Bio-Rad Mini-PROTEAN Tetra Cell User Manual

Mini-PROTEAN®

Tetra Cell

Instruction Manual

Catalog Numbers

165-8000 165-8004

165-8001 165-8005

165-8002 165-8006

165-8003 165-8007

Table of Contents

Section 1 General Information |

1 |

|

1.1 |

Introduction |

1 |

1.2 |

Components |

1 |

1.3 |

Specifications |

4 |

1.4 |

Safety |

5 |

Section 2 Setup and Basic Operation |

6 |

|

2.1 |

Gel Cassette Preparation |

6 |

2.2 |

Electophoresis Module Assembly and |

|

|

Sample Loading |

9 |

Section 3 Separation Theory and Optimization |

15 |

|

3.1 |

Introduction |

15 |

3.2 |

SDS-PAGE (Laemmli) Buffer System |

16 |

3.3 |

Native PAGE |

17 |

Section 4 Reagent Preparation and Stock Solutions |

19 |

|

4.1 |

Volumes Required per Gel |

19 |

4.2 |

SDS-PAGE (Laemmli) Buffer System |

19 |

4.3 |

Discontinuous Native PAGE (Ornstein-Davis) |

22 |

4.4 |

Continuous Native PAGE |

24 |

Section 5 References |

27 |

|

Section 6 Maintenance |

27 |

|

Section 7 Troubleshooting Guide |

28 |

|

Section 8 Product Information and Accessories |

31 |

|

Section 9 Warranty Information |

35 |

|

Section 1

General Information

1.1 Introduction

The Mini-PROTEAN® Tetra cell runs both handcast gels and Ready Gel® precast gels interchangeably. The Mini-PROTEAN Tetra system includes a casting stand and glass plates with permanently bonded gel spacers that simplify handcasting and eliminate leaking during casting. The cell can run one or four gels, and the mini

tank is compatible with other Bio-Rad electrode modules for tank blotting, 2-D electrophoresis, and electroelution.

1.2 Components

To get the best performance from your Mini-PROTEAN Tetra Cell, familiarize yourself with the components by assembling and disassembling the cell before using it (refer to Figures 1 and 2).

Spacer Plate |

The spacer plate is the taller glass plate |

|

with permanently bonded gel spacers. |

|

Spacer plates are available in 0.75 mm, 1.0 |

|

mm, and 1.5 mm thicknesses, which are |

|

marked directly on each spacer plate. |

Short Plate |

The short plate is the shorter, flat glass |

|

plate that combines with the spacer plate |

|

to form the gel cassette sandwich. |

Casting Frame |

The casting frame, when placed on the |

|

benchtop, evenly aligns and secures the |

|

spacer plate and the short plate together |

|

to form the gel cassette sandwich prior to |

|

casting. |

Gel Cassette Assembly |

One casting frame, a spacer plate, and a |

|

short plate form one gel cassette assembly. |

Casting Stand |

The casting stand secures the gel cassette |

|

assembly during gel casting. It contains |

|

pressure levers that seal the gel cassette |

|

assembly against the casting gaskets. |

Gel Cassette Sandwich |

A spacer plate and short plate with |

|

polymerized gel form a gel sandwich. |

Buffer Dam |

The molded, one-piece buffer dam is used |

|

when running only one or three gels. |

1

Electrode Assembly |

The electrode assembly holds the gel |

|

sandwich. It houses the sealing gasket, |

|

the upper and lower electrodes, and the |

|

connecting banana plugs. The anode |

|

(lower electrode) banana plug is identified |

|

with a red marker and the cathode (upper |

|

electrode) banana plug with a black marker. |

Companion Assembly |

The companion assembly allows you to run |

|

gels 3 and 4. It holds the gel sandwich and |

|

houses the sealing gasket. |

Mini Tank and Lid |

The mini tank and lid combine to fully |

|

enclose the inner chamber during |

|

electrophoresis. The lid cannot be removed |

|

without disrupting the electrical circuit. |

|

The mini tank and lid are also compatible |

|

with other Bio-Rad electrode modules |

|

for blotting, first-dimension of 2-D |

|

electrophoresis, and electroelution. |

2

Lid

Banana plug jacks

Notch on

U-shaped gasket

Gel cassette

Electrode assembly

Mini tank

Fig. 1. Assembling the Mini-PROTEAN Tetra Cell.

Fig. 2. Assembling the Mini-PROTEAN Tetra Cell casting frame and casting stand

3

1.3 Specifications

Casting Stand*

Pin, retaining ring, and spring

Casting Frames*

Gray gaskets

Electrode Assembly

Electrodes

Gasket, electrode inner core Mini Tank and Lid

Sample Loading Guides** Combs*

Overall Size

Precast Gel Compatibility

Voltage Limit

Shipping Weight

Polycarbonate Stainless steel Polysulfone

Thermoplastic rubber (gray)

Glass-filled polybutylene terephthalate

Platinum wire, 0.010 inches diameter Silicone rubber (green) Polycarbonate

Delrin Polycarbonate

(W x L x H, cm) 12 x 16 x 18

Ready Gel and Mini-PROTEAN precast gels (for more information, go to www.bio-rad.com/mpgels)

600 V DC and 500 W

2.0 kg

Maximum Sample Volume per Well

# Wells |

Well Width |

0.75 mm |

1.0 mm |

1.5 mm |

|

|

|

|

|

5 |

12.7 mm |

20 µl |

105 µl |

160 µl |

|

|

|

|

|

9 |

5.08 mm |

33 µl |

44 µl |

66 µl |

|

|

|

|

|

10 |

5.08 mm |

33 µl |

44 µl |

66 µl |

|

|

|

|

|

15 |

3.35 mm |

20 µl |

26 µl |

40 µl |

|

|

|

|

|

IPG |

6.2 mm |

– |

420 µl |

730 µl |

|

|

|

|

|

Prep/2-D |

|

|

|

|

|

|

|

|

|

Reference well |

3.1 mm |

13 µl |

17 µl |

30 µl |

|

|

|

|

|

Sample well |

71.1 mm |

310 µl |

400 µl |

680 µl |

|

|

|

|

|

*US patent No. 6,162,342

**US patent No. 5,656,145

4

Chemical Compatibility

Mini-PROTEAN Tetra cell components are not compatible with acetone or ethanol. Use of organic solvents voids all warranties. Call 1-800-4-BIORAD (US) or your local Bio-Rad representative for technical information regarding chemical compatibility of the Mini-PROTEAN Tetra cell with various laboratory reagents.

The Mini-PROTEAN are not compatible with repeated exposure to 100% TEMED. Rubbing the combs with TEMED prior to casting will destroy the structural integrity of the combs over time.

1.4 Safety

Power to the Mini-PROTEAN Tetra cell is supplied by an external DC voltage power supply (not included). The output of this power supply must be isolated from external ground to ensure that the DC voltage output floats with respect to ground. All Bio-Rad power supplies meet this important safety requirement. Regardless of the power supply used, the maximum specified operating parameters for the Mini-PROTEAN Tetra cell are as follows

•600 V DC maximum voltage limit

•500 W maximum power limit

•40°C maximum ambient temperature limit

The current to the cell enters the unit through the lid assembly, which provides a safety interlock to the user. The current to the cell is broken when the lid is removed. Always turn off the power supply before removing the lid. Do not attempt to use the cell without the safety lid.

Important: This Bio-Rad product is designed and certified to meet IEC61010-1 and EN61010-1* safety standards. Certified products are safe to use when operated in accordance with the instruction manual. This instrument should not be modified or altered in any way. Alteration of this instrument will

•Void the warranty

•Void the IEC61010-1 and EN61010-1 certifications, and

•Create a potential safety hazard

Bio-Rad is not responsible for any injury or damage caused by use of this instrument for purposes other than those for which it is intended or by modifications of the instrument not performed by Bio-Rad or an authorized agent.

*IEC61010-1 and EN61010-1 are internationally accepted electrical safety standards for laboratory instruments.

5

Section 2

Setup and Basic Operation

2.1 Gel Cassette Preparation

Handcast Gels

1.Glass Cassette and Casting Stand Assembly Note: All glass plates should be clean and dry.

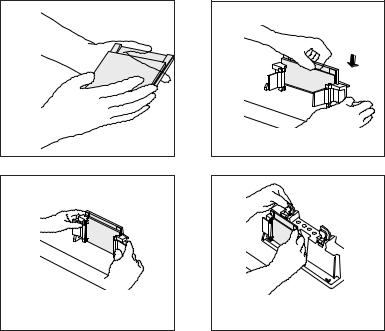

a.Place the casting frame upright with the pressure cams in the open position and facing forward on a flat surface.

b.Select a spacer plate of the desired gel thickness and place a short plate on top of it (see Figure 3a).

c.Orient the spacer plate so that the labeling is up. Slide the two glass plates into the casting frame, keeping the short plate facing the front of the frame (side with pressure cams) (see Figure 3b).

Note: Ensure that both plates are flush on a level surface and that the labels on the spacer plate are oriented correctly. Leaking may occur if the plates are misaligned or oriented incorrectly.

d.When the glass plates are in place, engage the pressure cams to secure the glass cassette sandwich in the casting frame (see Figure 3c). Check that both plates are flush at the bottom.

e.Place the casting frame into the casting stand by positioning the casting frame (with the locked pressure cams facing out) onto the casting gasket while engaging the spring-loaded lever of the casting stand onto the spacer plate (see Figure 3d).

Note: The gray casting stand gaskets must be clean and dry. The casting stand gaskets are made of a special thermoplastic material that swells when soaked in water, so we recommend that you do not soak the gaskets for prolonged periods prior to casting. If the gaskets do get accidentally soaked and display swelling and/or deformation, just allow them to air dry and they will regain their original shape, size and performance.

6

f. Repeat steps a–e for additional gels.

3a |

3c |

3b |

3d |

Fig. 3. Assembling the Mini-PROTEAN casting stand and frame.

2.0 Gel Casting

a.Discontinuous Polyacrylamide Gels

i.Place a comb completely into the assembled gel cassette. Mark the glass plate 1 cm below the comb teeth. This is the level to which the resolving gel is poured. Remove the comb.

ii.Prepare the resolving gel monomer solution by combining all reagents except APS and TEMED. (Refer to section 4 for gel formulations.) Degas the solution under vacuum for at least 15 min. Do not use a sink water aspirator.

iii.Add APS and TEMED to the degassed monomer solution and pour to the mark using a glass or disposable plastic pipet. Pour the solution smoothly to prevent it from mixing with air.

7

iv.Immediately overlay the monomer solution with water or t-amyl alcohol.

Note: If water is used, add it slowly and evenly to prevent mixing. Do not overlay with butanol or isobutanol.

v. Allow the gel to polymerize for 45 min to 1 hr. Rinse

the gel surface completely with distilled water. Do not leave the alcohol overlay on the gel for more than 1 hr because it will dehydrate the top of the gel.

Note: At this point the resolving gel can be stored at room temperature overnight. Add 5 ml of 1:4 dilution of 1.5 M Tris-HCl, pH 8.8 buffer (for Laemmli system) to the resolving gel to keep it hydrated. If using another buffer system, add 5

ml 1x resolving gel buffer for storage.

vi.Prepare the stacking gel monomer solution. Combine all reagents except APS and TEMED. Degas under vacuum for at least 15 min.

vii.Dry the top of the resolving gel with filter paper before pouring the stacking gel.

viii.Add APS and TEMED to the degassed stacking gel monomer solution and pour the solution between the glass plates. Continue to pour until the top of the short plate is reached.

b.Continuous Polyacrylamide Gels

i.Prepare the monomer solution by combining all reagents except the APS and the TEMED. Degas under vacuum for

15 min (refer to section 4 for gel formulations).

ii.Add APS and TEMED to the degassed monomer solution and pour the solution between the glass plates. Continue to pour until the top of the short plate is reached.

iii.Insert the desired comb between the spacers starting at the top of the spacer plate, making sure that the tabs at the ends of each comb are guided between the spacers. Seat the comb in the gel cassette by aligning the comb ridge with the top of the short plate.

iv.Rinse the casting frame(s) and stand with distilled, deionized water after use.

8

Ready Gel® Precast Gels

1. Ready Gel Cassette Preparation

Note: The Mini-PROTEAN Tetra cell is guaranteed for use with Bio-Rad’s Ready Gel and Mini-PROTEAN® precast gels. For more information, go to www.bio-rad.com/mpgels.

a.Remove the Ready Gel from the storage pouch.

b.Gently remove the comb and rinse the wells thoroughly with distilled water or running buffer.

c.Cut along the dotted line at the bottom of the Ready Gel cassette with a razor blade.

d.Pull the clear tape at the bottom of the Ready Gel cassette to expose the bottom edge of the gel.

e.Repeat for second Ready Gel.

Note: If only one or three gels are to be run, use the mini cell buffer dam.

2.2 Electrophoresis Module Assembly and Sample Loading

Required materials:

•Clean and dry Mini-PROTEAN Tetra cell tank

•Electrophoresis module (electrode assembly module only for 1 or 2 gels; for 3 or 4 gels also use the companion running module)

•Running buffer (700 ml for 2 gels; 1000 ml for 4 gels)

•Ready Gel precast gels or hand-cast gels

•PowerPac™ Basic power supply

1. Assembly

Note: When running 2 gels only, use the electrode assembly (the one with the banana plugs), not the companion running module (the one without the banana plugs). When running 4 gels, both the electrode assembly and the companion running module must be used, for a total of 4 gels (2 gels per assembly).

9

a.Set the clamping frame to the open position on a clean flat surface (see Figure 4a).

b.Place the first gel sandwich or gel cassette (with the short plate facing inward) onto the gel supports; gel supports are molded into the bottom of the clamping frame assembly; there are two supports in each side of the assembly. Note that the gel will now rest at a 30° angle, tilting away from the center of the clamping frame.Please use caution when placing the first gel, making sure that the clamping frame remains balanced and does not tip over. Now, place the second gel on the other side of the clamping frame, again by resting the gel onto the supports. At this point there will be two gels resting at an angle, one on either side of the clamping frame, tilting away from the center of the frame (see Figure 4b).

Note: It is critical that gel cassettes are placed into the clamping frame with the short plate facing inward. Also, the clamping frame requires 2 gels to create a functioning assembly. If an odd number of gels (1 or 3) is being run, you must use the buffer dam (see Figure 4b).

c.Using one hand, gently pull both gels towards each other, making sure that they rest firmly and squarely against the green gaskets that are built into the clamping frame; make certain that the short plates sit just below the notch at the top of the green gasket.

d.While gently squeezing the gel sandwiches or cassettes against the green gaskets with one hand (keeping constant pressure and both gels firmly held in place), slide the green arms of the clamping frame over the gels, locking them into place. Alternatively, you may choose to pickup the entire assembly with both hands, making sure that the gels do not shift, and simultaneously sliding both arms of the clamping frame into place (see Figure 4c).

The arms of the clamping frame push the short plates of each gel cassette up against the notch in the green gasket, creating a leak-proof seal (check again to make certain that the short plates sit just below the notch at the top of the green gasket). At this point, the sample wells can be washedout with running buffer, and sample can be loaded (Figure 4d).

Note: If running more than 2 gels, repeat steps 1a–d with the companion running module

10

Loading...

Loading...