Denon DN-V500BD Service Manual

Ver. 1

Ver. 1

SERVICE MANUAL

MODEL |

JP E3 E2 EK E2A E2C E1K EUT |

DN-V500BD 3

BLU-RAY DISC/DVD VIDEO PLAYER

●For purposes of improvement, specifications and design are subject to change without notice.

●Please use this service manual with referring to the operating instructions without fail.

●Some illustrations using in this service manual are slightly different from the actual set.

PROFESSIONAL BUSINESS COMPANY

X0460 V.01 DE/CDM 0909

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis resistance check. if the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the unit is defective.

LASER RADIATON

Caition - Class 1M visible and invisible laser radiation when open.

Do not view directly optical instruments.

CAUTION Please heed he points listed below during servicing and inspection.

Heed the cautions!

Spots requiring particular attention when servicing, such as the cabinet, parts, chassis,etc., have cautions indicated on labels. be sure to heed these causions and the cautions indicated in the handling instructions.

Caution concerning electric shock!

(1)An AC voltage is impressed on this set, so touching internal metal parts when the set is energized could cause electric shock. Take care to avoid electric shock, by for example using an isolating transformer and gloves when servicing while the set is energized, unplugging the power cord when replacing parts, etc.

(2)Tere are high voltage parts inside. Handle with extra care when the set is energized.

Caution concerning disassembly and

assembly!

Through great care is taken when manufacturing parts from sheet metal, there may in some rare cases be burrs

RQ WKH HGJHV RI SDUWV ZKLFK FRXOG FDXVH LQMXU\ LI ¿QJHUV are moved across them. Use gloves to protect your hands.

Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been serviced have been negatively affected, conduct an inslation check on the external metal connectors and between the blades of the power plug, and otherwise check that safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect the antenna, plugs, etc., and turn the power switch on. Using a 500V insulation resistance tester, check that the inplug and the externally exposed metal parts (antenna terminal, headphones terminal, input terminal, etc.) is

0ȍ RU JUHDWHU ,I LW LV OHVV WKH VHW PXVW EH LQVSHFWHG DQG repaired.

CAUTION Concerning important safety parts

Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be sure to use parts which have the same poroperties. In particular, for the important safety parts that are marked z on wiring diagrams and parts lists, be sure to use the designated parts.

Be sure to mount parts and arrange the wires

as they were originally!

For safety seasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from the surface of printed circuit boards. Care is also taken with the positions of the wores omsode amd clamps are used to keep wires away from heating and high voltage parts, so be sure to set everything back as it was originally.

Many of the electric and structural parts used in the set have special safety properties. In most cases these properties are difficult to distinguish by sight, and using replacement parts with higher ratings (rated power and withstand voltage) does not necessarily guarantee that safety performance will be poreserved. Parts with safety properties are indicated as shown below on the wiring diagrams and parts lists is this service manual. Be sure to replace them with parts with the designated part number.

(1)Schematic diagrams ......Indicated by the z mark.

(2)Parts lists ......Indicated by the z mark.

Using parts other than the designated

SDUWV FRXOG UHVXOW LQ HOHFWULF VKRFN ¿UHV or other dangerous situations.

2 DN-V500BD

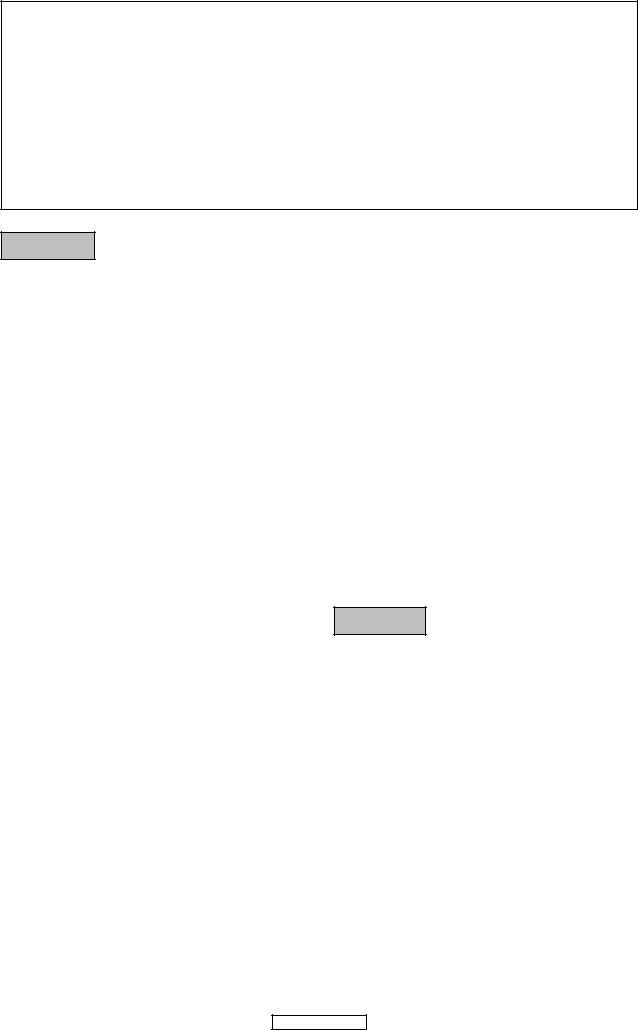

%JNFOTJPO

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 DN-V500BD

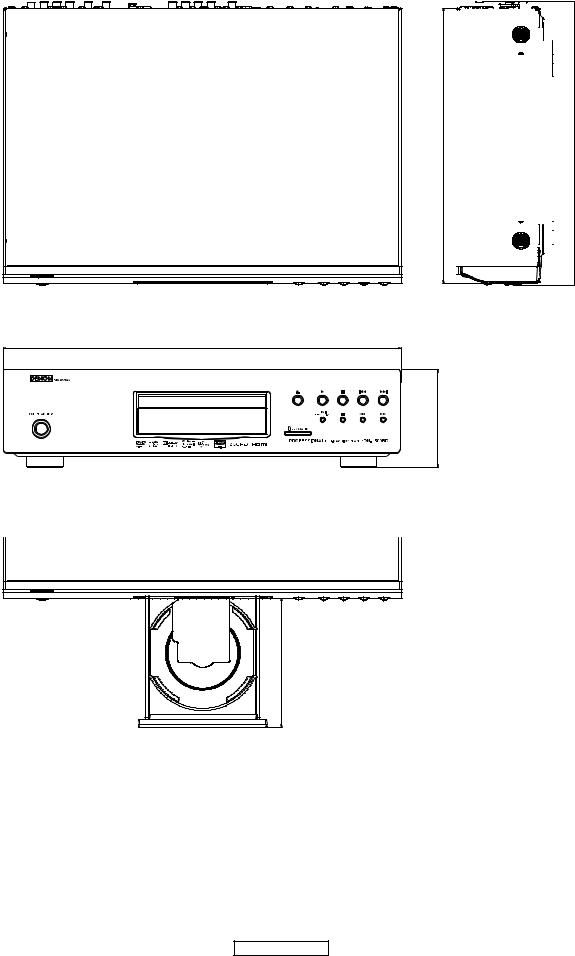

WIRE ARRANGEMENT

If wire bundles are untied or moved to perform adjustment or parts replacement etc., be sure to rearrange them neatly as they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

Wire arrangement viewed from the top

4 DN-V500BD

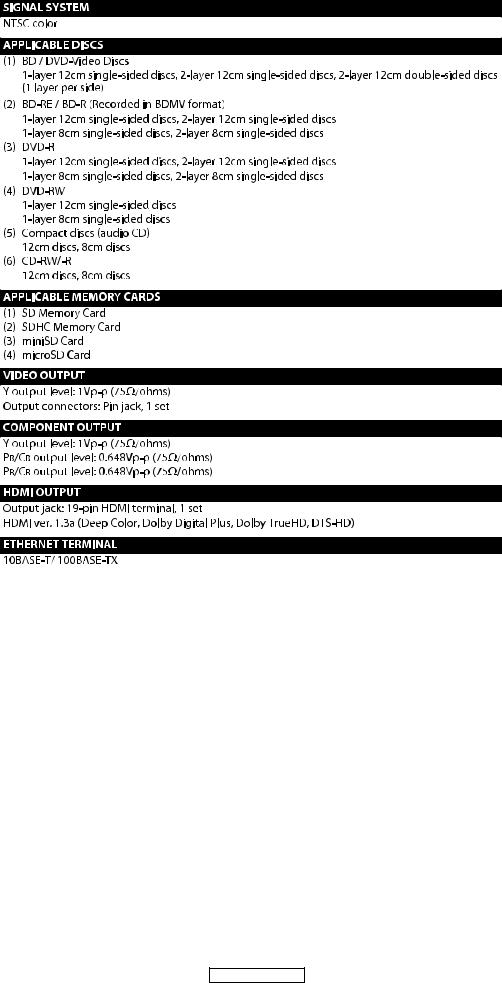

SPECIFICATIONS

5 DN-V500BD

(Standby: 0.8W, Power saving: 0.75W)

(Standby: 0.8W, Power saving: 0.75W)

4.8kg (10.6lbs)

6 DN-V500BD

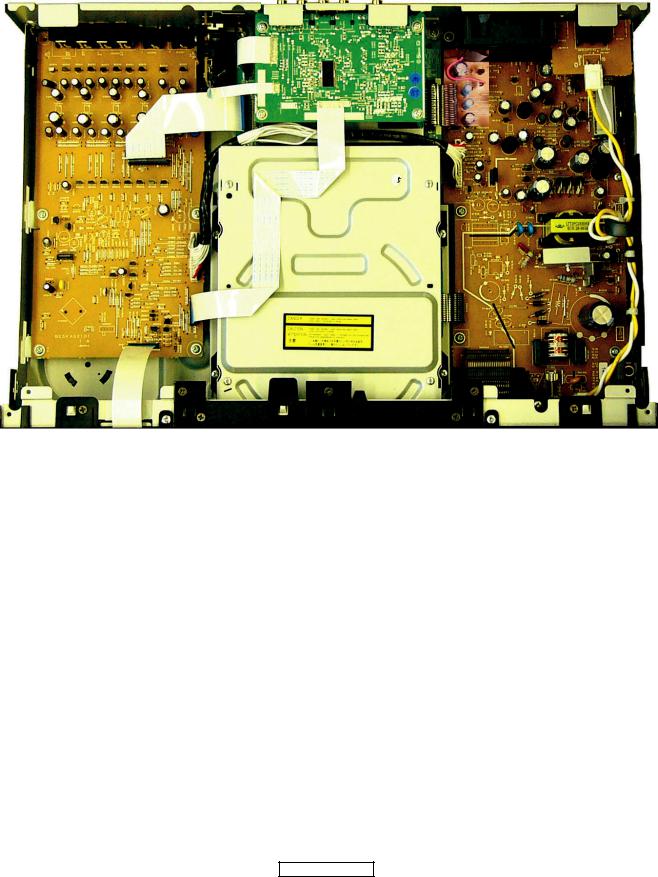

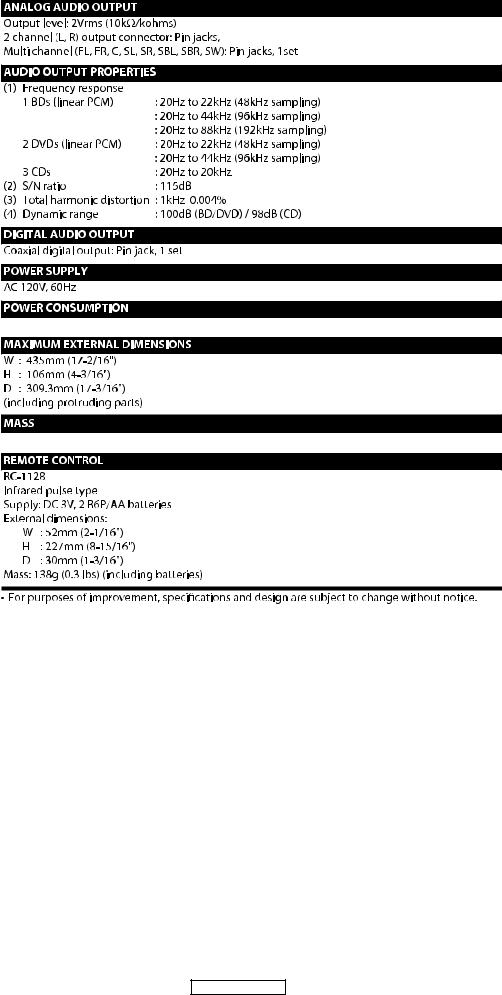

LASER BEAM SAFETY PRECAUTIONS

This BD player uses a pickup that emits a laser beam.

Do not look directly at the laser beam coming from the pickup or allow it to strike against your skin.

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep your eyes at least 30 cm away from the pickup lens when the diode is turned on. Do not look directly at the laser beam.

CAUTION: Use of controls and adjustments, or doing procedures other than those specified herein, may result in hazardous radiation exposure.

Drive Mechanism Assembly

Laser Beam Radiation

Laser Pickup

Turntable

Location: Inside Top of BD mechanism.

7 DN-V500BD

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts, and wires have been returned to their original positions. Afterwards, do the following tests and confirm the specified values to verify compliance with safety standards.

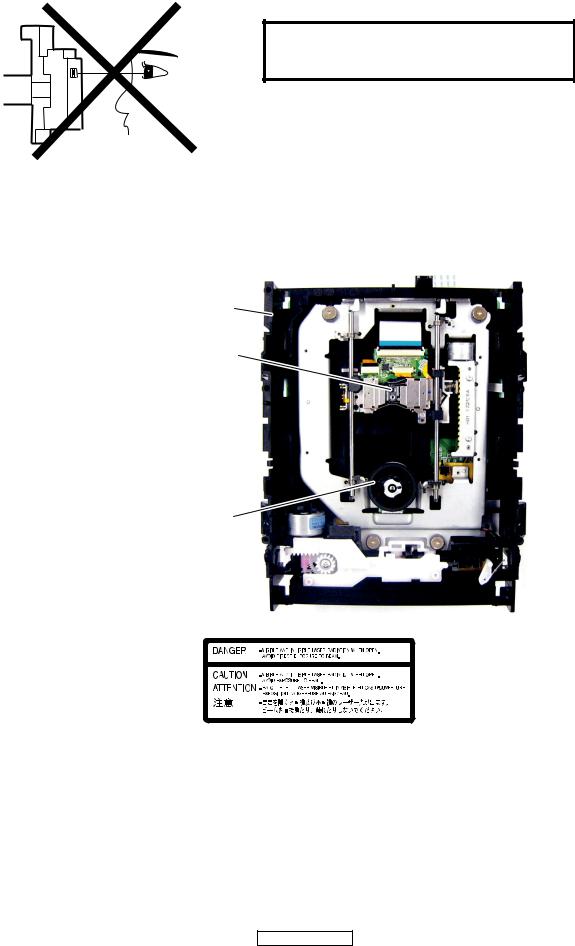

1. Clearance Distance

When replacing primary circuit components, confirm |

|

|

||

specified clearance distance (d) and (d’) between |

Chassis or Secondary Conductor |

|||

soldered terminals, and between terminals and |

||||

|

|

|||

surrounding metallic parts. (See Fig. 1) |

|

|

||

Table 1: Ratings for selected area |

|

Primary Circuit |

||

|

|

|||

AC Line Voltage |

Clearance Distance (d), (d’) |

d' |

d |

|

120 V |

t3mm(d) |

|

|

|

t4mm(d’) |

|

|

||

|

|

|

||

Note: This table is unofficial and for reference only. Be |

|

|

||

sure to confirm the precise values. |

|

|

||

|

|

|

Fig. 1 |

|

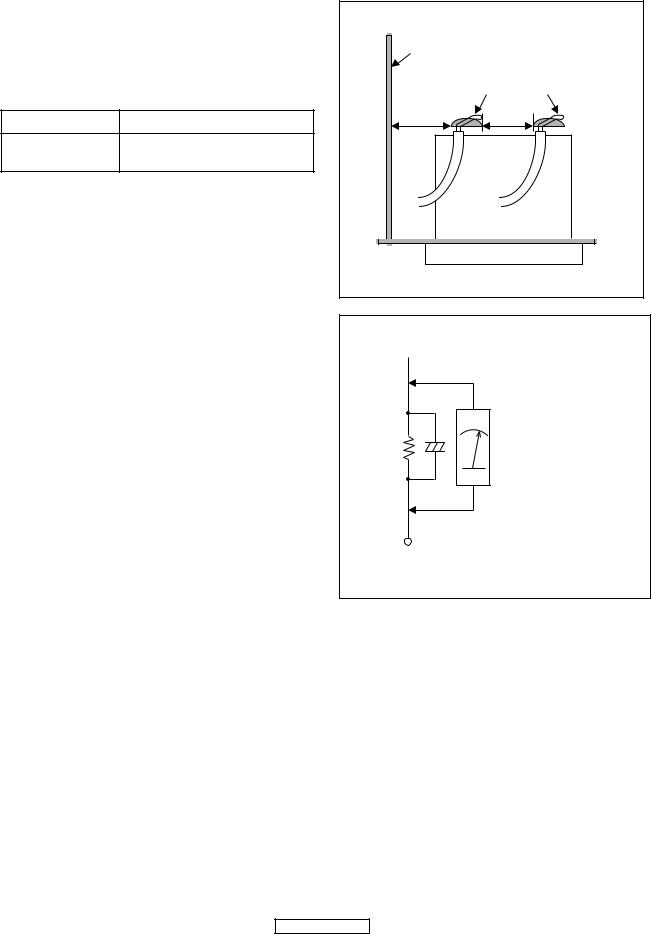

2. Leakage Current Test

Confirm the specified (or lower) leakage current between B (earth ground, power cord plug prongs) and externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks, etc.) is lower than or equal to the specified value in the table below.

Measuring Method (Power ON):

Insert load Z between B (earth ground, power cord plug prongs) and exposed accessible parts. Use an AC voltmeter to measure across the terminals of load Z. See Fig. 2 and the following table.

Table 2: Leakage current ratings for selected areas

Exposed Accessible Part

Exposed Accessible Part

Z |

AC Voltmeter |

|

(High Impedance) |

||

|

BOne side of

Power Cord Plug Prongs

Fig. 2

AC Line Voltage |

Load Z |

Leakage Current (i) |

One side of power cord plug |

|

prongs (B) to: |

||||

|

|

|

||

|

|

|

|

|

|

2k: RES. |

id0.7mA AC Peak |

RF or |

|

|

Connected in |

|||

|

id2mA DC |

Antenna terminals |

||

|

parallel |

|||

120 V |

|

|

||

|

|

|

||

50k: RES. |

id0.7mA AC Peak |

|

||

|

|

|||

|

Connected in |

A/V Input, Output |

||

|

id2mA DC |

|||

|

parallel |

|

||

|

|

|

||

|

|

|

|

Note:This table is unofficial and for reference only. Be sure to confirm the precise values.

8 DN-V500BD

STANDARD NOTES FOR SERVICING

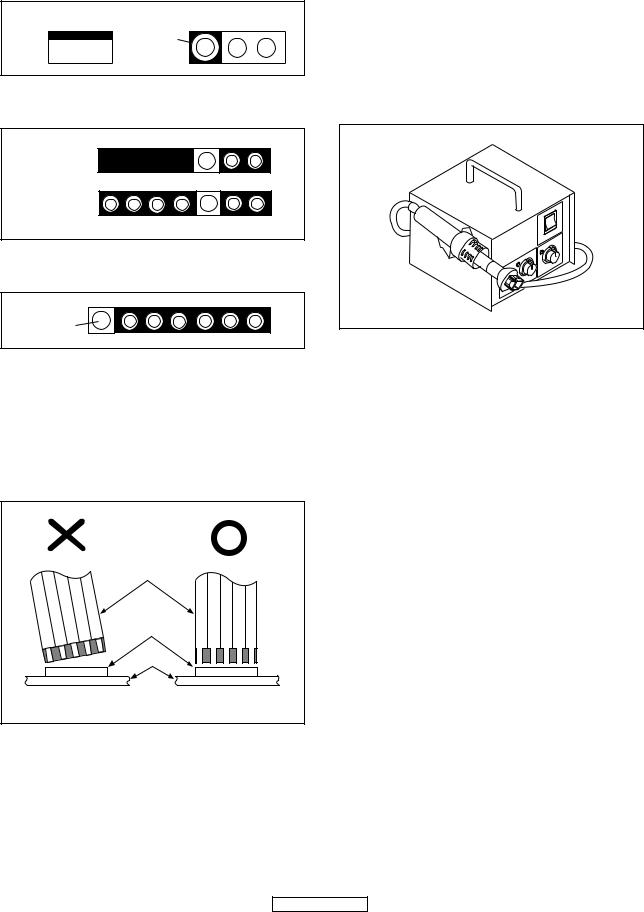

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is indicated as shown.

Top View |

Bottom View |

Out |

Input |

In |

2. For other ICs, pin 1 and every fifth pin are indicated as shown.

5

Pin 1

10

3. The 1st pin of every male connector is indicated as shown.

Pin 1

Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible Foil Connector) cable, be sure to first disconnect the AC cord.

2. FFC (Flexible Foil Connector) cable should be inserted parallel into the connector, not at an angle.

FFC Cable

Connector

CBA

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

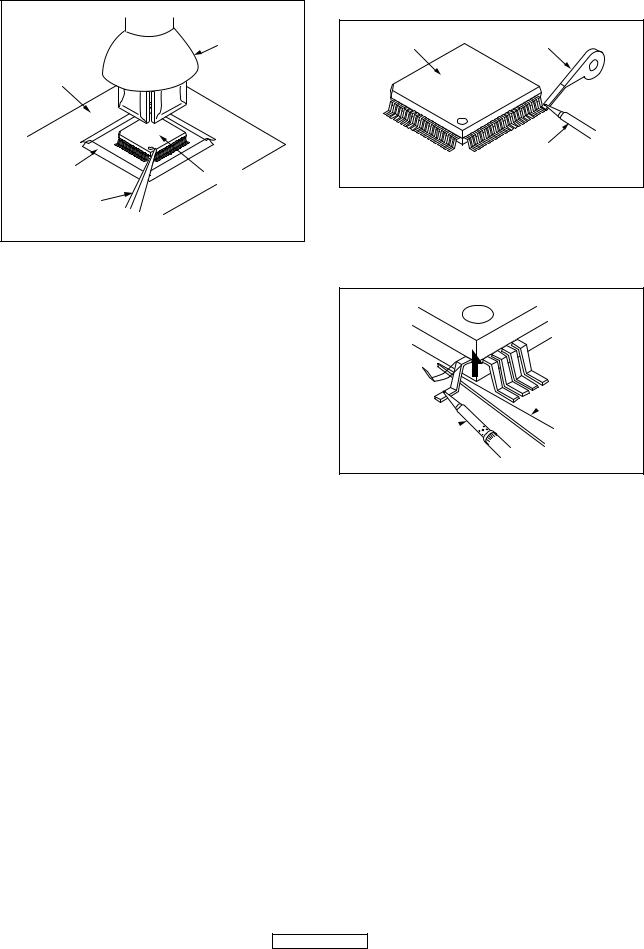

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering machine, then apply hot air to the Flat Pack-IC (about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

2. Remove the flat pack-IC with tweezers while applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the CBA; when removing entire flat pack-IC, first apply soldering iron to center of the flat pack-IC and heat up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using tweezers. (Fig. S-1-6)

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use an appropriate hot-air flat pack-IC desoldering machine, whose shape matches that of the Flat Pack-IC.

2. Do not supply hot air to the chip parts around the flat pack-IC for over 6 seconds because damage to the chip parts may occur. Put masking tape around the flat pack-IC to protect other parts from damage. (Fig. S-1-2)

* Be careful to avoid a short circuit.

9 DN-V500BD

3. The flat pack-IC on the CBA is affixed with glue, so be careful not to break or damage the foil of each pin or the solder lands under the IC when removing it.

|

Hot-air |

|

Flat Pack-IC |

|

Desoldering |

CBA |

Machine |

|

|

Masking |

Flat Pack-IC |

Tape |

|

Tweezers |

|

|

Fig. S-1-2 |

With Soldering Iron:

1. Using desoldering braid, remove the solder from all pins of the flat pack-IC. When you use solder flux which is applied to all pins of the flat pack-IC, you can remove it easily. (Fig. S-1-3)

Flat Pack-IC |

Desoldering Braid |

|

Soldering Iron

Fig. S-1-3

2. Lift each lead of the flat pack-IC upward one by one, using a sharp pin or wire to which solder will not adhere (iron wire). When heating the pins, use a fine tip soldering iron or a hot air desoldering machine. (Fig. S-1-4)

Sharp

Pin

Pin

Fine Tip

Soldering Iron

Fig. S-1-4

3. Bottom of the flat pack-IC is fixed with glue to the CBA; when removing entire flat pack-IC, first apply soldering iron to center of the flat pack-IC and heat up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using tweezers. (Fig. S-1-6)

10 DN-V500BD

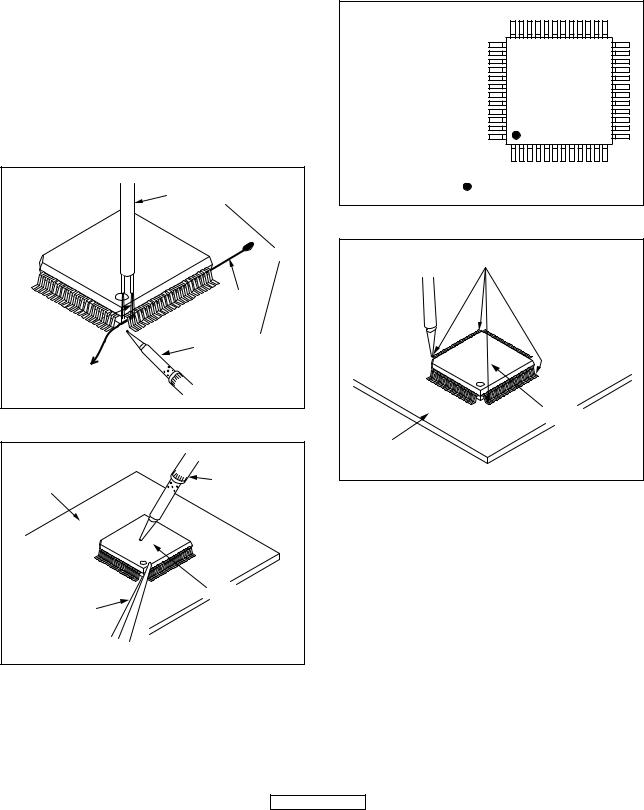

With Iron Wire:

1. Using desoldering braid, remove the solder from all pins of the flat pack-IC. When you use solder flux which is applied to all pins of the flat pack-IC, you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering iron or hot air blower, pull up the wire as the solder melts so as to lift the IC leads from the CBA contact pads as shown in Fig. S-1-5.

4. Bottom of the flat pack-IC is fixed with glue to the CBA; when removing entire flat pack-IC, first apply soldering iron to center of the flat pack-IC and heat up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be taken to ensure that the flat pack-IC is not being held by glue. When the flat pack-IC is removed from the CBA, handle it gently because it may be damaged if force is applied.

Hot Air Blower |

or |

Iron Wire |

Soldering Iron |

To Solid |

Mounting Point |

Fig. S-1-5 |

CBA |

Fine Tip |

Soldering Iron |

|

|

Flat Pack-IC |

Tweezers |

|

|

Fig. S-1-6 |

2. Installation

1. Using desoldering braid, remove the solder from the foil of each pin of the flat pack-IC on the CBA so you can install a replacement flat pack-IC more easily.

2. The “●” mark on the flat pack-IC indicates pin 1. (See Fig. S-1-7.) Be sure this mark matches the pin 1 on the PCB when positioning for installation. Then presolder the four corners of the flat pack-IC. (See Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that none of the pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC |

|

is indicated by a " " mark. |

Fig. S-1-7 |

|

|

Presolder |

|

|

Flat Pack-IC |

CBA |

|

|

Fig. S-1-8 |

11 DN-V500BD

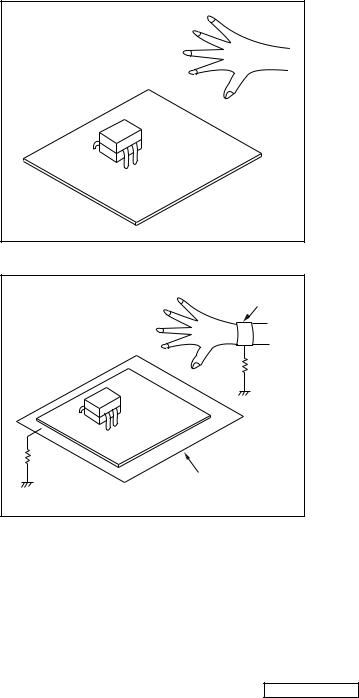

Instructions for Handling Semiconductors

Electrostatic breakdown of the semi-conductors may occur due to a potential difference caused by electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 M:) that is properly grounded to remove any static electricity that may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate with proper grounding (1 M:) on the workbench or other surface, where the semi-conductors are to be placed. Because the static electricity charge on clothing will not escape through the body grounding band, be careful to avoid contacting semi-conductors with your clothing.

<Incorrect> |

|

|

CBA |

<Correct> |

Grounding Band |

|

1MΩ |

|

CBA |

1MΩ |

|

Conductive Sheet or

Copper Plate

12 DN-V500BD

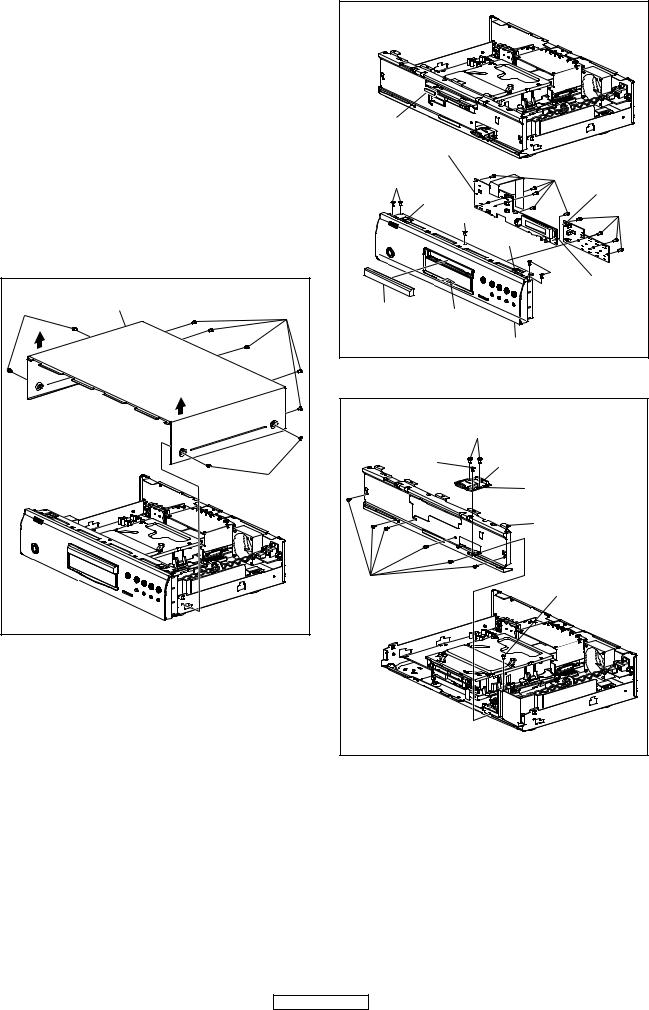

CABINET DISASSEMBLY INSTRUCTIONS

1. Disassembly Flowchart

This flowchart indicates the disassembly steps to gain access to item(s) to be serviced. When reassembling, follow the steps in reverse order. Bend, route, and dress the cables as they were originally.

|

|

|

|

|

[1] Top Cover |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

[2] Tray Panel |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[5] Front B CBA |

|

|

[3] Front |

|

|

|

|

[4] Front A CBA |

|

||||||

|

|

Assembly |

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[6] Front Bracket |

|

|

|

|

[9] Motor |

|

||||

|

|

|

|

|

|

|

|

|

DC Fan |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

[11] RS232C |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

[8] Rear Panel |

|

|

|

|

[10] Inlet CBA |

|

||||||||

CBA |

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

[12] Audio CBA |

|

[13] Video CBA |

|

|

|

|

[7] SD CBA |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

[14] AV PCB |

|

|

|

|

[17] Power |

|

||||

|

|

|

|

|

Bracket |

|

|

|

|

Supply CBA |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

[15] BD Main CBA |

|

|

|

[18] Power |

|

||||||

|

|

|

|

& BD Mechanism |

|

|

|

Holder |

|

|

|||||

|

|

|

|

Assembly |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

[16] Loader |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Bracket |

|

|

|

|

|

|

||||

2. Disassembly Method |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ID/ |

|

|

|

|

|

|

Removal |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Remove/*Unhook/ |

|

|

||||||||

Loc. |

|

Part |

|

Fig. |

|

|

|||||||||

|

|

|

Unlock/Release/ |

Note |

|||||||||||

No. |

|

|

|

|

|

||||||||||

|

|

|

|

No. |

|

||||||||||

|

|

|

|

|

Unplug/Desolder |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[1] |

Top Cover |

|

D1 |

9(S-1) |

|

|

--- |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[2] |

Tray Panel |

|

D2 |

--------------- |

|

|

|

1 |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[3] |

Front |

|

D2 |

*2(L-1), *(L-2), 5(S-2), |

2 |

|

|||||||||

|

Assembly |

|

|

9(S-3), *CN2002 |

|

|

|||||||||

[4] |

Front A |

|

D2 |

*CN3001 |

|

|

--- |

|

|||||||

CBA |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[5] |

Front B |

|

D2 |

--------------- |

|

|

|

--- |

|

||||||

CBA |

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[6] |

Front |

|

D3 |

7(S-4), (S-5) |

|

|

--- |

|

|||||||

Bracket |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[7] |

SD CBA |

|

D3 |

2(S-6), *CN5001 |

--- |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5(S-7), (S-8), 2(S-9), |

|

|

|||||||

[8] |

Rear Panel |

|

D4 |

(S-10), (S-11), |

--- |

|

|||||||||

|

11(S-12), 2(S-13), |

|

|||||||||||||

|

|

|

|

|

|

2(S-14), *CN1006 |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[9] |

Motor DC |

|

D4 |

--------------- |

|

|

|

--- |

|

||||||

Fan |

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ID/ |

|

|

Removal |

|

|

|

|

|

|

||

|

|

Remove/*Unhook/ |

|

||

Loc. |

Part |

Fig. |

|

||

Unlock/Release/ |

Note |

||||

No. |

|

No. |

|||

|

Unplug/Desolder |

|

|||

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

[10] |

Inlet CBA |

D4 |

*CN1001 |

--- |

|

|

|

|

|

|

|

[11] |

RS232C |

D4 |

*CN5501 |

|

|

CBA |

|

||||

|

|

|

|

||

|

|

|

|

|

|

[12] |

Audio CBA |

D5 |

5(S-15), *CN2005, |

--- |

|

*CN2007, *CN2008 |

|||||

|

|

|

|

|

|

[13] |

Video CBA |

D6 |

4(S-16), *CN7101 |

--- |

|

|

|

|

|

|

|

[14] |

AV PCB |

D6 |

4(S-17) |

--- |

|

Bracket |

|||||

|

|

|

|

||

|

|

|

|

|

|

|

BD Main |

|

|

|

|

[15] |

CBA & BD |

D6 |

4(S-18), *CN6001, |

3 |

|

Mechanism |

*CN7601 |

||||

|

Assembly |

|

|

|

|

|

|

|

|

|

|

[16] |

Loader |

D6 |

6(S-19) |

--- |

|

Bracket |

|||||

|

|

|

|

||

|

|

|

|

|

|

|

Power |

|

|

|

|

[17] |

Supply |

D7 |

3(S-20), 2(S-21) |

--- |

|

|

CBA |

|

|

|

|

|

|

|

|

|

|

[18] |

Power |

D7 |

3(S-22) |

--- |

|

Holder |

|||||

|

|

|

|

||

|

|

|

|

|

|

p |

p |

p |

p |

p |

|

(1) |

(2) |

(3) |

(4) |

(5) |

Note:

(1)Identification (location) No. of parts in the figures

(2)Name of the part

(3)Figure Number for reference

(4)Identification of parts to be removed, unhooked, unlocked, released, unplugged, unclamped, or desoldered.

P = Spring, L = Locking Tab, S = Screw, CN = Connector

* = Unhook, Unlock, Release, Unplug, or Desolder e.g. 2(S-2) = two Screws (S-2),

2(L-2) = two Locking Tabs (L-2)

(5)Refer to “Reference Notes.”

About tightening screws

When tightening screws, tighten them with the following torque.

Torque

0.45 ± 0.05 N·m

13 DN-V500BD

Reference Note

1. How to remove tray panel

1)Connect the wall plug to an AC outlet and press the [A] button to open the tray.

2)To lift up, the tray panel is removed.

3)Press the [A] button again to close the tray.

4)Press the [ON/STANDBY] button to turn the power off.

5)Unplug an AC cord.

2. CAUTION 1: Locking Tabs (L-1) and (L-2) are fragile. Be careful not to break them.

3. The BD Main CBA & BD Mechanism Assembly is adjusted as a unit at factory. Therefore, do not disassemble it. Replace the BD Main CBA & BD Mechanism Assembly as a unit.

(S-1) |

[1] Top Cover |

(S-1) |

|

|

(S-1) |

|

Fig. D1 |

CN2002 |

|

|

|

[4] Front A CBA |

|

|

|

(S-2) |

(S-3) |

[5] Front B |

|

|

CBA |

||

(L-1) |

|

||

|

|

|

|

|

(S-2) |

|

(S-3) |

|

|

|

|

|

(L-1) |

|

|

|

(S-2) |

CN3001 |

|

|

|

|

|

[2] Tray Panel |

(L-2) |

|

|

|

|

|

|

|

[3] Front Assembly |

Fig. D2 |

|

|

(S-6) |

|

|

(S-5) |

CN5001 |

|

|

[7] SD CBA

[6] Front Bracket

(S-4) |

(S-4) |

|

Fig. D3

14 DN-V500BD

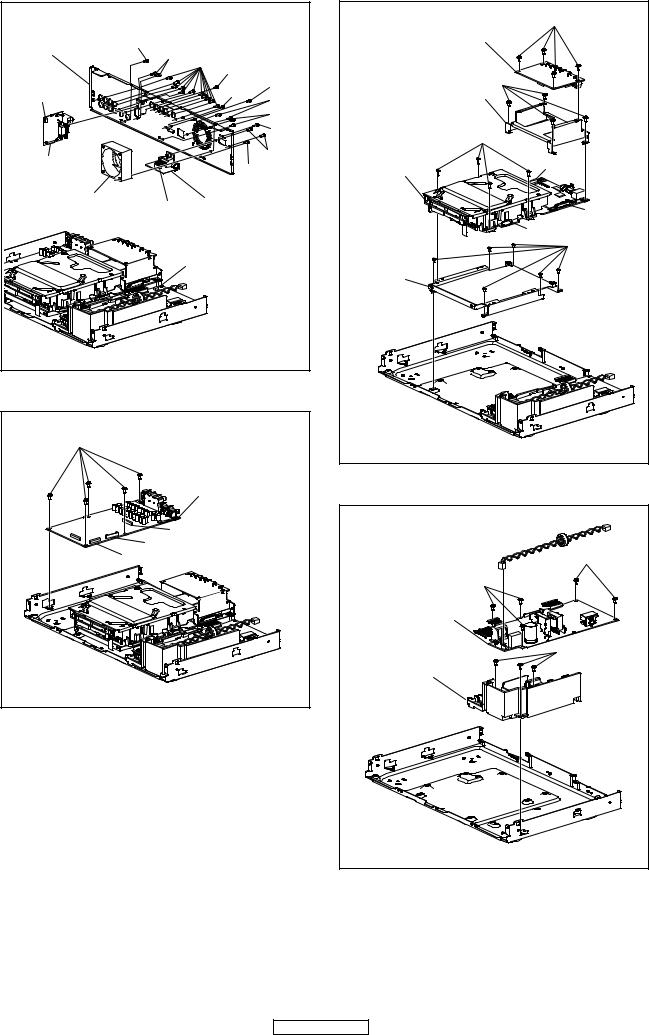

[8] Rear Panel |

(S-7) |

|

|

|

(S-13) |

|

|

|

|

(S-12) |

|

|

|

(S-7) |

|

CN5501 |

|

(S-11) |

(S-10) |

|

(S-14) |

||

|

|

||

|

|

|

|

|

|

|

(S-7) |

|

|

|

(S-8) |

[11] RS232C |

|

|

(S-9) |

|

(S-7) |

||

CBA |

|

||

|

|

|

|

[9] Motor DC Fan |

[10] Inlet CBA |

||

CN1001 |

|

||

|

|

CN1006 |

|

|

|

|

Fig. D4 |

(S-15) |

|

|

|

|

|

[12] Audio CBA |

|

CN2007

CN2008

CN2005

Fig. D5

|

(S-16) |

|

[13] Video CBA |

|

|

(S-17) |

|

|

[14] AV PCB Bracket |

|

|

[15] *BD Main CBA (S-18) |

|

|

& BD Mechanism |

CN7101 |

|

Assembly |

||

|

||

|

CN6001 |

|

|

CN7601 |

|

|

(S-19) |

|

[16] Loader |

|

|

Bracket |

|

|

* See Reference Notes 3. |

Fig. D6 |

|

|

(S-21) |

|

(S-20) |

|

[17] Power Supply

CBA

(S-22)

[18] Power Holder

Fig. D7

15 DN-V500BD

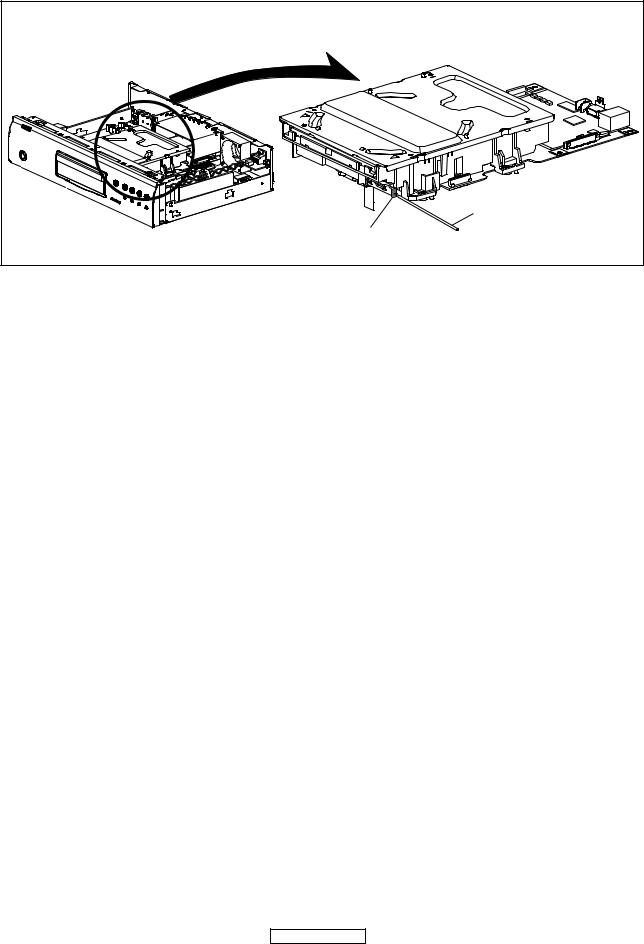

3. How to Eject Manually

1.Remove the Top Cover.

2.Insert a screwdriver, etc. into the straightly so that the Portion A is pushed.

3.Pull the tray out manually and remove a disc.

|

Screwdriver, |

Portion A |

hexagon wrench |

|

16 DN-V500BD

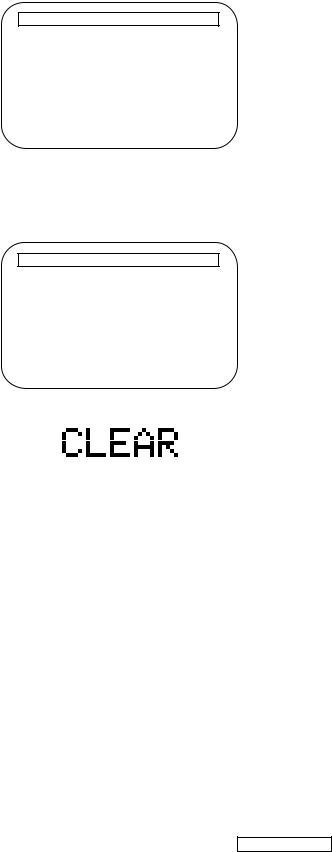

HOW TO INITIALIZE THE BLU-RAY DISC PLAYER

To put the program back at the factory-default, initialize the BD player as the following procedure.

1. Turn the power on.

2. Remove the disc on the tray and close the tray.

3. Press [1], [2], [3], [4], and [DISPLAY] buttons on the remote control unit in that order.

Fig. a appears on the screen.

"*******" differ depending on the models.

Version Info

F/W Name |

: ******* |

Version |

: *.*** |

Region |

: *-* |

EEPROM CLEAR <STOP> EXIT <POWER>

Fig. a

4. Press [ C ] button on the remote control unit. Fig. b appears on the screen and Fig. c appears on the VFD.

"*******" differ depending on the models.

Version Info

F/W Name |

: ******* |

Version |

: *.*** |

Region |

: *-* |

EEPROM CLEAR : OK

EEPROM CLEAR <STOP> EXIT <POWER>

Fig. b

Fig. c

5. To exit this mode, press [POWER OFF] button.

17 DN-V500BD

FIRMWARE RENEWAL MODE

Note: The file extension of the available firmware is “b20”.

1. Turn the power on and remove the disc on the tray and close the tray.

2. To put the BD player into version up mode, press [9], [8], [7], [6], and [POP UP MENU/MENU] buttons on the remote control unit in that order. The tray will open automatically.

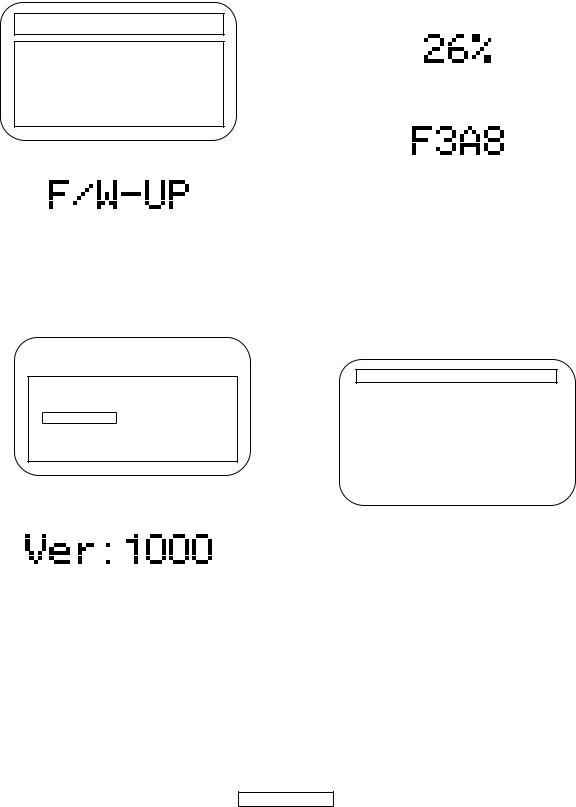

Fig. a appears on the screen and Fig. b appears on the VFD.

"*******" differs depending on the models.

F/W VERSION UP MODE |

F/W Name: ******* Ver. *.*** |

Please insert a Disc

for F/W Version Up

Fig. a Version Up Mode Screen

Fig. b VFD in Version Up Mode

3. Load the disc for version up.

4. The BD player enters the F/W version up mode automatically. Fig. c appears on the screen and Fig. d appears on the VFD. Make sure to insert the proper F/W for the state of this model.

|

|

|

"*******" differs depending on the models. |

||

|

|

F/W VERSION UP MODE |

F/W Name: ******* Ver. *.*** |

|

|

|

|

|

|

|

|

|

|

1. ALL |

|

|

|

|

|

|

Ver. *.*** |

************A*.b20 |

|

(*1) |

|

|

Now Loading... |

|

|

|

|

|

|

||

EXIT : POWER

Fig. c Programming Mode Screen (Example)

The appearance shown in (*1) of Fig. c is described as follows:

No. |

Appearance |

State |

|

|

|

|

|

|

|

|

|

1 |

Now Loading... |

Loading the disc |

|

|

|

|

|

|

|

Sending files into the |

|

2 |

Reading... |

memory. |

|

After reading, automatically |

|||

|

|

||

|

|

the tray opens. |

|

|

|

|

|

|

|

Writing new version data, |

|

3 |

See FL Display |

the progress will be displayed |

|

|

|

as shown in Fig. e. |

|

|

|

|

Fig. e VFD in Vresion Up Mode

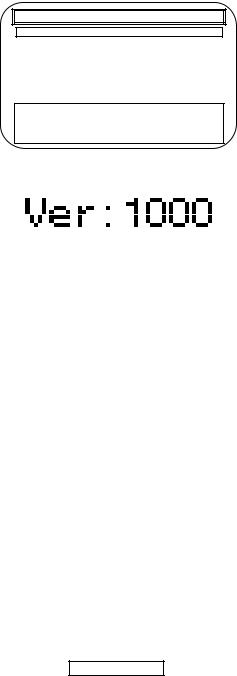

5. After programming is finished, the checksum on the VFD (Fig. f).

Fig. f VFD upon Finishing the Programming Mode (Example)

Checksum appears on the VFD then the tray will open automatically. Remove the disc on the tray.

At this time, no button is available.

6. Unplug the AC cord from the AC outlet. Then plug it again.

7. Turn the power on.

8. Press [1], [2], [3], [4], and [DISPLAY] buttons on the remote control unit in that order.

Fig. g appears on the screen.

"*******" differ depending on the models.

Version Info

F/W Name |

: ******* |

Version |

: *.*** |

Region |

: *-* |

EEPROM CLEAR <STOP> EXIT <POWER>

Fig. g

Fig. d VFD in Programming Mode (Example)

18 DN-V500BD

9.Press [ C ] button on the remote control unit.

Fig. h appears on the screen and Fig. i appears on the VFD.

"*******" differ depending on the models.

Version Info

F/W Name |

: ******* |

Version |

: *.*** |

Region |

: *-* |

EEPROM CLEAR : OK

EEPROM CLEAR <STOP> EXIT <POWER>

Fig. h

Fig. i

To exit this mode, press [POWER OFF] button.

19 DN-V500BD

FIRMWARE RENEWAL MODE (Network Update)

1. Press [SETUP] button on the remote control unit in stop mode.

2. Use [} / O] button to select “CUSTOM”, then press [ENTER] button.

3. Use [} / O] button to select “Other”, then press [ENTER] button.

4. Use [X / Y] button to select “Network Update”, then press [ENTER] button.

Confirmation message will appear.

5. Use [X / Y] button to select “Yes”, then press [ENTER] button.

NOTE:

If any error message concerning the network environment appears, please confirm the setting of your unit according to the error message. If you need to change any of your network environmental setting in order to execute the update, please contact to the internet service provider.

6. Confirmation message will appear.

Use [X / Y] button to select “Yes”, then press [ENTER] button.

The unit will start downloading the latest firmware version.

7. When the download completes, confirmation message will appear.

Press [ENTER] button.

The unit will start updating the firmware version. It may take a while to complete the updating. (Please wait until “100%” appears on the front panel display.)

8. After updating finishes, this unit will restart and open the disc tray automatically.

How to Verify the Firmware Version

1. Turn the power on.

2. Remove the disc on the tray and close the tray.

3. Press [1], [2], [3], [4], and [DISPLAY] buttons on the remote control unit in that order.

Fig. j appears on the screen.

"*******" differ depending on the models. |

||

Version Info |

|

|

F/W Name |

: ******* |

|

Version |

: *.*** |

|

Region |

: *-* |

|

EEPROM CLEAR <STOP> EXIT <POWER>

Fig. j

4. To exit this mode, press [POWER OFF] button.

20 DN-V500BD

SERVICE MODE

Service Mode

|

1st level |

|

2nd level |

|

3rd level |

Description |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

Tray Aging |

|

|

Aging of tray open/close |

|

|

|

|

|

|

|

|

|

1 |

MECHA TEST |

2 |

TOC Read |

|

|

TOC reading |

|

|

|

|

|

|

|||

|

|

3 |

Heat Run |

|

|

Tray close -> TT1 playback -> TT10 |

|

|

|

|

|

playback -> Tray open -> Tray close |

|||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

2 |

VFD/LED TEST |

1 |

All On |

|

|

Turning on all VFD |

|

|

|

|

|

|

|||

2 |

All Off |

|

|

Turning off all VFD |

|||

|

|

|

|

||||

|

|

|

|

|

|

|

|

3 |

ERROR RATE |

|

|

|

|

Displaying Error rate, Jitter |

|

|

|

|

|

during playback |

|||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

1 |

Off |

Turning off LD |

|

|

|

|

|

|

|

|

|

|

|

1 |

LD Power |

2 |

BD |

Turning on BD LD |

|

|

|

|

|

|

|||

4 |

LD TEST |

3 |

DVD |

Turning on DVD LD |

|||

|

|

||||||

|

|

|

|

|

|||

|

|

|

|

4 |

CD |

Turning on CD LD |

|

|

|

|

|

|

|

|

|

|

|

2 |

Operating Time |

|

|

Displaying LD Operation Time (with |

|

|

|

|

|

clear function) |

|||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

1 |

Center/Subwoofer/ |

|

|

|

|

|

|

Front LR |

|

||

|

|

1 |

TEST TONE |

|

|

||

|

|

|

|

|

|||

|

|

2 |

Surround LR/ |

|

|||

|

|

|

|

|

|||

|

|

|

|

Surround Back LR |

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

2 |

Front Lch |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

Center |

|

|

|

|

|

CHANNEL |

|

|

|

|

|

|

5 |

4 |

Front Rch |

|

|

|

||

TEST |

|

|

|

||||

|

5 |

Surround Rch |

|

|

|

||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

6 |

Surround Back |

|

|

|

|

|

|

Rch |

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

7 |

Surround Back Lch |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

Surround Lch |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

Sub woofer |

|

|

|

|

|

|

|

|

|

|

|

|

6 |

SD CARD TEST |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

DEFAULT |

|

|

|

|

Default setting |

|

SETTING |

|

|

|

|

|||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

Note: If some test are performed continuously, any error will occur |

|

||||||

21 DN-V500BD

Entering Service Mode

In power on condition, no discs and tray close, it will be entered into service mode by the following operation using the remote controller. However, it will not be entered when Media Select Item is SD Memory.

Service Mode by using remote controller

Press the following buttons on the remote controller in power on condition, no discs and tray close;

[2]->[5]->[8]->[0]->[CLEAR]

Release from Service Mode

Press the [POWER OFF] button to turn off power.

Screen saver/Auto Power Off in Service Mode

These functions are not performed in Service Mode.

After entering, Fig. k appears on the screen and Fig. l appears on the VFD.

*Firmware Version differs depending on the models, and this indication is one example.

SERVICE MODE

1:MECHA TEST

2:VFD/LED TEST

3:ERROR RATE MEASURE

4:LD TEST

5:CHANNEL TEST

6:SD CARD TEST

7:DEFAULT SETTING

F/W Name |

:******* |

Region |

:*-* |

Release Ver. |

:*.*** |

|

|

ADSP1/2 Ver. :---/--- |

PLD Ver. |

:--- |

|

FPGA Ver. |

:--- |

I/P Scaler Ver.:--- |

|

Fig. k Service Mode (Main Menu)

|

|

Fig. I Service Mode |

Available button in service mode |

||

|

|

|

|

Button |

condition |

|

|

|

|

|

|

|

ENTER |

Enter the next level |

|

|

|

|

POWER |

Turn the power off (when the service mode is completed) |

|

|

|

|

1~7 |

Enter the selected item (next level) |

|

|

|

|

OTHER |

Not available |

|

|

|

Note: Press the number key to select items. Or, press the cursor button (up/down) to select items and press [ENTER] button.

INDICATION |

DESCRIPTION |

REMARK |

|

|

|

|

|

|

F/W Name |

Model Name |

E5K***D, etc. |

|

|

|

Region |

BD region - DVD region |

A-1, etc. |

|

|

|

Release Ver. |

Release version |

D.jpp, etc. |

|

|

|

22 DN-V500BD

Loading...

Loading...