Yamaha TT600RE 2004 User Manual [ru]

2004

TT600RE

5CH5-ME1

SERVICE MANUAL

EASB0000

TT600RE

SERVICE MANUAL

© 2003 by Belgarda S.p.A. First edition, July 2003

All rights reserved. Any reproduction or unauthorized use without the written permission of Belgarda S.p.A.

is expressly prohibited. Printed in Italy

EASB0001

NOTICE

This manual was produced by the Belgarda S.p.A. primarily for use by Yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on Yamaha vehicles should have a basic understanding of mechanics and the techniques to repair these types of vehicles. Repair and maintenance work attempted by anyone without this knowledge is likely to render the vehicle unsafe and unfit for use.

Belgarda S.p.A. is continually striving to improve all of its models. Modifications and significant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers and will appear in future editions of this manual where applicable.

NOTE:

Designs and specifications are subject to change without notice.

EAS00004

IMPORTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following.

|

|

|

|

|

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFE- |

|

|

|

|

|

|

TY IS INVOLVED! |

|

|

|

|

|

|

Failure to follow WARNING instructions could result in severe injury or death to |

|

|

|

|

WARNING |

|||

|

|

|

the motorcycle operator, a bystander or a person checking or repairing the |

|||

|

|

|

|

|

||

|

|

|

|

|

motorcycle. |

|

|

|

|

|

|

A CAUTION indicates special precautions that must be taken to avoid damage |

|

|

CAUTION: |

|

||||

|

|

to the motorcycle. |

||||

NOTE: |

||||||

A NOTE provides key information to make procedures easier or clearer. |

||||||

EAS00007

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order.

1 The manual is divided into chapters. An abbreviation and symbol in the upper right corner of each page indicate the current chapter.

Refer to "SYMBOLS".

2 Each chapter is divided into sections. The current section title is shown at the top of each page, except in Chapter 3 ("PERIODIC CHECKS AND ADJUSTMENTS"), where the sub-section title(s) appears.

3 Sub-section titles appear in smaller print than the section title.

4 To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each removal and disassembly section.

5 Numbers are given in the order of the jobs in the exploded diagram. A circled number indicates a disassembly step.

6 Symbols indicate parts to be lubricated or replaced. Refer to "SYMBOLS".

7A job instruction chart accompanies the exploded diagram, providing the order of jobs, names of parts, notes in jobs, etc.

8 Jobs requiring more information (such as special tools and technical data) are described sequentially.

1 |

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

ILLUSTRATED SYMBOLS |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The following symbols are not relevant to every |

|

GEN |

|

|

|

|

|

|

|

SPEC |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

vehicle. |

|||||||

|

INFO |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Illustrated symbols 1 to 8 are printed on the top |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

right of each page and indicate the subject of |

3 |

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

each chapter. |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INSP |

|

|

|

|

|

|

CHAS |

|

|

|

|

|

1 General information |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

2 Specifications |

||||||||

|

ADJ |

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 Periodic inspections and adjustments |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 Chassis |

5 |

|

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 Engine |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ENG |

|

|

|

|

|

|

CARB |

|

|

|

|

|

6 Carburetor |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

7 Electrical system |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 Troubleshooting |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ELEC |

|

|

|

|

|

|

|

TRBL |

? |

|

|

||||||||

|

|

|

|

|

|

|

|

SHTG |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Illustrated symbols 9 to y are used to identify |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

the specifications appearing in the text. |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 Can be serviced with engine mounted |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 Filling fluid |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

q Lubricant |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

w Special tool |

q |

|

|

|

|

|

|

|

|

w |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

e Torque |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

r Wear limit, clearance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

t Engine speed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

y Electrical data |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

e |

|

|

|

|

|

|

|

|

r |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

t |

|

|

|

|

|

|

y |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

u |

|

|

|

|

i |

|

|

o |

|

|

|

|

|

Illustrated symbols u to s in the exploded dia- |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

grams indicate the types of lubricants and lubrica- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

tion points. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

u Apply engine oil |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

i Apply gear oil |

p |

|

a |

|

|

s |

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

o Apply molybdenum disulfide oil |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

p Apply wheel bearing grease |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a Apply lightweight lithium-soap base grease |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

s Apply molybdenum disulfide grease |

d |

|

|

|

|

|

f |

|

|

|

|

|

Illustrated symbols d to f in the exploded dia- |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

New |

|

grams indicate the following: |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

d Apply locking agent (LOCTITE® ) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

f Replace the part |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E004000 |

TABLE OF CONTENTS |

|

GENERAL INFORMATION |

|

|

|

GEN |

|

1 |

|

|

INFO |

|

|

|

|

|

|

SPECIFICATIONS |

|

|

|

SPEC |

|

2 |

|

|

|

||

|

|

|

|

PERIODIC INSPECTION |

|

|

|

AND ADJUSTMENTS |

INSP |

|

3 |

|

ADJ |

|

|

|

|

|

|

CHASSIS |

|

|

|

CHAS |

|

4 |

|

|

|

||

|

|

|

|

ENGINE |

|

|

|

ENG |

|

5 |

|

|

|

||

|

|

|

|

CARBURETION |

|

|

|

CARB |

|

6 |

|

|

|

||

|

|

|

|

ELECTRICAL |

|

|

|

ELEC |

|

7 |

|

|

|

||

|

|

|

|

TROUBLESHOOTING |

? |

|

|

TRBL |

|

8 |

|

|

SHTG |

|

|

GEN 1 INFO

|

|

GEN |

|

|

|

INFO |

|

CHAPTER 1. |

|

|

|

GENERAL INFORMATION |

|

|

|

MOTORCYCLE IDENTIFICATION ...................................................................................... |

1-1 |

||

VEHICLE IDENTIFICATION NUMBER.......................................................................... |

1-1 |

||

MODEL LABEL .............................................................................................................. |

1-1 |

||

IMPORTANT INFORMATION .............................................................................................. |

1-2 |

||

PREPARATION FOR REMOVAL PROCEDURES ........................................................ |

1-2 |

||

REPLACEMENT PARTS .............................................................................................. |

1-2 |

||

GASKETS, OIL SEALS AND O-RINGS ........................................................................ |

1-2 |

||

LOCK WASHERS/PLATES AND COTTER PINS ........................................................ |

1-3 |

||

BEARINGS AND OIL SEALS ........................................................................................ |

1-3 |

||

CIRCLIPS ...................................................................................................................... |

1-3 |

||

CHECKING OF CONNECTIONS ........................................................................................ |

1-4 |

||

SPECIAL TOOLS.................................................................................................................. |

1-5 |

||

GEN INFO

GEN

VEHICLE IDENTIFICATION INFO

1 |

GENERAL INFORMATION

VEHICLE IDENTIFICATION

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number 1 is stamped into the frame.

MODEL LABEL

The model label 1 is affixed to the frame under the seat.

This information will be needed to order spare parts.

1-1

IMPORTANT INFORMATION

EB101000

GEN INFO

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL PROCEDURES

1.Remove all dirt, mud, dust and foreign material before removal and disassembly.

2.Use proper tools and cleaning equipment. Refer to the “SPECIAL TOOLS” section.

3.When disassembling the machine, always keep mated parts together. This includes gears, cylinders, pistons and other parts that have been “mated” through normal wear.

Mated parts must always be reused or replaced as an assembly.

4.During machine disassembly, clean all parts and place them in trays in the order of disassembly. This will speed up assembly and allow for the correct installation of all parts.

5.Keep all parts away from any source of fire.

EB101010

REPLACEMENT PARTS

1.Use only genuine Yamaha parts for all replacements. Use oil and grease recommended by Yamaha for all lubrication jobs. Other brands may be similar in function and appearance, but inferior in quality.

EB101020

GASKETS, OIL SEALS AND O-RINGS

1.Replace all gaskets, seals and O-rings when overhauling the engine. All gasket surfaces, oil seal lips and O-rings must be cleaned.

2.Properly oil all mating parts and bearings during reassembly. Apply grease to the oil seal lips.

1-2

|

|

|

|

GEN |

|

|

IMPORTANT INFORMATION |

|

INFO |

|

|

|

|

EB101030 |

|||

|

|

||||

|

|

LOCK WASHERS/PLATES AND COTTER PINS |

|||

|

|

1. Replace all lock washers/plates 1 and cotter |

|||

|

|

pins after removal. Bend lock tabs along the |

|||

OR |

|

bolt or nut flats after the bolt or nut has been |

|||

|

|

tightened to specification. |

|||

|

|

|

|

|

|

EB101040

BEARINGS AND OIL SEALS

1.Install bearings and oil seals so that the manufacturer’s marks or numbers are visible. When installing oil seals, apply a light coating of lightweight lithium base grease to the seal

lips. Oil bearings liberally when installing, if appropriate.

1 Oil seal

CAUTION:

Do not use compressed air to spin the bearings dry. This will damage the bearing surfaces.

1 Bearing

EB101050

CIRCLIPS

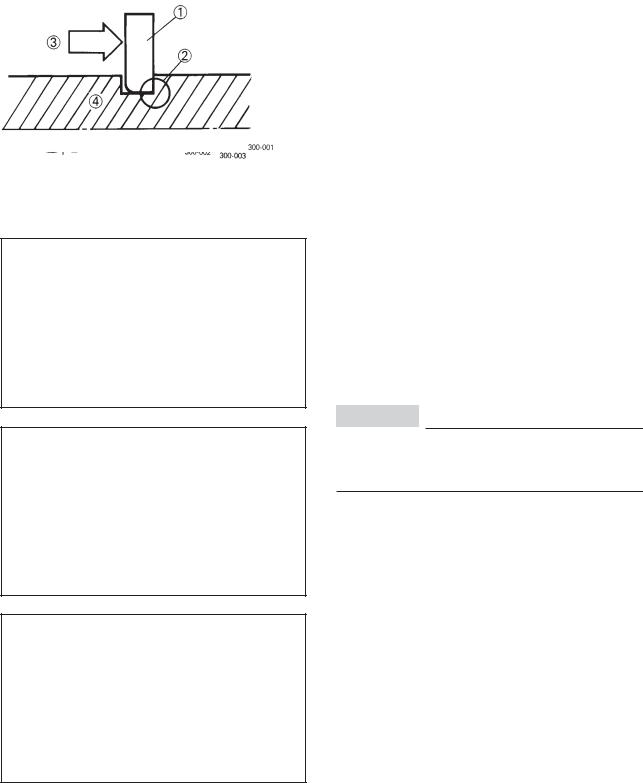

1.Check all circlips carefully before reassembly. Always replace piston pin clips after one use. Replace distorted circlips. When installing a circlip 1, make sure that the sharp-edged corner 2 is positioned opposite the thrust 3 it receives. See sectional view.

4 Shaft

1-3

CHECKING OF CONNECTIONS

EB801000

GEN INFO

CHECKING OF CONNECTIONS

Check the connectors for stains, rust, moisture, etc.

1.Disconnect:

•connector

2.Check:

•connector

Moisture → Dry each terminal with an air blower.

Stains/rust → Connect and disconnect the terminals several times.

3.Check:

•connector leads

Looseness → Bend up the pin 1 and connect the terminals.

4.Connect:

• connector terminals

NOTE:

The two terminals “click” together.

5.Check:

• continuity (using a pocket tester)

NOTE:

•If there is no continuity, clean the terminals.

•When checking the wire harness be sure to perform steps 1 to 3.

•As a quick remedy, use a contact revitalizer available at most part stores.

•Check the connector with a pocket tester as shown.

1-4

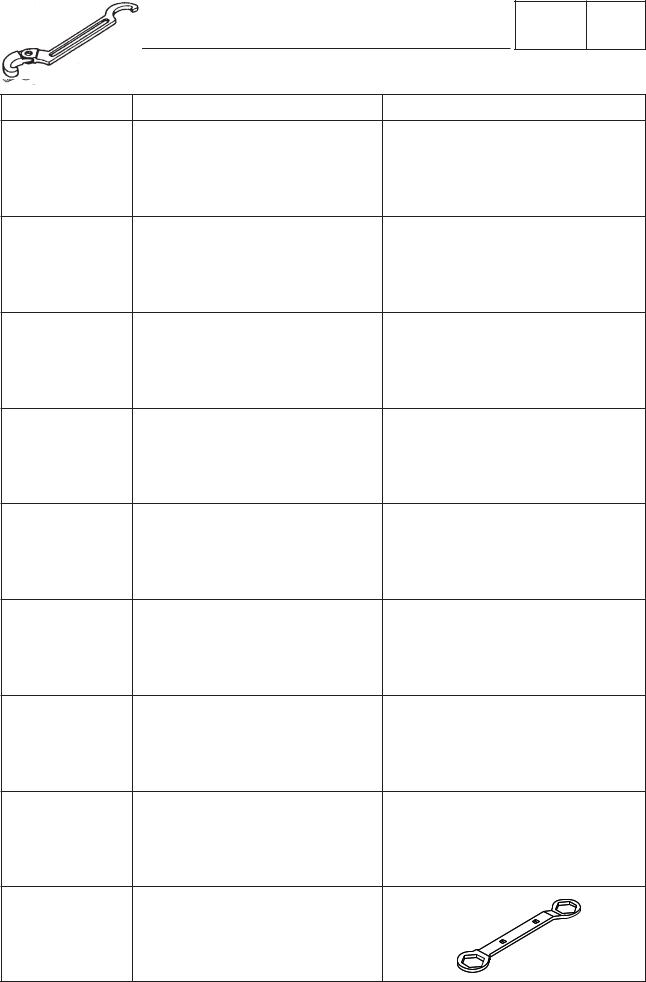

SPECIAL TOOLS

SPECIAL TOOLS

GEN INFO

The following special tools are necessary for complete and accurate tune-up and assembly. Use only the appropriate special tools; this will help prevent damage caused by the use of inappropriate tools or improvised techniques.

When placing an order, refer to the list provided below to avoid any mistakes.

Tool No. |

Tool name / Usage |

Illustration |

|

|

|

|

Engine tachometer |

|

90890-03113 |

|

|

|

This tool is needed for detecting engine rpm. |

|

|

|

|

|

Timing light |

|

90890-03141 |

|

|

|

This tool is needed for detecting ignition |

|

|

timing. |

|

|

|

|

|

Pocket tester |

|

90890-03112 |

|

|

|

These instruments are invaluable for check- |

|

|

ing the electrical system. |

|

|

|

|

|

Ignition checker |

|

90890-06754 |

|

|

|

This instrument is necessary for checking |

|

|

the ignition system components. |

|

|

|

|

|

Compression gauge |

|

90890-03081 |

|

|

|

These tools are used to measure the engine |

|

|

compression. |

|

|

|

|

|

Adapter (compression gauge) |

|

90890-04082 |

|

|

|

This tool serves to measure the engine com- |

|

|

pression. |

|

|

|

|

|

Fuel level gauge |

|

90890-01312 |

|

|

|

This gauge is used to measure the fuel level |

|

|

in the float chamber. |

|

|

|

|

|

Piston pin clip puller |

|

90890-01304 |

|

|

|

This tool serves for removing the piston pin |

|

|

clip. |

|

|

|

|

1-5

|

|

|

|

GEN |

|

|

|

SPECIAL TOOLS |

INFO |

|

|

|

|

|

|

|

|

Tool No. |

Tool name / Usage |

Illustration |

|||

|

|

|

|

|

|

|

Rocker arm shaft puller bolt |

|

|

|

|

90890-01083 |

|

|

|

|

|

|

These tools are used when removing the |

|

|

|

|

|

rocker arm shafts. |

|

|

|

|

|

|

|

|

|

|

|

Weight |

|

|

|

|

90890-01084 |

|

|

|

|

|

|

These tools are used when removing the |

|

|

|

|

|

rocker arm shafts. |

|

|

|

|

|

|

|

|

|

|

|

Valve spring compressor |

|

|

|

|

90890-04019 |

|

|

|

|

|

|

These tools are used when removing or |

|

|

|

|

|

installing the valve and the valve spring. |

|

|

|

|

|

|

|

|

|

|

|

7 mm (0.28 in) valve guide puller |

|

|

|

|

90890-01225 |

|

|

|

|

|

|

This tool is used to remove the valve guides. |

|

|

|

|

|

|

|

|

|

|

|

7 mm (0.28 in) valve guide installer |

|

|

|

|

90890-04017 |

|

|

|

|

|

|

This tool is necessary to install the valve |

|

|

|

|

|

slides properly. |

|

|

|

|

|

|

|

|

|

|

|

7 mm (0.28 in) valve guide reamer |

|

|

|

|

90890-01227 |

|

|

|

|

|

|

This tool is used to re-ream the new valve |

|

|

|

|

|

guide. |

|

|

|

|

|

|

|

|

|

|

|

Valve adjusting tool |

|

|

|

|

90890-01311 |

|

|

|

|

|

|

This tool is necessary for adjusting valve |

|

|

|

|

|

clearance. |

|

|

|

|

|

|

|

|

|

|

|

Rotor holder |

|

|

|

|

90890-01701 |

|

|

|

|

|

|

This tool is used for loosing and tightening |

|

|

|

|

|

the rotor nut. |

|

|

|

|

|

|

|

|

|

|

|

Rotor screw puller |

|

|

|

|

90890-01362 |

|

|

|

|

|

|

This tool is used to disassemble the magne- |

|

|

|

|

|

to flywheel rotor. |

|

|

|

|

|

|

|

|

|

|

1-6

GEN

SPECIAL TOOLS INFO

Tool No. |

Tool name / Usage |

Illustration |

All-purpose clutch holder

90890-04086

This tool is used to lock the clutch, when the clutch boss lock nut is being loosened or tightened.

Crankcase separating tool

90890-01135

This tool is necessary to disassemble the crankcase.

Crankshaft installation hose

90890-01274

This tool is used to install the crankshaft.

Crankshaft installation bolt

90890-01275

This tool is used to install the crankshaft.

#10 (M14) adapter

90890-04059

This tool is used to install the crankshaft.

Crank spacer

90890-04081

This tool is used to install the crankshaft.

SEALANT (QUICK GASKET) ®

Yamaha Bond No. 1215 ®

90890-85505

This sealant (adhesive) is used for crankcase mating surfaces etc.

Ringnut wrench

90890-01268

This tool is used to loosen and tighten the steering ringnut.

Ringnut wrench

90890-01348

This tool is used to loosen and tighten the steering ringnut.

1-7

GEN

SPECIAL TOOLS INFO

Tool No. |

Tool name / Usage |

Illustration |

T-handle

90890-01326

This tool is needed to loosen and tighten the front fork damper rod holding bolt.

Front fork damper rod holder

90890-01460

This tool is needed to hold the front fork damper rod when loosening and tightening the holding bolt.

DU bush/oil seal guide

90890-11043

This tool is used to install the DU bush and the fork oil seal.

1-8

SPEC 2

|

|

SPEC |

|

|

|

|

|

CHAPTER 2. |

|

|

|

SPECIFICATIONS |

|

|

|

GENERAL SPECIFICATIONS ............................................................................................ |

2-1 |

||

MAINTENANCE SPECIFICATIONS .................................................................................... |

2-4 |

||

ENGINE ........................................................................................................................ |

2-4 |

||

CHASSIS .................................................................................................................... |

2-12 |

||

ELECTRICAL .............................................................................................................. |

2-17 |

||

GENERAL TORQUE SPECIFICATIONS............................................................................ |

2-19 |

||

CONVERSION TABLE........................................................................................................ |

2-19 |

||

LUBRICATION POINTS AND LUBRICANT TYPES.......................................................... |

2-20 |

||

ENGINE ...................................................................................................................... |

2-20 |

||

CHASSIS .................................................................................................................... |

2-21 |

||

LUBRICATION LAYOUT .................................................................................................... |

2-22 |

||

CABLE ROUTING .............................................................................................................. |

2-26 |

||

SPEC

GENERAL SPECIFICATIONS SPEC

SPECIFICATIONS

GENERAL SPECIFICATIONS

|

Item |

|

Standard |

Limit |

|

|

|

|

|

Model |

|

|

TT600RE: 5CH5 |

|

|

|

|

|

|

Dimensions |

|

|

|

|

Overall length |

|

2,220 mm |

••• |

|

Overall width |

|

865 mm |

••• |

|

Overall height |

|

1,195 mm |

••• |

|

Seat height |

|

890 mm |

••• |

|

Wheelbase |

|

1,480 mm |

••• |

|

Ground clearance |

|

280 mm |

••• |

|

Minimum turning radius |

|

3,300 mm (right) |

|

|

|

|

|

3,100 mm (left) |

••• |

|

|

|

|

|

Basic weight (with oil and full |

|

|

|

|

fuel tank) |

|

164.5 kg |

••• |

|

|

|

|

|

|

Engine |

|

|

|

|

Engine type |

|

Air cooled 4-stroke, SOHC |

|

|

Cylinder arrangement |

|

Forward inclined single cylinder |

|

|

Displacement |

|

595 cm3 |

••• |

|

Bore x stroke |

|

95.0 x 84.0 mm |

••• |

|

Compression ratio |

|

8.5 : 1 |

••• |

|

Starting system |

|

Electric starter |

|

|

Lubrication system |

|

Dry sump with separate oil tank |

|

|

|

|

|

|

|

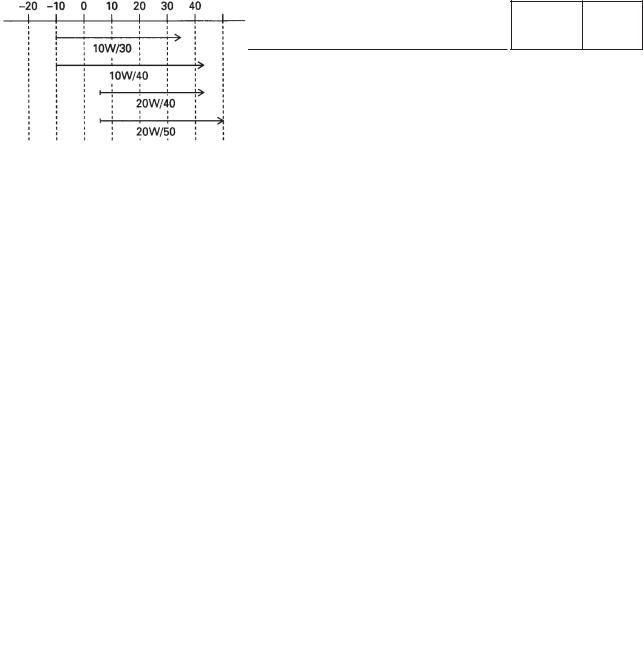

Engine oil |

|

|

|

|

Type |

Temp. |

°C |

SAE20W40SE or SAE10W30SE |

••• |

|

|

|

||

Recommended engine oil classification |

API Service SE, SF, SG or higher |

••• |

||

Quantity: |

|

|

|

|

Without oil filter cartridge |

|

|

|

|

replacement |

|

2.4 L |

••• |

|

With oil filter cartridge |

|

|

|

|

replacement |

|

2.5 L |

••• |

|

Total amount (dry engine) |

|

3.0 L |

••• |

|

|

|

|

|

|

Air filter |

|

|

Wet type element |

|

|

|

|

|

|

Fuel |

|

|

|

|

Type |

|

|

Regular unleaded gasoline |

|

Fuel tank capacity |

|

10 L |

••• |

|

Fuel reserve amount |

|

3.0 L |

••• |

|

|

|

|

|

|

Carburetor |

|

|

|

|

Manufacturer |

|

TEIKEI |

|

|

Model x quantity |

|

Y30PV-2ATK x 1 |

|

|

|

|

|

|

|

2-1

GENERAL SPECIFICATIONS SPEC

Item |

|

Standard |

Limit |

|

|

|

|

Spark plug |

|

|

|

Manufacturer/model |

|

NGK/DPR8EA-9 or NGK/DPR9EA-9 |

|

Gap |

|

0.8–0.9 mm |

••• |

|

|

|

|

Clutch type |

|

Wet. Multiple-disc |

|

|

|

|

|

Transmission |

|

|

|

Primary reduction system |

|

Spur gear |

|

Primary reduction ratio |

|

71/34 (2.088) |

|

Secondary reduction system |

Chain drive |

|

|

Secondary reduction ratio |

|

47/15 (3.133) |

|

Number of drive chain sprocket |

|

|

|

teeth (front/rear) |

|

15/47 |

|

Transmission type |

|

Constant mesh 5-speed |

|

Operation |

|

Left foot |

|

Gear ratio |

1st |

2.583 |

|

|

2nd |

1.588 |

|

|

3rd |

1.200 |

|

|

4th |

0.955 |

|

|

5th |

0.792 |

|

Chassis |

|

|

|

Frame type |

|

Open cradle backbone frame/detachable |

|

|

|

rear frame |

|

Caster angle |

|

27° |

••• |

Trail |

|

117 mm |

••• |

|

|

|

|

Tires |

|

|

|

Front: |

|

|

|

Type |

|

With tube |

|

Size |

|

90/90-21-(54R) / 90/90-21-(54S) |

|

Manufacturer/model |

|

Pirelli / MT70 - Michelin / T63 |

|

Rear: |

|

|

|

Type |

|

With tube |

|

Size |

|

130/80-18-(66R) / 130/80-18-(66S) |

|

Manufacturer/model |

|

Pirelli / MT70 - Michelin / T63 |

|

Maximum load* |

|

180 kg |

••• |

Tire air pressure |

|

|

|

(measured on cold tires): |

|

|

|

Up to 90 kg* |

Front |

200 kPa; 2.00 kgf/cm2; 2.00 bar |

••• |

|

Rear |

220 kPa; 2.20 kgf/cm2; 2.20 bar |

••• |

90 kg–maximum* |

Front |

210 kPa; 2.10 kgf/cm2; 2.10 bar |

••• |

|

Rear |

240 kPa; 2.40 kgf/cm2; 2.40 bar |

••• |

Off-road riding |

Front |

150 kPa; 1.50 kgf/cm2; 1.50 bar |

••• |

|

Rear |

160 kPa; 1.60 kgf/cm2; 1.60 bar |

••• |

High-speed riding |

Front |

210 kPa; 2.10 kgf/cm2; 2.10 bar |

••• |

|

Rear |

240 kPa; 2.40 kgf/cm2; 2.40 bar |

••• |

* Total weight of rider, passenger, |

|

|

|

cargo and accessories |

|

|

|

|

|

|

|

Wheels |

|

|

|

Front: |

|

|

|

Type |

|

Spoke wheel |

|

Size |

|

21” x 1.85 |

|

Rear: |

|

|

|

Type |

|

Spoke wheel |

|

Size |

|

18” x MT 2.50 |

|

|

|

|

|

2-2

GENERAL SPECIFICATIONS SPEC

Item |

|

Standard |

Limit |

|

|

|

|

Brakes |

|

|

|

Front: |

|

|

|

Type |

Single Ø 267 mm disk brake, |

|

|

|

2 x 28 mm |

|

|

Operation |

Right hand |

|

|

Fluid |

DOT 4 |

|

|

Rear: |

|

|

|

Type |

Single Ø 220 mm disk brake, |

|

|

|

1 x 34 mm caliper |

|

|

Operation |

Right foot |

|

|

Fluid |

DOT 4 |

|

|

|

|

|

|

Suspension |

|

|

|

Front |

Telescopic fork Outside tube |

|

|

|

dia. 46 mm |

|

|

Rear |

Deltabox Swingarm with |

|

|

|

adjustable shock absorber |

|

|

|

|

|

|

Spring/shock absorber |

|

|

|

Front |

Coil spring / oil damper |

|

|

Rear |

Coil spring / gas-oil damper, spring |

|

|

|

preload adjustable |

|

|

|

|

|

|

Wheel travel |

|

|

|

Front |

230 mm |

••• |

|

Rear |

230 mm |

••• |

|

|

|

|

|

Electrical system |

|

|

|

Ignition system |

Transistorized coil ignition (digital) |

|

|

Charging system: |

|

|

|

Type |

A.C. magneto |

|

|

Standard output |

14V, 13.5A at 5.000 r/min |

••• |

|

Battery: |

|

|

|

Model |

GT9B-4 |

|

|

Voltage, capacity |

12V, 8Ah |

••• |

|

|

|

|

|

Headlight type |

Quartz bulb (halogen) |

|

|

|

|

|

|

Bulb voltage, wattage x quantity |

|

|

|

Headlight |

12V |

60W / 55W x 1 |

••• |

Tail/brake light |

12V |

5W / 21W x 1 |

••• |

Turn signal light |

12V |

10W x 4 |

••• |

Auxiliary light |

12V |

5W x 1 |

••• |

Meter lighting |

12V |

3W x 1 |

••• |

Turn signal indicator light |

12V |

1.2W x 1 |

••• |

Neutral indicator light |

12V |

1.2W x 1 |

••• |

Auxiliary indicator light |

12V |

1.2W x 1 |

••• |

High beam indicator light |

12V |

1.2W x 1 |

••• |

|

|

|

|

Fuse |

20A |

|

••• |

|

|

|

|

2-3

MAINTENANCE SPECIFICATIONS SPEC

MAINTENANCE SPECIFICATIONS

ENGINE

Item |

Standard |

Limit |

Cylinder head |

|

|

Max. warpage |

••• |

0.03 mm |

|

|

|

Cylinder |

|

|

Bore |

94.970 - 95.020 mm |

95.10 mm |

Measuring point |

50 mm |

••• |

|

|

|

Camshaft |

|

|

Drive system |

Chain drive (left) |

|

Camshaft cap inside diameter |

23.000 - 23.021 mm |

••• |

Camshaft journal diameter |

22.967 - 22.980 mm |

••• |

Camshaft-journal-to-camshaft-cap |

|

|

clearance |

0.020 - 0.054 mm |

••• |

Camshaft lobe dimensions: |

|

|

Intake-measurement |

A |

36.470 - 36.570 mm |

••• |

Intake-measurement |

B |

30.060 - 30.160 mm |

••• |

Intake-measurement |

C |

6.41 mm |

••• |

Exhaust-measurement |

A |

36.620 - 36.720 mm |

••• |

Exhaust-measurement |

B |

30.110 - 30.210 mm |

••• |

Exhaust-measurement |

C |

6.51 mm |

••• |

Max. camshaft runout |

|

••• |

0.030 mm |

2-4

MAINTENANCE SPECIFICATIONS SPEC

Item |

|

Standard |

Limit |

|

|

|

|

Timing chain |

|

|

|

Model/number of links |

|

75-010/126 |

|

Tensioning system |

|

Automatic |

|

|

|

|

|

Rocker arm/rocker arm shaft |

|

|

|

Arm inside diameter |

|

12.000 - 12.018 mm |

••• |

Shaft outside diameter |

|

11.976 - 11.991 mm |

••• |

Arm-to-shaft clearance |

|

0.009 - 0.042 mm |

••• |

|

|

|

|

Valve, valve seat, valve guide |

|

|

|

Valve clearance (cold) |

intake |

0.05 - 0.10 mm |

••• |

|

exhaust |

0.12 - 0.17 mm |

••• |

|

|

|

|

|

|

|

|

Valve dimensions: |

|

|

|

Valve head diameter A |

intake |

36.90 - 37.10 mm |

••• |

|

exhaust |

31.90 - 32.10 mm |

••• |

Valve face width B |

intake |

2.260 mm |

••• |

|

exhaust |

2.260 mm |

••• |

Valve seat width C |

intake |

1.00 - 1.20 mm |

1.80 mm |

|

exhaust |

1.00 - 1.20 mm |

1.80 mm |

Valve margin thickness D |

intake |

1.00 - 1.40 mm |

0.80 mm |

|

exhaust |

0.80 - 1.20 mm |

0.65 mm |

Valve stem diameter |

intake |

6.975 - 6.990 mm |

6.995 mm |

|

exhaust |

6.955 - 6.970 mm |

6.925 mm |

Valve guide inside |

|

|

|

diameter |

intake |

7.000 - 7.012 mm |

7.042 mm |

|

exhaust |

7.000 - 7.012 mm |

7.042 mm |

Valve stem to valve |

|

|

|

guide clearance |

intake |

0.010 - 0.037 mm |

0.08 mm |

|

exhaust |

0.030 - 0.057 mm |

0.10 mm |

Valve stem runout |

|

••• |

0.010 mm |

Valve seat width |

intake |

1.10 mm |

1.80 mm |

|

exhaust |

1.10 mm |

1.80 mm |

2-5

MAINTENANCE SPECIFICATIONS SPEC

Item |

|

Standard |

Limit |

|

|

|

|

Valve spring |

|

|

|

Inner spring: |

|

|

|

Free length |

intake |

40.10 mm |

38.10 mm |

|

exhaust |

40.10 mm |

38.10 mm |

Installed length |

|

|

|

(valve closed) |

intake |

22.70 mm |

••• |

|

exhaust |

22.70 mm |

••• |

Compressed spring force |

|

|

|

(installed) |

intake |

164.80 - 190.20 N |

••• |

|

|

16.80 - 19.39 kg |

••• |

|

exhaust |

164.80 - 190.20 N |

••• |

|

|

16.80 - 19.39 kg |

••• |

Spring tilt intake |

intake |

••• |

2.5 °/1.7 mm |

|

exhaust |

••• |

2.5 °/1.7 mm |

Winding direction |

|

|

|

(top view) |

intake |

Clockwise |

|

|

exhaust |

Clockwise |

|

Outer spring: |

|

|

|

Free length intake |

intake |

43.80 mm |

38.10 mm |

|

exhaust |

43.80 mm |

38.10 mm |

Installed length |

|

|

|

(valve closed) |

intake |

34.20 mm |

••• |

|

exhaust |

34.20 mm |

••• |

Compressed spring force |

intake |

71.60 - 87.30 N |

••• |

(installed) |

|

7.3 - 8,9 kg |

••• |

|

exhaust |

149.10 - 182.40 N |

••• |

|

|

15.2 - 18.6 kg |

••• |

Spring tilt |

intake |

••• |

2.5 °/1.7 mm |

|

exhaust |

••• |

2.5 °/1.9 mm |

Winding direction |

|

|

|

(top view) |

intake |

Counterclockwise |

|

|

exhaust |

Counterclockwise |

|

|

|

|

|

Piston |

|

|

|

Piston-to-cylinder clearance |

|

0.045 - 0.065 mm |

0.15 mm |

Diameter D |

|

94.915 - 94.965 mm |

••• |

Height H |

|

5.0 mm |

••• |

Piston pin bore inside diameter |

22.004 - 22.015 mm |

••• |

|

Offset |

|

2.00 mm |

••• |

Offset direction |

|

Intake side |

|

Piston pin outside diameter |

|

21.991 - 22.000 mm |

••• |

|

|

|

|

|

|

|

|

2-6

MAINTENANCE SPECIFICATIONS SPEC

Item |

Standard |

Limit |

Piston ring

Top ring:

Ring type |

Barrel |

|

Dimensions (B x T) |

1.20 x 3.80 mm |

••• |

End gap |

|

|

(installed) |

0.30 - 0.45 mm |

0.70 mm |

Ring side clearance |

0.040 - 0.080 mm |

0.130 mm |

2nd ring: |

|

|

Ring type |

Plain |

|

Dimensions (B x T) |

1.20 x 3.80 mm |

••• |

End gap |

|

|

(installed) |

0.30 - 0.45 mm |

0.80 mm |

Ring side clearance |

0.030 - 0.070 mm |

0.130 mm |

Oil ring: |

|

|

Dimensions (B x T) |

2.50 x 3.40 mm |

••• |

End gap |

|

|

(installed) |

0.20 - 0.70 mm |

••• |

Ring side clearance |

0.020 - 0.060 mm |

••• |

|

|

|

Crankshaft |

|

|

Width A |

74.95 - 75.00 mm |

••• |

Max. runout C |

••• |

0.030 mm |

Big end side clearance D |

0.350 - 0.650 mm |

••• |

Big end radial clearance |

0.010 - 0.025 mm |

••• |

Small end free play F |

0.80 mm |

••• |

2-7

MAINTENANCE SPECIFICATIONS SPEC

Item |

Standard |

Limit |

|

|

|

Ballancer |

|

|

Ballancer drive method |

Gear |

|

|

|

|

Clutch |

|

|

Clutch release method |

Inner push, cam push |

|

Friction plate thickness |

2.72 - 2.88 mm |

••• |

Wear limit |

••• |

2.60 mm |

Plate quantity |

6 pcs |

|

Friction plate thickness |

2.94 - 3.06 mm |

••• |

Wear limit |

••• |

2.8 mm |

Plate quantity |

2 pcs |

|

Clutch plate thickness |

1.20 mm |

••• |

Plate quantity |

7 pcs |

|

Max. warpage |

••• |

0.20 mm |

Clutch spring free length |

42.8 mm |

••• |

Plate quantity |

5 pcs |

|

Clutch housing thrust clearance |

0.070 - 0.071 mm |

••• |

|

|

|

Transmission |

|

|

Max. main axle runout |

••• |

0.08 mm |

Max. drive axle runout |

••• |

0.08 mm |

Shift mechanism type |

Cam drum and guide bar |

|

|

|

|

Carburetor |

|

|

ID mark |

5CH5 10 |

|

Main jet |

#1:#150 #2:#145 |

|

Main air jet |

#1:1.0 #2:0.9 |

|

Jet needle |

#1:5C5A-3/5 #2:5Y18-3/5 |

|

Needle jet |

2.600 |

|

Cutaway |

4.00 |

|

Pilot air jet 1 |

# 0.8 mm |

|

Pilot jet |

# 50 |

|

Bypass 1 |

# 1.0 |

|

Pilot screw turns out |

2-3/4 +/- 1/2 |

|

Valve seat size |

2.5 |

|

Starter jet 1 |

# 74 |

|

Float height |

6.0 - 8.0 mm |

••• |

|

|

|

Engine idle speed |

1,150-1,450 r/min |

••• |

CO% |

1.5 - 3 |

••• |

Intake vacuum |

30.6-33.36 kPa - 230-250 mm Hg |

••• |

|

|

|

Lubrication system |

Dry sump |

|

Oil filter type |

Paper type |

|

Oil pump: |

|

|

Oil pump type |

Trochoid type |

|

Inner rotor to outer rotor tip clearance |

0.12 mm |

0.20 mm |

Outer rotor to pump housing |

|

|

clearance |

0.030 - 0.080 mm |

0.150 mm |

Bypass valve opening pressure |

80.0 - 120.0 kPa (0.8 - 1.2 kgf/cm2) |

••• |

Relief valve operating pressure |

80.0 - 120.0 kPa (0.8 - 1.2 kgf/cm2) |

••• |

Oil pressure (hot) |

13.0 kPa (0.13 kgf/cm2)/1,300 r/min |

••• |

Pressure check location |

Oil filter chamber |

••• |

|

|

|

2-8

MAINTENANCE SPECIFICATIONS SPEC

ENGINE

Cylinder head tightening steps:

Crankcase tightening steps:

Left crankcase |

Right crankcase |

2-9

Loading...

Loading...