ERROR

To clear the error message, press the CL key.

®

), you can receive the lists output by the display

If the display unit receives invalid parameter values, it sets the

respective operating parameter to the default setting.

Example: “P01 INCH = INCH = 3”

The value 3 is not allowed. The parameter P01 is set to the

default setting “P01 MM = MM = 0”.

52

Input/Output of Parameter and Compensation-Value Lists

Page 53

Output Format of the Parameter List

1st line

Each parameter output begins with the start character < * > ( HEX: 0x2A)

* <CR> <LF>

3 characters

2nd line

Output of the counter designation

N D - 2 8 1 B M M <CR> <LF>

13 characters 5 characters 2 characters

Model of display unit Unit of meas. End of line

Subsequent lines for the individual parameters:

a: Parameters:

Parameter settings can be changed with the MINUS key (e.g.: counting direction positive/counting direction negative etc.)

Examples:

P 1 1 S C L = S C A L I N G . O F F = 0 <CR> <LF>

15 characters 3 char. 13 characters 3 char. 6 characters 2 characters

P 5 0 R S 2 3 2 = 3 8 4 0 0 B A U D = 3 8 4 0 0 <CR> <LF>

15 characters 3 char. 13 characters 3 char. 6 characters 2 characters

Parameter designation Text Separator Parameter in plain language Separator Parameter value End of line

left-aligned right-aligned block right-aligned block right-aligned

Output Format of the Parameter List

53

Page 54

b: Parameters:

Parameter settings can be changed by entering a value

(e.g.: LINEAR COMP. 13.600 etc.)

P 1 8 L . C L A S S . = + 1 2 0 . 0 0 0 0 <CR> <LF>

15 characters 3 char. 13 characters 2 characters

P 4 1 L . C O M P . = - 1 4 0 0 . 0 <CR> <LF>

15 characters 3 char. 13 characters 2 characters

Parameter designation Text Separator Parameter value End of line

left-aligned right-aligned block right-aligned

Last line:

Each parameter list ends with the final character <*> (HEX: 0x2A)

* <CR> <LF>

Output Format of the Parameter List

The parameter text is sent in the language you have set and corresponds to the dialog text that is shown on the display unit.

The parameter value, not the text, is definitive when the parameters are transferred to the display unit.

54

Page 55

Parameter list for ND 281 B: "Linear measurement" mode of operation (factory default setting)

Parameter list Description

* Start character (*);

ND-281 B MM Model of display unit; MM or IN;

P01 MM = MM = 0 Unit of measure: MM = 0; INCH = 1;

P02 X1/X2 = X1 11 uAPP = 0 Encoder input: X1 11µAPP = 0; X2 1VPP = 1;

P11 SCL = SCALING OFF = 0 SCALING OFF = 0; ON = 1;

P12 SCL = 1.000000 SCALING = 1.000000; (value input without sign)

P17 CLASS. = CLASS. OFF = 0 Sorting: CLASS. OFF = 0; CLASS. ON = 1;

P18 L.CLASS. = + 0.0000 Lower limit: L.CLASS = 0; (value input)

P19 U.CLASS. = + 0.0000 Upper limit: U.CLASS = 0; (value input)

P21 SERIES = DISPL. OFF = 0 SERIES: DISPL.OFF =0; MIN=1; MAX=2; ACTL=3; DIFF=4;

P23 DISPL. = DISPL. ACTL. = 0 DISPLAY: ACTUAL = 0; HOLD = 1; STOP = 2;

P30 DIR = DIRECT. POS = 0 COUNTING DIRECTION POS = 0; NEG = 1;

P31 S. PER. = 10 SIGNAL PERIOD = 10 µm; (value input without sign)

P33 STEP = COUNT 0-5 = 5 COUNTING MODE 0-5 = 5; 0-2 = 2; 0-1 = 1;

P38 DEC. = DP POS 4 = 4 DECIMAL PLACES 4 (range: 1-8)

P40 COMP. = COMP. OFF = 0 COMPENSATION OFF = 0; LIN = 1; MULTI = 2;

P41 L.COMP. = + 0.0 LINEAR COMPENSATION= 0 µm/m (value input)

P42 BKLASH = + 0.0000 BACKLASH compensation= 0.0000 mm (value input)

P43 REF = SINGLE REF. = 0 SINGLE REF. = 0; 500; 1000; 2000; 5000S P;

P44 REF = REF. ON = 1 REF.ON = 1; REF. OFF = 0;

P45 ALARM = FRQ.+ CONT. = 3 OFF = 0; FRQ. = 1; CONTAMINAT. = 2; FRQ + CONT. = 3;

P50 RS232 = 9600 BAUD = 9600 BAUD RATE = 9600; (110-38400)

P51 RS232 = BK LINE 1 = 1 LINE FEEDS = 1; (0-99)

P62 A1 = + 0.0000 Switching limit 1: A1 = 0; (value input)

P63 A2 = + 0.0000 Switching limit 2: A2 = 0; (value input)

P79 PRESET = + 0.0000 DATUM SETTING= 0; (value input)

P80 ENT-CL = CL-ENT OFF = 0 CL-ENT OFF=0; CL-ON = 1; CL-ENT ON = 2;

P82 DISPL.ON = ENT..CL ON = 1 DISPLAY: ENT...CL ON = 1; ENT...CL OFF = 0;

P85 EXT.REF = EXT.REF OFF = 0 EXTERNAL REF OFF = 0; EXTERNAL REF ON= 1;

P86 MOD = MOD START = 0 MOD key: START= 0; PRINT = 1; MIN = 2; ACTL = 3; MAX = 4; DIFF = 5;

P98 LANGUA. = LANGUAGE DE = 1 NATIONAL LANGUAGE: 0 = EN; 1 = DE; 2 = FR; 3 = IT; 4 = NL; 5 = ES;

* 6 = DA; 7 = SV; 8 = FI; 9 = CS; 10 = PL; 11 = HU;

12 = PT;

Final character(*);

Output Format of the Parameter List

55

Page 56

56

Parameter list for ND 281 B: "Angular measurement" mode of operation (factory default setting)

Parameter list Description

* Start character (*);

ND-281 B DEC Model of display unit; DEC (decimal) or DMS (min-sec);

P02 X1/X2 = X1 11 uAPP = 0 Encoder input: X1 11µAPP = 0; X2 1VPP = 1;

P08 DISPL. = DEC. DEGREE = 0 Display: DEC.DEGREE = 0; DEG.MIN.SEC = 1;

P09 ANGLE = +/-180 DEG. = 0 Angle: +/- 180 DEG. = 0; 360 DEG. = 1; ENDLESS = 2;

P17 CLASS = CLASS. OFF = 0 Sorting: CLASS. OFF = 0; CLASS. ON = 1;

P18 L.CLASS. = + 0.0000 Lower limit: L.CLASS = 0; (value input)

P19 U.CLASS. = + 0.0000 Upper limit: U.CLASS = 0; (value input)

P23 DISPL. = DISPL. ACTL. = 0 DISPLAY: ACTUAL = 0; HOLD = 1; STOP = 2;

P30 DIR = DIRECT. POS = 0 COUNTING DIRECTION POS = 0; NEG = 1;

P36 SP/R = 36000 SIGNAL PERIODS / R = 36000 (value input);

P37 STEP = COUNT 0-5 = 5 COUNTING MODE 0-5 = 5; 0-2 = 2; 0-1 = 1;

P38 DEC. = DP POS. 4 = 4 DECIMAL PLACES 4 (range: 1-8)

P40 COMP. = COMP. OFF = 0 COMPENSATION OFF = 0; LIN = 1; MULTI = 2;

P43 REF = SINGLE REF. = 0 SINGLE REF. = 0; 500; 1000; 2000; 5000 SP;

P44 REF = REF. ON = 1 REF.ON = 1; REF. OFF = 0;

P45 ALARM = FRQ.+ CONT. = 3 OFF = 0; FRQ.= 1; CONTAMINAT.= 2; FRQ+CONT. = 3;

P50 RS232 = 9600 BAUD = 9600 BAUD RATE = 9600; (110-38400)

P51 RS232 = BK LINE 1 = 1 LINE FEEDS = 1; (0-99)

Output Format of the Parameter List

P62 A1 = + 0.0000 Switching limit 1: A1 = 0; (value input)

P63 A2 = + 0.0000 Switching limit 2: A2 = 0; (value input)

P79 PRESET = + 0.0000 DATUM SETTING = 0; (value input)

P80 ENT-CL = CL-ENT OFF = 0 CL-ENT OFF= 0; CL-ON = 1; CL-ENT ON = 2;

P82 DISPL.ON = ENT..CL ON = 1 DISPLAY: ENT...CL ON = 1; ENT...CL OFF = 0;

P85 EXT.REF = EXT.REF OFF = 0 EXTERNAL REF OFF = 0; EXTERNAL REF ON = 1;

P86 MOD = PRINT OFF = 0 MOD KEY: PRINT OFF = 0; PRINT ON = 1;

P98 LANGUA. = LANGUAGE DE = 1 NATIONAL LANGUAGE: 0 = EN; 1 = DE; 2 = FR;

* 3 = IT; 4 = NL; 5 = ES;

Final character (*);

6 = DA; 7 = SV; 8 = FI;

9 = CS; 10 = PL; 11= HU;

12 = PT;

Page 57

Output Format of the Compensation-Value Table

Line: Start

Each compensation-value output begins with the start character < * > ( HEX: 0x2A)

* <CR> <LF>

3 characters

Line: Counter model designation

Output of model designation and unit of measure

N D - 2 8 1 B M M <CR> <LF>

13 characters 5 characters 2 characters

Model display unit, left-aligned Unit of meas. End of line

Line: Compensation value 0

Output of compensation-value no. 0

C M P . N R . 0 0 = + 0 . 0 0 0 0 <CR> <LF>

13 characters 3 char. 13 characters 2 characters

Compensation-value no., left-aligned Sep. block Compensation value, right-aligned End of line

Output of compensation values 1 - 63

Output of compensation values

C M P . N R . 6 3 = + 0 . 0 1 2 3 <CR> <LF>

13 characters 3 char. 13 characters 2 characters

Compensation-value no., left-aligned Sep. block Compensation-value, right-aligned End of line

Last line:

Each compensation-value table ends with the final character <*> (HEX: 0x2A)

* <CR> <LF>

3 characters

Output Format of the Compensation-Value Table

57

Page 58

Compensation-value table for ND 281 B (linear measurement): factory default setting

Compensation-value table Description:

* Start character ( * );

ND-281 B MM Model of display unit; unit of measure (MM or IN);

SCALING = 14 Spacing = 14 ( range: 6 – 20)

DATUM = + 0.0000 Datum point 0 mm (value input)

CMP. NR. 00 = + 0.0000 Compensation value 0 = 0.000 mm (compensation value 0 is always 0)

CMP. NR. 01 = ---------- Compensation value 1 = no value entered

CMP. NR. 02 = ---------- Compensation values 2 – 63: no values entered (axis is not corrected)

CMP. NR. 03 = ---------- Compensation-value table is empty

CMP. NR. 04 = ---------CMP. NR. 05 = ---------CMP. NR. 06 = ---------CMP. NR. 07 = ---------.

.

.

.

.

.

.

.

.

.

.

.

Output Format of the Compensation-Value Table

CMP. NR. 60 = ---------CMP. NR. 61 = ---------CMP. NR. 62 = ---------CMP. NR. 63 = ----------

58

* Final character (*);

Page 59

Compensation-value table for ND 281 B (angular measurement): Active compensation

Compensation-value table Description:

* Start character ( * );

ND-281 B DMS Model of display unit; DEC (decimal) or DMS (deg-min-sec);

CMP. NR. 00 = + 0.00.00 Compensation value 0 = 0.0000mm (compensation value 0 is always 0)

CMP. NR. 01 = + 0.00.03 Compensation values 1 – 18 are assigned values (value input)

CMP. NR. 02 = + 0.00.05 i.e. a rotary encoder is corrected in 5-degree steps from 0 - 90 degrees

CMP. NR. 03 = + 0.01.01 Input in deg-min-sec

CMP. NR. 04 = + 0.00.43

CMP. NR. 05 = + 0.00.21

CMP. NR. 06 = + 0.00.06

CMP. NR. 07 = - 0.00.04

CMP. NR. 08 = - 0.00.12

CMP. NR. 09 = - 0.00.24

CMP. NR. 10 = - 0.00.44

CMP. NR. 11 = - 0.00.52

CMP. NR. 12 = - 0.00.43

CMP. NR. 13 = - 0.00.35

CMP. NR. 14 = - 0.00.24

CMP. NR. 15 = - 0.00.19

CMP. NR. 16 = - 0.00.13

CMP. NR. 17 = - 0.00.05

CMP. NR. 18 = + 0.00.00

CMP. NR. 19 = ---------- Compensation values 11 – 71: no values entered (memory empty)

CMP. NR. 20 = ---------.

.

.

CMP. NR. 70 = ---------CMP. NR. 71 = ---------* Final character (*);

Output Format for the Compensation-Value Table

59

Page 60

Remote Operation over the RS-232-C/V.24

Data Interface

You can operate the display unit remotely over the RS-232-C/

V.24 data interface. The following commands are available on

the ND 281 B:

Format:

<ESC>TXXXX<CR> Pressed key

<ESC>AXXXX<CR> Output of screen contents

<ESC>FXXXX<CR> Execute function

<ESC>SXXXX<CR> Special function

Sequence of commands Meaning

<ESC>T1000<CR> ‘CE+0‘ keys

<ESC>T1001<CR> ‘CE+1‘ keys

<ESC>T1002<CR> ‘CE+2‘ keys

<ESC>T1003<CR> ‘CE+3‘ keys

<ESC>T1004<CR> ‘CE+4‘ keys

<ESC>T1005<CR> ‘CE+5‘ keys

<ESC>T1006<CR> ‘CE+6‘ keys

<ESC>T1007<CR> ‘CE+7‘ keys

<ESC>T1008<CR> ‘CE+8‘ keys

<ESC>T1009<CR> ‘CE+9‘ keys

Remote Operation over the RS-232-C/V.24 Data Interface

60

Sequence of commands Meaning

<ESC>T0000<CR> ‘0‘ key

<ESC>T0001<CR> ‘1‘ key

<ESC>T0002<CR> ‘2‘ key

<ESC>T0003<CR> ‘3‘ key

<ESC>T0004<CR> ‘4‘ key

<ESC>T0005<CR> ‘5‘ key

<ESC>T0006<CR> ‘6‘ key

<ESC>T0007<CR> ‘7‘ key

<ESC>T0008<CR> ‘8‘ key

<ESC>T0009<CR> ‘9‘ key

<ESC>T0100<CR> ‘CL' key

<ESC>T0101<CR> ‘-‘ key

<ESC>T0102<CR> ‘.‘ key

<ESC>T0104<CR> ‘ENT‘ key

<ESC>T0105<CR> ‘MOD‘ key

<ESC>T0107<CR> ‘1/2‘ (datum) key

<ESC>A0000<CR> Output of model designation

<ESC>A0100<CR> Output of 14-segment display

<ESC>A0200<CR> Output of current value

<ESC>A0301<CR> Output of error text

<ESC>A0400<CR> Output of software number

<ESC>A0900<CR> Output of status indicators

<ESC>F0000<CR> REF function

<ESC>F0001<CR> Start measurement

<ESC>F0002<CR> Print

<ESC>S0000<CR> Counter RESET

<ESC>S0001<CR> Lock keypad

<ESC>S0002<CR> Release keypad

1)

Only in the linear measurement mode.

1)

Page 61

Description of RS-232-C/V.24 commands:

The display unit supports the XON-XOFF protocol when

executing commands. As soon as the internal character buffer

(100 characters) is full, the display unit sends the control

character XOFF to the sender. After the buffer has been

executed, the display unit sends the control character XON to

the sender and is then ready to receive data again.

Pressed key (TXXXX commands)

The display unit acknowledges each identified key command

by sending the control character ACK (Acknowledge ControlF). Then the key command becomes effective.

Output of 14-segment display:

The contents displayed are transmitted (also dialogs and error

messages).

<STX> - 1 2 3 4 5 . 6 7 8 9 <CR> <LF>

String: STX;

Min. 10 to max. 13 characters; CR; LF; (depending on

the number of commas and decimal points)

Output of current value:

The current position value (without decimal point, with leading

zeros) is transmitted.

The display unit responds to commands that cannot be

identified or to invalid commands by sending the control

character NAK (No acknowledge Control-U).

Output of model designation:

The model of display unit, software number, and the date of

software release are transmitted.

Example:

<STX> N D - 2 8 1 B <CR> <LF>

3 4 9 7 9 7 - 0 4 <CR> <LF>

2 0 0 1 - 0 5 - 0 4 <CR> <LF>

String: STX;

10 characters; CR; LF;

10 characters; CR; LF;

10 characters; CR; LF;

<STX> + 1 2 3 4 5 6 7 8 9 <CR> <LF>

String: STX;

Algebraic sign; numerical value with 9 characters;

CR; LF;

Output of error text:

The displayed error text is transmitted. (Functions only if an

error message is displayed.)

<STX> F O R M A T . E R R . <CR> <LF>

String: STX;

13 characters; CR; LF;

Remote Operation over the RS-232-C/V.24 Data Interface

61

Page 62

Remote Operation over the RS-232-C/V.24 Data Interface

62

Output of software number:

The current software number is transmitted.

<STX> 3 4 9 7 9 7 - 0 4 <CR> <LF>

String: STX;

10 characters; CR; LF;

Output of status indicators:

The condition of the status display is transmitted.

Example:

0 = status indicator dark