Bio-Rad Bio-Dot and Bio-Dot SF Microfiltration Apparatus User Manual

Bio-Dot

®

SF

Microfiltration

Apparatus

Instruction

Manual

Catalog Number

170-6542

170-6543

For technical service call your local Bio-Rad office or in the U.S., call 1-800-424-6723.

Table of Contents

Page

Section 1 Introduction ..................................................................................1

1.1 Specifications............................................................................................1

Section 2 Special Handling and Features ..................................................1

2.1 Autoclaving ..............................................................................................1

2.2 Chemical Stability ....................................................................................1

Section 3 Bio-Dot SF Assembly ..................................................................3

3.1 Assembly ..................................................................................................3

3.2 Helpful Hints..............................................................................................5

Section 4 Protein Slot Blotting ....................................................................6

4.1 General Recommendations ......................................................................6

4.2 Immunoassay Procedure..........................................................................6

Section 5 DNA Slot Blotting ........................................................................8

Section 6 RNA Slot Blotting ........................................................................9

6.1 Alkaline RNA Denaturation and Fixation ..................................................9

6.2 Glyoxal RNA Denaturation and Fixation ..................................................9

Section 7 Hybridization Protocols for Nucleic Acids ..............................11

7.1 Probe Recommendations ......................................................................11

7.2 Hybridization Protocols for DNA or RNA Bound to

Nitrocellulose or Zeta-Probe

®

Membrane ..............................................11

7.3 Hybridization Protocols for RNA Probes ................................................13

7.4 Probe Stripping and Rehybridization ......................................................14

Section 8 Solutions for Protein Applications ..........................................15

8.1 Solutions for Nitrocellulose Membrane ..................................................15

8.2 Solutions for Zeta-Probe Membrane ......................................................16

Section 9 Solutions for Nucleic Acid Applications..................................17

Section 10 Troubleshooting Guide..............................................................19

Section 11 References..................................................................................22

Section 12 Ordering Information ................................................................24

Section 1

Introduction

The Bio-Dot SF blotting apparatus has an evenly spaced, slot shaped sample template for easy

slot blot sample comparisons. Because the Bio-Dot SF apparatus focuses the applied samples in

a thin line instead of a circle, this slot format makes it easy to use a densitometer to quantitate

results. The Bio-Dot SF apparatus is provided as a complete unit, or as a modular addition to the

Bio-Dot microfiltration system. Conversion of the Bio-Dot SF apparatus to the

Bio-Dot blotting apparatus is accomplished by purchasing the Bio-Dot module, which provides

the 96-well sample template.

The Bio-Dot SF slot format sample template has 48 wells with dimensions of 7 mm x 0.75 mm. The

wells are arranged in 8 rows and 6 columns. Sample can be applied using a standard pipet or

with an 8-channel pipet. The material used in the construction of the Bio-Dot SF blotting

apparatus can withstand rigorous sterilization and cleanup procedures. The Bio-Dot SF

apparatus can be repeatedly autoclaved, and is resistant to many chemicals, including acids,

bases, and ethanol.

1.1 Specifications

Materials

Bio-Dot SF apparatus Molded polysulfone

Bio-Dot SF gasket Silicone rubber

Stopcock Polytetrafluoroethylene (PTFE)

Shipping weight 600 grams

Overall size 13 x 15 x 6 cm

Membrane size 12 x 9 cm sheet

Autoclaving 15 minutes at 250°F (121°C) with a 1 minute fast exhaust

Chemical compatibility The Bio-Dot SF apparatus can be used with 100% alcohol solutions

and concentrated alkali or acid solutions. It cannot be used with

aromatic or chlorinated hydrocarbons. (See Table 1)

1

Section 2

Special Handling and Features

The Bio-Dot apparatus withstands autoclave temperatures for sterilization, as well as cleaning

with alcohols, acids, and base solutions.

2.1 Autoclaving

The Tygon tubing and flow valve cannot be autoclaved. All other components of the apparatus

withstand the autoclave treatment. After repeated autoclaving (~25 cycles) the silicone rubber

gasket may need replacing. The autoclave conditions that should be used are a maximum

sterilization temperature of 250°F (121°C) for 15 minutes, followed by a 1 minute fast exhaust.

Higher temperatures or increased exposure times will significantly reduce the life of the

apparatus. Do not autoclave the unit with the thumbscrews tightened, as this may cause the unit

to warp during exposure to the elevated temperatures.

2.2 Chemical Stability

The apparatus is stable in both acid and base solutions. It is stable in all concentrations of

alcohol solutions. Both of these features allow rapid cleanup and sterilization of the apparatus

and gaskets. The unit is not compatible with polar, aromatic, or chlorinated hydrocarbons, esters,

and ketones. These solvents will cause degradation of the plastic. See Table 1 for list of chemical

stability. For color development in the apparatus, the unit is compatible with both the methanol

used in the horseradish peroxidase (HRP) color development systems and the low concentration

of DMF used to solubilize the alkaline phosphatase (AP) color development reagents. However,

high concentrations of DMF will attack the plastic. Also, the unit is completely compatible with the

low concentrations of diethyl pyrocarbonate (DEPC) used as an alternative to autoclaving for

elimination of RNase activity.

Table 1. Chemical Compatibility

Chemicals compatible with Bio-Dot SF apparatus

Hydrochloric acid Methanol

Sulfuric acid Ethanol

Phosphoric acid Butanol

Glacial acetic acid Isopropanol

Sodium hydroxide Formaldehyde

Potassium hydroxide Hydrogen peroxide

Ammonium hydroxide Ethylene glycol

Heptane 5% acetone in H

2

O

Nitric acid

Chemicals that will attack polysulfone

Ethyl acetate Toluene

Butyl acetate Benzene

Acetone Methyl ethyl ketone

Chloroform Methylene chloride

Trichloroacetic acid

2

Section 3

Bio-Dot SF Assembly

3.1 Assembly

1. Clean and dry the Bio-Dot SF apparatus and gasket prior to assembly.

2. Place the gasket support plate into position in the vacuum manifold. (There is only one way to

slide the plate into the manifold.) Place the sealing gasket on top of the vacuum manifold.

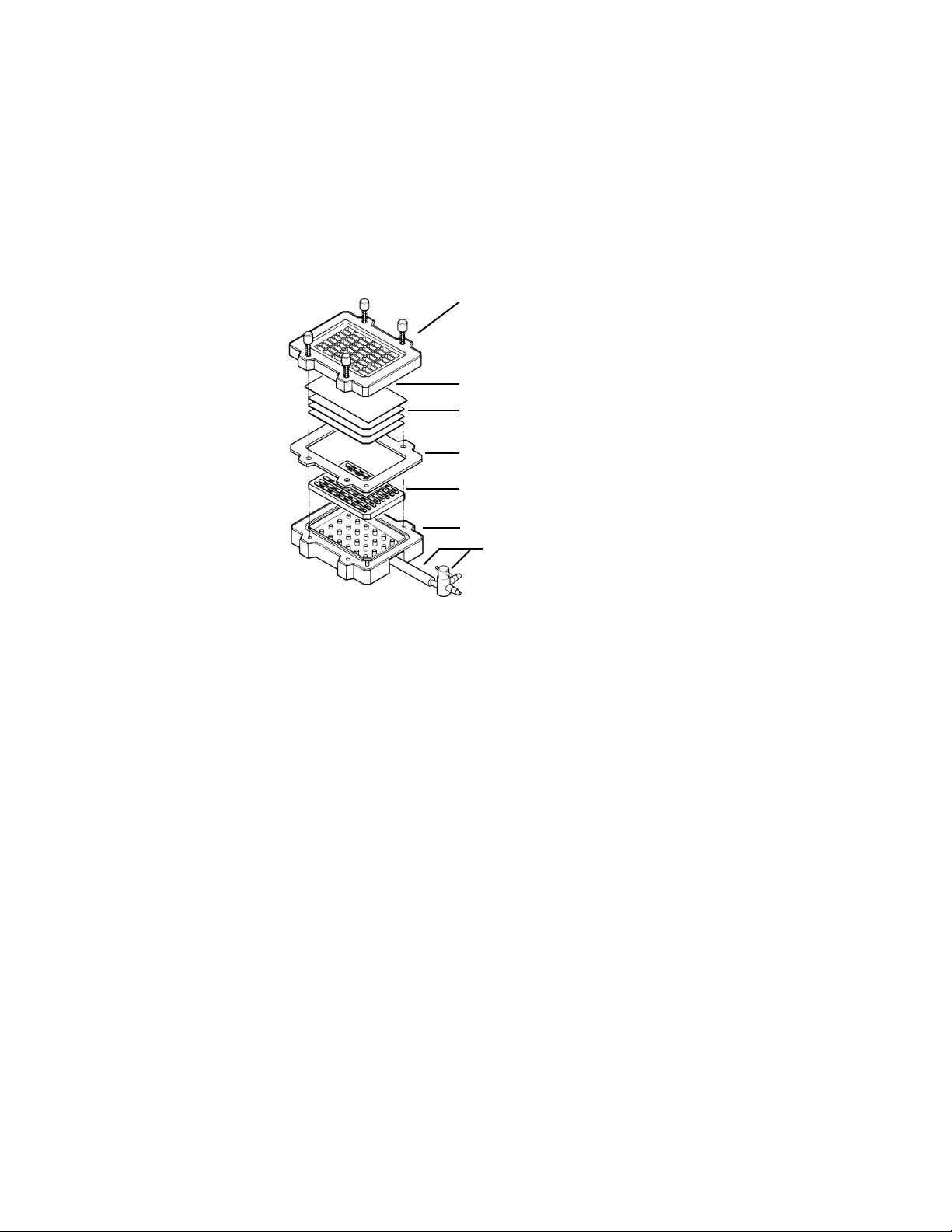

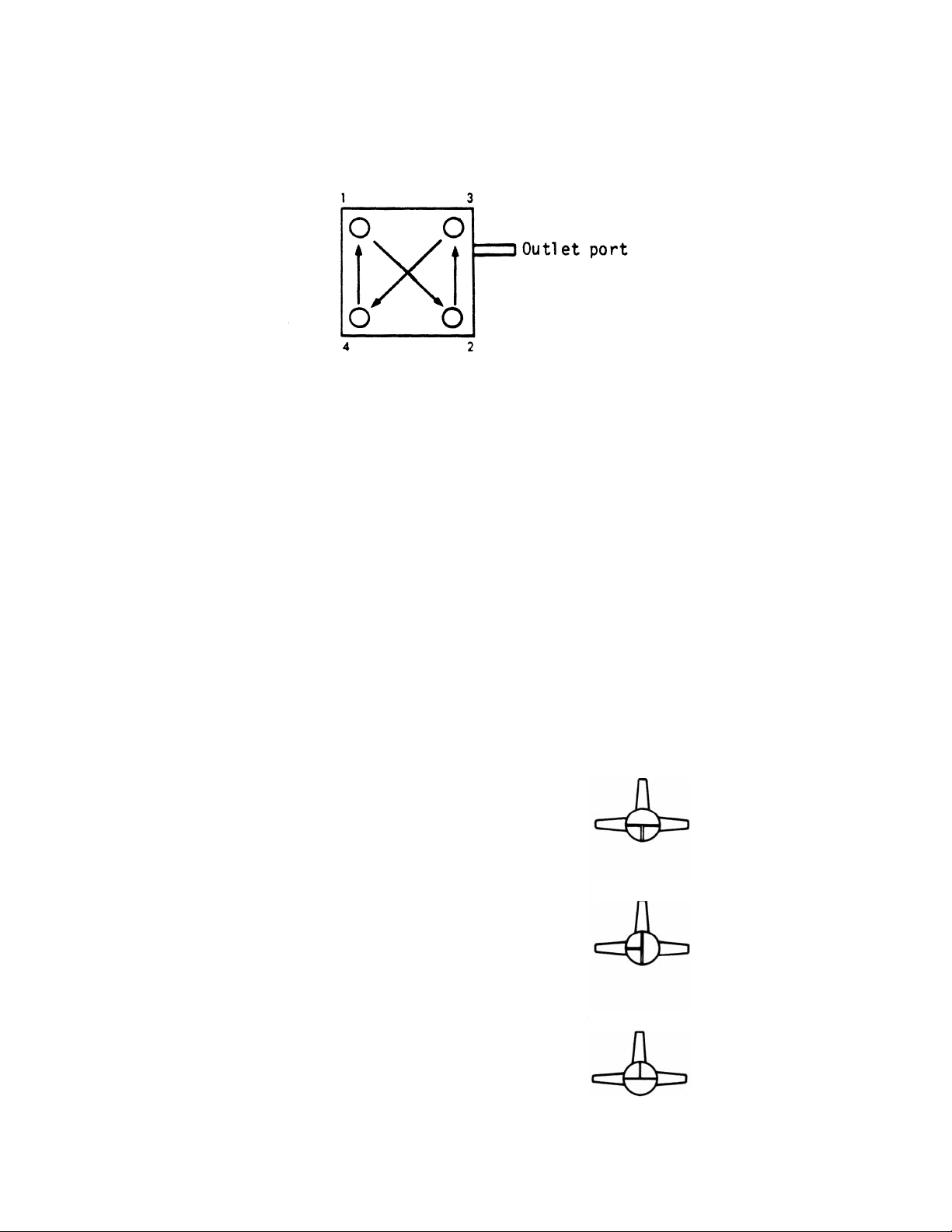

Fig.1. Diagram of proper Bio-Dot SF apparatus assembly.

3. Moisten three sheets of Bio-Dot SF filter paper (catalog number 162–0161) in wetting

solution. Use the same solution that is used to prewet the membrane (step 4). Place the

three sheets onto the membrane support. The filter paper is precut to fit inside the sealing

gasket. Use of Bio-Dot SF filter paper ensures high quality results and eliminates the chance

of cross-well contamination.

4.

Always use forceps or wear gloves when handling membranes. Prewet the nitrocellulose or

Zeta-Probe

®

membrane by slowly sliding it at a 45° angle into wetting solution. Nitrocellulose

is wetted in 6x sodium, sodium citrate (SSC) for nucleic acid applications, and in Tris-buffered

saline (TBS) for protein binding. Zeta-Probe membrane is wetted in distilled water. See

Sections 9 and 10 for solution preparation. A 10 minute soak is recommended for complete

wetting of the membrane to ensure proper drainage of solutions. Remove the membrane from

the wetting solution. Let the excess liquid drain from the membrane. (Touching the membrane

to a sheet of filter paper is a simple method for removing excess buffer.) Lay the membrane

on the filter paper in the apparatus so it extends over the edges of the filter paper. For the best

slot blot results, use membrane sheets that have been precut to a 9 x 12 cm size (catalog

number 162–0117 for nitrocellulose, 162-0153 for Zeta-Probe membrane). In all cases, the

membrane should not extend beyond the edge of the gasket after the Bio-Dot SF apparatus is

assembled. Remove any air bubbles trapped between the membrane and the filter paper.

Note: PVDF membrane is not recommended.

3

Vacuum manifold

Membrane

Filter paper (3 sheets)

Sealing gasket

Tubing and flow valve

Sample template with attached sealing screws

Gasket support plate

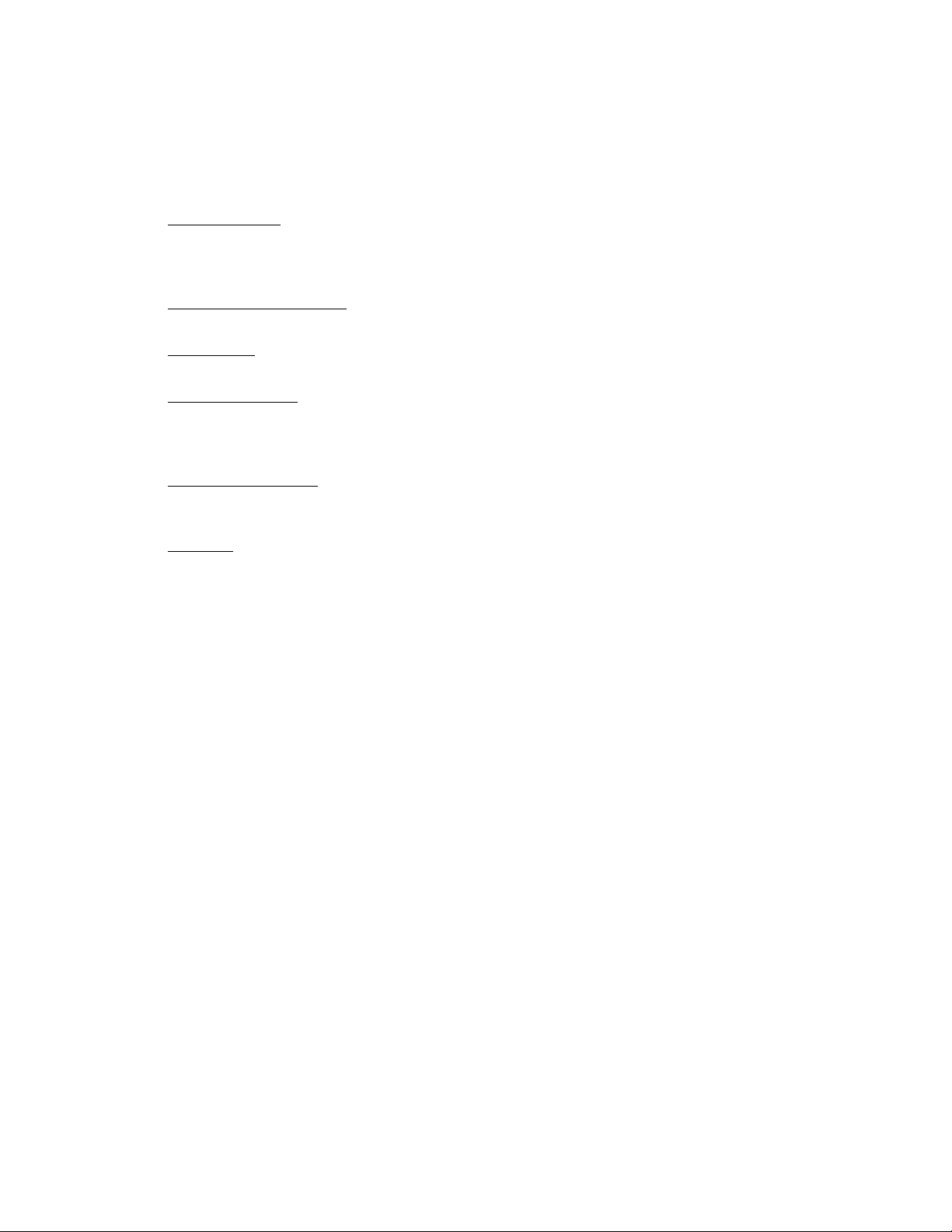

5. Place the sample template on top of the membrane. The guide pins ensure that the template

will be properly aligned. Finger-tighten the four screws. When tightening the screws, use a

diagonal crossing pattern to ensure uniform application of pressure on the membrane surface

(see Figure 2).

Fig. 2. Diagonal crossing pattern for tightening screws in the Bio-Dot apparatus.

6. Attach a vacuum source (house vacuum or vacuum pump) to the flow valve with a waste trap

set up and positioned between the vacuum outlet and flow valve. Turn on the vacuum and

set the 3-way valve to apply vacuum to the apparatus (flow valve setting one, Figure 3).

7. With vacuum applied, repeat the tightening process using the diagonal crossing pattern.

Tightening while vacuum is applied ensures a tight seal, preventing cross contamination

between slots. Failure to tighten screws during application of vacuum prior to starting

the assay may lead to leaking between the wells.

8. Adjust the flow valve so that the vacuum manifold is open to air (flow valve setting two,

Figure 3). Apply 100 µl to all the sample wells. Use of an 8-channel pipet and buffer

reservoirs (see Section 13 for information) will simplify the process of adding solutions to the

Bio-Dot SF apparatus. Addition of buffer is necessary to rehydrate the membrane following

the vacuum procedure in step 7. If this step is not performed prior to applying samples, assay

results will show halos or weak detection signal.

9. Gently remove the buffer from the wells by vacuum (flow valve setting three, Figure 3).

Watch the sample wells. As soon as the buffer solution drains from all the wells, adjust the

flow valve so that the unit is exposed to air and disconnect the vacuum. At this point, the unit

is ready for sample application.

Flow Valve Setting 1.

The vacuum manifold is exposed to the vacuum

source only. Use for applying vacuum to the

Bio-Dot SF apparatus.

Flow Valve Setting 2.

The manifold is exposed to air.

Use for gravity filtration procedures.

Flow Valve Setting 3.

The manifold is exposed to both air and the

vacuum. Use this setting for gentle vacuum

applications where the amount of vacuum

is regulated by putting a finger over the port

exposed to the atmosphere.

Fig. 3. Optional settings for the 3-way flow valve to obtain optimal performance from the Bio-Dot SF apparatus.

4

Vacuum

Bio-Dot

Air

Air

Vacuum

Vacuum

Bio-Dot

Bio-Dot

Air

3.2 Helpful Hints

1. During the assay, do not leave the vacuum on. This may dehydrate the membrane and may

cause halos around the wells. Apply vacuum only until solutions are removed from the

sample wells, then adjust the flow valve so that the unit is exposed to air and disconnect the

vacuum source.

2. If some sample wells are not used in a particular assay, those wells must be closed off to

insure proper vacuum to the wells in use. There are three ways to close off unused wells.

One is to apply a 3% gelatin solution to those wells. Gelatin will clog the membrane and cut

off the vacuum flow to the clogged wells. The second method is to cover the unused portion

of the apparatus with tape to prevent air from moving through those wells. The third method

is to add buffer to the empty wells at each step instead of sample or wash solutions.

3. Any particulate in samples or solutions will block the membrane and restrict flow of solutions

through the membrane. For best results, filter or centrifuge samples to remove particulate matter.

4. Check the wells after sample has been applied to insure that there are no air bubbles in the

wells. Air bubbles will prevent the sample from binding to the membrane. Air bubbles may be

removed by pipetting the liquid in the well up and down.

5. Proper positioning of the flow valve relative to the level of the apparatus is important for

proper drainage. The speed of filtration is determined by the difference in hydrostatic

pressure between the fluid in the sample wells and the opening of the flow valve which is

exposed to air. If the opening of the flow valve is above the level of the sample wells very

little drainage will occur. When the flow valve is positioned where it is at a level below the

sample wells proper drainage will occur during filtration applications.

6. The recommended sample loading volume is at least 200 µl. If sample volumes of less than

200 µl are loaded, they must be carefully applied to the center of the well. Applying the

solution on one side of the well results in unequal distribution of sample. This results in

unevenly shaped bands, leading to distorted densitometer readings.

7. The Bio-Dot SF apparatus is designed for use with an 8-channel pipet allowing eight sample

or wash solutions to be quickly and easily applied to one row at a time.

8. The best method for removing the blotted membrane from the Bio-Dot SF apparatus is to

leave the vacuum on following the wash step. With the vacuum applied, loosen the screws

and remove the sample template. Next, turn off the vacuum and remove the membrane.

5

Section 4

Protein Slot Blotting

4.1 General Recommendations

1. Solution Volume.

The liquid in the incubation vessel should be least 0.25 cm deep to ensure the membrane is

completely submerged during incubation. There should be at least 0.5 ml of reagent per cm

2

of membrane. Larger volumes may be used for convenience.

2. Handling the mMembrane.

Wear clean plastic gloves or use forceps to avoid fingerprints on the membrane.

3. Temperature.

All steps are performed at room temperature (22–25°C).

4. Incubation Vessels.

Incubation vessels may be made of plastic or glass. However, since avidin binds to

unsiliconized glass, plastic or siliconized glass vessels should be used whenever biotin-avidin

systems are employed for detection.

5. Membrane Incubation.

Agitation with a rotating shaker platform enhances incubation efficiency. If a shaker platform

is not available, hand mixing every few minutes and extended incubation periods will suffice.

6. Detection.

It is best to incubate only one membrane per vessel. Should it become necessary to use

more than one membrane per incubation vessel, calculate the solution volume based on the

membrane surface area, not the vessel size.

4.2 Immunoassay Procedure

Detailed instructions, including a comprehensive troubleshooting guide, for performing

immunoassays are given in the Immun-Blot

®

instruction manuals.

1. Assemble the Bio-Dot SF apparatus as described in Section 3.1. Prewet the membrane prior

to placing it in the apparatus. Nitrocellulose membranes are prewetted in TBS; Zeta-Probe

membrane is prewetted in distilled water (see Section 10 for solution preparation). Make sure

that all the screws have been tightened under vacuum to ensure that there will not be any

cross-well contamination.

2. Rehydrate the membrane to ensure uniform binding of the antigen. Use 100 µl TBS per well

for nitrocellulose membranes. Use 100 µl distilled water per well for the Zeta-Probe

membrane.

3. Adjust the flow valve so that the vacuum chamber is open to air (flow valve setting 2, Figure

3). Fill the appropriate wells with antigen (protein) solution, applying 50–500 µl per well. The

recommended sample loading volume is at least 200 µl. If less than 200 µl is applied, the

sample must be carefully applied to the center of the well. Applying the solution on one side

of the well results in unequal distribution of sample. This results in unevenly shaped bands,

leading to distorted densitometer readings.

Note: The solution applied should be free of insoluble particles to avoid clogging of wells.

4. Allow the entire sample to filter through the membrane by gentle vacuum. Make sure that the

flow valve is positioned at a level below the sample wells to ensure proper drainage during

filtration applications. Slow, gentle filtration is necessary for quantitative antigen binding.

Each well should be filled with the same volume of sample solution to ensure homogeneous

filtration of all sample wells.

6

Loading...

Loading...