fagor 8037 Installation Manual

CNC 8037

Installation manual

Ref. 1310

Soft: V01.4x

All rights reserved. No part of this documentation may be transmitted, transcribed, stored in a backup device or translated into another language without Fagor Automation’s consent. Unauthorized copying or distributing of this software is prohibited.

The information described in this manual may be subject to changes due to technical modifications. Fagor Automation reserves the right to change the contents of this manual without prior notice.

All the trade marks appearing in the manual belong to the corresponding owners. The use of these marks by third parties for their own purpose could violate the rights of the owners.

It is possible that CNC can execute more functions than those described in its associated documentation; however, Fagor Automation does not guarantee the validity of those applications. Therefore, except under the express permission from Fagor Automation, any CNC application that is not described in the documentation must be considered as "impossible". In any case, Fagor Automation shall not be held responsible for any personal injuries or physical damage caused or suffered by the CNC if it is used in any way other than as explained in the related documentation.

The content of this manual and its validity for the product described here has been verified. Even so, involuntary errors are possible, hence no absolute match is guaranteed. However, the contents of this document are regularly checked and updated implementing the necessary corrections in a later edition. We appreciate your suggestions for improvement.

The examples described in this manual are for learning purposes. Before using them in industrial applications, they must be properly adapted making sure that the safety regulations are fully met.

This product uses the following source code, subject to the terms of the GPL license. The applications busybox V0.60.2; dosfstools V2.9; linux-ftpd V0.17; ppp V2.4.0; utelnet V0.1.1. The librarygrx V2.4.4. The linux kernel V2.4.4. The linux boot ppcboot V1.1.3. If you would like to have a CD copy of this source code sent to you, send 10 Euros to Fagor Automation for shipping and handling.

Installation manual

I N D E X

|

About the product ......................................................................................................................... |

7 |

|

|

|

|

Declaration of conformity .............................................................................................................. |

9 |

|

|

|

|

Version history ............................................................................................................................ |

11 |

|

|

|

|

Safety conditions ........................................................................................................................ |

13 |

|

|

|

|

Warranty terms ........................................................................................................................... |

17 |

|

|

|

|

Material returning terms.............................................................................................................. |

19 |

|

|

|

|

Additional remarks ...................................................................................................................... |

21 |

|

|

|

|

Fagor documentation.................................................................................................................. |

23 |

|

|

|

CHAPTER 1 |

CNC CONFIGURATION |

|

|

|

|

|

|

|

|

|

|

|

1.1 |

CNC structure ................................................................................................................ |

26 |

|

|

|

1.1.1 |

Connectors................................................................................................................. |

28 |

|

|

CHAPTER 2 |

HEAT DISSIPATION |

|

|

|

|

|

|

|

|

|

|

|

2.1 |

Heat dissipation by natural convection .......................................................................... |

52 |

|

|

|

2.2 |

Heat dissipation by forced convection with inside fan.................................................... |

53 |

|

|

|

2.3 |

Heat dissipation by air flow to the outside using a fan ................................................... |

54 |

|

|

CHAPTER 3 |

REMOTE MODULES (BUS CAN WITH CANOPEN PROTOCOL) |

|

|

|

|

|

|

|

|

|

|

|

3.1 |

Installation of the modules ............................................................................................. |

57 |

|

|

|

3.2 |

Power supply ................................................................................................................. |

58 |

|

|

|

3.3 |

Digital inputs and digital outputs (single module)........................................................... |

64 |

|

|

|

3.4 |

Digital inputs and digital outputs (double module) ......................................................... |

66 |

|

|

|

3.5 |

Electrical characteristics of the inputs and outputs ........................................................ |

68 |

|

|

|

3.6 |

Numbering of the digital inputs and outputs................................................................... |

70 |

|

|

CHAPTER 4 |

MACHINE AND POWER CONNECTION |

|

|

|

|

|

|

|

|

|

|

|

4.1 |

Digital inputs and outputs............................................................................................... |

74 |

|

|

|

4.2 |

Analog inputs and outputs ............................................................................................. |

75 |

|

|

|

4.3 |

Setup.............................................................................................................................. |

76 |

|

|

|

4.4 |

Connection of the emergency input and output ............................................................. |

80 |

|

|

CHAPTER 5 |

MACHINE PARAMETERS |

|

|

|

|

|

|

|

|

|

|

|

5.1 |

Parameters that may be modified from the oscilloscope, OEM program or OEM |

|

|

|

|

|

subroutine................................................................................................................ |

89 |

|

|

|

5.2 |

General machine parameters ........................................................................................ |

91 |

|

|

|

5.3 |

Axis parameters .......................................................................................................... |

131 |

|

|

|

5.4 |

Spindle parameters...................................................................................................... |

159 |

|

|

|

5.5 |

Drive parameters ......................................................................................................... |

176 |

|

|

|

5.6 |

Serial line parameters .................................................................................................. |

178 |

|

|

|

5.7 |

Ethernet parameters .................................................................................................... |

181 |

|

|

|

5.8 |

PLC Parameters ......................................................................................................... |

185 |

|

|

|

5.9 |

Tables ......................................................................................................................... |

192 |

|

|

|

5.9.1 |

Miscellaneous (M) function table.............................................................................. |

192 |

|

|

|

5.9.2 |

Leadscrew error compensation table ....................................................................... |

194 |

|

|

|

5.9.3 |

Cross compensation parameter table ...................................................................... |

196 |

|

|

CHAPTER 6 |

CONCEPTS |

|

|

CNC 8037 |

|

|

|

|

|||

|

|

|

|

|

|

|

6.1 |

Axes and coordinate systems ...................................................................................... |

197 |

|

|

|

6.1.1 |

Rotary axes .............................................................................................................. |

200 |

|

|

|

6.1.2 |

Gantry axes.............................................................................................................. |

202 |

|

|

|

6.1.3 |

Incline axis ............................................................................................................... |

203 |

|

|

|

6.2 |

Jog ............................................................................................................................... |

205 |

|

SOFT: V01.4X |

|

6.2.1 |

Relationship between the axes and the JOG keys .................................................. |

205 |

|

|

|

6.2.2 |

Path-jog mode.......................................................................................................... |

206 |

|

|

·3·

|

|

Installation manual |

6.3 |

Movement with an electronic handwheel.................................................................... |

208 |

6.3.1 |

Standard handwheel ................................................................................................ |

209 |

6.3.2 |

Path handwheel ....................................................................................................... |

210 |

6.3.3 |

Feed handwheel mode ............................................................................................ |

211 |

6.3.4 |

"Additive handwheel" mode ..................................................................................... |

212 |

6.4 |

feedback system.......................................................................................................... |

214 |

6.4.1 |

Counting speed limitation......................................................................................... |

215 |

6.4.2 |

Resolution ................................................................................................................ |

216 |

6.5 |

Axis adjustment ........................................................................................................... |

220 |

6.5.1 |

Drive setting ............................................................................................................. |

221 |

6.5.2 |

Gain setting.............................................................................................................. |

222 |

6.5.3 |

Proportional gain setting .......................................................................................... |

223 |

6.5.4 |

Feed-forward gain setting ........................................................................................ |

224 |

6.5.5 |

Derivative (AC-forward) gain setting ........................................................................ |

225 |

6.5.6 |

Leadscrew backlash compensation. ........................................................................ |

226 |

6.5.7 |

Leadscrew error compensation................................................................................ |

227 |

6.5.8 |

Circle geometry test ................................................................................................. |

229 |

6.6 |

Reference systems ...................................................................................................... |

231 |

6.6.1 |

Home search............................................................................................................ |

232 |

6.6.2 |

Setting on systems without distance-coded feedback ............................................. |

235 |

6.6.3 |

Setting on systems with distance-coded feedback .................................................. |

237 |

6.6.4 |

Axis travel limits (software limits) ............................................................................. |

238 |

6.7 |

Unidirectional approach ............................................................................................... |

239 |

6.8 |

Auxiliary M, S, T function transfer................................................................................ |

240 |

6.8.1 |

Transferring M, S, T using the AUXEND signal ....................................................... |

242 |

6.8.2 |

Transferring the auxiliary (miscellaneous) M functions without the AUXEND signal 243 |

|

6.9 |

Spindle......................................................................................................................... |

244 |

6.9.1 |

Spindle types ........................................................................................................... |

244 |

6.9.2 |

Spindle speed (S) control......................................................................................... |

245 |

6.9.3 |

Spindle gear change ................................................................................................ |

247 |

6.9.4 |

Spindle in closed loop .............................................................................................. |

249 |

6.10 |

Treatment of emergency signals ................................................................................. |

255 |

6.11 |

Digital CAN servo ........................................................................................................ |

258 |

6.11.1 |

Communications channel......................................................................................... |

258 |

6.11.2 |

Drive’s absolute feedback........................................................................................ |

261 |

6.12 |

Fagor handwheels: HBA, HBE and LGB .................................................................... |

262 |

6.13 |

Machine safety related functions ................................................................................. |

266 |

6.13.1 |

Maximum machining spindle speed......................................................................... |

266 |

6.13.2 |

Cycle start disabled when hardware errors occur.................................................... |

267 |

6.14 |

Tool magazine ............................................................................................................. |

268 |

6.14.1 |

Tool change via PLC................................................................................................ |

268 |

6.14.2 |

Tool magazine management ................................................................................... |

269 |

6.15 |

Gear ratio management on axes and spindle.............................................................. |

270 |

6.15.1 |

Axis example: Encoder at the motor ........................................................................ |

271 |

6.15.2 |

Axis example: external feedback device without a gear box |

................................... 272 |

6.15.3 |

Axis example: external feedback device with gear box ........................................... |

275 |

6.15.4 |

Spindle example: Encoder at the motor................................................................... |

277 |

6.15.5 |

Spindle example: external encoder without gear box .............................................. |

279 |

6.15.6 |

Spindle example: external encoder with gear box ................................................... |

281 |

CHAPTER 7 |

PLC RESOURCES |

|

|

|

|

|

|

|

7.1 |

Inputs ........................................................................................................................... |

283 |

|

7.2 |

Outputs ........................................................................................................................ |

284 |

|

7.3 |

Marks ........................................................................................................................... |

285 |

|

7.4 |

Registers...................................................................................................................... |

287 |

|

7.5 |

Timers.......................................................................................................................... |

288 |

|

7.5.1 |

Monostable mode. TG1 input................................................................................... |

291 |

|

7.5.2 |

Delayed activation mode. TG2 input........................................................................ |

293 |

|

7.5.3 |

Delayed deactivation mode. TG3 input.................................................................... |

295 |

|

7.5.4 |

Signal limiting mode. TG4 Input............................................................................... |

297 |

CNC 8037 |

7.6 |

Counters ...................................................................................................................... |

299 |

7.6.1 |

Operating mode of a counter ................................................................................... |

302 |

|

CHAPTER 8 |

INTRODUCTION TO THE PLC |

|

||

|

|

|

|

|

|

8.1 |

PLC resources ............................................................................................................. |

304 |

|

|

8.2 |

PLC program execution ............................................................................................... |

305 |

|

SOFT: V01.4X |

8.3 |

Loop time ..................................................................................................................... |

308 |

|

|

8.4 |

Modular structure of the program ................................................................................ |

309 |

|

|

8.4.1 |

First cycle module (CY1).......................................................................................... |

310 |

|

|

8.4.2 |

Main module (PRG) ................................................................................................. |

311 |

|

|

8.4.3 |

Periodic execution module (PE t)............................................................................. |

312 |

|

|

8.4.4 |

Priority of execution of the PLC modules................................................................. |

313 |

|

·4·

Installation manual |

|

|

||

CHAPTER 9 |

PLC PROGRAMMING |

|

||

|

|

|

|

|

|

9.1 |

Module structure .......................................................................................................... |

316 |

|

|

9.2 |

Directing instructions.................................................................................................... |

317 |

|

|

9.3 |

Consulting instructions................................................................................................. |

320 |

|

|

9.4 |

Operators and symbols................................................................................................ |

322 |

|

|

9.5 |

Action instruction.......................................................................................................... |

323 |

|

|

9.5.1 |

Binary assignment instructions ................................................................................ |

324 |

|

|

9.5.2 |

Conditional binary action instructions....................................................................... |

325 |

|

|

9.5.3 |

Sequence breaking action instructions .................................................................... |

326 |

|

|

9.5.4 |

Arithmetic action instructions ................................................................................... |

327 |

|

|

9.5.5 |

Logic action instructions........................................................................................... |

329 |

|

|

9.5.6 |

Specific action instructions....................................................................................... |

331 |

|

CHAPTER 10 |

CNC-PLC COMMUNICATION |

|

|

|

|

|

|

|

10.1 |

Auxiliary M, S, T functions ........................................................................................... |

334 |

|

10.2 |

Auxiliary M, S, T function transfer ................................................................................ |

337 |

|

10.2.1 Transferring M, S, T using the AUXEND signal ....................................................... |

338 |

|

10.2.2Transferring the auxiliary (miscellaneous) M functions without the AUXEND signal 339

|

10.3 |

Displaying messages, errors and screens ................................................................... |

340 |

|

|

10.4 |

Access to the PLC from the CNC ................................................................................ |

342 |

|

|

10.5 |

Access to the PLC from a PC, via DNC....................................................................... |

343 |

|

CHAPTER 11 |

LOGIC CNC INPUTS AND OUTPUTS |

|

||

|

|

|

|

|

|

11.1 |

General logic inputs ..................................................................................................... |

346 |

|

|

11.2 |

Axis logic inputs. .......................................................................................................... |

355 |

|

|

11.3 |

Spindle logic inputs. ..................................................................................................... |

360 |

|

|

11.4 |

Key inhibiting logic inputs............................................................................................. |

365 |

|

|

11.5 |

Logic inputs of the PLC channel .................................................................................. |

366 |

|

|

11.6 |

General logic outputs ................................................................................................... |

368 |

|

|

11.7 |

Logic outputs of the axes ............................................................................................. |

375 |

|

|

11.8 |

Spindle logic outputs.................................................................................................... |

377 |

|

|

11.9 |

Logic outputs of key status .......................................................................................... |

378 |

|

CHAPTER 12 |

|

ACCESS TO INTERNAL CNC VARIABLES |

|

|

|

|

|

|

|

|

12.1 |

Variables associated with tools.................................................................................... |

381 |

|

|

12.2 |

Variables associated with zero offsets......................................................................... |

385 |

|

|

12.3 |

Variables associated with machine parameters........................................................... |

386 |

|

|

12.4 |

Variables associated with work zones ......................................................................... |

387 |

|

|

12.5 |

Variables associated with feedrates ............................................................................ |

389 |

|

|

12.6 |

Variables associated with coordinates......................................................................... |

392 |

|

|

12.7 |

Variables associated with electronic handwheels........................................................ |

394 |

|

|

12.8 |

Variables associated with feedback............................................................................. |

396 |

|

|

12.9 |

Variables associated with the main spindle ................................................................. |

397 |

|

|

12.10 |

Variables associated with local and global parameters ............................................... |

400 |

|

|

12.11 |

Operating-mode related variables................................................................................ |

401 |

|

|

12.12 |

Other variables............................................................................................................. |

404 |

|

CHAPTER 13 |

|

AXES CONTROLLED FROM THE PLC |

|

|

|

|

|

|

|

|

13.1 |

PLC execution channel ................................................................................................ |

414 |

|

|

13.1.1 |

Considerations ......................................................................................................... |

415 |

|

|

|

13.1.2 Blocks which can be executed from the PLC........................................................... |

417 |

|

|

|

13.1.3 Control of the PLC program from the CNC .............................................................. |

421 |

|

|

13.2 |

Action CNCEX1 ........................................................................................................... |

423 |

|

CHAPTER 14 |

PLC PROGRAMMING EXAMPLE |

|

||

|

|

|

|

|

|

14.1 |

Definition of symbols (mnemonics) .............................................................................. |

426 |

|

|

14.2 |

First cycle module. ....................................................................................................... |

428 |

|

|

14.3 |

Main module. ............................................................................................................... |

429 |

|

CNC 8037

SOFT: V01.4X

·5·

|

|

Installation manual |

APPENDIX |

|

|

A |

CNC technical characteristics...................................................................................... |

439 |

B |

Probe connection......................................................................................................... |

443 |

C |

Summary of internal CNC variables. ........................................................................... |

445 |

D |

Summary of PLC commands....................................................................................... |

451 |

E |

Summary of PLC inputs and outputs ........................................................................... |

455 |

F |

2-digit BCD code output conversion table ................................................................... |

461 |

G |

Key code...................................................................................................................... |

463 |

H |

Logic outputs of key status .......................................................................................... |

465 |

I |

Key inhibiting codes..................................................................................................... |

467 |

J |

Machine parameter setting chart ................................................................................. |

469 |

K |

M functions setting chart.............................................................................................. |

475 |

L |

Leadscrew error compensation table........................................................................... |

477 |

M |

Cross compensation table ........................................................................................... |

479 |

N |

Maintenance ................................................................................................................ |

481 |

CNC 8037

SOFT: V01.4X

·6·

ABOUT THE PRODUCT

BASIC CHARACTERISTICS

|

|

|

|

|

|

Monitor |

7.5" Color LCD |

|

|

Block processing time |

7 ms |

|

|

Look-ahead |

75 blocks |

|

|

RAM memory |

1 Mb |

|

|

Flash memory |

128 MB |

|

|

PLC cycle time |

3 ms / 1000 instructions |

|

|

Minimum position loop |

4 ms |

|

|

USB |

Standard |

|

|

RS-232 serial line |

Standard |

|

|

DNC ( via RS232 ) |

Standard |

|

|

Ethernet |

Option |

|

|

5 V or 24 V probe inputs |

2 |

|

|

Local digital inputs and outputs. |

16 I / 8 O |

|

40 I / 24 O |

|

56 I / 32 O |

|

|

Feedback inputs for the axes and spindle |

4 TTL / 1Vpp inputs |

|

|

Feedback inputs for handwheels |

2 TTL inputs |

|

|

Analog outputs |

4 for axes and spindle |

|

|

CAN servo drive system for Fagor servo drive connection. |

Option |

|

|

Remote CAN modules, for digital I/O expansion (RIO). |

Option |

|

|

Before start-up, verify that the machine that integrates this CNC meets the 89/392/CEE Directive.

CNC 8037

·7·

About the product

CNC 8037

SOFTWARE OPTIONS

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model |

|

|

|

M |

|

T |

|

TC |

|

|

|

|||

|

|

|

|

|

|

Number of axes |

3 |

|

2 |

|

2 |

|

|

|

|

|

|

Number of spindles |

1 |

|

1 |

|

1 |

|

|

|

|

|

|

Electronic threading |

Standard |

|

Standard |

|

Standard |

|

|

|

|

|

|

Tool magazine management: |

Standard |

|

Standard |

|

Standard |

|

|

|

|

|

|

Machining canned cycles |

Standard |

|

Standard |

|

Standard |

|

|

|

|

|

|

Multiple machining |

Standard |

|

----- |

|

----- |

|

|

|

|

|

|

Rigid tapping |

Standard |

|

Standard |

|

Standard |

|

|

|

|

|

|

DNC |

Standard |

|

Standard |

|

Standard |

|

|

|

|

|

|

Tool radius compensation |

Standard |

|

Standard |

|

Standard |

|

|

|

|

|

|

Retracing |

Standard |

|

----- |

|

----- |

|

|

|

|

|

|

Jerk control |

Standard |

|

Standard |

|

Standard |

|

|

|

|

|

|

Feed forward |

Standard |

|

Standard |

|

Standard |

|

|

|

|

|

|

Oscilloscope function (Setup assistance) |

Standard |

|

Standard |

|

Standard |

|

|

|

|

|

|

Roundness test (Setup assistance) |

Standard |

|

Standard |

|

Standard |

|

|

|

|

|

|

·8·

DECLARATION OF CONFORMITY

The manufacturer:

Fagor Automation S. Coop.

Barrio de San Andrés Nº 19, C.P. 20500, Mondragón -Guipúzcoa- (SPAIN).

Declares:

Under their responsibility that the product:

8037 CNC

Consisting of the following modules and accessories:

8037-M, 8037-T, 8037-TC Remote modules RIO

ETHERNET, ETHERNET-CAN-CAN AXES, ETHERNET-CAN AXES

Note. Some additional characters may follow the references mentioned above. They all comply with the directives listed. However, check that that's the case by checking the label of the unit itself.

Referred to by this declaration with following directives:

Low voltage regulations.

EN 60204-1: 2006 Electrical equipment on machines — Part 1. General requirements.

Regulation on electromagnetic compatibility.

EN 61131-2: 2007 PLC — Part 2. Requirements and equipment tests.

As instructed by the European Community Directives 2006/95/EEC on Low Voltage and 2004/108/EC on Electromagnetic Compatibility and its updates.

In Mondragón, March 14th, 2012

CNC 8037

·9·

VERSION HISTORY

Here is a list of the features added in each software version and the manuals that describe them. The version history uses the following abbreviations:

INST |

Installation manual |

PRG |

Programming manual |

OPT |

Operating manual |

OPT-TC |

Operating manual for the TC option. |

Software V01.42 |

March 2012 |

First version.

CNC 8037

·11·

Version history

CNC 8037

·12·

SAFETY CONDITIONS

Read the following safety measures in order to prevent harming people or damage to this product and those products connected to it.

This unit may only be repaired by authorized personnel at Fagor Automation.

Fagor Automation shall not be held responsible of any physical damage or defective unit resulting from not complying with these basic safety regulations.

PRECAUTIONS AGAINST PERSONAL DAMAGE

•Interconnection of modules.

Use the connection cables provided with the unit.

•Use proper Mains AC power cables

To avoid risks, use only the Mains AC cables recommended for this unit.

•Avoid electrical overloads.

In order to avoid electrical discharges and fire hazards, do not apply electrical voltage outside the range selected on the rear panel of the central unit.

•Ground connection.

In order to avoid electrical discharges, connect the ground terminals of all the modules to the main ground terminal. Before connecting the inputs and outputs of this unit, make sure that all the grounding connections are properly made.

•Before powering the unit up, make sure that it is connected to ground.

In order to avoid electrical discharges, make sure that all the grounding connections are properly made.

•Do not work in humid environments.

In order to avoid electrical discharges, always work under 90% of relative humidity (non-condensing) and 45 ºC (113º F).

•Do not work in explosive environments.

In order to avoid risks or damages, do no work in explosive environments.

CNC 8037

·13·

Safety conditions

CNC 8037

PRECAUTIONS AGAINST PRODUCT DAMAGE

•Working environment.

This unit is ready to be used in industrial environments complying with the directives and regulations effective in the European Community.

Fagor Automation shall not be held responsible for any damage suffered or caused when installed in other environments (residential or homes).

•Install this unit in the proper place.

It is recommended, whenever possible, to install the CNC away from coolants, chemical product, blows, etc. that could damage it.

This unit complies with the European directives on electromagnetic compatibility. Nevertheless, it is recommended to keep it away from sources of electromagnetic disturbance such as:

Powerful loads connected to the same AC power line as this equipment.

Nearby portable transmitters (Radio-telephones, Ham radio transmitters).

Nearby radio/TV transmitters.

Nearby arc welding machines.

Nearby High Voltage power lines.

Etc.

•Enclosures.

The manufacturer is responsible of assuring that the enclosure involving the equipment meets all the currently effective directives of the European Community.

•Avoid disturbances coming from the machine tool.

The machine-tool must have all the interference generating elements (relay coils, contactors, motors, etc.) uncoupled.

DC relay coils. Diode type 1N4000.

AC relay coils. RC connected as close to the coils as possible with approximate values of R=2201 W y C=0,2 µF / 600 V.

AC motors. RC connected between phases, with values of R=300 / 6 W y C=0,47 µF / 600 V.

•Use the proper power supply.

Use an external regulated 24 Vdc power supply for the inputs and outputs.

•Grounding of the power supply.

The zero volt point of the external power supply must be connected to the main ground point of the machine.

•Analog inputs and outputs connection.

It is recommended to connect them using shielded cables and connecting their shields (mesh) to the corresponding pin.

•Ambient conditions.

The working temperature must be between +5 ºC and +40 ºC (41ºF and 104º F) The storage temperature must be between -25 ºC and +70 ºC. (-13 ºF and 158 ºF)

•Central unit enclosure (8037 CNC).

Make sure that the needed gap is kept between the central unit and each wall of the enclosure. Use a DC fan to improve enclosure ventilation.

•Power switch.

This power switch must be mounted in such a way that it is easily accessed and at a distance between 0.7 meters (27.5 inches) and 1.7 meters (5.5ft) off the floor.

·14·

PROTECTIONS OF THE UNIT ITSELF (8037)

•Central Unit.

It has a 4 A 250V external fast fuse (F).

|

|

|

|

X1 |

|

X7 |

|

|

|

X8 |

FUSE |

|

|

|

|

|

|

|

|

|

|

+24V |

|

|

|

|

|

0V |

|

X9 |

X10 |

X11 |

X12 |

|

|

X2 |

X3 |

X4 |

X5 |

X6 |

|

•Inputs-Outputs.

All the digital inputs and outputs have galvanic isolation via optocouplers between the CNC circuitry and the outside.

Safety conditions

CNC 8037

·15·

Safety conditions

CNC 8037

PRECAUTIONS DURING REPAIR

Do not get into the inside of the unit. Only personnel authorized by Fagor Automation may manipulate the inside of this unit.

Do not handle the connectors with the unit connected to main AC power. Before manipulating the connectors (inputs/outputs, feedback, etc.) make sure that the unit is not connected to AC power.

SAFETY SYMBOLS

• Symbols which may appear on the manual.

Symbol for danger or prohibition.

It indicates actions or operations that may cause damage to people or to units.

Warning symbol.

It indicates situations that may be caused by certain operations and the actions to be taken to prevent them.

Obligation symbol.

It indicates actions and operations that must be carried out.

i |

Information symbol. |

It indicates notes, warnings and advises. |

·16·

WARRANTY TERMS

INITIAL WARRANTY

All products manufactured or marketed by FAGOR carry a 12-month warranty for the end user which could be controlled by the our service network by means of the warranty control system established by FAGOR for this purpose.

In order to prevent the possibility of having the time period from the time a product leaves our warehouse until the end user actually receives it run against this 12-month warranty, FAGOR has set up a warranty control system based on having the manufacturer or agent inform FAGOR of the destination, identification and on-machine installation date, by filling out the document accompanying each FAGOR product in the warranty envelope. This system, besides assuring a full year of warranty to the end user, enables our service network to know about FAGOR equipment coming from other countries into their area of responsibility.

The warranty starting date will be the one appearing as the installation date on the above mentioned document. FAGOR offers the manufacturer or agent 12 months to sell and install the product. This means that the warranty starting date may be up to one year after the product has left our warehouse so long as the warranty control sheet has been sent back to us. This translates into the extension of warranty period to two years since the product left our warehouse. If this sheet has not been sent to us, the warranty period ends 15 months from when the product left our warehouse.

This warranty covers all costs of material and labour involved in repairs at FAGOR carried out to correct malfunctions in the equipment. FAGOR undertakes to repair or replace their products within the period from the moment manufacture begins until 8 years after the date on which it disappears from the catalog.

FAGOR has exclusive competence in deciding whether the repair enters within the term defined as the warranty period.

EXCLUDING CLAUSES

Repairs will be carried out on our premises. Therefore, all expenses incurred as a result of trips made by technical personnel to carry out equipment repairs, despite these being within the above-mentioned period of warranty, are not covered by the warranty.

Said warranty will be applied whenever the equipment has been installed in accordance with instructions, has not be mistreated, has not been damaged by accident or by negligence and has not been tampered with by personnel not authorized by FAGOR. If, once servicing or repairs have been made, the cause of the malfunction cannot be attributed to said elements, the customer is obliged to cover the expenses incurred, in accordance with the tariffs in force.

Other warranties, implicit or explicit, are not covered and FAGOR AUTOMATION cannot be held responsible for other damages which may occur.

CNC 8037

·17·

Warranty terms

CNC 8037

WARRANTY ON REPAIRS

In a similar way to the initial warranty, FAGOR offers a warranty on standard repairs according to the following conditions:

PERIOD |

12 months. |

|

|

CONCEPT |

Covers parts and labor for repairs (or replacements) at the network's own |

|

facilities. |

|

|

EXCLUDING CLAUSES |

The same as those applied regarding the chapter on initial warranty. |

|

If the repair is carried out within the warranty period, the warranty extension |

|

has no effect. |

|

|

When the customer does not choose the standard repair and just the faulty material has been replaced, the warranty will cover just the replaced parts or components within 12 months.

For sold parts the warranty is 12 moths length.

MAINTENANCE CONTRACTS

The SERVICE CONTRACT is available for the distributor or manufacturer who buys and installs our CNC systems.

·18·

MATERIAL RETURNING TERMS

When sending the central nit or the remote modules, pack them in its original package and packaging material. If the original packaging material is not available, pack it as follows:

1.Get a cardboard box whose three inside dimensions are at least 15 cm (6 inches) larger than those of the unit. The cardboard being used to make the box must have a resistance of 170 kg. (375 pounds).

2.Attach a label indicating the owner of the unit, person to contact, type of unit and serial number.

3.In case of failure, also indicate the symptom and a short description.

4.Wrap the unit in a polyethylene roll or similar material to protect it.

5.When sending the central unit, protect especially the screen.

6.Pad the unit inside the cardboard box with polyurethane foam on all sides.

7.Seal the cardboard box with packing tape or industrial staples.

CNC 8037

·19·

Material returning terms

CNC 8037

·20·

ADDITIONAL REMARKS

Mount the CNC away from coolants, chemical products, blows, etc. which could damage it. Before turning the unit on, verify that the ground connections have been properly made.

In case of a malfunction or failure, disconnect it and call the technical service. Do not get into the inside of the unit.

CNC 8037

·21·

Additional remarks

CNC 8037

·22·

FAGOR DOCUMENTATION

OEM manual

It is directed to the machine builder or person in charge of installing and starting-up the CNC.

USER-M manual

Directed to the end user.

It describes how to operate and program in M mode.

USER-T manual

Directed to the end user.

It describes how to operate and program in T mode.

TC Manual

Directed to the end user.

It describes how to operate and program in TC mode.

It contains a self-teaching manual.

CNC 8037

·23·

Fagor documentation

CNC 8037

·24·

CNC CONFIGURATION

1

The CNC is prepared to be used in industrial environments, especially on milling machines, lathes, etc.

The CNC can control machine movements and devices.

CNC 8037

SOFT: V01.4X

·25·

Installation manual

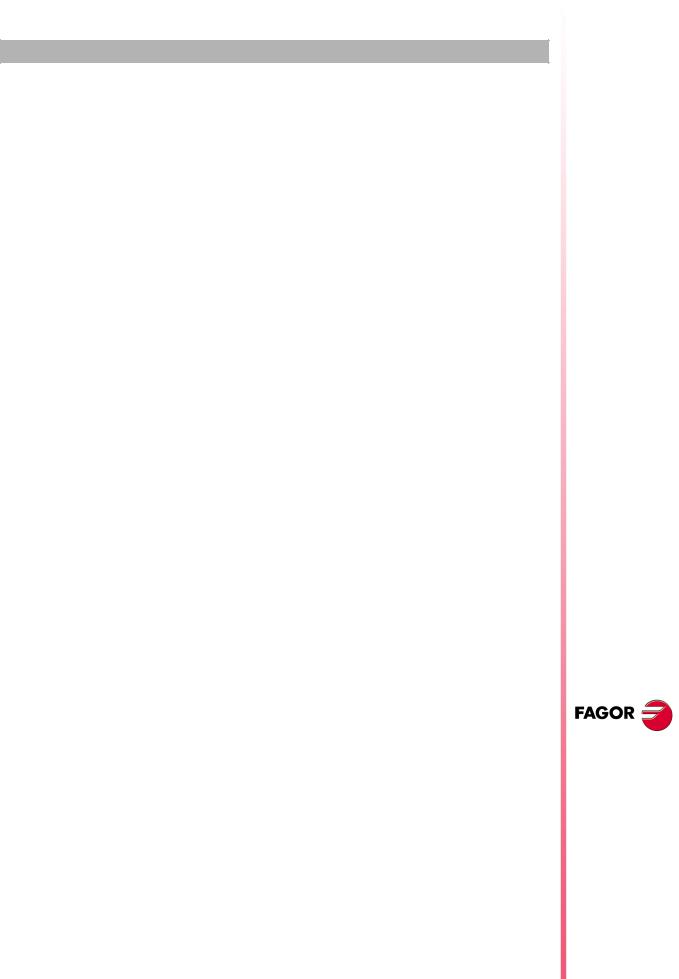

1.1CNC structure

The central unit is located on the rear of the monitor.

1.

CONFIGURATION |

CNC structure |

CNC |

|

CNC 8037

SOFT: V01.4X

Keyboard auto-identification

The keyboard has an auto-identification system. With this system, parameter CUSTOMTY is updated (refreshed) automatically.

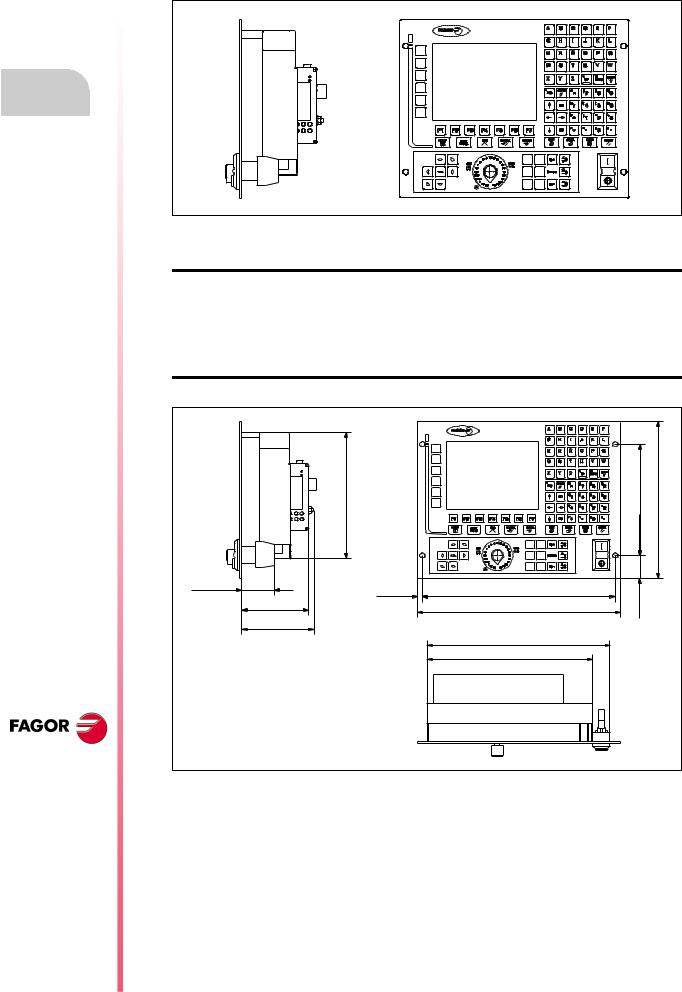

Dimensions |

|

|

|

|

|

222.35 [8.8] |

|

193 [7.6] |

273 [10.7] |

56.3 [2.21] |

8.5 [0.3] |

335 [13.2] |

[1.6] |

|

|

|

|||

115.5 [4.54] |

|

|

|

|

|

352 [13.9] |

40 |

|

|

|

|

|

||

125 [4.92] |

|

|

|

|

|

|

318 [12.51] |

|

|

|

|

287.8 [11.3] |

|

|

·26·

Installation manual

Enclosure |

|

|

|

|

|

335 [13.2] |

|

|

|

6 [ 0.236] |

323 [12.72] |

|

|

|

M5x0.7 |

|

|

|

|

|

[7.6] |

[10.12] |

|

1. |

|

193 |

257 |

CONFIGURATION |

CNC structure |

|

32 [1.26] |

|||

|

|

|||

|

|

|

CNC |

|

The minimum distance from each side of the monitor to its enclosure in order to guarantee the required ambient conditions is shown below:

180 [7.087] |

50 [1.968] |

50 [1.968] |

|

50 [1.968] |

|

|

50 [1.968] |

|

It is up to the installer to make sure that the enclosure has forced ventilation or ventilation grooves in order to prevent the inside temperature to exceed the specified ambient temperature.

Between 5º C and +50º C (41º F and 122º F)

Relative humidity between 5% and 95% non condensing

When using a fan to better ventilate the enclosure, a DC fan must be used since an AC fan may generate electromagnetic interference resulting in distorted images being displayed by the CRT.

CNC 8037

SOFT: V01.4X

·27·

Installation manual

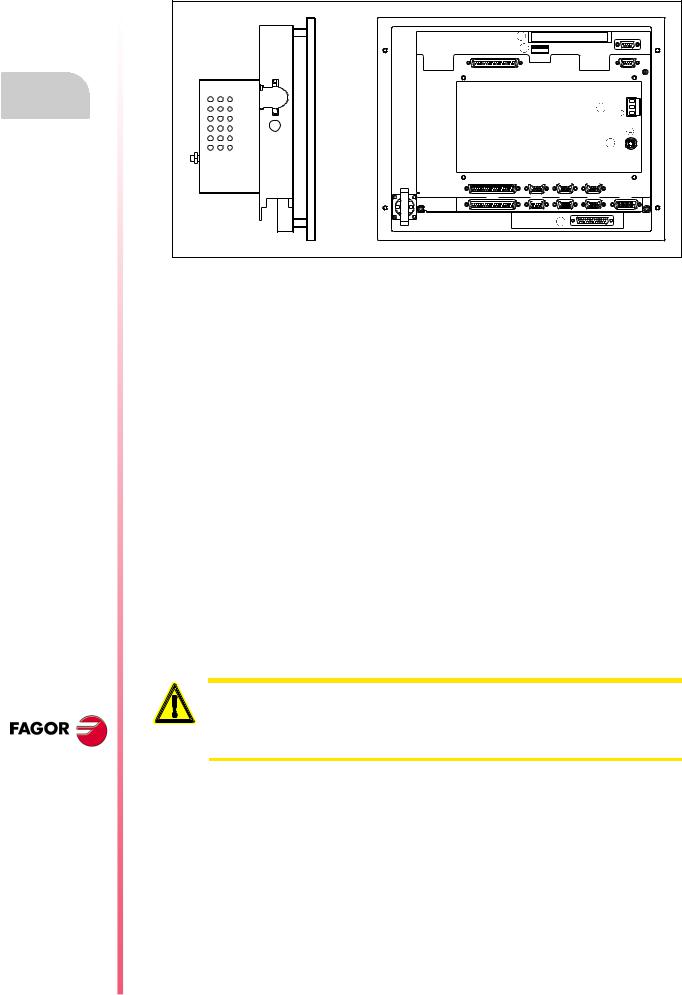

1.1.1Connectors

The connectors are located in the rear of the CNC.

|

|

|

E |

|

|

|

|

|

|

C |

|

|

X1 |

1. |

|

X7 |

|

|

|

X8 |

|

|

|

|

|

||

|

|

|

|

A |

+24V |

|

|

|

|

|

0V |

||

CONFIGURATION |

CNC structure |

F |

|

|

|

|

|

|

|

|

B |

||

X9 |

X10 |

X11 |

X12 |

|

||

X2 |

X3 |

X4 |

X5 |

X6 |

||

|

|

D |

|

|

||

CNC |

|

|

|

|

|

|

(A) |

Power supply. |

|

|

(B) |

Ground connection. |

|

|

(C) |

To connect the USB hard disk (Pen Drive) or USB extension cable. |

|

|

(D) |

To connect the keyboard signal. |

|

|

(E) |

Communications board |

|

|

(F) |

Compact flash memory with the CNC configuration (KeyCF). |

|

|

X1 |

For RS232 serial line connection. |

|

|

X2 |

For digital I/O connection (I1 through I16 and O1 through O8). |

|

|

X3 |

For probe connection. |

|

|

X4 |

For analog spindle connection. |

|

|

X5 |

For electronic handwheel connection. |

|

|

X6 |

For Operator Panel connection. |

|

|

X7 |

For digital I/O connection (I97 to I104 and O33 to O56). |

|

|

X8 |

For axis velocity command connection. |

|

|

X9 |

For digital input connection (I65 to I96). |

|

|

X10 |

For feedback connection of the first axis. |

|

|

X11 |

For feedback connection of the second axis. |

|

|

X12 |

For feedback connection of the third axis. |

|

|

Do not get into the inside of the unit. Only authorized personnel from Fagor Automation may do it. Do not handle the connectors with the unit connected to main AC power. Before manipulating these connectors, make sure that the unit is not connected to main AC power.

The machine manufacturer must comply with the EN 60204-1 (IEC-204-1) standard in terms of protection against electrical shock due to faulty I/O contacts with external power supply.

CNC 8037

SOFT: V01.4X

·28·

Installation manual

Protection at the connectors

It detects over-currents or short-circuits at the +5 V of the feedback of the handwheels, spindle and probe and it issues the relevant error message.

Besides this, it also detects the 24V of the external supply at the digital outputs.

Hardware protections

The axis board installed in the CNC includes the recognition of the 24V at the inputs and outputs.

Signal adapters

The following signal adapters are available to be used with the feedback inputs.

SA-TTL-TTLD |

Adapter for "Non-differential TTL" to "differential TTL" signals |

SA-FS-P |

Adapter for Fagor sinusoidal signal to Vpp signal. |

Technical characteristics of the feedback inputs

Feedback inputs for the axes and spindle

Power supply consumption of +5 V 1 A (250 mA per axis).

Work levels for differential square signal (axes and spindle).

Maximum frequency: |

1000 kHz. |

Maximum gap between flanks: |

460 ns. |

Phase shift: |

90º ± 20º. |

Vmax in common mode: |

± 7 V. |

Vmax in differential mode: |

± 6 V. |

Hysteresis: |

0.2 V. |

Maximum differential input current: |

3 mA. |

Work levels for non-differential square signal (axes and spindle).

Maximum frequency: |

400 kHz. |

Maximum gap between flanks: |

460 ns. |

Phase shift: |

90º ± 20º. |

High threshold (logic level "1") VIH: |

1,25 V < VIH < 7 V. |

Low threshold (logic level "0") VIL: |

-7 V < VIL < 1 V. |

Vmax: |

± 7 V. |

Hysteresis: |

0.25 V. |

Maximum differential input current: |

3 mA. |

1.

CONFIGURATION |

CNC structure |

CNC |

|

CNC 8037

SOFT: V01.4X

·29·

1.

CONFIGURATION |

CNC structure |

CNC |

|

CNC 8037

SOFT: V01.4X

Installation manual

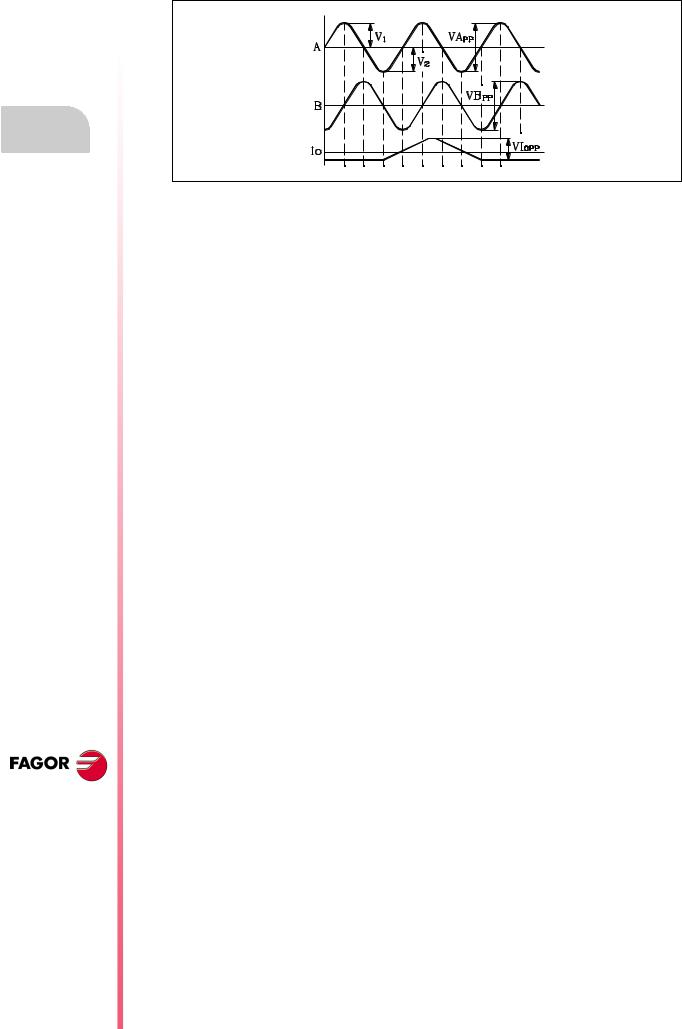

Work levels for sinusoidal signal (only for axes).

Maximum frequency 500 kHz.

A and B signals Amplitude: 0.6 ÷ 1.2 Vpp

Centered: |V1-V2| / 2 Vpp =< 6,5%

Relationship: VApp / VBpp = 0.8 ÷ 1.25

Phase shift: 90º ± 10º

Reference mark (I0) Amplitude: 0.2 ÷ 0.85 V

Width: T-90º =< I0 =< T+180º

Feedback input for the handwheels

Power supply consumption of +5 V 1 A (250 mA per axis).

Work levels for differential square signal.

Maximum frequency: |

400 kHz. |

Maximum gap between flanks: |

460 ns. |

Phase shift: |

90º ± 20º. |

Vmax in common mode: |

± 7 V. |

Vmax in differential mode: |

± 6 V. |

Hysteresis: |

0.2 V. |

Maximum differential input current: |

3 mA. |

Work levels for non-differential square signal.

Maximum frequency: |

400 kHz. |

Maximum gap between flanks: |

460 ns. |

Phase shift: |

90º ± 20º. |

High threshold (logic level "1") VIH: |

1,25 V < VIH < 7 V. |

Low threshold (logic level "0") VIL: |

-7 V < VIL < 1 V. |

Vmax: |

± 7 V. |

Hysteresis: |

0.25 V. |

Maximum differential input current: |

3 mA. |

·30·

Loading...

Loading...