Bio-Rad Microplate Manager Software User Manual

Microplate

Manager

®

5.0 PC

User Guide

Life Science

Group

Bio-Rad

Laboratories

2000 Alfred Nobel Drive

Hercules, CA 94547

P/N 4000138 RevB

Catalog Number 170-9520

Bio-Rad Technical Services Department

Open Monday–Friday, 8:00 a.m. to 4:00 p.m., Pacific Standard Time.

Phone: (800) 424-6723, option 2, option 3

(510) 741-6576

Fax: (510) 741-5802

E-mail: LSG.TechServ.US@Bio-Rad.com (U.S.)

LSG.TechServ.Intl@Bio-Rad.com (International)

Notice:

No part of this publication may be reproduced or transmitted in any form or by any

means, electronic or mechanical, including photocopy, recording, or any information

storage or retrieval system, without permission in writing from Bio-Rad.

Microplate Manager is a registered trademark and Ultramark is a trademark of

Bio-Rad Laboratories. Windows and Windows NT are registered trademarks of Microsoft

Corporation. All other trademarks and registered trademarks are of their respective

companies.

Copyright © 1999 by Bio-Rad Laboratories. All rights reserved.

Warranty

Bio-Rad Laboratories warrants that the Microplate Manager software shall

substantially conform, in all operational features, to Bio-Rad’s current specifications

as published in Bio-Rad’s user and installation guides and that, when properly

installed, it will be free of material defects which affect system performance.

The Purchaser must notify Bio-Rad in writing, within 30 days of delivery of the

software (not including delivery of any subsequent modifications to the software), of

any defect. If the software is found to be defective by Bio-Rad, Bio-Rad’s sole

obligation under this warranty is to remedy the defect in a manner consistent with

Bio-Rad’s regular business practices. For a defect which adversely affects the

performance of the software, Bio-Rad shall use its best efforts to cure such defect as

soon as reasonably practicable after receipt of Purchaser’s notice. For minor defects,

Bio-Rad shall use its best efforts to correct such minor defects in the next release of

its software. If, however, Bio-Rad is unable to cure a major defect within 90 days of

receipt of Purchaser’s notice, Purchaser shall have the option to cancel this

agreement, whereupon Bio-Rad shall refund only the software fees paid.

The warranties set forth in this agreement are in lieu of all other representations and

warranties, expressed or implied, including warranties of merchantability and fitness

for a particular purpose and any other statutory or common-law warranty. Bio-Rad on

its own behalf expressly disclaims and excludes any and all such other

representations and warranties. Liability of Bio-Rad to Purchaser, if any, for breach

of warranty, or any other claim relating to this agreement, shall be limited to the total

amount of software fees paid by purchaser to Bio-Rad. In no event shall Bio-Rad be

liable for incidental or consequential damages, loss of business or profits, special or

indirect damages of any nature whatsoever. No amendment, waiver, or other

alteration of the warranties in this agreement may be made except by mutual

agreement in writing.

Purchaser agrees that Bio-Rad’s liability arising out of contract, negligence, strict

liability in tort or warranty shall not exceed the amount of software license fees paid

by Purchaser.

This manual and the software (computer program) described in it are copyright BioRad Laboratories, Inc. with all rights reserved worldwide. Under the copyright laws,

iii

this manual and the software program contained herein may not be copied, in whole

or in part, without the prior written consent of Bio-Rad, except in the normal use of

the software or to make a backup copy. This exception does not allow copies to be

made for others, whether or not sold, but all of the materials purchased (with all

backup copies) may be sold, given or loaned to another person. Under the law,

copying includes translating into another language or format.

A multi-use license may be purchased to allow the software to be used on more than

one computer owned by the purchaser, including a shared disk system.

iv

Table of Contents

1. Introduction..............................................................1

1.1 Overview of Microplate Manager...................................................1

1.2 Types of Files ...............................................................................3

1.3 New Features in Version 5.0.........................................................4

2. Installation and Setup..............................................7

2.1 Instrument Specifications..............................................................7

2.1.1 Host Computer and Operating System ........................................7

2.1.2 Microplate Readers ......................................................................7

2.2 Connecting the Microplate Readers to the Host Computer...........7

2.3 Attaching the Hardware Protection Key........................................8

2.4 Installing Microplate Manager.......................................................8

2.5 Starting Microplate Manager......................................................... 9

2.6 Selecting a Serial Port ..................................................................9

2.7 Setting Filters.............................................................................. 10

2.7.1 Ultramark Setup .........................................................................10

2.7.2 Model 550 Setup ........................................................................11

2.8 Preferences................................................................................11

2.9 Sample Data Files.......................................................................13

3. Getting Started.......................................................15

3.1 Menus, Toolbars, and Other Features........................................15

v

3.2 Opening and Saving Files...........................................................17

3.3 Reading Data from Other Applications........................................17

3.4 Quick Start..................................................................................17

3.5 Typical Scenarios........................................................................18

4. Templates...............................................................23

4.1 Opening a Template...................................................................23

4.1.1 Opening an Existing Template ...................................................23

4.1.2 Opening a New Template...........................................................24

4.2 Viewing the Template.................................................................28

4.3 Features of a Template...............................................................29

4.4 Formatting a Template................................................................33

4.4.1 Step 1. Define the Assays.........................................................34

4.4.2 Step 2. Define the Well Types...................................................36

4.4.3 Step 3. Enter the Concentrations of the Standards...................40

4.4.4 Step 4. Enter Dilutions of Unknowns.........................................41

4.4.5 Step 5. Select Regression Curve ..............................................43

4.4.6 Step 6. Select External Standards.............................................44

4.4.7 Step 7. Saving the Template.....................................................47

5. Protocols................................................................49

5.1 Features Common to All Protocols .............................................51

5.1.1 Reader Identification...................................................................51

5.1.2 Selecting a Template..................................................................51

5.1.3 Setting the Reading Parameters ................................................53

5.1.4 Incubator Controls (Ultramark and Model 550 only)...................53

5.1.5 Mix Settings................................................................................54

5.1.6 Reader Door (Ultramark only)....................................................54

5.1.7 Reports.......................................................................................55

5.1.8 Running a Protocol.....................................................................57

5.1.9 Saving a Protocol .......................................................................57

vi

5.2 Features Unique to Endpoint Protocols.......................................58

5.3 Features Unique to Kinetic Protocols ..........................................59

5.3.1 Reading Sets..............................................................................60

5.3.2 Analysis Options.........................................................................61

5.4 Features Unique to Multiple Plate Protocols...............................64

6. Data Formatting and Reports................................71

6.1 Summary of Available Reports....................................................71

6.2 Saving Your Data........................................................................73

6.3 Manually Editing Data.................................................................73

6.4 Identifying Outliers......................................................................74

6.5 Editing or Replacing the Template in a Data File........................76

6.6 Reports.......................................................................................77

6.6.1 Labels.........................................................................................77

6.6.2 Raw Image Report (Ultramark only)...........................................79

6.6.3 Reports Available for Endpoint and Multiple Plate Data Only.....83

6.6.4 Reports Available for Kinetic Data Only .....................................84

6.6.5 Reports Common to all Reading Types .....................................88

6.7 Standard Curve Comparison.......................................................97

6.8 Standard Curve Fitting................................................................98

7. Data Output..........................................................101

7.1 Printing.....................................................................................101

7.2 Data Import and Export.............................................................102

7.2.1 Exporting Data..........................................................................103

7.2.2 Importing Data..........................................................................104

7.2.3 Kinetic Data Formats................................................................104

vii

8. Quick Guides........................................................107

8.1 Creating a New Template.........................................................107

8.2 Creating and Running a New Kinetic Prot ocol with a

Stored Template.......................................................................108

8.3 Creating and Running a New Kinetic Prot ocol and Cr eating

the Template Simultaneously....................................................109

8.4 Creating and Running a New Endpoint Prot ocol with a

Stored Template.......................................................................110

8.5 Creating and Running a New Endpoint Prot ocol and

Creating the Template Simultaneously.....................................111

8.6 Creating and Running a Multiple Plate Protocol with a

Stored Template.......................................................................112

8.7 Creating and Running a New Multiple Plate Protocol and

Creating the Template Simultaneously.....................................113

9. Glossary...............................................................115

10. Ordering Information...........................................117

Index...........................................................................119

Appendix A. Menus ..................................................123

viii

List of Figures

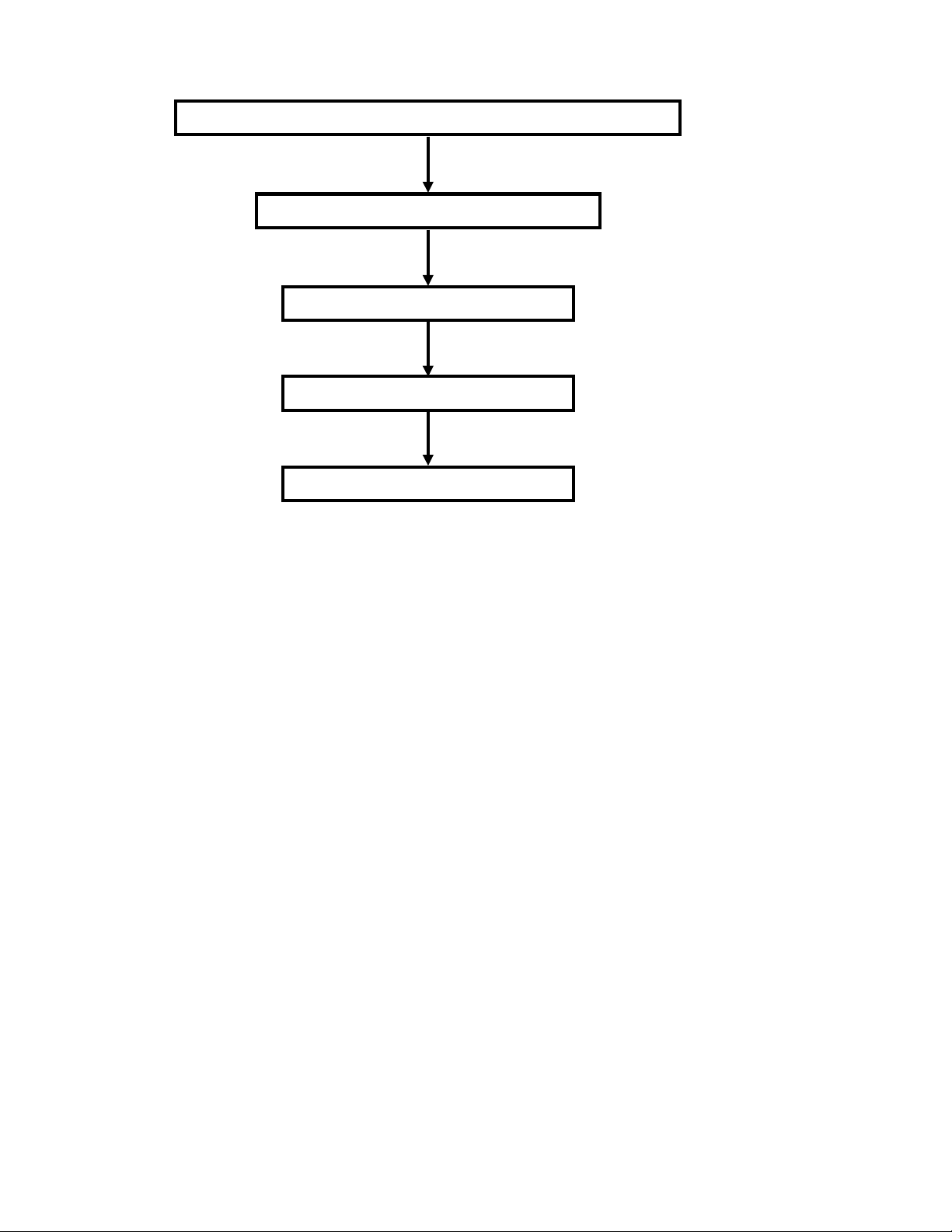

Figure 1. Workflow of Microplate Manager............................................................2

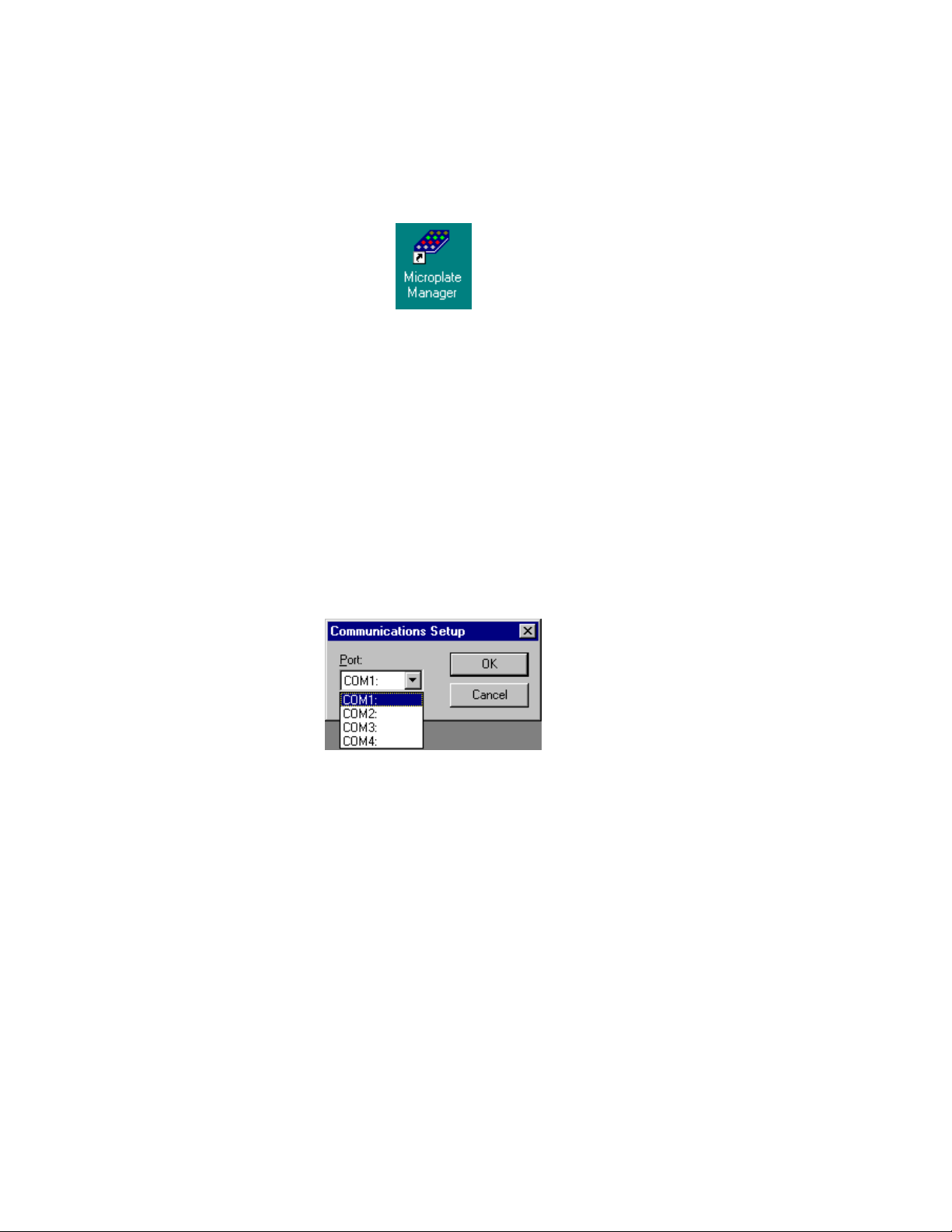

Figure 2. Microplate Manager desktop icon. .........................................................9

Figure 3. Communications Setup dialog box.........................................................9

Figure 4. Ultramark Setup dialog box..................................................................10

Figure 5. Model 550 Setup dialog box.................................................................11

Figure 6. Preferences dialog box.........................................................................12

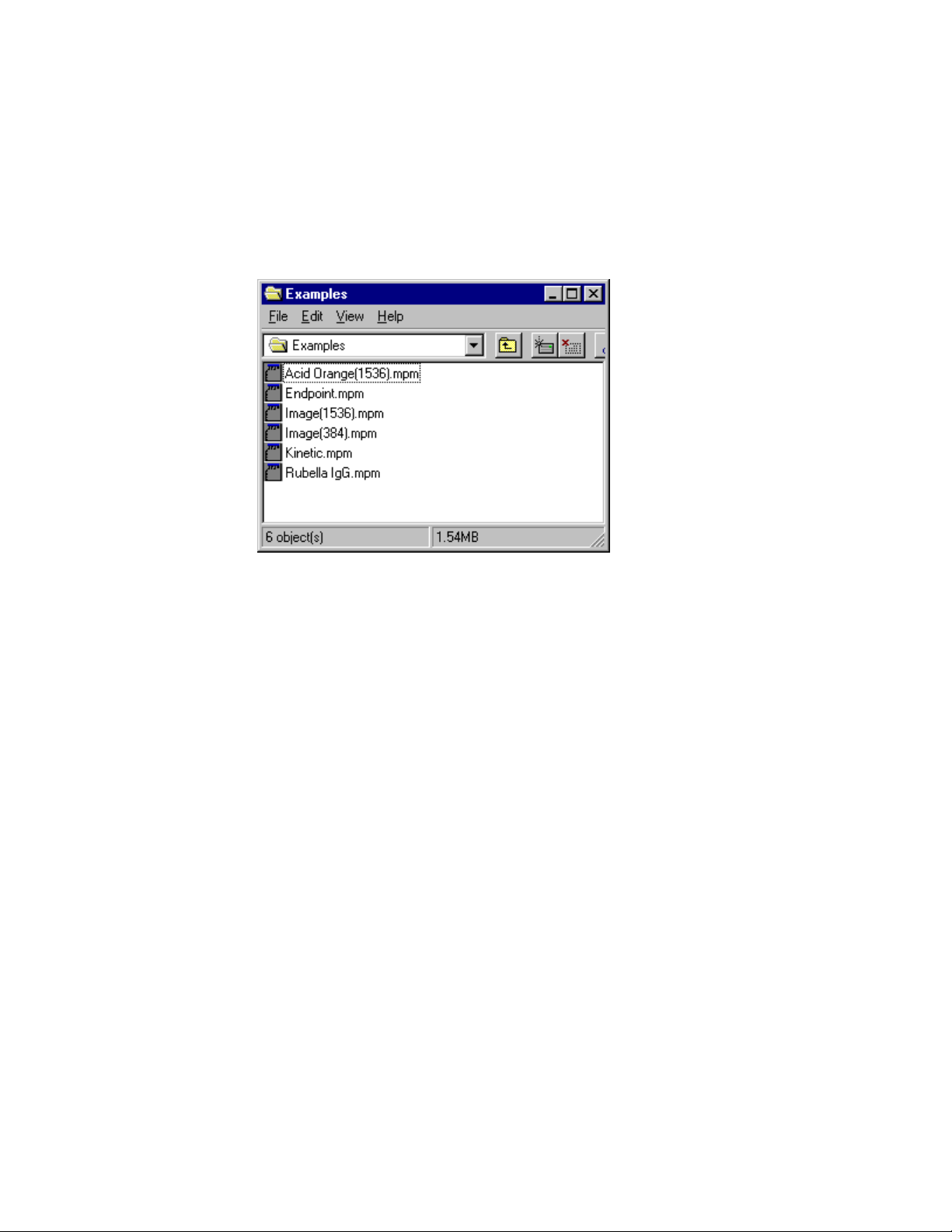

Figure 7. Examples directory...............................................................................13

Figure 8. Default menu bar and main toolbar......................................................15

Figure 9. Example of commands available by clicking right mouse button.........16

Figure 10. Performing an endpoint reading.........................................................19

Figure 11. Defining the Reading Sets..................................................................20

Figure 12. Comparing external and internal standards. ......................................22

Figure 13. Selecting a template...........................................................................24

Figure 14. Creating a custom template. ..............................................................25

Figure 15. Defining the format of a plate.............................................................26

Figure 16. Entering the physical dimensions of your plate..................................27

Figure 17. Example of cursor feedback in a template.........................................28

Figure 18. Well Info dialog box............................................................................29

Figure 19. Blank 12 x 8 template.........................................................................30

Figure 20. Example of a plate template with two different assays defined..........32

Figure 21. Format menu and template toolbar....................................................33

Figure 22. Defining an assay with the Assay tool................................................35

Figure 23. Assay Information dialog box. ............................................................36

Figure 24. Autofilling a row of standards. ............................................................37

Figure 25. Defining a replicate groups of unknowns. ..........................................38

Figure 26. Defining multiple standard replicate groups in a row..........................39

Figure 27. Edit Standards dialog box. .................................................................40

Figure 28. Edit Unknowns dialog box..................................................................42

Figure 29. Standard Curve dialog box.................................................................43

Figure 30. External Standards dialog box. ..........................................................45

Figure 31. Selecting the source file for the external standards. ..........................45

Figure 32. Selecting the source assay for your external standards.....................46

Figure 33. Example of a protocol dialog box. ......................................................50

Figure 34. Selecting a new template in a protocol dialog box. ............................52

Figure 35. Reading Parameters in the protocol dialog box. ................................53

Figure 36. Incubator settings...............................................................................54

ix

Figure 37. Ultramark reader door controls. .........................................................54

Figure 38. Reports dialog box for endpoint and multiple plate protocols.............55

Figure 39. Define Labels dialog box....................................................................56

Figure 40. Example of a running protocol............................................................57

Figure 41. Features unique to an endpoint protocol dialog box. .........................58

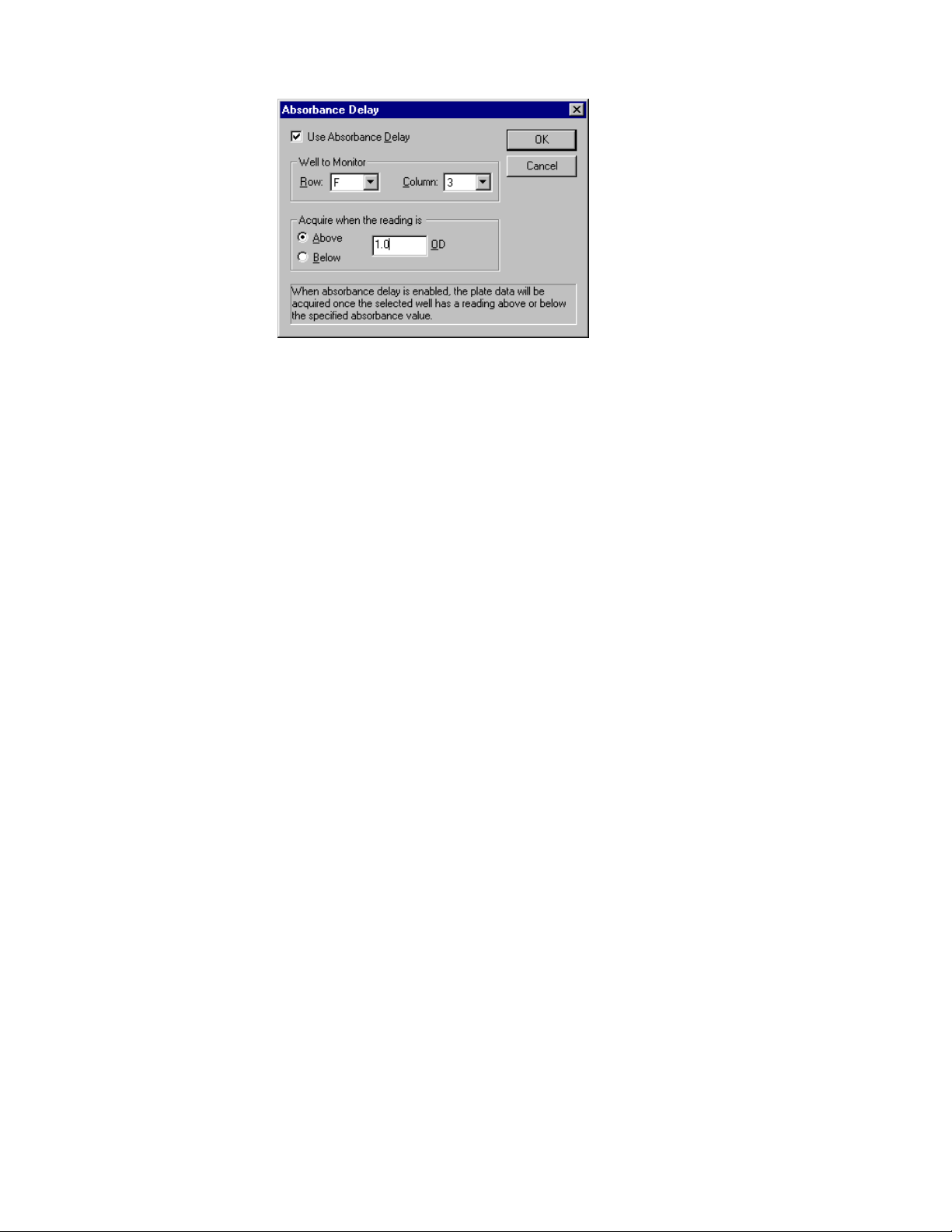

Figure 42. Absorbance Delay dialog box.............................................................59

Figure 43. Features of a kinetic protocol dialog box............................................60

Figure 44. Analysis Options in the kinetic protocol dialog box. ...........................62

Figure 45. Features of a Multiple Plate Protocol dialog box................................65

Figure 46. Plate Handler Options dialog box.......................................................66

Figure 47. Absorbance Delay dialog box.............................................................68

Figure 48. Editing raw data..................................................................................73

Figure 49. Select Outliers dialog box...................................................................75

Figure 50. Define Labels dialog box....................................................................77

Figure 51. Dialog box for adding or inserting labels. ...........................................78

Figure 52. Fill Labels dialog box..........................................................................78

Figure 53. Example of a Raw Image Report (1536-well plate)............................79

Figure 54. Image menu. ......................................................................................80

Figure 55. Close-up of a microplate image. ........................................................82

Figure 56. Raw Data Report................................................................................83

Figure 57. Absorbance Report. ...........................................................................84

Figure 58. Velocity Report...................................................................................84

Figure 59. Adjusted Velocity Report....................................................................85

Figure 60. Kinetic Correlation Coefficient Report. ...............................................86

Figure 61. Kinetic Standard Errors Report. .........................................................86

Figure 62. Kinetic Plots Report............................................................................87

Figure 63. Kinetic Zoom Plot. ..............................................................................88

Figure 64. Limit Report........................................................................................89

Figure 65. Limits dialog box.................................................................................90

Figure 66. Matrix Report......................................................................................91

Figure 67. Control Report....................................................................................92

Figure 68. Normalization Report..........................................................................93

Figure 69. Standard Curve Report. .....................................................................94

Figure 70. Unknown Concentration Report.........................................................96

Figure 71. Analysis of Variance box....................................................................97

Figure 72. Print dialog box.................................................................................101

Figure 73. Export to Excel dialog box................................................................104

x

1. Introduction

This manual assumes that you are familiar with your computer and standard

Windows commands and functions, such as opening, closing, and saving files, and

moving and clicking your mouse.

Some of the features and functions in Microplate Manager may be slightly different

depending on whether you are using the Ultramark, Model 550, or Benchmark

microplate reader. These differences are noted in the text.

1.1 Overview of Microplate Manager

Microplate Manager is designed to collect, analyze, and output data from Bio-Rad’s

Ultramark, Model 550, and Benchmark microplate readers. It runs as a Windows 95,

Windows 98, or Windows NT 4.0 application on a computer that is directly

connected to the reader. It features a standard Windows

menus, toolbars, and keyboard shortcuts.

Using Microplate Manager, you first select the type of reading you want to perform

and specify the layout of your microplate. Then you capture your data using the

microplate reader. Finally, you display your reports and print and/or export your data.

®

interface, with pulldown

1

Microplate Manager User Guide

Select Type of Reading (Endpoint, Kinetic, or Multiple Plate Protocol)

Define or Select Microplate Template

Take Reading

Generate and Format Reports

Print/Export Data

Figure 1. Workflow of Microplate Manager

Microplate Manager can perform three general types of microplate readings. These

are called “protocols.”

• Endpoint protocols are used to acquire a single absorbance reading from each

well.

• Kinetic protocols are used to acquire a series of absorbance readings from each

well over a user-defined interval. These protocols are used to calculate reaction

velocities.

• Multiple plate protocols are used with a stack loader to collect endpoint data

from a series of plates. Multiple plate protocols save each endpoint data set in a

separate file.

First you select the type of protocol you want to create. Then you specify the settings

for your particular protocol and define or select a template for your microplate.

2

Chapter 1. Introduction

Finally you take the reading. If you want to use the pa rticular protoc ol you’ve created

again, you can save it as a file.

Once absorbances have been read, you can save them as a data file and display them

in a selection of reports. Your data can be viewed, printed, or exported to other

applications.

1.2 Types of Files

There are two types of files used by Microplate Manager. Protocol files contain the

settings for reading a microplate. Data files contain the data from the reading and any

formatting associated with that data.

Protocol Files

A protocol file contains the parameters of a reading. It includes such information as

mixing times and measurement wavelengths. Each of the three protocol types

(endpoint, kinetic, and multiple plate) is slightly different, to accommodate the

different parameters used in each type. File names for protocols have the extensions

.epr (endpoint reading), .mpr (multiple plate reading), or .kpr (kinetic plate reading).

The protocol file also includes a plate template. The template specified in the

protocol file is copied into the data file at the completion of a plate reading. If there

is no template specified in the protocol file, then the default template is copied into

the data file. Defining a template in the protocol file before a reading allows you to

create data files that contain all the information necessary to evaluate the absorbance

data and automatically generate the desired reports.

(You can edit or replace the template in the data file after a reading. However,

changes made to the protocol file template after a reading are not updated in the data

file.)

You may specify labels for reports; these are stored in the protocol file.

A list of reports to be printed and/or displayed at the end of a run are saved in the

protocol file.

3

Microplate Manager User Guide

Data Files

The data file contains the raw data from the microplate reader. It has the extension

.mpm.

For an endpoint reading, this data consists of the individual absorbance readings

from the wells on the microplate. For a kinetic reading, this data is the time course

series of the individual absorbance readings. A multiple-plate reading creates a new

data file for each plate; each file contains endpoint absorbance measurements.

The data file also contains a plate template, which contains all the information

necessary to analyze the absorbance data, including a description of the assay, well

types, concentrations, dilutions, and the regression method used for computing

unknowns from standards. When the data file is first created after the ab sorbance data

is collected, the template associated with the protocol file is copied into the data file.

You can later edit the template or completely replace it with a template from another

data file.

Finally, the data file includes some information on how the plate was read (e.g.,

measurement wavelength, date/time of reading).

1.3 New Features in Version 5.0

This version of Microplate Manager features an enhanced user interface with image

display and grid overlay features. Some of the new features of the software include:

• Flexible plate definition to handle images reads of plates from 1 to 1,536 wells,

including drag-and-drop well layout and multilevel undo when formatting

images.

• Improvements in template formatting, including automatic scrolling when

formatting large plates, noncontiguous well selection for cha nging assay and

replicate set asso ciation, better handling of renumbering standard s and unknowns

on densely formatted plates, and autofilling for rapidly assigning standard and

unknown replicate sets.

• Automated setup. The software automatically identifies the microplate reader

and establishes the connection to the reader.

4

Chapter 1. Introduction

• Major improvements in associating protocols and templates.

• More flexibility in tagging outliers in replicate sets.

• Up to 12 different assays on one plate, each with its own blanks, controls, and

standards.

• More status bar and cursor feedback in templates and reports, including well

information and cursor positions.

• External standards and standard curve checking. A quantitative method for

comparing two standard curves is now available. A statistical analysis of the

comparison is provided.

• Improved display of graphics reports such as standard curve and kinetic zoom.

o

• Incubator temperature adjustments as small as 0.2

• Improved handling of multipage printouts for larger plates.

• Permanent tagging of user-edited or imported data on screen and in printouts.

• Fully integrated simulated scanner for demos and practice runs, capable of

producing simulated data.

• Complete reading protocols. Reading parameters, plate template, analysis

options, and print settings may be saved for repeated applications.

C.

• Auto-scaling of kinetic data in Kinetic Zoom Plot windows.

5

2. Installation and Setup

2.1 Instrument Specifications

2.1.1 Host Computer and Operating System

Microplate Manager will run under Windows 95, Windows 98, or Windows NT 4.0.

The host machine must be based on a Pentium Intel class CPU or higher. It should

have a hard disk of at least 200 MB, and a minimum of 16 MB RAM. It must have a

monitor and video card capable of displaying 256 colors at 1024 by 768 resolution.

There must be a SCSI-2 port available for connecting to the reader. A mouse is

required to use the software. A parallel port is required in order to print reports

directly from the PC.

The Ultramark communicates with the host computer via a SCSI-2 connection. You

can use the SCSI-2 cable and Adaptec card provided by Bio-Rad (cat. no. 170-9521)

or purchase them from any computer store.

The Model 550 and Benchmark microplate readers communicate with the host

computer via a standard serial port and cable.

2.1.2 Microplate Readers

Microplate Manager 5.0 supports Bio-Rad’s Ultramark, Model 550, and Benchmark

microplate readers.

2.2 Connecting the Microplate Readers to the

Host Computer

A SCSI-2 cable and card (cat. no. 170-9521) are required to connect the Ultramark to

the host PC. Make sure all devices are turned off before making or changing cable

connections. See the hardware manual for details.

7

Microplate Manager User Guide

A serial cable is included with the Model 550 or Benchmark and is used to connect

the instrument to the host PC. Make sure all devices are turned off before making or

changing cable connections. See the hardware manual for details.

2.3 Attaching the Hardware Protection Key

A hardware protection key (HPK) is included with this version of Microplate

Manager. You must attach the HPK to your computer before you can run Microplate

Manager.

Before attaching the HPK, turn off your computer. If you have a printer attached to

your computer’s parallel port, turn that off as well.

The HPK attaches to the parallel port on the back of your PC. If a printer cable is

attached to this port, disconnect it. After you have attached the HPK, you can attach

the printer cable to the key itself and restart your computer and printer.

The HPK has a driver that is automatically installed when you install Microplate

Manager.

2.4 Installing Microplate Manager

Insert the Setup disk (Disk 1) into the floppy disk drive on your computer. On your

Windows taskbar, click the Start button, then select Run. Type a:\setup in the field,

and click on OK.

The installer will prompt you to insert the remaining disks. The default program

directory is C:\Program Files\Bio-Rad\Microplate Manager. You can select a

different directory when prompted to do so by the installer.

The installer will place a startup icon on your desktop and create a Microplate

Manager directory on your Windows Start menu. When the installer is finished, click

on the Finish button.

8

Chapter 2. Installation and Setup

2.5 Starting Microplate Manager

To start Microplate Manager, click on the application icon on your desktop or select

Microplate Manager from the Programs directory on your Start menu.

Figure 2. Microplate Manager desktop icon.

The software will open, displaying the menu bar, main toolbar, main application

window, and status bar.

2.6 Selecting a Serial Port

The Ultramark connects to the computer via the SCSI port. If you are connecting to a

microplate reader other than the Ultramark, you can specify the serial port connection

by selecting Communications Setup from the OPTIONS menu in Microplate

Manager. This opens a dialog box in which you can select one of the available ports

on your computer.

Figure 3. Communications Setup dialog box.

9

Microplate Manager User Guide

When you open a protocol, Microplate Manager will look first for a reader at the

serial port you select. If a reader is not found at that port, the software will scan the

remaining ports as well as the SCSI bus for a reader.

If a reader is found at a particular port, that port will be selected. If no reader is found

at any serial port or the SCSI port, you will receive an error message.

2.7 Setting Filters

If you change the filters in the Ultramark or Model 550 microplate readers, you can

specify the wavelengths of the new filters from within Microplate Manager.

(Benchmark users should refer to the hardware manual for instructions on changing

filter settings.)

2.7.1 Ultramark Setup

Select Ultramark Setup from the OPTIONS menu

Figure 4. Ultramark Setup dialog box.

For each filter, enter the appropriate wavelength. The wavelengths of the filters that

are shipped with the Ultramark will be included with your Ultramark documentation.

If you change any of the filters, you will need to change these settings.

10

Chapter 2. Installation and Setup

Click on OK to implement your changes.

2.7.2 Model 550 Setup

Select Model 550 Setup from the OPTIONS menu

Figure 5. Model 550 Setup dialog box.

For each filter, enter the appropriate wavelength. The wavelengths of the filters that

are shipped with the Model 550 will be included with your reader documentation. If

you change any of the filters, you will need to change these settings.

Click on OK to implement your changes.

2.8 Preferences

To set the user-defined preferences for Microplate Manager, select Preferences from

the FILE menu.

11

Microplate Manager User Guide

Figure 6. Preferences dialog box.

In the Preferences dialog box, you can enter or select the Default File Location for

opening and saving files. To select the directory, click on the “...” button next to the

text field and scroll thro ugh the directory tree. You can also type the full director y

path and name directly in the field. If an invalid path is entered, it will be ignored,

and the working directory will be used as the home directory.

Microplate Manager has a number of “warning” messages that pop up if you try to

perform certain operations. Those messages include a checkbox to disable the

warning (“Don’t show this warning again”). If you select that checkbox, and then

decide that you want to display the warning again, click on the Reset All Warnings

button in the Preferences dialog box.

If you are not connected to a microplate reader, the Allow Simulated Scanner

checkbox allows you to operate the software as if you were connected to an

Ultramark. In this mode, all the controls will appear active, but instead of real

readings, you will create “dummy” reports containing manufactured data. This is

useful for practice and demonstration purposes.

To enter simulated mode, the checkbox must be checked and, if you are connected to

a reader, the reader must be turned off.

When the simulated scanner function is enabled, you can also select Allow Random

Variations. This will generate random numbers in your simulated scans.

½ The Advanced button accesses additional preferences that should not be changed

except with the assistance of Bio-Rad support personnel.

12

Chapter 2. Installation and Setup

When you are finished making your selectio ns, click on the OK button.

2.9 Sample Data Files

Six sample data files are installed with Microplate Manager, in a directory called

Examples in your Microplate Manager directory on your hard drive.

Figure 7. Examples directory.

Clicking on any one of these data files will open Microplate Manager and display the

template for that file. Then you can view the sample data using the commands

described in Chapter 6.

13

3. Getting Started

3.1 Menus, Toolbars, and Other Features

Menu Bar

Microplate Manager has a standard menu bar with pulldown menus that include all

the commands and functions in the software. The available menus and menu items

are different depending on the specific actions you are performing.

For example, when the software first opens, the menus will include basic file opening

and set-up features. When you are formatting a template, the menus will change to

include functions for formatting a template. When you are creating a protocol, the

menus will change to include related functions. After you have read a microplate and

the data is displayed, the menus will change again to include functions for creating

different reports and exporting your data.

Toolbars

Microplate Manager has a main toolbar that contains standard file and formatting

tools . It is displayed below the menu bar. Display of the main toolbar can be toggled

on and off from the VIEW menu.

Figure 8. Default menu bar and main toolbar.

Other tools are associated with particular features of the software, and only appear

when you are using those features. For example, the template toolbar is only

displayed when you are formatting a template. It is located at the top of the template

form.

15

Microplate Manager User Guide

Right-click Commands

You can access many of the commands associated with the action you are currently

performing by using the right mouse button. For example, if you are in the process

of defining an assay on your template, clicking the right mouse button will display

many of the commands associated with that action. The commands are displayed in a

drop-down menu next to the cursor.

Figure 9. Example of commands available by clicking right mouse button.

Status Bar

The status bar appears at the bottom of the Microplate Manager window. If your

cursor is positioned over a button or menu command, a brief description of that

function will appear in the status bar.

In some reports (Raw Image, Standard Curve), the status bar indicates the position

of the cursor. It also indicates the position of the cursor when you are working with

templates.

Display of the status bar can be toggled on and off from the VIEW menu.

16

Chapter 3. Getting Started

3.2 Opening and Saving Files

Microplate Manager has two basic file types: Protocol files and data files. Protocol

files have a .kpr, .epr., or .mpr extension. Data files have a .mpm extension.

To open an existing protocol file or data file, select Open... from the FILE menu ,

select the name of the file you want to open, and click on the Open button.

To save a protocol file, select Save Protocol or Save Protocol As... from the FILE

menu. To save a data file, select Save Data/Template or Save Data/Template As...

from the FILE menu. If you are saving a new file or renaming an old file, enter the

new file name and click on the Save button.

See the individual chapters on templates (Chapter 4), protocols (Chapter 5), and data

and reports (Chapter 6) for more information.

3.3 Reading Data from Other Applications

The software will read files from the previous version of the Microplate Manager/PC

software (version 4.0.x). It also imports data in several ASCII formats, including tab

delimited and comma delimited (CSV). Kinetic data is imported from one of three

formats defined in Kinetic Collector PC: COL, ROW, MTX. The software will not

read native files from the Macintosh Microplate Manager software, but it will read

tab delimited files generated by the Macintosh Microplate Manager software.

Data from all reports can be copied onto the clipboard, as well as exported to a file in

either tab delimited or comma delimited formats. Both tab delimited and comma

delimited formats may be exported into Excel

®

.

3.4 Quick Start

To read a plate immediately, perform the following steps:

1. Turn on the plate reader and let it warm up. Prepare a microplate and place it in

the plate reader.

17

Microplate Manager User Guide

2. Open Microplate Manager.

3. Under the FILE menu, select New Endpoint Protocol, New Kinetic Protocol, or

New Multiple Plate Protocol, depending on the type of analysis you want to

perform. The protocol dialog box will open.

4. In the dialog box, select the size of your microplate from the Plate Type:

pulldown list and click on the Run button. The plate will be read and your raw

absorbance or velocity data will be displayed.

At this point, you can format the template, save and analyze the data, and generate,

display, and print any additional reports. (See the following chapters for information

about to perform these functions.)

3.5 Typical Scenarios

The following scenarios describe the workflow for typical kinds of analysis. Refer to

the following chapters for details on how to perform the particular functions.

Scenario 1. Endpoint Assay with Previously Formatted Template

You want to perform an endpoint assay using a template layout that you have already

defined. From the FILE menu, you select New Endpoint Protocol. This opens the

Endpoint Protocol dialog box. You enter Mix Time, Initial Wait, and Incubator

settings for the reader.

18

Chapter 3. Getting Started

Figure 10. Performing an endpoint reading.

You have a data file saved from a previous run with the template you want to use for

this plate, so you click on Pick Template... and choose that data file. Now that

everything is set, you click on the Run button.

After the reading is complete, the raw data values pop up. The plate template is also

displayed. Since the template already contains the concentrations of the standards,

you go straight to the Unknown Concentration Report (select Unknown

Concentration Report from the VIEW menu). You select Print... from the FILE

menu to print this report.

You decide that you will be repeating this operation frequently, so you go back to the

Endpoint Protocol dialog box. The Reports... button opens a dialog box in which

you specify the reports to view and/or print after each reading. Select the Unknown

Concentration Report for printing, and click on OK. You select Save Protocol from

the FILE menu and enter a file name to store this protocol on disk.

The next day, you want to repeat the protocol. Select the protocol file name from the

Open dialog box, place your plate in the reader, click on the Run button, and wait at

the printer for a hard copy of the new Unknown Concentration Report.

19

Microplate Manager User Guide

Scenario 2. Kinetic Assay

You want to perform a new kinetic assay. From the FILE menu, you select New

Kinetic Protocol. The Kinetic Protocol dialog box opens.

For this assay, you would like to make five readings at 21-second intervals followed

by 20 readings at one-minute intervals. You want to shake the plate for one second

before each of the first five readings.

To accomplish this, you define two reading sets. The first set has 5 repetitions, a 1second mix time, and a 22-second interval (the interval you want plus the mix time).

The second set has 20 repetitions, 0 seconds mix time, and a 60-second interval.

Interval includes

mix time

Figure 11. Defining the Reading Sets.

After inserting your 12 x 8 plate into the reader, you click on Run and the reader

begins collecting data. At this point, both the template and the Kinetic Plots Report

automatically pop up.

The Kinetic Plots Report shows a graph of absorbance versus time for each well. As

each reading is completed, the graphs are updated. After all of the data has been read,

you can display any relevant report (Limit, Control, etc.) by selecting it from the

VIEW menu. To change the velo city calculation, you go to Analysis Options... under

the OPTIONS menu and select one of the two calculation methods under Kinetic

Mode. When you click on OK, the velocities are automatically recalculated.

20

Loading...

Loading...