Bio-Rad GS-800 Calibrated Densitometer User Manual

Model GS-800 ™

Calibrated Imaging

Densitometer

User Guide

For Catalog Numbers

170-7980 GS-800 Densitometer, PC

For Technical Service

Call Your Local Bio-Rad Office or In the U.S. Call 1-800-4BIORAD (1-800-424-6723)

WWW.BIO-RAD.COM

4000188 Rev. B |

Copyright 2002 Bio-Rad Laboratories Inc. |

Warranty Statement

Bio-Rad Model GS-800 Calibrated Imaging Densitometer

This warranty may vary outside of the United States. Please contact your local Bio-Rad office for the exact terms of your warranty.

Bio-Rad Laboratories warrants to the customer that the Model GS-800 Calibrated Imaging Densitometer (Catalog Number 170-7980) will be free from defects in material and workmanship, and will meet all performance specifications for the period of one year from the date of shipment. This warranty covers all parts and labor.

In the event that the instrument must be returned for repair under warranty, the instrument must be packed for return in the original packaging.

Bio-Rad shall not be liable for any incidental, special or consequential loss, damage, or expense directly or indirectly arising from the use of the Model GS-800 Calibrated Imaging Densitometer. Bio-Rad makes no warranty whatsoever in regard to products or parts furnished by third parties, such being subject to the warranty of their respective manufacturers. Service under this warranty shall be requested by contacting the customer’s nearest Bio-Rad office.

This warranty does not extend to any instruments or parts thereof that have been subject to misuse, neglect or accident, or that have been modified by anyone other than Bio-Rad or Bio-Rad's authorized agent, or that have been used in violation of Bio-Rad instructions.

For any inquiry or request for repair service, contact Bio-Rad Laboratories. Inform BioRad of the model and serial number of your instrument.

2

|

Table of Contents |

|

SECTION 1 GENERAL INFORMATION ................................................................................................................. |

4 |

|

1.1 |

INTRODUCTION ................................................................................................................................................... |

4 |

1.2 INSTALLATION QUALIFICATION AND OPERATIONAL QUALIFICATION ( IQ/OQ )................................. |

4 |

|

1.3 |

SAFETY................................................................................................................................................................... |

5 |

SECTION 2 SETTING UP............................................................................................................................................. |

6 |

|

2.1 |

CHECKING THE CONTENTS ............................................................................................................................... |

6 |

2.2 |

UNPACKING THE CONTENTS ............................................................................................................................ |

6 |

2.3 |

UNLOCKING THE DENSITOMETER AND THE TRANSPARENCY MODULE.................................................. |

7 |

2.4 |

LOCKING THE DENSITOMETER AND THE TRANSPARENCY MODULE ....................................................... |

8 |

2.5 |

TAKING A CLOSER LOOK ................................................................................................................................... |

8 |

SECTION 3 INSTALLATION.................................................................................................................................... |

10 |

|

3.1 |

ABOUT USB DEVICES ........................................................................................................................................ |

10 |

3.2 |

INSTALLATION WITH A PC .............................................................................................................................. |

10 |

3.3 |

CONNECT THE DENSITOMETER TO THE COMPUTER .................................................................................. |

10 |

3.3 |

TESTING THE DENSITOMETER......................................................................................................................... |

12 |

SECTION 4 OPERATION .......................................................................................................................................... |

13 |

|

4.1 OVERVIEW OF OPERATIONAL COMPONENTS ............................................................................................... |

13 |

|

4.2 START-UP ............................................................................................................................................................. |

15 |

|

4.3 |

REFLECTIVE SCANNING ................................................................................................................................... |

15 |

4.4 |

TRANSMITTANCE SCANNING ......................................................................................................................... |

16 |

SECTION 5 MAINTENANCE ................................................................................................................................... |

17 |

|

5.1 |

CLEANING THE IMAGE WINDOW GLASS ...................................................................................................... |

17 |

5.2 |

CLEANING THE CABINET EXTERIOR .............................................................................................................. |

17 |

SECTION 6 TROUBLESHOOTING......................................................................................................................... |

18 |

|

6.1 |

TROUBLESHOOTING.......................................................................................................................................... |

18 |

6.2 |

TECHNICAL SERVICE ........................................................................................................................................ |

20 |

SECTION 7 : SUPPORT DOCUMENTATIONS................................................................................................... |

21 |

|

7.1 TECHNICAL SPECIFICATIONS ............................................................................................................................. |

21 |

|

7.2 |

DECLARATION OF CONFORMITY:................................................................................................................... |

21 |

3

Section 1 General Information

1.1 Introduction

The Model GS-800 Calibrated Imaging Densitometer is a high performance, calibrated imaging densitometer that converts transparent and opaque electrophoretic samples into digital data. These data are analyzed with Quantity One® software operating in Microsoft

Windows® computer systems. For a step-by-step guide to scanning and analyzing images, please refer to your QuantityOne software user manual.

The main features of the Model GS-800 Calibrated Imaging Densitometer include:

•Adjustable resolution from 36.3 microns to 127.0 microns;

•Reflectance and transmittance

•Scanning area of 29 cm by 40 cm

•Sampling rate of up to 700 dots per inch (dpi).

•Variable wavelength filter architecture for improved color discrimination

•Analog to digital conversion at full 12-bit accuracy

•Calibrated transmission tablet to ensure accurate OD readings

•Reflective gray scale tablet to ensure reproducible reflectance values

•Supported by Quantity One software, which provides versatile image display, optimization, and quantitation features

•USB interface

1.2Installation Qualification and Operational Qualification (IQ/OQ)

The calibration of the Model GS-800 Calibrated Imaging Densitometer can be validated by following the GS-800 Calibrated Densitometer Installation Qualification and Operational Qualification protocols. These protocols are available as an accessory to the GS-800 Calibrated Imaging Densitometer (Catalog number 170-7956) these straightforward and simple to follow IQ/OQ protocols include instructions for the installation of the hardware and software, and instructions for the verification of the reflectance and transmittance calibration functions.

Following proper installation, a linear dynamic range of 3.0 OD for the Transmissive scanning and 2.0 OD for Reflectance scanning can be confirmed with greater than 95% confidence. For additional details, contact your local Bio-Rad Representative.

4

1.3 Safety

The Model GS-800 Calibrated Imaging Densitometer system uses high voltage and high current and should be operated with care at all times. To avoid shock, set up the GS-800 Densitometer in a dry area. Immediately wipe up any spilled solutions.

•Turn off the Densitometer, and then disconnect the power plug when you want to clean the Densitometer case or glass plate, or when the Densitometer needs service or repair.

•Place the Densitometer on a level surface.

•To ensure proper ventilation, allow a minimum of 15 cm free space around each side of the Densitometer.

•Do not leave photographs, gels, or film on the glass plate for excessive periods of time. The heat from the light source in the Densitometer may cause them to deteriorate.

•Do not operate the Densitometer when the environmental temperature falls below 5° C or rises above 40° C.

•Do not operate the Densitometer when the environmental humidity falls below 20% or rises above 85%.

1.4 Regulatory Compliance*

Declaration of Compliance

The party responsible for product compliance

Corporate Name:UMAX Technologies, Inc.

Address: |

Techville, Inc. |

|

11343 N. Central Expwy |

|

Dallas, TX 75243 USA |

Telephone No.: Tel.: (214) 739-7033

*See UMAX PowerLook 2100XL Operation Manual

5

Section 2 Setting Up

2.1 Checking the Contents

Your Model GS-800 Calibrated Imaging Densitometer system should arrive complete with one of each of the following:

•GS-800 Calibrated Imaging Densitometer

•GS-800 Calibrated Imaging Densitometer User Guide

•Quantity One™ Image Analysis Software

•UMAX PowerLook 2100XL Operation Manual

•USB Cable

•Power Cord

•Warranty Card (please complete and return to Bio-Rad)

•MagicScan CD and manual

These components may arrive in several boxes. If your system is missing any of these items, immediately contact your local Bio-Rad office for a prompt replacement. Please retain all packaging material. Additional charges will be assessed if packaging is not available for instrument warranty service shipping.

Caution: Use care when unpacking your equipment. The equipment is delicate and damage can occur if it is dropped or otherwise mistreated.

2.2 Unpacking the Contents

Unpacking the Model GS-800 Calibrated Imaging Densitometer shipping container:

Warning: The Model GS-800 Calibrated Imaging Densitometer weighs approximately 46.17 lbs. (20.8 kg). To avoid personal injury, two people may be needed to lift the Densitometer out of the shipping container. Lifting the unit just by the lid may cause damage to the instrument

1.Carefully lift the Model GS-800 Calibrated Imaging Densitometer out of the shipping carton and place it on a stable, dry, flat surface. The chassis of the Model GS-800 Calibrated Imaging Densitometer attempts to conform to any uneven surface. This may result in a poor-quality scan.

2.Remove the plastic wrapping and the packing materials from the Densitometer.

3.The Model GS-800 Calibrated Imaging Densitometer should be located close to the computer system to which it will be connected. Select a flat, dry surface that provides adequate ventilation on all sides to prevent overheating.

6

4.The Model GS-800 Calibrated Imaging Densitometer can operate with 100V AC to 240V AC. Check the power cord to insure that it is suitable for your area.

Caution: The power cord plug provided has a third grounding pin. This plug fits in a grounding-type outlet only. This is a safety feature. If you are unable to plug the power cord into a wall outlet, locate another outlet that can accommodate the plug or contact your electrician to change the outlet. Do not change the plug.

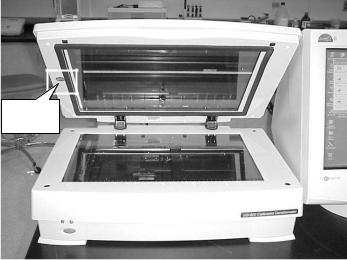

2.3 Unlocking the Densitometer and the Transparency Module

The optical assembly of the Densitometer’s transparency module (located in the lid) is held in place during shipment by a carriage lock (Figure 2.1) on the underside of the transparency module. The carriage lock must be unlocked before the instrument will work properly. Additionally, if the carriage lock is not unlocked prior to use, the optical system may be damaged while scanning. Insert a coin into the Carriage Lock. Turn it until the mark points align with the unlocked mark.

Note: Leave the locking screw in place so that it can be re-locked if you have to move the Densitometer over long distances.

Carriage

Lock

Fig. 2.1 Front view of Densitometer. Unlock the carriage lock by turning with a coin.

Warning: Always lower the transparency module slowly and release it only when it lies flat on the body of the Densitometer.

7

Loading...

Loading...