Page 1

HEIDENHAIN

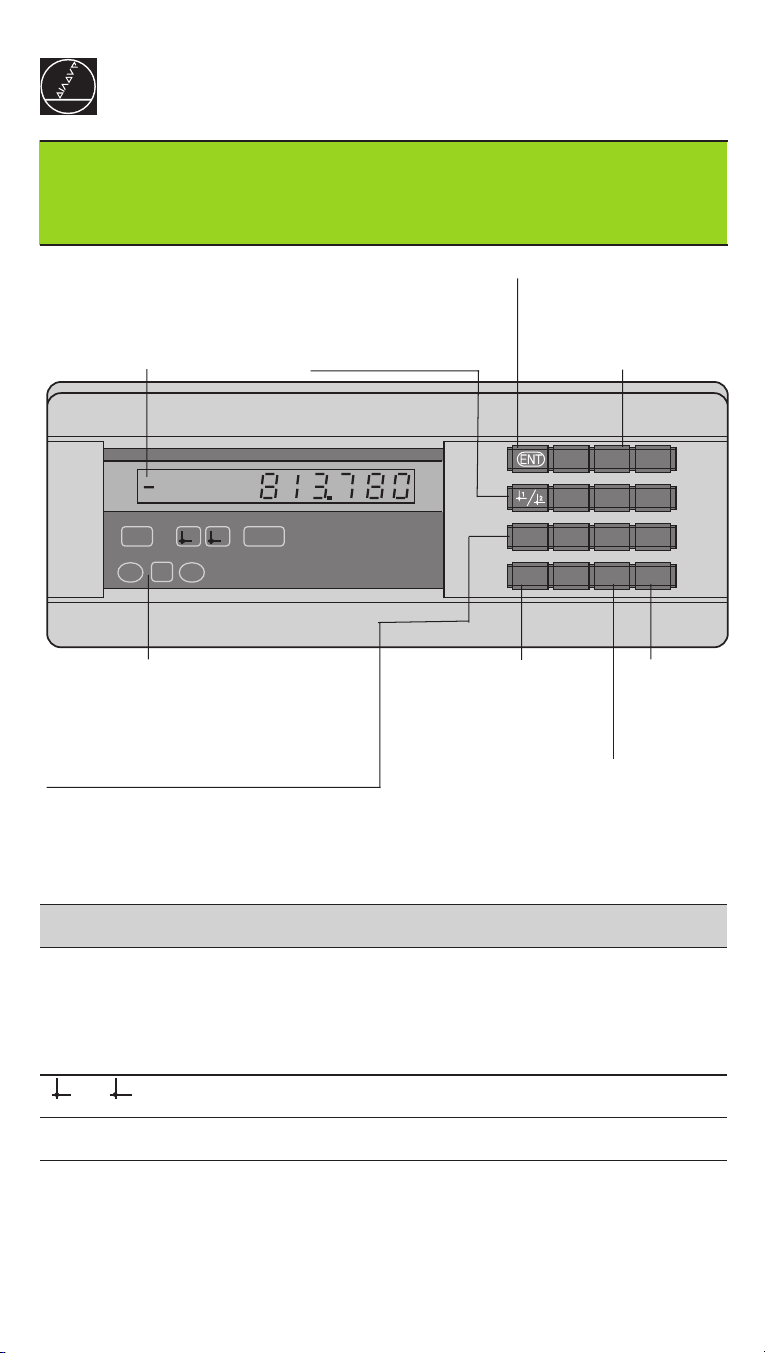

Working with the measured

value display unit

Actual value and input display

(7-segment LED,

9 decades and sign)

• Select datum

• Page backward in

parameter list

ND 261

• Confirm entry value

• Set display to value from

P79 (P80!)

Numeric keypad

789

456

REF21 SET

=

<>

HEIDENHAIN

Status display

• Output measured value over data

interface (P86!)

• Go to parameter list after switch-on

• Page forward in parameter list

Indicator Meaning

REF If decimal points are blinking:

Display is waiting for the reference mark to be crossed over.

If decimal points are not blinking: Reference mark was crossed

over — datum points are now stored in nonvolatile memory.

Blinking: Waiting for operator to press ENT or CL.

1 / 2 Datum 1 / Datum 2 currently active.

• Clear entry

• Reset to zero (P80!)

• CL plus MOD:

parameter list

• CL plus 2-digit number: select parameter

• Clear parameter entry

and show parameter

number

MOD

123

0

CL

.

–

• Algebraic

sign

• Decrease

parameter

value

• Decimal point

• Increase parameter value

SET Blinking: Waiting for operator to confirm entry values.

< / = / > Sorting mode: Measured value less than lower limit /

within tolerance / greater than upper limit.

Page 2

The ND 261 is designed for use with HEIDENHAIN angle encoders with sinusoidal

output signals: either ND 261A for 11 µA

(Id. Nr. 322 352 ..). These angle encoders have one reference mark or several

distance-coded

When a reference mark is crossed over, it generates a signal identifying that position

as a reference point. After switch-on, simply crossing over a reference mark

restores the relationship between axis positions and display values as it was last

defined by datum setting.

With distance-coded reference marks, a maximum traverse of only 10° or 20°

suffices to restore the datum.

reference marks.

(Id. Nr. 283 482 ..) or ND 261V for 1 V

PP

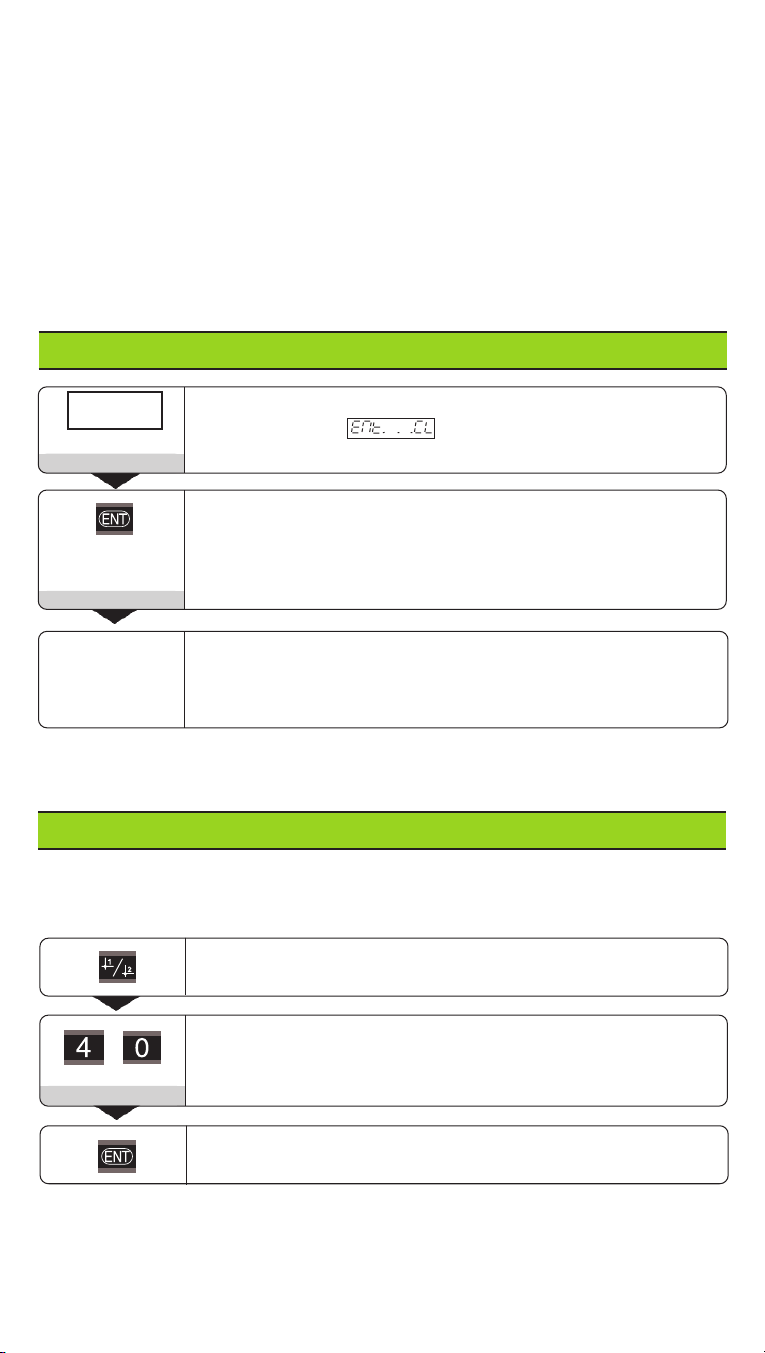

Switch-On

PP

0 ➤1

Ent...CL

5 , 6 9 7

If you do not wish reference mark evaluation, press CL instead of ENT.

Turn on the power (switch located on rear panel).

• Display shows .

• REF blinks.

Switch on reference mark evaluation

• Display shows the value last assigned to the

reference mark position.

• REF indicator glows.

• Decimal point blinks.

Cross over reference mark

Move the axis until the display becomes active and the

decimal point no longer blinks.

Setting the Datum

The datum setting procedure assigns a display value to a specific axis position.

The ND 261 allows you to set two separate datum points.

Select datum 1 or 2.

Enter a value, such as 40.

4 0

Confirm entered value.

You can switch from one datum to the other at any time.

Use datum 2 when you want to display incremental dimensions.

Page 3

Sorting and Tolerance Check Mode

In this mode, the display value is compared with an upper and a lower limit value.

Status indicators and the trigger signal outputs at the D-sub EXT connection (see

that section) indicate whether the display value is less than the lower limit, greater

than the upper limit, or between the two limit values.

Indicator Meaning

= Measured value is between the limit values

< Measured value is less than the lower limit value

> Measured value is greater than the upper limit value

Operating parameters for the sorting mode:

• P17: Sorting on/off

• P18, P19: Limit values

Page 4

Data Output

There are three ways to output data:

➤ PRINT function: Press the MOD key (this method can be inhibited with

operating parameter P86); or

➤ Input the command STX (CTRL B) over the RXD input; or

➤ Input a latch command over the D-sub connection EXT.

A connecting cable (to a PC, for example) is available from HEIDENHAIN

(Id.-Nr. 274 545 ..); cable length up to 20 m (66 ft).

Operating parameters for data output: P50, P51

Wiring and pin layout

Connecting cable is either completely wired (left) or only partially wired (right).

ND

CHASSIS

SIGNAL

TXD

RXD

RTS

CTS

DSR

GND

DTR

2

3

4

5

6

7

20

20

11GND

CHASSIS

2

3

4

5

6

7

SIGNAL

GND

TXD

RXD

RTS

CTS

DSR

GND

DTR

CHASSIS GND: Chassis Ground; TXD: Transmitted Data, RXD: Received Data,

RTS: Request To Send, CTS: Clear To Send; DSR: Data Set Ready; SIGNAL GND:

Signal Ground; DTR: Data Terminal Ready

Signals Signal level "active" Signal level "not active"

ND

CHASSIS

TXD

RXD

RTS

CTS

DSR

GNDSIGNAL

DTR

1GND

2

3

4

5

6

7

20

1 GND

CHASSIS

2

3

4

5

6

7

20

TXD

RXD

RTS

CTS

DSR

GNDSIGNAL

DTR

TXD, RXD –3 V to –15 V +3 V to +15 V

RTS, CTS, DSR, DTR +3 V to +15 V -3 V to -15 V

Data transfer format and control characters

Format ASCII code

Data word 1 start bit, 7 data bits, parity bit (even parity), 2 stop bits

Control characters Call measured value: STX (CTRL B), interrupt DC3 (CTRL S),

resume DC1 (CTRL Q)

Enquire error message: ENQ (CTRL E)

Sequence • Sign • Numerical value with up to 2 decimal points

• Blank space (or ? for error)

• Comparison result (<, >, =; ? if P18 > P19) or blank space

• 1 blank space • Carriage return • Line feed

Storage and transfer times

The duration of data transfer depends on the selected baud rate and the number of

additional line feeds. Display of degrees, minutes and seconds increases the storage

and transfer times.

Latch signal STX (CTRL B) EXT (pulse) EXT (contact) PRINT

Storage time ≤ 1 ms ≤ 1 µs ≤ 5 ms ≤ 42 ms

Transfer time ≤ 44 ms ≤ 44 ms ≤ 48 ms ≤ 85 ms

Page 5

D-Sub Connection EXT

Danger to internal components!

Voltage sources from external circuitry must conform to the recommendations in EN 50178 for low-voltage electrical separation. Connect inductive

loads only with a quenching diode parallel to the inductance.

Use only shielded cable!

Connect the shield to the connector housing.

Pin Function Pin Function

15 Meas. value ≥ trigger limit A1 (P62) 1 0 V

16 Meas. value ≥ trigger limit A2 (P63) 10 0 V

17 Meas. value < lower sorting limit (P18) 5 Do not use

18 Meas. value > upper sorting limit (P19) 6 Do not use

OutputsInputs

19 Error (see “Error Messages” ) 7 Do not use

14 Display value is zero 8 Do not use

2 Reset display to zero, clear error message 9 Do not use

3 Preset display to value from P79 12 Do not use

25 Cross over reference marks 13 Do not use

4 Ignore reference mark signal 24 Do not use

22 Pulse: output the measured value 11 Vacant

23 Contact: output the measured value 20 Vacant

21 Vacant

Signal levels LOW HIGH

Inputs –0.5 V ≤ U ≤ 0.9 V I ≤ 6 mA 3.9 V ≤ U ≤ 15 V

Outputs U ≤ 0.4 V I ≤ 100 mA U ≤ 32 V I ≤ 10 µA

Description of input and output signals

Input signals • Internal pull-up resistor 1 kΩ

• Triggering by make contact against 0 V or

• LOW level over TTL component

• Delay for Zero reset/Preset: t

• Minimum pulse duration for all signals: t

Output signals • Open collector outputs,

• active LOW

• Signal output delay:

≤ 42 ms

• t

d

• Zero crossover signal

minimum duration,

trigger outputs A1, A2:

t0 ≥ 180 ms

d

B

≤ 2 ms

C

U

CE

E

Pin 1.10

≥ 42 ms

min

I ≤ 100 mA

+ UB ≤ 32 V

0 V

Note that these times will increase if features are active (such as the sorting

mode) or if the measured values are being displayed in degrees/minutes/seconds.

Page 6

Display Freeze by Measured Value Output Signal

The effect of the signal for measured value output on the display is defined in user

parameter P23.

➤ Concurrent display: No display freeze. The unit shows the current measured

value ( ).

➤ Frozen display: The display is frozen and is updated with each signal for meas-

ured value output ( ).

➤ Frozen/concurrent display: The display freezes only as long as the signal is

present ( ).

Error Messages

To clear error message

When you have removed the cause of the error,

➤ press CL.

Message Cause and effect

Last measured value not yet latched

External device not ready for data transfer

( only appears once)

Data interface:

Parity error or wrong format

1)

Incorrect input value

Overflow caused by external preset

Overflow, trigger limit 1

Overflow, trigger limit 2

Overflow, lower sorting limit

Overflow, upper sorting limit

Encoder signal too weak1) (encoder may be contaminated)

Input frequency too high for encoder input

(will occur for example when traverse speed too high)

Internal counter overflow

Error while crossing over reference marks

To clear the error message: Switch off the display unit.

Should any of these error codes recur, contact your HEIDENHAIN

service agency

1)

1)

1)

1)

Offset compensation values for encoder signals have been

erased: contact your HEIDENHAIN service agency.

Erase the operating parameters.

If all decimal points light up, the measured value is too large or too small.

In this case, set a new datum or retract.

If all sorting indicators light up, this means that the upper sorting limit is less

than the lower limit.

1)

These errors are significant for a connected device. The error signal (pin 19) at the

EXT D-sub connection is active.

Page 7

Operating Parameters

The parameters are divided into “user parameters“ and “protected operating

parameters," which can only be accessed by entering a code number.

User parameters

User parameters are operating parameters that you can change without entering

the code number: They are designated P00 to P30, P50, P51, P79, P86

Calling user parameters

To call user parameters immediately after switch-on:

➤➤

➤ Press the MOD key as long as is visible in the display.

➤➤

To call user parameters during operation:

➤➤

➤ Press and hold the CL key, then press MOD.

➤➤

To go directly to a specific user parameter:

➤➤

➤ Press and hold the CL key, then press the first digit of the parameter number.

➤➤

➤➤

➤ Release both keys and press the second digit.

➤➤

Protected operating parameters

Before you can change protected operating parameters you must enter the code

number 95 148 through : They remain accessible until you switch

off the position display.

To page through the parameter list

➤➤

➤ Forward paging: Press the MOD key.

➤➤

➤➤

➤ Backward paging: Press the 1 / 2 key.

➤➤

By paging on, you automatically enter any change you've made in a parameter.

To change operating parameters

➤➤

➤ Increase the parameter value with the decimal point key, or

➤➤

➤➤

➤ Decrease the parameter value with the minus key, or

➤➤

➤➤

➤ Enter the numerical value for the operating parameter, e.g. for P79 ( SET blinks).

➤➤

To correct your entries and show the parameter designation

➤➤

➤ Press the CL key.

➤➤

To exit the operating parameters

➤➤

➤ Press ENT. All changes made become effective.

➤➤

Operating Parameter List

Parameter Meaning Function / Effect Setting

Enter code number 95 148 to change a protected operating

parameter.

Display mode Decimal degrees

Display

Classification

Angle display

Sorting mode Sorting on

Lower sorting limit (ensure that P18 < P19)

Upper sorting limit

Degrees, minutes, seconds

+

/– 180°

360°

+

∞

/–

Sorting off

(ensure that P19 > P18)

Page 8

Parameter Meaning Function / Effect Setting

Display value Concurrent display, no freeze

Display

Direction

Subdivision

Decimal point

Encoder

Preset

MesMes

Messa

MesMes

Mod

e PRINT not inhibited

with measured Frozen display / update with signal

value output Frozen/concurrent display

Counting Normal (

direction Inverse (

Angle subdivision

400, 250, 200, 100, 80, 50, 40, 25, 20, 10, 8, 4, 2.5, 2, 1, 0.4, 0.2

Counting 0-1-2-3-4-5-6-7-8-9-0

mode 0-2-4-6-8-0

0-5-0

Places after decimal 1 / 2 / 3 / 4 / 5 / 6

Reference One reference mark

marks Distance-coded with 500 • SP

(SP = signal period)

Distance-coded with 1000 • SP

(e.g. for ROD 250 C / ROD 700 C)

Distance-coded with 2000 • SP

Distance-coded with 5000 • SP

Reference mark Evaluation

evaluation No evaluation

Encoder No monitoring (

monitoring Contamination

Frequency

Contamination and frequency

Baud rate

Additional line feeds

Trigger limit 1 Enter numerical value

Trigger limit 2 Enter numerical value

Value for Enter numerical value

datum switching input or with ENT key

Reset/Preset No zero resert/Preset with CL/ENT

Display after message displayed

gg

ge

switch-on message not displayed

gg

External REF REF over D-sub connection EXT

Inhibit PRINT PRINT inhibited

110, 150, 300, 600, 1200, 2400, 4800, 9600

Zero reset with CL (

no preset with ENT

Zero reset with CL and

preset with ENT to value in P79

No REF over EXT connection

Positive

Negative

(

)

)

Alarm Off

Linefeed

)

) 0 to 99

for datum setting over

Set Zero

),

Page 9

Parameter Settings for HEIDENHAIN Angle Encoders

Model

Subdivision

P36

11 µA

/ 1 V

PP

PP

Signal

periods per

revolution

P43

Reference

marks

Display

step

/ RPD 486 3 600 one single 0.01° 10 1

/ ROD 1080 0.005° 20 5 3

0.001° 100 1 3

ROD 250C/ROD 280C 9 000 one single 0.005° 85 3

RON 255C/RON 285C 0.001° 40 1 3

ROD 250C/ROD 280C 18 000 dist.c 1000 0.001° 20 1 3

/ROD 282C 0.000 5° 40 5 4

RON 255C/RON 285C 0.000 1° 200 1 4

/RON 287C

ROD 700C/ROD 780C

RON 705C/RON 785C

RON 706C/RON 786C

RON 905 / 36 000 one single 0.000 1° 100 1 4

ROD 800C/ROD 880C 36 000 dist.c 1000 0.000 1° 100 1 4

RON 806C/ROD 886C

Count.

mode

P37

Decim.

places

P38

Example: Set parameters for any encoder

s

Angle encoder with line count

Desired display step

Subdivision P36

a

= 0.001°

= =

= 360° / s / a = 20

= =

= 18 000

Counting mode P37 = 1 (display counts 1, 2, 3, ....)

Decimal places of a: P38 = 3

Convert decimal degrees to degrees, minutes, seconds

1 degree (1°) = 60 minutes (60'); 1 minute (1') = 60 seconds (60'')

1 second (1'') ≈ 0.000278°

Page 10

Rear View

RS-232-C/V.24

data interface

100 ... 240 V

50 ... 60 Hz

X31 (V.24 /RS-232-C)

X41 (EXT)

X1

D-sub connection

EXT

Power switch

Ground terminal

ND 261A, Id. Nr. 283 482 ..

Angle encoder input: 11 µA

Connecting cable: max. 30 m

PP

Max. input frequency: 100 kHz

ND 261V, Id. Nr. 322 352 ..

Angle encoder input: 1 V

Connecting cable: max. 60 m

PP

Max. input frequency: 300 kHz

Interfaces X1, X31 and X41 interfaces comply with the recommendations

in EN 50178 for separation from line power.

Installation

172 ± 0.2

You can fix the display unit to a flat surface with M4

6.77 ± .008"

bolts (see illustration at right).

The units can also be stacked. Adhesive inserts (in-

cluded in delivery) prevent them from sliding.

Power Supply and Connection

Danger of electrical shock!

Unplug the power cord before opening the housing.

Connect a protective ground. This connection must never be interrupted.

Danger to internal components!

Do not engage or disengage any connections while the unit is under power.

Use only original replacement fuses.

Primary-clocked power supply.

Voltage range: 100V to 240V (– 15% to + 10%) Frequency: 48 Hz to 62 Hz

Power consumption typ. 8 W Line fuse: F 1 A (in unit)

Minimum cross-section of the power line: 0.75 mm

2

140 ± 0.2

5.51 ± .008"

To increase noise immunity, connect the ground terminal on the rear panel to

the central ground point of the machine. (Minimum cross section of the connecting cable: 6 mm²).

Ambient Conditions

Temperature range Operation: 0 °C to + 45 °C (32 °F to 113 °F)

Storage: – 30 °C to + 70 °C (– 22 °F to 158 °F)

Rel. humidity Annual average: < 75%; maximum: < 90%

Weight 1.5 kg

DR. JOHANNES HEIDENHAIN GmbH

Dr.-Johannes-Heidenhain-Straße 5

D-83301 Traunreut, Germany

(0 86

69) 31-0 . 56 832

FAX

(0 86

69) 50 61

Service (0 86 69) 31-12 72

TNC-Service (0

FAX

86

69) 98 99

(0

http://www.heidenhain.de

284 250-26 · SW 246 183 01 · 1 · 2/2000 · H · Printed in Germany · Subject to change without notice

Tx

86

69) 31-14 46

Loading...

Loading...