Page 1

Level detector

LD-60

Instructions Manual

C-MI-LD60 Rev.: 2 English version

Page 2

TECHNICAL DATA

Material: Fork: EN 1.4404 (AISI 316L). Others on demand.

Housing: Polycarbonate.

Pipe fittings: Threads G1 (BSP), 1 NPT.

Models: 24-250 Vac. Maximum load 350 mA. 2 wire connection with series

load

12 - 55 Vdc. Maximum load 350 mA. 3 wire connection

Switching time: > 1s

Hysteresis: ± 2 mm with H

O

2

Working Limits: Viscosity. Up to 10.000 cSt

Density. > 0,6 kg / l

Process temperature (product). -30 a 120ºC

Ambient temperature. -20 a 70ºC

Standard pressure: PN 16

Ingress Protection: IP65

Conforms with the Directives 73/23/CE & 89/336/CE

Conforms with the Pressure Equipment Directive 97/23/CE

This equipment is considered as being a pressure accessory and NOT a safety

!

accessory as defined in the 97/23/CE directive, Article 1, paragraph 2.1.3.

WORKING PRINCIPLE

The LD-60 level switch is based on the variation of the natural resonant frequency of a vibrating

fork, when it comes into contact with a liquid or solid

This variation is detected by the internal electronics and is used to determine the state of the

output .

2

Page 3

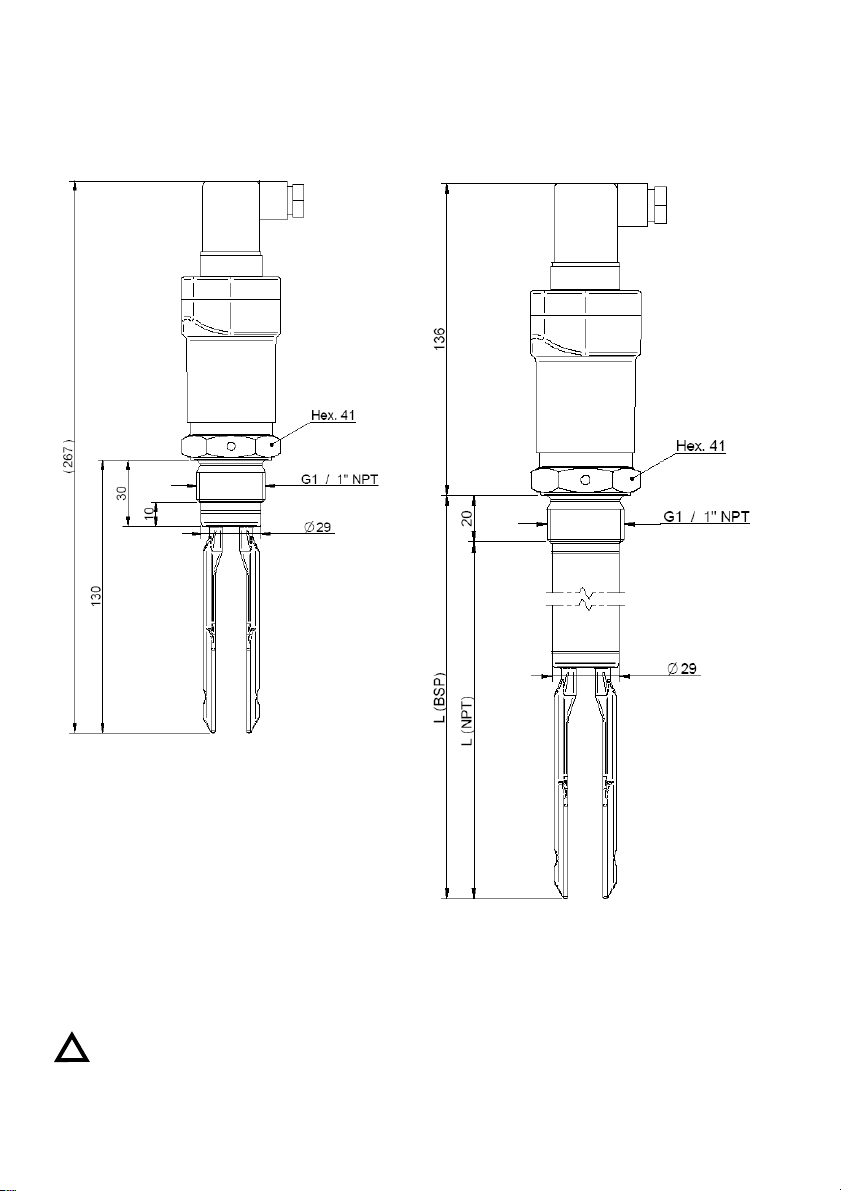

Dimensions:

G1 or 1 NPT Thread LD-61 ML

RECEPTION

The LD-60 level detectors are supplied ready for installation and operation.

They are supplied packed for their protection during storage and haulage.

!

To handle the detectors, they should always be held by the head, never by the vibrating fork.

The vibrating fork should not be modified or bent, as this can damage the detector beyond

repair.

3

Page 4

ELECTRICAL CONNECTION

The LD-60 can be installed as a detector of minimum or maximum level. The electrical connection

is made by means of a DIN 43650-A connector with a PG-9 cable gland. Multiple conductor cable

with sections about 0,5 mm

To open the connector, remove the centre screw and prise open using a small screwdriver in the

slot shown in the following drawing (looking at the female connector from the contact side).

The working mode (maximum or minimum) is chosen by means of the cable connection, as

shown in the following figure.

2

should be used.

Máximo

Maximum

Ranura de apertura

Slot to open the connector

Minimum

Mínim o

Carga

Load

-

+

Tierra

Earth Earth

L

N

Tierra

Earth

1

2

3

a) DC version.

Máximo

1

Carga

Load

2

3

b) AC ve r sion.

NOTE: The AC version has a power consumption of 6 mA when the load is deactivated.

This should be taken into account when the load is a relay. You must make sure that the

dropout voltage of the relay is greater than the voltage across the coil when a current of 6

mA flows through it. If the dropout voltage is equal or smaller then the relay can be in an

activated position independent of the LD-60 state.

4

-

+

Tierra

L

N

Tierra

Earth

1

2

3

Minimum Maximum

Mínim o

1

2

3

Page 5

!

With the AC version. the connection without a load will damage the instrument !

Carga

Load

(relé, electroválvula, etc...)

(relay, electrovalve, etc...)

The LD-60 detector cannot be connected in series. Each detector must have its own load.

Carga

Load

(r elé, e lec troválvula, etc... )

(relay, electrovalve, etc...)

When the LD-60 is connected to detect a maximum level, the load is “activated” when the fork is

not in contact with the product. In the same way, when the LD-60 is connected to detect a

minimum level, the load is “activated” when the fork is in contact with the product.

The LD-60 has a bi-colour LED that indicates the state of the load “activated” (green colour) or

“open” (red colour).

5

Page 6

MOUNTING

The LD-60 detector can be mounted in any

position. The more usual insertion points are

shown in the drawing.

In positions 1 the LD-60 acts as a maximum

level detector. In positions 2 the LD-60 acts as

a minimum level detector and in position 3 it

acts as an empty pipe detector (for example,

to protect a pump).

If the LD-60 is installed in a horizontal position

it is recommended to install it with the tines

vertical to avoid accumulation of substances,

especially in the case of high viscosity

materials.

To indicate the position of the tines the LD-60

has a round mark on two of the flats of the nut.

These marks should be in a vertical position

when the detector is installed in a horizontal

position.

Punto de

Positioning mark

posicionamiento

1

1

2

2

3

In the same way, when the detector is installed where there is flow, the position must be taken

into account. The flat part of the tines must be aligned parallel with the flow direction.

If the viscosity is high, the tines must be kept away from other objects (such as the wall of the

tank). In these cases it is preferable to install a longer detector.

6

Page 7

The cable gland should be situated on the lower side of the connector. If it is necessary, the

position of the connector can be changed by 90º or 180º. To do this, open the connector and

rotate. This operation must be done with the power disconnected

OPERATION TEST

The operation of the installation can be checked by placing a magnet in the zone shown in the

following figure. This magnet will change the output to the opposite state. In this way the correct

installation of the instrument can be checked without having to change the level in the tank. At the

same time, the bi-colour LED will indicate the change of state of the output.

IP65

min

LD-61

LD-60

Nº 00000

24..250 Vac 350 mA

max

Test zone

ACCESSORIES

An accessory that permits changing the length of the LD-60 which penetrates in the tank is available. This permits adjustment of the detection level.

136

7

Page 8

MAINTENANCE

The life of the vibrating fork depends basically on the abrasive characteristics of the product used.

The LD-60 detector only needs maintenance when the product, which can adhere to the tines, will

not let the detector change to a non detection state. In these cases the tines must be cleaned.

Cleaning

To clean the tines, brush suitable for removing the incrusted product, must be used . You should

not try to knock off the adhered product from the tines.

During the cleaning process, be careful not to apply force against the tines as this can bend them

and damage the detector beyond repair.

WARRANTY

Tecfluid S.A. GUARANTEES ALL ITS PRODUCTS FOR A PERIOD OF 24 MONTHS, after

consignment, against all defects in materials and workmanship.

This warranty does not cover failures which can be impu te d to misuse, use in an appli catio n dif fe ren t

to that specified in the or der, the result of service or modification b y un-authorized persons, bad

handling or accident.

This warranty is limited to cover the repair or replacement defective parts which have not been

damaged by misuse.

This warranty is limited to the repair of the equipment and all further and eventually following

damages are not covered by this warranty.

Any consignment of equipment to our factory or distributor must be previously authorised. The

consignment should be done with the equipment well packed, clean of any liquids, grease or

hazardous materials. Tecfluid S.A. will not accept any responsibility for damage done during

transport.

Together with the equipment, a note should be enclosed indicating the failure obs erved, the name,

address and telephone number of the sender.

TECFLUID, S.A.

Narcís Monturiol, 33

E-08960 Sant Just Desvern

Tel. + 34 93 3724511 - Fax + 34 93 4734449

E-mail: tecfluid@tecfluid.com

Internet: www.tecfluid.com

The technical data in this pamphlet is subject to modification without notification.

Loading...

Loading...