Bosch MDCI8-1, MDCI10-1, MDCI12-1, MDCI14-1, MDCI16-1 Installation Manual

Installation manual

6 720 874 421 (2017/04) ZA

Before using your air conditioning unit, please read this manual carefully and keep it for future reference.

Mini VRF Heat Pump Outdoor Unit

Climate 5000 VRF

MDCI series, SINGLE PHASE

6 720 874 421 (2017/04) ZA Mini VRF Heat Pump Outdoor Unit

2 | PRECAUTIONS

1. PRECAUTIONS

■ Before installing this equipment, ensure all local and national

regulations are complied with.

■ Read these ”PRECAUTIONS” carefully prior to Installation.

■ Before performing maintenance ensure the electrical power

circuit has been turned off. Failure to do so will result in serious

injury.

■ Ensure both the installation manual and the owners manual are

kept together and handed to the customer upon completion.

CAUTION

New Refrigerant Air Conditioner Installation

CAUTION

An all-pole disconnection device which has at least 3 mm separation

distance in all poles and a residual current device (RCD) shall be

incorporated into the fixed wiring in accordance with national wiring

regulations.

WARNING

The appliance shall be installed in accordance with national wiring

regulations.

When installing, ensure communication and electrical power supply

cables do not touch the copper pipework.

The temperature of the refrigeration circuit will be high and may damage

cables.

An all-pole disconnection device which has at least 3 mm separation

distance between all poles and a residual current device(RCD)with the

rating of above 10 mA shall be incorporated in the fixed wiring according

to the national regulations.

Ensure only qualified persons carry out works on this equipment.

Incorrect installation may result in can damage or serious injury.

Do not modify this unit by removing any of the safety guards or bypassing any of the safety interlock switches.

Exposing the unit to water or other moisture before installation may

cause a short-circuit on the electrical components.

Do not store the unit where it can be exposed to water or moisture.

After unpacking, ensure you inspect the unit for damage.

When installing this equipment, anti vibration pads must be installed to

stop vibration.

To avoid personal injury (with sharp edges), care must be taken when

handling components.

Installation of the unit must be done as per the instructions set in this

installation manual.

Incorrect installation may result in component failure, damage to property

or injury.

When the air conditioning unit is installed in a small room, provide

appropriate measures to ensure that the concentration of refrigerant

leakage in the room does not exceed the thickness level should a leak

occur.

Install the air conditioning unit securely in a location where the base can

sustain the weight adequately.

If refrigerant gas has leaked during the installation work, ventilate the

room immediately.

If the leaked refrigerant gas comes in contact with a naked flame, noxious gas

may be generated..

After installation is complete, ensure a satisfactory strength/tightness

test has been performed to ensure there is no refrigerant gas leakage.

Electrical work must be performed by a qualified electrician in

accordance with the Installation Manual.

Ensure equipment is grounded.

Do not connect ground wires to gas pipes, water pipes, lightning rods or

ground wires for telephone cables.

Conform with national wiring standards.

Inappropriate grounding may cause electric shock.

Do not install the air conditioner in a location where it is at a risk of

exposure to a combustible gas.

CONTENTS PAGE

1. PRECAUTIONS .................................................................... 2

2. ATTACHED FITTINGS ........................................................... 3

3. OUTDOOR UNIT INSTALLATION ............................................ 3

4. INSTALLING THE CONNECTIVE PIPEWORK ............................5

5. ELECTRICAL WIRING ........................................................... 9

6. TEST RUNNING ................................................................. 12

7. PRECAUTIONS ON REFRIGERANT LEAKAGE ........................ 12

Mini VRF Heat Pump Outdoor Unit 6 720 874 421 (2017/04) ZA

ATTACHED FITTINGS | 3

2. ATTACHED FITTINGS

Ensure all fittings are supplied with unit prior to installation.

NAME SHAPE QUANTITY

INSTALLATION FITTINGS

1. Outdoor unit installation manual 1

2. Outdoor unit owner’s manual 1

3. Indoor unit owner’s manual 1

4. Outflow connecting tube 1

CAUTION

■ Install the unit so that its discharge port faces to the wall of the

building. Keep a distance of 2000 mm or more between the unit and

the wall surface.

2000

Fig. 2-1

Strong

wind

Strong

wind

Fig. 2-2

■ Do not install the unit in the following locations as component failure

will occur.

• Where machine oil is present.

• Where sulphuric acid is present.

• Where high frequency radio waves are likely to be generated.

3. OUTDOOR UNIT INSTALLATION

3.1 Installation location

The following locations may cause component failure.

• Where there is a combustible gas leakage.

• Where there is oil surrounding.

• Where there is salty air surrounding.

• Where there is caustic gas (the sulfide, for example) existing in

the air.

• A location where discharge air will affect others.

• A location where noise affects neighbors.

• A location that is too weak to bear the weight of the unit.

• A location which is uneven.

• A location where there is insufficient ventilation.

• Near a private power station or high Frequency equipment.

• A location where the indoor/outdoor unit, power cord and

connecting wires are less than 1m away from a tv or radio.

• Installing the unit where there is insufficient maintenance access.

CAUTION

Keep the indoor and outdoor power supply wiring and communication

wiring at least 1 meter away from televisions and radios. This is to

prevent image and noise interference. In certain circumstances, 1m

may not be sufficient.

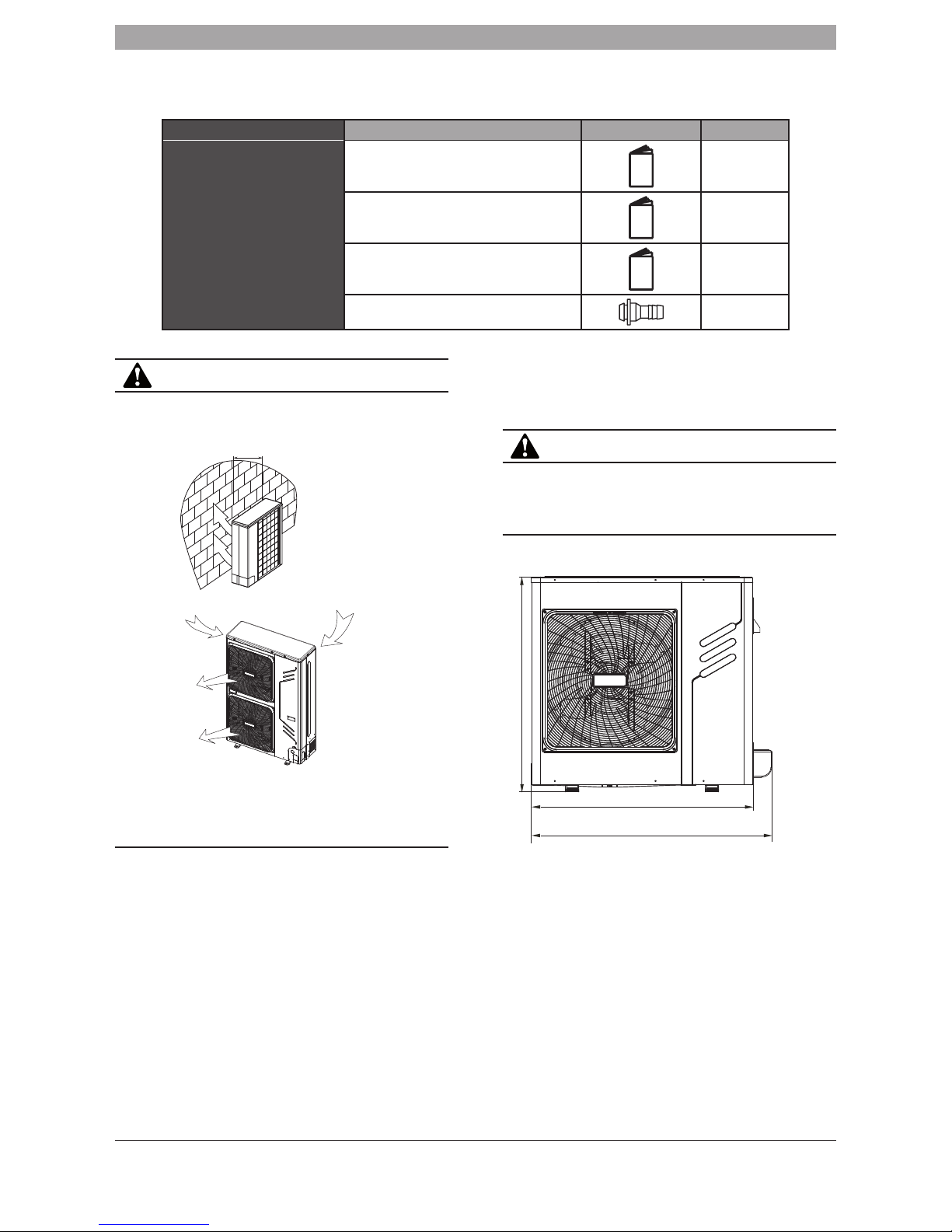

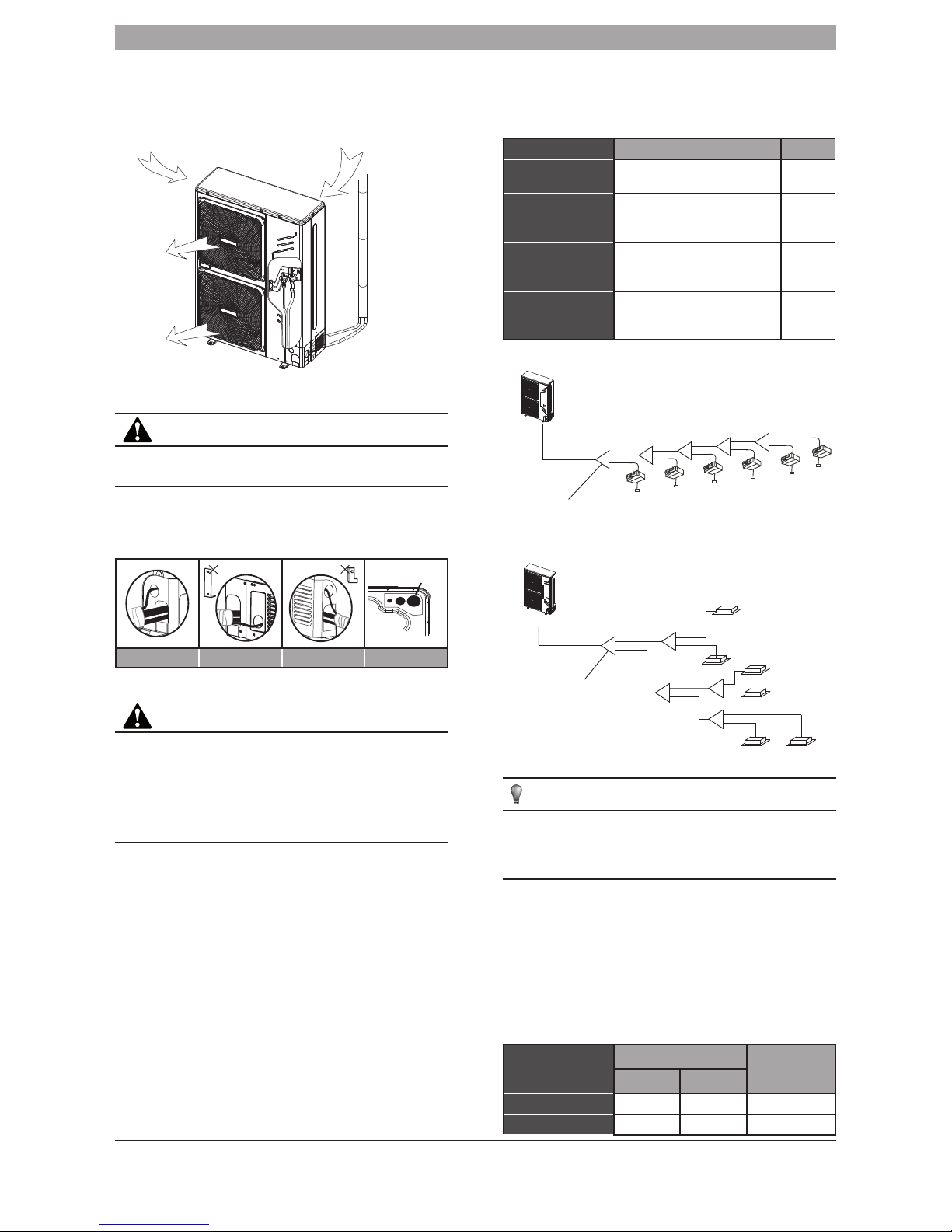

3.2 Installation clearances (Unit:mm)

H

G

A

Fig. 3-1

6 720 874 421 (2017/04) ZA Mini VRF Heat Pump Outdoor Unit

4 | OUTDOOR UNIT INSTALLATION

H

A

Fig. 3-2

B

C

D

E

F

Fig. 3-3

MODEL (kW) A B C D E F G H Fig.

8/10.5 990 624 380 339 396 366 1073 966

Fig. 3-1

Fig. 3-3

12/14/16/18 1280 600 366 320 400 360 – 1327

Fig. 3-2

Fig. 3-3

• Single unit installation

>300

>600

>300

>2000

(Wall or obstacle)

Maintain

channel

Air outlet

Air inlet

Air inlet

Fig. 3-4

• Parallel connection of two or more units.

>600

>2000

>300

Fig. 3-5

• Parallel connection for units facing each other.

>2000 >500 >3000 >3000 >300

Fig. 3-6

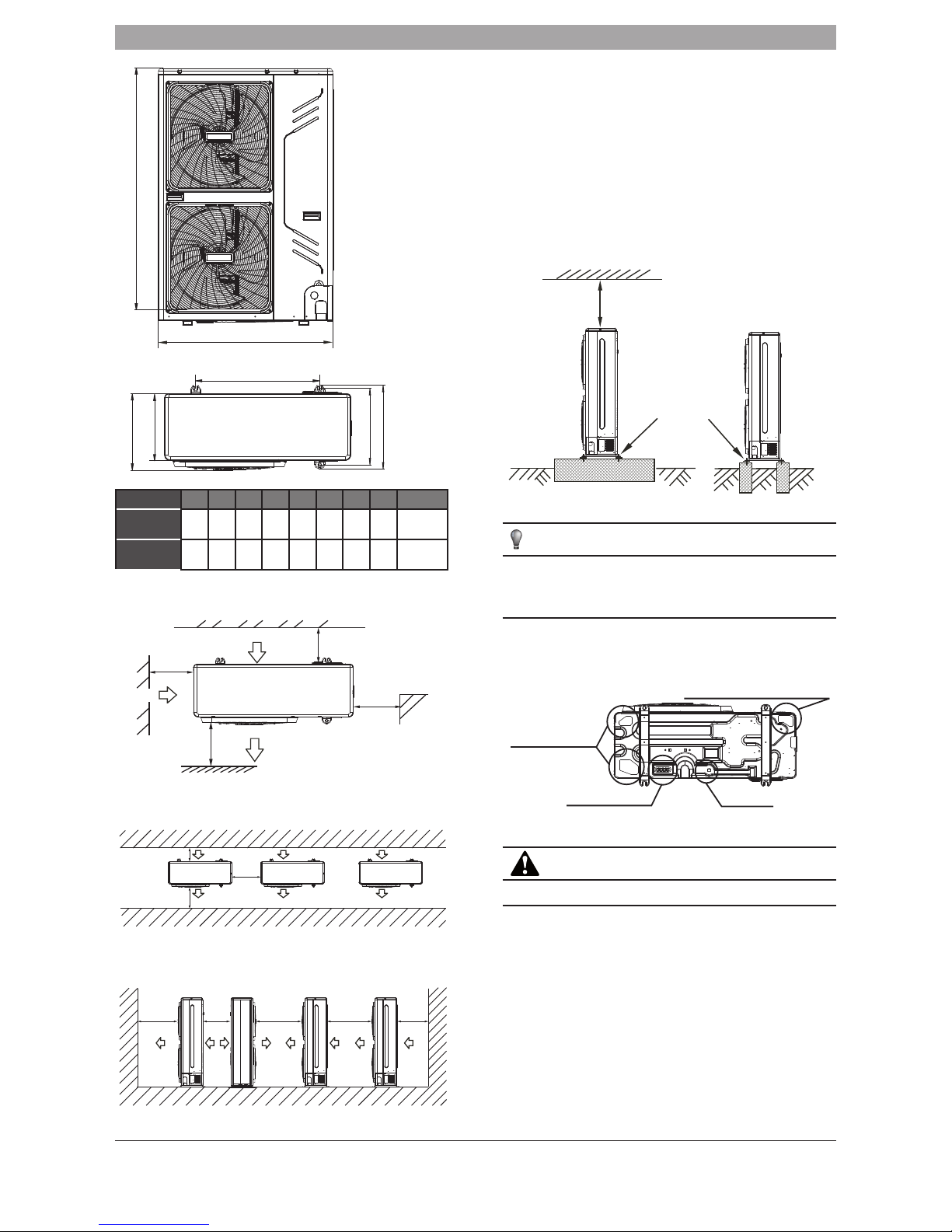

3.3 Handling and installation

• Caution must be taken when handling the outdoor unit, the

weight is not in the centre of the unit. The unit is heavier on the

front right side. For lifting advice consult HSE and use specified

lifting equipment.

• Do not touch the fan blades. The fan blades are sharp and could

cause an injury.

• When handling the unit, ensure you do not lean the unit more than

45 degrees as this will cause internal damage to the compressor.

• Fasten the feet of this unit with bolts firmly to prevent it from

toppling over. (Refer to Fig.3-7)

>60c m

Fix with bolt

Fig. 3-7

NOTE

All the pictures in this manual are for illustration purposes only. The

illustrations may be slightly different from the air conditioning unit you have

purchased (dependent on model).

3.4 Condensate Outlet

There are four condense water outlets on the body of the unit shown on

the figure below.

Reserve water outlet

Reserve water outlet

Water Outlet

Outlet for power and connecting pipes

Remove knockout

if required

(With rubber stopper)

Fig. 3-8

CAUTION

When installing the outdoor unit, consider the drainage points.

Mini VRF Heat Pump Outdoor Unit 6 720 874 421 (2017/04) ZA

INSTALLING THE CONNECTIVE PIPEWORK | 5

4. INSTALLING THE CONNECTIVE

PIPEWORK

Ensure the pipe limitations in this manual have been complied with.

Failure to do so will cause the unit to malfunction.

Strong

wind

Strong

wind

Fig. 4-1

4.1 Refrigerant pipework

CAUTION

To prevent the refrigerant pipework from oxidising, it is necessary to purge

nitrogen through the piping whilst brazing.

The outdoor unit can be piped in various ways. The pipes can run from the

back, front and under the unit. Remove knock outs where appropriate.

Table 4-1

Fat pipe

Front Side Back Undersurface

CAUTION

When piping from the side please remove the metal L shape plate, otherwise

cabling will not fit.

When piping from the back, ensure you take out the rubber support blanket

beside the inner outlet pipe.

When piping from the front side cut out the front knock out hole.

When piping the undersurface: Remove the knockouts from inside to outside.

Ensure you use the correct size hole when you are piping the unit.

4.2 Pipework Insulation

■ All refrigerant pipework must be correctly insulated in accordance

with national standards.

4.3 Connecting method

■ Select refrigerant pipe

Table 4-2

Pipe definition Pipe location Code

Main pipe The pipe between outdoor unit to

the first branch of indoor unit.

L1

The main pipes for

indoor unit

The pipe after the first branch

which does not connect directly to

the indoor unit.

L2~L5

The branch pipes for

indoor unit

The pipe after the branch which

does not connect directly to the

indoor unit.

a, b, c,

d, e, f

Indoor unit branch

joint assembly

The branch connector, where the

main pipe connects to the branch

pipe supplying the indoor units.

A, B, C,

D, E

• The first connection method

a

b

c

e

f

d

L1

L2

L3

L4

L5

A

B

C

D

E

The First pipe branch

Outdoor Unit

Fig. 4-4

• The second connection method

N1

(28)

N

3

(28)

N

5

(28)

N

6

(22)

N

2

(28)

N

4

(28)

A

B

D

E

C

a

b

c

e

f

d

L

1

L2

L5

L3

L4

The First pipe branch

Outdoor Unit(Take Model 160 for example)

Intdoor Units

Fig. 4-5

NOTE

• When the distance between the first branch and the last branch is

greater than 15m, refer to installation method 2..

• The pipe between the indoor unit to the closest branch must be less

than 15 m.

4.4 Confirmation for the diameters of indoor unit

connecting pipes

■ Size of main pipe and corresponding branch joint and branch header

1) R410A Indoor unit connecting pipe diameters 4-3.

2) Example 1: In the Fig.4-5. The downstream inner units of L2, and

its total capacity is 28×2=56, refer to the Table4.4, the air/liquid

side for L2 is Ø15.9/Ø9.5.

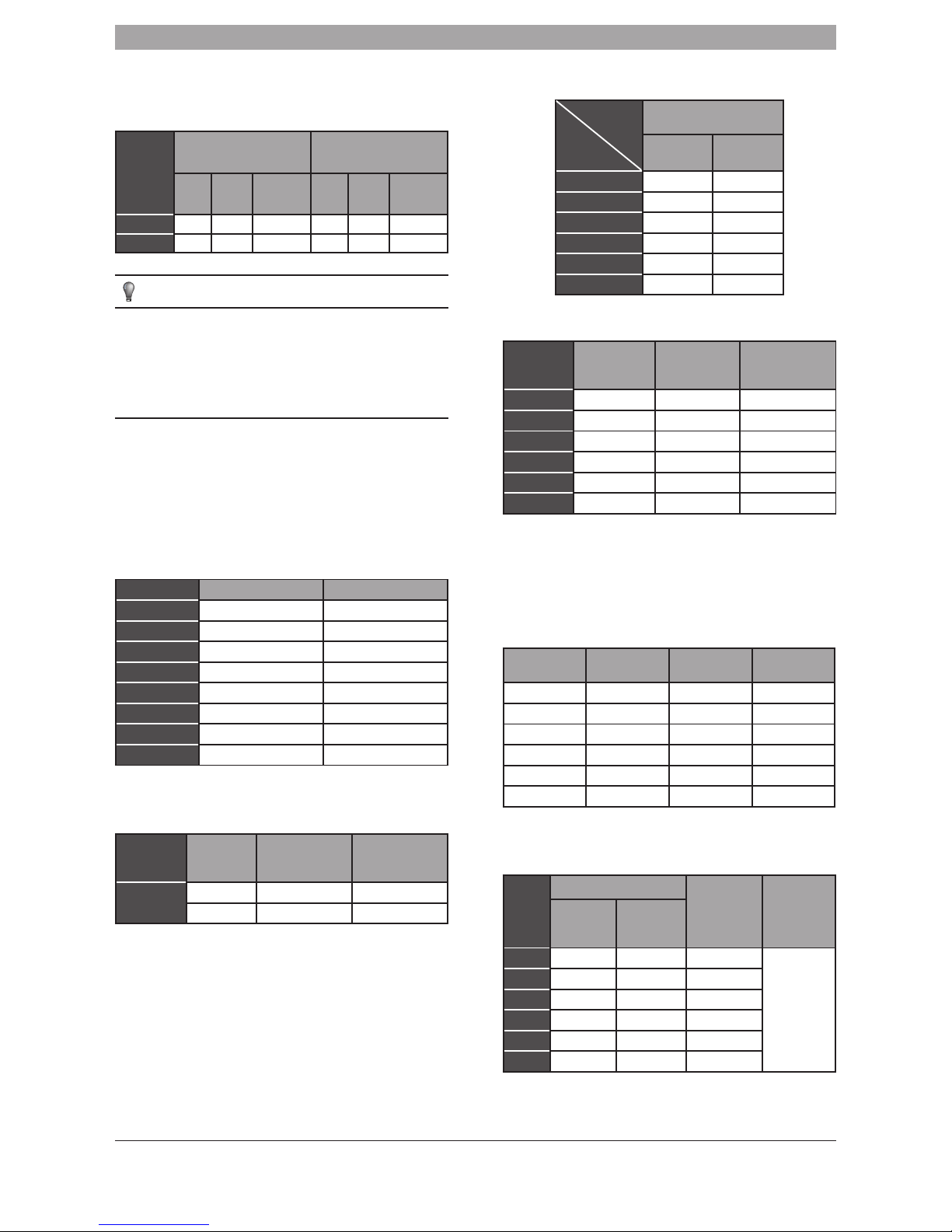

Table 4-3 R410A Indoor unit connecting pipes diameters

Total capactiy of the

downstream inner

units

Main pipe size (inches) Branch Pipe

Gas pipe Liquid pipe

A<166 Ø15.9 Ø9.5 IDU - 01

166≤A<230 Ø19.1 Ø9.5 IDU - 01

6 720 874 421 (2017/04) ZA Mini VRF Heat Pump Outdoor Unit

6 | INSTALLING THE CONNECTIVE PIPEWORK

4.5 Confirmation for the diameters of outdoor unit

connecting pipes

Table 4-4 R410A outdoor unit connecting pipes diameters

Total capactiy

of the

outdoor units

Main pipe size when the total

equivalent pipework length of liquid

+ gas side is <90 m

Main pipe size when the total

equivalent pipework length of liquid

+ gas side is ≥90 m

gas

side

(inches)

liquid

side

(inches)

The first Line

Branch Pipe

gas

side

(inches)

liquid

side

(inches)

The first Line

Branch Pipe

A<160 Ø15.9 Ø9.5 IDU - 01 Ø19.1 Ø9.5 IDU - 01

160≤A<230 Ø19.1 Ø9.5 IDU - 01 Ø22.2 Ø9.5 IDU - 02

NOTE

• When installing branch joints ensure there is at least 0.5 m of straight

pipe before and after the branch joint;

• The straight distance between branchpipes must be at least 0.5 m;

• The straight distance where the branch pipes connect to the indoor

unit must be at least 0.5 m;

• Branch header must be connected with the indoor units directly,

further branch connections are not allowed.

• Select branch joint

• Select the branch joint required by the total designed capacity of the

indoor units which it connects to. If this capacity is more than that of

the outdoor unit, then select the connection according to the outdoor

unit.

• The selection of branch header depends on the quantity of branches

it connects to.

■ Connection method

Table 4-5

Gas side Liquid side

8kW Flaring Flaring

10.5kW Flaring Flaring

12kW Flaring Flaring

14kW Flaring Flaring

16kW Flaring Flaring

18kW Flaring Flaring

Indoor unit Flaring Flaring

Branch pipe Brazing or Flaring Brazing or Flaring

■ Pipework sizes at the branch pipe

Table 4-6

Refrigerant Indoor Unit

Capacity

A(x100W)

Gas Side (Ø) Liquid Side (Ø)

R410A A≤45 12.7(Flaring nut) 6.4(Flaring nut)

A≥56 15.9(Flaring nut) 9.5(Flaring nut)

■ Pipe diameter of the connections onto the outdoor unit.

Table 4-7

Pipework

side

MODEL

(kW)

Pipe diameter of outdoor

unit‘s connections (inches)

Gas Side Liquid Side

8 Ø15.9 Ø9.5

10.5 Ø15.9 Ø9.5

12 Ø15.9 Ø9.5

14 Ø15.9 Ø9.5

16 Ø19.1 Ø9.5

18 Ø19.1 Ø9.5

Table 4-8

Outdoor Unit

(kW)

Capacity of

Outdoor unit

(horse power)

Maximum

Quantity of

Indoor units

Sum Capacity of

Indoor unit (horse-

power)

8 2.5 4 45%~130%

10.5 3 5 45%~130%

12 4 6 45%~130%

14 5 6 45%~130%

16 6 7 45%~130%

18 6.5 9 45%~130%

When connecting more than one indoor unit, the largest capacity connected

should be less than 8KW.

When the total capacity of the indoor units is greater than 100% of the

outdoor units capacity, ensure you turn the indoor units on one by one one.

Too many at once will cause damage to the compressor.

When the total capacity of the indoor units is greater than or equal to

16.8 kW, the size of primary gas pipe should be enlarged from Ø16 to Ø19.

Table 4-9

Capacity

ranking

Capacity

(horsepower)

Capacity

ranking

Capacity

(horsepower)

18 0.6 80 2.5

22 0.8 10.5 3

28 1 120 4

36 1.25 140 5

45 1.7 160 6

56 2

■ When the outdoor unit connects to one indoor unit

Table 4-10

MODEL

(kW)

The max height drop (m)

The length of

refrigerant pipe

(m)

The number

of bends

When out-

door

unit is top

When

outdoor unit is

bottom

8 25 20 50

less than 10

10.5 25 20 50

12 25 20 50

14 25 20 50

16 25 20 50

18 25 20 50

Mini VRF Heat Pump Outdoor Unit 6 720 874 421 (2017/04) ZA

INSTALLING THE CONNECTIVE PIPEWORK | 7

4.6 Illustration

N1

(28)

N

3

(28)

N

5

(28)

N

6

(22)

N

2

(28)

N

4

(28)

A

B

D

E

C

a

b

c

e

f

d

L

1

L2

L5

L3

L4

Outdoor Unit((Take Model 160 For Example)

The First Branch Pipe

Indoor units

Fig. 4-6

Caution: Ensure both liquid and gas pipework combined does not exceed

90m.

• Indoor unit branch pipe

Inner branch pipes are a~f, for size selection please refer to Table4-6.

Note: The Maximum length of the branch pipe should not exceed

more than 15m.

• The main pipes for the indoor units and the indoor unit branch pipe

components.

■ The downstream inner units of the main pipe L2 are N1,

N2, and its total capacity is 28×2=56, the size of pipe

L2 is Ø15.9/Ø9.5, and the branch pipe B should be

IDU - 01.

■ The downstream inner units of the main pipe L4 are N3,

N4, and its total capacity is 28×2=56, the size of pipe

L4 is Ø15.9/Ø9.5, and the branch pipe D should be

IDU - 01.

■ The downstream inner units of the main pipe L5 are N5,

N6, and its total capacity is 28+22=50, the size of pipe

L5 is Ø15.9/Ø9.5, and the branch pipe E should be

IDU - 01.

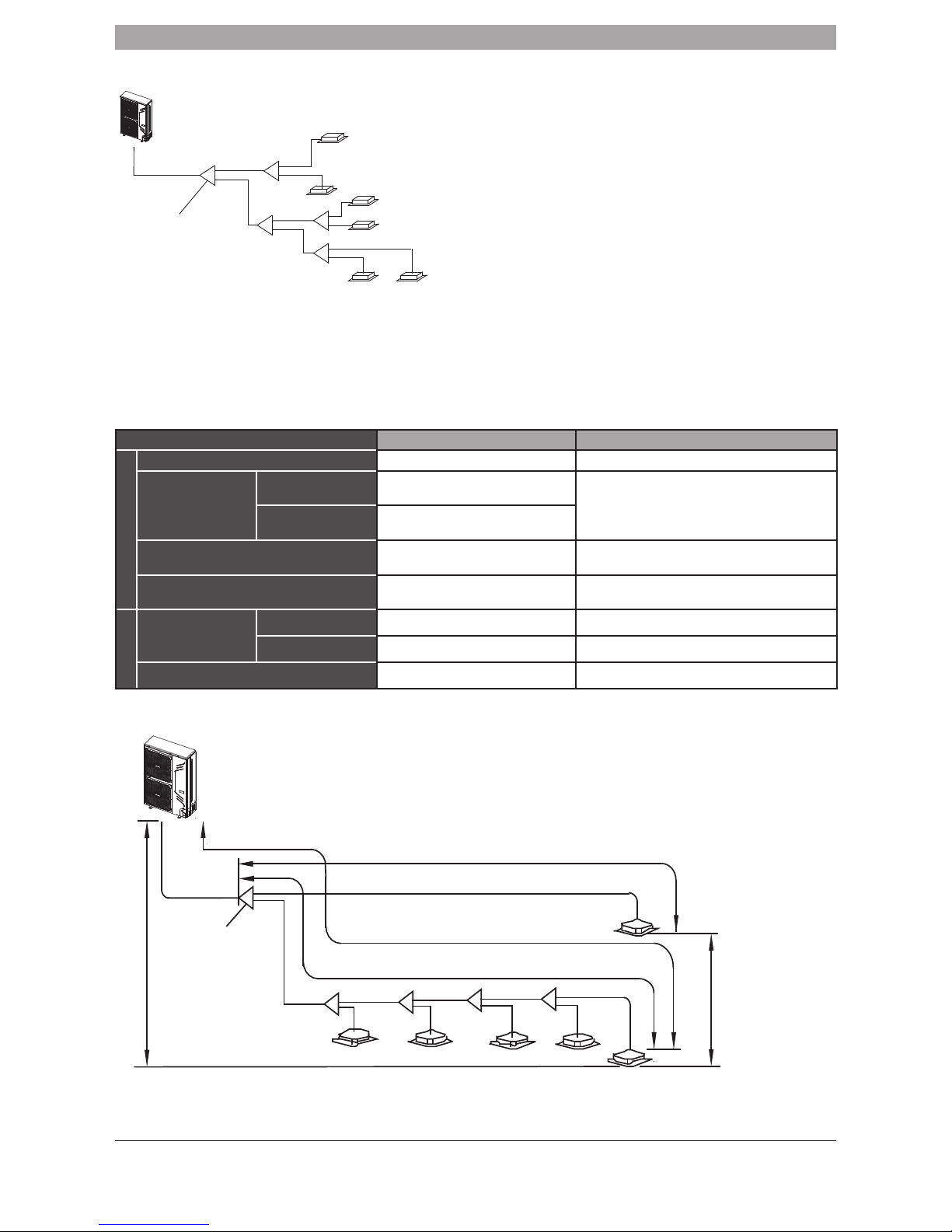

• Allowable length and height difference of refrigerant pipes

Table 4-11

Permitted value Pipework

Pipe Length

Total Pipe Length (Actual) ≤100 m L1+L2+L3+L4+L5+a+b+c+d+e+f

Maximum Pipework (L)

Actual Length

≤45 m (8 kW, 10.5 kW)

≤60 m (12 kW, 14 kW, 16 kW, 18kW)

L1+L2+L3+L4+L5+f

(The first connection method)

Equivalent Length

≤50 m (8 kW, 10.5 kW)

≤70 m (12 kW, 14 kW, 16 kW, 18kW)

or L1+L3+L5+f

(The second connection method)

Pipe Length (from the first line branch pipe

to furthest indoor unit)(m)

≤20 m L2+L3+L4+L5+f (The first connection method)

or L3+L5+f (The second connection method)

Pipe Length (from the nearest branch pipe

equivalent length(m)

≤15 m

a, b, c, d, e

Drop Height

Indoor Unit-Outdoor

Unit Drop Height (H)

Outdoor Unit up

≤30 m

______________

Outdoor Unit Down

≤20 m

______________

Indoor Unit to Indoor Unit Drop Heihgt (H)

≤8 m

______________

Note: When the distance of the refrigerant pipework is over 90m, the system will decrease in capacity. You must increase the gas pipe by one size.

• The first connection method

Drop height between indoor unit and outdoor unit

Indoor Unit

The First Line Branch Pipe

Outdoor unit

a

A

L2

L1

B

C

D

E

L3 L4 L5

b

c

d

e f

Pipe length(From the nearest branch pipe equivalent length)

Maximum pipe equivalent length

(From the first line branch pipe) Maximum pipe equivalent length

Indoor Unit to Indoor

Unit Drop height

Fig. 4-7

6 720 874 421 (2017/04) ZA Mini VRF Heat Pump Outdoor Unit

8 | INSTALLING THE CONNECTIVE PIPEWORK

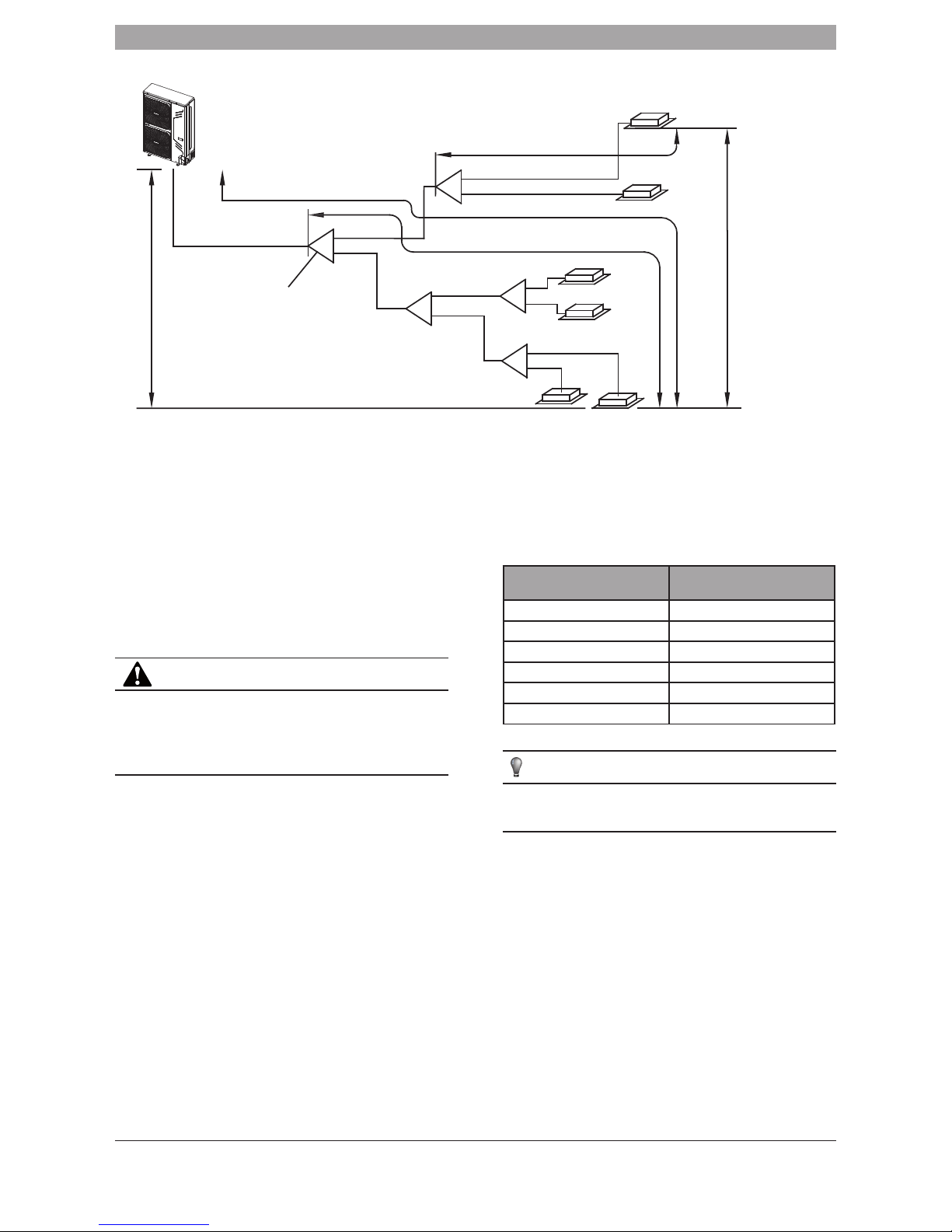

• The second connection method

Indoor unit

a

N

1

3

N

5

N

6

N

2

N

4

N

Outdoor unit

A

B

D

E

C

b

c

e

f

d

1

L

2

L

5

L

3

L

4

L

Drop height between indoor unit and outdoor unit

Maximum equivalent pipe length

Equivalent pipe length to the nearest

branch.

(From the first line branch pipe)

Maximum equivalent pipe length

Indoor Unit to Indoor Unit Drop height

The First Line Branch Pipe

Fig. 4-8

4.7 Removing The Contaminants in the Pipework

Ensure pipework is clear from any water or dirt prior to connecting onto the

outdoor unit.

When cleaning pipework, use nitrogen to flush through the system. Do not

use refrigerant or water to clean the pipework.

4.8 Strength/Tightness Test

Pressure test the system with nitrogen to 44kgf/cm2. Ensure a 24 hour

strength test has been completed for all new installations. For guidance on

tightness testing for existing installations, please refer to F Gas Regulations.

CAUTION

1 Pressured nitrogen [4.3 MPa (44kg/cm2) for R410A] should be used

for strength testing.

2 The high pressure/low pressure valves must be closed when applying

pressured nitrogen.

4.9 Vacuuming the installation

• Use a vacuum pump to create the vacuum. do not use refrigerant to

expel air.

• Vacuuming should be done on liquid, gas and oil balance pipework.

4.10 Refrigerant Amount to be Added

Calculate the additional refrigerant to be added according to the diameter

and the length of the liquid side pipe.

• When the outdoor unit connects 1 indoor unit:

Table 4-12

Liquid Side Pipework

Diameter

Refrigerant to be Added

Per Meter Of Pipework

Ø6.4 0.022 kg

Ø9.5 0.054 kg

Ø12.7 0.110 kg

Ø15.9 0.170 kg

Ø19.1 0.260 kg

Ø22.2 0.360 kg

NOTE

Additional refrigerant volume of divergent pipe is 0.1 kg per meter

(Consider the liquid side of divergent pipe only)

Loading...

Loading...