Page 1

Operating Instructions

ND 2100G

GAGE-CHEK

Software Version

2.60.x

English (en)

10/2011

Page 2

Page 3

ND 2100G Introduction

quit

cancel

enter

finish

+/-0

4

1

7

5 6

2 3

8 9

11

2345789

6

quit

cancel

enter

finish

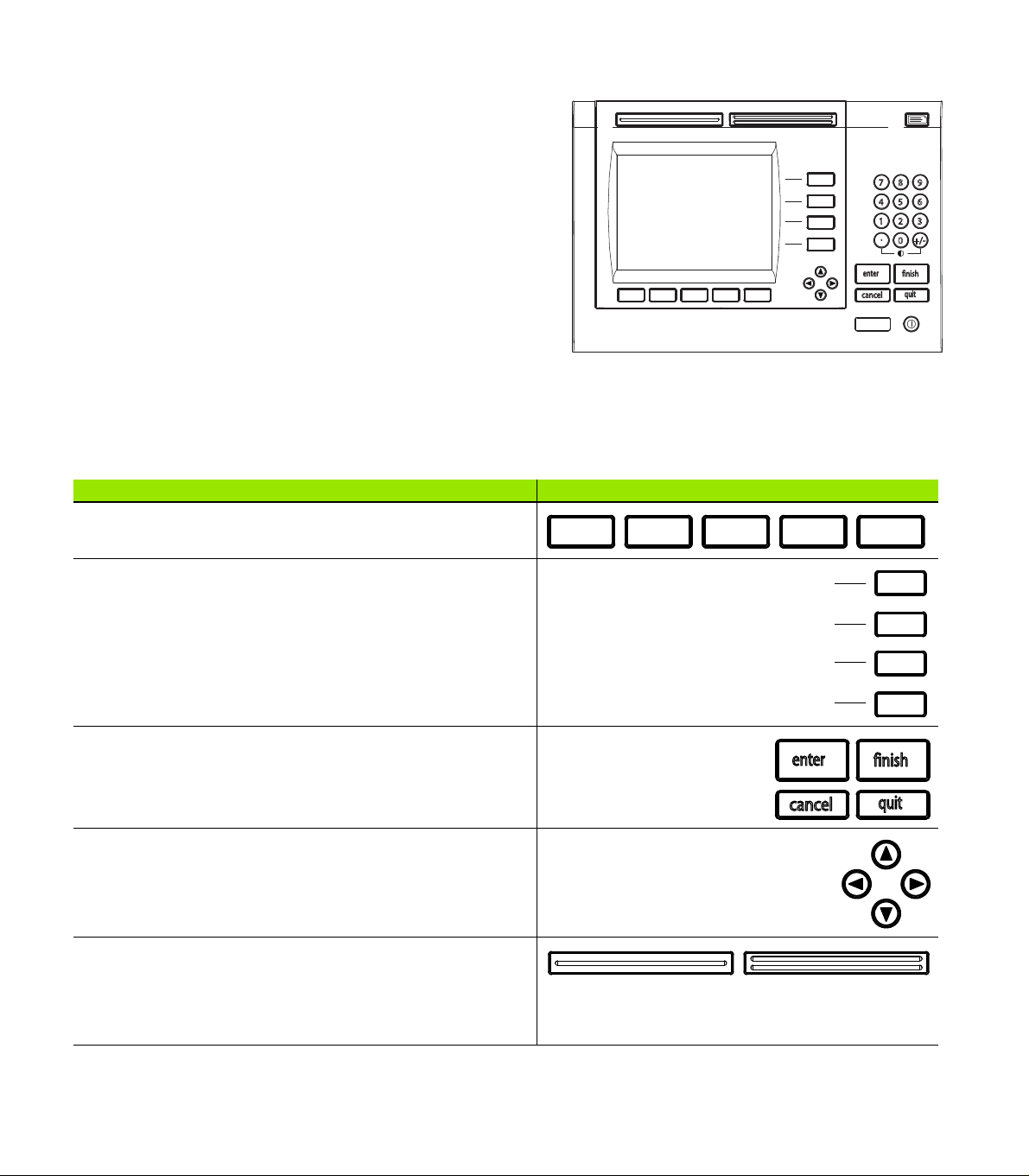

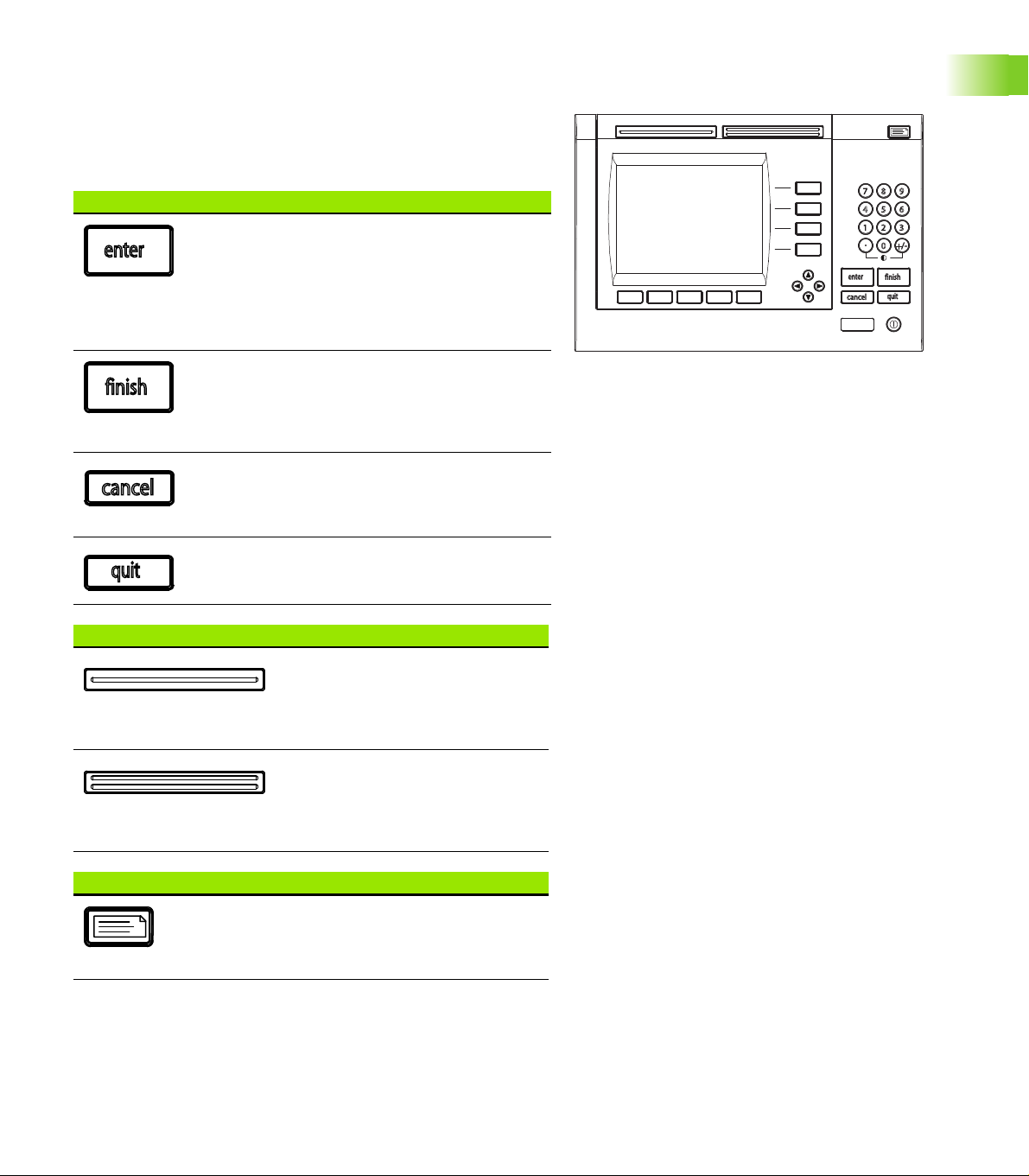

1 LCD screen

2 Soft keys

3 Dimension keys

4 Command keys

5 Arrow cursor keys

6 Numeric Keypad

7 Fast track keys

8 Send key

9 LCD on/off key

ND 2100G panel keys

Panel keys are used to initiate feature measurements, apply

tolerances, send reports of measurement results and configure

operational parameters.

Panel function key Panel key

Soft keys: Functions change in support of the activities displayed

on the LCD.

Dimension keys: Can be assigned one of six hot key functions

for use when DRO screen is displayed. When graph, bar value or

data screens are displayed, dimension keys are used to display

values for single dimensions or a smaller group of dimensions.

Command keys: Control measurement and data entry

processes.

Arrow cursor keys: Used to scroll through lists and navigate

menus and setup screen data fields.

Fast track keys: Two programmable fast track keys are used to

perform frequently used functions. These keys can easily be

located by touch without taking your eyes off the part. Users can

program either fast track key as described later in the Hotkeys

portion of Chapter 2: Installation, Setup and Specifications.

ND 2100G GAGE-CHEK 3

Page 4

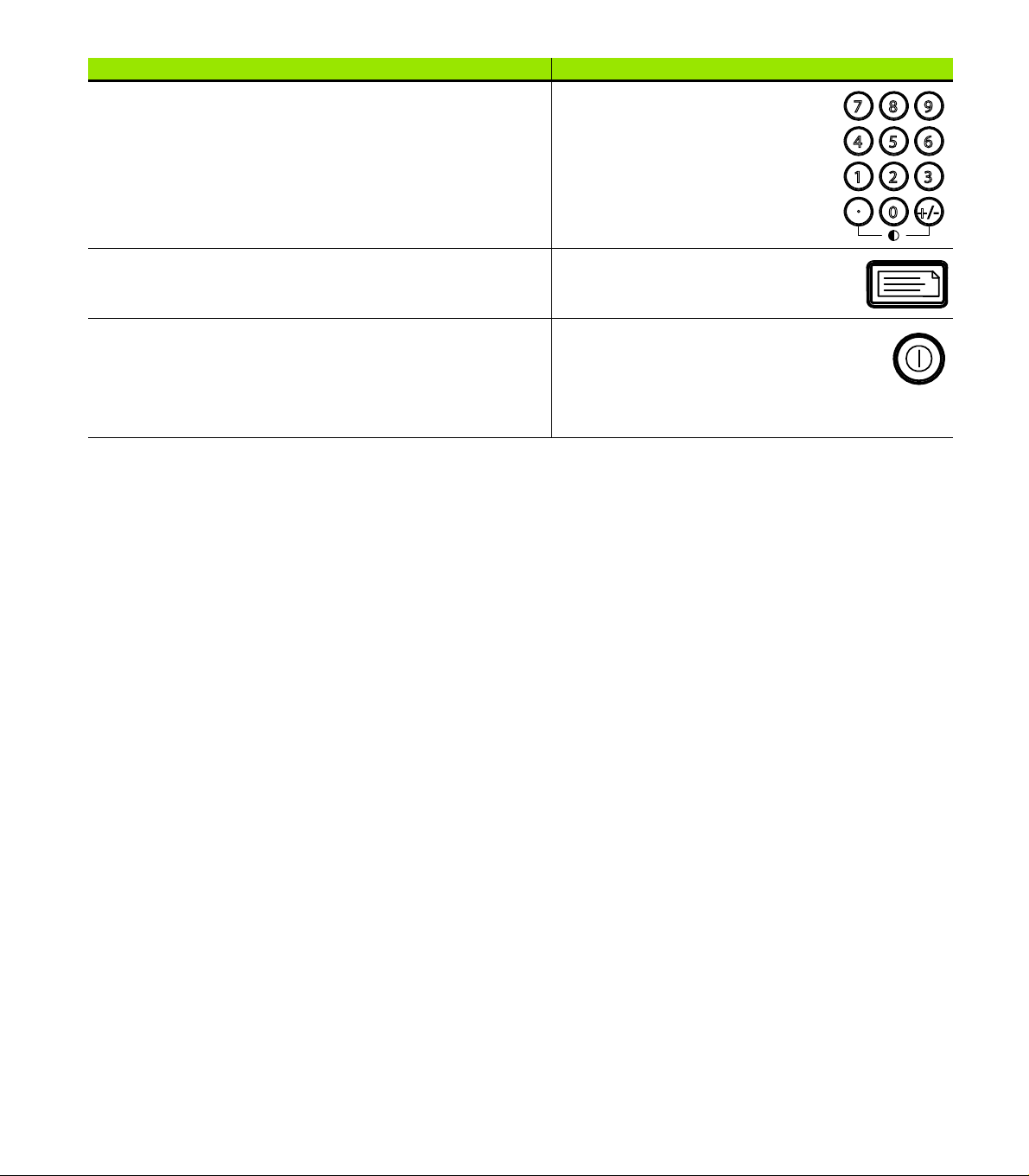

Panel function key Panel key

+/-0

4

1

7

5 6

2 3

8 9

Numeric keypad: Used to enter numeric data. Additionally, the

decimal point key and +/- key are used to adjust the contrast

of the LCD display.

Send key: Used to transmit measurement results to a computer,

USB printer or USB flash drive.

LCD On/Off key: Press the LCD on/off button to turn the LCD

display off without removing power from the ND 2100G. Press

the button a second time to restore the LCD display. Additionally,

the LCD On/Off key can be used to clear channel calibrations,

delete data stored for a single part or delete data stored for all

parts.

4 Preface

Page 5

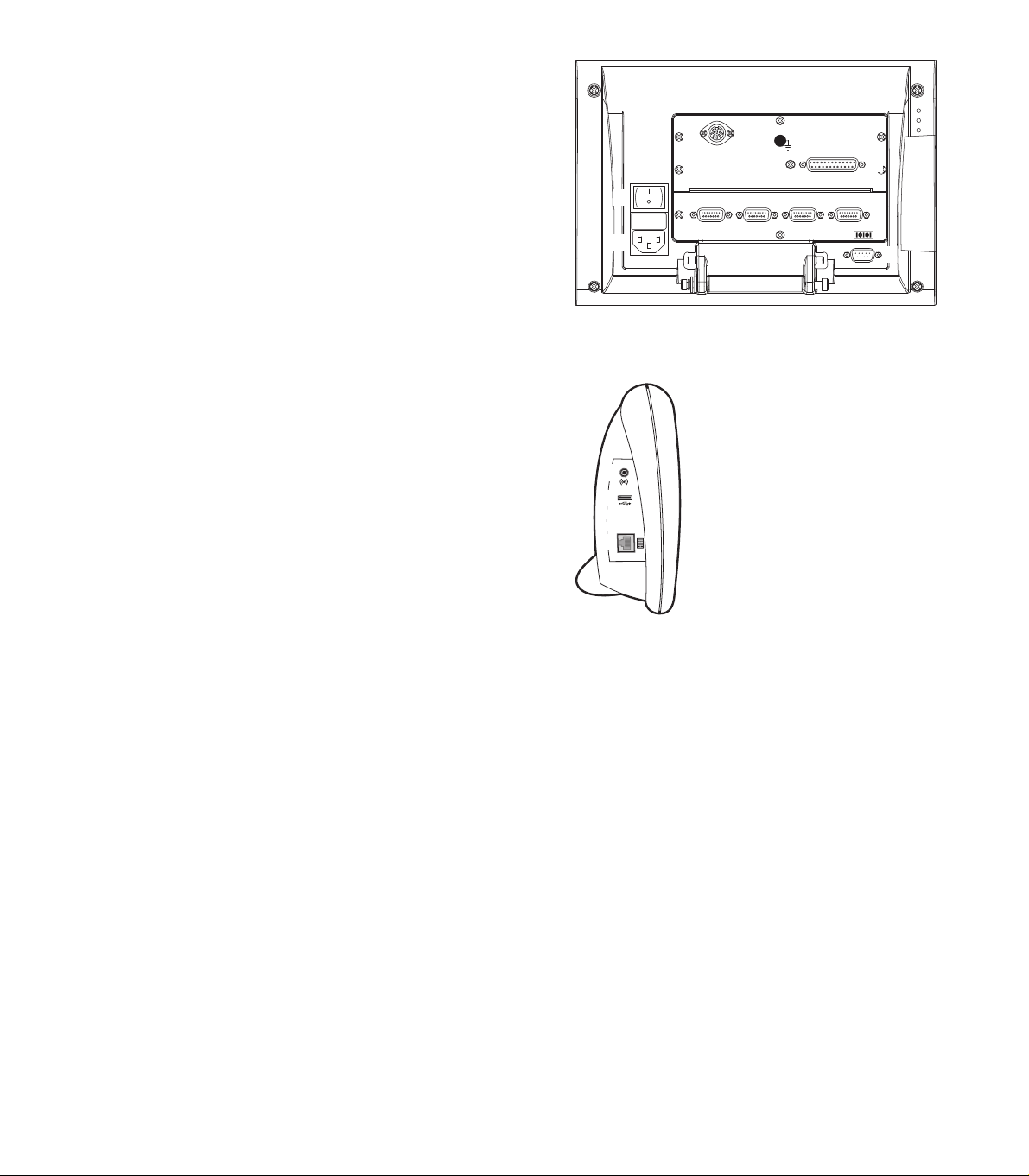

ND 2100G rear panel

1321516147

11

12

3

1 Power switch

2 Power connection with fuse

3 Ground (protective ground)

4 Encoder inputs

5 Relay outputs

6 Parallel I/O port

7 RS-232-C interface

ND 2100G side panel

1 Speaker/headset jack

2 USB Type A connector

3 RJ-45 Foot switch/hand switch/keypad connector

ND 2100G GAGE-CHEK 5

Page 6

Information contained in this

manual

This User's manual covers the operation, installation, setup and

specifications of the ND 2100G. Operating information is contained in

chapter 1. Installation, setup instructions and specifications are

contained in chapter 2.

Fonts used in this manual

The following fonts are used to indicate operator controls or to show

emphasis:

Operator controls - soft keys and other panel keys are shown in

upper case

Emphasis - Items of special interest or concepts that are

emphasized to the user are shown in bold type

Showing sequences of key presses

The ND 2100G user performs sequences of soft key and panel key

presses to measure part features and complete other tasks. These

sequences are indicated using text as shown in the following

example:

Press the MENU... soft key, press the DATUM... soft key and then

press the MASTER soft key is sometimes abbreviated as:

Press MENU/DATUM/MASTER

Symbols within notes

Notes are marked with symbols on the left indicating the type, or

potential severity of the information.

General Information

This is additional or supplementary information about an

activity or concept.

Warning

This warns of a situation or condition that could lead to

measurement errors, equipment malfunction or

equipment damage. Do not proceed until the message is

read and understood.

Caution - Risk of electric shock

This warns of a situation or condition that could lead to

electrical shock and to personal injury or death. Do not

proceed until the message is read and understood.

6 Preface

Page 7

Safety considerations

General accepted safety precautions must be followed when

operating the system. Failure to observe these precautions could

result in damage to the equipment, or injury to personnel. It is

understood that safety rules within individual companies vary. If a

conflict exists between the material contained in this manual and the

rules of a company using this system, the more stringent rules should

take precedence.

The ND 2100G is equipped with a 3-wire power plug that

includes a separate ground connection. Always connect

the power plug to a 3-wire grounded outlet. Use of 2-wire

power plug adapters or any other connection accessories

that remove the third grounded connection create a safety

hazard and should not be permitted.

Unplug the ND 2100G from the power outlet and seek the

assistance of a qualified service technician if:

The power cord is frayed or damaged or the power plug

is damaged

Liquid is spilled or splashed onto the enclosure

The ND 2100G has been dropped or the exterior has

been damaged

The ND 2100G exhibits degraded performance or

indicates a need for service some other way

ND 2100G channel inputs

The ND 2100G can be connected to the following channel

configurations.

1, 4, or 8 single input channels

Up to 16 networked RS-232 input channels

Or combinations of single input channels and networked RS-232

input channels for a total of up to 16 channels

Software version

The software version is shown in the About setup screen discussed

later in chapter 2.

Cleaning

Use only a cloth dampened with water and a mild detergent for

cleaning the exterior surfaces. Never use abrasive cleaners, and never

use strong detergents or solvents. Only dampen the cloth, do not use

a cleaning cloth that is dripping wet.

ND 2100G GAGE-CHEK 7

Page 8

8 Preface

Page 9

1 Operation .... 17

1.1 ND 2100G Overview .... 18

Overview .... 18

1.2 Basic operation of the ND 2100G .... 20

Switching on the ND 2100G .... 20

Switching off the ND 2100G .... 20

1.3 Panel key descriptions .... 21

Dimension keys .... 23

1.4 LCD screens and menus .... 26

Screen navigation .... 26

Home screen .... 27

DRO screen .... 27

View soft keys and screens .... 28

View soft keys for subgroups of one .... 28

Dimension graphs for SPC subgroups of one .... 28

Dimension histograms for SPC subgroups of one .... 29

Bar and dial current value displays .... 30

Dimension data tables for SPC subgroups of one .... 31

View soft keys for subgroups greater than one .... 32

Dimension x

Dimension r charts for subgroups greater than one .... 33

Dimension data tables for subgroups greater than one .... 34

in/mm menu items .... 35

Master menu items and screens .... 35

Master screen for calibrating encoder datums .... 35

Master screen for calibrating transducer ranges .... 36

Menu soft keys .... 37

The datum menu functions .... 37

The Extra menu functions .... 38

Fast3 .... 39

Setup menu functions .... 40

charts for subgroups greater than one .... 32

ND 2100G GAGE-CHEK 9

Page 10

1.5 Operating instructions .... 41

Select a part to begin a measurement .... 42

Establish a reference for the measurement .... 43

Calibrating channels using the Master function .... 43

Calibration of a single reference point .... 44

Calibration groups (G1, G2, G3...G18) .... 45

Calibrations of transducer resolution (Min-Max calibrations) .... 46

Establishing a temporary dimension reference .... 48

Zeroing a dimension reference .... 48

Presetting a dimension reference to a specific value .... 49

Clearing channel calibrations .... 50

Clearing dimension references (presets) .... 50

Conducting measurements .... 51

Manual measurements .... 51

Sequential measurements .... 52

Dynamically sampled measurements .... 53

Semi-automated measurements .... 54

Reviewing measurements .... 55

Printing reports or sending results to a computer .... 55

Printing reports .... 55

Sending data to a computer .... 56

Data reports .... 57

Clearing stored measurement data .... 58

10

Page 11

2 Installation, Setup, Formulas and Specifications .... 59

2.1 ND 2100G Shipment Contents .... 60

Items included with the ND 2100G .... 60

Optional items possibly included .... 60

Repackaging the ND 2100G .... 61

2.2 Hardware Installation .... 62

Assembling the mounting stand .... 62

Benchtop location and mounting .... 62

Arm mounting (optional) .... 63

Connecting power .... 64

Connecting channel inputs .... 65

Connecting a computer .... 66

Connecting headphones and USB printer .... 66

Connecting headphones .... 66

Connecting a USB printer .... 66

Connecting an optional foot switch or remote keypad .... 67

2.3 Software setup .... 68

Setup menu .... 69

Accessing and navigating the Setup menu .... 70

Using dimension keys in the setup mode .... 71

Entering data into setup fields .... 71

Deleting data entries .... 72

Entering setup parameters .... 72

Changing the channel or dimension number .... 72

Entering parameters .... 73

Copying parameters to other parts, dimensions or channels .... 73

Saving a parameter and advancing to the next .... 74

Saving a parameter and returning to the Setup menu .... 74

Discarding changes and returning to the Setup menu .... 74

Leaving the Setup menu .... 75

Printing ND 2100G setup configurations .... 75

Saving or loading ND 2100G configurations .... 75

Minimum setup requirements .... 76

Setup screens .... 76

About setup screen .... 76

Dimensions setup screen .... 77

Creating part numbers .... 77

Selecting part numbers .... 77

Labeling parts and dimensions .... 78

Defining visible and hidden dimensions .... 78

Copying dimension parameters to other parts .... 79

Deleting parts .... 79

Formats setup screen .... 80

Specifying a dimension .... 80

Specifying radius or diameter .... 80

Display resolution .... 81

Formulas setup screen .... 82

Variables setup screen .... 83

ND 2100G GAGE-CHEK 11

Page 12

Tolerances setup screen .... 84

Nominal values with tolerances .... 85

Nominal with +/- tolerances .... 85

Nominal with ++ tolerances .... 86

Nominal with -- tolerances .... 87

Nominal with fixed limits .... 88

Specifying an audio alert .... 89

Mirror values .... 90

SPC setup screen .... 91

Subgroup size .... 91

Max subgroups .... 91

Graph points .... 92

Next record ID .... 92

Dimension .... 92

UCL and LCL .... 93

x

, r Ucl and Lcl .... 93

Warning limits .... 95

Showing and hiding SPC graphs .... 95

Header setup screen .... 96

Labels .... 96

Prompts .... 96

Memory setup screen .... 97

S labels setup screen .... 97

S formulas setup screen .... 98

Globals setup screen .... 98

Channels setup screen .... 99

Specifying the input channel .... 99

Selecting the channel input type .... 100

Specifying input channel setup parameters .... 101

Master link probe balancing .... 101

Setting the resolution for the linked channels .... 102

Specifying channel input resolution .... 103

Specifying units of measure .... 104

Reversing channel input polarity .... 104

Specifying encoder reference marks .... 105

Changing the machine zero position .... 106

Enabling scale error notification .... 106

Calibrating LVDT and HBT transducer gain .... 106

Centering (nulling) LVDT and HBT transducers .... 107

Selecting an external RS-232 channel .... 108

Specifying an RS-232 input port .... 108

EnDat 2.2 encoder interface .... 109

Master setup screen .... 111

Specifying the number of calibration points .... 111

Selecting calibration type .... 111

Locking the calibration process if warnings occur .... 112

Specifying a calibration interval .... 112

Using dynamic Min/Max values for calibration .... 113

Specifying Min and Max calibration warnings .... 114

12

Page 13

SLEC setup screen .... 115

SLEC or LEC, which is right for my application? .... 115

LEC (Linear error correction) .... 115

SLEC (Segmented linear error correction) .... 116

SLEC setup procedure .... 118

Clear all datums .... 118

Cycle power & set machine zero .... 119

Clear old values & disable SLEC .... 120

Enter machine zero offset .... 121

Enter new station values .... 122

Enable SLEC .... 123

Display setup screen .... 123

Radix for numeric displays .... 123

Display mode for angles .... 123

Startup angular and linear display modes .... 124

Bar graph orientation .... 125

Bar graph or dial displays .... 125

Colors that indicate measurement results .... 125

Units of measure .... 126

Home screen .... 126

Report setup screen .... 127

Record number .... 128

Lines per page .... 128

Columns per page .... 129

Type of records to be printed .... 129

Report characters setup screen .... 130

Send setup screen .... 132

Auto Send Rec .... 132

Record Number .... 132

Record date, label and units of measure .... 132

Record content .... 133

Min Dimen Size .... 133

Send characters setup screen .... 134

Parallel setup screen .... 135

Remote control .... 135

I/O Debounce interval .... 135

RS-232 setup screen .... 136

Uart Id .... 136

Baud rate .... 136

Word length .... 136

Stop bits .... 137

Parity .... 137

Handshaking .... 137

End of character (EOC) delay .... 137

Specifying end of line (EOL) delay .... 138

Serial port data type .... 138

ND 2100G GAGE-CHEK 13

Page 14

USB setup screen .... 139

Data .... 139

Destination .... 139

File type .... 140

Current auto (file) number .... 140

Hot Keys setup screen .... 141

Front panel keys for hot key mapping .... 141

Remote switches and parallel port pins for hot key mapping .... 142

Assigning hot key functions .... 143

Clock setup screen .... 152

Setting the date and time .... 152

Date format .... 152

Time format .... 153

External edge setup screen (optional) .... 154

Edge input .... 154

External edge probe timing .... 154

Edge Type .... 155

Direction factor .... 155

Teaching a probe diameter .... 157

Misc. setup screen .... 158

Key delay .... 158

Speaker volume .... 158

Data entry message time .... 158

Switch view .... 159

Cpk/Ppk display .... 159

Slew limit .... 159

Start Scr saver .... 159

Scr Saver Off .... 160

Startup hold .... 160

Strict Unit Check .... 160

Supervisor setup screen .... 161

Password .... 161

Unlocking and locking critical functions .... 161

14

Page 15

2.4 Formulas .... 163

Introduction to formulas .... 163

How do formulas relate inputs to dimensions? .... 165

Visible or hidden dimensions? .... 165

Visible dimensions .... 165

Hidden dimensions .... 165

When are dimensions stored in the ND 2100G database? .... 166

What can formulas do? .... 166

When are formulas constructed or edited? .... 167

How can formulas be recorded for safekeeping? .... 167

Constructing and editing formulas .... 168

Formula setup screen .... 168

Formula construction example .... 171

Long formulas .... 175

Deleting formula elements .... 175

Formula functions .... 176

Basic and advanced formula functions .... 177

Basic formula functions .... 178

Channel functions .... 179

Dimension functions .... 181

Arithmetic operators .... 183

Units of measure .... 184

Basic math functions .... 185

Exponent function (exp) .... 186

Trig and inverse trig functions (sin through atan) .... 187

Absolute value (abs) function .... 188

Integer function (int) .... 189

Pi and other constants .... 190

Advanced formula functions .... 191

Commas (,) .... 194

Semicolon (;) .... 195

Logical and control .... 196

Din .... 198

Dout .... 198

MinIndex and MaxIndex .... 199

RsetDyn .... 199

If function .... 200

Case function .... 201

Minimum (min) and maximum (max) functions .... 204

Average (avg) and median (md) functions .... 206

Modulo (mod) function .... 207

Sequence (seq) function .... 208

Trip function and measurement automation .... 212

Dynamic minimum (Dmn) and dynamic maximum (Dmx) functions .... 215

Dynamic average (Davg) and dynamic median (Dmd) functions .... 217

Fail function .... 218

ND 2100G GAGE-CHEK 15

Page 16

Xtra menu functions .... 219

Ask function .... 222

Beep function .... 223

Clear all data function .... 224

Clear data function .... 224

ClrTrig, SetTrig and user defined events .... 225

OnEvent function .... 226

DateStr function .... 228

TimeStr function .... 228

Time function .... 229

Din and DinBin function .... 230

Din .... 230

DinBin .... 232

Dout and DoutBin function .... 233

Dout .... 233

DoutBin .... 235

Display function .... 237

FnDefine, FnParam and FnCall functions .... 238

Variable and Global functions .... 240

Variables .... 240

Globals .... 242

Loop function .... 243

Remark function .... 244

HwDmn and HwDmx functions .... 245

RsetDyn function .... 245

HwLx function .... 246

Lookup and data lookup .... 247

Master function .... 250

MaxIndex and MinIndex functions .... 251

PartNo function .... 252

Preset function .... 253

Recall function .... 254

Relay function .... 255

Report function .... 257

Scan function .... 258

Send function .... 263

SendMsg function .... 264

SendRec function .... 265

SetColor function .... 266

Setup function .... 267

Xlatch function .... 268

2.5 Specifications .... 270

Dimensions .... 272

Arm mount bracket .... 273

16

Page 17

Operation

Page 18

1.1 ND 2100G Overview

Overview

The ND 2100G is an advanced digital readout system for performing

single or multiple gage measurements at very high levels of precision

and accuracy. Dimensional inspections of components are performed

using encoders or transducers as part of in-line production activities,

or final quality inspection. Measurements are conducted under

operator control, or are semi-automated and conducted in conjunction

with a fixtured gage system.

The ND 2100G is configured at the factory to support

One, four or eight single-input channels, or

Up to 16 multiplexed RS-232 input channels, or

1.1 ND 2100G Overview

Combinations of single-input channels and multiplexed RS-232 input

channels for a total of up to 16 channels

Channel inputs can be algebraically combined or processed by

powerful math and control formulas to display dimensions such as

flatness, volume and runout. Formulas are created as part of the

ND 2100G setup using straightforward screen control and math

functions.

C1=28.846 mm Sum=C1+C2 Sum=12.820

C2=-16.026 mm Dif=C1-C2 Dif=44.872

Channel inputs are processed by formulas to display dimensions.

18 1 Operation

Page 19

The intuitive user interface includes a large character color LCD for fast

and accurate measurement feedback. User interface screens include

a digital readout of current values, bar and dial position value

indicators, graphs of values, histograms of measurement statistics

and tables of measurement and of SPC data.

Digital readout (DRO) Horizontal bar Vertical bar Dial

Graph of values Histogram of values Measurement data SPC data

1.1 ND 2100G Overview

ND 2100G GAGE-CHEK 19

Page 20

1.2 Basic operation of

finish

the ND 2100G

Switching on the ND 2100G

Switch on the ND 2100G. The POWER switch is

located on the rear of the enclosure. After switching

the power on, or after a power failure, the power-up

screen will be displayed.

Press the FINISH key to advance from the power-up

screen to the home screen.

Your ND 2100G is now ready for operation.

1.2 Basic operation of the ND 2100G

Switching off the ND 2100G

Power-up screen.

Switch the ND 2100G off. The parts, formulas and

dimensions that have been saved during operation

will be retained in memory.

20 1 Operation

Page 21

1.3 Panel key descriptions

quit

cancel

enter

finish

+/-0

4

1

7

5 6

2 3

8 9

enter

finish

cancel

quit

Descriptions of panel key functions are provided in the following

pages for Command, Fast Track, Send, LCD On/Off and Arrow Cursor

keys. Soft key functions are also described later as part of LCD

screens and menus.

Command keys Function

Enter data: Press the ENTER key to enter

data for a measurement. Information on the

LCD is stored as measurement or

configuration data. This information includes

current dimension values or alphanumeric

data for a configuration or user prompt data

field.

Exit a screen: Press the FINISH key to exit a

screen saving any changes that were made.

The FINISH key may also be used to return

from the display of measurement or SPC data

to the current home screen.

Delete data or features: Press the CANCEL

key to erase the last data value entered into

the system from the numeric keypad or

delete data in configuration fields.

Quit current activity: Press the QUIT key to

abort the current task and return to the home

screen or to exit the current menu.

Fast Track keys Function

Left frequently used function:

Press the LEFT WIDE key to initiate

the function programmed for this

key. The factory default function for

this key is RSETDYN.

Right frequently used function:

Press the RIGHT WIDE key to

initiate the function programmed for

this key. The factory default function

for this key is ENTER.

ND 2100G Panel keys.

1.3 Panel key descriptions

Send key Function

Transmit measurement results: Press the

SEND key to transmit measurement data to a

computer, a USB printer or a USB memory

drive.

ND 2100G GAGE-CHEK 21

Page 22

LCD On/Off key Function

+/-0

4

1

7

5 6

2 3

8 9

Turn the LCD off or clear data: Press the

LCD ON/OFF key to toggle between LCD on

and LCD off, or to clear channel calibrations,

delete data stored for a single part or delete

data stored for all parts

Arrow cursor keys Function

Numeric keys Function

1.3 Panel key descriptions

Navigate menus and setup screen

data fields.

The numeric keypad is used primarily

for numeric data entry. The decimal

point key and +/- key can also be used

to increase or decrease the LCD

screen contrast when a decimal point

or +/- input are not expected by the

system as part of a data entry

process. The screen contrast setting

will be saved when the system is

powered down and used as the

default contrast setting the next time

the system is turned on.

22 1 Operation

Page 23

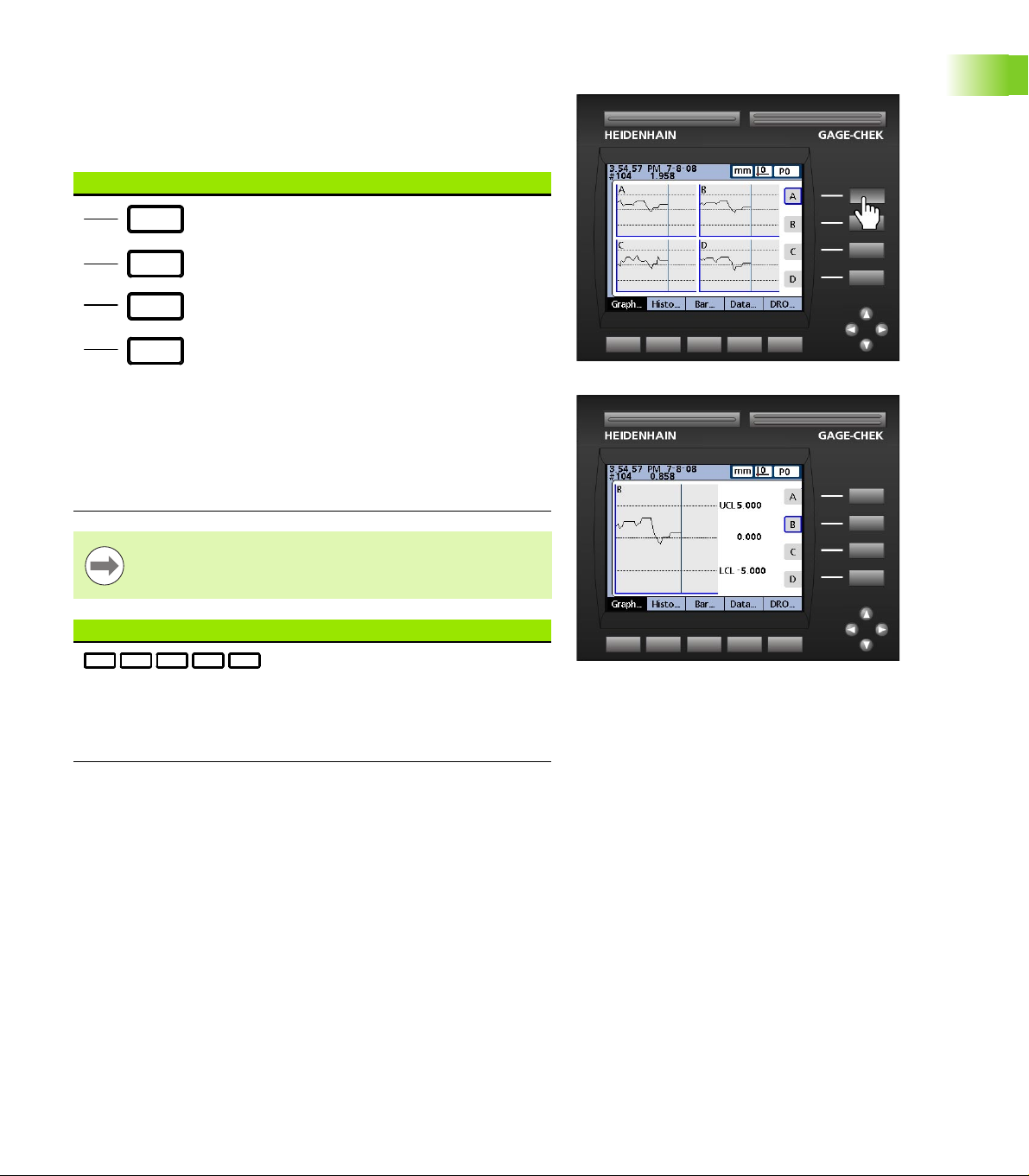

Dimension keys

Dimension keys can be assigned one of six hot key functions for use

when the DRO screen is displayed. When graph, bar value and data

screens are displayed, the dimension keys are used to display values

for single dimensions or a smaller group of dimensions.

Dimension keys Function

Pressing a dimension key in the:

DRO screen: performs the function

assigned in the hotkey setup

screen. By default no hotkey

function is assigned until the user

makes the assignment

Graph screens: displays a single

graph for the corresponding

dimension

Bar screens: Displays a single bar

showing current values for the

corresponding dimension

Data screens: displays a single data

table of stored values for the

corresponding dimension

Hot key assignments are discussed in detail on page 141.

1.3 Panel key descriptions

Soft keys Function

Soft keys initiate functions that are

labeled above the keys at the bottom

of the LCD screen. As different

system functions are selected, the

soft key labels change in support of

those functions.

ND 2100G GAGE-CHEK 23

Pressing the dimension A key in a graph screen

selects the A graph for display.

Page 24

Pressing the VIEW... soft key changes soft key labels to show five

screen viewing options, graph, histogram, bar, data and DRO.

Pressing the VIEW... soft key causes soft key labels to change,

offering five options for viewing data.

When viewing graphs of stored data, current value bars or tables of

1.3 Panel key descriptions

stored data, pressing a different soft key changes to the view

indicated by the soft key label.

Pressing the DATA... soft key when viewing bars causes the

dimension data table to be displayed.

24 1 Operation

Page 25

Pressing the currently highlighted soft key alternates between singledimension and multiple-dimensions displays.

Pressing the BAR... soft key when viewing multiple-dimensions

causes the currently selected dimension to be displayed by itself.

The left most soft keys can be designated hotkeys to

provide quick access to commonly used functions when

the home screen is displayed. Hot key assignments are

discussed in detail in Chapter 2: Installation, Setup and

Specifications.

1.3 Panel key descriptions

ND 2100G GAGE-CHEK 25

Page 26

1.4 LCD screens and menus

The ND 2100G LCD presents a variety of screens and menus selected

by the user to display current dimension values, pass fail test results,

dimension value graphs, statistical process control graphs and data

tables, and setup and part configuration options.

Screen navigation

ND 2100G screen navigation is straightforward. For example, to

display a bar graph of current values from the home screen, press the

MENU... soft key, then press the VIEW... soft key and then the BAR...

soft key.

1.4 LCD screens and menus

Press the VIEW... soft key then the BAR... soft key.

26 1 Operation

Page 27

Home screen

The home screen is displayed after the startup screen when power is

applied to the ND 2100G, and is displayed after the FINISH key is

pressed to complete a measurement or screen evaluation.The default

home screen is the DRO, but can be reassigned to another screen in

the Display setup screen.

The assignment of the home screen is discussed in detail

in Chapter 2: Installation, Setup and Specifications.

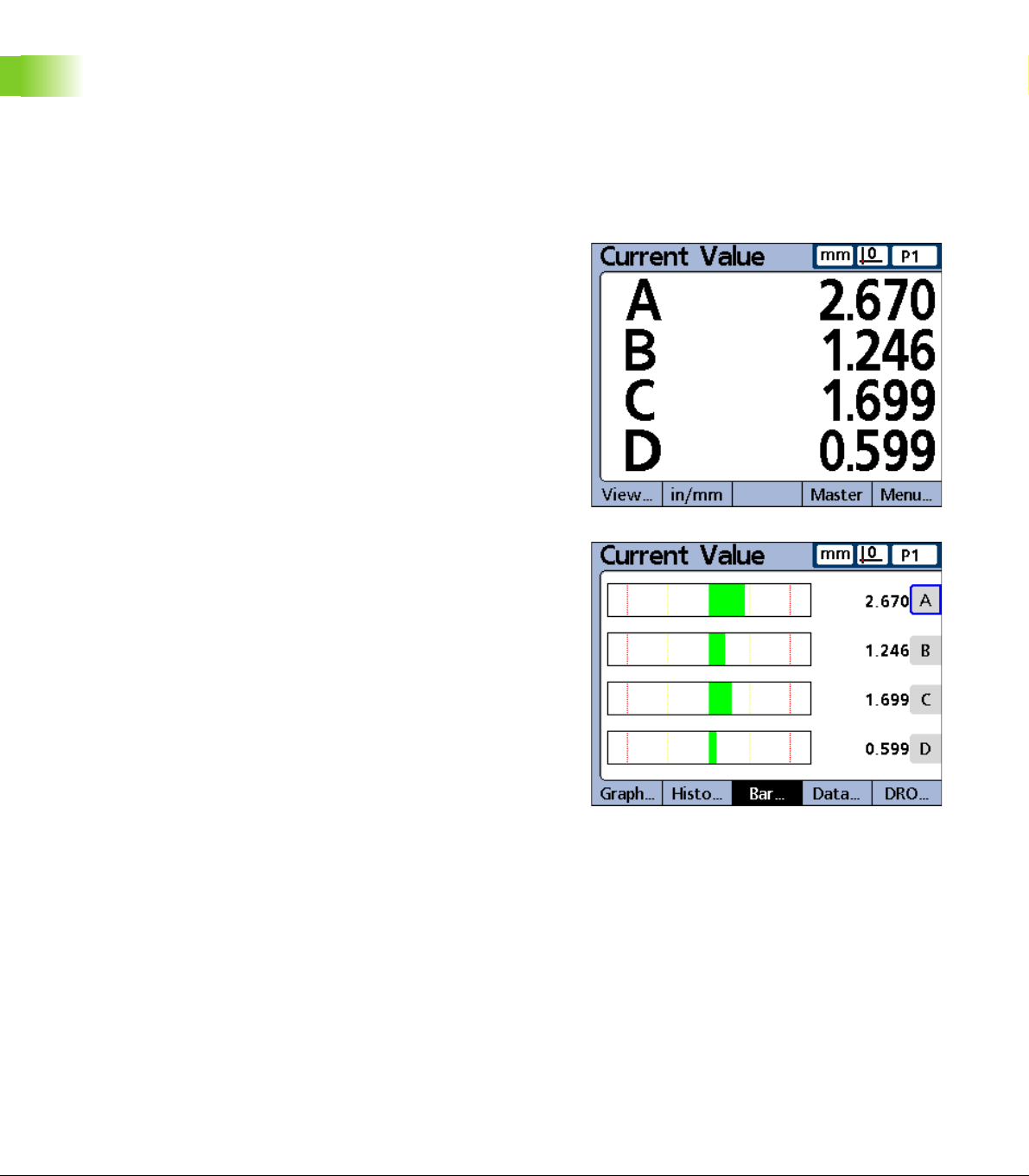

DRO screen

The DRO screen is the default home screen displayed after power is

applied and the startup screen is shown.The DRO screen provides

numeric displays of the current values of up to four dimensions. The

unit of measure, current datum and current part number or part name

are displayed in the upper right corner of the screen.

Use the arrow cursor keys to scroll dimensions when more than four

dimensions are active.

1.4 LCD screens and menus

DRO screen

ND 2100G GAGE-CHEK 27

Page 28

View soft keys and screens

View soft keys for subgroups of one

Pressing the VIEW... soft key when using subgroups of one, changes

soft key labels to show five screen viewing options. Graph, histogram,

bar, data and DRO.

View soft keys Function

GRAPH... Displays data in a line graph

HISTO... Displays data in a histogram

BAR... Displays data in a bar graph

DATA... Displays numerical data

DRO... Displays the DRO screen

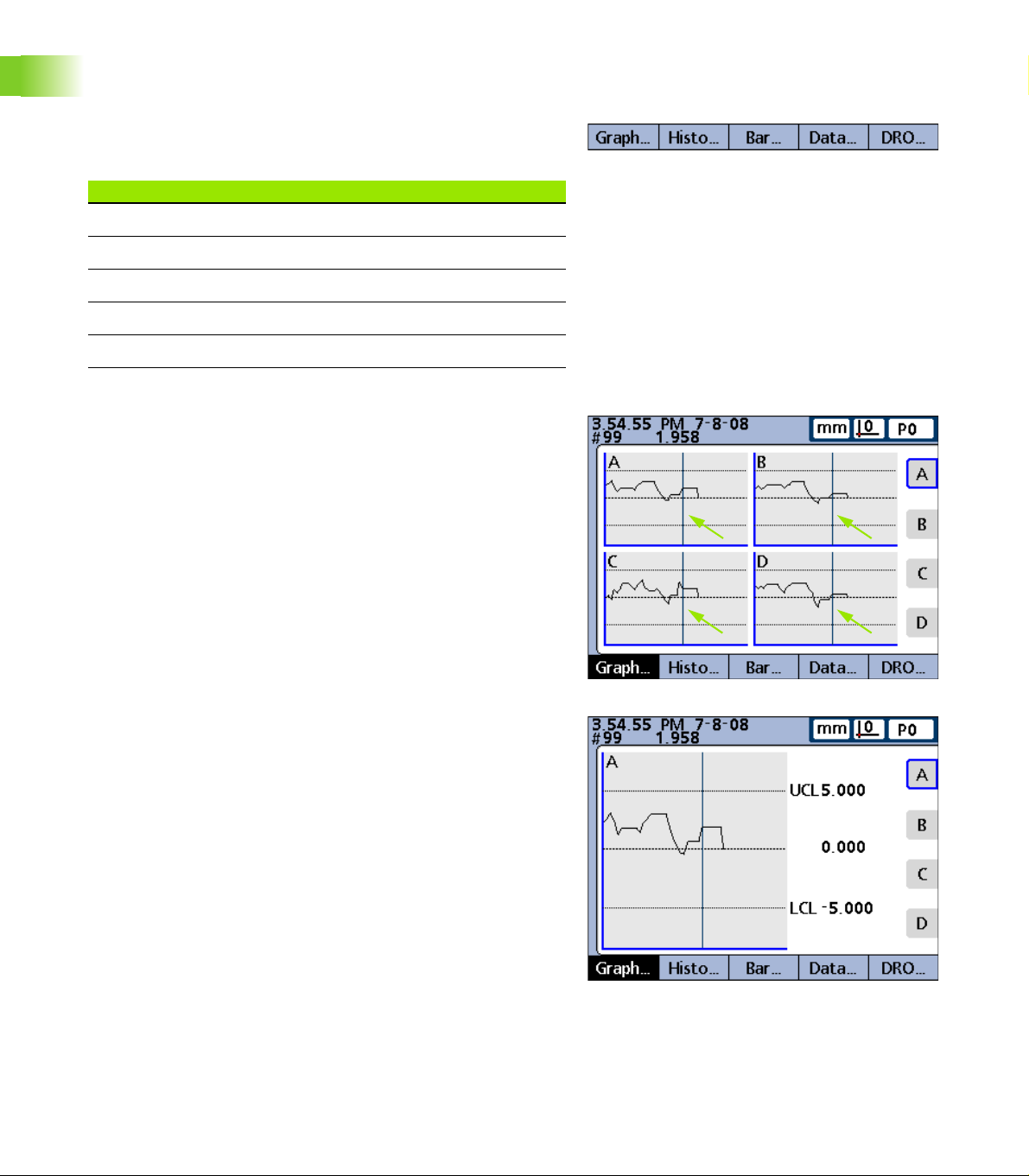

Dimension graphs for SPC subgroups of one

1.4 LCD screens and menus

The dimension graph screen is displayed for SPC subgroups of 1, and

displays graphs for up to 16 dimensions.

Press the GRAPH... soft key to change the number of graphs

presented on the screen. Press a dimension soft key to display a graph

of the dimension and the minimum additional dimensions. Use the

arrow cursor keys to scroll the graphs when more data is stored than

will fit on the screen.

Individual samples are selected by a vertical line on the graph. Move

the vertical line left and right through the stored data using the arrow

cursor keys. The time and date that the selected sample was stored

are shown in the upper left corner of the screen. The ID number of the

sample for the dimension and the value of the data are also shown in

the upper left corner. Displays of a single dimension also show the

nominal and control limit values.

View soft keys for subgroups of one.

Vertical selection lines.

Dimension line graphs for subgroups of one.

28 1 Operation

Page 29

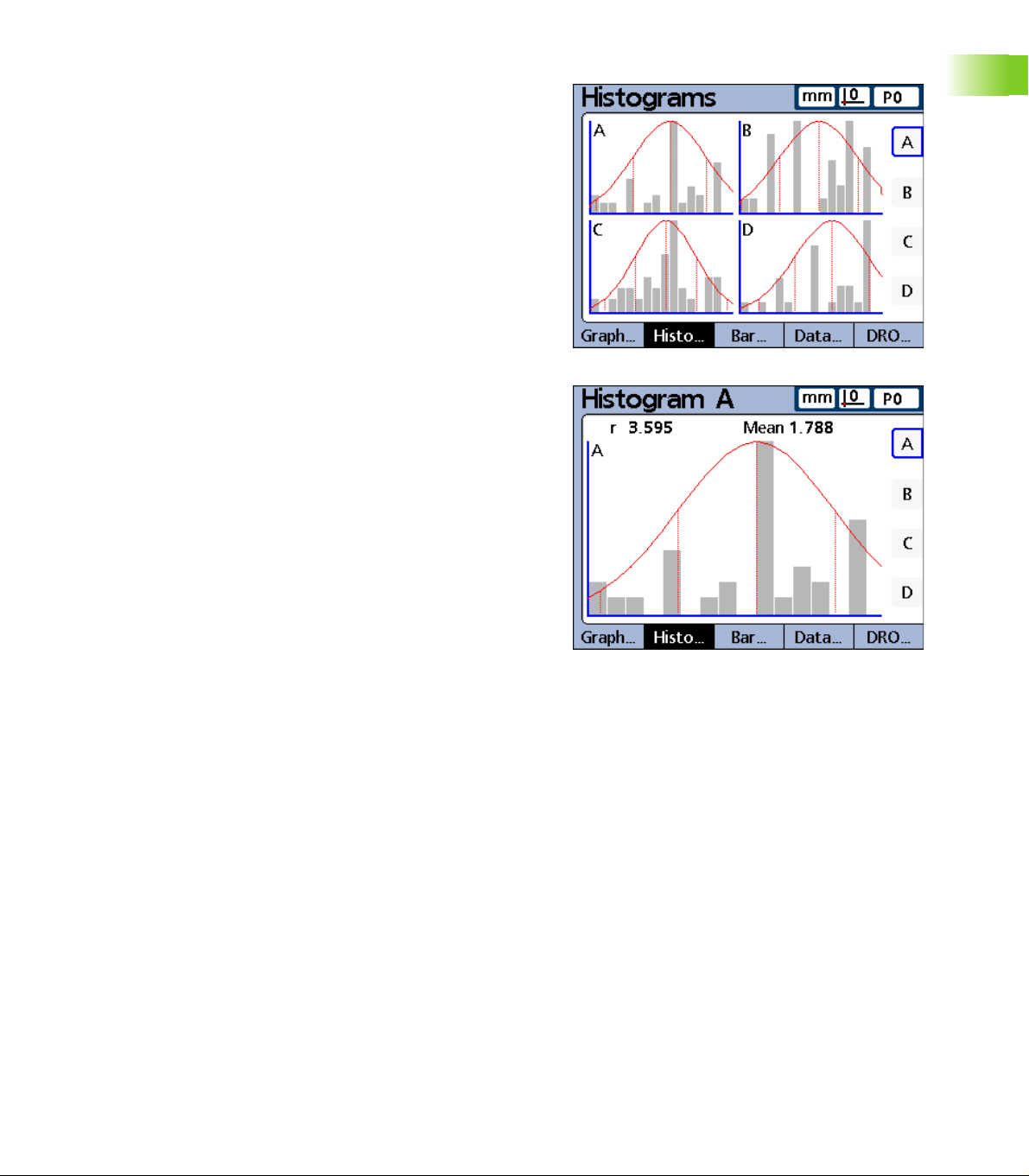

Dimension histograms for SPC subgroups of one

The dimension histogram screen displays histograms of values for up

to 16 dimensions. The dimension histogram screens are displayed for

SPC subgroups of one.

Press the HISTO... soft key to change the number of histograms

presented on the screen. Press a dimension soft key to display the

histogram of a single dimension.

The display of a single dimension also shows the total range and mean

of the values.

1.4 LCD screens and menus

Dimension histograms for subgroups of one.

ND 2100G GAGE-CHEK 29

Page 30

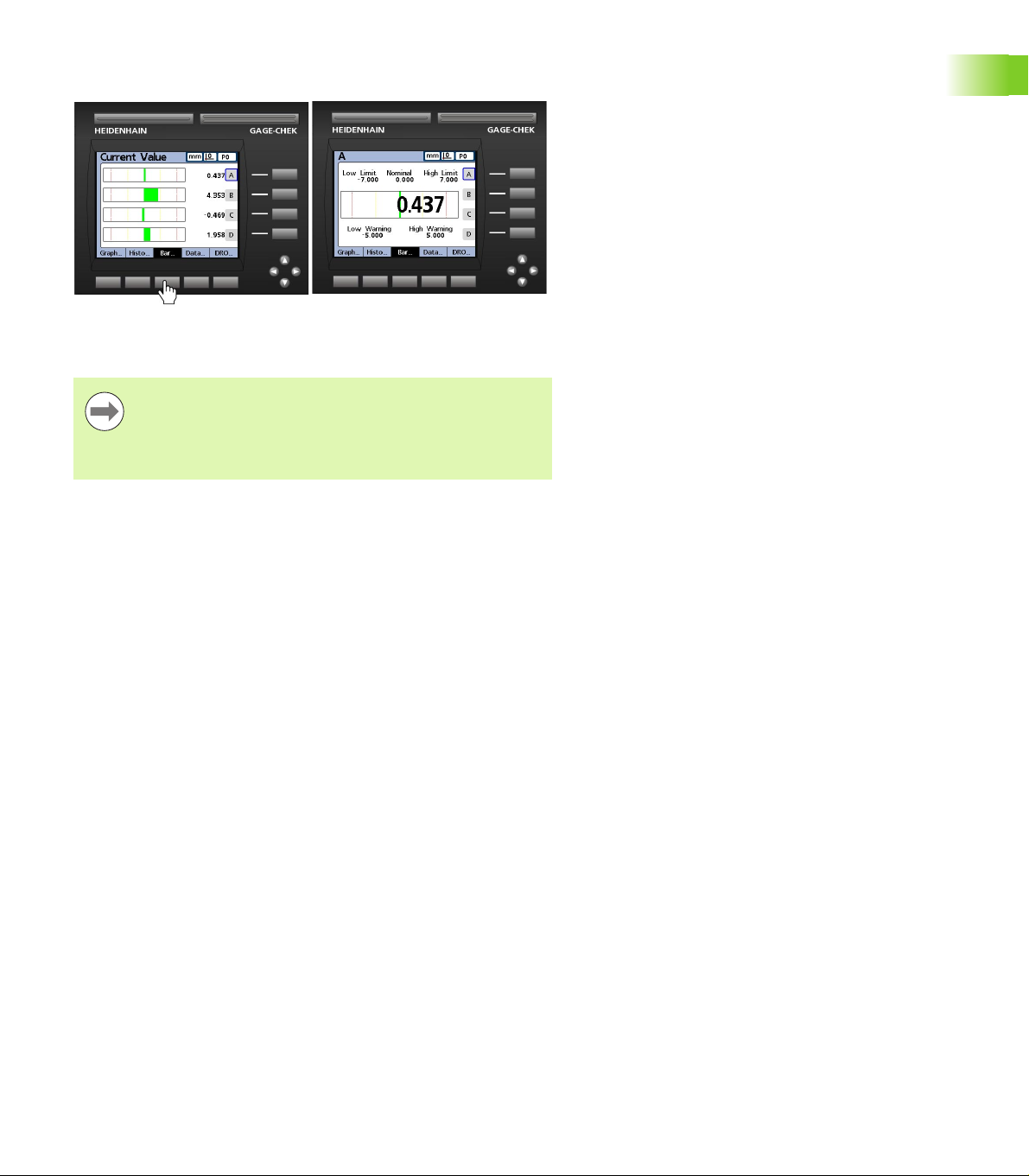

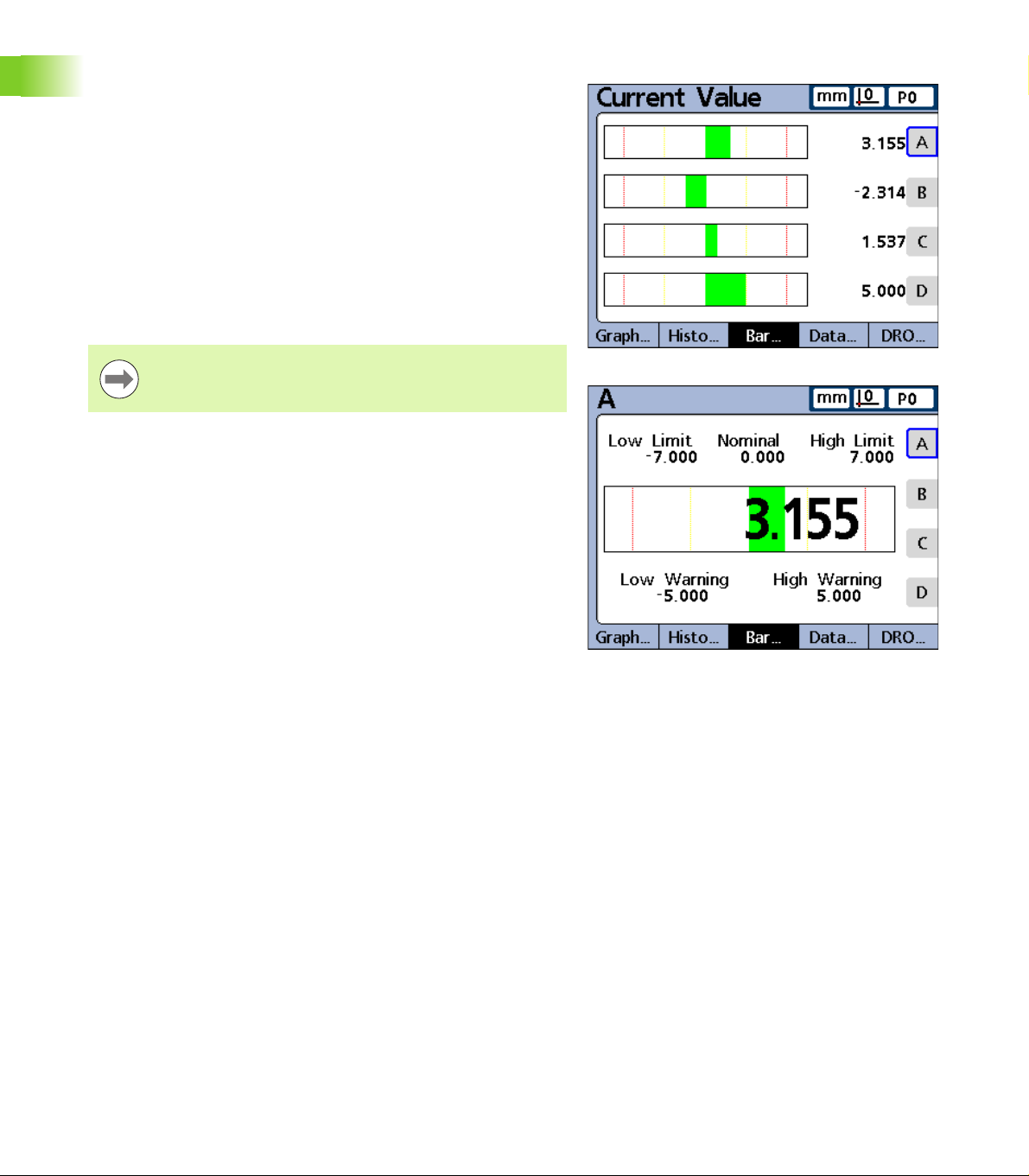

Bar and dial current value displays

The bar and dial screens provide graphic displays of the current values

of up to 16 dimensions. The default bar screen can be configured to

display current value bars in horizontal or vertical orientation using the

Display setup screen.

Bar displays of multiple dimensions show current values. Bar displays

of single dimensions include the current value, nominal value, and high

and low warning and limit values.

Press the BAR... soft key to change the number of bars presented on

the screen. Press a dimension soft key to display a bar for a single

dimension.

The display can be configured in the Display setup screen to include a

dial in addition to the bars. When the dial display is also available, press

the BAR... soft key to toggle between the bars and the dial.

The display of a single dimension can be configured to be

a bar or a dial, but cannot be toggled between a single bar

and a single dial.

1.4 LCD screens and menus

Bar graphs for subgroups of one.

30 1 Operation

Page 31

Dimension data tables for SPC subgroups of one

Dimension data screens contain measurement data stored for up to 4

dimensions. Press the DATA... soft key to toggle between views of

data for all dimensions and data for a single dimension that includes

SPC statistics.

Press a dimension soft key to display data for a single dimension. Use

the arrow cursor keys to scroll the tables when more data is stored

than will fit on the screen.

1.4 LCD screens and menus

Dimension data tables for subgroups of one.

ND 2100G GAGE-CHEK 31

Page 32

View soft keys for subgroups greater than one

Pressing the VIEW... soft key, when using subgroups greater than

one, changes soft key labels to show five screen viewing options. x

Bar, Data and DRO.

View soft keys Function

... Displays the mean (x) of each subgroup for up

x

r... Displays the range ( r ) of each subgroup for

BAR... Displays data in a bar graph

DATA... Displays numerical data

DRO... Displays the DRO screen

to 16 dimensions

up to 16 dimensions

, r,

VIEW soft keys for subgroups greater than one.

Dimension x

1.4 LCD screens and menus

For SPC subgroups greater than 1, the dimension x

in place of the dimension graph screen discussed earlier. The

dimension x screen graphs the mean (x) of each subgroup for up to 16

dimensions.

Press the x

the screen. Press a dimension soft key to display a graph of a single

dimension.

Use the arrow cursor keys to scroll the graphs when more data is

stored than will fit on the screen.

Individual subgroups are selected by a vertical line on the graph. Move

the vertical line left and right through the stored data using the arrow

cursor keys. The time and date when the selected subgroup data was

stored are shown in the upper left corner of the screen. The ID number

of the subgroup and the value of the data for the dimension are also

shown in the upper left corner. Displays of single dimensions also

show the control limits.

charts for subgroups greater than one

screen is displayed

... soft key to change the number of graphs presented on

Vertical line.

charts for subgroups greater than one.

x

32 1 Operation

Page 33

Dimension r charts for subgroups greater than one

For SPC subgroups greater than 1, the dimension r screen is displayed

in place of the Histogram screen discussed earlier. The dimension r

screen graphs the range ( r ) of each subgroup for up to 16 dimensions.

The range is not recalculated for each measurement, but is

recalculated each time a subgroup is completed. Refer to "SPC setup

screen" on page 91.

Use the arrow cursor keys to scroll the graphs when more data is

stored than will fit on the screen.

Individual subgroups are selected by a vertical line on the graph. Move

the vertical line left and right through the stored data using the arrow

cursor keys. The time and date when the selected subgroup data was

stored are shown in the upper left corner of the screen. The ID number

of the subgroup and the value of the data for the dimension are also

shown in the upper left corner. Displays of single dimensions also

show the range control limits.

1.4 LCD screens and menus

r charts for subgroups greater than one.

ND 2100G GAGE-CHEK 33

Page 34

Dimension data tables for subgroups greater than one

Dimension data screens display measurement data for up to 4

dimensions. The Data screen for a single dimension is slightly

different for SPC subgroups greater than 1 than those for SPC

subgroups of 1. Individual subgroups are indicated by a horizontal line

in tables for single dimensions. The data table for multiple dimensions

remains unchanged for SPC subgroups greater than 1.

Press the DATA... soft key to toggle between views of data for all

dimensions and data for a single dimension that includes SPC

statistics. Press a dimension soft key to display data for a single

dimension.

Use the arrow cursor keys to scroll the tables when more data is

stored than will fit on the screen.

The time and date when the highlighted subgroup data was stored are

shown in the upper left corner of the screen. The ID number of the

data record and the value of the data for the dimension are also shown

in the upper left corner.

1.4 LCD screens and menus

Dimension data tables for subgroups greater than one.

34 1 Operation

Page 35

in/mm menu items

Press the IN/MM soft key to toggle the display between inch and

millimeter units of measure. This does not alter the channel

configurations in the Channel setup screen. The ND 2100G calculates

the conversion from one unit of measure to another as a convenience

to the user.

Master menu items and screens

Master screens are used to calibrate the encoder datums or

transducer input channel ranges. The Master function is configured in

the Master setup screen to either calibrate datum D0 for encoders, or

calibrate datum D0 and the entire channel range for transducers.

Prior to applying, and after clearing a mastered channel

value, the ND 2100G machine zero is used as the absolute

datum.

Master screen for calibrating encoder datums

When the Master setup screen is configured to perform full

calibrations of transducer input channels (Master type set to MinMax), the full range of any channel input can be calibrated at any time

using the Master function Min and Max screens. Up to 18 range

calibration values can be stored for each ND 2100G transducer input

channel. Any of these groups can be quickly recalled and applied later.

Instructions for calibrating channel datums are provided

later in this chapter.

1.4 LCD screens and menus

Pressing the MASTER soft key brings up the Channel

Master screen for calibrating encoder datums.

ND 2100G GAGE-CHEK 35

Page 36

Master screen for calibrating transducer ranges

When the Master setup screen is configured to perform full

calibrations of transducer input channels (Master type set to MinMax), the full range of any channel input can be calibrated at any time

using the Master function Min and Max screens. Up to 18 range

calibration values can be stored for each ND 2100G transducer input

channel. Any of these groups can be quickly recalled and applied later.

Instructions for calibrating transducer input channels Min

and Max range values are provided later in this chapter.

1.4 LCD screens and menus

Master Min screen for calibrating transducer range.

Master Max screen for calibrating transducer range.

36 1 Operation

Page 37

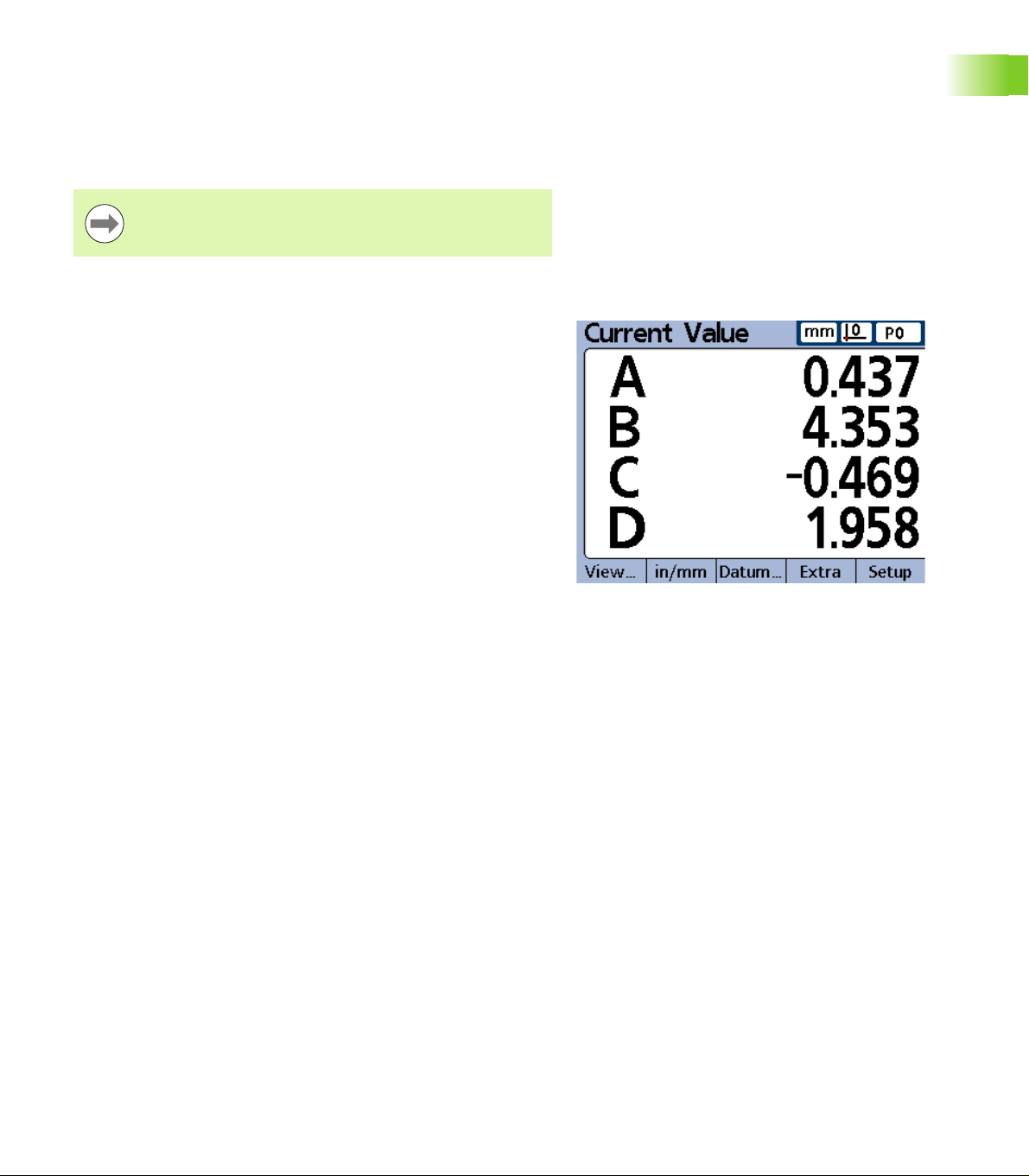

Menu soft keys

Pressing the MENU... soft key changes soft key labels to show Menu

options: View..., in/mm, Datum..., Extra and Setup.

Menu soft keys Function

VIEW... Pressing the VIEW... soft key provides

access to View menu options. Refer to "View

soft keys and screens" on page 28.

IN/MM Pressing IN/MM soft key toggles between

inch and millimeter units of measure for

applicable dimensions. Refer to "in/mm menu

items" on page 35.

DATUM... Pressing the DATUM... soft key provides

access to Datum menu options.

EXTRA Pressing the EXTRA soft key provides access

to Extra menu options.

SETUP Pressing the SETUP soft key provides access

to Setup menu options.

The datum menu functions

The DATUM... functions provide the means to ZERO, PRESET, CLEAR

and toggle between measurement reference datums.

Datum soft keys Function

D0/D1 Pressing the D0/D1 soft key toggles between

the absolute datum (D0) and the incremental

datum (D1).

Menu soft keys.

1.4 LCD screens and menus

Datum soft keys.

ZERO... The Zero menu function can be used at any

time to simultaneously zero all incremental

datums, or to zero any specific incremental

datum.

MASTER The Master functions are used to calibrate

PRESET The Dimension Preset screen is used to

CLEAR The Clear menu function can be used at any

ND 2100G GAGE-CHEK 37

the encoder datums or transducer input

channel ranges.

preset incremental datums.

The incremental datum of a dimension can be

preset to a specific value at any time by

pressing the PRESET soft key, pressing a

dimension soft key and entering the desired

value.

time to simultaneously clear all incremental

datums. Cleared incremental datums (D1) are

made equal to absolute datums (D0).

Page 38

The Extra menu functions

The Extra menu provides quick access to a variety of display and other

system functions. To use any Extra menu function, highlight the

desired function, and then press the ENTER key.

Extra menu

functions

Cycle Advances to the next defined part. Part

DMS/DD Toggles the display of angles between

Fast3 Refer to "Fast3" on page 39.

Hold Toggle function that holds (freezes) or

1.4 LCD screens and menus

Part? Displays a pop-up screen that allows the user

Rad/Dia Toggles between the radius and diameter

Recall Applies the last used incremental datum (D1)

RsetDyn Resets the minimum and maximum values

Function

numbers are cycled in a continuous loop.

Degrees, Minutes, Seconds (DMS) and

Decimal Degrees (DD).

releases the current value of a single

dimension when a dimension soft key is

pressed, or of all dimensions when the ALL

soft key is pressed.

to specify a new part number.

measurement types on the DRO screen, if

radius or diameter was specified in the

Formats setup screen.

preset that was entered by the user.

accumulated during dynamic measurements.

This function must be initiated prior to new

dynamic measurements.

EXTRA menu functions.

Send Sends the specified current dimension

values, or all current dimension values to the

RS-232 serial port for transmission to a

computer. The user is prompted to send one

or all.

SendRec Sends stored records to the RS-232 serial

port for transmission to a computer. Refer to

"Report setup screen" on page 127.

38 1 Operation

Page 39

Fast3

Channel input

values stored

Channel input

values stored

Channel 2

input value

Sample

increment

X-Axis (ch 1)

Y-Axis

(ch 2)

High

limit

Low

limit

The Fast3 function samples the channel 2 input each time the channel

1 input changes a specified sample increment. If the sampled value of

channel 2 falls outside a specified range, all base-channel (first 1, 4 or

8 channels) input values will be stored in a dedicated memory array,

otherwise samples will not be stored.

This sampling process continues until:

The user aborts the process by pressing the QUIT or the CANCEL

key

The user clears memory and restarts the process by pressing the

ENTER key

The user successfully completes the process by pressing the

FINISH key

The process is automatically completed after 50,000 sets of channel

positions have been stored

For the duration of the Fast3 function process, the

ND 2100G adopts an X-Y axis paradigm. Channel 1 is

referred to as the X-axis, and channel 2 as the Y-axis.

In the example shown, the channel 2 (Y-axis) input values exceed the

user-specified limits five times, but channel input values are stored

only twice when the channel 2 value exceeds the limits at a sample

point between intervals.

1.4 LCD screens and menus

ND 2100G GAGE-CHEK 39

Page 40

When the Fast3 function is successfully completed, the stored sets of

channel input values are processed by the ND 2100G dimension

formulas in the order that they were collected. The formula results are

then stored in the ND 2100G database. During the processing of

formulas, a percentage of completion will be displayed. Since up to

50,000 sets of channel input values can be collected and processed by

formulas, considerable time could be required to complete the

processing.

Since the values processed by formulas after Fast3 data

collection are contained in memory storage, no user

interaction is possible. For this reason functions that

require user interaction such as the Ask function must be

avoided in formulas when the Fast3 Extra menu function

is used.

If any key is pressed while the ND 2100G is processing

formulas, the remaining channel input values will be

deleted from memory and formula processing will be

1.4 LCD screens and menus

aborted.

To access the Fast3 function:

U Press the MENU... soft key

U Press the EXTRA soft key

U Use the arrow cursor keys to highlight Fast3

U Press the ENTER key

You will then be prompted to:

U Enter a Y axis (channel 2) upper limit

U Enter a Y axis (channel 2) lower limit

U Enter an X axis (channel 1) capture increment

U Enter an X axis (channel 1) resolution factor (this is a multiplier of

scale resolution)

Once these parameters are entered, the Fast3 function will begin to

read the input values for channels 1 and 2.

FAST3 highlighted.

Setup menu functions

ND 2100G operating parameters and formulas that define dimension

values are entered into the system from Setup menu screens.

Setup menu functions and formulas and are discussed in

Chapter 2: Installation, Setup and Specifications

40 1 Operation

Page 41

1.5 Operating instructions

Basic operation of the ND 2100G is illustrated by the typical process

steps below.

Select Part Establish a

Measurement

Reference

Specify part

number

Measurement steps and the resulting data collected depend entirely

on setup parameters and dimension formulas defined to satisfy a

specific application.

Examples used in this chapter use encoder probes to

emphasize concepts. However, the concepts apply

equally well to all types of input devices.

Absolute datum

(D0)

• Hard stop zero

• Set datum

• Calibrate datum

and range

Incremental datum

(D1)

• Zero datum

• Preset datum

Conduct a

Measurement

Manual:

• Probe & Enter

Sequence:

• Series of probes

& Enters

Dynamic:

• Probe samples &

Enter

Semi-automated:

• Probe &

automatic Enter

Review

Measurement

Data

SPC Subgroup = 1

• Dimension graphs

Histograms

• Dimension data

tables

• SPC data

SPC Subgroups > 1

• x

graphs

• r graphs

• Dimension data

tables

• SPC data

Report or Send

Results

Print reports

Send data to

computer

1.5 Operating instructions

ND 2100G GAGE-CHEK 41

Page 42

Select a part to begin a measurement

The correct part (number) must be selected prior to conducting

measurements.

Select Part Establish a

Measurement

Conduct a

Measurement

Reference

One hundred part configurations can be stored in the ND 2100G. Each

part configuration includes all the ND 2100G settings and dimension

formulas required to conduct measurements and report results for the

part.

To select a part:

U Press the MENU... soft key

U Press the EXTRA soft key

1.5 Operating instructions

U Use the arrow cursor keys to highlight Cycle or Part?

U Press the ENTER key. If Part? was highlighted, you will be prompted

for a part number.

U Use the numeric keypad to specify the part

U Press the ENTER key

If Cycle was highlighted, the part number will be incremented.

Continue incrementing to select the desired part number.

Review

Measurement

Data

Cycle highlighted.

Report or Send

Results

Part? highlighted.

42 1 Operation

Page 43

Establish a reference for the measurement

A measurement reference should be established prior to conducting

measurements. Measurement references can be established by

calibrating channels or presetting dimensions.

Select Part

An input calibration is applied to any parts that use that

channel in a formula. For example, a channel calibration

performed for channel 1 and part number 0 will also apply

to any other parts using channel 1.

Calibrating channels using the Master function

Channel calibrations are performed using the Master function. A

single-point calibration defines the reference value of the absolute

datum (D0) of an input channel. A full calibration defines the reference

value of the absolute datum, and the resolution of the channel input.

Since encoders have fixed resolutions based on etched scales or

some other permanent device characteristic, typically only a single

point is calibrated to define a reference position. Transducers such as

LVDT and Half-bridge devices do not have fixed resolutions. The use

of these devices requires calibrating both ends of the transducer’s

measurement range to derive resolution. Once a full calibration has

been performed, single-point calibrations can be performed as

required to define new measurement reference positions.

Establish a

Measurement

Reference

Conduct a

Measurement

Review

Measurement

Data

Report or Send

Results

1.5 Operating instructions

ND 2100G GAGE-CHEK 43

Page 44

Calibration of a single reference point

A single measurement reference point can be calibrated for encoders

and fully-calibrated transducers.

The Master type should be set to Mean in the Master

setup screen to perform a calibration of a single encoder

point. Refer to "Master setup screen" on page 111.

To calibrate a single reference point

U Press the MASTER soft key

U Use the arrow cursor keys to select the desired channel

U Position the probe against the reference surface

U Use the numeric keypad to enter the reference value (zero or the

desired offset) into the Master Value data field

U Press the ENTER key

U Press the YES soft key to calibrate the measurement reference

1.5 Operating instructions

A green dot will appear next to the actual value indicating that the

reference point is calibrated.

Channel 1 selected. Reference value of 0.

Press the YES soft key.

Channel 1 calibrated.

44 1 Operation

Page 45

Calibration groups (G1, G2, G3...G18)

All calibration values shown on the screen are simultaneously applied

when the ENTER key is pressed. While this is acceptable in most

cases, some applications require entering a series of calibrations at

different times. The example shown here illustrates this difference.

When measuring runout at two points on a

rod, both channels are measuring a

common surface and can be calibrated

simultaneously. In this example, both

channels are calibrated to zero on the rod

surface in calibration group 1 (G1).

Completed calibrations are indicated by

filled circles at the right of the actual channel

values.

When measuring the low and high lifts of

two offset cams, simultaneous calibration

on the offset surfaces is not possible. First

one channel must be calibrated to zero on

the low surface of one cam, then after

turning the cam shaft 90 degrees, the

second channel must be calibrated to zero

on the low surface of the second cam.

The first calibration is performed in

calibration group 1 (G1), then the camshaft

is turned 90 degrees, and the second

calibration is performed in calibration group

2 (G2). By performing the calibrations in

different groups, the calibrations are made

independent. Completed calibrations are

indicated by filled circles at the right of the

actual channel values.

Calibrating two points on a rod.

1.5 Operating instructions

Calibrating offset surfaces Master G1.

Calibrating offset surfaces Master G2.

ND 2100G GAGE-CHEK 45

Page 46

Calibrations of transducer resolution (Min-Max calibrations)

Transducers such as LVDT and half bridge devices do not have fixed

resolutions based on etched scales or other permanent device

characteristics. The use of these devices requires calibrating both

ends of the transducer range of measurement to derive transducer

resolution. Full transducer calibrations are performed periodically on a

schedule determined by your application using the Master function.

Full calibrations are performed only after performing the transducer

gain and null setup steps described in Chapter 2: Installation, Setup

and Specifications.

The Master type should be set to Min-Max in the Master

setup screen to perform a full transducer calibration. Refer

to "Master setup screen" on page 111.

To perform a full transducer calibration:

1.5 Operating instructions

Calibrate minimum level:

U Press the MASTER soft key

U Press the MIN soft key to display the Master Min screen

U Use the arrow cursor keys to select the desired channel

U Press the G1, G2...G18 soft key to select a group to store the

calibration data in. Refer to "Calibration groups (G1, G2, G3...G18)"

on page 45.

U Position the channel’s probe against the measurement Min

reference surface

U Use the numeric keypad to enter the Min reference value into the

Master Value data field for the channel

U Press the ENTER key

U Press the YES soft key to set the Min value or offset the absolute

datum (D0) for the channel. This calibrates the low end of the

channel measurement range.

The completed minimum level calibration will be indicated by a filled

green circle in the Mn column at the right of the Actual channel value.

Completed minimum level calibration.

46 1 Operation

Page 47

Calibrate maximum level:

U Press the MAX soft key

U Use the arrow cursor keys to select the same channel as in step 1

if necessary

U Position the channel probe against the measurement Max reference

surface for the maximum end of the channel calibration range

U Use the numeric keypad to enter the Max value into the Master

Value data field for the channel

U Press the ENTER key

U Press the YES soft key to calibrate the maximum value for the

channel input

The completed maximum level calibration will be indicated by a filled

green circle in the Mx column at the right of the Actual channel value.

Completed maximum level calibration.

1.5 Operating instructions

ND 2100G GAGE-CHEK 47

Page 48

Establishing a temporary dimension reference

Establishing a temporary dimension reference is useful when quick

point to point measurements are desired. The temporary reference is

only applied to the associated dimension, and only to the current part.

For example, a temporary reference established for dimension A and

part number 0 will not apply to any dimensions or to any other parts

that might include their own dimension A.

Temporary dimension references can be established for encoders and

transducers. Since only one point is used as a reference, transducer

resolution remains unchanged.

Dimension references can be zeroed or preset to specific values.

Zeroing a dimension reference

Dimensions can be zeroed at any time using the Datum/Zero function.

The zero reference is temporary in the sense that it uses the

incremental datum D1, and has no effect on the absolute datum D0.

1.5 Operating instructions

To zero a dimension:

U Press the MENU... soft key

U Press the DATUM soft key

U Press the ZERO... soft key. The soft keys across the bottom of the

screen will be labeled to support zeroing specific or all dimensions.

U Use the left and right arrow cursor keys to scroll through dimensions

when there are more dimensions defined than ND 2100G soft keys

U Press the desired ZERO key to zero the corresponding dimension

Dimension A prior to zeroing.

Dimension A zeroed.

48 1 Operation

Page 49

Presetting a dimension reference to a specific value

Dimensions can be preset to a user-specified value using the Datum/

Preset function. The reference is temporary in the sense that it uses

the incremental datum D1, and has no effect on the absolute datum

D0.

To preset a dimension reference:

U Press the MENU... soft key

U Press the DATUM soft key

U Press the PRESET soft key. The Select dimensions screen will be

displayed.

U Press the dimension key associated with the dimension you wish to

preset. A text line will be displayed

U Use the numeric keypad to enter the reference value (preset) of the

new reference

U If desired, press the W/NOM soft key to change the nominal value

in the Tolerance setup screen to the new preset reference value

U Press the ENTER key to preset the dimension measurement

reference

Dimension preset text line.

1.5 Operating instructions

Enter the reference value.

Dimension A preset.

ND 2100G GAGE-CHEK 49

Page 50

Clearing channel calibrations

The reference calibrations and full calibrations of all channels can be

cleared using the LCD ON/OFF key.

To clear calibrations:

U Press the LCD ON/OFF key

U Press the CLR CAL soft key

U Press the YES soft key to clear channel mastered values and full

calibrations

Channel mastered values and full calibrations will be cleared, indicated

by the empty circles at the right of the screen. The values will be

retained in the Master values fields, and can be reactivated at any time

by pressing the ENTER key.

1.5 Operating instructions

Press the YES soft key to confirm clearing channel

calibrations.

Empty circles indicate channel mastered values and

full calibrations are cleared.

Clearing dimension references (presets)

Dimension references can be cleared at any time using the Datum/

Clear function.

To clear dimension references:

U Press the MENU... soft key

U Press the DATUM soft key

U Press the CLEAR soft key

U Press the YES soft key to clear dimension preset references. When

a preset reference is cleared, D0 becomes the new reference.

Press the YES soft key to confirm clearing dimension

references.

50 1 Operation

Page 51

Conducting measurements

Once a part number is selected and a reference is established,

measurements can be conducted.

Select Part Establish a

Measurement

Reference

Measurements can:

Be conducted manually, completely under the control of the

operator

Follow a predetermined sequence of steps shown on the screen

Be based on dynamic samples of changing input data

Be semi-automated to increase the throughput of repetitive

measurements

Typically a setup person will configure the ND 2100G for operation in

the Setup screens and then will construct formulas defining

dimensions in the Formula screens described in Chapter 2:

Installation, Setup and Specifications.

Once the ND 2100G is configured and dimension formulas are

constructed, measurement instructions are usually given to the

operator that reflect the specific measurement requirements and gage

equipment setup. Instructions provided in this guide are generic and

meant to be used as guidelines when applying the ND 2100G to

specific measuring applications.

Manual measurements

Manual measurements are performed completely under the control of

an operator. Measurement results can be displayed as current values,

in graphs or in data tables using the screens described earlier in this

chapter. Please refer to the descriptions of Views on page 28.

Measurements can also be printed or transmitted to a computer. The

data printed or transmitted are specified and formatted in the setup

screens described in Chapter 2: Installation, Setup and Specifications.

To conduct manual measurements:

U Probe a single point with one channel, or multiple points

simultaneously with multiple channels

U When the measurement data are displayed on the LCD, press the

ENTER key to store the data

Conduct a

Measurement

Review

Measurement

Data

Report or Send

Results

1.5 Operating instructions

ND 2100G GAGE-CHEK 51

Page 52

Sequential measurements

The ND 2100G can be configured in the Formula setup screen to direct

the user through a sequence of predetermined measurement steps.

Typically a setup person will provide instructions describing how to

conduct the measurements. However, the ND 2100G operation is

fundamentally the same for all sequential measurements.

Measurement results can be displayed as current values, in graphs or

in data tables using the screens described earlier in this chapter.

Please refer to the descriptions of Views on page 28.

Measurements results can also be printed or transmitted to a

computer. The data printed or transmitted are specified and formatted

in the setup screens described in Chapter 2: Installation, Setup and

Specifications.

To perform a sequential measurement:

U Probe the dimension underlined on the DRO screen

U Press the ENTER key to store the data. The underline will advance

1.5 Operating instructions

to highlight the next dimension in the measurement sequence.

U Continue probing the underlined dimensions and pressing the

ENTER key, following the sequence of underlined steps on the LCD

When measurements specified for the part are complete, the

ND 2100G will return to underline the first dimension in the series to

indicate the beginning of a new sequence.

Press the ENTER key to store data and advance to

next dimension.

52 1 Operation

Page 53

Dynamically sampled measurements

The ND 2100G can be configured in the Formula setup screen to

sample input channels and retain the minimum and maximum values

of all samples for each channel. Typically a setup person specifies

dynamic measurements to evaluate rotational or curved surfaces and

will provide instructions describing how to conduct the

measurements. The ND 2100G operation is essentially the same for

all dynamic measurements.

Measurement results can be displayed as current values, in graphs or

in data tables using the screens described earlier in this chapter.

Please refer to the descriptions of Views on page 28.

Measurement results can also be printed or transmitted to a

computer. The data printed or transmitted is specified and formatted

in the setup screens described in Chapter 2: Installation, Setup and

Specifications.

In the example shown here, the runout of a shaft is measured. The

minimum and maximum values are sampled as the shaft is turned.

To perform a dynamic measurement:

U Perform a dynamic reset by pressing the LEFT WIDE key (factory

default), or by highlighting RsetDyn in the Extra menu

U Press the ENTER key to clear old dynamic measurement data prior

to a new measurement

U Position the probe(s) against the surface to be measured

U Rotate or move the surface slowly while observing the resulting

dimension value(s)

1.5 Operating instructions

Measuring the runout of a shaft.

The sampling rate for LVDT, HBT (Half-bridge) and serial

transducers will be slower than for encoders. If your

system includes these input devices, the part must be

rotated or moved slowly to ensure that all points on the

surface are sampled.

U Repeat the rotation or movement until the dimension values that

reflect minimum or maximum values no longer change

U Press the ENTER key to store the measurement data

ND 2100G GAGE-CHEK 53

Page 54

Semi-automated measurements

Normally, measurements shown on the DRO screen are not stored in

the ND 2100G database until the user presses the ENTER key.

However, the ND 2100G can be configured in the Formula setup

screen to perform and store measurements automatically when the

gage is loaded with a new part.

Measurement results can also be printed or transmitted to a

computer. The data printed or transmitted is specified and formatted

in the setup screens described in Chapter 2: Installation, Setup and

Specifications.

In the example shown here, the flatness of a sheet is measured. The

measurement is performed and entered into the database a short time

after the gage is lowered to position the probes against the surface of

the sheet. The channels are reset for a new measurement when the

probes are lifted away from the sheet.

Typically, a setup person specifies semi-automated measurements to

increase the throughput of repetitive measurements, and will provide

1.5 Operating instructions

instructions describing how to conduct the measurements, and load

and unload the gage.

Measurement results can be displayed as current values, in graphs or

in data tables using the screens described earlier in this chapter.

Please refer to the descriptions of Views on page 28.

The instructions for performing semi-automated measurements

depend entirely on the measurement application and equipment

setup, and must be provided by the setup person. Refer to "Trip

function and measurement automation" on page 212 for more details

regarding semi-automated measurements.

Load part: Channels ready

Gage closed: Channels measure

Unload part: Channels reset

54 1 Operation

Page 55

Reviewing measurements

Measurement results can be reviewed in graphs or in data tables using

the screens described earlier in this chapter. Please refer to the

descriptions of Views on page 28.

Select Part Establish a

Measurement

Reference

Conduct a

Measurement

Printing reports or sending results to a computer

Measurement data can be printed or transmitted to a computer. The

report and data transmission formats are prepared in the Header,

Report, Send, Parallel and RS-232 setup screens described in Chapter

2: Installation, Setup and Specifications.

Select Part Establish a

Measurement

Reference

Printing reports

Reports of current dimension values, stored measurement results or

ND 2100G setup parameters can be printed by displaying the desired

screen and pressing the PRINT key. In some cases, the user will be

prompted to provide additional information.

Conduct a

Measurement

Review

Measurement

Data

Review

Measurement

Data

Report or Send

Results

Report or Send

Results

1.5 Operating instructions

ND 2100G GAGE-CHEK 55

Page 56

Sending data to a computer

Current dimension values, or a collection of stored dimension

measurement results can be transmitted to a computer using the

Send and SendRec functions in the Extra menu. Refer to "The Extra

menu functions" on page 38 for more details regarding the Extra

menu.

To send current dimension values:

U Press the MENU... soft key

U Press the EXTRA soft key

U Use the arrow cursor keys to highlight Send

U Press the ENTER key to send the current dimension values to a

computer

To send stored measurement results:

U Press the MENU... soft key

U Press the EXTRA soft key

U Use the arrow cursor keys to highlight SendRec

1.5 Operating instructions

U Press the ENTER key to send a file of stored measurement results

Use Send to send current values.

Use SendRec to send stored measurement values.

56 1 Operation

Page 57

Data reports

Report type Screen User actions

Current dimensions (Numeric display) DRO

U Press PRINT key

Graphs of dimension values

Graph...

(SPC subgroups = 1)

Histograms of dimension values

Histo... U Press PRINT key

(SPC subgroups = 1)

chart of subgroup mean values

x

x chart U Press PRINT key

(SPC subgroups> 1)

r chart of subgroup range values

r chart U Press PRINT key

(SPC subgroups>1)

Current dimension values (Bar display) Bar...

Current dimension values (Dial display) Dial...

Data table multiple-dimensions Data...

Data table single-dimensions Data...

U Press PRINT key

U Press PRINT key

U Press PRINT key

U Press PRINT key

U Respond to prompt

U Press DIMENSION soft key

U Press PRINT key

U Respond to prompt

1.5 Operating instructions

ND 2100G GAGE-CHEK 57

Page 58

Clearing stored measurement data

Stored measurement data can be cleared for a single part, or for all

parts by pressing the LCD ON/OFF key.

Erased data cannot be restored.

To clear stored data for a single part:

U Select the desired part

U Press the LCD ON/OFF key

U Press the CLR PRT soft key

Stored data for the selected part will be erased.

To clear stored data for all parts:

U Select the desired part

1.5 Operating instructions

U Press the LCD ON/OFF key

U Press the CLR ALL soft key

Stored data for all parts will be erased.

58 1 Operation

Page 59

Installation, Setup, Formulas and Specifications

Page 60

2.1 ND 2100G Shipment Contents

The contents of your ND 2100G shipment are described below.

Repackaging instructions are also included for return shipments for

distributors and OEM customers that are configuring an ND 2100G

and shipping it to an end-user.

Save the ND 2100G packaging materials for possible

return shipment or shipment to an end user.

Items included with the ND 2100G

The following items are shipped with the ND 2100G:

ND 2100G instrument

Mounting stand hardware

Power cord

ND 2100G Quick Reference Guide

Warranty registration card

2.1 ND 2100G Shipment Contents

Optional items possibly included

The following items might be shipped with your ND 2100G, depending

on the options and accessories ordered at the time of purchase:

Remote foot switch

Remote keypad

ND 2100G Protective cover

QUADRA-CHEK Wedge communication software

If any components were damaged in shipment, save the

packaging materials for inspection and contact your

shipping agent for mediation. Contact your HEIDENHAIN

distributor or OEM for replacement parts.

60 2 Installation and Specifications

Page 61

Repackaging the ND 2100G

When shipping the ND 2100G on to an end-user, repackage all

ND 2100G components in the original packaging as received from the

factory.

The original packaging must be duplicated and the LCD

must be inserted face-up to prevent damage to the

screen.

It is not necessary to ship the mounting stand and

hardware with the instrument when returning the

ND 2100G for service.

Connect the mounting screws and washer to the ND 2100G

instrument

Replace the contents of the cardboard box insert if shipping the

ND 2100G on to an end-user. The cardboard box can be empty if

returning the ND 2100G to the factory for service.

Repackage the instrument, foam and cardboard box insert as

originally shipped from the factory. The instrument should be

oriented face-up in the carton.

Replace the warranty card and slip sheets originally found at the top

of the carton when shipping on to an end-user. The “Before you

begin” slip sheet should be inserted last.

2.1 ND 2100G Shipment Contents

ND 2100G GAGE-CHEK 61

Page 62

2.2 Hardware Installation

5

4

3

2

1

The ND 2100G is easy to install in a variety of measurement

applications. This section describes how to install the ND 2100G

hardware.

Assembling the mounting stand

The ND 2100G is secured to the swivel slots of the mounting stand by

a shoulder screw, a cap screw and associated washers.

To assemble the ND 2100G to the mounting stand as shown, and then

tighten the cap screw (5) and washers (3 & 4) so that the ND 2100G

will be secure when adjusted to the desired tilt position.

U Tighten the shoulder screw (1)

U Tighten the cap screw (5) and washers (3 & 4) so that the ND 2100G

will be secure when adjusted to the desired tilt position

2.2 Hardware Installation

U Adjust the ND 2100G to the desired tilt position

Benchtop location and mounting

Rest the ND 2100G on a flat, stable surface, or bolt it to a stable

surface from the bottom using four 10/32 screws fastened in the

pattern shown at the right.

The dimensions are shown in millimeters.

Mounting stand assembly.

Mounting hole pattern.

62 2 Installation and Specifications

Page 63

Arm mounting (optional)

Secure the arm mount adapter to the ND 2100G and bolt the adapter

and ND 2100G to the arm as shown at the right.

2.2 Hardware Installation

Optional arm mounting.

ND 2100G GAGE-CHEK 63

Page 64

Connecting power

1

2

1

3

Connect the ND 2100G to power through a high-quality power surge

suppressor. Surge suppressors limit the amplitude of potentially

damaging power line transients caused by electrical machinery or

lightning, and protect the ND 2100G from most power line transients

that can corrupt system memory or damage circuits.

Do not locate the power cord where it can be walked on or will create

a tripping hazard. Connect the 3-wire power plug to only a 3-wire

grounded power outlet.

Never connect 2-wire to 3-wire adapters to the power cord

or remove the third ground wire to fit the plug into a 2-wire

electrical outlet. Modifying or overriding the third-wire

ground creates a safety hazard and should not be

permitted.

2.2 Hardware Installation

The power connector assembly includes:

1 Power switch

2 Fuse compartment

3 Power cord connector

Always disconnect the power cord from the source of AC

power before unplugging it from the ND 2100G power

connector. The AC voltage available at electrical outlets is

extremely dangerous and can cause serious injury or

death.

Power switch, fuse and connector.

64 2 Installation and Specifications

Page 65

Connecting channel inputs

1

Channel input devices are attached to standard interface connectors

or to the RS-232 port on the rear of the ND 2100G. Many device

interfaces are available to match the wide variety of encoder and

transducer devices that can be used with the ND 2100G. The number

and type of channel input connectors will vary depending on the

application. Four standard interface connectors are shown here as

examples.

1 Channel input connections

Connect the channel input devices tightly to their connectors. A

channel number is provided near each connector.

Channel input devices must be configured using the Channels setup

screen. Refer to "Channels setup screen" on page 99

Systems can be configured at the factory to support a combination of

single-channel and multi-channel RS-232 networked input devices.

These configurations can include one of the following:

1, 4 or 8 single-input channels

Up to 16 networked RS-232 input channels

A combination of single-input channels and networked RS-232 input