Bio-Rad Bio-Plex Pro Wash Stations User Manual

Instructions for Use for

Bio-Plex Pro™ & Bio-Plex Pro II Wash Stations

Revision B

Attention!

Use only the magnetic carrier which arrived with your instrument.

See page 17 for more details.

ii |

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

Notice

Every effort has been made to avoid errors in text and diagrams; however,

Bio-Rad Laboratories assumes no responsibility for any errors that may appear in this publication.

Bio-Rad reserves the right to change specifications at any time with appropriate validation, verification, and approvals.

Copyright Information

The contents of this document are the property of Bio-Rad Laboratories and are not to be copied, reproduced, or transferred to another person or persons without written permission.

Copyright ©2008 Bio-Rad Laboratories All rights reserved.

Declaration of Conformity

See page 79.

About the Instructions for Use (IFU)

This document describes the use of the Bio-Plex Wash Stations, designed for performing hands-free wash programs on Bio-Plex and other xMAP assays.

It contains instruction for the use of the instrument and is intended as a reference for the user. It contains information about the following:

•Installing the instrument

•Operating the instrument

•Programming of wash programs

•Definition of wash parameters

•Cleaning and maintenance procedures

Trademarks

The following product names and any registered or unregistered trademarks mentioned in this document are used for identification purposes only and remain the exclusive property of their respective owners:

•Microcide is a registered trademark of Global Biotechnologies Inc., Portland, Maine, USA

•MagPlex and xMAP are trademarks of Luminex Corporation, Austin, TX, USA

•Tween is a registered trademark of ICI Americas, Inc., Wilmington, DE, USA

•Decon and Neutracon are registered trademarks of Decon Laboratories Limited, Sussex, UK

•HydroControl is a trademark of Tecan Group Ltd, Männedorf, Switzerland

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

iii |

iv |

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

Table of Contents |

|

TABLE OF CONTENTS.......................................................................................................................................... |

V |

BASIC OPERATION AND MAINTENANCE ................................................................................................... |

11 |

INSTRUMENT OPTIONS..................................................................................................................................... |

11 |

MICROPLATE REQUIREMENTS .......................................................................................................................... |

12 |

INSTALLING THE INSTRUMENT........................................................................................................................... |

13 |

Bio-Plex Pro Installation Diagram.............................................................................................................. |

14 |

Bio-Plex Pro II Installation Diagram........................................................................................................... |

15 |

Installing the Tubing Bracket (Bio-Plex Pro II only).................................................................................. |

16 |

Selecting and Installing a Plate Carrier ..................................................................................................... |

17 |

Changing the Vacuum Configuration ........................................................................................................ |

18 |

INSTALLING THE MICROPLATE .......................................................................................................................... |

19 |

TURNING ON THE POWER................................................................................................................................. |

19 |

KEYPAD BASICS .............................................................................................................................................. |

20 |

Primary Menu ............................................................................................................................................ |

20 |

Secondary Menu ....................................................................................................................................... |

20 |

PRIMING THE INSTRUMENT............................................................................................................................... |

20 |

Failure to Prime ......................................................................................................................................... |

21 |

PLATE WASHING PROGRAMS ........................................................................................................................... |

22 |

WHICH WASH PROGRAM DO I USE?................................................................................................................. |

23 |

Quick Guide............................................................................................................................................... |

23 |

RINSING.......................................................................................................................................................... |

24 |

RINSING.......................................................................................................................................................... |

25 |

Rinse Day .................................................................................................................................................. |

25 |

Rinse Night................................................................................................................................................ |

26 |

Instrument state at the end of the wash .................................................................................................... |

26 |

CHANGING THE PLATE CARRIER....................................................................................................................... |

27 |

PREVENTIVE MAINTENANCE PLAN .................................................................................................................... |

28 |

Daily........................................................................................................................................................... |

28 |

Weekly....................................................................................................................................................... |

28 |

Every Six Months....................................................................................................................................... |

29 |

As Needed................................................................................................................................................. |

29 |

Yearly (Service Engineer Required).......................................................................................................... |

29 |

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

v |

REFERENCE SECTION .................................................................................................................................. |

30 |

PURPOSE OF REFERENCE SECTION .................................................................................................................. |

30 |

INSTRUMENT DETAILS.................................................................................................................................. |

31 |

INSTRUMENT SAFETY....................................................................................................................................... |

31 |

INTENDED USE ................................................................................................................................................ |

32 |

CONFIGURATIONS............................................................................................................................................ |

33 |

INSTRUMENT SPECIFICATIONS ......................................................................................................................... |

34 |

DESCRIPTION .................................................................................................................................................. |

36 |

BIO-PLEX PRO DIMENSIONS ............................................................................................................................ |

37 |

BIO-PLEX PRO II DIMENSIONS.......................................................................................................................... |

38 |

REAR PANEL CONNECTIONS ............................................................................................................................ |

38 |

REAR PANEL CONNECTIONS ............................................................................................................................ |

39 |

DETAILED INSTALLATION ............................................................................................................................ |

40 |

REQUIRED WORKING AREA.............................................................................................................................. |

40 |

POWER REQUIREMENTS .................................................................................................................................. |

40 |

UNPACKING AND INSPECTION CHECKLISTS ....................................................................................................... |

40 |

DETAILED OPERATING INSTRUCTIONS ..................................................................................................... |

42 |

SWITCHING THE INSTRUMENT ON ..................................................................................................................... |

42 |

COMPLETE INSTRUMENT KEYPAD FUNCTIONS................................................................................................... |

43 |

Alphabetical list of LCD text with explanations.......................................................................................... |

45 |

DEFINING CUSTOM WASH PROGRAMS.............................................................................................................. |

48 |

WASH MODES ................................................................................................................................................. |

48 |

Washing Positions..................................................................................................................................... |

49 |

ASPIRATING MODES ........................................................................................................................................ |

50 |

Normal AspirationMode............................................................................................................................. |

50 |

Crosswise Aspiration Mode....................................................................................................................... |

50 |

DRIP MODE..................................................................................................................................................... |

51 |

DEFINING NEW PROGRAMS......................................................................................................................... |

53 |

INTRODUCTION ................................................................................................................................................ |

53 |

PROGRAM MENU ............................................................................................................................................. |

53 |

DEFINE/EDIT A PROGRAM ................................................................................................................................ |

54 |

Process Step: Aspirate.............................................................................................................................. |

55 |

Process Step: Dispense ............................................................................................................................ |

56 |

Process Step: Wash.................................................................................................................................. |

58 |

Process Step: Soak................................................................................................................................... |

59 |

Process Step: User Prompt....................................................................................................................... |

59 |

Process Step: Vacuum Filtration............................................................................................................... |

59 |

SHOW PROGRAM............................................................................................................................................. |

60 |

CLEAR PROGRAM ............................................................................................................................................ |

61 |

SETTINGS MENU ............................................................................................................................................. |

61 |

Edit Plates ................................................................................................................................................. |

62 |

Options Submenu...................................................................................................................................... |

62 |

Vacuum Filtration....................................................................................................................................... |

62 |

Bubble Sensor........................................................................................................................................... |

63 |

PROCEDURES MENU ....................................................................................................................................... |

63 |

Rinse ......................................................................................................................................................... |

63 |

Prime ......................................................................................................................................................... |

63 |

Empty Prime Tray...................................................................................................................................... |

63 |

MAINTENANCE AND CLEANING .................................................................................................................. |

65 |

CLEANING PROCEDURES ................................................................................................................................. |

65 |

vi |

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

Cleaning the Cover and Display................................................................................................................ |

65 |

Cleaning the Liquid System....................................................................................................................... |

65 |

Cleaning the Manifold................................................................................................................................ |

66 |

Cleaning Waste Bottles ............................................................................................................................. |

66 |

LIQUID OR FOAM SPILLS .................................................................................................................................. |

67 |

REPLACING THE MANIFOLD .............................................................................................................................. |

68 |

Removing the Manifold.............................................................................................................................. |

69 |

Installing the Manifold................................................................................................................................ |

70 |

INSTRUMENT DISINFECTION ............................................................................................................................. |

71 |

Disinfection Solutions ................................................................................................................................ |

71 |

Disinfection Procedure .............................................................................................................................. |

72 |

DISPOSAL OF INSTRUMENT .............................................................................................................................. |

73 |

Disposal of Operating Material .................................................................................................................. |

73 |

Disposal of the Instrument......................................................................................................................... |

73 |

TROUBLESHOOTING AND ERROR MESSAGES......................................................................................... |

75 |

ERRORS WITHOUT MESSAGES......................................................................................................................... |

75 |

ERROR MESSAGES.......................................................................................................................................... |

75 |

Plate Error ................................................................................................................................................. |

75 |

Program Too Big Error .............................................................................................................................. |

75 |

Transport Error .......................................................................................................................................... |

75 |

Manifold Arm Error .................................................................................................................................... |

76 |

Sensor Defect Error................................................................................................................................... |

76 |

RS485 Error............................................................................................................................................... |

76 |

PC (Process Control) System Error .......................................................................................................... |

77 |

No Aspiration at Vacuum Filtration Error................................................................................................... |

77 |

LLD Errors ................................................................................................................................................. |

78 |

DECLARATION OF CONFORMITY ................................................................................................................ |

79 |

INDEX............................................................................................................................................................... |

80 |

Symbols

Indicates the possible presence of biologically hazardous material.

Indicates the possible presence of a strong magnetic field.

Warnings, Cautions, and Notes

The following types of notices are used in this publication to highlight important information or to warn the user of a potentially dangerous situation:

Information

Gives helpful information.

Caution

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

vii |

Indicates a possibility of instrument damage or data loss if instructions are not followed.

WARNING

Indicates the possibility of severe personal injury, loss of life, or equipment damage if the instructions are not followed.

WARNING

This symbol Indicates the possible presence of biologically hazardous material. Proper laboratory safety precautions must be observed.

Attention

Negative environmental impacts associated with the treatment of waste.

zDo not treat electrical and electronic equipment as unsorted municipal waste

zCollect waste electrical and electronic equipment separately

WARNING

Risk of fire and explosion!

Ethanol is flammable and when improperly handled can lead to explosions. Proper laboratory safety precautions must be observed.

viii |

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

Abbreviations

A |

Ampere |

°C |

Degrees Celsius |

CE |

Conformité Européenne |

cm |

Centimeter |

CV |

Coefficient of Variation |

ELISA |

Enzyme-Linked ImmunoSorbent Assay |

EN |

European Norm: a voluntary European standard of the European Committee for |

|

Standardization or Comité Européen de Normalisation (CEN) |

°F |

Degrees Fahrenheit |

IEC |

International Electrotechnical Commission |

IFU |

Instructions for Use |

in. |

Inch |

IVD |

In Vitro Diagnostics |

IVD-D |

In Vitro Diagnostics Directive |

kg |

Kilogram |

l; L |

Liter |

m |

Meter |

mBar |

Millibar |

ml |

Milliliter |

mm |

Millimeter |

mS |

Millisiemens |

µl |

Microliter |

PC |

Process Control |

PCR |

Polymerase Chain Reaction |

ppm |

Parts Per Million |

QC |

Quality Control |

REF |

Reference Number/ Order Number |

s |

Second |

SN |

Serial Number |

T |

Träge (Slow Blow Fuse) |

torr |

Torr – Millimeter of Mercury (mmHg) |

TYPE |

Name and Type of instrument |

USB |

Universal Serial Bus |

V |

Volt |

VA |

Volt Ampere |

WEEE |

Waste Electrical and Electronic Equipment |

|

|

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

ix |

Basic Operation and Maintenance

10 |

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

Basic Operation and Maintenance

Basic Operation and Maintenance

This section gives you instructions to configure, install, prime, and use the Bio-Plex Pro™ and Bio-Plex Pro II Wash Stations. You can perform your first plate wash simply by using these instructions and the onboard wash program. This section also contains references to more detailed information throughout this manual.

Instrument Options

The Bio-Plex Pro and Bio-Plex Pro II Wash Stations are designed for strip-wise washing of 96-well microplates. They are designed primarily for the processing of Bio-Plex and other xMAP assays.

The wash station is available in two versions.

Wash Configuration |

Bio-Plex Pro |

Bio-Plex Pro II |

|

|

|

Vacuum filtration |

No |

Yes |

|

|

|

Magnetic separation |

Yes |

Yes |

|

|

|

Both wash stations are delivered with the standard carrier installed and the appropriate programs for performing your assays. Replace the standard carrier with the appropriate carrier for your assays as outlined on page 17.

Which Wash Program Do I Use? On page 23 describes the standard wash programs necessary for the different assays.

To run standard ELISAs or other plate-based assays, you must modify programs and plate definitions, using the HydroControl™ software available on the CD that ships with both instruments. This software is not needed for Bio-Plex or Bio-Plex Pro assay processing. Follow the instructions in Defining New Programs on page 53.

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

11 |

Basic Operation and Maintenance

Microplate Requirements

Use recommended microplates. If you use different microplates, your assay results may not be reproducible, and you may experience excessive bead loss.

Recommended microplates for magnetic assays:

Bio-Rad Part # |

Description |

Default for Magnetic Products |

|

|

|

171-025001 |

Bio-Plex Pro |

Yes |

|

flat-bottom plates |

|

|

|

|

*For a complete list of suitable plates, please contact Bio-Rad technical support.

Only these recommended filter plates should be used with the Bio-Plex Pro II, when configured for standard Bio-Plex or other polystyrene bead based xMAP assays.

Recommended microplates for vacuum filtration:

Vendor |

Manufacturer Part # |

Default for Vacuum |

|

|

Products |

|

|

|

Millipore |

MSBVS1210 |

Yes |

|

|

|

If using other microplates, you will have to enter new microplate definitions, using the Hydrocontrol software included on the CD. Please note the following requirements.

Parameters |

Characteristics |

|

|

Max. overall microplate height |

14.35 mm ± 0.76 mm |

|

(0.5650 inches ± 0.0299 inches) |

|

|

Footprint |

9.0 mm (0.3543 inches) |

|

|

Pitch size (center to center) |

9.0 mm (0.3543 inches) |

|

|

Bottom shape |

Round, V-shaped, and flat |

|

|

12 |

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

Basic Operation and Maintenance

Installing the Instrument

Unpack the instrument and install the instrument according to the instructions below.

Additional helpful information is located on the following pages:

•Unpacking checklist on page 40

•Bio-Plex Pro installation diagram on page 14

•Bio-Plex Pro II installation diagram on page 15

Caution

Do NOT turn the instrument on until you have completed the steps below.

Caution

Before the instrument is installed and switched on, it should be left to stand for at least three hours, so there is no possibility of condensation causing a short circuit.

1.Ensure that the on/off switch in the rear panel of the instrument is in the off position.

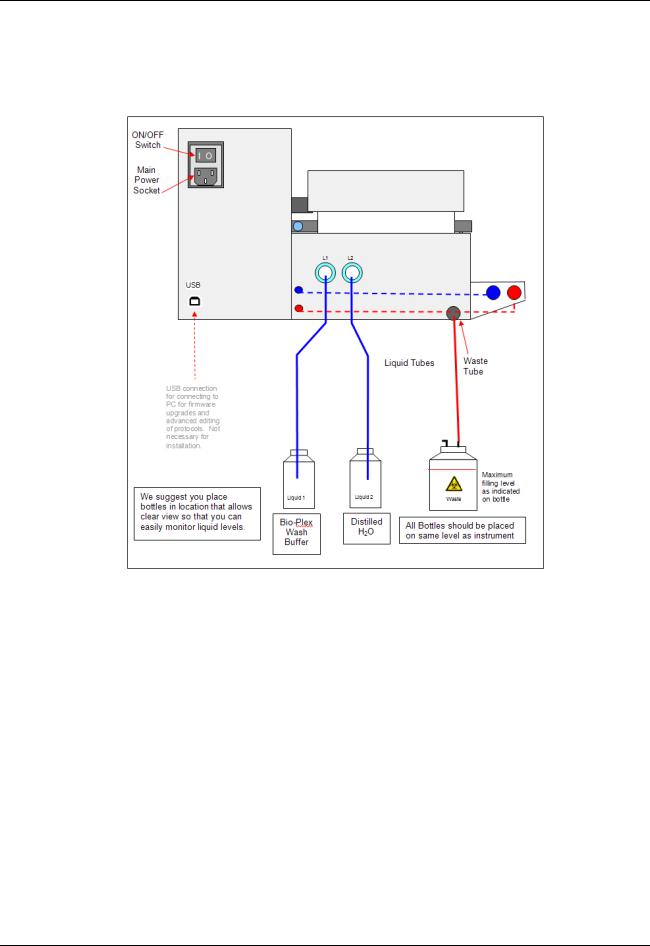

2.Connect the solution tubes (L1 and L2) to the inlet connectors on the rear panel of the instrument. See the diagrams on the following pages.

3.Connect the solution tubes to the corresponding liquid bottles.

4.Connect the waste tube to the waste bottle (do not kink the tubes).

5.IF your instrument is a Bio-Plex Pro II, install the tubing bracket as shown on page 16.

6.Fill Liquid 1 bottle with Bio-Plex wash buffer.

7.Fill Liquid 2 bottle with distilled or higher grade water.

8.Remove the standard ELISA carrier and install the appropriate plate carrier based on the assays you will be running (Selecting and Installing a Plate Carrier on page 17).

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

13 |

Basic Operation and Maintenance

Bio-Plex Pro Installation Diagram

14 |

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

Basic Operation and Maintenance

Bio-Plex Pro II Installation Diagram

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

15 |

Basic Operation and Maintenance

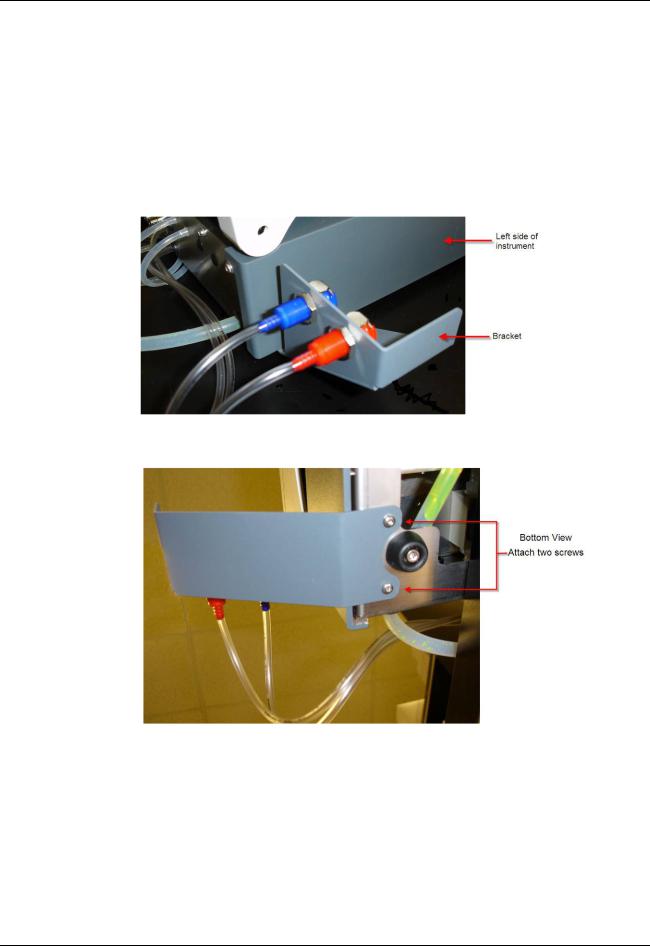

Installing the Tubing Bracket (Bio-Plex Pro II only)

Your Bio-Plex Pro II is shipped with the liquid hoses attached. Attach the tubing bracket to the left side of the instrument, as shown in the pictures below.

Location of Tubing Bracket

A tool is provided for the installation of the bracket. It is located in a bag containing a USB cable and cleaning pins for the manifold.

16 |

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

Basic Operation and Maintenance

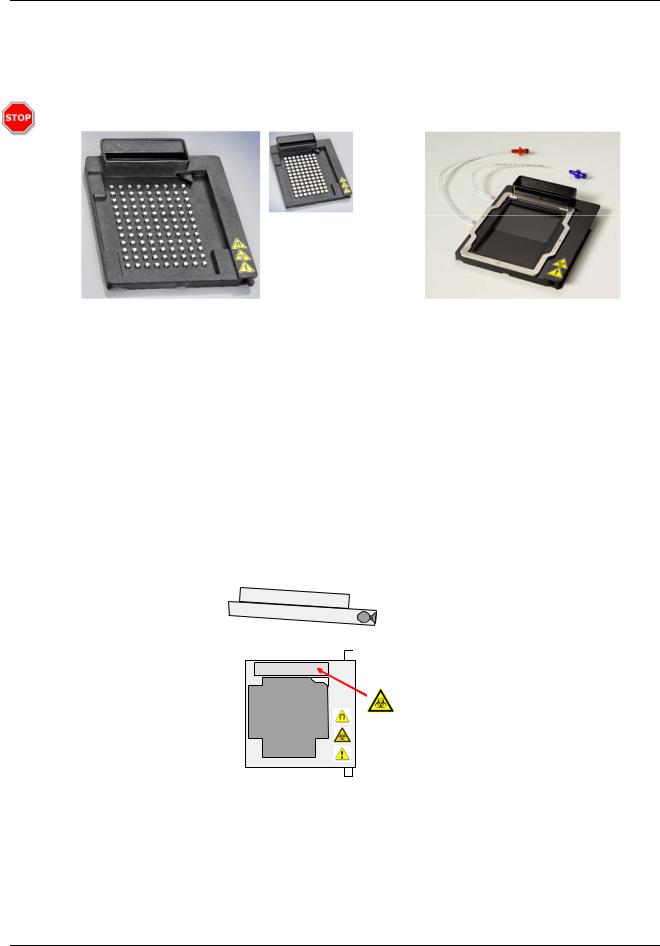

Selecting and Installing a Plate Carrier

Magnetic Plate Carrier |

Vacuum Plate Carrier |

|

(Version B) |

(Version A) |

|

Attention!

Use only the type of magnetic carrier which arrived with your instrument.

If your wash station arrived with version B use of version A on your wash station will result in poor assays results.

Version B is backcompatible with previously installed wash stations.

Use magnetic plate carrier with:

•Bio-Plex Pro assays

•Bio-Plex Precision Pro™ assays

•Any assay with MagPlex™ microspheres

Use vacuum plate carrier with:

•Bio-Plex assays (non magnetic)

•Any assay on Bio-Plex COOH beads

•Any assay on MicroPlex microspheres

Remove the standard ELISA plate.

1.Make sure the instrument is turned off.

2.Lift the manifold arm.

3.Slightly tilt the plate carrier towards the right.

4.Carefully slide the plate carrier toward the front of the instrument until it clears the guide bar.

Guide Bar

Guide Bar

Prime Tray

Installing the plate carrier is the reverse of the procedure above:

1.Carefully guide the plate carrier onto the guide bar in a slightly tilted position, as shown above.

2.Push the plate carrier completely into the instrument, so that the front of the carrier is even with or past the Bio-Rad logo.

3.Lower the plate carrier.

4.Lower the manifold arm.

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

17 |

Basic Operation and Maintenance

Changing the Vacuum Configuration

You must set the vacuum system appropriately for the plate carrier used. This is done through the VACUUM FILTR menu. Follow the procedure shown below to:

•Enable Low VAC when using the vacuum carrier

•Disable Low VAC when

1). using the magnetic carrier

2). using the standard ELISA plate carrier

Disabling/Enabling the Vacuum Carrier

Go through these menus to disable or enable the vacuum carrier. If you are disabling the vacuum, the menus will display “Disable” in place of “Enable.”

SETTINGS

<> OK

OPTIONS

-+ EXIT OK

VACUUM FILTR.

-+ EXIT OK

Enable Low VAC

EXIT YES

Enable Low VAC

EDIT LLD CHANNEL

- |

+ |

EXIT OK |

Navigate to Settings in the Primary menu and press OK

Select and press OK for OPTIONS

Select and press OK for VACUUM FILTR.

Enable vacuum carrier by choosing YES

(“Disable Low VAC” will be displayed if already enabled)

System enables vacuum carrier

System places you in the Options menu at EDIT LLD CHANNEL. EXIT to Primary menu (press EXIT until it is no longer an option)

Failure to set Vacuum Filtration settings appropriately for the installed plate carrier will result in a MANIFOLD HEAD UP error. This indicates that the manifold arm cannot lower appropriately.

PROGRAM

< |

> |

OK |

The instrument must be turned off and then back on for the change to take effect.

18 |

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

Basic Operation and Maintenance

Installing the Microplate

Insert the 96-well microplate into the plate transport for washing and ensure that the microplate is correctly oriented (position A1 of the plate corresponds to position A1 marked on the plate transport). If using the vacuum plate carrier for polystyrenebased assays, see Changing the Plate Carrier on page 23.

Turning on the Power

The power switch is located at the rear of the instrument, above the power cable connection. Make sure the instrument is plugged in using the provided power cable before you attempt to operate.

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

19 |

Basic Operation and Maintenance

Keypad Basics

All the functions you need to run Bio-Plex programs are easily accessed using the keypad on your wash station. The system is organized into primary and secondary menus.

Primary Menu

The instrument menu has the following options:

Primary |

Functions |

Secondary Menu Options |

Menu |

|

|

Options |

|

|

|

|

|

Programs |

Wash programs used to process assays |

Start, Define/Edit, Show, Clear |

|

|

|

Settings |

Rarely accessed advanced features |

Edit Plates, Options, Bubble Sensor |

|

|

|

Procedures |

Preparation or maintenance processes |

Prime, Rinse, Empty Prime Tray, |

|

|

Vacuum Filtration |

|

|

|

Secondary Menu

If you choose OK when any of the primary menu options (Programs, Settings, and Procedures) are visible on the LED, you will navigate to the secondary menus. You may Select a choice from the secondary menu, or press Exit to return to the primary menu.

LCD |

PROGRAM |

|

|

|

< |

> |

OK |

|

|

|

|

Keypad |

< |

> |

|

buttons |

Navigate |

Select or |

|

|

|||

|

to other |

Exit |

|

|

options |

|

|

If you get confused about where you are, press Exit, until you no longer see Exit as an option.

Priming the Instrument

You should prime both Channel 1 and 2 after installation and if the instrument has not been used for an extended period of time. Priming is performed to fill the liquid system of the instrument and to remove all air from the tubes. A priming step must also be performed when switching to a different wash buffer.

Caution

Do not use your new instrument until you have primed both channels.

20 |

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

Basic Operation and Maintenance

Perform priming for both channels using the following procedure:

|

PROCEDURE |

|

Navigate to the Procedure in the primary |

||

|

< |

> |

OK |

menu and press OK |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

PRIME |

|

|

Select and press OK for PRIME |

|

< |

> |

OK |

|||

|

|||||

|

|

|

|

|

|

PRIME SOLUTION OK? < > YES

WASTE BOTTLE OK? < > YES

Confirm rinsing solution and tube in bottle

Confirm waste bottle is connected and sufficiently empty

VOLUME |

|

Press OK if you see VOLUME. If you see |

|

< |

> |

OK |

TIME, scroll down to VOLUME, then press OK |

|

|||

|

|

|

|

VOLUME 30 mL

+- OK

CHANNEL 1

-+ EXIT OK

PROGRAM |

|

|

< |

> |

OK |

Press OK

Select CHANNEL 1 using the choice keys (< , >)

Select OK and the prime procedure starts

Instrument will perform the prime step and will then be ready to perform wash protocols

Repeat for channel 2.

Failure to Prime

If you have a new instrument or it has not been used for a long time the pump may fail to draw fluid from the liquid bottles. This problem is easily solved.

1.Disconnect the L1 tube from the bottle (leaving it connected to the instrument).

2.Hold the free end of the tube high and pipette 3 - 4 ml of deionized water to the tube while performing the prime procedure in channel 1 as described above.

Alternately you may carefully use a syringe to inject 1 - 2 ml of water directly into the L1 port of the instrument, reconnect the tubing, and run a prime procedure.

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

21 |

Basic Operation and Maintenance

Plate Washing Programs

Instructions for running the preconfigured wash program are detailed below.

Instructions for setting new Wash, Dispense, and Aspirate modes into a new wash program, and instrument rinse instructions, are found in the Defining New Programs section on page 53.

PROGRAM |

|

|

< |

> |

OK |

START |

|

|

< |

> |

OK |

Navigate to PROGRAM in the primary menu and press OK.

Use the keys under the < and > symbols to access the Program menu if it is not already displayed

Press OK

RUN1: Program X

<> EXIT OK

SSSSSSSSSSSS |

|

|

+ |

- |

OK |

Select the required program and press OK to continue

Choose OK.

Rows are represented by S (selected) or N (not selected). All rows should be selected.

It is highly recommended that all wells are selected and the entire plate is washed.

22 |

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

Basic Operation and Maintenance

Which Wash Program Do I Use?

In this instance. |

Use Wash Station Program |

First wash, magnetic assay |

MAG x2 |

All other washes, magnetic assay |

MAG x3 |

Prewash, vacuum assay |

PREVAC |

First wash, vacuum assay |

VAC x2 |

All other washes, vacuum assay |

VAC x3 |

Third party kits which require 200 µl washes (Vacuum only) |

V 200 x2 or V 200 x3 |

For all protocols, it is highly recommended that you wash the entire plate. See page 18 for details.

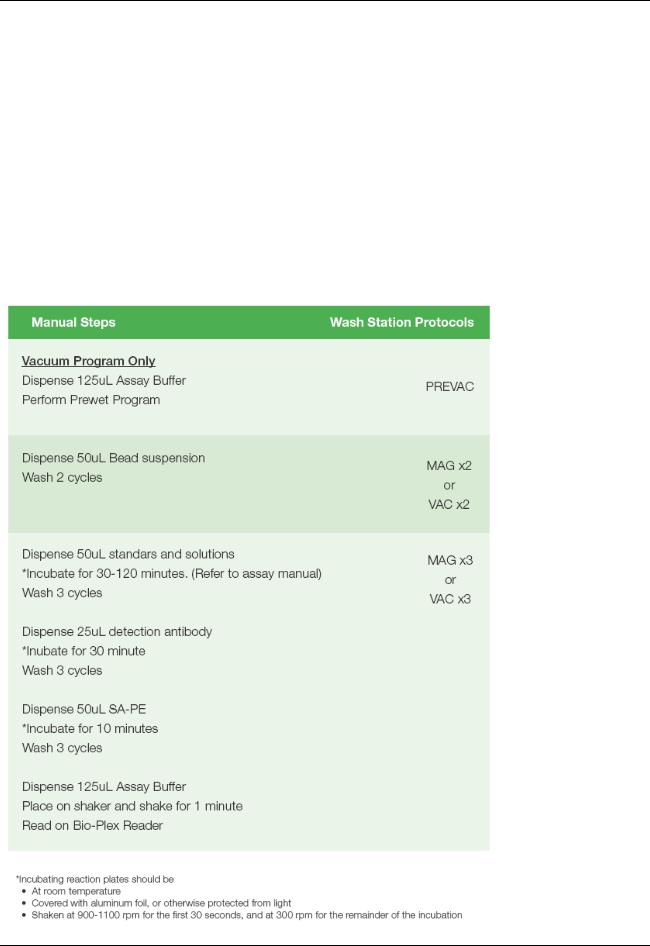

Quick Guide

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

23 |

Basic Operation and Maintenance

Important Vacuum Protocol Precautions

•Carefully place the plate so that it is flat and squarely seated between the metal frames on the vacuum carrier before stating a vacuum protocol

•It may be necessary to apply a small amount of pressure to the plate for the first vacuum cycle of the day

•Monitor your plate periodically to ensure complete removal of wash buffer before the next dispense cycle

•Blot the bottom of the filter plate on a paper towel within 5 seconds after each program is completed. If you are not sure how much time has elapsed, run a PREVAC program to clear any residual buffer that may have wicked back into the wells before proceeding to the next step

Vacuum protocols will not work if you do not have buffer in every well.

24 |

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

Basic Operation and Maintenance

Rinsing

The instrument should always be rinsed after use. Afterwards, the instrument can either be left switched on, with the manifold in the rinsing solution, or switched off after performing the correct maintenance.

Rinse Day

If the instrument will be left to stand for a short time (i.e. up to 2 hours), you may perform Rinse Day with wash buffer so that you do not have to prime before the next run.

Perform Rinse Day by making these menu choices:

Navigate to PROCEDURE in the primary menu and press OK.

Use the keys under the < and > symbols to access the

PROCEDURE menu if it is not already displayed

Select and press OK for RINSE

Select and press OK for RINSE DAY

Press OK when presented with the option to the left

If presented with TIME you can use the default settings here as well. Or navigate to

VOLUME using < and > .

Press OK when presented with the option to the left

Or use the default time settings

Select CHANNEL 1 or 2 (using the choice keys <, >)

Remember to prime channel 1 before performing the next wash protocol if you rinse with channel 2

Instrument will perform rinse procedure.

When the rinsing procedure is complete, the following message is displayed:

RINSE DAY

STOP END

The manifold remains in the prime tray until END is pressed.

Press STOP to abort the procedure (prime tray will not be aspirated).

Bio-Plex Pro and Bio-Plex Pro II Wash Stations |

25 |

Loading...

Loading...