heidenhain iTNC 530 User Manual

User’s Manual

Touch Probe Cycles

iTNC 530

NC Software

340 422-xx

340 423-xx

340 480-xx

340 481-xx

English (en)

7/2005

TNC Model, Software and Features

This manual describes functions and features provided by TNCs as of

the following NC software numbers.

TNC model NC software number

iTNC 530 340 422-11

iTNC 530 E 340 423-11

iTNC 530 340 480-11

iTNC 530 E 340 481-11

iTNC 530 programming station 374 150-11

The suffix E indicates the export version of the TNC. The export

version of the TNC has the following limitations:

Linear movement is possible in no more than 4 axes simultaneously.

The machine tool builder adapts the useable features of the TNC to his

machine by setting machine parameters. Some of the functions

described in this manual may not be among the features provided by

your machine tool.

TNC functions that may not be available on your machine include:

Tool measurement with the TT

Please contact your machine tool builder to become familiar with the

features of your machine.

Many machine manufacturers, as well as HEIDENHAIN, offer

programming courses for the TNCs. We recommend these courses as

an effective way of improving your programming skill and sharing

information and ideas with other TNC users.

User’s Manual:

All TNC functions that have no connection with touch

probes are described in the User's Manual of the

iTNC 530. Please contact HEIDENHAIN if you need a copy

of this User’s Manual.

Location of use

The TNC complies with the limits for a Class A device in accordance

with the specifications in EN 55022, and is intended for use primarily

in industrially-zoned areas.

HEIDENHAIN iTNC 530 3

Functions new since the predecessor versions 340 420-xx and 340 421-xx

Saving the active basic rotation in the preset table (see “Saving the

basic rotation in the preset table” on page 31).

Writing measured values in a preset table (see “Writing the

measured values from touch probe cycles in the preset table” on

page 25).

New Cycle 419 for setting an individual datum in any axis (see

“DATUM IN ONE AXIS (touch probe cycle 419, ISO: G419)” on page

87).

Cycle 3 was expanded to allow the user to enter a retraction path MB

and select the coordinates in which the measurement results are to

be saved (see “MEASURING (touch probe cycle 3)” on page 131).

Cycle 403 optionally sets a rotary axis in the preset table or active

datum table to 0. In addition, an angle can be entered for alignment

(see “BASIC ROTATION compensation via rotary axis (touch probe

cycle 403, ISO: G403)” on page 50).

Cycle 9 automatically calibrates for length (see “CALIBRATE TS

LENGTH (touch probe cycle 9)” on page 130).

The datum setting cycles 410, 411, 412, 413, 414, 415, 416 and 418

have been expanded to allow the datum to be optionally set in the

touch probe axis (see “DATUM FROM INSIDE OF RECTANGLE

(touch probe cycle 410, ISO: G410)” on page 61).

New manual touch probe functions: Datum setting in center line

(see “Center line as datum” on page 35).

Touch probe functions for the TNC can also be used in combination

with mechanical probes or dial gauges (see “Using the Touch Probe

Functions with Mechanical Probes or Dial Gauges” on page 40).

4

Functions changed since the predecessor versions 340 420-xx and 340 421-xx

New input parameter for saving the determined datum in cycles for

automatic datum setting (see “Save calculated datum” on page 60).

Before programming, note the following:

The function for the preset table was introduced with the

release of the NC software versions 340 422-01 and

340 423-01, as well as 340 480-01 and 340 481-01. Please

pay attention to the resulting changes in connection with

the touch probe cycles for datum setting.

Writing measured values in a datum table (see “Writing the

measured values from touch probe cycles in datum tables” on page

24).

Cycle 403 expanded by the possibility to zero the rotary axis after

alignment (see “BASIC ROTATION compensation via rotary axis

(touch probe cycle 403, ISO: G403)” on page 50).

Cycles 400, 401 and 402 expanded by the possibility to write the

determined basic rotation in the preset table (see “BASIC

ROTATION (touch probe cycle 400, ISO: G400)” on page 43), (see

“BASIC ROTATION from two holes (touch probe cycle 401, ISO:

G401)” on page 45) and (see “BASIC ROTATION over two studs

(touch probe cycle 402, ISO: G402)” on page 47).

Datum setting with manual probing cycles has been changed. The

datum must now be set by soft key instead of by the ENT key (see

“To set the datum in any axis (see figure at right)” on page 32).

HEIDENHAIN iTNC 530 5

New/changed descriptions in this manual

A description of required input data for automatic tool calibration has

been included in the tool table (see “Entries in the tool table

TOOL.T” on page 138).

6

Contents

Introduction

Touch Probe Cycles in the Manual and

Electronic Handwheel Modes

Touch Probe Cycles for Automatic

Workpiece Inspection

Touch Probe Cycles for Automatic Tool

Measurement

1

2

3

4

HEIDENHAIN iTNC 530 7

1 Introduction ..... 13

1.1 General Information on Touch Probe Cycles ..... 14

Function ..... 14

Touch probe cycles in the Manual and Electronic Handwheel modes ..... 15

Touch probe cycles for automatic operation ..... 15

1.2 Before You Start Working with Touch Probe Cycles! ..... 17

Maximum traverse to touch point: MP6130 ..... 17

Safety clearance to touch point: MP6140 ..... 17

Orient the infrared touch probe to the programmed probe direction: MP6165 ..... 17

Multiple measurement: MP6170 ..... 17

Confidence interval for multiple measurement: MP6171 ..... 17

Touch trigger probe, probing feed rate: MP6120 ..... 18

Touch trigger probe, rapid traverse for pre-positioning: MP6150 ..... 18

Running touch probe cycles ..... 19

Contents

HEIDENHAIN iTNC 530 9

2 Touch Probe Cycles in the Manual and Electronic Handwheel Modes ..... 21

2.1 Introduction ..... 22

Overview ..... 22

Selecting probe cycles ..... 22

Contents

Recording measured values from the touch probe cycles ..... 23

Writing the measured values from touch probe cycles in datum tables ..... 24

Writing the measured values from touch probe cycles in the preset table ..... 25

2.2 Calibrating a Touch Trigger Probe ..... 26

Introduction ..... 26

Calibrating the effective length ..... 26

Calibrating the effective radius and compensating center misalignment ..... 27

Displaying calibration values ..... 28

Managing more than one block of calibrating data ..... 29

2.3 Compensating Workpiece Misalignment ..... 30

Introduction ..... 30

Measuring the basic rotation ..... 30

Saving the basic rotation in the preset table ..... 31

Displaying a basic rotation ..... 31

Cancel a basic rotation ..... 31

2.4 Setting the Datum with a 3-D Touch Probe ..... 32

Introduction ..... 32

To set the datum in any axis (see figure at right) ..... 32

Corner as datum—using points that were already probed for a basic rotation (see figure at right) ..... 33

Corner as datum—without using points that were already probed for a basic rotation ..... 33

Circle center as datum ..... 34

Center line as datum ..... 35

Setting datum points using holes/cylindrical studs ..... 36

2.5 Measuring Workpieces with a 3-D Touch Probe ..... 37

Introduction ..... 37

To find the coordinate of a position on an aligned workpiece: ..... 37

Finding the coordinates of a corner in the working plane ..... 37

Measuring workpiece dimensions ..... 38

To find the angle between the angle reference axis and a side of the workpiece ..... 39

2.6 Using the Touch Probe Functions with Mechanical Probes or Dial Gauges ..... 40

Introduction ..... 40

10 Contents

3 Touch Probe Cycles for Automatic Workpiece Inspection ..... 41

3.1 Measuring Workpiece Misalignment ..... 42

Overview ..... 42

Characteristics common to all touch probe cycles for measuring workpiece misalignment ..... 42

BASIC ROTATION (touch probe cycle 400,

ISO: G400) ..... 43

BASIC ROTATION from two holes (touch probe cycle 401, ISO: G401) ..... 45

BASIC ROTATION over two studs (touch probe cycle 402, ISO: G402) ..... 47

BASIC ROTATION compensation via rotary axis (touch probe cycle 403, ISO: G403) ..... 50

BASIC ROTATION (touch probe cycle 404, ISO: G404) ..... 53

Compensating workpiece misalignment by rotating the C axis (touch probe cycle 405, ISO: G405) ..... 54

3.2 Automatic Datum Determination ..... 58

Overview ..... 58

Characteristics common to all touch probe cycles for datum setting ..... 59

DATUM FROM INSIDE OF RECTANGLE (touch probe cycle 410, ISO: G410) ..... 61

DATUM FROM OUTSIDE OF RECTANGLE (touch probe cycle 411, ISO: G411) ..... 64

DATUM FROM INSIDE OF CIRCLE (touch probe cycle 412, ISO: G412) ..... 67

DATUM FROM OUTSIDE OF CIRCLE (touch probe cycle 413, ISO: G413) ..... 70

DATUM FROM OUTSIDE OF CORNER (touch probe cycle 414, ISO: G414) ..... 73

DATUM FROM INSIDE OF CORNER (touch probe cycle 415, ISO: G415) ..... 76

DATUM CIRCLE CENTER (touch probe cycle 416, ISO: G416) ..... 79

DATUM IN TOUCH PROBE AXIS (touch probe cycle 417, ISO: G417) ..... 82

DATUM AT CENTER BETWEEN 4 HOLES (touch probe cycle 418, ISO: G418) ..... 84

DATUM IN ONE AXIS (touch probe cycle 419, ISO: G419) ..... 87

Contents

HEIDENHAIN iTNC 530 11

Contents

3.3 Automatic Workpiece Measurement ..... 93

Overview ..... 93

Recording the results of measurement ..... 94

Measurement results in Q parameters ..... 95

Classification of results ..... 95

Tolerance monitoring ..... 95

Tool monitoring ..... 96

Reference system for measurement results ..... 96

REFERENCE PLANE (touch probe cycle 0, ISO: G55) ..... 97

DATUM PLANE (touch probe cycle 1) ..... 98

MEASURE ANGLE (touch probe cycle 420, ISO: G420) ..... 99

MEASURE HOLE (touch probe cycle 421, ISO: G421) ..... 101

MEASURE CIRCLE OUTSIDE (touch probe cycle 422, ISO: G422) ..... 104

MEASURE RECTANGLE FROM INSIDE (touch probe cycle 423, ISO: G423) ..... 107

MEASURE RECTANGLE FROM OUTSIDE (touch probe cycle 424, ISO: G424) ..... 110

MEASURE INSIDE WIDTH (touch probe cycle 425, ISO: G425) ..... 113

MEASURE RIDGE WIDTH (touch probe cycle 426, ISO: G426) ..... 115

MEASURE COORDINATE (touch probe cycle 427, ISO: G427) ..... 117

MEASURE BOLT HOLE CIRCLE (touch probe cycle 430, ISO: G430) ..... 119

MEASURE PLANE (touch probe cycle 431, ISO: G431) ..... 122

3.4 Special Cycles ..... 128

Overview ..... 128

CALIBRATE TS (touch probe cycle 2) ..... 129

CALIBRATE TS LENGTH (touch probe cycle 9) ..... 130

MEASURING (touch probe cycle 3) ..... 131

MEASURE AXIS OFFSET (touch probe cycle 440, ISO: G440) ..... 132

4 Touch Probe Cycles for Automatic Tool Measurement ..... 135

4.1 Tool Measurement with the TT Tool Touch Probe ..... 136

Overview ..... 136

Setting the machine parameters ..... 136

Entries in the tool table TOOL.T ..... 138

Display the results of measurement ..... 139

4.2 Available Cycles ..... 140

Overview ..... 140

Differences between Cycles 31 to 33 and Cycles 481 to 483 ..... 140

Calibrating the TT (touch probe cycle 30 or 480, ISO: G480) ..... 141

Measuring the tool length (touch probe cycle 31 or 481, ISO: G481) ..... 142

Measuring the tool radius (touch probe cycle 32 or 482, ISO: G482) ..... 144

Measuring the tool radius (touch probe cycle 33 or 483, ISO: G483) ..... 146

12 Contents

Introduction

1.1 General Information on Touch

Probe Cycles

The TNC must be specially prepared by the machine tool

builder for the use of a 3-D touch probe.

If you are carrying out measurements during program run,

be sure that the tool data (length, radius) can be used from

the calibrated data or from the last TOOL CALL block

(selected with MP7411).

Function

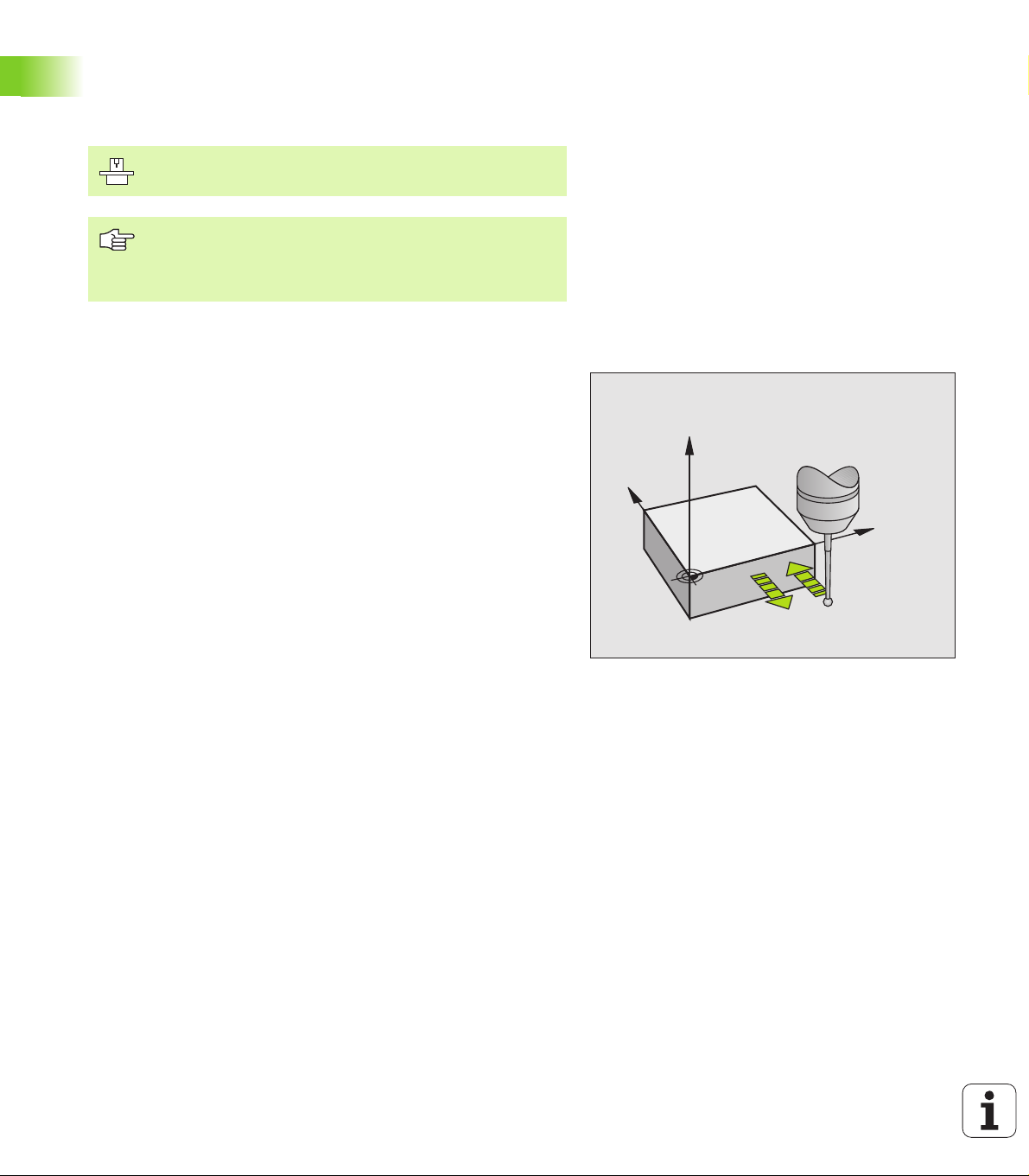

Whenever the TNC runs a touch probe cycle, the 3-D touch probe

approaches the workpiece in one linear axis. This is also true during an

active basic rotation or with a tilted working plane. The machine tool

builder determines the probing feed rate in a machine parameter (see

“Before You Start Working with Touch Probe Cycles” later in this

chapter).

When the probe stylus contacts the workpiece,

the 3-D touch probe transmits a signal to the TNC: the coordinates

of the probed position are stored,

the touch probe stops moving, and

returns to its starting position at rapid traverse.

If the stylus is not deflected within a distance defined in MP 6130, the

TNC displays an error message.

Z

Y

F

F MAX

X

1.1 General Information on Touch Probe Cycles

14 1 Introduction

Touch probe cycles in the Manual and Electronic Handwheel modes

In the Manual and Electronic Handwheel operating modes, the TNC

provides touch probe cycles that allow you to:

Calibrate the touch probe

Compensate workpiece misalignment

Datum setting

Touch probe cycles for automatic operation

Besides the touch probe cycles, which you can use in the Manual and

Electronic handwheel operating modes, several cycles are available

for a wide variety of applications in automatic operation:

Calibrating the touch probe (Chapter 3)

Compensating workpiece misalignment (Chapter 3)

Setting datums (Chapter 3)

Automatic workpiece inspection (Chapter 3)

Automatic workpiece measurement (Chapter 4)

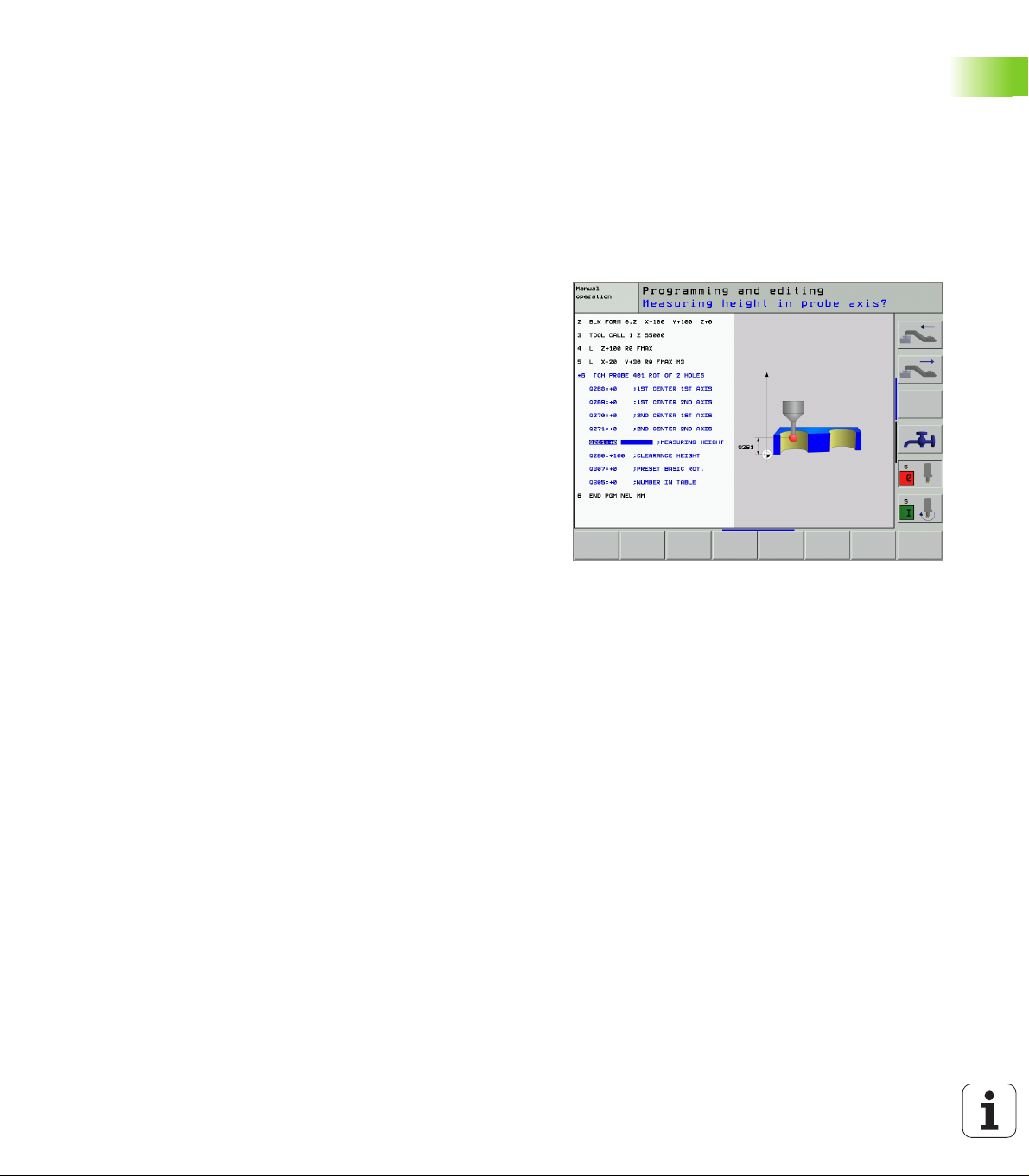

You can program the touch probe cycles in the Programming and

Editing operating mode via the TOUCH PROBE key. Like the most

recent fixed cycles, touch probe cycles use Q parameters with

numbers of 400 and above as transfer parameters. Parameters with

specific functions that are required in several cycles always have the

same number: For example, Q260 is always assigned the clearance

height, Q261 the measuring height, etc.

To simplify programming, the TNC shows an illustration during cycle

definition. In the illustration, the parameter that needs to be entered is

highlighted (see figure at right).

1.1 General Information on Touch Probe Cycles

HEIDENHAIN iTNC 530 15

Defining the touch probe cycle in the Programming and Editing

operation mode

8 The soft-key row shows all available touch probe

functions divided into groups.

8 Select the desired probe cycle, for example datum

setting. Digitizing cycles and cycles for automatic tool

measurement are available only if your machine has

been prepared for them.

8 Select a cycle, e.g. datum setting at pocket. The TNC

initiates the programming dialog and asks all required

input values. At the same time a graphic of the input

parameters is displayed in the right screen window.

The parameter that is asked for in the dialog prompt

is highlighted.

8 Enter all parameters requested by the TNC and

conclude each entry with the ENT key.

8 The TNC ends the dialog when all required data has

been entered.

Group of measuring cycles Soft key

Cycles for automatic measurement and compensation

of workpiece misalignment

Cycles for automatic datum setting

Example: NC blocks

5 TCH PROBE 410 DATUM INSIDE RECTAN.

Q321=+50 ;CENTER IN 1ST AXIS

Q322=+50 ;CENTER IN 2ND AXIS

Q323=60 ;1ST SIDE LENGTH

Q324=20 ;2ND SIDE LENGTH

Q261=-5 ;MEASURING HEIGHT

Q320=0 ;SET-UP CLEARANCE

Q260=+20 ;CLEARANCE HEIGHT

Q301=0 ;TRAVERSE TO CLEARANCE HEIGHT

Q305=10 ;NO. IN TABLE

Q331=+0 ;DATUM

Q332=+0 ;DATUM

Q303=+1 ;MEAS. VALUE TRANSFER

Cycles for automatic workpiece inspection

Automatic calibration cycle

1.1 General Information on Touch Probe Cycles

Cycles for automatic tool measurement (enabled by

the machine tool builder)

16 1 Introduction

1.2 Before You Start Working with

Touch Probe Cycles!

To make it possible to cover the widest possible range of applications,

machine parameters enable you to determine the behavior common

to all touch probe cycles:

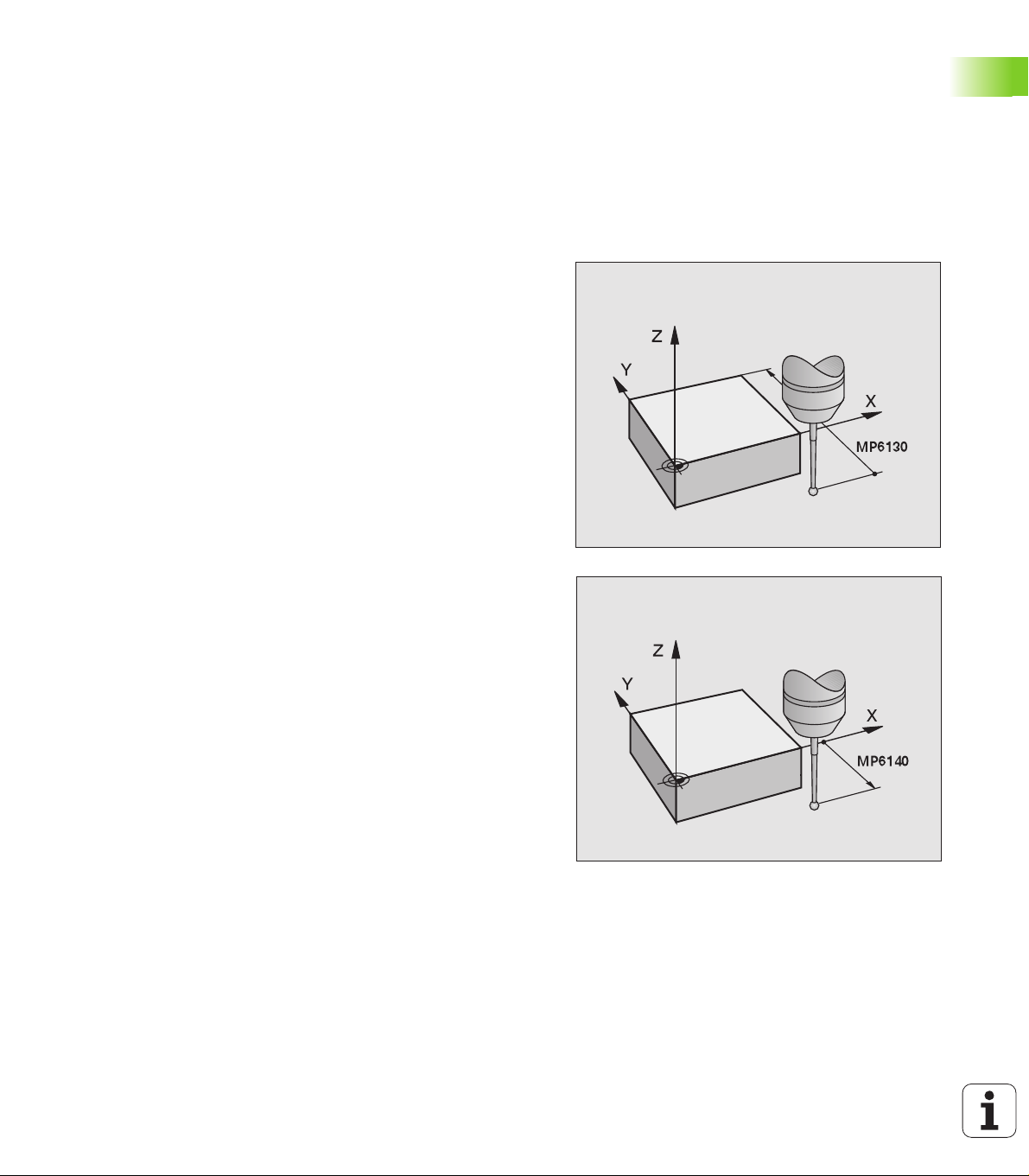

Maximum traverse to touch point: MP6130

If the stylus is not deflected within the path defined in MP6130, the

TNC outputs an error message.

Safety clearance to touch point: MP6140

In MP6140 you define how far from the defined (or calculated) touch

point the TNC is to pre-position the touch probe. The smaller the value

you enter, the more exactly must you define the touch point position.

In many touch probe cycles you can also define a setup clearance in

addition that is added to Machine Parameter 6140.

Orient the infrared touch probe to the programmed probe direction: MP6165

To increase measuring accuracy, you can use MP 6165 = 1 to have an

infrared touch probe oriented in the programmed probe direction

before every probe process. In this way the stylus is always deflected

in the same direction.

Multiple measurement: MP6170

To increase measuring certainty, the TNC can run each probing

process up to three times in sequence. If the measured position

values differ too greatly, the TNC outputs an error message (the limit

value is defined in MP6171). With multiple measurement it is possible

to detect random errors, e.g., from contamination.

If the measured values lie within the confidence interval, the TNC

saves the mean value of the measured positions.

Confidence interval for multiple measurement: MP6171

In MP6171 you store the value by which the results may differ when

you make multiple measurements. If the difference in the measured

values exceeds the value in MP6171, the TNC outputs an error

message.

HEIDENHAIN iTNC 530 17

1.2 Before You Start Working with Touch Probe Cycles!

Touch trigger probe, probing feed rate: MP6120

In MP6120 you define the feed rate at which the TNC is to probe the

workpiece.

Touch trigger probe, rapid traverse for prepositioning: MP6150

In MP6150 you define the feed rate at which the TNC pre-positions the

touch probe, or positions it between measuring points.

1.2 Before You Start Working with Touch Probe Cycles!

18 1 Introduction

Running touch probe cycles

All touch probe cycles are DEF active. This means that the TNC runs

the cycle automatically as soon as the TNC executes the cycle

definition in the program run.

Make sure that at the beginning of the cycle the

compensation data (length, radius) from the calibrated

data or from the last TOOL CALL block are active

(selection via MP7411, see the User's Manual of the

iTNC 530, “General User Parameters”).

You can also run the touch probe cycles 410 to 419 during

an active basic rotation. Make sure, however, that the

basic rotation angle does not change when you use Cycle

7 DATUM SHIFT with datum tables after the measuring

cycle.

Touch probe cycles with a number greater than 400 position the touch

probe according to a positioning logic:

If the current coordinate of the south pole of the stylus is less than

the coordinate of the clearance height (defined in the cycle), the TNC

retracts the touch probe in the probe axis to the clearance height

and then positions it in the working plane to the first starting

position.

If the current coordinate of the south pole of the stylus is greater

than the coordinate of the clearance height, the TNC first positions

the probe in the working plane to the first starting position and then

moves it immediately to the measuring height in the touch probe

axis.

HEIDENHAIN iTNC 530 19

1.2 Before You Start Working with Touch Probe Cycles!

Touch Probe Cycles in the Manual and Electronic Handwheel Modes

2.1 Introduction

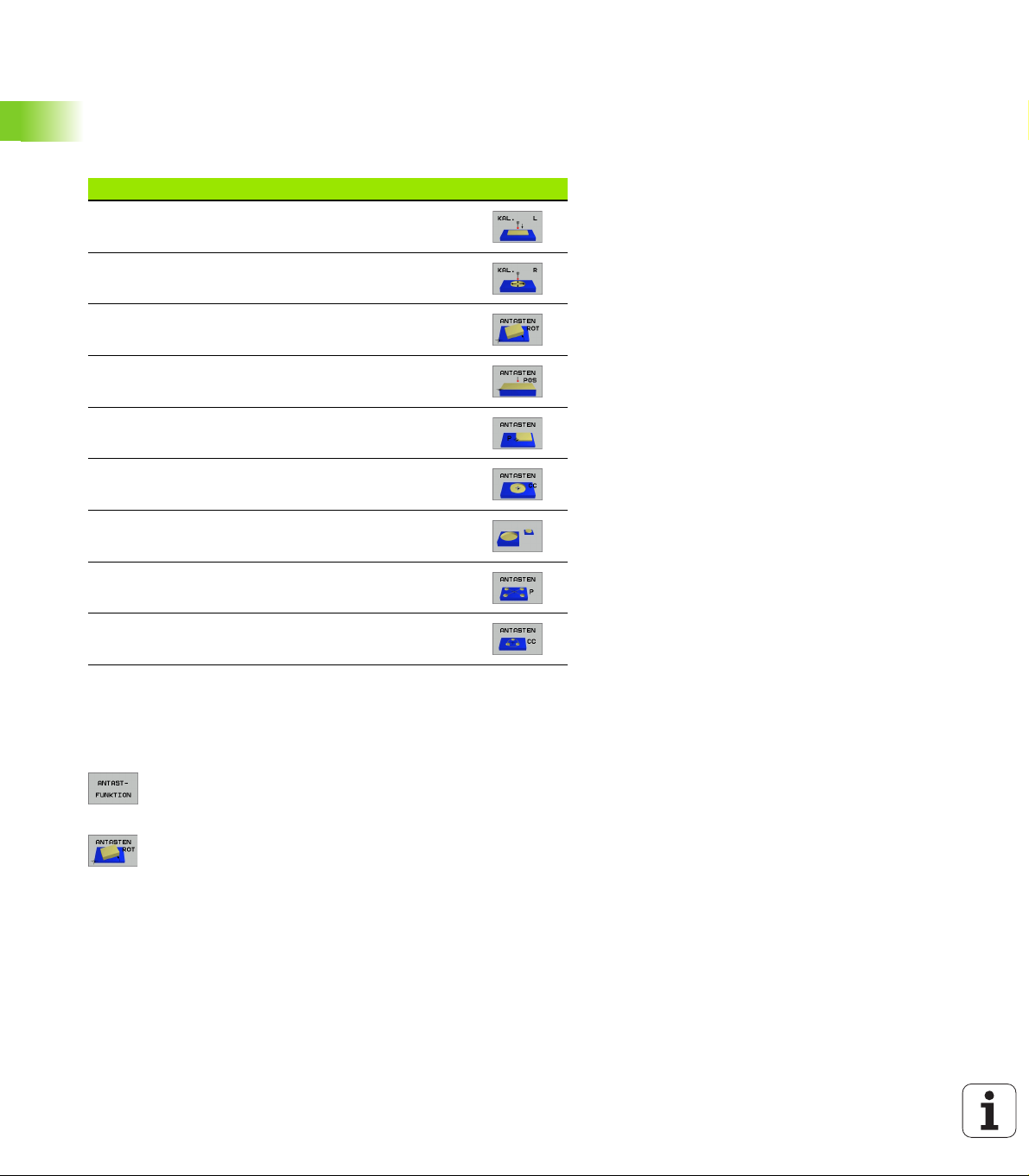

Overview

The following touch probe cycles are available in the Manual mode:

Function Soft key

Calibrate the effective length

2.1 Introduction

Calibrate the effective radius

Measure a basic rotation using a line

Datum setting in any axis

Set the datum at a corner

Set the datum at a circle center

Measure a basic rotation using two holes/cylindrical

studs

Set the datum using four holes/cylindrical studs

Set the circle center using three holes/cylindrical studs

Selecting probe cycles

8 Select the Manual Operation or Electronic Handwheel mode of

operation.

8 To choose the touch probe functions, press the

TOUCH PROBE soft key. The TNC displays additional

soft keys—see table above.

8 To select the probe cycle, press the appropriate soft

key, for example PROBING ROT, and the TNC

displays the associated menu.

22 2 Touch Probe Cycles in the Manual and Electronic Handwheel Modes

Recording measured values from the touch probe cycles

The TNC must be specially prepared by the machine tool

builder for use of this function. The machine tool manual

provides further information.

After executing any selected touch probe cycle, the TNC displays the

PRINT soft key. If you press this soft key, the TNC will record the

current values determined in the active touch probe cycle. You can

then use the PRINT function in the menu for setting the data interface

(see the User's Manual Chapter 12, “MOD Functions, Setting the

Data Interfaces”) to define whether the TNC is to

print the measuring result,

store the measuring results on the TNC’s hard disk, or

store the measuring results on a PC.

If you store the measuring results, the TNC creates the ASCII file

%TCHPRNT.A. Unless you define a specific path and interface in the

interface configuration menu, the TNC will store the %TCHPRNT file

in the main directory TNC:\.

When you press the PRINT soft key, the %TCHPRNT.A

file must not be

active in the Programming and Editing mode of operation.

The TNC will otherwise display an error message.

The TNC stores the measured data in the %TCHPRNT.A

file only. If you execute several touch probe cycles in

succession and want to store the resulting measured data,

you must make a backup of the contents stored in

%TCHPRNT.A between the individual cycles by copying

or renaming the file.

Format and contents of the %TCHPRNT file are preset by

the machine tool builder.

2.1 Introduction

HEIDENHAIN iTNC 530 23

Writing the measured values from touch probe cycles in datum tables

This function is active only if you have datum tables active

on your TNC (bit 3 in machine parameter 7224.0 =0).

Use this function if you want to save measured values in

the workpiece coordinate system. If you want to save

measured values in the machine-based coordinate system

(REF coordinates), press the ENTER IN PRESET TABLE

2.1 Introduction

With the ENTER IN DATUM TABLE soft key, the TNC can write the

values measured during a touch probe cycle in a datum table:

8 Select any probe function.

8 Enter the desired coordinates of the datum in the appropriate input

fields (depends on the touch probe cycle being run).

8 Enter the datum number in the Number in table= input box.

8 Enter the name of the datum table (complete path) in the Datum

table input box.

8 Press the ENTER IN DATUM TABLE soft key. The TNC saves the

datum in the indicated datum table under the entered number.

soft key (see “Writing the measured values from touch

probe cycles in the preset table” on page 25).

Note that during an active datum shift the TNC always

bases the probed value on the active preset (or on the

datum most recently set in the Manual operating mode),

although the datum shift is included in the position display.

24 2 Touch Probe Cycles in the Manual and Electronic Handwheel Modes

Writing the measured values from touch probe cycles in the preset table

Use this function if you want to save measured values in

the machine-based coordinate system (REF coordinates).

If you want to save measured values in the workpiece

coordinate system, press the ENTER IN DATUM TABLE

soft key (see “Writing the measured values from touch

probe cycles in datum tables” on page 24).

With the ENTER IN PRESET TABLE soft key, the TNC can write the

values measured during a probe cycle in the preset table. The

measured values are then stored referenced to the machine-based

coordinate system (REF coordinates). The preset table has the name

PRESET.PR, and is saved in the directory TNC:\.

Note that during an active datum shift the TNC always

bases the probed value on the active preset (or on the

datum most recently set in the Manual operating mode),

although the datum shift is included in the position display.

8 Select any probe function.

8 Enter the desired coordinates of the datum in the appropriate input

fields (depends on the touch probe cycle being run).

8 Enter the preset number in the Number in table: input box.

8 Press the ENTER IN PRESET TABLE soft key. The TNC saves the

datum in the preset table under the entered number.

2.1 Introduction

HEIDENHAIN iTNC 530 25

2.2 Calibrating a Touch Trigger

Probe

Introduction

The touch probe must be calibrated in the following cases:

Commissioning

Stylus breakage

Stylus exchange

Change in the probe feed rate

Irregularities caused, for example, when the machine heats up

During calibration, the TNC finds the “effective” length of the stylus

and the “effective” radius of the ball tip. To calibrate the touch probe,

clamp a ring gauge of known height and known internal radius to the

machine table.

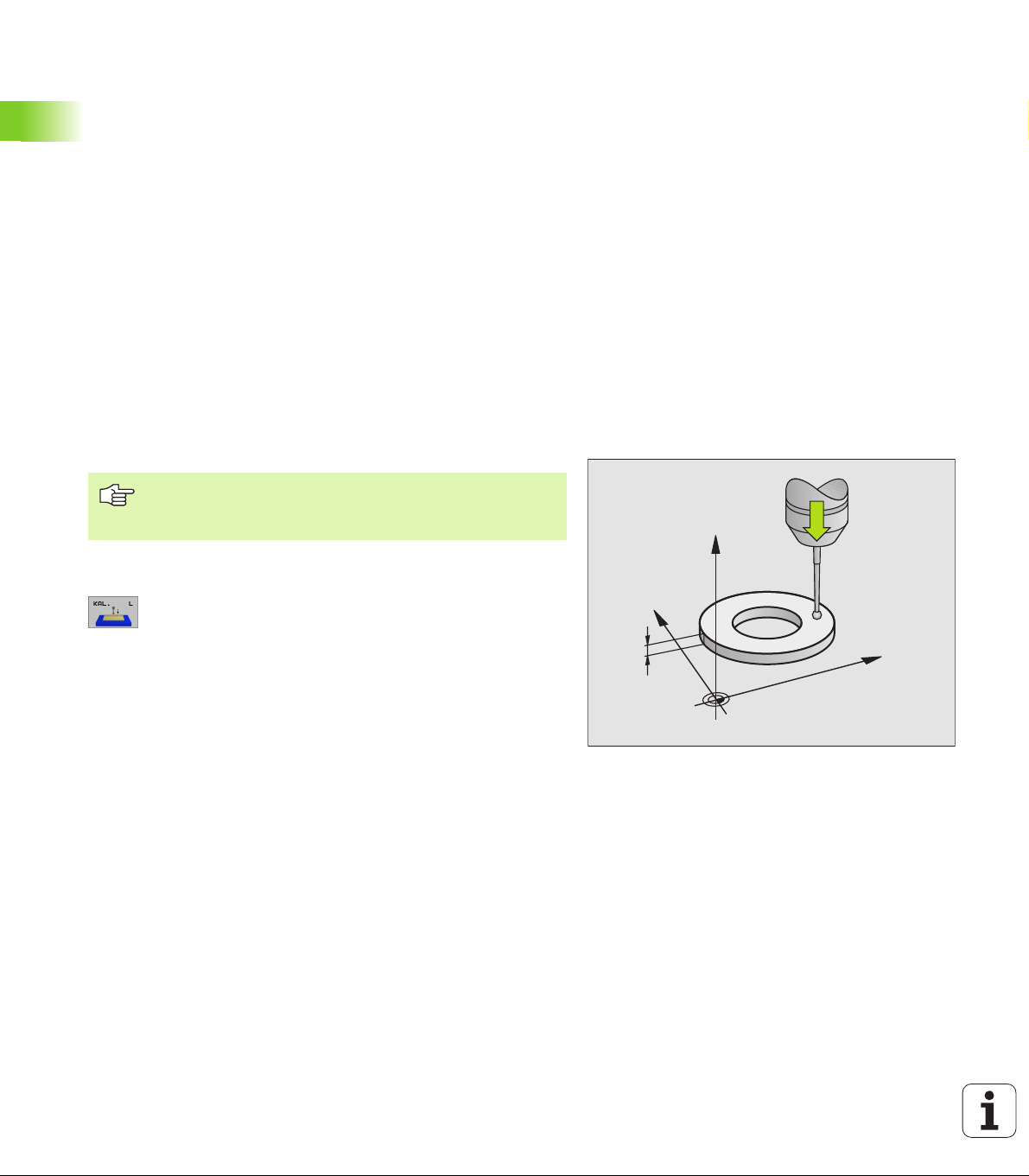

Calibrating the effective length

The effective length of the touch probe is always

referenced to the tool datum. The machine tool builder

2.2 Calibrating a Touch Trigger Probe

8 Set the datum in the spindle axis such that for the machine tool table

Z=0.

usually defines the spindle tip as the tool datum.

8 To select the calibration function for the touch probe

length, press the TOUCH PROBE and CAL. L soft

keys. The TNC then displays a menu window with

four input fields.

8 Enter the tool axis (with the axis key).

8 Datum: Enter the height of the ring gauge.

8 The menu items Effective ball radius and Effective

length do not require input.

8 Move the touch probe to a position just above the ring

gauge.

8 To change the traverse direction (if necessary) press a

soft key or an arrow key.

8 To probe the upper surface of the ring gauge, press

the machine START button.

Z

Y

5

X

26 2 Touch Probe Cycles in the Manual and Electronic Handwheel Modes

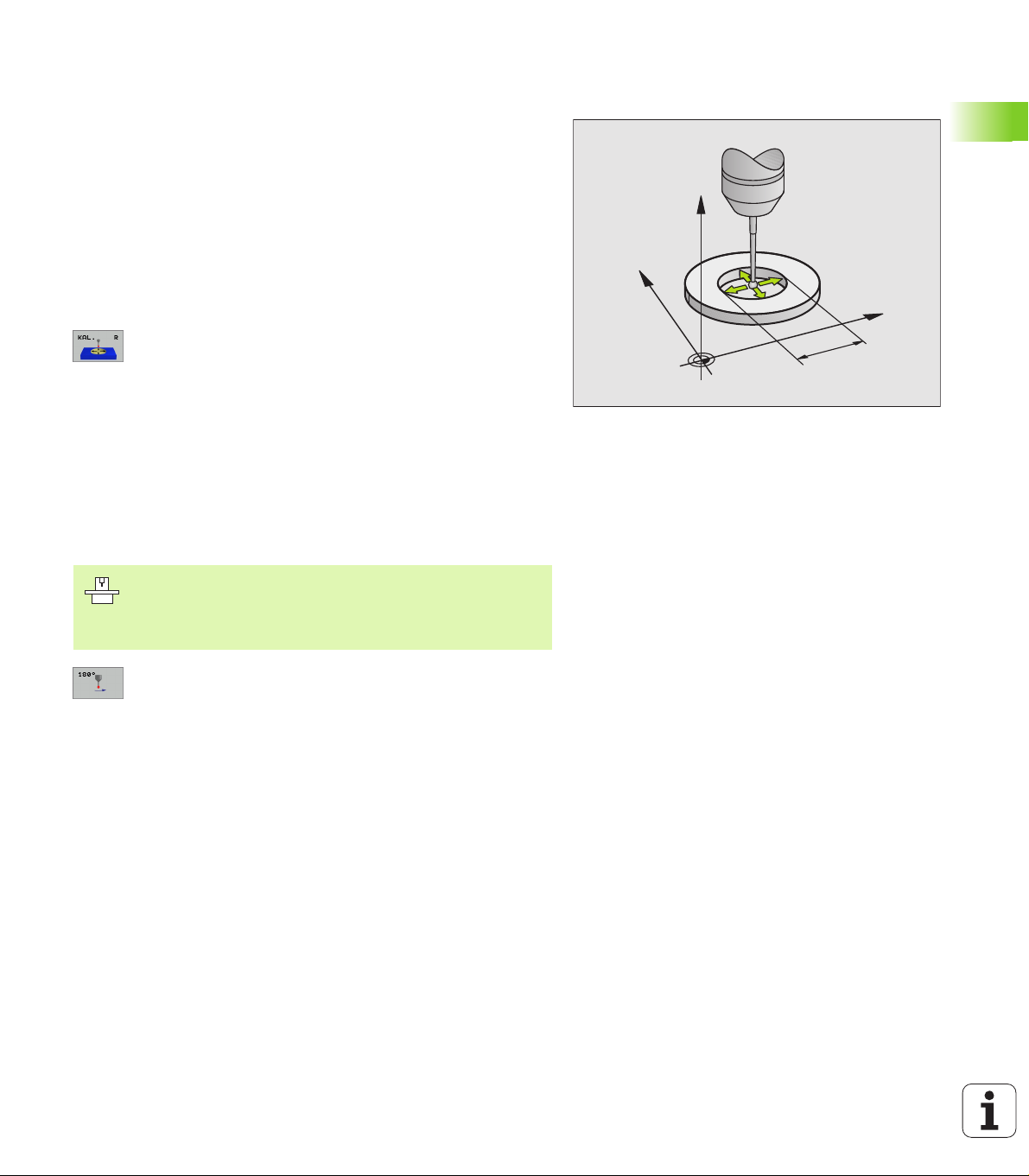

Calibrating the effective radius and compensating center misalignment

After the touch probe is inserted, it normally needs to be aligned

exactly with the spindle axis. The misalignment is measured with this

calibration function and compensated electronically.

For this operation the TNC rotates the 3-D touch probe by 180°. The

rotation is initiated by a miscellaneous function that is set by the

machine tool builder in machine parameter 6160.

The center misalignment is measured after the effective ball tip radius

is calibrated.

8 In the Manual Operation mode, position the ball tip in the bore of the

ring gauge.

8 To select the calibration function for the ball-tip radius

and the touch probe center misalignment, press the

CAL. R soft key.

8 Select the tool axis and enter the radius of the ring

gauge.

8 To probe the workpiece, press the machine START

button four times. The touch probe contacts a

position on the bore in each axis direction and

calculates the effective ball-tip radius.

8 If you want to terminate the calibration function at this

point, press the END soft key.

Z

Y

X

10

2.2 Calibrating a Touch Trigger Probe

In order to be able to determine ball-tip center

misalignment, the TNC needs to be specially prepared by

the machine manufacturer. The machine tool manual

provides further information.

8 If you want to determine the ball-tip center

misalignment, press the180° soft key. The TNC

rotates the touch probe by 180°.

8 To probe the workpiece, press the machine START

button four times. The touch probe contacts a

position on the bore in each axis direction and

calculates the ball-tip center misalignment.

HEIDENHAIN iTNC 530 27

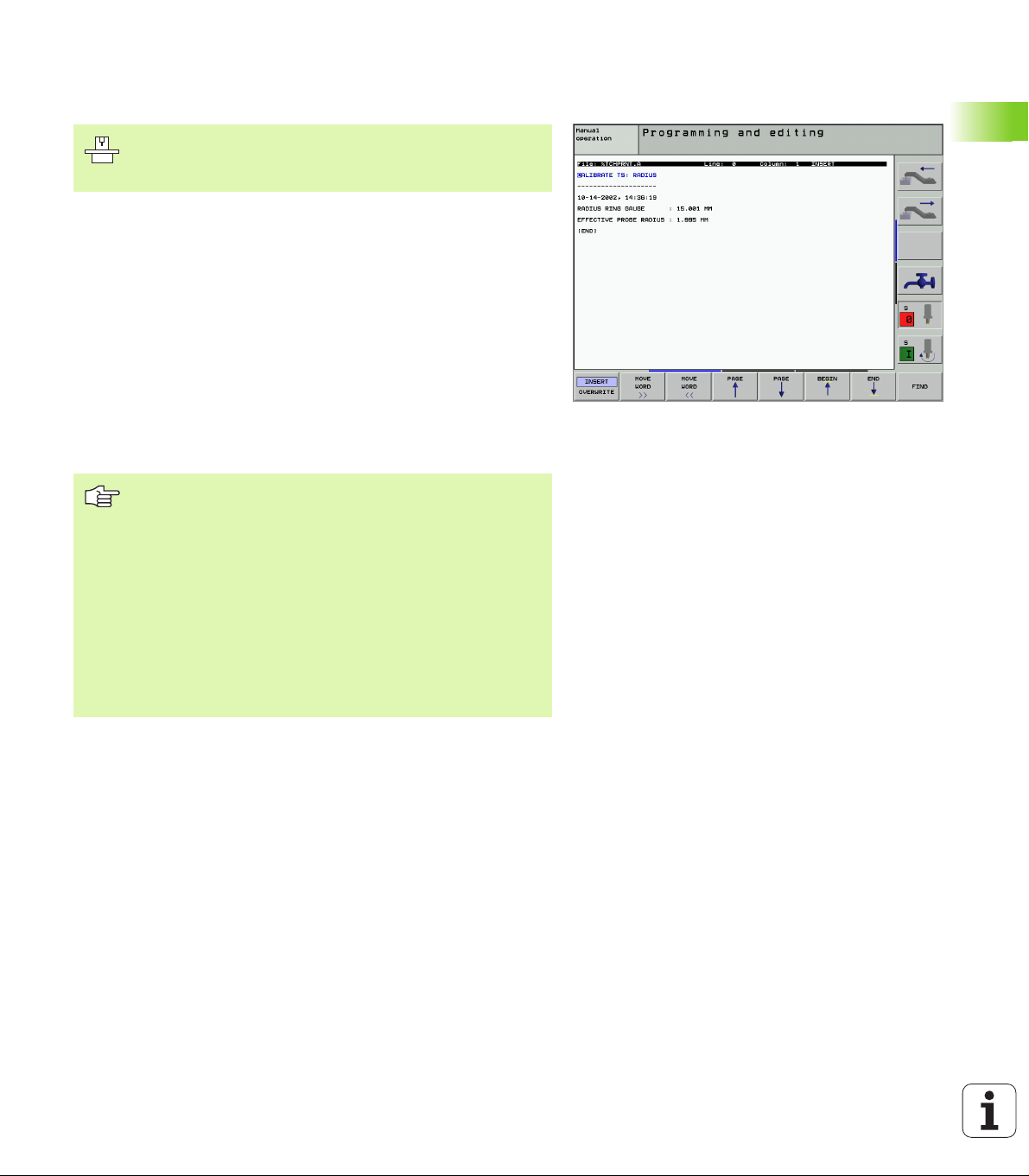

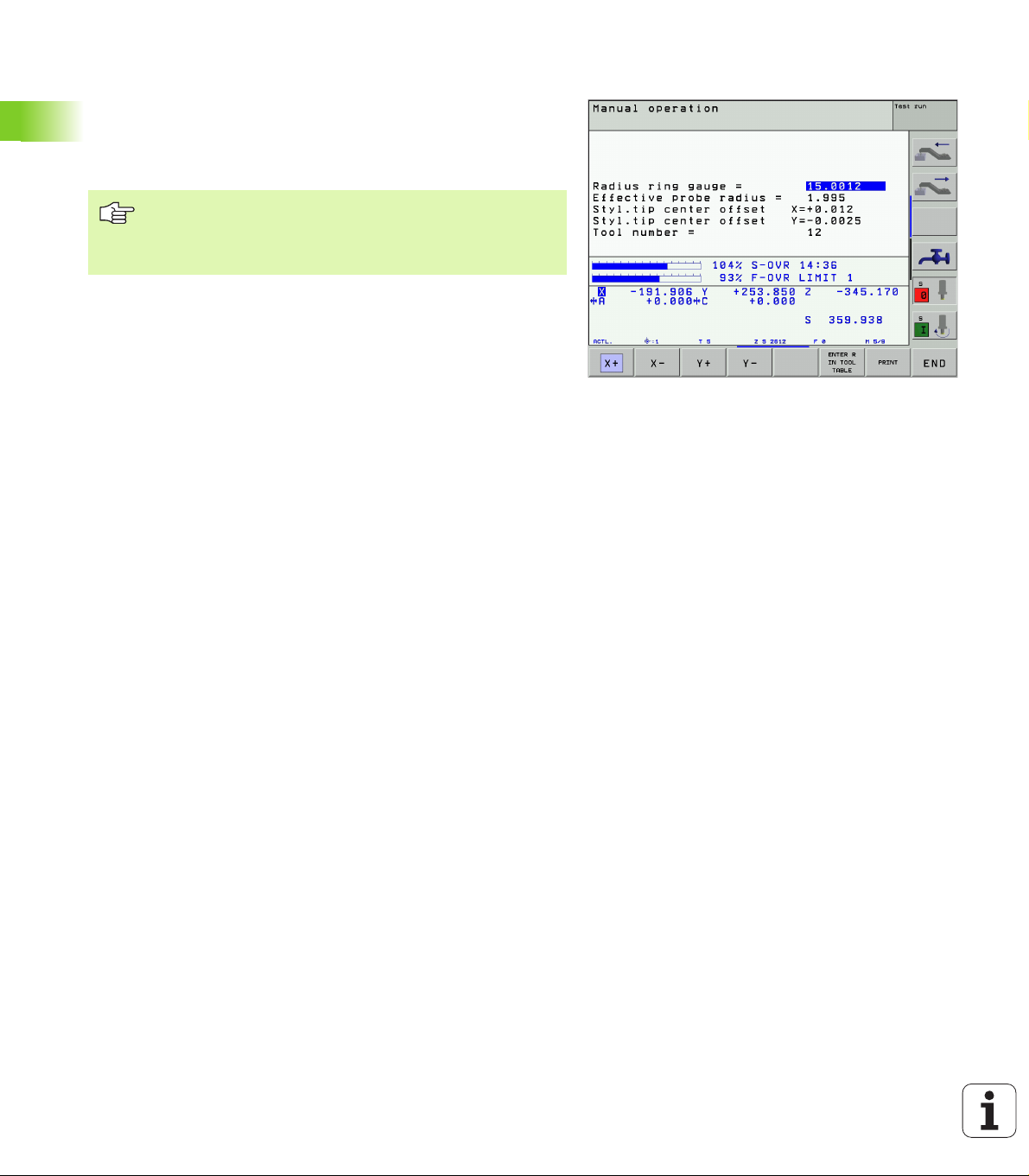

Displaying calibration values

The TNC stores the effective length and radius, as well as the center

misalignment, for use when the touch probe is needed again. You can

display the values on the screen with the soft keys CAL. L and CAL. R.

Storing calibration values in the TOOL.T tool table

This function is only available if bit 0 in Machine Parameter

7411 = 1 is set (activate touch probe data with TOOL CALL),

and tool table TOOL.T is active (Machine Parameter 7260

not equal to 0).

If you conduct measurements during program run, the compensation

data for the touch probe can be activated from the tool table via a TOOL

CALL. To store the calibration data in the TOOL.T tool table, enter the

tool number in the calibration menu (confirm with ENT) and then press

the ENTER R IN TOOL TABLE or the ENTER L IN TOOL TABLE soft

key.

2.2 Calibrating a Touch Trigger Probe

28 2 Touch Probe Cycles in the Manual and Electronic Handwheel Modes

Managing more than one block of calibrating data

If you use several touch probes or measuring contacts arranged in a

cross shape on your machine, you must also use several sets of

calibration data, if required.

To be able to use more than one block of calibration data, you must set

bit one in Machine Parameter 7411. Although the calibration data

(length, radius, center misalignment, and spindle angle) are calculated

in the calibration menu, you must always save them in the tool table

TOOL.T under a tool number that can be selected in the calibration

menu (see also User's Manual, section 5.2, “Tool Data”).

8 Execute the calibration function (as described previously).

8 Enter the tool number in the corresponding input box.

8 Enter the calculated calibration data in the tool table by pressing the

ENTER-R IN TOOL TABLE or ENTER L IN TOOL TABLE soft key.

If you use the touch probe afterwards, you must first

activate the corresponding tool number with a tool call

before executing a touch probe cycle, regardless of

whether you wish to run the touch probe cycle in

automatic mode or manual mode.

You can view and edit the calibration data in the calibration

menu, but you must make sure to write the changes back

into the tool table by pressing the ENTER R IN TOOL

TABLE or ENTER L IN TOOL TABLE soft key. The TNC

does not write the calibration values into the table

automatically!

2.2 Calibrating a Touch Trigger Probe

HEIDENHAIN iTNC 530 29

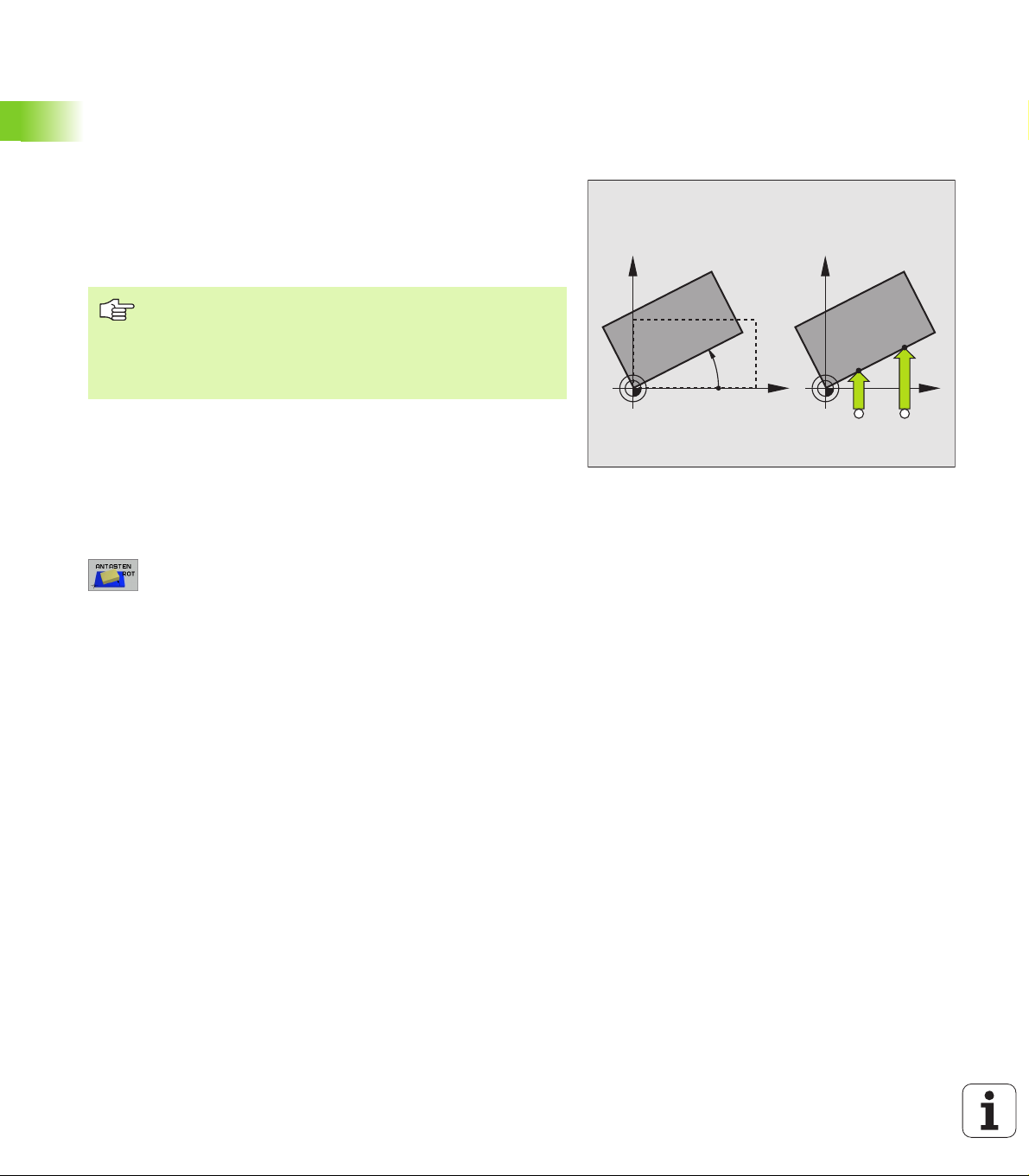

2.3 Compensating Workpiece

Misalignment

Introduction

The TNC electronically compensates workpiece misalignment by

computing a “basic rotation.”

For this purpose, the TNC sets the rotation angle to the desired angle

with respect to the reference axis in the working plane. See figure at

right.

Select the probe direction perpendicular to the angle

reference axis when measuring workpiece misalignment.

To ensure that the basic rotation is calculated correctly

during program run, program both coordinates of the

working plane in the first positioning block.

Measuring the basic rotation

8 Select the probing function by pressing the PROBING

ROT soft key.

2.3 Compensating Workpiece Misalignment

8 Position the ball tip at a starting position near the first

touch point.

8 Select the probe direction perpendicular to the angle

reference axis: Select the axis by soft key.

8 To probe the workpiece, press the machine START

button.

8 Position the ball tip at a starting position near the

second touch point.

8 To probe the workpiece, press the machine START

button. The TNC determines the basic rotation and

displays the angle after the dialog Rotation angle =

Y

PA

Y

X

A B

X

30 2 Touch Probe Cycles in the Manual and Electronic Handwheel Modes

Loading...

Loading...