Bio-Rad iMark Microplate Absorbance Reader User Manual

iMark™

Microplate Absorbance Reader

Instruction Manual

Warranty Statement

This warranty may vary outside of the continental United States. Contact your local Bio-Rad office for the exact terms of your warranty.

Bio-Rad Laboratories warrants to the customer that the iMark Microplate Absorbance Reader will be free from defects in material and workmanship, and will meet all performance specifications for a period of one year from the date of shipment. This warranty covers all parts and labor.

In the event that the instrument must be returned to the factory for repair under warranty, the instrument must be packed for return in original packaging. Please contact your local Bio-Rad representative for the necessary return documents. The required documentation includes a decontamination certificate.

Bio-Rad shall not be liable for any incidental, special, or consequential loss, damage, or expense directly or indirectly arising from the use of the iMark Microplate Absorbance Reader. Bio-Rad makes no warranty whatsoever in regard to products or parts furnished by third parties, such being subject to the warranty of their respective manufacturers. Service under this warranty shall be requested by contacting your nearest Bio-Rad office.

The following items are considered customer-installable consumables: thermal printer paper and light bulbs. These parts are not covered by this warranty. All customer-installed parts are warranted only to be free from defects in workmanship. This warranty does not extend to any instrument or parts thereof that have been subject to misuse, neglect, or accident, or that have been modified by anyone other than Bio-Rad or that have been used in violation of Bio-Rad instructions.

The foregoing obligations are in lieu of all other obligations and liabilities including negligence and all warranties of merchantability, fitness for a particular purpose, or otherwise expressed or implied in fact or by law, and state Bio-Rad’s entire and exclusive liability and buyer’s exclusive remedy for any claims or damages in connection with the furnishing of goods or parts, their design, suitability for use, installation or operation. Bio-Rad will in no event be liable for any special, incidental or consequential damages whatsoever, and Bio-Rad’s liability under no circumstances will exceed the contract price for the goods for which liability is claimed.

i

Regulatory Notices

Electro Magnetic Compatibility:

This instrument is designed to meet the Class-A emissions and immunity levels of the EN 61326 product family standard for the CE mark. This rating requires that it only be used in a laboratory environment.

NOTE: These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his/her own expense.

Safety

This instrument is designed to meet EN 61010-1 requirements for the CE mark, which are internationally accepted safety standards for electrical equipment for measurement, control and laboratory use. EN 61010-1 applies to equipment which is used under the following conditions:

•Indoor use

•Altitude up to 2,000 m

•MAINS supply voltage fluctuations up to ±10%

This instrument has been tested, and its compliance has been confirmed under the following environmental conditions:

•Overvoltage category II

•Pollution degree 2

If the instrument is used in a manner not specified in this manual, the protection provided by the instrument may be impaired. This instrument should not be modified or altered in any way. Alteration of this instrument will result in the following:

•Void the manufacture’s warranty.

•Void regulatory compliance.

•Create a potential safety hazard.

Protective Ground

This instrument has a detachable, three-wire power cord for connection to both the power source and protective ground. The protective ground contact is connected to the accessible metal parts of the instrument. To prevent electrical shock, always use a power source outlet that has a properly grounded protective-ground contact.

ii

Table of Contents |

|

|

Introduction .................................................................................................. |

|

1 |

Description ......................................................................................................... |

|

1 |

USB Interface ..................................................................................................... |

|

1 |

Built-in Printer .................................................................................................... |

|

1 |

External Features................................................................................................. |

3 |

|

Keypad Guide ..................................................................................................... |

|

4 |

Instrument Setup ............................................................................................ |

|

5 |

Unpacking the Instrument..................................................................................... |

5 |

|

Initial Instrument Startup...................................................................................... |

5 |

|

Instrument Shutdown ........................................................................................... |

6 |

|

Software Overview......................................................................................... |

|

7 |

Capabilities......................................................................................................... |

|

7 |

Quick Guide to Reading a Plate ............................................................................ |

7 |

|

Instrument Functions ...................................................................................... |

|

8 |

Calculations ........................................................................................................ |

|

8 |

Security password................................................................................................ |

8 |

|

Memory Back-Up................................................................................................ |

8 |

|

Limits ............................................................................................................... |

|

9 |

Report Types ............................................................................................... |

|

10 |

End-point Protocol Reports................................................................................. |

10 |

|

1. |

Raw data report.......................................................................... |

10 |

2. |

Absorbance report ...................................................................... |

10 |

3. |

Limit report ............................................................................... |

10 |

4. |

Matrix report ............................................................................. |

10 |

5. |

Cutoff report.............................................................................. |

11 |

6. |

Curve Fit Report ........................................................................ |

12 |

7. |

Concentration Report.................................................................. |

12 |

8. |

Difference Report....................................................................... |

12 |

9. |

TeSeE Screening Report ............................................................. |

13 |

Kinetic Protocol Reports .................................................................................... |

15 |

|

1. |

Absorbance Report ..................................................................... |

15 |

2. |

Kinetic Plots Report ................................................................... |

15 |

3. |

Linear Regression Report............................................................ |

15 |

4. |

GALT Report ............................................................................ |

15 |

iii

Screen by Screen Procedures......................................................................... |

17 |

Initial Startup .................................................................................................... |

17 |

Configuring the System...................................................................................... |

18 |

Printing Reports and Protocol information............................................................ |

20 |

Memory Recall Operation .................................................................................. |

21 |

Editing the Kinetic Protocol................................................................................ |

22 |

Checkmark Value Setting (Administrator only)..................................................... |

24 |

Editing End Point Protocol ................................................................................. |

25 |

Cutoff Setting Procedure .................................................................................... |

26 |

Standard Setting Procedure................................................................................. |

29 |

Mode Setting Procedure ..................................................................................... |

32 |

Plate Map Setting Procedure............................................................................... |

33 |

Instrument Maintenance................................................................................ |

36 |

Installing Interference Filters .............................................................................. |

36 |

Changing the Lamp ........................................................................................... |

36 |

Troubleshooting and Error Messages.............................................................. |

37 |

Instrument Specifications.............................................................................. |

39 |

iv

iMark Microplate Absorbance Reader Instruction Manual

Introduction

Description

The iMark™ Microplate Absorbance Reader (catalog #168-1130) is an eight-channel, vertical pathlength photometer that measures the absorbance of the contents in the wells of a 96-well microtitration plates. It can perform single or dual wavelength measurements and can report absorbance values to three decimal places.

The iMark reader can be programmed by entering commands through the membrane keypad to define plate reading and data analysis parameters as testing protocols and select report types. Hard copy reports can be produced by an optional on-board thermal printer or external printer.

The iMark reader can also be controlled by the Windows-based Microplate Manager® software (catalog # 168-9520) program, through its built-in USB 2.0 interface device. Microplate Manager software provides a complete, user-friendly solution for protocol programming as well as data analysis, for all microplate absorbance readers from Bio-Rad Laboratories.

USB Interface

The iMark Microplate Reader has a built-in USB interface. This allows external computers to control the instrument. When an external computer is in control of the microplate reader, the printer and the membrane keys, except for the Start/Stop and Open/Close keys, are automatically deactivated, and the LCD display appears as below.

Remote mode

The reader will remain in remote control mode until it is released or until the Start/Stop key is pressed on the reader.

Built-in Printer

The iMark Microplate Reader has a built-in printer. It can generate all types of reports, including graphs and kinetic plots.

1

iMark Microplate Absorbance Reader Instruction Manual

Catalog # |

Description |

168-1130 |

iMark Microplate Absorbance Reader with built-in printer |

168-1135 |

iMark Microplate Absorbance Reader with built-in printer, |

|

including Microplate Manager 6 software |

168-6940 |

Checkmark Absorbance Reader Performance Validation Kit |

Accessories |

|

Catalog # |

Description |

168-1011 |

405 nm filter |

168-1013 |

415 nm filter |

168-1020 |

450 nm filter |

168-1028 |

490 nm filter |

168-1038 |

540 nm filter |

168-1040 |

550 nm filter |

168-1044 |

570 nm filter |

168-1049 |

595 nm filter |

168-1054 |

620 nm filter |

168-1056 |

630 nm filter |

168-1061 |

655 nm filter |

168-1080 |

750 nm filter |

168-1006 |

Replacement lamp for iMark Microplate Absorbance Reader |

168-2007 |

Replacement printer paper, package contains 3 rolls |

Custom filters between 400 and 750 nm may be ordered. Corresponding catalog numbers can be found on www.bio-rad.com, or you can order by specifying the wavelength and the model number of the reader.

Checkmark Absorbance Reader Performance Validation Kit (catalog item 168-6940) consists of a plate with absorbance standards and software to calculate the accuracy and precision of the iMark Microplate Absorbance Reader.

2

|

|

iMark Microplate Absorbance Reader Instruction Manual |

|

|

|

|

|

External Features |

Release latch for rear cover |

Rear cover |

|

|

|

|

|

|

|

|

|

Power button |

Printer slot |

|

Liquid crystal display (LCD)

Keypad

Reading chamber door

Cooling vents and fan

|

|

|

|

|

|

|

|

USB 2.0 interface |

Serial number label |

Power cord receptacle |

|

3

iMark Microplate Absorbance Reader Instruction Manual

Keypad Guide

Main |

Returns to MAIN SCREEN. |

Start/Stop |

Initiates plate reading using current active protocol. |

|

Stops plate reading and printing. |

Paper Feed |

Advances paper strip in internal printer. |

Prints out the plate data and protocol information. |

|

Edit |

Enters the Edit Menu, and sets up the instrument. |

Memory Recall |

Reads out protocol and plate data. |

Open/Close |

Opens or closes the reading chamber door. |

Open/Close |

Memory |

Edit |

|

Recall |

|||

START |

|

||

|

|

||

/ |

|

|

|

STOP |

|

|

|

Main |

Paper Feed |

Up Arrow |

Moves the cursor upward. |

|

Selects the alphabet or the symbol. |

Left Arrow |

Returns to the previous screen. |

|

Moves the cursor to the left. |

Down Arrow |

Moves the cursor downward. |

|

Selects the alphabet or the symbol. |

Right Arrow |

Moves the cursor to the right. |

|

Changes or selects the value and type. |

Enter |

Completes or seals a field entry. |

A => Z

+−••

ENTER

Back Change

Z => A

Dot/Function |

Inputs the dot. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Changes the input mode. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Ten Keys |

Inputs numbers or well type in plate mapping. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

CP |

|

|

|

|

|

CN |

|

|

|

|

CW |

|

||||||

|

0 |

/ EMP |

: Empty |

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

7 |

|

|

|

8 |

|

9 |

|||||||||

|

5 |

/ QC |

: QC control |

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

1 |

/ SMP |

: Sample |

|

|

|

CO |

|

|

|

|

|

|

QC |

|

|

CAL |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

6 |

/ CAL |

: Calibrator |

|

|

|

|

4 |

|

|

|

|

5 |

|

6 |

|||||

|

|

|

|

|

|

|

|

|

||||||||||||

|

2 |

/ BLK |

: Blank |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SMP |

|

|

|

BLK |

|

|

|

STD |

|

||||||||

|

7 |

/ CP |

: Positive Control |

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

1 |

|

|

|

|

2 |

|

3 |

||||||

|

3 |

/ STD |

: Standard |

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

8 |

/ CN |

: Negative Control |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

EMP |

|

FUNC |

|

|

|||||||||||||

|

4 |

/ CO |

: Cutoff control |

|

|

0 |

|

|

0 |

|

|

|||||||||

|

|

|

|

|

||||||||||||||||

|

9 |

/ CW |

: Weak Positive Control |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4

iMark Microplate Absorbance Reader Instruction Manual

Instrument Setup

Unpacking the Instrument

The shipping carton contains the following items:

•iMark™ Microplate Reader, with 415 nm, 450 nm, 490 nm, 595 nm, 655 nm, and 750 nm interference filters installed on the filter wheel

•Power cord

•USB cable

•Dust cover

•Instruction manual

•Warranty card

•One roll of thermal printer paper

Inspect the exterior of the instrument for any signs of shipping damage. Contact your local Bio-Rad representative if any of these items are damaged or missing.

Initial Instrument Startup

1.Place the instrument on a clean, sturdy table or bench. It is important to keep the instrument in a clean, relatively dust free environment to ensure optimal performance.

2.Connect the power cord to the back of the instrument. Before connecting the instrument to the main electrical supply, check that the AC voltage is appropriate for the instrument.

3.To turn the power on press the green power button on the top of the instrument. The LCD will display the version number of the on-board firmware. After about three seconds, the instrument will perform an initial self-diagnosis that requires about fifteen seconds. The login screen displays for you to choose your user level (administrator or common user), and enter the password (initial password: 00000). Please allow three minutes for the instrument to warm up (reach thermal equilibrium) before reading plates.

System Login

User: Administrator

Password:*****

Press ENTER

Change password

Select “Change Password” in the Security Menu.

Enter the current Password then move the cursor to the 3rd line and enter a new password. Press Enter to complete the field entry. The system will return to the previous Security Menu.

Change user mode

Select “Change user” in the Security Menu.

Select a desired user mode by pressing the Right Arrow key. Enter the appropriate password for the selected user mode. Press Enter to complete the field entry. The system will return to the previous Security Menu.

5

iMark Microplate Absorbance Reader Instruction Manual

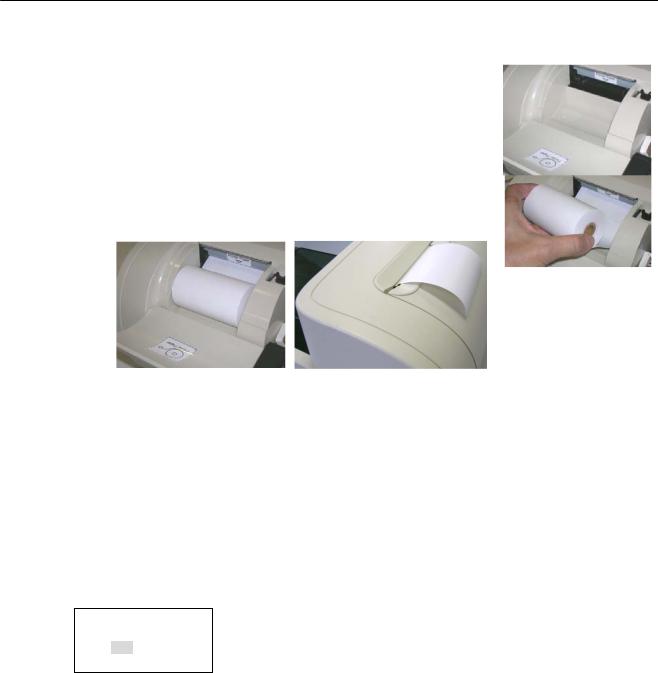

4.Install the printer paper. The thermal printer paper is printable on one side only and must be properly installed for the printer to function. The outside of the roll is the printable side.

a.Open the rear cover of the instrument.

b.Tear off a small piece at the beginning of a new roll at an angle to form a point.

c.Place the roll of paper in the small pan-like holder positioned below the printer. The roll should be positioned so that it will feed from the bottom.

d.While pressing the PAPER FEED key, feed the pointed end of the paper into the paper feed slot in the underside of the printer until the printer grabs the paper and feeds it through the slot in the top of the instrument.

e.Securely close the rear compartment.

Multi-language support

The iMark LCD can produce text in three languages; English, Russian and Chinese. To switch to English from Russian or Chinese, press the Main button, then the Edit button to get to the configuration screen. Press the downward-pointing arrow on the key pad six times to navigate to the language options line. Press Enter twice to select English, and then press Enter a third time to shut down the reader. When restarted, the iMark will display in English.

Instrument Shutdown

To shut down the instrument, press the green power button on the top of the instrument for a few seconds. Then the LCD will display a Power off, Yes or No screen. Select “Yes” to shut down the instrument.

Power off

>>Yes No

6

iMark Microplate Absorbance Reader Instruction Manual

Software Overview

Capabilities

The iMark Microplate Reader has on-board software that allows the user to set the plate reading and data analysis conditions, to save these settings as a test protocol, to read a microplate under this protocol, and to print reports from the built-in printer. The software communicates through the 4-line, 20-character LCD and is controlled through the instrument's membrane keypad.

The software has three different protocol types: End-point analysis, Kinetic analysis, and Checkmark validation. The Checkmark validation function is used only by the administrator to verify quality control.

The display shows the current mode. The user can choose between these protocol types, or can press the Memory Recall key to use the current protocol type.

Quick Guide to Reading a Plate

1.Turn on the instrument. Allow about 30 seconds for self-diagnosis. The instrument needs to warm up for about three minutes prior to reading a plate.

2.Upon power up, the login screen will appear. Enter the login password (initial password: 00000), press Enter.

3.Program a protocol for your assay. See page 22 for information on Editing a Kinetic protocol, or page 25 for Editing an End Point Protocol. Make sure filters installed correlate with information entered in reader firmware.

4.Select the protocol of choice, if programmed. See the Memory Recall section on page 21 for detailed operation.

5.Review or print parameters set in the protocol. See the Editing End Point Protocol section on page 25 for details.

6.Verify settings on Cutoff, Report, Limit, STDs, Mode, Mapping, and kit name parameters are as desired.

7.Protocol setting can be printed; see the Printing Reports and Protocols section on page 20 for information.

8.All reports other than the raw data report require plate mapping. Set the plate map with instructions from the Plate Map Setting Procedure section on page 33.

9.The Matrix and Limit reports require assignment of upper and lower limits. Set the upper and lower limits in the Editing End Point Protocol Limit setting window.

10.The Cutoff report requires definition of the cutoff setting. Refer to the Cutoff Setting Procedure section on page 26.

11.The Curve fit and Concentration reports require that standard concentration and locations must be defined. Refer to page 29 for details on how to define the standards and the curve fit parameters.

12.Set the general reading mode (single or dual wavelength reading, plate shaking, read mode) following the instructions in the Mode Setting Procedure section on page 32.

After warm-up is complete:

13.Press the “Main” key. The main screen appears on the LCD.

14.Carefully place the microplate in the reading chamber. Press the “Start/Stop” key to read.

7

iMark Microplate Absorbance Reader Instruction Manual

Instrument Functions

Calculations

The Microplate Reader uses Beer's Law to calculate the absorbance value of each well. Beer's Law states that absorbance is equal to the log10 of the ratio of the baseline measurement intensity (Io) to the sample measurement intensity (I).

Beer's Law: Absorbance = Log10 (Io/I)

Before measuring the plate, the reader takes a reading for all eight photodiode channels. These values are recorded as the baseline measurement (Io) values for each channel, respectively. The reader then records the sample measurement (I) value for each well, and calculates the absorbance using these values. Channel-to-channel error is significantly reduced because the Io value for a given channel is used only in determining the absorbance of the wells of that channel.

Security password

The iMark Microplate Reader requires a user login with password. This security feature helps to prevent any unwarranted modifications to the analysis conditions/protocols and data stored in the instrument, and identifies the operator on reports. The reader has two user settings, the Administrator and the Common user. Each user level has its own security password.

Memory Back-Up

The battery back-up provides memory even after the reader is turned off.

The following information will be saved in the memory until new reading parameters are set by the user or a new plate is read by the instrument. Note that if a run is aborted before it is finished, all the previous plate reading data remain in memory and none of the data from the aborted reading is stored.

•The ten latest sets of End-point protocol plate reading results

•The two latest sets of Kinetic plate reading results (max. 30 series of readings for each Kinetic Protocol)

•64 End-point Protocol settings and 2 Kinetic Protocol settings

•A set of Checkmark reference data and the one latest set of Checkmark reading result

•A set of standard curve data for the storage of standard curves and graphs

•Eight wavelength values for filters

•Laboratory name

•Two security passwords (for the Administrator and the Common user)

•Instrument serial number

In addition to the battery back-up memory, the instrument has a small amount of non-volatile memory to keep the system information after the battery is dead. The serial number is stored in this memory. The average battery life is 5 years.

8

iMark Microplate Absorbance Reader Instruction Manual

The first time the instrument is turned on, or after a battery failure, the following default information is held in the memory.

1.Both Administrator and Common user security passwords are set to "00000".

2.Laboratory name is "Bio-Rad Laboratories".

3.All wavelength values of the filters are set to "---" nm.

4.The date and time of the calendar chip are set to 1 day, 1 month, 00 year, 0 hour and 0 minute.

5.No plate reading data is available.

6.End-point protocol is chosen and the protocol number is set to #1.

7.No standard curve data for the storage of standard curves and graphs is available.

Limits

The Microplate Reader displays absorbance readings with absolute values as 3.500. Out-of-range absorbance values, (those with absolute values greater than 3.500) are displayed as either "*.***" or "-*.***". For example, if the absorbance is 4.500, then the display will read "*.***", and if the absorbance is -4.500, the display will read "-*.***".

9

Loading...

Loading...