Page 1

- Data Brochure

•

•

•

•

•

•

•

•

Universal Reset Module 422

D 422

08/07

1

Information

Brochure

Choose controls

to match

application

2

Application

Brochure

Design your

mechanical

applications

3

Rough-in

Rough-in

instructions

Wiring

wiring

4

Wiring

Brochure

Wiring and

installation of

specific control

5

Data

Brochure

Control settings

and sequence of

operation

6

Job

Record

Record settings &

wiring details for

future reference

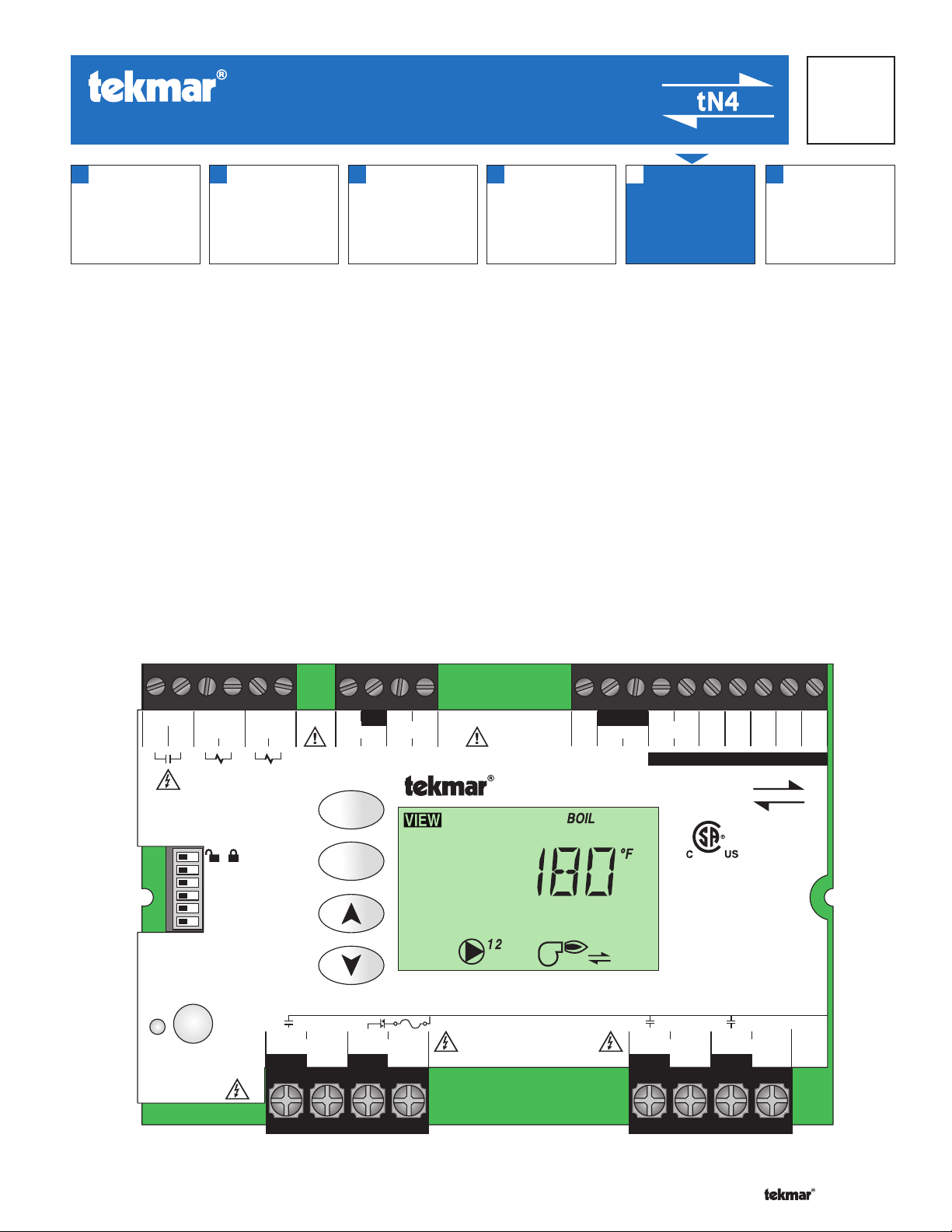

Introduction

The Universal Reset Module 422 provides outdoor reset to a hydronic heating system in order to maximize comfort and

efficiency. The 422 can operate a single on / off boiler or a single modulating boiler. The 422 can override the outdoor reset

water temperature to provide Domestic Hot Water or Setpoint operations. The 422 can operate two outdoor reset water

temperatures, either one boiler water temperature and a single mix water temperature, or two mix water temperatures. To

operate two mixing devices, a Mixing Expansion Module must be connected to the 422. The single mix output can operate

a floating action mixing valve or a variable speed injection pump.

Features:

• tN4 Compatible

• Two Outdoor Reset Temperatures

• Single On-Off or Modulating Boiler

• Powered Pump Outputs

• DHW Operation

• Variable Speed Injection Pump

• Floating Action Valve

• Includes Sensors

Boiler DHW Setpoint C C2 tN4 C Com Boil Mix Com Out+Opn Cls

51

H7008B

Var. Pump Fuse

Demand Demand 24 V (ac) Boil/Mix2 R R Mod (dc)

52 53 54 55 56 57 58 59 60 61 62 63 64 65

/

tN4 Boiler / Mix 2

Boil Sens Sup / Ret

Boiler On-Off / Mod

Off / tekmar Stager

Off / Flushing

Meets Class B: Canadian

ICES & FCC Part 15

Made in Canada

Test

T2.5 A 250 V

71 72 73 74

DHW Variable Speed

Pump Pump

R

Menu

Item

2.5 A

NN

Floating Output:

24 V (ac) 8 VA

Powered OutputOutput 1 VA

Universal Reset Module 422

–

66 67 68 69 70

Do not apply power

tektra 991-03

Var. Pump: 115 V (ac) 2.5 A

Demands: 20 - 260 V (ac)

Relay Rating: 115 V (ac) 5 A

75 76 77 78

Primary Mix Sys P1

Pump NPump

N

tN4

10 A

max.

1 of 32 © 2007 D 422 - 08/07

Page 2

Table of Contents

•

•

•

•

tN4 Boiler / Mix 2

Boil Sens Sup / Ret

Boiler On-Off / Mod

Off / tekmar Stager

Off / Flushing

/

Table of Contents ...........................................................2

Display and DIP Switches ..............................................2

Dip Switch Settings ................................................2

Access Level ...........................................................3

Display and Symbols Description............................4

User Interface ........................................................5

Display Menus ................................................................6

View Menu ..............................................................6

Adjust Menu ............................................................8

Miscellaneous Menu .............................................13

Testing the Control ....................................................... 14

Sequence of Operation ................................................. 16

®

tekmarNet

4 Communication ...............................16

Outdoor Reset ...................................................... 16

Boiler Temperature Control .................................. 19

tekmar Stager Operation ......................................21

Boil Enable ............................................................22

Direct Fired - DHW Tank as a Heat Source .........22

Zone Load Shedding ............................................22

Mixing Operation ..................................................22

Domestic Hot Water Temperature Operation .......23

DHW with Low Temperature Boilers .....................25

Setpoint Temperature Operation ...........................25

Pump Operation ....................................................27

Pump Exercising ................................................... 27

Error Messages ............................................................28

Troubleshooting ............................................................ 31

Warranty .......................................................................32

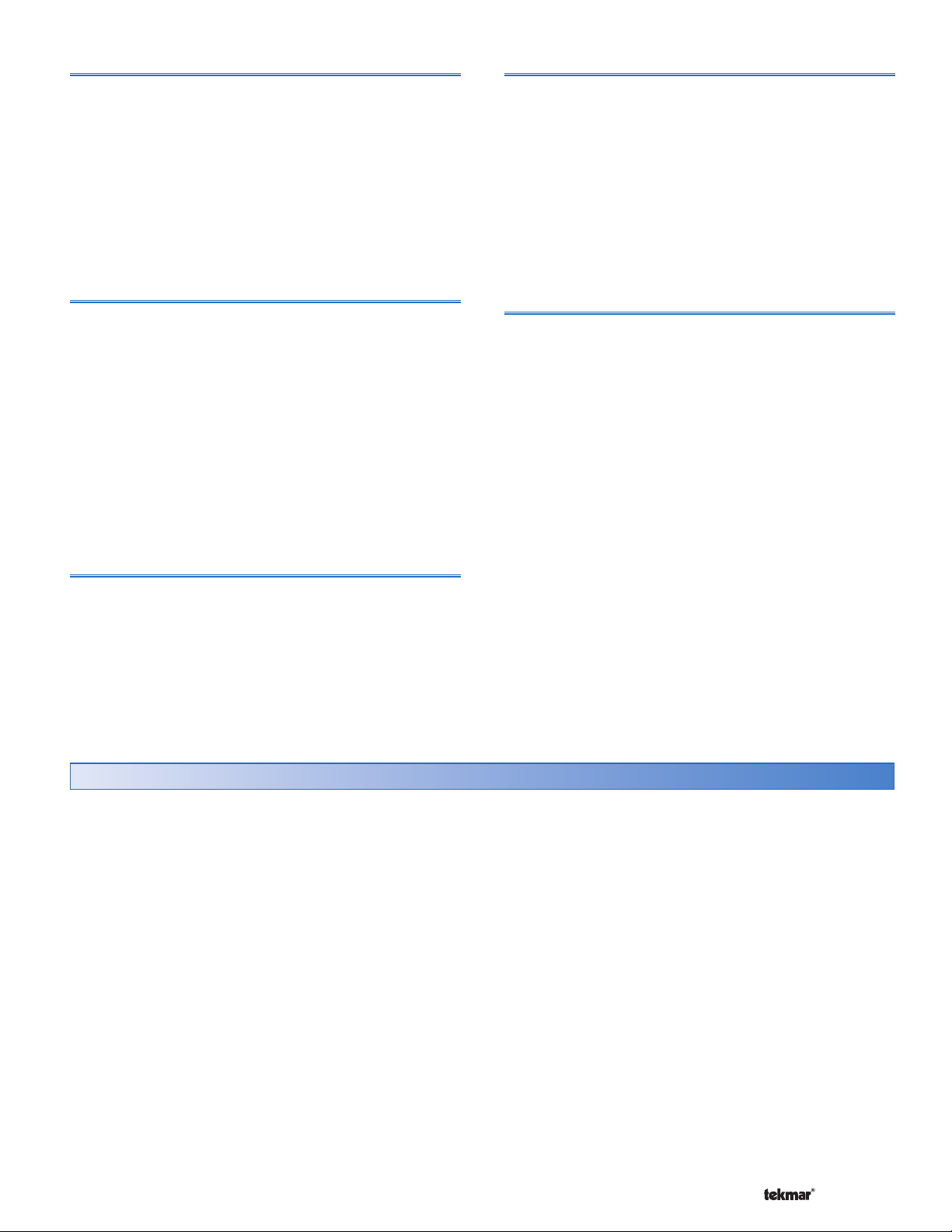

Display and DIP Switches

Dip Switch Settings

Set the DIP switch settings prior to making adjustments

to the control through the user interface. Setting the DIP

switches determines which menu items are displayed in

the user interface.

If you change a DIP switch setting while the control is

powered up, the LCD display returns to the View menu.

Lock / Unlock

Use the Lock / Unlock DIP switch to lock and unlock the Access

Level of the 422 and all connected tN4 devices, including

tN4 thermostats. For details, see “Access Levels”

• Once locked, the access level in all devices cannot be

viewed or changed.

• To determine if the control is currently locked a small

segment representing a padlock is viewed in the bottom

right hand corner of the display.

• To unlock the Access Level, set the DIP switch to

Unlock.

• To lock the Access Level, set the DIP switch to Lock.

Boiler DHW Setpoint C C2 tN4 C Com Boil Mix Com Out+Opn Cls

Demand Demand 24 V (ac) Boil/Mix2 R R Mod (dc)

51

52 53 54 55 56 57 58 59 60 61 62 63 64 65

H7008B

/

tN4 Boiler / Mix 2

Boil Sens Sup / Ret

Boiler On-Off / Mod

Off / tekmar Stager

Off / Flushing

Meets Class B: Canadian

ICES & FCC Part 15

Made in Canada

Test

Var. Pump Fuse

T2.5 A 250 V

R

Menu

Item

71 72 73 74

DHW Variable Speed

NN

Pump Pump

Floating Output:

24 V (ac) 8 VA

Universal Reset Module 422

2.5 A

Powered OutputOutput 1 VA

–

66 67 68 69 70

Do not apply power

tektra 991-03

Var. Pump: 115 V (ac) 2.5 A

Demands: 20 - 260 V (ac)

Relay Rating: 115 V (ac) 5 A

75 76 77 78

Primary Mix Sys P1

Pump NPump

N

tN4

10 A

max.

© 2007 D 422 - 08/07 2 of 32

Page 3

tN4 Boiler / Mix 2

•

•

•

•

•

•

•

•

•

•

•

•

Off / Flushing

Use the tN4 Boiler / Mix 2 DIP switch to select whether

the second tN4 bus (terminals 59-60) is to operate as

a boiler water temperature or as a second mixing water

temperature.

• If set to Boiler, this creates a system with one boiler and

one mix water temperature.

• If set to Mix 2, this creates a system with two mix water

temperatures. If Mix 2 is selected, a mixing expansion

module must be connected to the Boiler / Mix 2 bus.

Boiler Sup / Ret

Use the Boiler Sensor Supply / Return DIP switch to select

the location of the boiler sensor.

• If the boiler sensor is located on the supply, this DIP

switch should be set to Sup. The 422 is the control that

determines the boiler water temperature. Set the boiler’s

aquastat at least 20°F (11.0°C) higher than the Boiler

Maximum setting.

• If the 422 provides a heat demand to an external boiler

control, this DIP switch must be set to Ret. Install the

boiler sensor on the return side of the boiler loop.

The boiler’s operating temperature is controlled by its

aquastat, or an external boiler reset control.

The Off / Flushing DIP switch selects whether the control

operates a Flushing feature. Heating systems that use

potable water require periodic flushing to prevent the water

from stagnating.

The flushing operation occurs if any zone has not operated

for 7 days. All zones, mixing device(s), and applicable

system pumps are turned on for 4 minutes.

• To activate the Flushing feature, set to Flushing.

• To deactivate the Flushing feature, set to Off.

tekmar Stager / Off

Use the tekmar Stager / Off DIP switch when a tekmar

staging control is be connected to the 422 in order to

operate multiple boilers. A tekmar stager may include Boiler

Controls 264, 265, and 268.

• If a tekmar Stager is installed, set to tekmar Stager. The

422 will then provide the stager with a target temperature

via a 0-10 V (dc) signal. When the tekmar Stager / Off

DIP switch is set to tekmar Stager, the Boiler Sensor

DIP switch must be set to Sup.

• If a tekmar Stager is not installed, set to Off.

Boil On-Off / Mod

The Boil On-Off / Mod DIP switch selects whether the

control operates an On-Off boiler or the firing rate of a

Modulating boiler.

• If set to Boil On-Off, the control operates an On-Off

boiler.

• If set to Mod, the control operates a Modulating boiler.

Access Level

The Access Level restricts the number of Menus, Items,

and Adjustments that can be accessed by the user. The

Access Level setting is found in the Miscellaneous (MISC)

menu. Select the appropriate access level for the people

who work with the control on a regular basis.

There are two Access Level settings:

• Installer (InS): This is the factory default setting. This

access level is sufficient for the normal set up of the

control.

• Advanced (Ad): All of the control settings are available

to the user.

In the following menu tables, the access level the item is

visible in is shown in the access column.

3 of 32 © 2007 D 422 - 08/07

Page 4

Display

Symbols Description S

Menu Field

Displays the

current menu

Status Field

Displays the current

status of the control’s

inputs, outputs and

operation. Most symbols

in the status field are

only visible when the

VIEW Menu is selected

Symbols Description

PUMP

Displays when the primary or mixing pump

is in operation.

Item Field

Displays an

abbreviated name

of the selected item

Number Field

Displays the

current value of

the selected item

BOILER DEMAND

Displays when a boiler demand is present.

BURNER

Displays when the burner contact is

closed.

LOCK

Displays when the access levels are

locked.

WARNING

Displays when an error exists.

COMMUNICATION BUS

Displays when tN4 thermostats are

connected.

DHW PUMP

Displays when the DHW Pump is in

operation.

°F, °C, %, HOURS, MINUTES

Units of measurement.

MIX 1 DEMAND

Displays when a mix 1 demand is present.

MIX 2 DEMAND

Displays when a mix 2 demand is present.

DHW DEMAND

Displays when a DHW demand is present.

SETPOINT DEMAND

Displays when a Setpoint demand is

present.

DEVICE OUTPUT SCALE

Displays output of the modulating boiler,

injection pump, or mixing valve.

OPEN / CLOSE

Displays whether the actuator is opening or

closing the mixing valve.

© 2007 D 422 - 08/07 4 of 32

Page 5

User Interface

•

•

•

•

Use the User Interface available on the Liquid Crystal Display

(LCD) to setup and monitor the operation of the system.

Use the four push buttons to the left of the LCD (Menu,

Item, Up, Down) to select settings. As you enter settings,

record the settings in the Job Record J 422.

Menu

The menus display in the Menu Field at the top left side

of the LCD. Three menus are available: View, Adjust, and

Miscellaneous.

• To select a menu, press and release the Menu button.

Item

In each menu, a group of items can be selected. The

abbreviated name of the selected item displays in the Item

field of the LCD display.

• To view the next available item, press and release the

Item button.

• To view the previous item, hold down the Item button.

and press and release the Up button.

Adjusting a Setting

To adjust a setting:

1. Select the appropriate menu using the Menu button.

2. Select the item using the Item button.

3. Use the Up or Down button to make the adjustment.

Default Item

• To set the default item in the View menu, display the

item for more than five seconds.

After navigating menus, the display reverts back to the

default item after 60 seconds of button inactivity.

Back to View Menu

Continue

to next Item

Continue

to next Item

Continue

to next Item

5 of 32 © 2007 D 422 - 08/07

Page 6

Display Menus

View Menu (1 of 2)

Item Field Range Access Description

The View menu items display the current operating

temperatures and status information of the system.

VIEW MENU

-76 to 149°F

(-60.0 to 65.0°C)

-22 to 266°F

(-30.0 to 130.0°C)

– – –, 35 to 230°F

(– – –, 1.5 to 110.0°C)

-22 to 266°F

(-30.0 to 130.0°C)

– – –, 35 to 230°F

(– – –, 1.5 to 110.0°C)

InS

Ad

InS

Ad

Ad

InS

Ad

Ad

OUTDOOR SECTION B

Current outdoor air temperature as measured by the

outdoor sensor.

MIX 1 SUPPLY SECTION B

Current Mix 1 supply water temperature as measured

by the Mix 1 supply sensor.

MIX 1 TARGET SECTION C

The Mix 1 target is the temperature the control

is currently trying to maintain at the Mix 1 supply

sensor. “– – –” is displayed when no heat is required

for Mix 1 zones.

MIX 2 SUPPLY SECTION B

Current Mix 2 supply water temperature as measured

by the Mix 2 supply sensor.

Note: This item is only available when the tN4 DIP

switch is set to Mix 2.

MIX 2 TARGET SECTION C

The mix 2 target is the temperature the control

is currently trying to maintain at the Mix 2 supply

sensor. “– – –” is displayed when no heat is required

for mix 2 zones.

Note: This item is only available when the tN4 DIP

switch is set to Mix 2.

-22 to 266°F

(-30.0 to 130.0°C)

Continued on next page.

© 2007 D 422 - 08/07 6 of 32

InS

Ad

BOILER SUPPLY SECTION C

Current boiler supply water temperature as measured

by the boiler sensor.

Note: This item is only available when the Boiler

Sensor Sup / Ret DIP switch is set to Sup.

Page 7

View Menu (2 of 2)

Item Field Range Access Description

VIEW MENU

– – –, 35 to 230°F

(– – –, 1.5 to 110.0°C)

-22 to 266°F

(-30.0 to 130.0°C)

0-100% Ad

0 to 9999 hr

Ad

InS

Ad

InS

Ad

BOILER TARGET

The boiler target is the temperature the control is currently

trying to maintain at the boiler supply sensor. “– – –” is

displayed when no heat is required for boiler zones.

Note: This item is only available when the Boiler

Sensor Sup / Ret DIP switch is set to Sup.

BOILER RETURN SECTION G

Current boiler return water temperature as measured

by the boiler sensor.

Note: This item is only available when the Boiler

Sensor Sup / Ret DIP switch is set to Ret.

BOILER MODULATION SECTION C

Current percent modulation of the boiler’s burner.

Note: This item is only available when the Boiler

On-Off / Mod DIP switch is set to Mod, and the Boiler

Sensor Sup / Ret DIP switch is set to Sup.

BOILER

The total running time of the boiler since this item

was last cleared. To clear this item, press the Up

and Down buttons simultaneously while viewing

this item.

Note: This item is only available when the Boiler

Sensor Sup / Ret DIP switch is set to Sup.

SECTION C

After the last item, the control returns to the first item in the menu.

7 of 32 © 2007 D 422 - 08/07

Page 8

Adjust Menu (1 of 5)

The Adjust Menu items are the programmable settings

used to operate the mechanical equipment.

Item Field

Range

-60 to 45°F

(-51.0 to 7.0°C)

Default = 10°F

(-12.0°C)

VAr, FLt

Default = VAr

1 HRF1

2 HRF2

3 Fancoil

4 Fin-tube Convector

5 Radiator

6 Baseboard

Default = 1

40 to 100°F

(4.5 to 38.0°C)

Default = 70°F (21.0°C)

Access Description

OUTDOOR DESIGN

InS

Ad

InS

Ad

InS

Ad

Ad

The design outdoor air temperature used in the heat

loss calculations for the heating system. Typically set

to the temperature of the coldest day of the year.

MIX 1 MODE SECTION G

Select the type of mixing device to be used for Mix 1.

Options are variable speed injection pump (VAr) or

floating action (FLt).

MIX 1 TERMINAL SECTION B

The type of heating terminal units that are being

used in Mix 1 zones.

MIX 1 INDOOR SECTION B

The design indoor air temperature used in the heat

loss calculation for Mix 1 zones. Typically set to

70°F (21.0°C).

SECTION B

ADJUST MENU

70 to 220°F

(21.0 to 104.5°C)

Default = 120°F

(49.0°C)

OFF, 40 to 150°F

(OFF, 4.5 to 65.5°C)

Default = OFF

80 to 220°F, OFF

(26.5 to 104.5°C, OFF)

Default = 140°F

(60.0°C)

Continued on next page.

© 2007 D 422 - 08/07 8 of 32

InS

Ad

Ad

Ad

MIX 1 DESIGN SECTION B

The supply water temperature required for the Mix 1

zones on the typical coldest day of the year.

MIX 1 MINIMUM SECTION G

The minimum allowed Mix 1 target temperature.

MIX 1 MAXIMUM SECTION G

The maximum allowed Mix 1 target temperature.

Page 9

Adjust Menu (2 of 5)

Item Field

Range

30 to 230 seconds

Default = 105

1 HRF1

2 HRF2

3 Fancoil

4 Fin-tube Convector

5 Radiator

6 Baseboard

Default = 1

40 to 100°F

(4.5 to 38.0°C)

Default = 70°F (21.0°C)

70 to 220°F

(21.0 to 104.5°C)

Default = 120°F

(49.0°C)

Access Description

MIX 1 MOTOR SECTION G

The time that the Mix 1 actuating motor requires to

Ad

InS

Ad

Ad

InS

Ad

operate from fully closed to fully open.

Note: This item is only available when the Mix 1

Mode setting is set to floating action (FLt).

MIX 2 TERMINAL SECTION B

The type of heating terminal units that are being

used in mix 2 zones.

Note: This item is only available when the tN4 DIP

switch is set to Mix 2.

MIX 2 INDOOR SECTION B

The design indoor air temperature used in the heat

loss calculation for mix 2 zones. Typically set to

70°F (21.0°C).

Note: This item is only available when the tN4 DIP

switch is set to Mix 2.

MIX 2 DESIGN SECTION B

The supply water temperature required for the mix 2

zones on the typical coldest day of the year.

Note: This item is only available when the tN4 DIP

switch is set to Mix 2.

ADJUST MENU

OFF, 40 to 150°F

(OFF, 4.5 to 65.5°C)

Default = OFF

80 to 220°F

(26.5 to 104.5°C)

Default = 140°F

(60.0°C)

30 to 230 seconds

Default = 105

1 HRF1

2 HRF2

3 Fancoil

4 Fin-tube Convector

5 Radiator

6 Baseboard

Default = 4

Ad

Ad

Ad

InS

Ad

MIX 2 MINIMUM SECTION G

The minimum allowed mix 2 target temperature.

Note: This item is only available when the tN4 DIP

switch is set to Mix 2.

MIX 2 MAXIMUM SECTION G

The maximum allowed mix 2 target temperature.

Note: This item is only available when the tN4 DIP

switch is set to Mix 2.

MIX 2 MOTOR SECTION G

The time that the mix 2 actuating motor requires to

operate from fully closed to fully open.

Note: This item is only available when the tN4 DIP

switch is set to Mix 2. Availability also depends on

the type of mixing module being used.

BOILER TERMINAL SECTION B

The type of heating terminal units that are being

used in boiler zones.

Note: This item is only available when the Boiler

Sensor Sup / Ret DIP switch is set to Sup and the

tN4 DIP switch is set to Boiler.

Continued on next page.

9 of 32 © 2007 D 422 - 08/07

Page 10

Adjust Menu (3 of 5)

Item Field

Range

40 to 100°F

(4.5 to 38.0°C)

Default = 70°F

(21.0°C)

70 to 220°F

(21.0 to 104.5°C)

Default = 180°F

(82.0°C)

OFF, 80 to 180°F

(OFF, 26.5 to 82.0°C)

Default = 140°F

(60.0°C)

120 to 225°F, OFF

(49.0 to 107.0°C, OFF)

Default = 200°F

(93.5°C)

Access Description

BOILER INDOOR

The design indoor air temperature used in the heat

loss calculation for the boiler zones. Typically set to

Ad

InS

Ad

InS

Ad

Ad

70°F (21.0°C).

Note: This item is only available when the Boiler

Sensor Sup / Ret DIP switch is set to Sup and the

tN4 DIP switch is set to Boiler.

BOILER DESIGN SECTION B

The supply water temperature required for boiler

zones on the typical coldest day of the year.

Note: This item is only available when the Boiler

Sensor Sup / Ret DIP switch is set to Sup and the

tN4 DIP switch is set to Boiler.

BOILER MINIMUM SECTION C

The minimum allowed boiler target temperature and

boiler return protection temperature. Check the boiler

manufacturer’s manual for recommend supply water

temperatures.

BOILER MAXIMUM SECTION C

The maximum allowed boiler target temperature.

Note: This item is only available when the Boiler

Sensor Sup / Ret DIP switch is set to Sup and the

tekmar stager DIP switch is set to OFF.

SECTION B

ADJUST MENU

0:00 to 3:00 min

Default = 0:10 min

Au, 2 to 42°F

(Au, 1 to 23.5°C)

Default = Au

10 to 230 seconds

Default = 30 seconds

Ad

Ad

Ad

FIRE DELAY SECTION C

The time delay the control can expect between the

time that the relay contact closes to fire the boiler

and when the burner actually fires.

Note: This item is only available when the Boiler

Sensor Sup / Ret DIP switch is set to Sup and the

tekmar stager DIP switch is set to OFF.

BOILER DIFFERENTIAL SECTION C

The temperature differential that the control is to use

when it is operating the boiler.

Note: This item is only available when the Boiler

Sensor Sup / Ret DIP switch is set to Sup and the

tekmar stager DIP switch is set to OFF.

BOILER MOTOR SECTION C

The amount of time required for the modulating

actuating motor to fully open the gas valve or operate

the fan speed from a stopped position to full speed

on a modulating boiler.

Note: This item is only available when the Boiler

Sensor Sup / Ret DIP switch is set to Sup, the Boiler

On-Off / Mod DIP switch is set to Mod and the tekmar

stager DIP switch is set to OFF.

Continued on next page.

© 2007 D 422 - 08/07 10 of 32

Page 11

Adjust Menu (4 of 5)

Item Field

Range

0 to 50%

Default = 0%

50 to 100%

Default = 100%

Au, 5 to 30 min

Default = Au

OFF, Mb1, Mb2,

Mb3, Mb4

Default = OFF

Access Description

MINIMUM MODULATION

The minimum percent modulation of the burner.

Ad

Ad

Ad

InS

Ad

Note: This item is only available when the Boiler

Sensor Sup / Ret DIP switch is set to Sup, the Boiler

On-Off / Mod DIP switch is set to Mod, and the tekmar

stager DIP switch is set to OFF.

MAXIMUM MODULATION SECTION C

The maximum percent modulation of the burner.

Note: This item is only available when the Boiler

Sensor Sup / Ret DIP switch is set to Sup, the Boiler

On-Off / Mod DIP switch is set to Mod, and the tekmar

stager DIP switch is set to OFF.

CYCLE LENGTH

The cycle length to which all tN4 devices will

synchronize.

SCHEDULE

Selects which network setback schedule the control

will follow.

SECTION C

ADJUST MENU

OFF,

1 (parallel, no priority)

2 (parallel, priority)

3 (pri-sec, no priority)

4 (pri-sec, priority)

Default = 1

100 to 220°F

(38.0 to 104.5°C)

Default = 180°F

(82.0°C)

OFF, ON

Default = OFF

OFF,

1 (parallel, no priority)

2 (parallel, priority)

3 (pri-sec, no priority)

4 (pri-sec, priority)

Default = 1

InS

Ad

Ad

Ad

Ad

DHW MODE SECTION H

Selects the DHW mode of operation. This determines

the operation of the primary pump in combination

with the DHW pump and whether or not DHW priority

is required.

DHW EXCHANGE OCCUPIED SECTION H

The minimum boiler target temperature to the DHW heat

exchanger during the Wake and Occupied periods.

Note: This item is only available when DHW Mode

is set 1 through 4.

DHW EXCHANGE UNOCCUPIED SECTION H

Selects whether the control should respond to DHW

demands during the Sleep and Unoccupied periods.

This item is only available when DHW Mode is set

1 through 4 and a network setback schedule is

selected.

SETPOINT MODE SECTION J

Selects the Setpoint mode of operation. This determines

the operation of the primary pump.

Continued on next page.

11 of 32 © 2007 D 422 - 08/07

Page 12

Adjust Menu (5 of 5)

Item Field

ADJUST MENU

Range

60 to 220°F

(15.5 to 104.5°C)

Default = 180°F

(82.0°C)

OFF, ON

Default = OFF

40 to 100°F, OFF

(4.5 to 38.0°C, OFF)

Default = 70°F (21.0°C)

40 to 100°F, OFF

(4.5 to 38.0°C, OFF)

Default = 60°F (15.5°C)

Access Description

SETPOINT OCCUPIED

The minimum boiler target temperature when a

Ad

Ad

InS

Ad

Ad

setpoint demand is present during the Wake and

Occupied periods.

Note: This item is only available when Setpoint Mode

is set 1 through 4.

SETPOINT UNOCCUPIED SECTION J

Selects whether or not a Setpoint demand will be

responded to during the Sleep and Unoccupied

periods.

Note: This item is only available when Setpoint Mode

is set 1 through 4 and a network setback schedule

is selected.

WWSD OCCUPIED SECTION B

The system’s warm weather shut down temperature

during the Wake and Occupied periods.

WWSD UNOCCUPIED SECTION B

The system’s warm weather shut down temperature

during the Sleep and Unoccupied period.

Note: This item is only available when the Schedule

is not set to OFF.

SECTION J

After the last item, the control returns to the first item in the menu.

© 2007 D 422 - 08/07 12 of 32

Page 13

Misc (Miscellaneous) Menu (1 of 1)

Item Field Range Access Description

InS (Installer)

Ad (Advanced)

InS

Ad

The Miscellaneous Menu Items set control

and display options such as access level and

temperature units.

ACCESS LEVEL

The access level of the control. The access column

shows which items are visible in each access level.

Note: This item is only available when the Lock / Unlock

DIP switch is set to Unlock.

MISC MENU

°F, °C

Default = °F

0 to 24 Ad

0 to 24 Ad

0 to 24 Ad

OFF, SEL Ad

InS

Ad

UNITS

Select temperature units between Fahrenheit and

Celsius.

BOILER BUS DEVICES

Displays the number of devices on the Boiler Bus.

Note: This item is only available when the tN4 Boil / Mix 2

DIP switch is set to Boil.

BUS 1 DEVICES

Displays the number of devices on Bus 1.

BUS 2 DEVICES

Displays the number of devices on Bus 2.

Note: This item is only available when the tN4 Boil / Mix 2

DIP switch is set to Mix 2.

FACTORY DEFAULT

Loads the factory defaults when the Up and Down

buttons are held down for 1 second.

422

After the last item, the control returns to the first item in the menu.

InS

Ad

13 of 32 © 2007 D 422 - 08/07

TYPE

Displays the type number of this product. Hold the

UP button to display the software version.

Page 14

Testing the Control

•

•

•

•

The control has a built-in test routine that tests the main

control functions. The control continually monitors the

sensors and displays an error message whenever a fault

is found. The individual outputs and relays are tested using

a test sequence.

Test Sequence

Each step in the test sequence lasts 10 seconds.

• Start the test sequence by pressing the Test button.

• Pause the test sequence by pressing the Test button

again. To advance to the next step, press the Test button

again.

• If the test sequence is paused for more than five minutes,

the control exits the entire test routine.

• To advance to a particular step, repeatedly press and

release the Test button to display the appropriate

device.

HAZARD

Access to the Test button requires the removal of the

front cover and exposes hazardous voltage while the

control is powered. Only trained, qualified and competent

personnel should operate the Test button.

Te s t

Press and Hold

for 1 second

Step 1 The Mix 1 device ramps up to 100% over 10 seconds

or according to the motor speed setting.

Step 2

Step 3 The Mixing 1 pump turns on for 10 seconds then

IF the tN4 DIP switch is set to Mix 2:

Step 4 The Mix 2 device ramps up to 100% over 10

Step 5

Step 6 The Mixing 2 pump on the mixing module turns

Step 7 The primary pump turns on and remains on for

Step 8 The boiler contact is closed to fire an on-off boiler

IF the On-Off / Modulating DIP switch is set to Modulating

or the tekmar Stager / Off DIP switch is set to tekmar

Stager:

Step 9 When a demand is present, the modulation

Step 10 When a demand is present, the modulation

The Mix 1 device ramps down to 0% over 10

seconds or according to the motor speed setting.

shuts off.

seconds or according to the motor speed

setting.

The Mix 2 device ramps down to 0% over

10 seconds or according to the motor speed

setting.

on for 10 seconds then shuts off.

the rest of the test sequence.

for 10 seconds or enable a modulating boiler.

output ramps up to 100%.

output ramps down to 0%.

© 2007 D 422 - 08/07 14 of 32

The boiler contact is opened and the boiler is

shut off.

Step 11 If DHW MODE is set to 1 or 2, the primary pump is

shut off and the DHW Pump contact is closed.

If DHW MODE is set to 3 or 4, the primary pump

stays on and the DHW Pump contact is closed.

The control exits the test sequence.

If a device fails to operate during the test sequence, refer

to the W 422 Wiring Brochure to check the operation

of the control. If the control works properly, refer to any

troubleshooting information supplied by the equipment

manufacturer.

Page 15

Max Heat

•

Zone Test

The control has a function called Max Heat. In this mode,

the control turns on and operates the system up to the

maximum set temperatures as long as there is a demand

for heat. tN4 thermostats operate to meet the occupied

setting +5°F (3°C). The control operates in this mode for

up to 24 hours or until the Test button is pressed. Use this

mode to run the circulators during system start-up to purge

air from the piping.

• The Mix 1, Mix 2 and Mix 3 Maximum settings are available in the Adjust Menu when in Max Heat.

HAZARD

Access to the Test button requires the removal of the

front cover and exposes hazardous voltage while the

control is powered. Only trained, qualified and competent

personnel should operate the Test button.

Te s t

Press and Hold

for 3 seconds

To enable Max Heat:

Press and hold the Test button for more than 3 seconds

and less than 6 seconds.

If there is a demand for heat, the ‘TEST’ and ‘MAX’ segments

are displayed on screen and the control will turn on all

outputs for up to 24 hours.

If there is no demand for heat, the ‘TEST’ and ‘MAX’

segments are still displayed but no outputs are turned on

until there is a demand for heat present.

To Cancel Max Heat:

Press the Test button to cancel Max Heat manually or wait

24 hours and the control will automatically leave the Max

Heat mode.

In Zone Test mode, each tN4 device is individually turned

on one at a time. The control tests each zone for up to 5

minutes of no button activity. Use this feature to purge air

out of each zone and assist in troubleshooting.

HAZARD

Access to the Test button requires the removal of the

front cover and exposes hazardous voltage while the

control is powered. Only trained, qualified and competent

personnel should operate the Test button.

Te s t

Press and Hold

for 6 seconds

To enable Zone Test:

1. Press and hold the Test button for more than 6 seconds.

The control displays ZN TEST OFF.

2. Press the Up button to change the display to ZN TEST

ON. After 3 seconds, the boiler, all pumps, and the

mixing valves are shut off.

3. The control operates stage one of the tN4 device with the

lowest address number. Device number one of the boiler

bus (b:01) has the lowest address number and device

24 of bus 3 (3:24) has the highest address number. All

other tN4 zones are shut off.

4. Pressing the Up button will turn off stage 1, and turn on

stage 2 of the same device (if that device has a second

stage) or turn on stage 1 of the device with the next

lowest address. The Down button can be pressed to

move to a device with a lower address number. The Up

and Down buttons will only move through devices on

the same bus.

5. Press the Item button to switch busses. The Up and

Down buttons can then be used to move through the

devices and the heating stages of each device on the

next bus.

6. To cancel the Zone Test, press the Test button. Once

the Zone Test ends or is cancelled, the control resumes

normal operation.

Tes t

Hold

for 6

seconds

Wait

3

seconds

Tes t

15 of 32 © 2007 D 422 - 08/07

Page 16

Sequence of Operation

tekmarNet®4 Communication Section A

tekmarNet®4 (tN4) communicates between tN4 devices

(thermostats, Reset Module and Expansion Modules).

Each tN4 device is connected to a tN4 communication

bus using two wires. Each tN4 bus adjusts a single water

temperature in the system using indoor temperature

feedback. The Universal Reset Module 422 allows for two

tN4 buses. This allows you to control a system with two

separate water temperatures.

A system that has more than one tN4 bus is referred to as

a tN4 network.

Network

Bus 1 Bus 2

Do not apply power

tN4

tN4

Menu

Item

Zone A1

Power

Zone Group Pump A

Zone A2

Zone Group Pump B

Zone A3

Zone B1

Zone B2

Zone B3

tekmarNet®4

Thermostats

tekmarNet®4

Thermostats

H7008B

/

Test

Outdoor Reset Module

The Universal Reset Module 422 is the system control

for a hydronic heating system. The 422 operates a single

heat source such as a boiler, one or two mixing devices,

a domestic hot water tank, and responds to other heating

requirements such as pool heating and snow melting. The

422 also coordinates and optimizes the operation of all the

tN4 thermostats.

tN4 Thermostat

The tN4 thermostat operates heating, cooling, and or

ventilation equipment for a zone. Several tN4 thermostats

may work in a group when operating a cooling system. Up

to 24 tN4 thermostats can connect to a single tN4 bus.

Outdoor Reset Section B

In a heating system, the rate of heat supplied to the building

must equal the rate of which heat is lost. If the two rates are

not equal, the building will either cool off or over heat.

The rate of building heat loss depends mostly on the outdoor

temperature. Outdoor Reset allows a hot water heating

system to increase the water temperature, adding heat to

the building, as the outdoor temperature drops. The rate

at which the water temperature is changed is defined by

the characterized heating curve.

Characterized Heating Curves

A characterized heating curve determines the amount the

supply water temperature is raised for every 1° drop in

outdoor air temperature. There is a characterized heating

curve for each tN4 communication bus.

The characterized heating curve takes into account the

type of terminal unit that the system is using. Since different

types of heating terminal units transfer heat to a space using

different proportions of radiation, convection and conduction,

the supply water temperature must be controlled differently.

Each tN4 bus is assigned a terminal unit setting that the

control uses to vary the supply water temperature to suit

to the terminal unit used. This improves the control of the

air temperature in the building.

Indoor Temperature Feedback

Most buildings have internal heat gains due to people,

passive solar heating and mechanical or electrical equipment.

Likewise, wind loads cause a building to lose heat faster than

during design conditions. If only the outdoor temperature is

measured, the control cannot compensate for these internal

heat gains or loses and the building may over or under heat.

In order to maintain the most comfortable temperature,

the control uses indoor temperature feedback from tN4

thermostats in order to adjust the water temperature on

each tN4 bus on a continual basis.

© 2007 D 422 - 08/07 16 of 32

Page 17

Terminal Unit

There is a terminal unit setting for each tN4 bus. The

Terminal Unit setting is found in the Adjust menu.

Hydronic Radiant Floor (1)

Terminal type 1 is a heavy, or high mass, hydronic radiant floor

system. This type of a hydronic radiant floor is embedded in

either a thick concrete or gypsum pour. This heating system

has a large thermal mass and is slow acting.

Hydronic Radiant Floor (2)

Terminal type 2 is a light, or low mass, hydronic radiant

floor system. Most commonly, this type of radiant heating

system is either attached to the bottom of a wood sub floor,

suspended in the joist space, or sandwiched between the

subfloor and the surface. This type of radiant system has

a relatively low thermal mass and responds faster than a

high mass system.

Radiator (5)

Terminal type 5 is a radiator terminal unit has a large heated

surface that is exposed to the room. A radiator provides

heat to the room through radiant heat transfer and natural

convection.

Baseboard (6)

Terminal type 6 is a baseboard terminal unit is similar to a

radiator, but has a low profile and is installed at the base

of the wall. The proportion of heat transferred by radiation

from a baseboard is greater than that from a fin-tube

convector.

Fancoil (3)

Terminal type 3 is a fancoil terminal unit or air handling

unit (AHU) consisting of a hydronic heating coil and either

a fan or blower. Air is forced across the coil at a constant

velocity by the fan or blower and is then delivered into the

building space.

Fin–tube Convector (4)

Terminal type 4 is a convector terminal unit is made up of

a heating element with fins on it. This type of terminal unit

relies on the natural convection of air across the heating

element to deliver heated air into the space. The amount

of natural convection is dependant on the supply water

temperature to the heating element and the room air

temperature.

Outdoor Design Temperature

The outdoor design temperature is typically the coldest

outdoor air temperature of the year. This temperature is

used when doing the heat loss calculations for the building

and is used to size the heating system equipment. If a cold

outdoor design temperature is selected, the supply water

temperature rises gradually as the outdoor temperature

drops. If a warm outdoor design temperature is selected,

the supply water temperature rises rapidly as the outdoor

temperature drops.

The outdoor design setting is found in the Adjust menu.

Warm Weather Shut Down (WWSD)

The Warm Weather Shut Down is the outdoor temperature

at which hydronic heating is no longer required. The control

closes mixing valves and variable speed pumps are not

operated. The boiler operates only when a Domestic Hot

Water (DHW) Demand or a Setpoint Demand is present.

The WWSD setting is found in the Adjust menu.

17 of 32 © 2007 D 422 - 08/07

Page 18

Boiler Outdoor Reset

•

•

•

•

•

Mix 1 and Mix 2 Outdoor Reset

There is a water temperature and therefore a characterized

heating curve for each communication bus. When using

boiler temperature water to heat zones, the installer will

be required to set a boiler characterized heating curve.

This requires the tN4 DIP switch to be set to Boiler and

the Boiler Sensor DIP switch set to Supply.

Boiler Terminal Unit Defaults

When a terminal unit is selected for boiler zones, the

control loads default values for the boiler design, boiler

maximum supply, and boiler minimum supply temperatures.

The factory defaults can be changed to better match the

installed system. Locate the Boiler Terminal Unit setting

in the Adjust menu.

Boiler Characterized Heating Curve

Boiler

Design

Terminal Unit

Outdoor

Design

Each tN4 communication bus operates on a separate water

temperature. Therefore a separate characterized heating

curve is required for Mix 1 and, if the tN4 DIP switch is

selected to Mix 2, for mix 2 as well.

Mix 1 and 2 Terminal Unit Defaults

When a terminal unit is selected for Mix 1 (or Mix 2),

the control loads default values for the mix design, mix

maximum supply, and mix minimum supply temperatures.

The factory defaults can be changed to better match the

installed system.

• Locate the Mix 1 and Mix 2 terminal unit settings in the

Adjust menu.

Mix Characterized Heating Curve

Mix

Terminal Unit

Outdoor

Design

Design

Boiler

Indoor

Decreasing Outdoor Temperatures

Terminal Unit

High Mass Radiant (1)

Low Mass Radiant (2)

Fancoil (3)

Fin-Tube Convector (4)

Radiator (5)

Baseboard (6)

BOIL DSGN BOIL MAX BOIL MIN

120°F (49°C) 140°F (60°C) OFF

140°F (60°C) 160°F (71°C) OFF

190°F (88°C) 210°F (99°C) 140°F (60°C)

180°F (82°C) 200°F (93°C) 140°F (60°C)

160°F (71°C) 180°F (82°C) 140°F (60°C)

150°F (76°C) 170°F (77°C) 140°F (60°C)

Increasing Water Temperatures

Boiler Indoor Design

The boiler indoor design temperature is the indoor temperature

the heating designer chose while calculating the heat loss for

the boiler water heated zones. This temperature is typically

70°F (21.0°C). This setting establishes the beginning of

the boiler characterized heating curve.

• Locate the Boiler Indoor Design setting in the Adjust

menu.

Boiler Design Temperature

The boiler design supply temperature is the boiler water

temperature required to heat the zones on the typical

coldest day of the year.

• Locate the Boiler Design setting in the Adjust menu.

Mix

Decreasing Outdoor Temperatures

Terminal Unit

High Mass Radiant (1)

Low Mass Radiant (2)

Fancoil (3)

Fin-Tube Convector (4)

Radiator (5)

Baseboard (6)

Indoor

MIX DSGN MIX MAX MIX MIN

120°F (49°C) 140°F (60°C) OFF

140°F (60°C) 160°F (71°C) OFF

190°F (88°C) 210°F (99°C) 100°F (38°C)

180°F (82°C) 200°F (93°C) OFF

160°F (71°C) 180°F (82°C) OFF

150°F (76°C) 170°F (77°C) OFF

Increasing Mix Temperature

Mix 1 and Mix 2 Indoor Design

The Mix 1 (or Mix 2) indoor design temperature is the indoor

temperature the heating designer picked while calculating

the heat loss for the building for the Mix 1 (or Mix 2) water

heated zones. This temperature is typically 70°F (21.0°C).

This setting establishes the beginning of the Mix 1 (or Mix 2)

characterized heating curve.

• Locate the Mix 1 and Mix 2 Indoor Design settings in

the Adjust menu.

Mix 1 and Mix 2 Design Temperature

The Mix 1 (or Mix 2) design supply temperature is the mix

supply water temperature required to heat the zones when

the outdoor temperature is as cold as the outdoor design

temperature.

• Locate the Mix 1 and Mix 2 Design settings in the Adjust

menu.

© 2007 D 422 - 08/07 18 of 32

Page 19

•

B

o

i

l

W

a

t

e

r

T

e

m

p

e

r

a

t

u

r

e

•

B

o

i

l

W

a

t

e

r

T

e

m

p

e

r

a

t

u

r

e

•

Boiler Temperature Control Section C

The 422 is able to operate a single, hot water, on-off or

modulating boiler as a heat source. For proper operation of

the boiler, the 422 must be the only control that determines

when the boiler is to fire. In this case, the boiler sensor

should be located on the boiler supply pipe and the Boiler

Sensor DIP switch is set to Supply.

*Important note: The boiler operator, also known as

an aquastat, remains in the burner circuit and acts as a

secondary upper limit on the boiler temperature. The boiler

operator temperature setting must be adjusted above the

422’s Boiler Maximum setting in order to prevent short

cycling of the boiler burner.

Boiler Target Temperature

The boiler target temperature is determined by connected

tN4 devices or by a DHW or Setpoint demand received by

the control. The tN4 devices determine the highest water

temperature required and then, requests this temperature

on the tN4 boiler bus. The temperature request creates a

Boiler Demand and this is indicated on the display. A DHW

demand and a Setpoint demand have temperature settings

to which the boilers are operated to meet and are able to

override the tN4 bus temperature if required.

The control displays the temperature that it is currently trying

to maintain as the boiler supply temperature in the View

menu. If the control does not presently have a requirement

for heat, it does not show a boiler target temperature.

Instead, “– – –” is displayed in the LCD.

Operation of the tN4 Boiler / Mix 2 Bus

The 422 has two available tN4 communication buses. One

bus is dedicated for a mix water temperature and is known

as Mix 1. The second bus can operate at either boiler

water temperatures or at mixing water temperatures. The

tN4 Boiler / Mix 2 DIP switch affects the operation of the

boiler target temperature. The mix 1 bus is connected to a

Zone manager via the plug on the underside of the board.

The boiler / Mix 2 bus is connected to a Zone manager via

terminals 59 and 60.

Boiler Temperature Zones

When the control is to operate boiler temperature zones,

the Boiler / Mix 2 tN4 DIP switch must be set to Boiler. The

Boiler Bus then operates the boiler directly in order to heat

the zones operated by tN4 thermostats connected to this

bus. The boiler water temperature target will be determined

based upon boiler outdoor reset and indoor feedback from

the tN4 thermostats.

Mix Temperature Zones

When the control is to operate mix temperature zones, the

Boiler / Mix 2 tN4 DIP switch must be set to Mix 2. The

Mix 2 Bus uses a second mixing device to maintain a mix 2

water temperature target. The boiler target temperature is

determined using Boiler Load Reset, in which the boiler

water temperature is maintained at the lowest possible

temperature that satisfies the heating load of the two mixing

devices. See Mixing Operation for more information.

Boiler Minimum

The boiler minimum is the lowest temperature that the

control is allowed to use as a boiler target temperature.

During mild conditions, if the control calculates a boiler

target temperature that is below the Boiler Minimum setting,

the boiler target temperature is adjusted to at least the

Boiler Minimum setting. During this condition, if the boiler is

operating, the minimum segment is turned on in the display

when viewing either the boiler supply temperature or the

boiler target temperature. Set the Boiler Minimum setting

to the boiler manufacturer’s recommended temperature.

• Locate the Boiler Minimum setting in the Adjust menu.

Boil MIN + ½ Boiler Differential

e

r

u

t

a

m

e

B

o

i

MIN segment on

T

r

e

t

l

a

W

r

e

p

Boil MIN– ½ Boiler Differential

Boil MIN

Boiler Maximum

The boiler maximum is the highest temperature that the

control is allowed to use as a boiler target temperature. If

the control does target the Boiler Maximum setting, and the

boiler temperature is near the boiler maximum temperature,

the maximum segment will be displayed in the LCD while

either the boiler target temperature or the boiler temperature

is being viewed. At no time does the control operate the

boiler above 248°F (120.0°C).

• Locate the Boiler Maximum setting in the Adjust menu.

Boil MIN + ½ Boiler Differential

MAX

segment

on

B

t

a

o

W

l

i

r

e

a

r

e

t

u

p

m

e

T

MAX

segment

r

e

Boil MIN – ½ Boiler Differential

on

Boil MAX

Fire Delay

The Fire Delay is the time delay that occurs between the

time that the control closes the boiler contact to fire the

boiler and when the burner fires.

• Locate the Fire Delay setting in the Adjust menu.

Boiler Contact Closed

Fire Delay

Burner On

Time

19 of 32 © 2007 D 422 - 08/07

Page 20

On-Off Boiler Operation

•

•

Modulating Boiler Operation

If the heat source is an On-Off Boiler, the Boil On-Off / Mod

DIP switch must be set to On-Off.

Differential

An on / off heat source must be operated with a differential

in order to prevent short cycling. With the control, either

a fixed or an auto differential may be selected. The boiler

differential is divided around the boiler target temperature.

The boiler contact closes when the supply water temperature

is 1/2 of the differential setting below the boiler target

temperature. As the supply temperature reaches 1/2 of

the differential above the boiler target temperature, the

boiler is shut off.

• Locate the Boiler Differential setting in the Adjust

menu.

Differential = 10°F (6°C)

165°F (74°C)

160°F (71°C)

155°F (68°C)

Boiler

On

Boiler

On

Target + 1/2 Differential

Target

Target – 1/2 Differential

Fixed Differential

If the user desires to have a fixed differential, this is set

using the Boiler Differential setting in the Adjust menu.

Auto Differential

In order to decrease temperature swings and increase boiler

efficiency, the Auto Differential feature automatically changes

the on / off differential of the boiler based on the heating

load. As the load increases, the differential will decrease to

minimize temperature swings. As the load decreases, the

differential will increase to prevent short cycling.

Off

Differential

Time

On

Heating Load

The 422 can operate a single hot-water modulating boiler.

This requires the use of the Mod (dc) output on the 422.

To operate a modulating boiler, the Boil On-Off / Mod DIP

switch must be set to Mod. The control operates the boiler

by first switching the boiler contact to allow the modulating

boiler to go through the ignition sequence (the boiler contact

may not be required on all modulating boilers). A 0-10 V (dc)

analog signal is used to modulate the boiler firing rate

from the Minimum Modulation setting using Proportional,

Integral and Derivative (PID) logic in order to satisfy the

boiler target temperature.

A modulating boiler requires all the same settings as an

on-off boiler in addition to the settings below.

Modulating Boiler Differential

A modulating boiler must be operated with a differential

while operating in low fire. The boiler differential is divided

around the boiler target temperature. The boiler burner

ignites at low fire when the supply water temperature is

1/2 of the Boiler Differential setting below the boiler target

temperature. The boiler is shut off in low fire as the supply

temperature reaches at least 1/2 of the differential above

the boiler target temperature. With the control, either a fixed

or an auto differential may be selected.

When the boiler is modulating above low fire, the differential

does not apply. Instead, the modulation output signal is

determined using Proportional, Integral and Derivative (PID)

logic in order to satisfy the boiler target temperature.

Boiler Motor Speed

The Boiler Motor Speed is the amount of time the boiler

requires to go from 0% modulation to 100% modulation.

Gas valve actuating motors have a design time from

fully closed to fully open which can be found in the

manufacturer’s manual. The Boiler Motor Speed should

be set to this time.

The Boiler Motor Speed setting for a Variable Frequency

Drive (VFD) is the amount of time required to go from a

stopped position to 100% fan speed. Since a VFD has a

very quick response rate, it may be necessary to increase

the Motor Speed setting in order to increase the stability

of the boiler modulation.

• Locate the Boiler Motor Speed setting in the Adjust

menu.

© 2007 D 422 - 08/07 20 of 32

Page 21

Minimum Modulation

•

•

The minimum modulation defines the minimum output

signal from the control to the boiler burner. It is based on

a percentage of the control’s output signal range.

The Minimum Modulation default setting is 0%.

For boilers with electronic operators, the boiler’s input signal

range may not match the output signal range of the 422

control. The Minimum Modulation setting limits the control

output range in order to match the boiler’s input range.

• Locate the Minimum Modulation setting in the Adjust

menu.

To calculate the Minimum Modulation, use the following

formula:

For 0-10 V (dc):

Minimum Modulation =

0 V (dc) - Boiler’s Minimum Input Signal x 100%

0-10 V (dc)

Example:

A boiler requires a 1.8 V (dc) signal to fire the boiler at

low fire. The boiler can be modulated to 10 V (dc) where

it reaches high fire.

This means the boiler’s input signal range is 1.8 to

10 V (dc). The 422 control has an output signal range of

0-10 V (dc).

To make the two signal ranges the same, the Minimum

Modulation required is:

Minimum Modulation = 0 V-1.8 V x 100% = 18%

0 V-10 V

10 V (dc)

Maximum Modulation

The maximum modulation defines the maximum output

signal from the control to the boiler burner. It is based on

a percentage of the control’s output signal range.

The Maximum Modulation default setting is 100%.

For boilers with electronic operators, the boiler’s input signal

range may not match the output signal range of the 422

control. The Maximum Modulation setting limits the control

output range in order to match the boiler’s input range.

• Locate the Maximum Modulation setting in the Adjust

menu.

To calculate the Maximum Modulation, use the following

formula:

For 0-10 V (dc):

Maximum Modulation =

0 V (dc) – Boiler’s Maximum Input Signal x 100%

0-10 V (dc)

Example:

A boiler’s input signal range is 2-9 V (dc). The 422 control

has an output signal range of 0-10 V (dc).

To make the two signal ranges the same, the Maximum

Modulation required is:

Maximum Modulation = 0 V-9 V x 100% = 90%

0 V-10 V

10 V (dc)

90%

Control

Range

Boiler

Range

2.0 V (dc)20%

0 Vdc

Control

Range

18%

Boiler

Range

0 Vdc 0 V (dc)

1.8 V (dc)

tekmar Stager Operation Section D

In some cases, multiple boilers may be required. In these

cases, the 422 allows for a connection to a tekmar Boiler

Control 264, 265, or 268. The 422 uses the modulating

output to provide a 0-10 V (dc) signal to the external input

terminals on the Boiler Control. The 422 controls the Boiler

Control target temperature by changing the voltage signal.

The Boiler Control responds to the boiler target by staging

the multiple boilers.

The following table can be used to convert a 0-10 V (dc)

signal to a boiler target temperature:

To use the tekmar Staging operation, the following DIP

switch settings are required:

1. Set the 422 Off / tekmar Stager DIP switch to tekmar

Stager.

2. Set the 422 Boil Sup / Ret DIP switch to Sup.

3. Set the 422 Boil On-Off / Mod DIP switch to Mod.

The 422 boiler sensor must be located on the supply pipe

leading from the boilers. On the Boiler Control 264, 265,

or 268, the External Input / Stand Alone DIP switch must

be set to External Input. Any domestic hot water (DHW)

demands or setpoint demands in the system must connect

to the 422 in order to allow for DHW or setpoint priority.

Voltage (dc)

Boiler Target

012345678910

Off 50°F (10°C) 68°F (20°C) 86°F (30°C) 103°F (40°C) 121°F (50°C) 139°F (60°C) 157°F (70°C) 174°F (80°C) 192°F (90°C) 210°F (99°C)

21 of 32 © 2007 D 422 - 08/07

Page 22

•

Boiler Enable Section E

If the 422 is one of many controls that can call for heat to

a single boiler or there is a boiler sequencer other than a

tekmar Stager (Boiler Control 264, 265, 268), operating

multiple boilers or multiple stages, then the boiler sensor

must be located on the return pipe of the boiler(s).

When the sensor is located on the return, the 422 provides

a boiler enable. The 422 no longer tries to control the

boiler supply water temperature directly, but allows another

operating control such as an aquastat to regulate the boiler

supply temperature.

When there is a requirement for heat from the 422 mixing

device(s), or a DHW Demand, or a Setpoint Demand is

present, the 422 boiler contact closes to enable the boiler.

The boiler contact remains closed until heat is no longer

required.

When the boiler sensor is located on the boiler return, the

control is able to provide boiler return protection through the

use of a mixing device. This protects the boiler sustained

flue gas condensation and thermal shock.

*Important note: The tN4 DIP switch cannot be set to Boiler

while the Boiler Sensor DIP switch is set to Return.

To operate the control without a boiler sensor and prevent

the control from displaying an error message, set the boiler

sensor DIP switch to Return and power up the control

without the boiler sensor connected.

The control operation will be similar to that as having the

boiler sensor on the return except that boiler return protection

is no longer provided.

Zone Load Shedding Section F

If the boiler temperature approaches the boiler minimum

setting, the control can turn off certain high temperature

zones in order to reduce the load on the boiler. This is

known as Zone Load Shedding. Zones are shed in the

following order:

1. The second stage of any 2-stage thermostats which

have “BOIL” selected as their heat source in order of

decreasing priority. Priority is determined by the address

number of the thermostat (b:01 is the highest priority,

3:24 is the lowest priority).

2. The first stage of any thermostats on the boiler bus,

again, in order of decreasing priority. The first stage

of the highest priority thermostat (lowest address

number) will not be shed unless there is also a setpoint

or DHW call.

When the boiler supply temperature goes above the

minimum setting, the control begins restoring the load by

turning first stages back on in the reverse order that they

were shed, followed by second stages in the reverse order

that they were shed.

Mixing Operation Section G

The 422 has two tN4 communication buses. The first bus

is dedicated for a mix water temperature and is known as

Mix 1. The second bus can be selected to be either boiler

or mixing depending on the tN4 DIP switch position. When

the tN4 DIP switch is set to Mixing, the second bus is known

as Mix 2. Mix 2 requires that a Mixing Expansion Module

be connected to the Mix 2 tN4 bus.

A Mixing Expansion Module is required in order to use the

second mixing temperature. The Mixing Expansion Module

operates at the percent output that the 422 determines is

required.

Each of the following settings must be set for the Mix 1

bus and for the Mix 2 bus when the tN4 DIP switch is set

to Mix 2.

© 2007 D 422 - 08/07 22 of 32

Mix 1 Mode

A mixing device allows the control to reduce the boiler

water temperature down to a lower water temperature. A

mixing device when used with a boiler sensor also allows

the control to protect the boiler from sustained flue gas

condensation and thermal shock.

The Mix 1 outputs are built-in to the 422. The type of mixing

device for Mix 1 is selected using the Mix 1 Mode setting.

The mixing devices that can be selected are variable speed

injection (VAr) and floating action (FLt).

• Locate the Mix 1 Mode setting in the Adjust menu.

Page 23

Variable Speed Injection

•

•

•

A standard wet rotor circulator can be connected to the

Variable Speed output on the control for Mix 1 and on

a Mixing Module for Mix 2. The control increases or

decreases the power output to the circulator when there

is a requirement for mixing. The circulator speed varies to

maintain the correct mixed supply water temperature at

the mix supply sensor. For correct sizing and piping of the

variable speed injection circulator, refer to essay E 021.

A visual indication of the current variable speed output is

displayed in the LCD in the form of a bar graph along with

the Mix 1 or the Mix 2 segment to indicate which mixing

device is being currently viewed.

Floating Action

A floating action actuator motor can be connected to the

control (Mix 1) or a Mixing Module (Mix 2) on the Opn and

Cls terminals. The control pulses the actuator motor open

or close to maintain the correct supply water temperature

at the mix supply sensor when there is a requirement for

mixing. The mixing valve that the actuator is connected

to can be either a 2-way, 3-way or 4-way valve. A visual

indication as to whether the control is currently opening or

closing the mixing valve is displayed in the LCD with the

words OPN and CLS while viewing the Mix Supply or Mix

Target temperatures. Also, a visual indication of the current

position of the valve is displayed in the form of a bar graph

along with the Mix 1 or the Mix 2 segment to indicate which

mixing device is being currently viewed.

Mix 1 and Mix 2 Minimum

The Mix 1 and Mix 2 Minimum settings are the lowest

temperature that the control is allowed to use as a mix

target temperature. During mild conditions, if the control

calculates a mix target temperature that is below the mix

minimum setting, the mix target temperature is adjusted

to match the mix minimum setting. During this condition,

if the mixing supply temperature is near the mix minimum

setting, the Min segment turns on in the LCD when either

the mix target temperature or the mix supply temperature

is being viewed.

• Locate the Mix 1 and the Mix 2 Minimum settings in the

Adjust menu.

Mix 1 and Mix 2 Maximum

The Mix 1 Maximum and Mix 2 Maximum set the highest

water temperature that the control is allowed to use as a

mix target temperature. If the control does target the mix

maximum setting, and the mix supply temperature is near

the mix maximum temperature, the Max segment turns on

in the LCD when either the mix target temperature or the

mix supply temperature is viewed.

• Locate the Mix 1 and the Mix 2 Maximum settings in the

Adjust menu.

Boiler Minimum Protection

The control is capable of providing boiler protection from

cold mixing system return water temperatures. If the boiler

water temperature is cooler than the Boiler Minimum setting

while the boiler is firing, the control reduces the output from

the mixing devices. Both mixing outputs are reduced at the

same rate. Reducing the mixing output limits the amount of

cool return water to the boiler and allows the boiler water

temperature to recover. This feature can only be used if

the boiler sensor is on the supply or on the return but is not

available when the boiler sensor is not present.

Domestic Hot Water Temperature Operation Section H

DHW Demand

A powered DHW Demand is required in order for the control

to provide heat to the DHW system. A DHW aquastat or

setpoint control is used as a switch in the DHW demand

circuit. The control registers a DHW Demand when a

voltage between 24 and 230 V (ac) is applied across the

DHW Demand terminals (53 and 54).

Once the control detects a DHW demand, the DHW Demand

segment turns on in the LCD.

23 of 32 © 2007 D 422 - 08/07

Boiler Target Temperature

The boiler target temperature is at least as hot as the DHW

Exchange setting. The DHW demand overrides the boiler

reset target temperature, except when the boiler reset target

is higher than the DHW exchange setting.

• Locate the DHW Exchange setting in the Adjust menu.

DHW During UnOccupied

The control has a DHW Exchange UnOccupied setting that

allows the installer to select On or Off. When set to On, and

the control receives a DHW Demand during an UnOccupied

or Sleep period, the control continues operation of the DHW

system as it would during the Occupied and Wake periods.

When set to Off, the control can ignore a DHW Demand for

the duration of the UnOccupied and Sleep periods.

Page 24

DHW Mode and Priority Operation

•

The control has four different settings available for DHW

Mode that affect pump operation. The required DHW Mode

setting will depend on the piping arrangement of the DHW

tank and whether or not priority for DHW is necessary. DHW

Priority stops or limits the delivery of heat to the building

heating system while the DHW tank calls for heat. This

allows for quick recovery of the DHW tank.

• Locate the DHW Mode setting in the Adjust menu.

DHW MODE 3 - DHW in Primary / Secondary no Priority

When a DHW Demand is present, the DHW Pump contact

is closed and the primary pump (P1) is operated.

Mode = 3

DHW

Pump

DHW MODE 1 - DHW in Parallel no Priority

When a DHW Demand is present, the DHW Pump contact

closes. The primary pump (P1) does not turn on, but may

operate based on either Boiler or Mixing requirements or

a Setpoint Demand.

It is assumed that the DHW pump will provide adequate

flow through the heat exchanger and the boiler.

Mode = 1

DHW

Pump

Primary

Pump

DHW MODE 2 - DHW in Parallel with Priority

When a DHW Demand is present, the DHW Pump contact

closes. The primary pump (P1) can operate when a boiler

demand is present. If the boiler is unable to maintain the

boiler target temperature, space heating zones are shut

off sequentially using tN4 communication in order to

provide priority to the DHW tank. This is known as zone

load shedding.

It is assumed that the DHW pump will provide adequate

flow through the heat exchanger and the boiler.

Primary

Pump

DHW MODE 4 - DHW in Primary / Secondary with

Priority

When a DHW Demand is present, the DHW Pump contact

is closed and the primary pump (P1) is operated. Priority

over space heating zones is achieved by shutting off the

zone pumps or zone valves through tN4 communication.

This is known as zone load shedding.

Mode = 4

OFF

DHW

Pump

Primary

Pump

DHW Priority Override

DHW Priority Override applies to DHW MODE 2 and 4.

To prevent the building from cooling off too much or the

possibility of a potential freeze up during DHW priority, the

control limits the amount of time for DHW priority. As the

outdoor air temperature becomes colder, the length of time

that the control provides DHW priority is reduced. Once the

allowed time for priority has elapsed, the control overrides

the DHW priority and resumes space heating.

Mode = 2

OFF

DHW

Pump

Primary

Pump

© 2007 D 422 - 08/07 24 of 32

DHW Priority Override Time

Increasing Time

Decreasing Outdoor Air Temperature

Page 25

Conditional DHW Priority

DHW Mixing Purge

If the boiler supply temperature is maintained at or above the

required temperature during DHW generation, this indicates

that the boiler has enough capacity for DHW and possibly

heating as well. As long as the boiler supply temperature

is maintained near the target, DHW and heating occurs

simultaneously.

After DHW operation, the boiler is extremely hot. At the same

time, the heating zones may have cooled off considerably

after being off for a period of time. When restarting the

heating system after a DHW demand with priority, the control

shuts off the boiler and continues to operate the DHW pump

while the primary pump is turned on. This allows some of

the DHW return water to mix with the cool return water from

DHW Post Purge

the zones and temper the boiler return water.

After the DHW Demand is removed, the control performs

a purge on the boiler. The control shuts off the boiler and

continues to operate the DHW pump and the primary pump

(P1) if applicable. This purges the residual heat from the

boiler into the DHW tank. The control continues this purge

for a maximum of four minutes or until the boiler supply

water temperature drops 20°F (-6.5°C) below the boiler

target temperature during the DHW operation. The control

also stops the purge if the boiler supply temperature drops

OFF

DHW

Pump

Primary

Pump

below the current boiler target temperature.

DHW with Low Temperature Boilers Section I

If DHW heating is to be incorporated into a low temperature

system such as a radiant floor heating system, a mixing

device is often installed to isolate the high DHW supply

temperature from the lower system temperature. If a mixing

device is not installed, high temperature water could be

supplied to the low temperature system while trying to

satisfy the DHW demand. This may result in damage to

the low temperature heating system.

The control is capable of providing DHW heating in such a

system while minimizing the chance that the temperature

in the heating system exceeds the design supply water

temperature. In order to do this, the control must be set

to DHW MODE 2 or DHW MODE 4 and Boil MIN must be

set to OFF.

On a call for DHW, the control provides DHW priority by

sending a message on the boiler temperature bus to the tN4

thermostats to shut off the heating zones for a period of time.

The length of time is based on the outdoor air temperature as

described in the DHW Priority Override section. However, if

the DHW Demand is not satisfied within the allotted time, the

boiler shuts off and the heat of the boiler is purged into the

DHW tank. A DHW mixing purge occurs in order to reduce

the boiler water temperature and once the boiler supply

temperature is sufficiently reduced, the DHW Pump contact

shuts off. The heating system zones are allowed to turn on

for a period of time to prevent the building from cooling off.

After a period of heating, and if the DHW Demand is still

present, the control shuts off the heating system and provides

heat to the DHW tank once again.

Setpoint Temperature Operation Section J

Setpoint

The control can operate to satisfy the requirements of a

setpoint load in addition to a space heating load and a

DHW load. A setpoint load overrides the current outdoor

reset temperature and WWSD setting in order to provide

heat to the setpoint load.

Setpoint Demand

A Setpoint Demand is required in order for the control to

provide heat to a setpoint load.

The control registers a setpoint demand when a voltage

between 24 and 230 V (ac) is applied across the Setpoint

Demand terminals (55 and 56). Once voltage is applied,

the Setpoint Demand segment turns on in the LCD.

25 of 32 © 2007 D 422 - 08/07

Page 26

Boiler Target During Setpoint

The boiler target temperature during a Setpoint Demand is

increased to at least the Setpoint setting. This temperature is

maintained as long as the control has a setpoint demand.

Setpoint Mode 3 – Setpoint in Primary / Secondary

Whenever a setpoint demand is present, the primary pump

(P1) is turned on and the boiler is operated to maintain the

setpoint target.

Setpoint During UnOccupied

The control has a Setpoint UnOccupied setting that allows

the installer to select On or Off. When set to On, and the

control receives a Setpoint Demand during an UnOccupied or

Sleep period, the control continues operation of the Setpoint

system as it would during Occupied and Wake periods. When

set to Off, the control can ignore a Setpoint Demand for the